Patents

Literature

48results about How to "High tensile elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant polymer blends

InactiveUS20070066737A1Improve flame retardant performanceGood solvent resistancePolyesterPolyetherimide

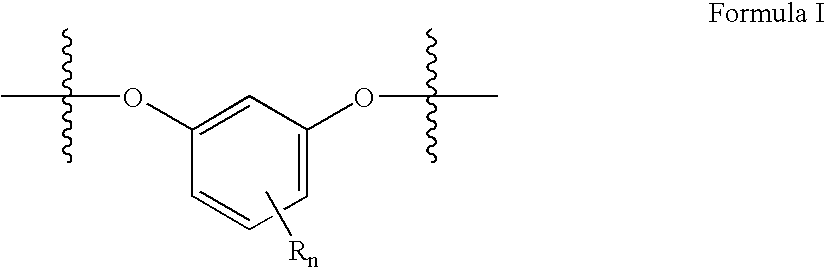

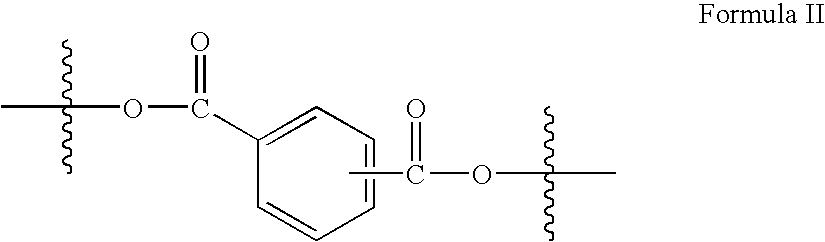

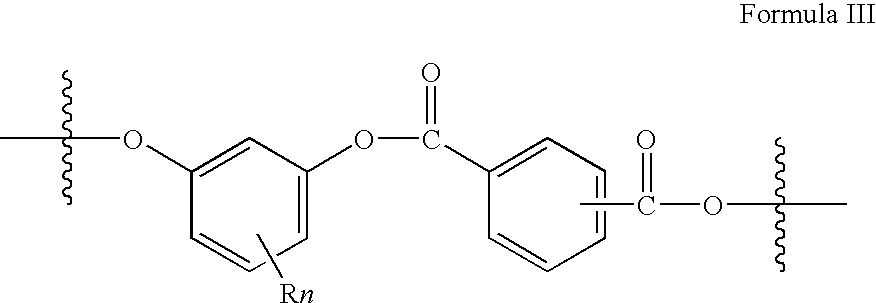

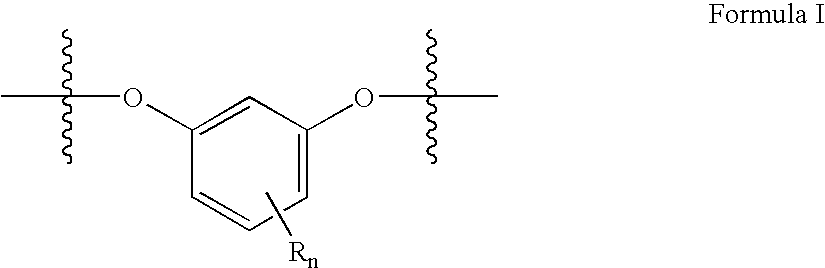

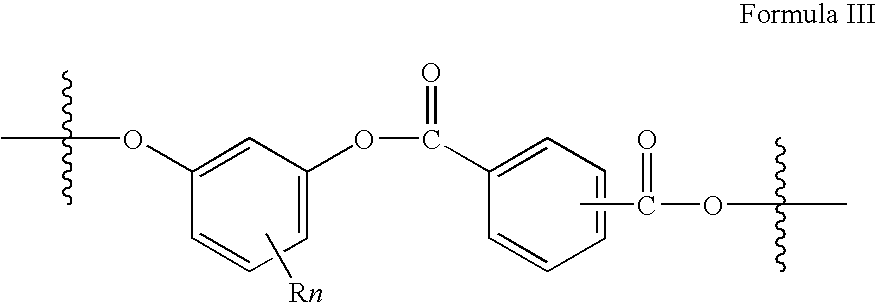

Blends of polyimides, polyetherimides or polyetherimide sulfones with resorcinol based polyesters, or resorcinol based polyester carbonate polymers, and silicone copolymers, have improved flame resistance. Peak heat release energy is reduced and the time to reach peak heat release is increased. In some instances the flame retardant blends show high percent transmission with low haze. Addition of metal oxides may further improve flame resistance.

Owner:SABIC GLOBAL TECH BV

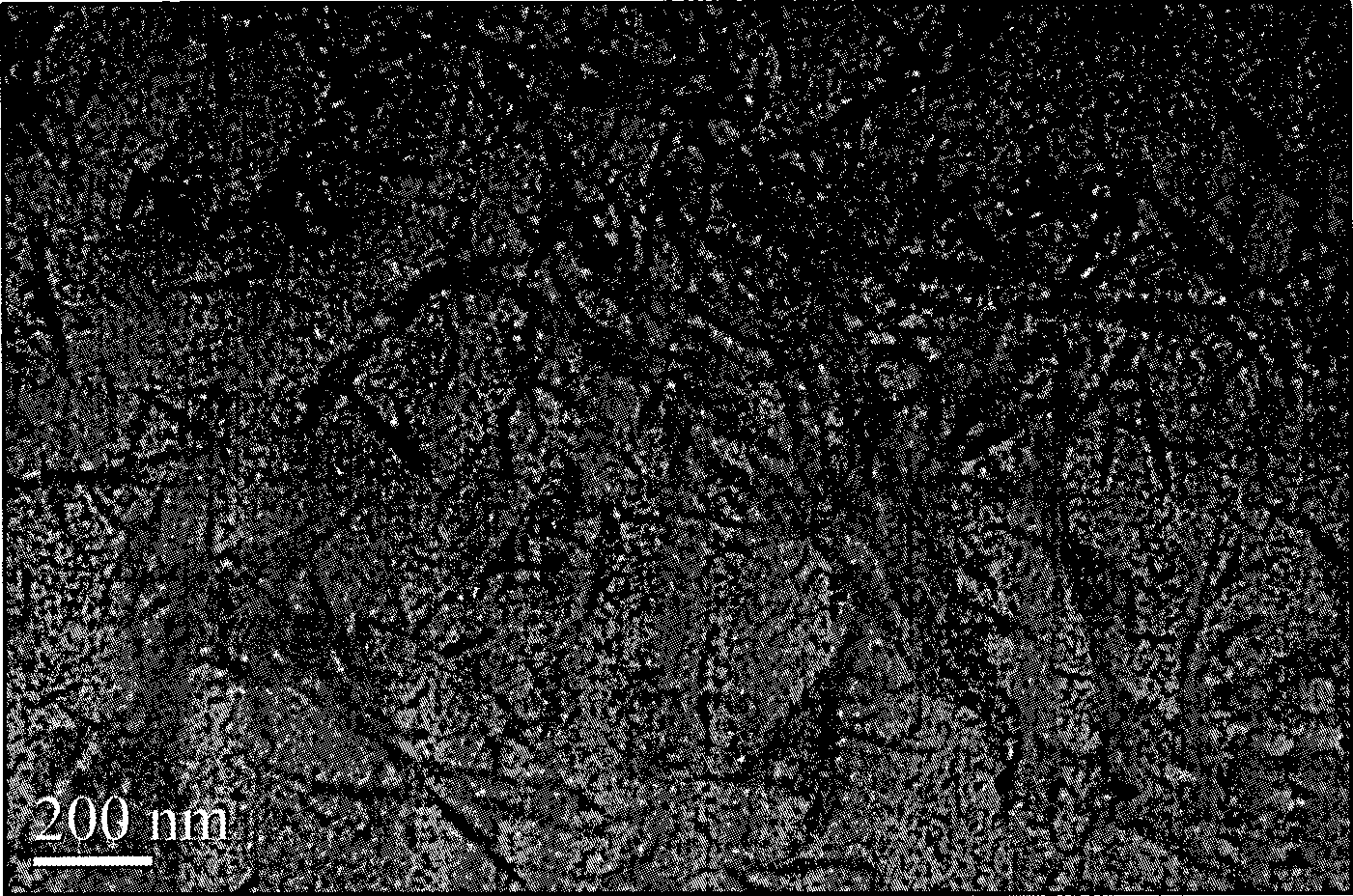

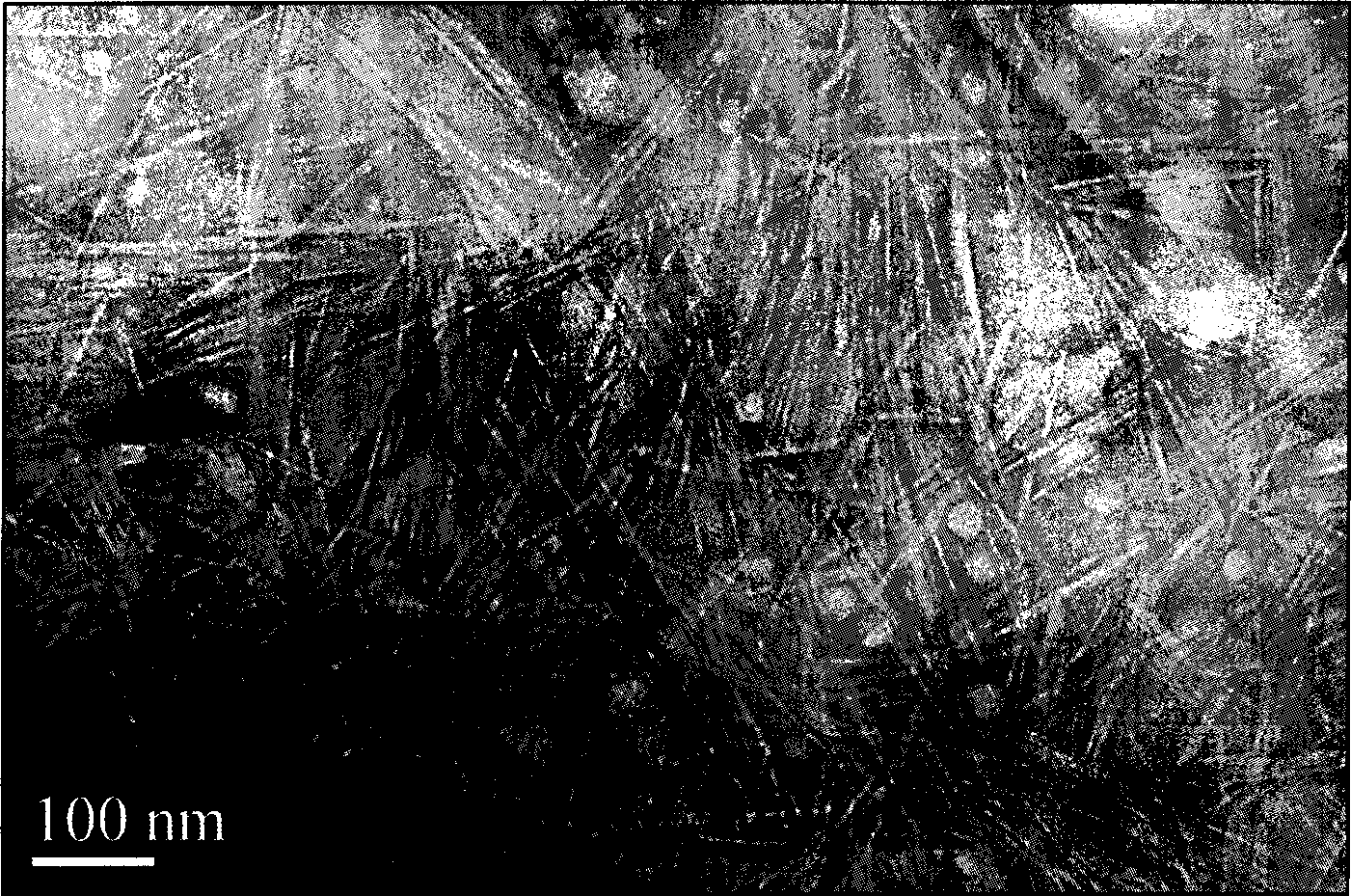

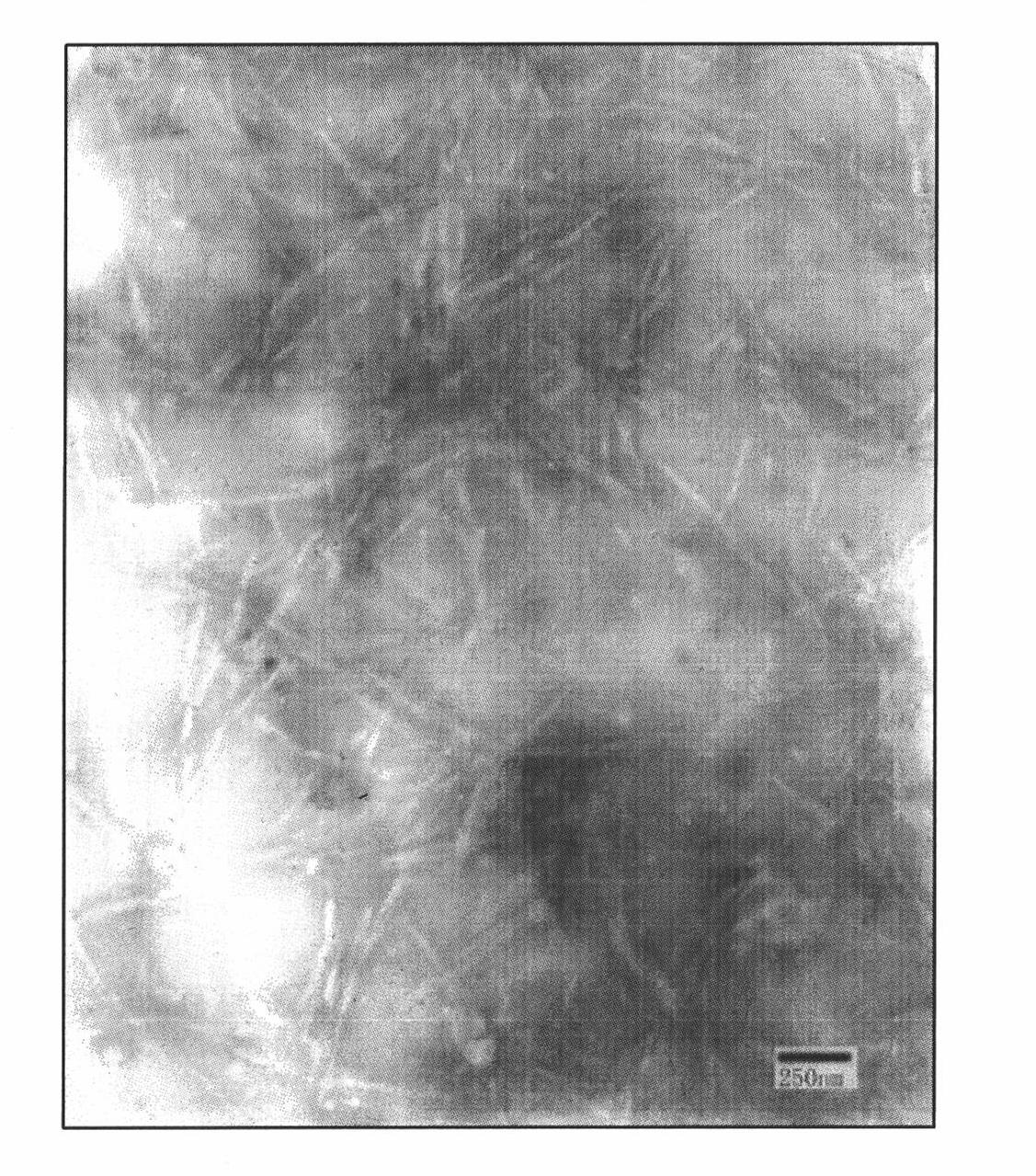

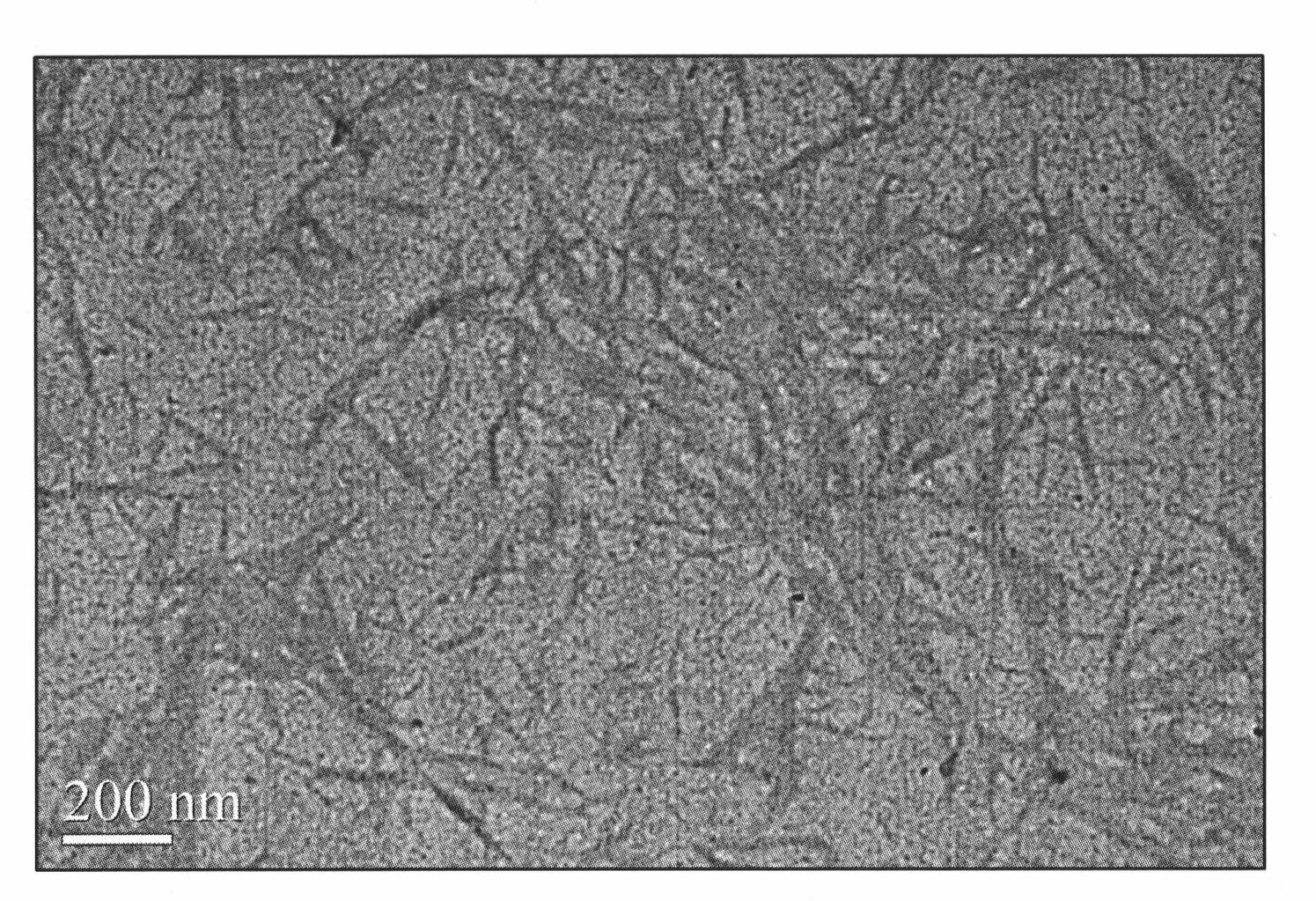

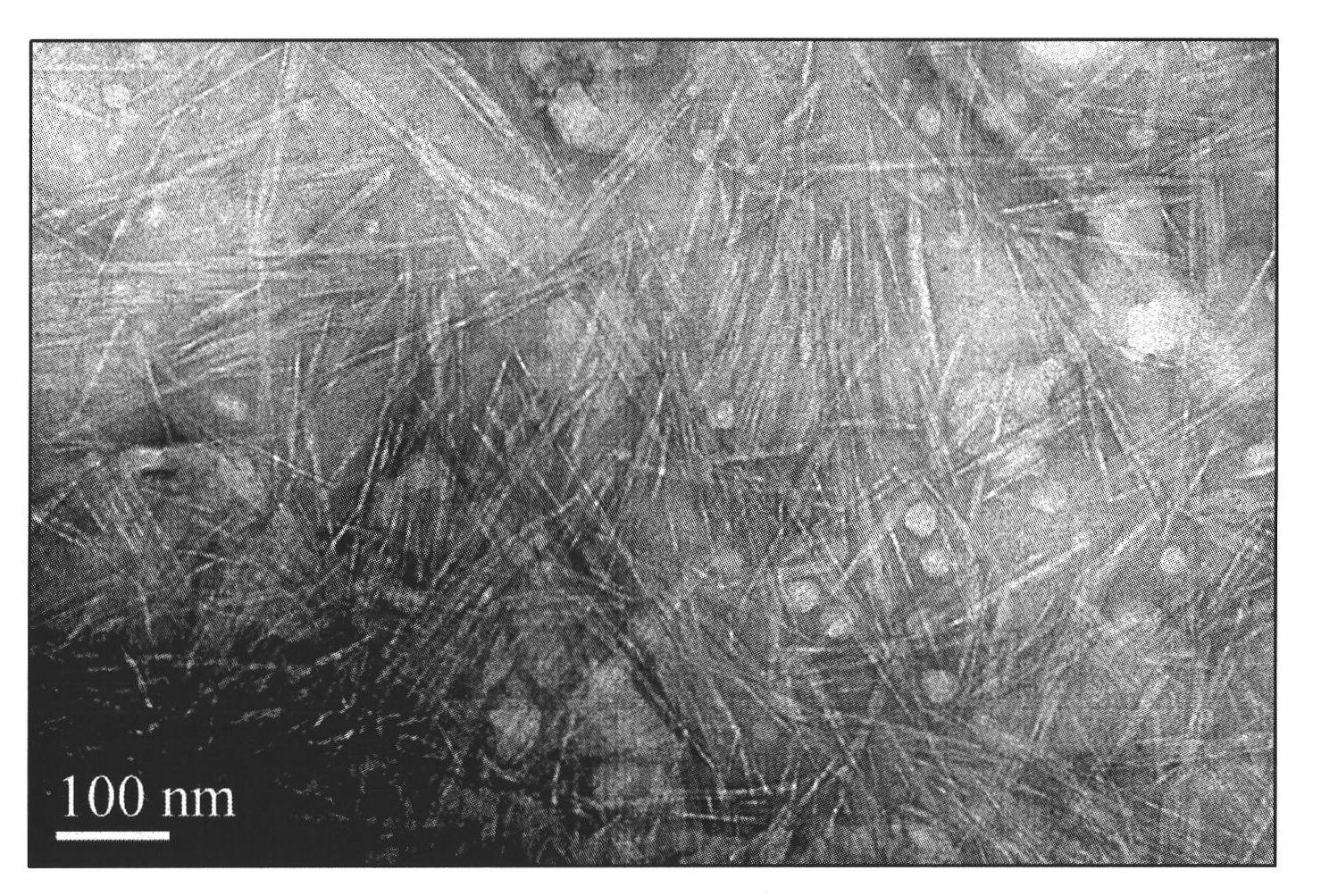

Method of preparing clubbed nano-cellulose

The invention discloses a method for preparing nano-rod cellulose, which comprises the following steps: dispersing fiber raw material into sulphuric acid water solution of which mass concentration is 50 to 65 percent, hydrolyzing the fiber raw material by single-mode microwave radiation for 5 to 60 minutes at a temperature of between 20 and 50 DEG C and at the microwave radiation power of 10 to 100 watts, then adding distilled water into hydrolysis solution and diluting the hydrolysis solution to have 10 times of volume, and obtaining stable nano-rod cellulose suspension through post treatment processes such as centrifugal separation, dialysis, filter, ultrasonic dispersion and the like of the diluent, so as to obtain the nano-rod cellulose of which width is about 10 nanometers and length is about 200 to 300 nanometers.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

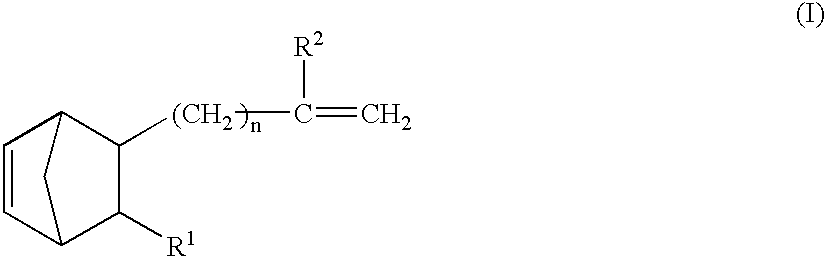

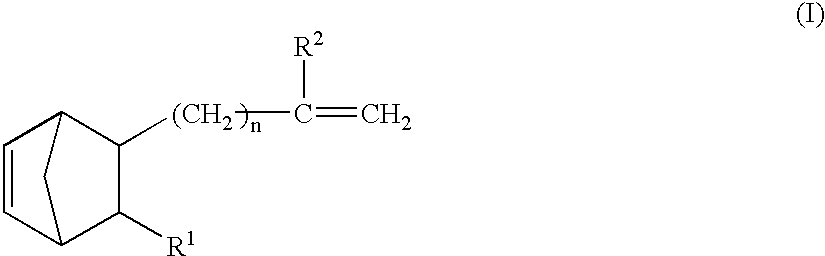

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition is crosslinkable at room temperature, has a gelation time at room temperature of 30 days or less, and can prepare a crosslinked rubber sheet by crosslinking the composition at room temperature, wherein the crosslinked rubber sheet has a tensile elongation of 20% or more, and is free of cracks after treatment at 40° C. in a 50 pphm ozone concentration for 96 hr. Specifically, it comprises an ethylene / alpha-olefin / non-conjugated polyene random copolymer rubber comprising a norbornene compound having a specific vinyl end group, an SiH group-containing compound, which has at least two SiH groups in one molecule, and optionally a platinum catalyst, a reaction inhibitor and / or a silane-coupling agent. The sealing, potting and coating materials and adhesives of the present invention comprise the above rubber composition.

Owner:MITSUI CHEM INC

Flame resistant polymer blends

ActiveUS20070100088A1Improvement in flame retardant (FR) performanceHigh tensile elongationSynthetic resin layered productsPolymer sciencePolycarbonate

Blends of siloxane copolymers, notably siloxane polyimides, with polyaryl esters or polyaryl ester carbonates containing linkages derived from resorcinol, show improved flame resistance, as measured by two minute and peak heat release, compared to conventional polycarbonates. In some instances transparent flame retardant blends can also be prepared. The compositions show good melt processability, high impact strength and high elongation, and can be used to make various flame retardant articles including sheets and films.

Owner:SHPP GLOBAL TECH BV

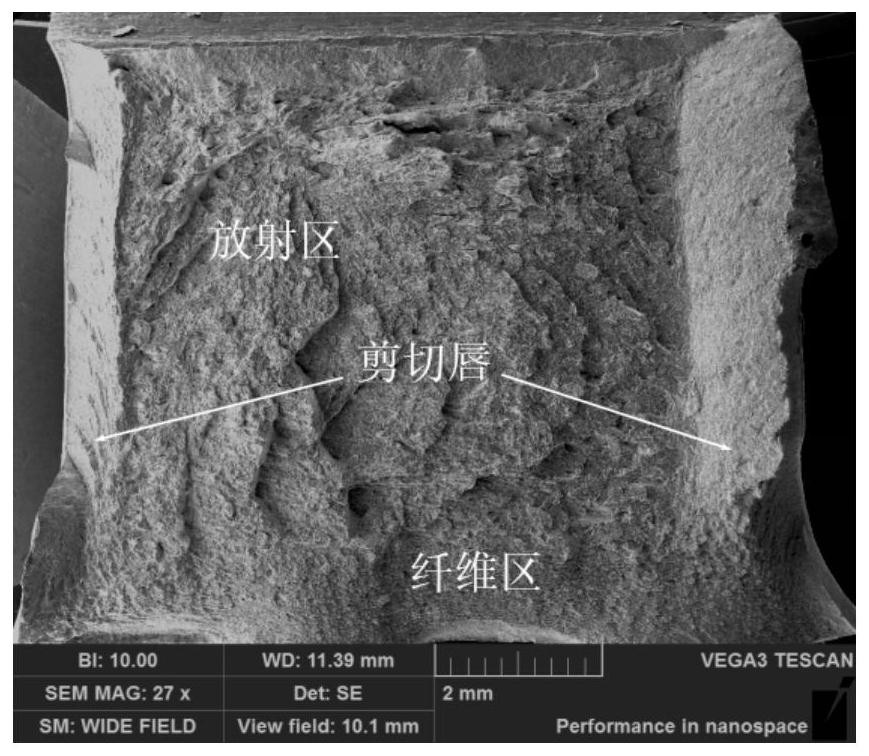

Carbon fiber, process for production thereof, prepregs, and golf club shafts

InactiveUS20070196648A1High compressive strengthTensile modulusSynthetic resin layered productsMonocomponent synthetic polymer artificial filamentCarbonizationGolf Ball

A carbon fiber tow composed of many carbon filaments and having a strand tensile strength of 3.8 to 5.5 GPa, a strand tensile modulus of 180 to 220 GPa and a carbon crystal size (Lc) of 13 to 18 Å. This carbon fiber tow can be produced by subjecting a precursor fiber tow composed of many polyacrylonitrile filaments which have a lightness difference (ΔL) of 50 or below and fineness of 1.1 to 1.7 dtex to oxidative stabilization and subjecting the stabilized fiber tow to carbonization with the maximum temperature within the range of 1,100 to 1,300° C. in an inert atmosphere while raising the temperature from 1,000° C. to the maximum temperature at a temperature rise rate of 100 to 2,000° C. / min.

Owner:TORAY IND INC

Nano-environment protection type polyurethane paving material for athletic ground and manufacture method thereof

The invention discloses a sports ground-used nanometer environmental-friendly type polyurethane paving material and a preparation thereof, and the paving material consists of A component, B component, black rubber particles and a catalyst; the A component is: diisocyanate: 20 to 50 percent; polyether polyol: 40 to 70 percent and a nanometer additive: 5 to 25 percent; the B component is: polyether polyol : 20 to 40 percent ; processing aid: 5 to 25 percent; nanometer additive: 0.1 to 5 percent; fillings: 40 to 70 percent, pigments: 0.1 to 2.0 percent; ultraviolet absorbent: 0.01 to 0.1 percent and antiaging agent: 0.01 to 0.1 percent, wherein, the weight proportion of the A component and the B component is 1:3 to 5, the black rubber particles account for 20 percent in the sum weight of the A composition and the B component, the catalyst accounts for 0.15 percent in the sum weight of the A composition and the B component. The preparation method is that, the A component and the B component are mixed according to the weight proportion of 1:3 to 5 of the A component and the B component, then the black rubber particles, the amount of which accounts for 25 percent in the sum weight of the A composition and the B composition are added, and after uniform mixing, zinc iso-octoate, the amount of which accounts for 0.15 percent in the sum weight of the A composition and the B composition are added, and then the track and field runway paving-used polyurethane elastomers are prepared after stirring and polymerization and solidification. The sports ground-used nanometer environment-friendly type polyurethane paving material takes low poisonous and high activity MDI as raw material and leads the environment-friendly property of the paving materials of plastic sports runways and sports playing courts to reach the international standard, and improve various physical index of products obviously.

Owner:TIANJIN JINGHONG SPORT FACILITIES TECH

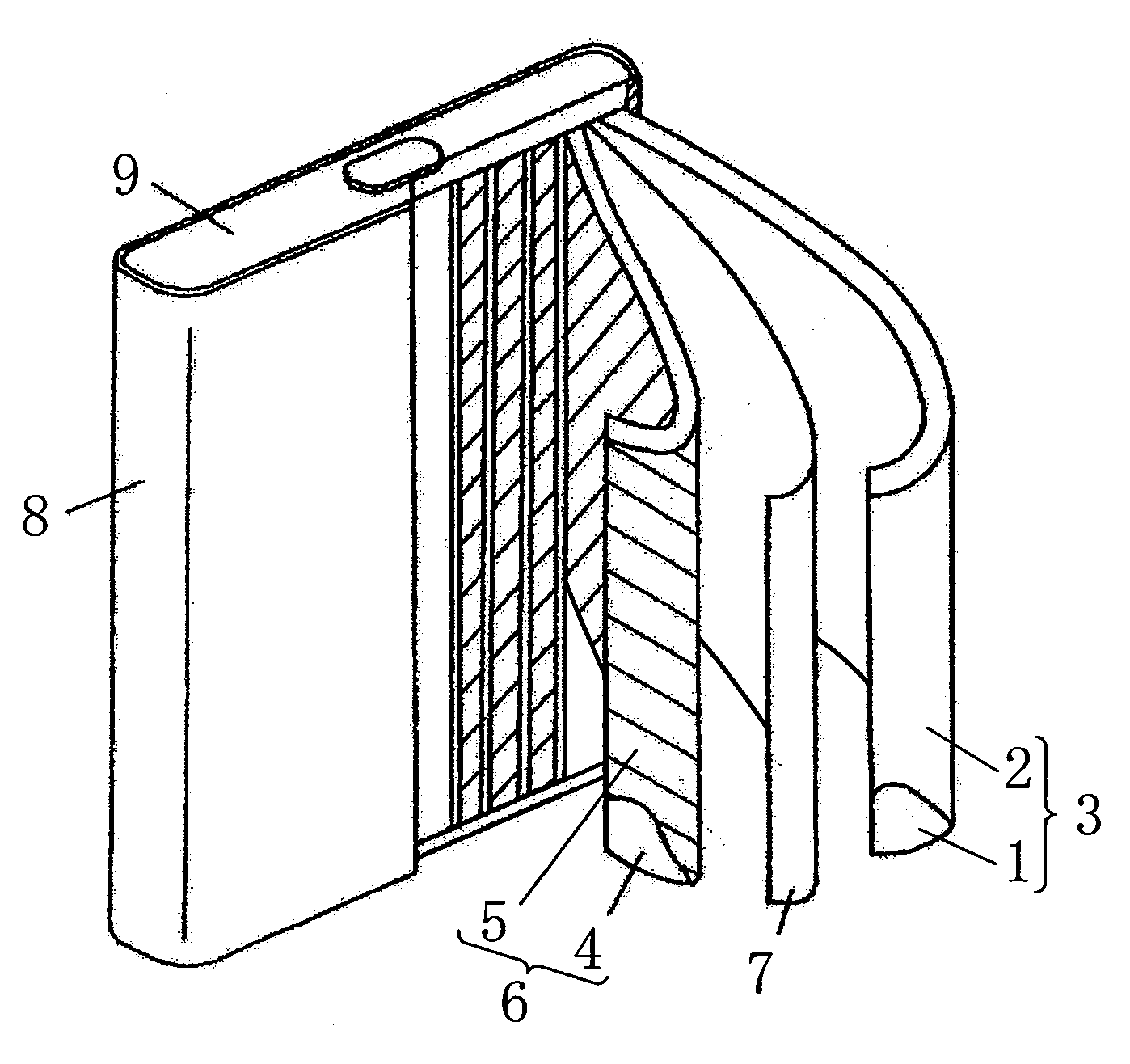

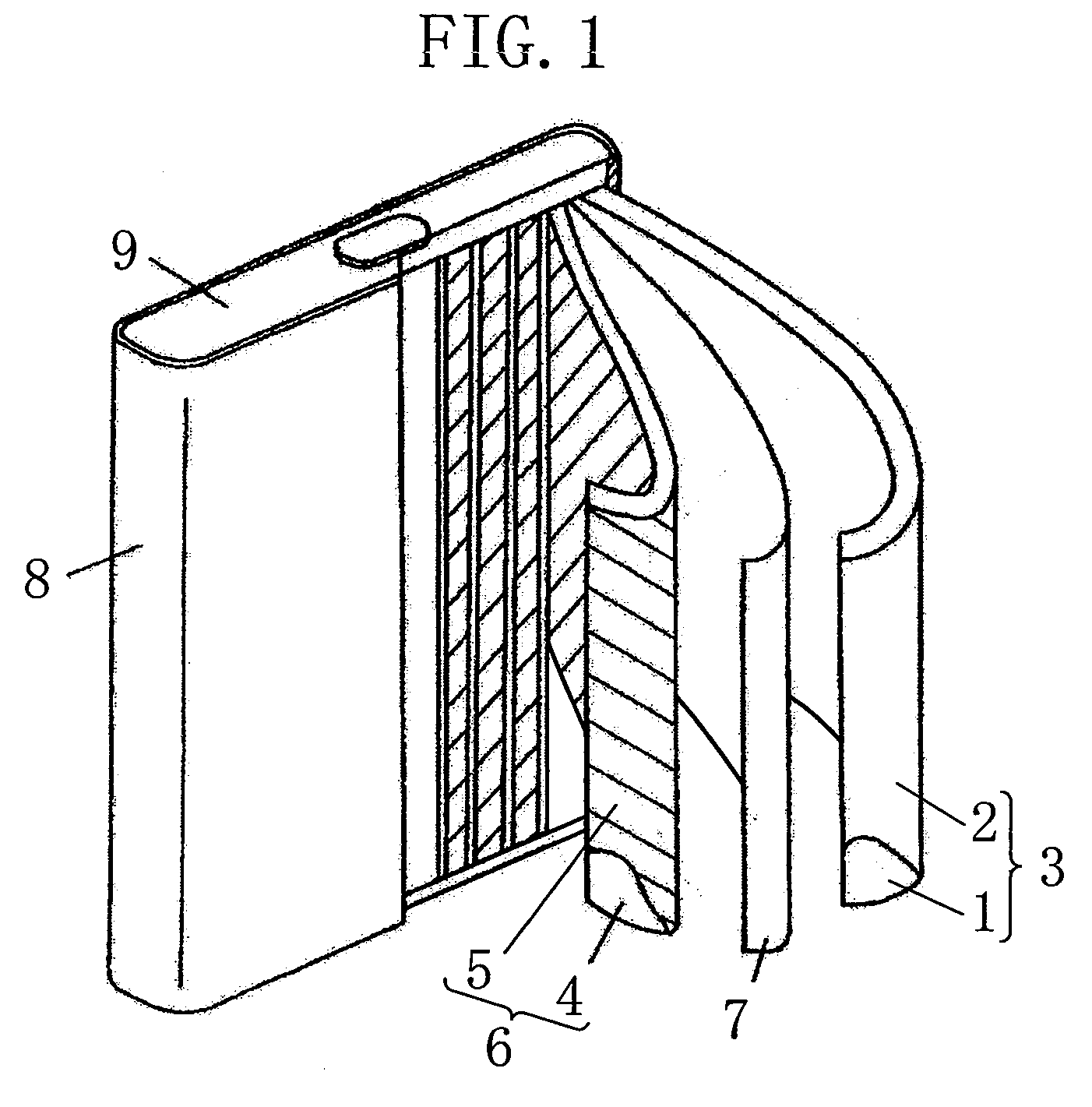

Lithium-based battery having extensible, ion-impermeable polymer covering on the battery container

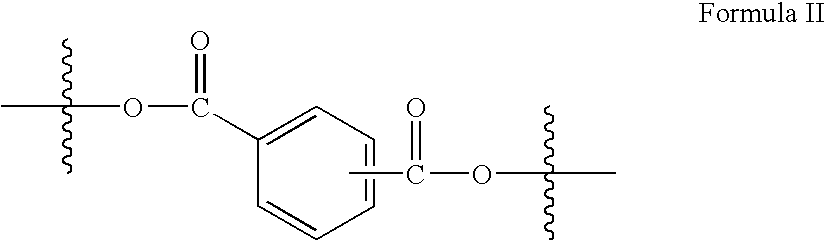

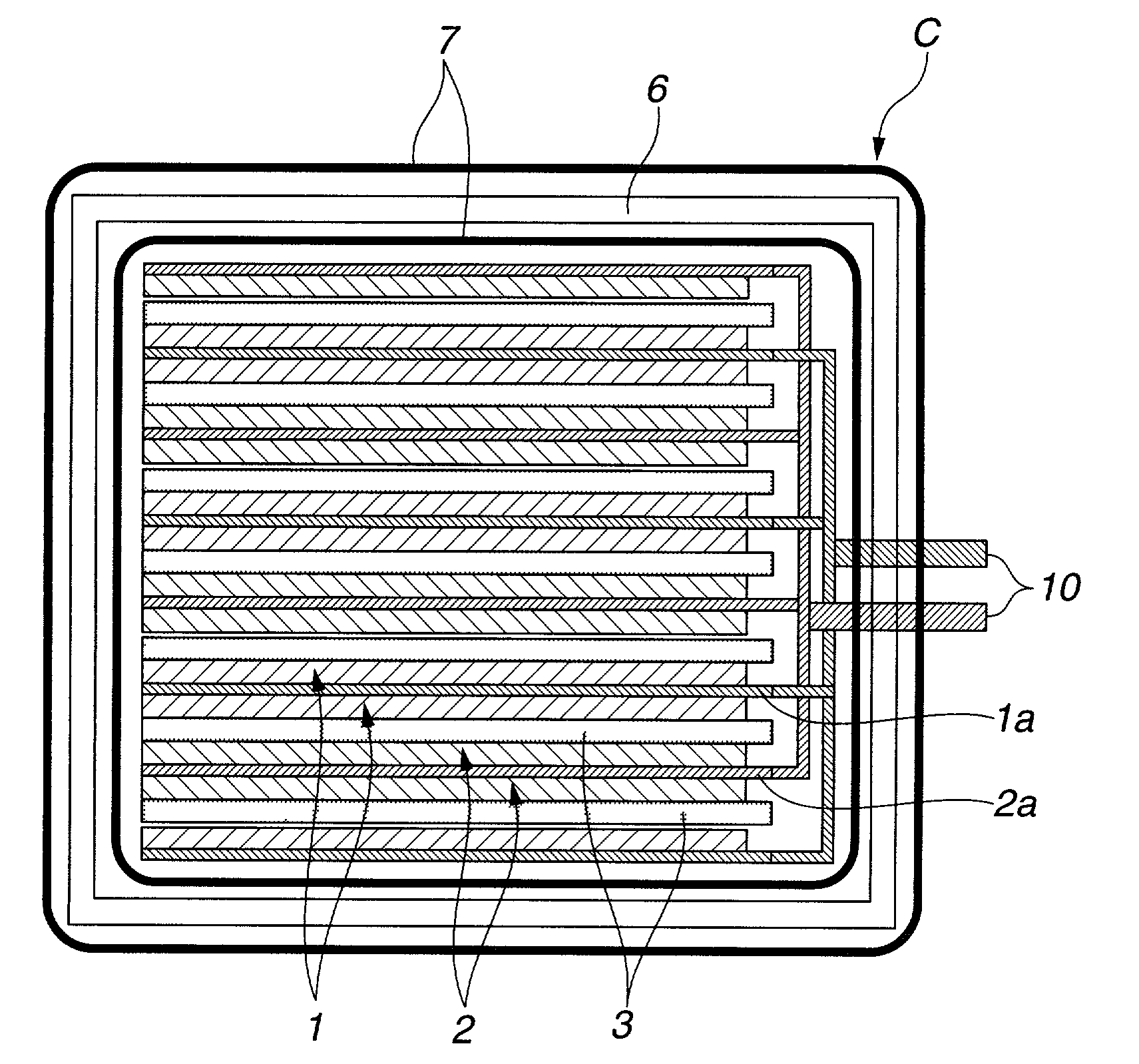

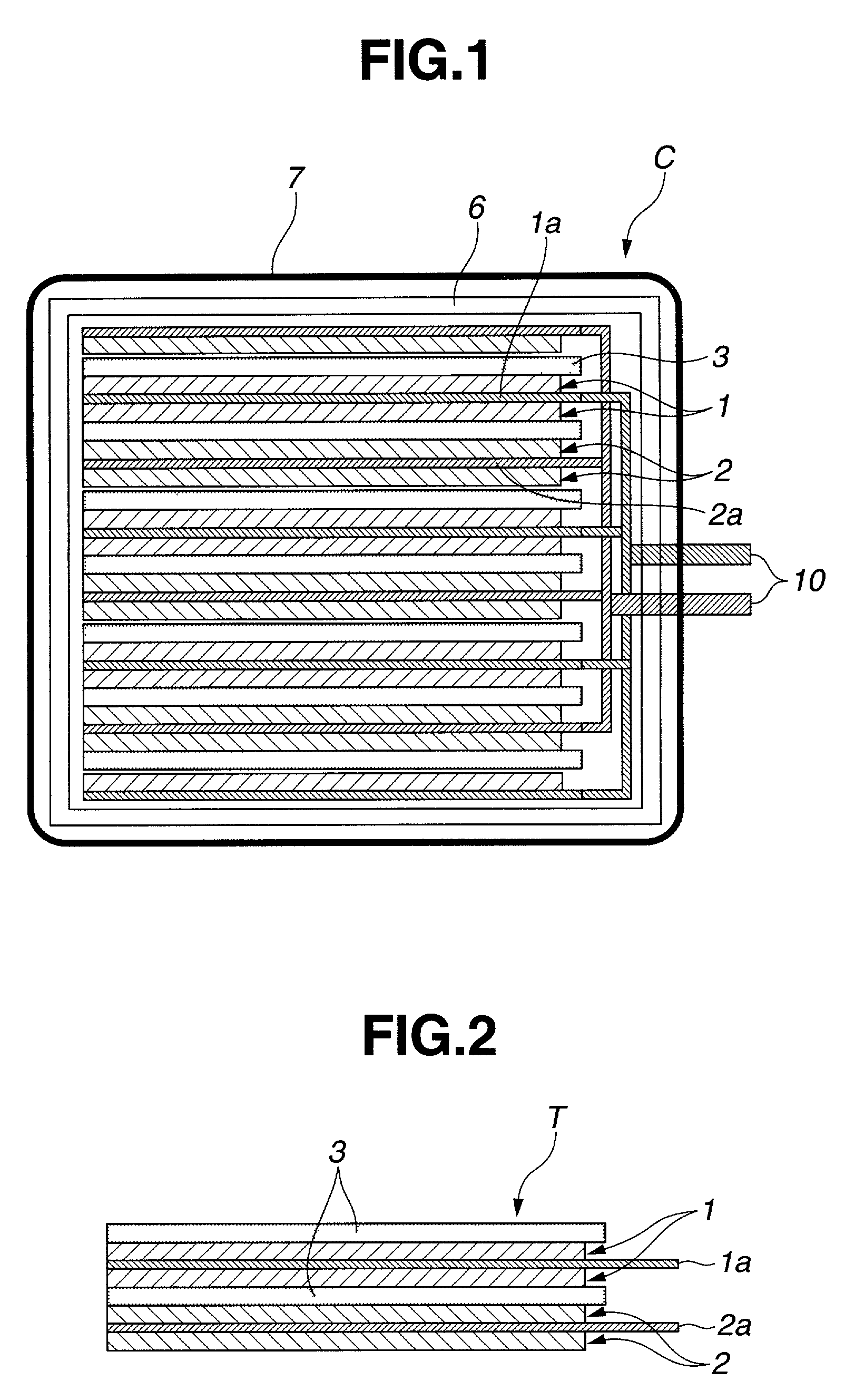

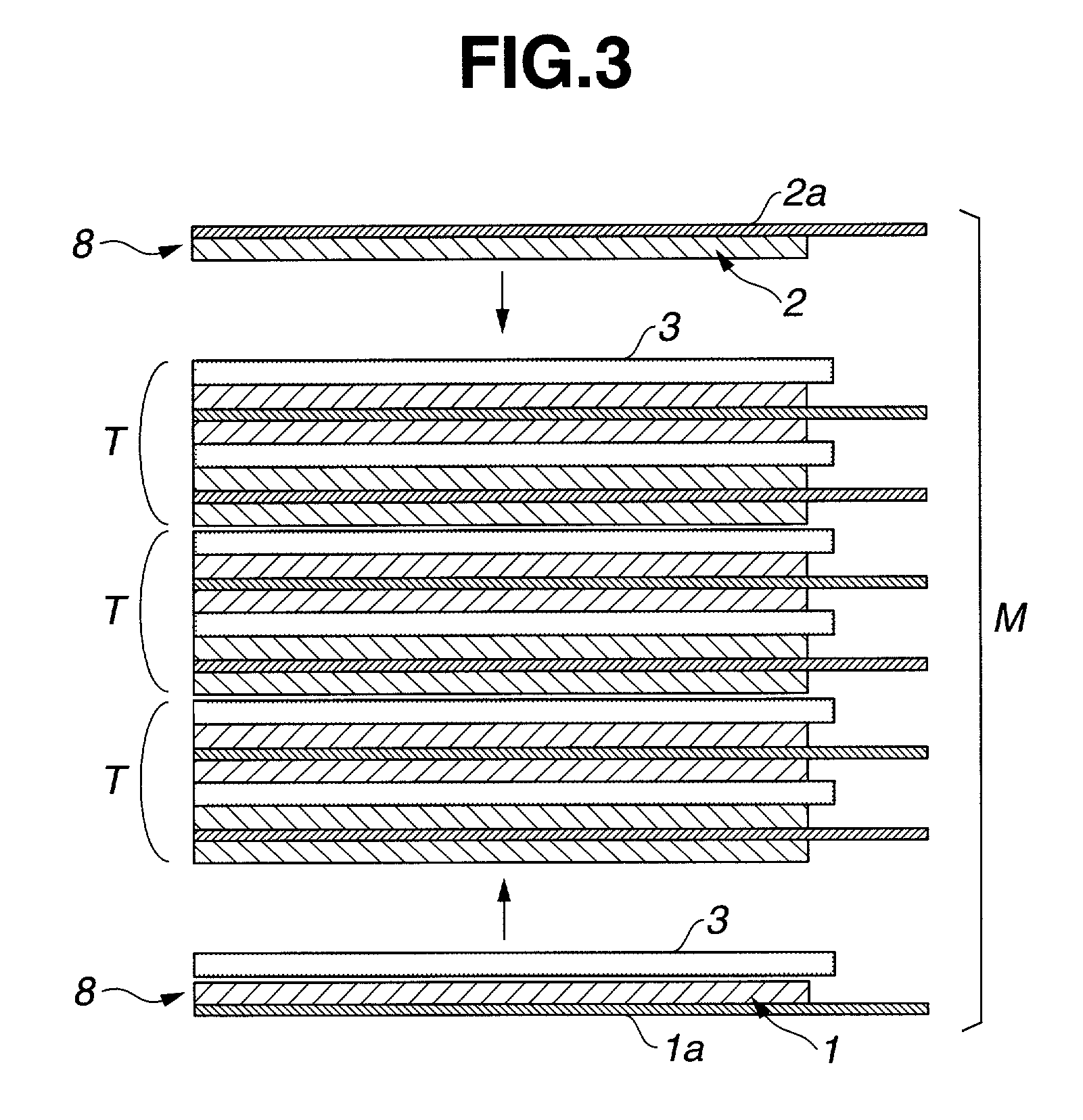

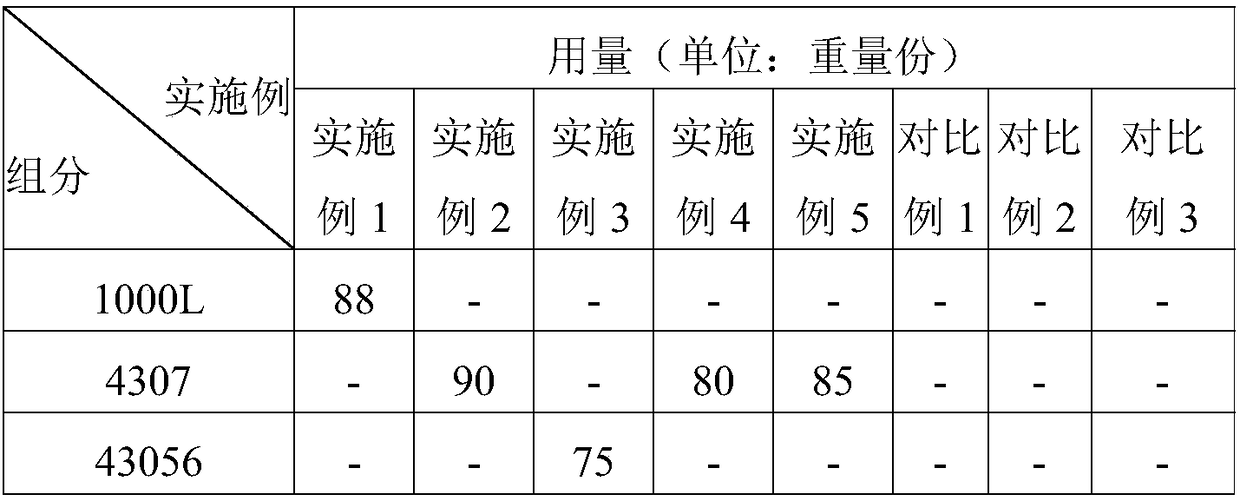

InactiveUS7332242B2Improve safetyHigh tensile elongationPrimary cell maintainance/servicingLarge-sized flat cells/batteriesUnit structureEngineering

A lithium based battery includes a cell structure group formed by stacking unit cells each including a positive electrode, a negative electrode, and a separator interposed therebetween, or formed by repeatedly folding or winding an integral body of the unit cells; a battery container for containing the cell structure group; and an electrolyte, which is poured in the battery container after the cell structure group is contained in the battery container. The outer peripheral surface of the battery container is covered with an ion impermeable and extensible high polymer sheet having a tensile elongation percentage of 1% or more. With this configuration, even if there happens such a severe accident that nail pieces the battery or the battery is crashed, it is possible to prevent a large short-circuit current from flowing between the positive and negative electrodes, and hence to ensure a higher safety of the battery.

Owner:ITOCHU CO LTD

Mo-Si-B-W multi-phase composite material and preparation method thereof

ActiveCN102424928AImprove high temperature strengthImprove reliabilityAlloyUltimate tensile strength

The invention discloses a Mo-Si-B-W multi-phase composite material, which is prepared with raw materials of the following atom percentages: 5-25 percent of silicon, 1-10 percent of tungsten, 5-30 percent of boron, and the resting being molybdenum. The mass purity of the silicon is no less than 98 percent, the mass purity of the tungsten is no less than 99 percent, the mass purity of the boron is no less than 99 percent, and the mass purity of the molybdenum is no less than 99 percent. The invention also discloses a preparation method of the Mo-Si-B-W multi-phase composite material. Mechanicalalloy and hot pressure sintering are adopted in the method to prepare the Mo-Si-B-W composite material, the method has the advantages of low energy consumption, short cycle and the like, and tungstenpowder is introduced into an Mo-Si-B composite material system so as to increase the high-temperature strength of the material and improve the reliability of the material in use. The composite material prepared in the method has a uniform and fine microstructure, the tensile strength of the composite material at 1400 DEG C is 400-460MPa, and the tensile elongation of the composite material is up to 400 percent.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

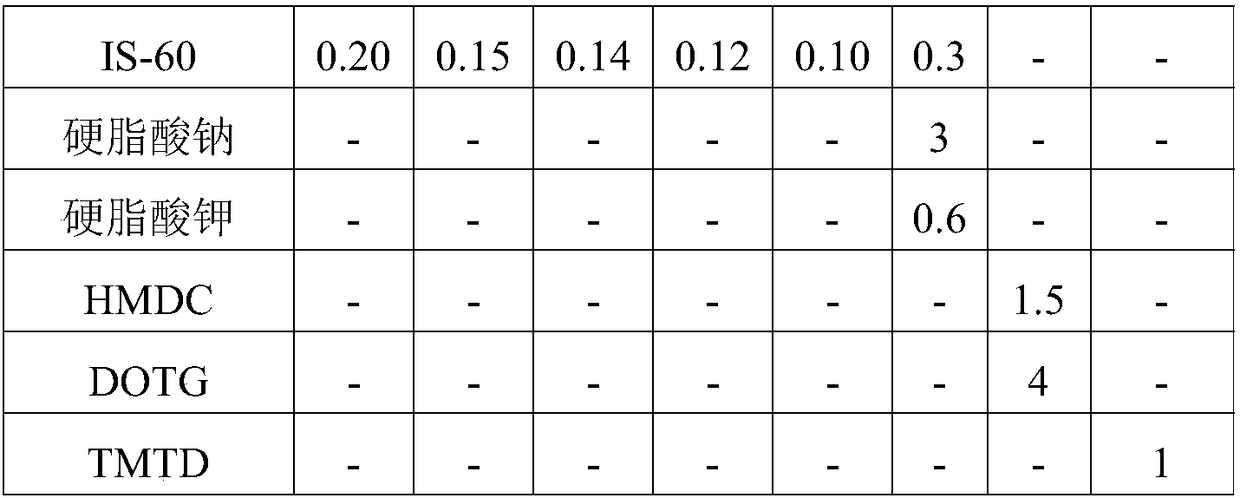

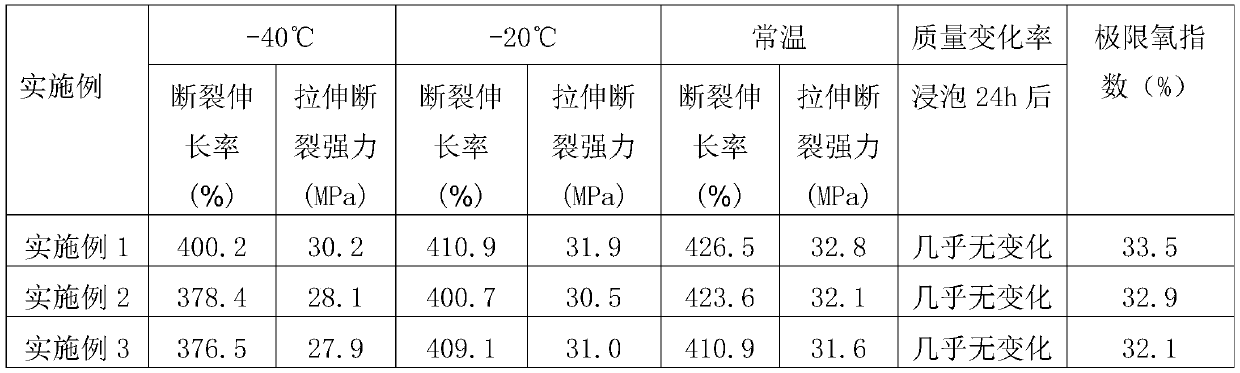

Hydrogenated butadiene-acrylonitrile rubber composition material and preparation method and application thereof

The invention discloses a hydrogenated butadiene-acrylonitrile rubber composition material, and a preparation method and application thereof. The hydrogenated butadiene-acrylonitrile rubber composition material is prepared from the following raw material components in parts by weight: 100 parts of hydrogenated butadiene-acrylonitrile rubber, 4-10 parts of zinc oxide, 0.5-2.5 parts of stearic acid,1-4 parts of an anti-ageing agent, 20-30 parts of carbon black with a particle size of 26-30 nm, 25-35 parts of carbon black with a particle size of 40-48 nm, 5-15 parts of white carbon black, 5-15 parts of a polyester polyether plasticizer, 2-4 parts of a vulcanizing agent and 1-3 parts of an auxiliary crosslinking agent. The acrylonitrile content of the hydrogenated butadiene-acrylonitrile rubber is 41.3-43.1%, the saturation degree of the hydrogenated butadiene-acrylonitrile rubber is 99% or more, and the Mooney viscosity ML(1+4) at a temperature of 100 DEG C of the hydrogenated butadiene-acrylonitrile rubber is 60-70. The composition material is relatively good in breaking strength, tearing strength and elastic ductility; the composition material has relatively good high-temperature resistance, low-temperature resistance and oil resistance; the composition material has a relatively long service life; and the composition material has excellent performance as an oil-seal material for an engine oil dipstick sleeve of an automobile. The preparation method of the composition material is simple in steps, easy in operation, and suitable for industrial production.

Owner:JIANGSU LUOSHI DAMPING MEMBER CO LTD

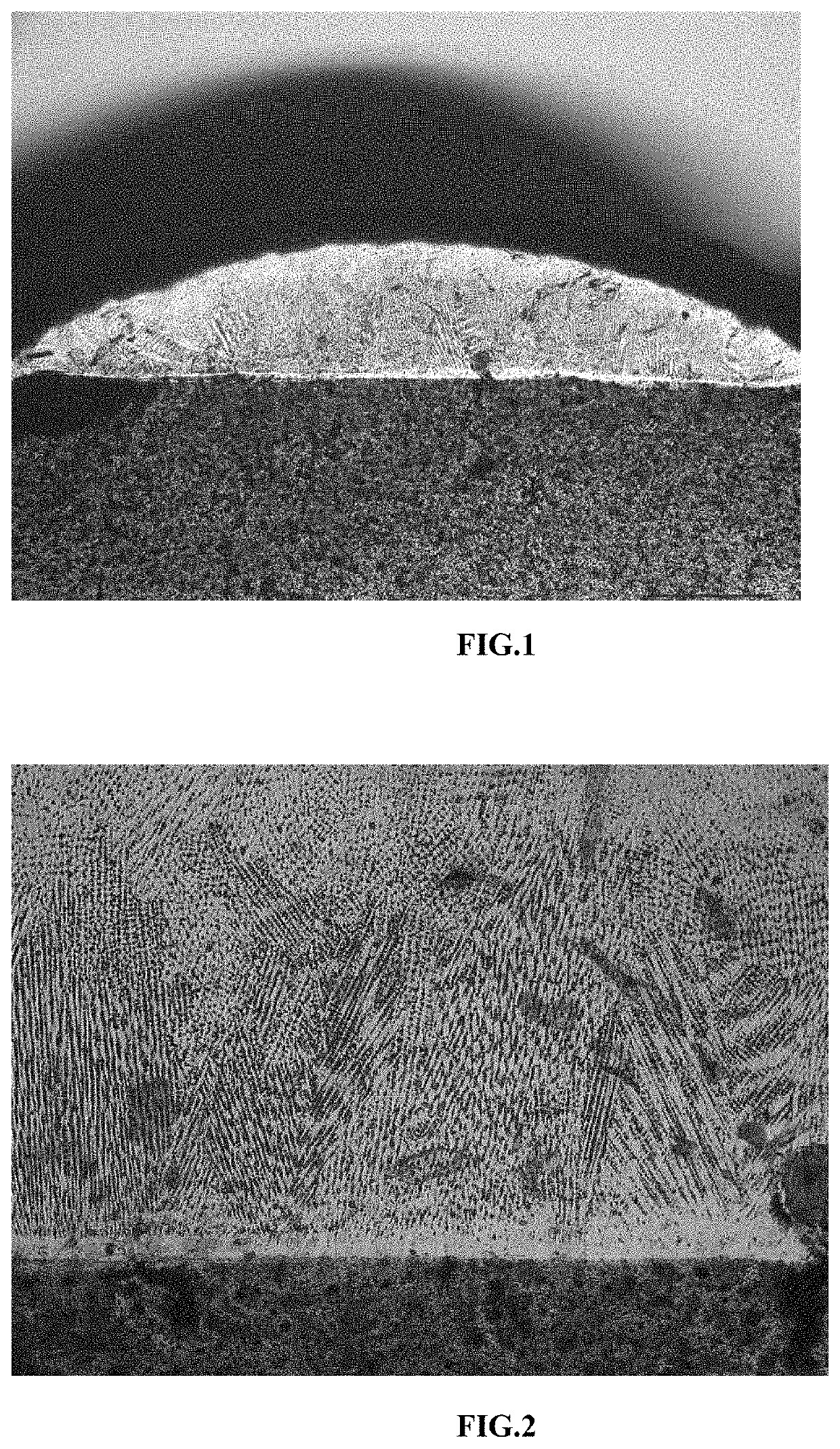

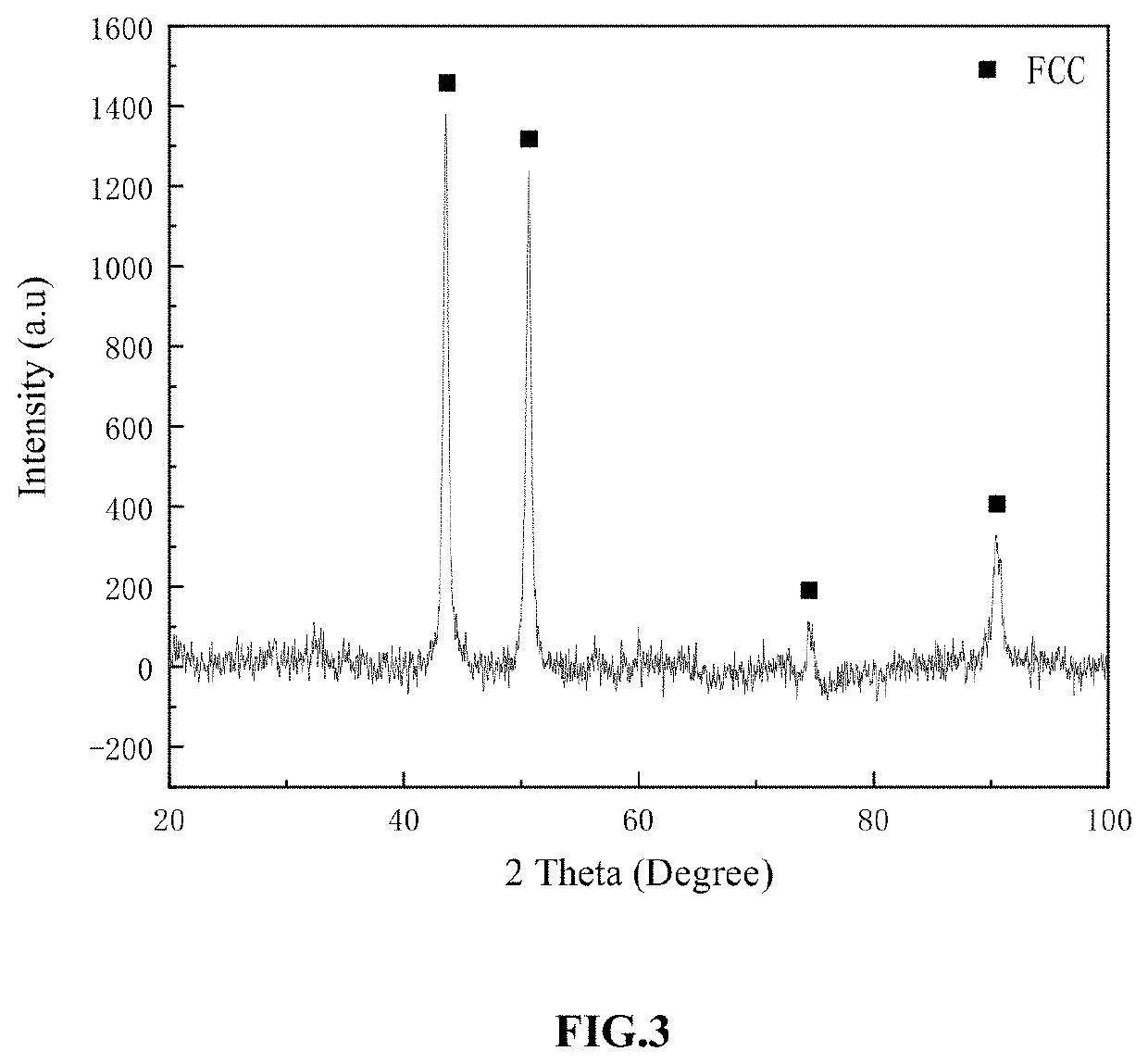

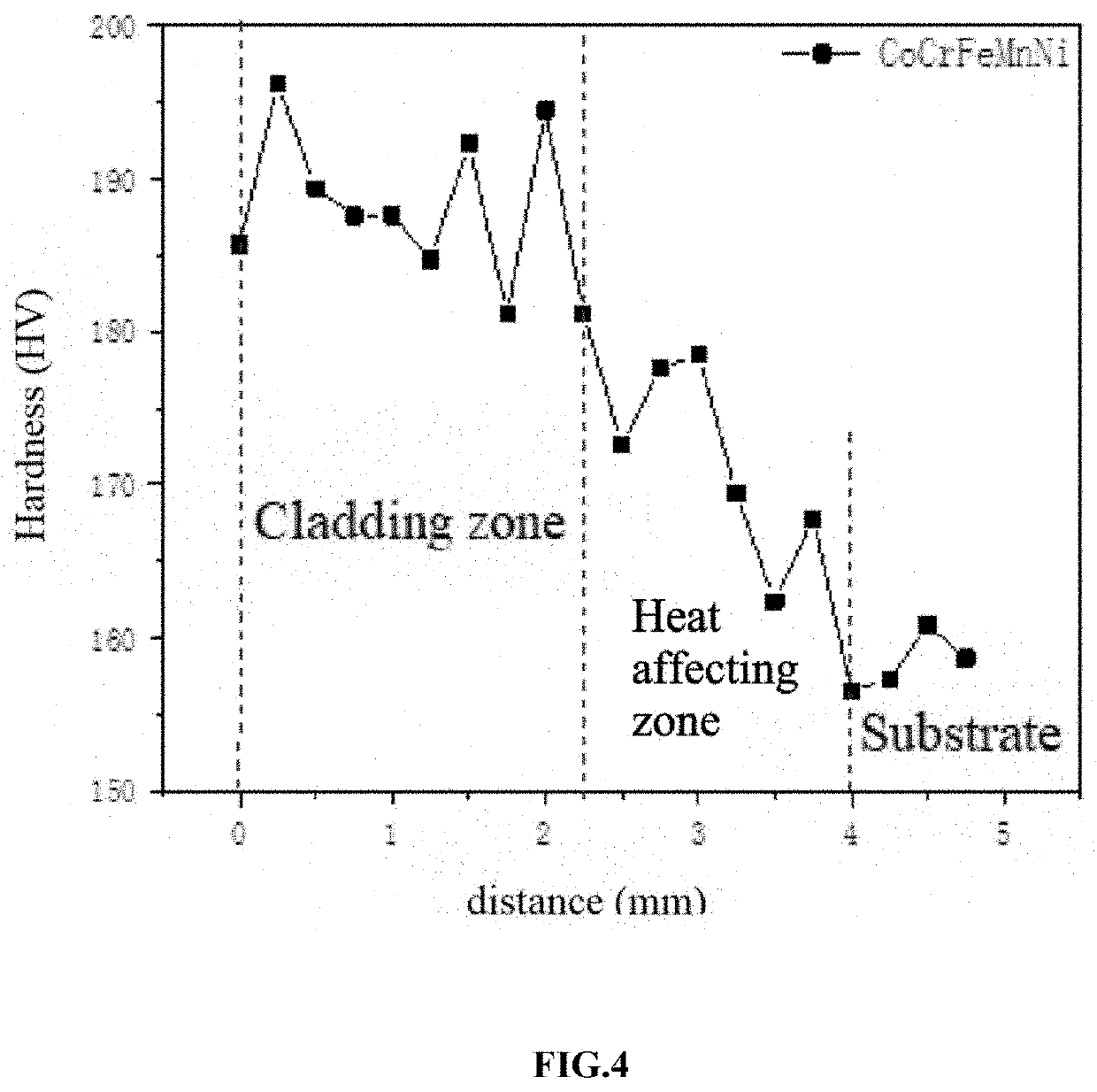

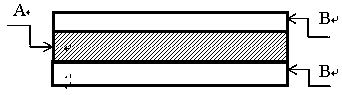

High entropy alloy powder for laser cladding and application method thereof

PendingUS20220097133A1High energy densityHigh cool speedAdditive manufacturing apparatusTransportation and packagingHigh entropy alloysTemperature treatment

The present disclosure discloses a high-entropy alloy powder for laser cladding and a use method thereof. The alloy powder is CoCrFeMnNiCx, and x has a value of 0.1-0.15. The specific method includes: subjecting a 45 steel substrate to surface pretreatment, mixing the weighed CoCrFeMnNi high-entropy alloy powder with different content of a nano-C powder uniformly and pre-placed on the pre-treated substrate surface to form a prefabricated layer, then placing the prefabricated layer at 80-90° C. for constant temperature treatment for 8-12 h, and under a protective atmosphere, subjecting the cladding powder to laser cladding on the surface of the 45 steel. The method of the present disclosure prepares a CoCrFeMnNiCx high-entropy alloy coating with performance superior to the CoCrFeMnNi high-entropy alloy coating.

Owner:KUNMING UNIV OF SCI & TECH

Easy-to-pull removable double-sided adhesive tape of TPU base material

ActiveCN109575826AHigh tensile strengthHigh tensile elongationNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceSilicone tape

The invention discloses an easy-to-pull removable double-sided adhesive tape of a TPU base material. The adhesive tape comprises the following components in parts by mass: 80-150 parts of rubber raw materials, 75-130 parts of tackifying resins, 100-350 parts of toluene, 0.1-5 parts of adhesion promoters and 5-15 parts of color paste. The adhesive tape of the TPU base material is a double-sided fixing adhesive tape with higher adhesive strength, can be used after stripping release paper or laminating release films when in use, can be removed only by stretching the adhesive tape when needed, andcan bring great convenience to workers in the maintenance of electronic components.

Owner:苏州世诺新材料科技有限公司

Ultrahigh-strength and high-ductility marine concrete material and preparation method thereof

The invention discloses an ultrahigh-strength and high-ductility marine concrete material and a preparation method thereof. The marine concrete material is a cement-based composite material. The cement-based composite material uses seawater, marine gravels and cement as raw materials which are subjected to mixing treatment to obtain the marine concrete material with compressive strength of larger than 150 MPa and ductility of larger than 6% under uniaxial tensile load. According to the invention, by adoption of the seawater to replace fresh water as mixing water, sea sand or coral sand to replace fine quartz sand or river sand as an aggregate and ultra-high-molecular-weight synthetic fiber as a micro-energy dissipative component, an ultra-high strength and high-ductility marine concrete material with the compressive strength exceeding 150 MPa and the ductility of larger than 6% under uniaxial tensile load can be prepared; thus, problems like shortage of fresh water and deterioration of the ecological environment can be alleviated; meanwhile, great technical benefits, economic benefits and environmental protection benefits brought by marine resourceful utilization can be realized.

Owner:SOUTHEAST UNIV

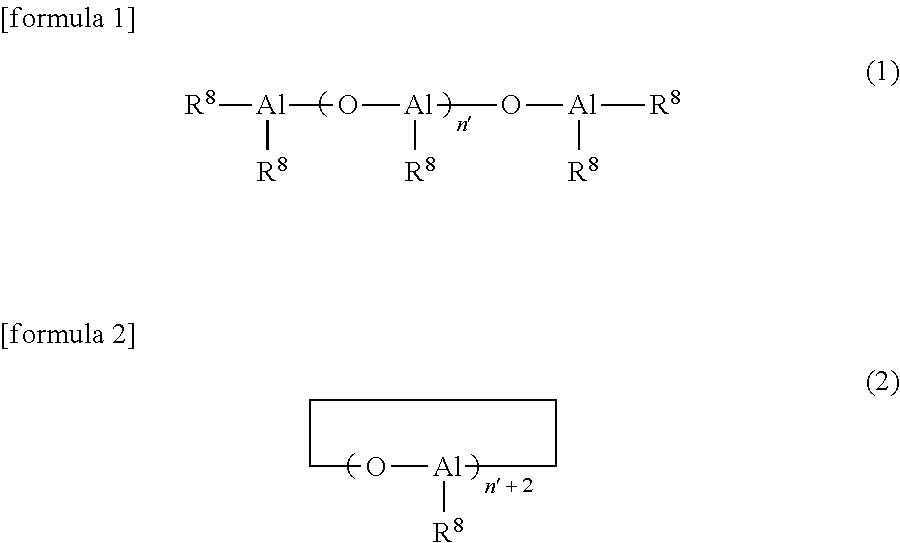

Process for producing conjugated diene polymer, conjugated diene polymer, and rubber composition

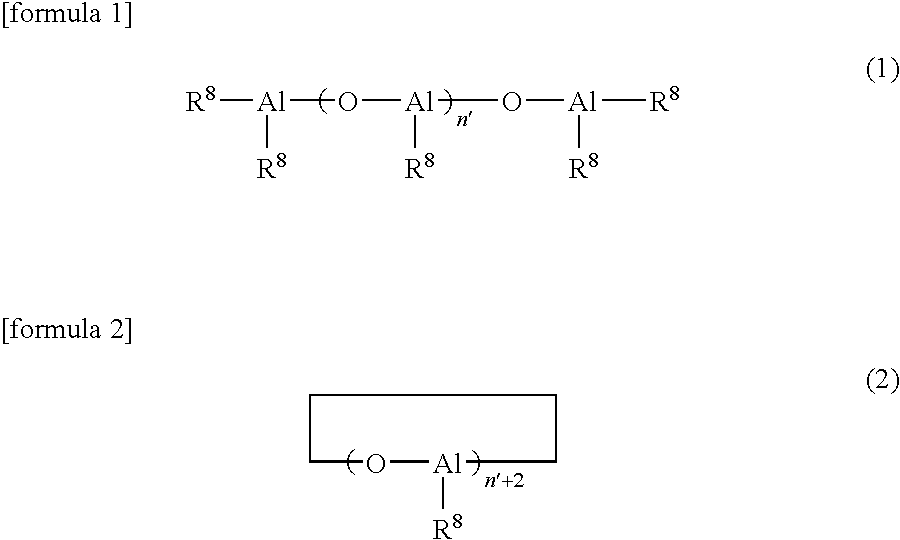

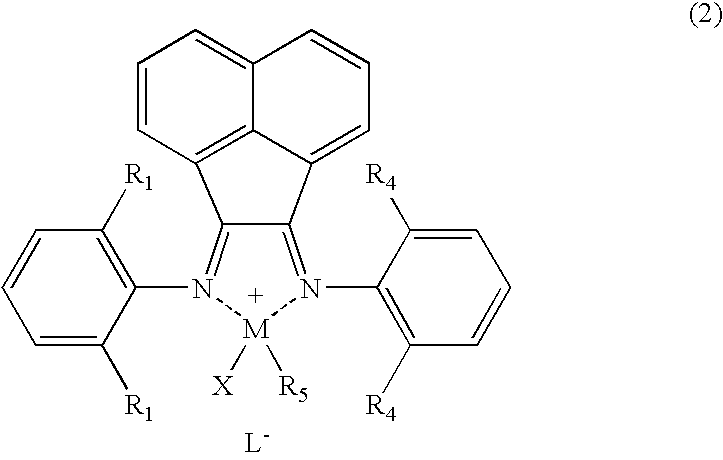

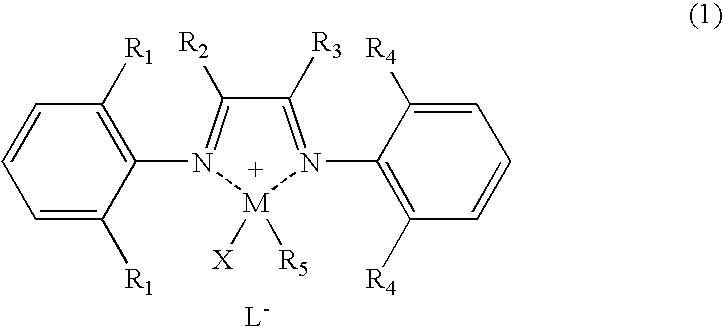

ActiveUS20090247695A1High cis-bond contentProduced simply and inexpensivelySpecial tyresPolymer scienceAluminoxane

A process for simply and inexpensively producing a conjugated diene polymer with a narrow molecular weight distribution and a high cis-bond content at a low cost is provided. The process comprises a polymerization step, wherein a conjugated diene polymer having a cis-1,4-bond content of 98.5 mass % or more and a ratio (Mw / Mn) of the weight average molecular weight (Mw) to the number average molecular weight (Mn) measured by gel permeation chromatography of 2.5 or less is obtained by carrying out a polymerization reaction in conjugated diene compounds using a catalyst composition containing a rare earth element-containing compound or a reaction product of the rare earth element-containing compound with a Lewis base, an aluminoxane and / or organoaluminum compound, and an iodine-containing compound.

Owner:ENEOS MATERIALS CORP +1

Method of preparing clubbed nano-cellulose

The invention discloses a method for preparing nano-rod cellulose, which comprises the following steps: dispersing fiber raw material into sulphuric acid water solution of which mass concentration is 50 to 65 percent, hydrolyzing the fiber raw material by single-mode microwave radiation for 5 to 60 minutes at a temperature of between 20 and 50 DEG C and at the microwave radiation power of 10 to 100 watts, then adding distilled water into hydrolysis solution and diluting the hydrolysis solution to have 10 times of volume, and obtaining stable nano-rod cellulose suspension through post treatment processes such as centrifugal separation, dialysis, filter, ultrasonic dispersion and the like of the diluent, so as to obtain the nano-rod cellulose of which width is about 10 nanometers and lengthis about 200 to 300 nanometers.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

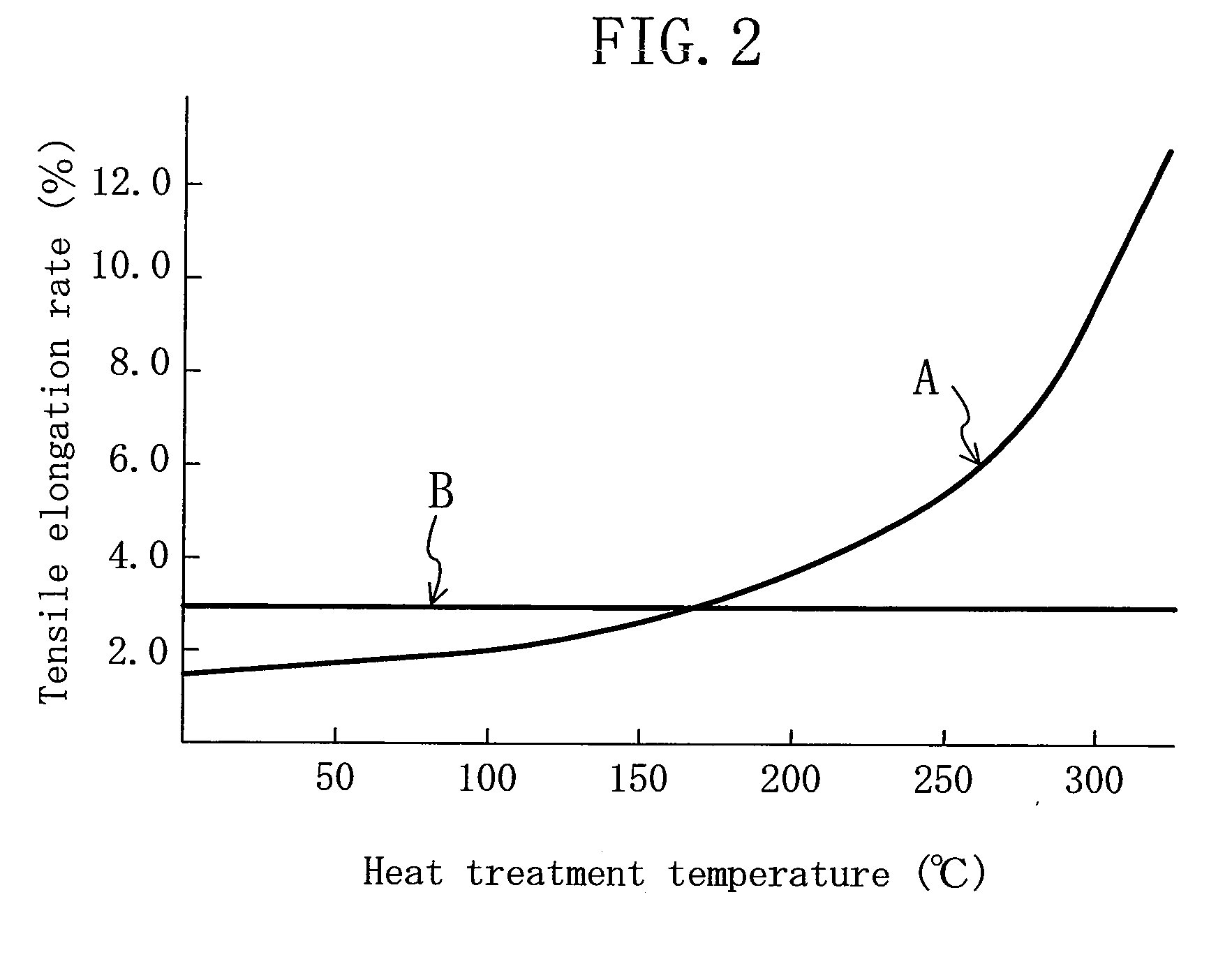

Nonaqueous electrolyte secondary battery and method for producing the same

InactiveUS20090274951A1Relieve pressureImprove stress conditionFinal product manufactureElectrode carriers/collectorsMaterials scienceCurrent collector

A nonaqueous electrolyte secondary battery includes an electrode group in which a positive electrode plate including a positive electrode active material formed on a positive electrode current collector and a negative electrode plate including a negative electrode active material formed on a negative electrode current collector are wound with a separator interposed therebetween, and a tensile elongation rate of the positive electrode plate is larger than a tensile elongation rate of the negative electrode plate.

Owner:PANASONIC CORP

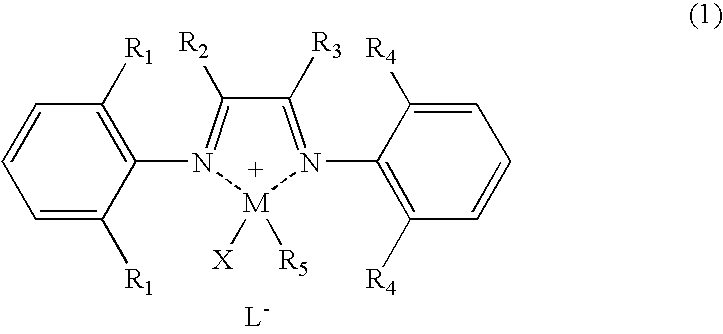

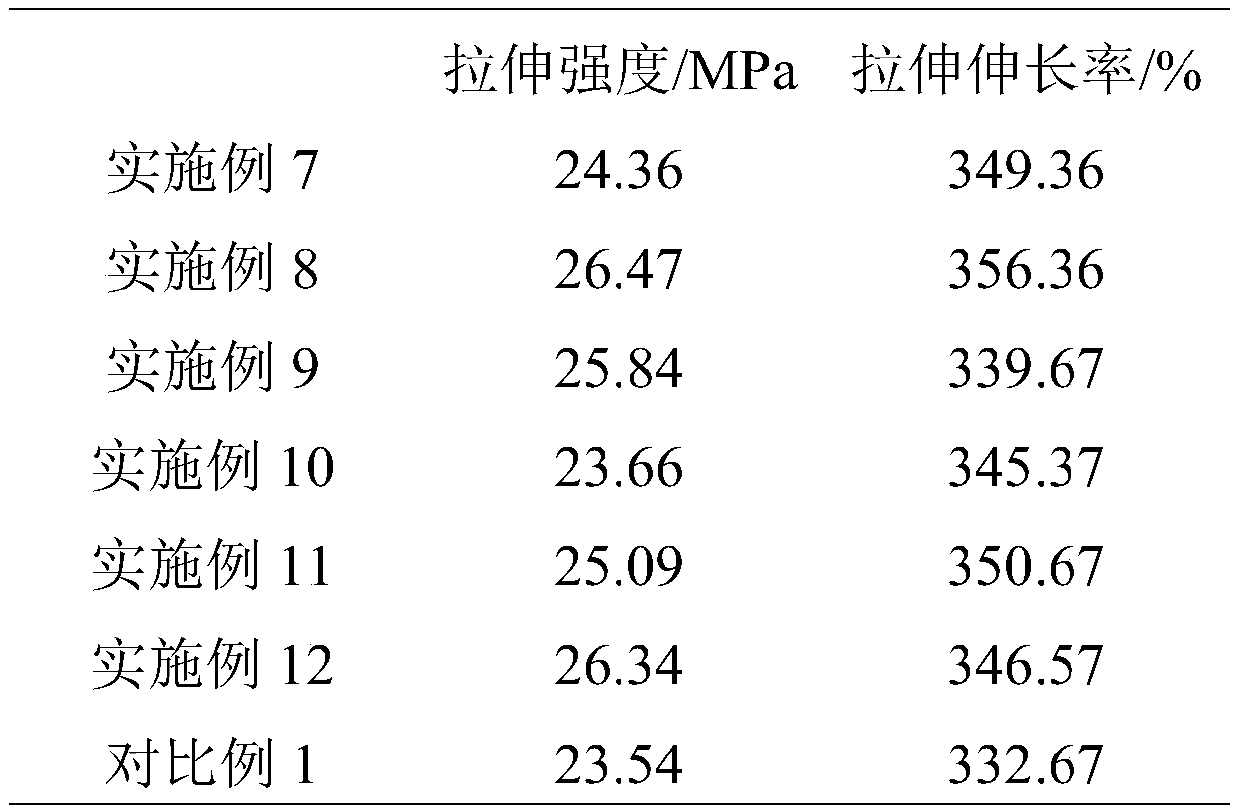

Polyolefin graft copolymer

The present invention provides a polyolefin copolymer in which an olefin monomer is graft-copolymerized to modified particles of a metallic compound. The polyolefin graft copolymer can be obtained by graft-copolymerizing the olefin monomer to modified particles of a metallic compound in the presence of a coordination polymerization catalyst in the presence of, particularly, a coordination polymerization catalyst of a late transition metal complex. Further, the property of a polyolefin resin can be improved by blending the polyolefin graft copolymer to a polyolefin resin.

Owner:KANEKA CORP

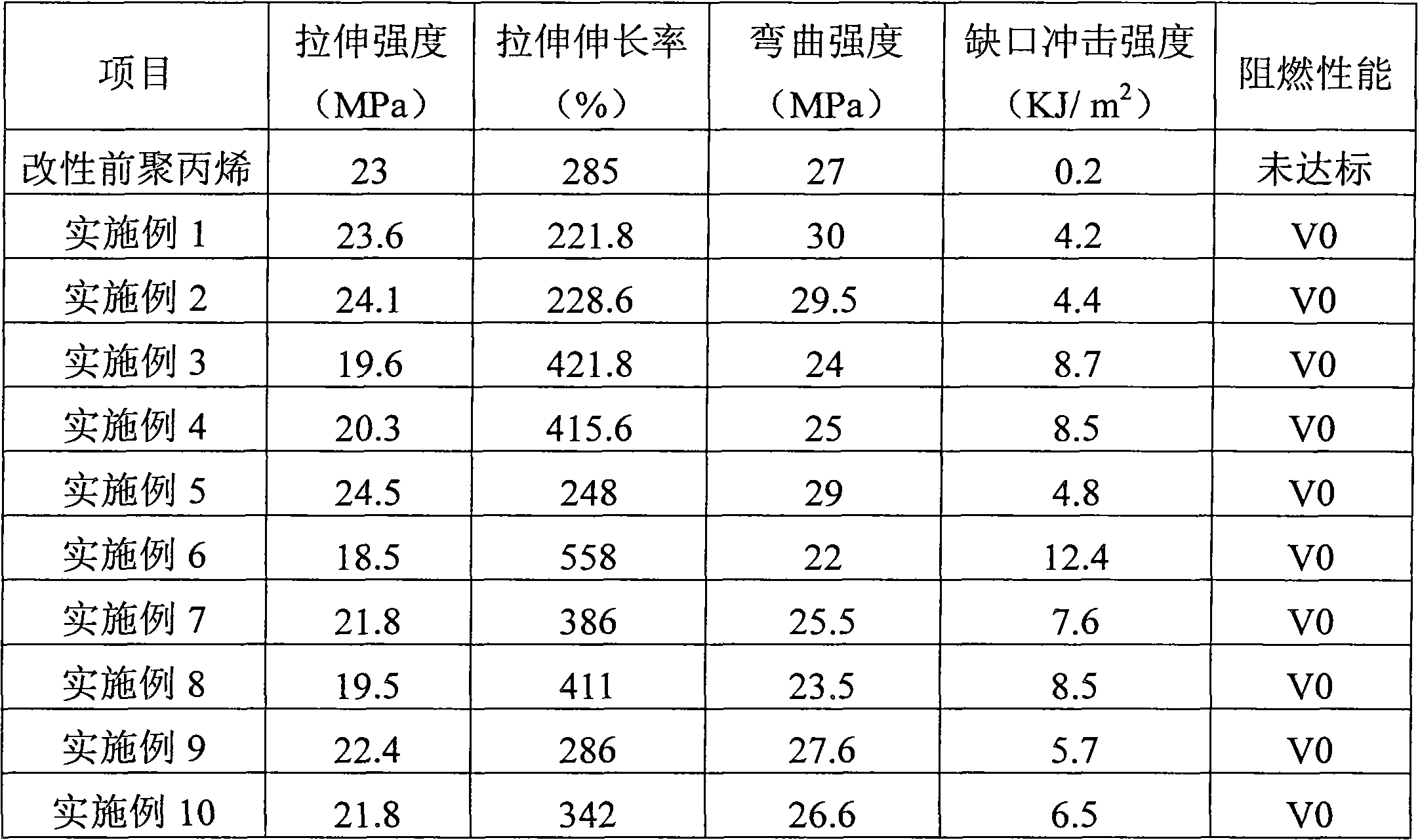

Fire-retarding and low-temperature resistant polypropylene material, preparation method thereof and use thereof

ActiveCN101974195AImprove flame retardant performanceReduce stretchPedestrian/occupant safety arrangementInsulated cablesThermoplastic elastomerFlexural strength

The invention discloses a fire-retarding and low-temperature resistant polypropylene material, a preparation method thereof and use thereof. The material consists of 50 to 75 weight parts of co-polypropylene, 15 to 25 weight parts of fire retardant, 10 to 25 weight parts of thermoplastic elastomer and 0.2 to 0.5 weight part of antioxygen. The preparation method comprises: mixing the components in a high-speed mixer; feeding the mixture in an double-screw extrude equipped with multistage heating zones; and uniformly dispersing, extruding to make grains, and obtaining the fire-retarding and low-temperature resistant polypropylene material. The fire resistance of polypropylene material reaches UL94-3.2mm V0, the polypropylene material can bear a temperature of -20DEG C, the tensile strength of the polypropylene material is over 18MPa, the tensile elongation of the polypropylene material is over 200 percent, and the bending strength of the polypropylene material is not less than 22MPa. The fire-retarding and low-temperature resistant polypropylene material can be used for making automobile safety cell, control wire twisted sleeve, various outdoor electric wire protective sleeves and the like.

Owner:合诚技术股份有限公司

Water-soluble high-strength high-elasticity putty paint and preparation method thereof

InactiveCN103788856AStrong adhesionHigh tensile elongationFilling pastesPolyurea/polyurethane coatingsWater solubleDiluent

The invention relates to a water-soluble high-strength high-elasticity putty paint and a preparation method thereof. The water-soluble high-strength high-elasticity putty paint comprises a component A and a component B in a weight ratio of 1: (0.8-1.2), wherein the component A is putty powder, and the component B comprises, in parts by weight, 400-500 parts of elastic resin, 60-100 parts of curing agent, 5-50 parts of tackifier, 5-50 parts of water repellent agent, 50-100 parts of diluent and 25-100 parts of foamed filaments. The putty paint prepared by rationally adjusting the composition and proportions of various raw materials is good in adhesion which is greater than or equal to 2MPa, high in elongation at break and thus capable of extending by 3-4 times, excellent in waterproofness and capable of resisting weather for 15 years, extra excellent in waterproofness and alkali resistance, exceeding 1000hr, respectively, and also environment-friendly and pollution-free; and the formed coating is thick to feel, soft in luster and even in chroma.

Owner:广东德普威涂料有限公司

Polyester resin composition and insulated wire using same

InactiveUS7541544B2Improve heat resistanceHigh tensile elongationPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

A polyester resin composition according to the present invention includes: a PBT resin; a styrene system elastomer; and a compound having a glycidyl group or a polyolefin composition in an amount of 50-80 wt %, 10-30 wt % and 10-30 wt %, respectively.

Owner:HITACHI CABLE

Oil resistant, high and low temperature resistant ethylene propylene diene monomer rubber/polyurethane rubber cable material

InactiveCN105111591AReduce oxidation activityImprove heat resistanceRubber insulatorsPolymer scienceEPDM rubber

The invention discloses an oil resistant, high and low temperature resistant ethylene propylene diene monomer / polyurethane rubber bable material. The raw material comprises the following components: ethylene propylene diene monomer rubber, polyurethane rubber, ethylene acrylate, EPDM rubber grafted with maleic anhydride, carbon black, pottery clay, coumarone resin, zinc oxide, stearate, magnesia, zinc methacrylate, benzoyl peroxide, trimerization thiocyanate, trimethylol propane trimethacrylate, accelerator M, accelerant DZ, antioxidant, dihydroxy higher alcohol, diethylene glycol dibenzoate, epoxidized soybean oil and N-(morpholine thiosulfate) phthalimide. The oil resistant, high and low temperature resistant ethylene propylene diene monomer / polyurethane rubber bable material disclosed by the invention is high in mechanical strength, excellent in oil resistance, high in temperature resistance and cold tolerance; and the cable made from the material is long in service life, so that the cost can be reduced.

Owner:繁昌县菲德通讯材料设计有限公司

Heat-resistant and oil-resistant sealing ring and preparation method thereof

The invention provides a heat-resistant and oil-resistant sealing ring and a preparation method thereof. Nitrile rubber is adopted as a main material and has excellent oil resistance and heat resistance, and the nitrile rubber is adopted as a main raw material for preparing the heat-resistant and oil-resistant sealing ring, so that the sealing ring has excellent oil resistance and heat resistance;a polyolefin elastomer can enable the sealing ring to have high tensile strength and tensile elongation; chlorosulfonated polyethylene is used for improving the heat resistance of the heat-resistantand oil-resistant rubber, so that the sealing ring has excellent aging resistance; and vinyltrimethoxysilane is used for improving the oil resistance of the sealing ring, so that the sealing ring still has high tensile strength and tensile elongation at break after being soaked in oil. Experimental results show that the heat-resistant and oil-resistant sealing ring has excellent heat resistance, oil resistance, mechanical properties and the like. The preparation method is simple, and the prepared heat-resistant and oil-resistant sealing ring has excellent elasticity, oil resistance and heat resistance.

Owner:河北新尔特橡塑密封有限公司

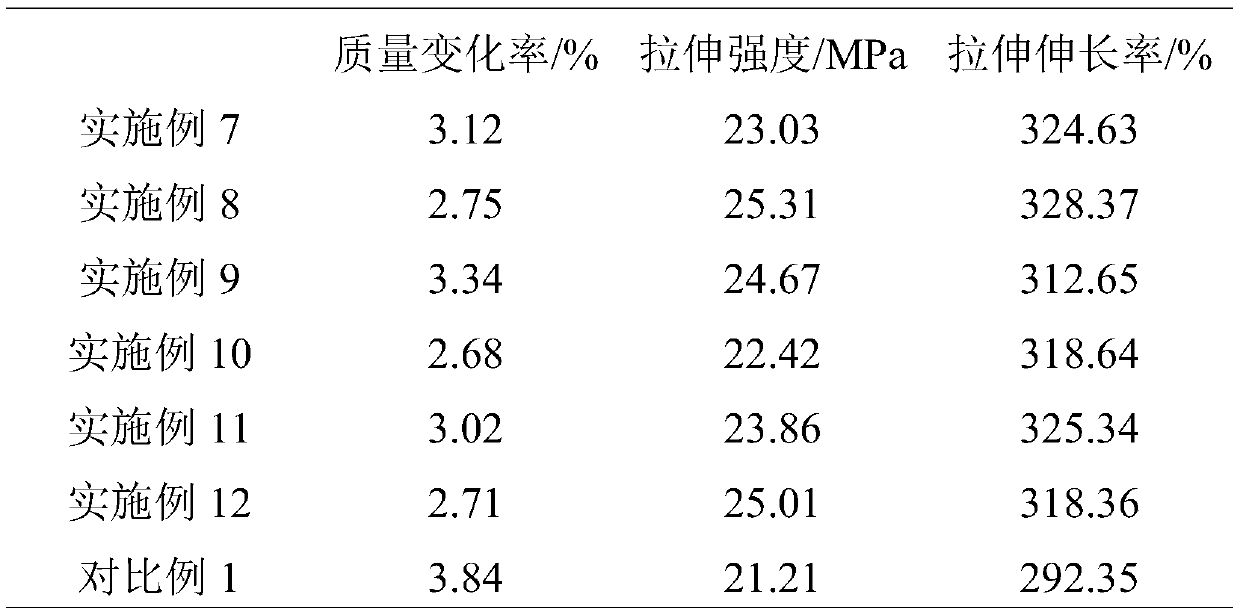

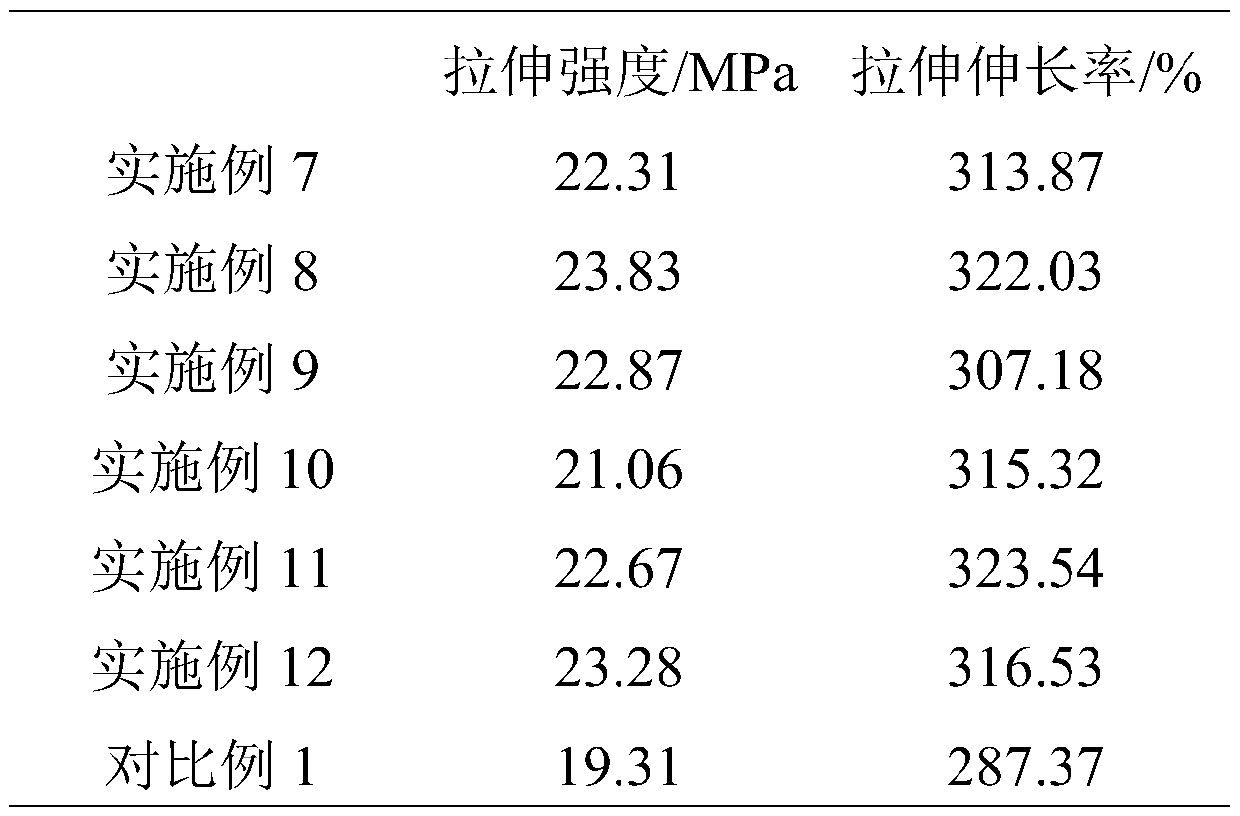

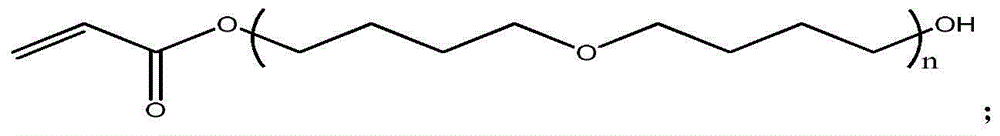

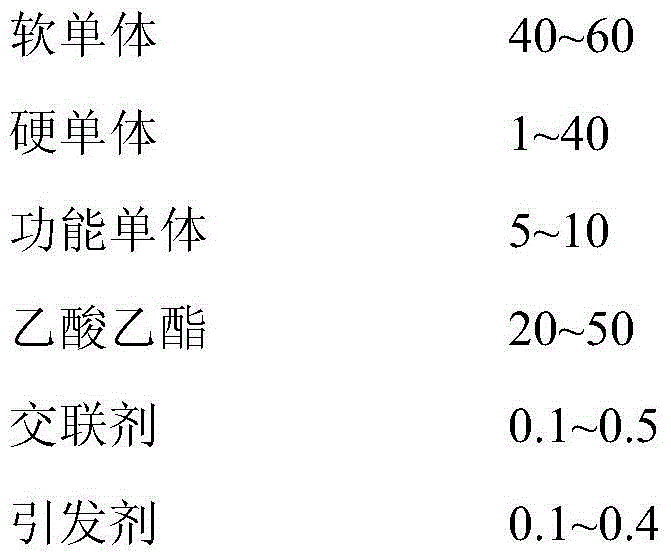

Method for preparing anti-breakage gum for wall

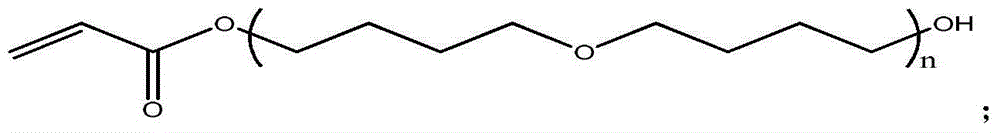

ActiveCN104694040AHigh bonding strengthGood weather resistanceFilm/foil adhesivesEster polymer adhesivesFunctional monomerCarbon chain

The invention relates to a method for preparing anti-breakage gum for a wall. The method comprises the following steps: coating a printing paper layer with an ink absorption coating, coating a release layer with an anti-breakage acrylate pressure sensitive adhesive layer, drying, and compounding, thereby obtaining the anti-breakage gum for the wall, wherein the anti-breakage acrylate pressure sensitive adhesive used in the anti-breakage acrylate pressure sensitive adhesive layer refers to an anti-breakage acrylate pressure sensitive adhesive for the wall and is mainly formed by copolymerization of a soft monomer, a hard monomer and functional monomers; the functional monomers refer to polytetrahydrofuran acrylate and pyridine-2-acrylic acid; the polytetrahydrofuran acrylate has a long carbon chain of ether bonds and is high in flexibility, and the tensile elongation of the pressure sensitive adhesive can be obviously improve; and the pyridine-2-acrylic acid can form coordination with Fe element in the wall, and the adhesive force with the wall is enhanced. Therefore, the anti-breakage gum for the wall has the advantages of high adhesive strength, high adsorption force, high weather resistance, high peel strength and high elongation at break and can be well applied to adhesion with the wall.

Owner:滁州云林数码影像耗材有限公司

Water-soluble film and chemical agent package

ActiveUS20180251613A1Improve mechanical propertiesHigh tensile strengthFlexible coversWrappersPolymer sciencePolyol

A water-soluble film is provided, which has excellent mechanical properties (higher tensile strength and higher tensile elongation) and can be formed into an excellent package which is free from deterioration of the tension of the water-soluble film over time even if containing liquid such as a liquid detergent packaged therein. The water-soluble film includes: (A) a polyvinyl alcohol resin; and (B) a plasticizer; wherein the plasticizer (B) includes a polyalcohol (b1) having a melting point of at least 80° C. and a polyalcohol (b2) having a melting point of not higher than 50° C.; wherein the plasticizer (B) is present in a proportion of at least 25 parts by weight based on 100 parts by weight of the polyvinyl alcohol resin (A).

Owner:MITSUBISHI CHEM CORP

Heat treatment method for X80 bent pipe welding joint with excellent low-temperature toughness

ActiveCN110592360AHigh tensile elongationGood tensile elongationFurnace typesHeat treatment furnacesEngineeringMechanical property

The invention discloses a heat treatment method for the X80 bent pipe welding joint with the excellent low-temperature toughness. The heat treatment method comprises the following steps of firstly, carrying out three-wire two-layer two-pass welding on the X80 pipeline steel by adopting a standard submerged arc welding wire to obtain a straight weld joint welding joint; secondly, the obtained straight weld joint welding joint is subjected to normalizing heat treatment through a high-temperature induction heating furnace, heat treatment is carried out at the same time, direct air cooling is conducted, and a bent pipe welding joint is obtained; and finally, the obtained bent pipe welding joint is placed in a box-type resistance furnace, and heat treatment is carried out again and air-cooled to room temperature. Compared with the prior art, the method is simple and easy to operate, the operation flow is simplified, the mechanical property reduction caused by heating bending of the X80 bentpipe welding joint is greatly improved, the low-temperature impact absorption work at the X80 bent pipe is guaranteed, the tensile elongation is good, and the yield strength and the tensile strengthare higher.

Owner:XIAN UNIV OF TECH

Production process of high-flame-retardant and oil-resistant PVC particles

A production process of high-flame-retardant and oil-resistant PVC particles include the following steps of preliminary preparation, raw material preparation, filler preparation, mixing, extrusion, granulation and qualification test. Raw materials are composed of, by mass, 45-55 parts of polyvinyl chloride resin, 20-30 parts of a plasticizer, 8-10 parts of a filler, 5-8 parts of nano rubber particles, 3-5 parts of a stabilizer, 3-5 parts of a fire retardant, 3-5 parts of a lubricant Hst1, 1-2 parts of calcium oxide, 1-2 parts of nano calcium carbonate, 1-2 parts of a viscosity reducer, and 1-2parts of other additives P-830. The production process of the high-flame-retardant and oil-resistant PVC particles is simple, the compatibility of the substances is significantly improved through thefiller, the oil resistance and cold resistance of PVC are improved through the nano rubber particles, the flame resistance of PVC is improved through the fire retardant, the formula of the raw materials is reasonable, all components are good in compatibility, play their own roles and have synergistic effects, and the prepared PVC particles have good flame resistance, oil resistance, cold resistance, mechanical properties and wide application prospects.

Owner:苏州华盟塑化有限公司

Wear-resistant rubber crawler belt for mine machinery and preparation method thereof

The invention belongs to the technical field of a machinery material, and provides a wear-resistant rubber crawler belt for mine machinery and a preparation method thereof. A polishing agent ingredient for the mine machinery invented by the invention is prepared from ferric trichloride, diluted hydrochloric acid, tetraploid castor oleate, sodium gluconate, sodium silicate, inorganic grinding materials, palm wax, organic polyternary carboxylic acid, dispersing agents and anti-foaming agents. The rubber crawler belt prepared from the ingredients according to the corresponding proportioning ratiohas high wear resistance performance, and is suitable for being used by mine machinery in severe environments.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

Polyamic acid, varnish containing same, film, touch panel display, liquid crystal display, and organic el display

ActiveCN112334521AImprove heat resistanceHigh tensile elongationCoatingsLiquid-crystal displayDisplay device

The purpose of the present invention is to provide: a film having high resistance, high bending strength (tensile elongation), small retardation in the thickness direction, a low linear expansion coefficient, and high transparency; and a polyamic acid or varnish for obtaining the film. The film satisfies all of requirements (i)-(vi) below. (i) The average value of the linear expansion coefficientin the range of 100-200 DEG C is 35 ppm / K or less. (ii) The absolute value of the retardation in the thickness direction is 200 nm or less per 10 [mu]m of thickness. (iii) The glass transition temperature is 340 DEG C or higher. (iv) The total light transmittance is at least 85%. (v) The b* value in the L*a*b* color system is 5 or less. (vi) The tensile elongation is at least 10%.

Owner:MITSUI CHEM INC

Nano modified high-impact geogrid and preparation method thereof

The invention relates to a nano modified high-impact geogrid. The nano modified high-impact geogrid is processed by the following raw material components in parts by weight: 70-80 parts of PP (polypropylene) resin, 20-30 parts of MLLDPE (metallocene polyethylene), 8-10 parts of maleic anhydride-grafted propylene, 8-10 parts of talcum powder, 1-2 parts of titanate, 5-10 parts of nano strong powder, 0.2-0.4 part of ZnO, 0.3-0.5 part of an antioxidant 1010 and 15-20 parts of modified filler. A preparation method of the nano modified high-impact geogrid comprises the following steps: mixing and extruding materials to obtain melt, molding the melt into a plate by virtue of a three-roller calender, punching the plate by virtue of a punching machine, stretching a pore plate after heating to obtain the geogrid. The geogrid processed by the preparation method disclosed by the invention has good mechanical performance, high impact strength and low cost.

Owner:ANHUI JIEAOMAKE SYNTHETIC MATERIAL TECH

Heat treatment method for x80 elbow welded joints with excellent low temperature toughness

ActiveCN110592360BHigh tensile elongationGood tensile elongationFurnace typesHeat treatment furnacesEngineeringWeld seam

The heat treatment method of the X80 elbow welded joint with excellent low-temperature toughness disclosed by the present invention, firstly, the X80 pipeline steel is welded with three wires, two layers and two passes with a standard submerged arc welding wire to obtain a straight seam welded joint; secondly, the obtained The welded joints of the straight seams are normalized in a high-temperature induction heating furnace, and the heat treatment is simultaneously bent and directly air-cooled to obtain the welded joints of the bent pipes; finally, the welded joints of the bent pipes obtained are placed in a box-type resistance furnace for another Heat treat and air cool to room temperature. The method disclosed by the invention is simpler and easier to operate than before, and the operation process is simplified, which greatly improves the reduction of the mechanical properties of the X80 elbow welded joint due to heat bending, and ensures that the low-temperature impact absorption energy of the X80 elbow is high and the tensile strength is high. Good elongation, high yield strength and high tensile strength and other comprehensive mechanical properties.

Owner:XIAN UNIV OF TECH

Process for producing conjugated diene polymer, conjugated diene polymer, and rubber composition

ActiveUS8153723B2Simply and inexpensively produceIncrease contentSpecial tyresRare-earth elementPolymer science

A process for simply and inexpensively producing a conjugated diene polymer with a narrow molecular weight distribution and a high cis-bond content at a low cost is provided. The process comprises a polymerization step, wherein a conjugated diene polymer having a cis-1,4-bond content of 98.5 mass % or more and a ratio (Mw / Mn) of the weight average molecular weight (Mw) to the number average molecular weight (Mn) measured by gel permeation chromatography of 2.5 or less is obtained by carrying out a polymerization reaction in conjugated diene compounds using a catalyst composition containing a rare earth element-containing compound or a reaction product of the rare earth element-containing compound with a Lewis base, an aluminoxane and / or organoaluminum compound, and an iodine-containing compound.

Owner:ENEOS MATERIALS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com