Ultrahigh-strength and high-ductility marine concrete material and preparation method thereof

A marine concrete, ultra-high-strength technology, applied in the field of building materials, can solve problems such as failure, concrete structure damage, etc., and achieve the effect of convenient operation, convenient transportation, and huge technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

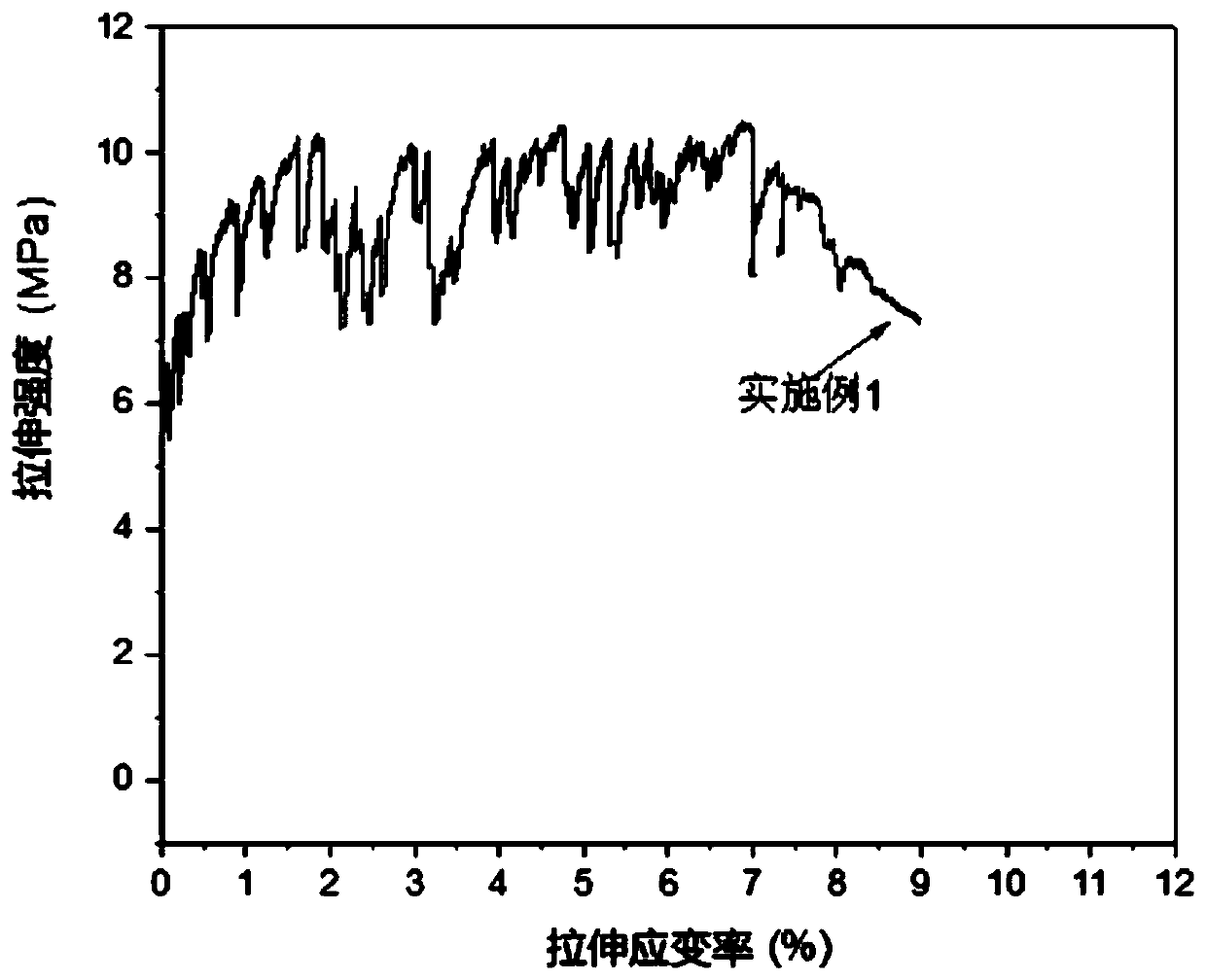

Embodiment 1

[0035] According to a kind of ultra-high strength and high ductility marine concrete material proposed by the present invention and preparation method thereof, its mixing ratio is shown in Table 1: (mass part ratio)

[0036]

[0037] The mix proportion of marine concrete material in table 1 embodiment 1

[0038] The cement is Portland cement; the ultra-high molecular weight synthetic fiber is polyethylene fiber with a length of 12 mm and a diameter of 38 μm; the seawater chloride ion concentration is 10000 mg / L.

[0039] A kind of ultra-high strength and high ductility marine concrete material proposed according to the present invention and its preparation method comprise the following steps:

[0040] 1) Dry mix cement, silica fume and sea sand with a mixer for 3 minutes to obtain a uniform dry mix;

[0041] 2) Mix and stir the water reducer and seawater for 2 minutes to obtain a uniformly mixed mixture;

[0042] 3) Pour the mixed solution into the dry mix and stir for 5 ...

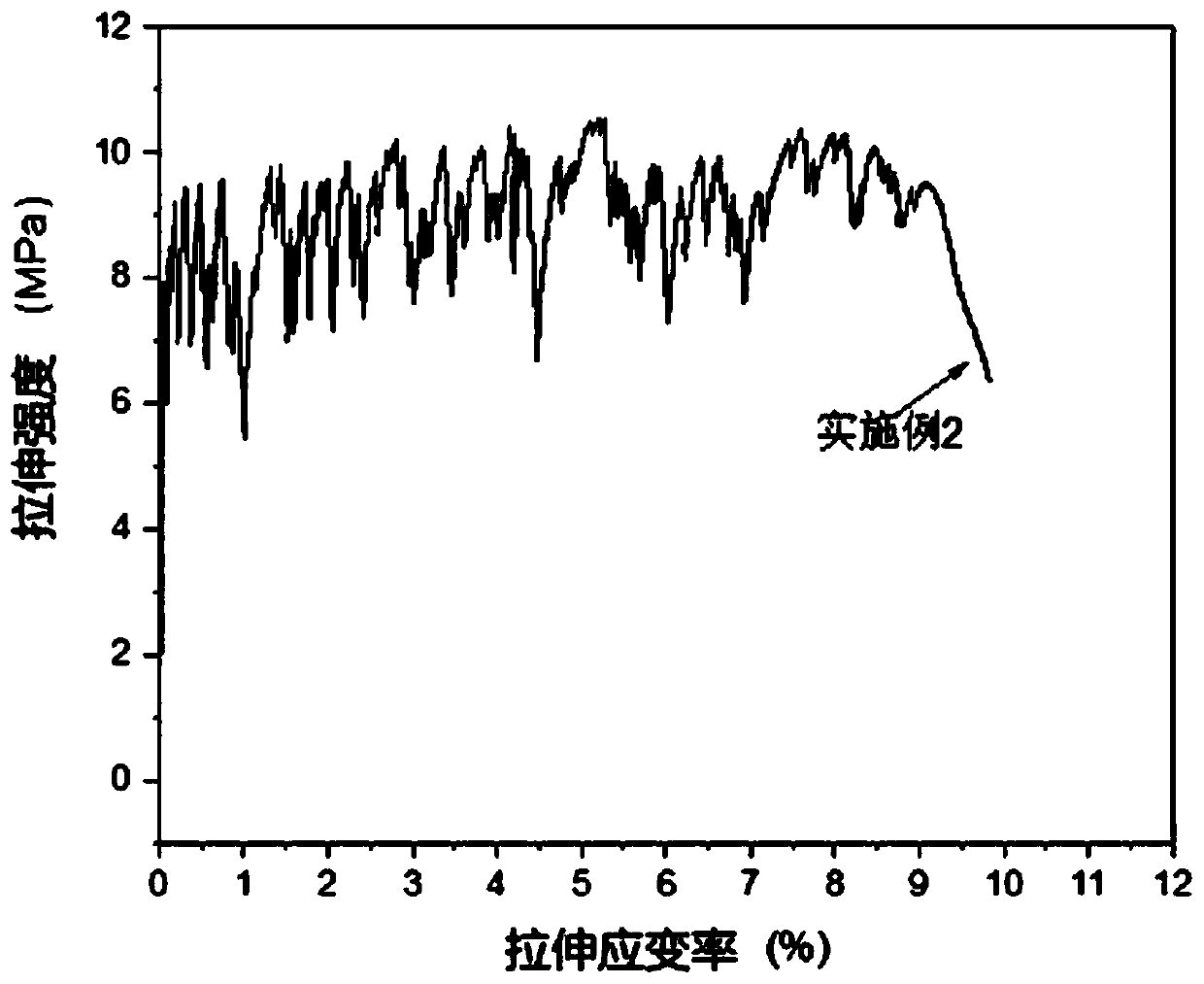

Embodiment 2

[0048] According to a kind of ultra-high strength and high ductility marine concrete material proposed by the present invention and its preparation method, its mixing ratio is shown in Table 2:

[0049] The compounding ratio of embodiment 2 is shown in Table 2: (mass part ratio)

[0050]

[0051] The mix proportion of marine concrete material in table 2 embodiment 2

[0052] The cement is ordinary Portland cement; the ultra-high molecular weight synthetic fiber is carbon fiber with a length of 12 mm and a diameter of 24 μm; the seawater chloride ion concentration is 20000 mg / L.

[0053] A kind of ultra-high strength and high ductility marine concrete material proposed according to the present invention and its preparation method comprise the following steps:

[0054] 1) Dry mix cement, silica fume and sea sand with a mixer for 3 minutes to obtain a uniform dry mix;

[0055] 2) Mix and stir the water reducer and seawater for 2 minutes to obtain a uniformly mixed mixture;

...

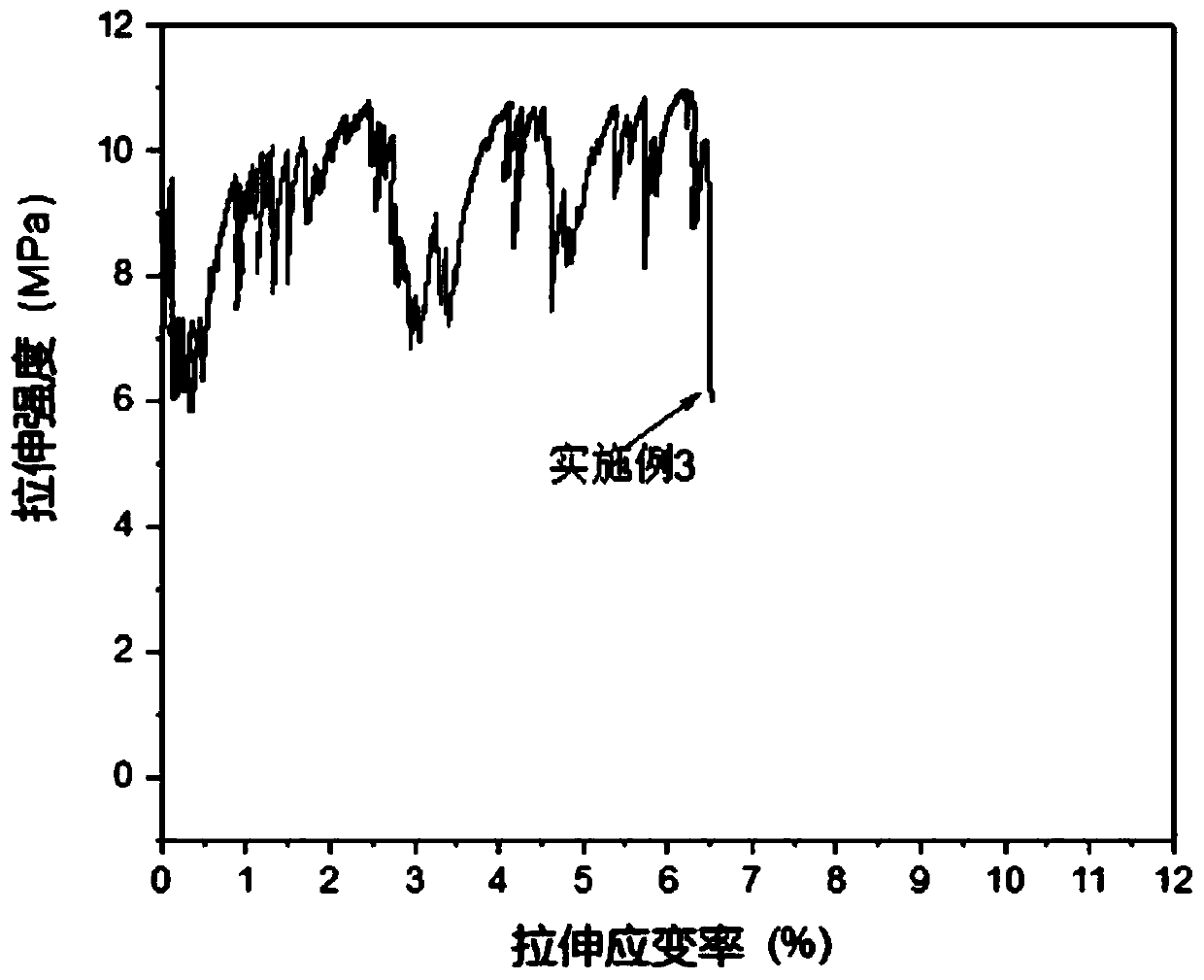

Embodiment 3

[0062] According to a kind of ultra-high strength and high ductility marine concrete material proposed by the present invention and its preparation method, its mixing ratio is shown in Table 3:

[0063] The compounding ratio of embodiment 3 is shown in Table 3: (mass part ratio)

[0064]

[0065] The mix proportion of marine concrete material in table 3 embodiment 3

[0066] The cement is composite Portland cement; the ultra-high molecular weight synthetic fiber is Kevlar fiber with a length of 8 mm and a diameter of 24 μm; the seawater chloride ion concentration is 30000 mg / L.

[0067] A kind of ultra-high strength and high ductility marine concrete material proposed according to the present invention and its preparation method comprise the following steps:

[0068] 1) Dry mix cement, silica fume and sea sand with a mixer for 5 minutes to obtain a uniform dry mix;

[0069] 2) Mix and stir the water reducing agent and seawater for 3 minutes to obtain a uniform mixed solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com