Patents

Literature

87results about How to "Achieve environmental benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

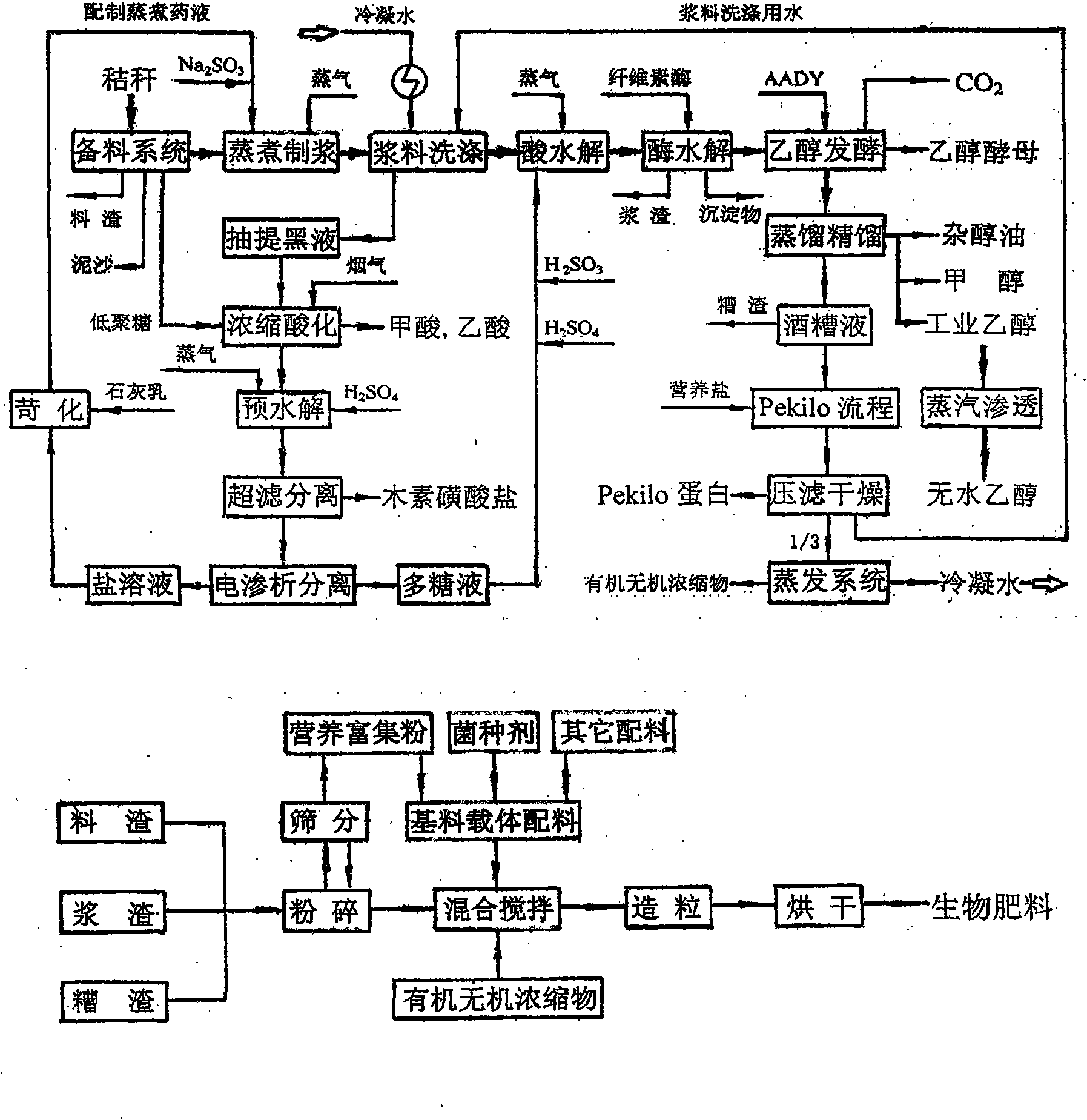

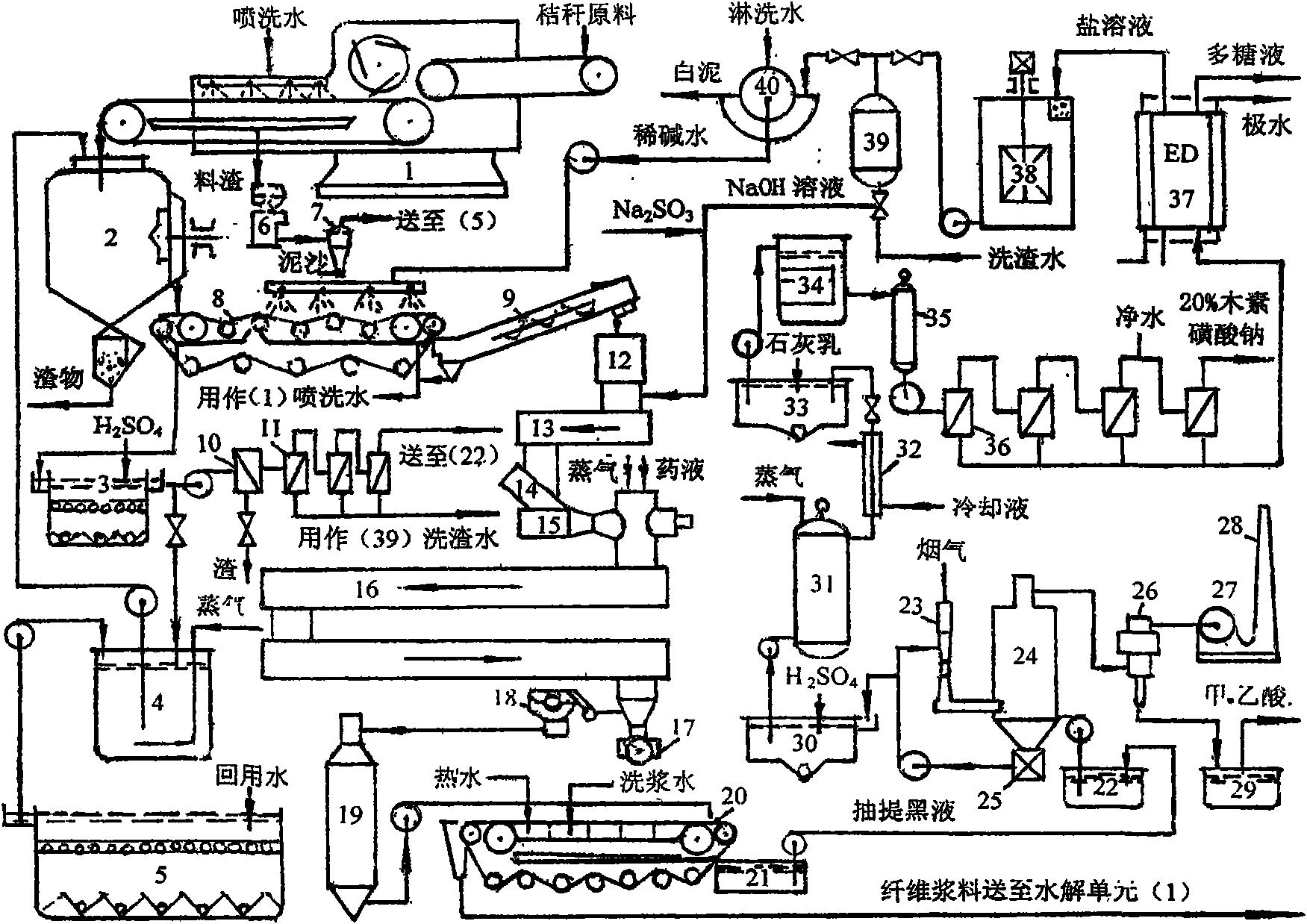

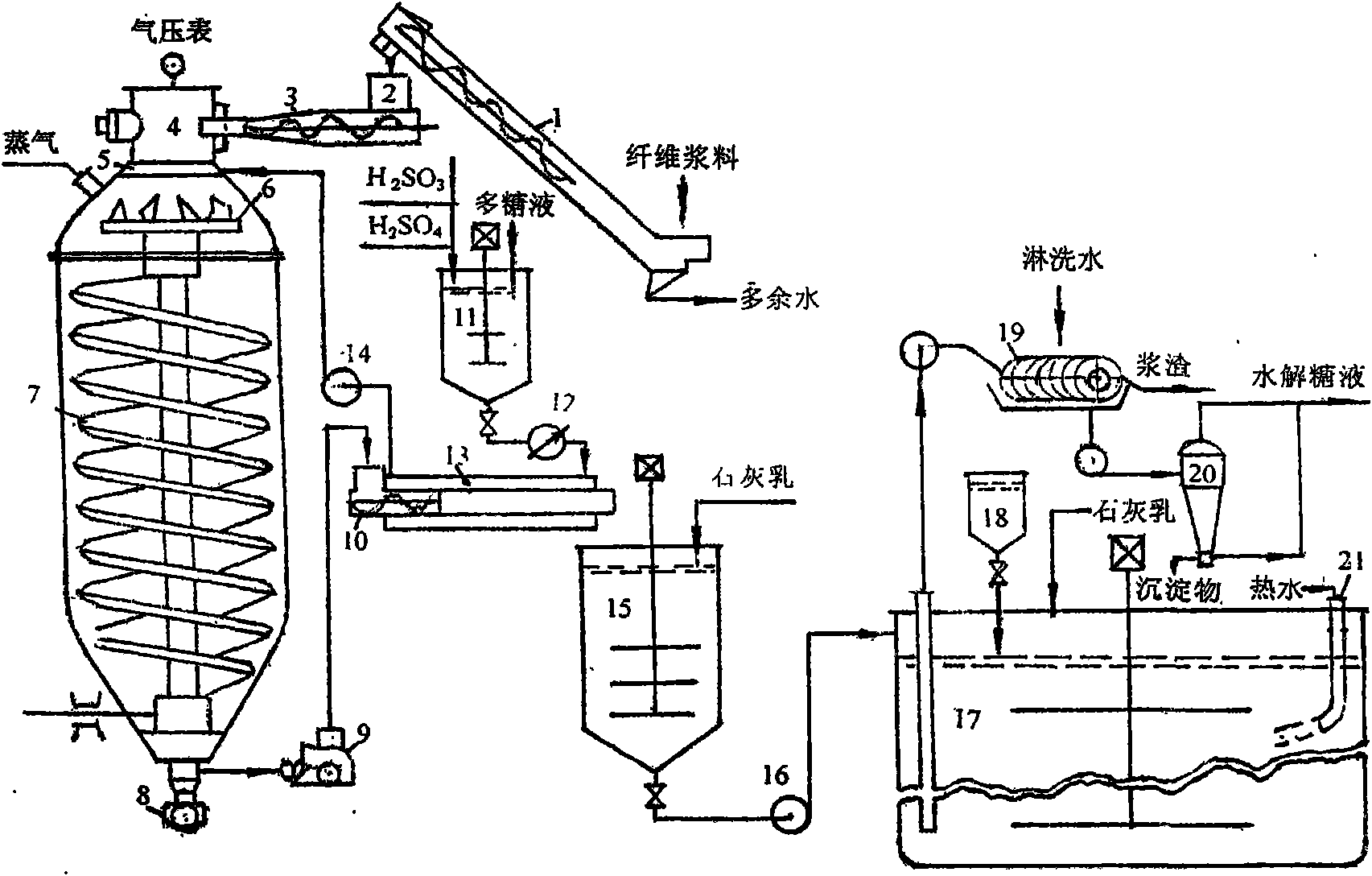

Ethanol-guiding straw bio-refining full-sealing integration system

InactiveCN101555495AImprove productivityStrong profitabilityBy-product recoveryFungiFiberLiquid waste

The invention relates to a fiber biomass refining technology, in particular to an ethanol-guiding straw bio-refining full-sealing integration system. Based on the clean pulping of the straw, a chemical and biological combined method is used for totally hydrolyzing amylose separated from a cellulose and a hemicellulose separated into pulps and braised waste liquid to prepare a hexose and a pentose;and the hexose and the pentose are converted into series of chemical and biological products which taking ethanol as dominant product. As a firstly separated and subsequently disposed straw bio-refin ing integration system, the cellulose and the hemicellulose in the straw raw material are utilized effectively; furthermore, 20-25% of the lignin in the raw material and the material slag, slurry slag, trough slag and ashes (mineral matter) produced in the production process are totally converted into the product with high additional values, thus realizing the environment objects of full sealing and zero draining and controlling the production cost (apportionment cost after the straw biomass is totally utilized) of the fuel ethanol within 1800-2000RMB / t.

Owner:徐守才

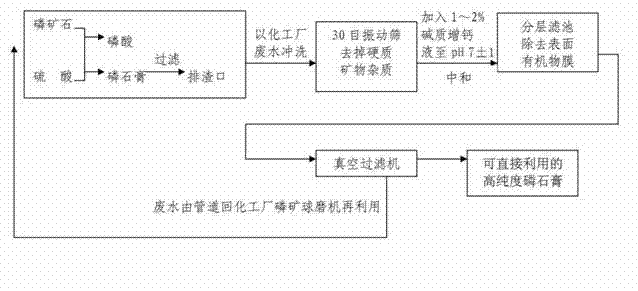

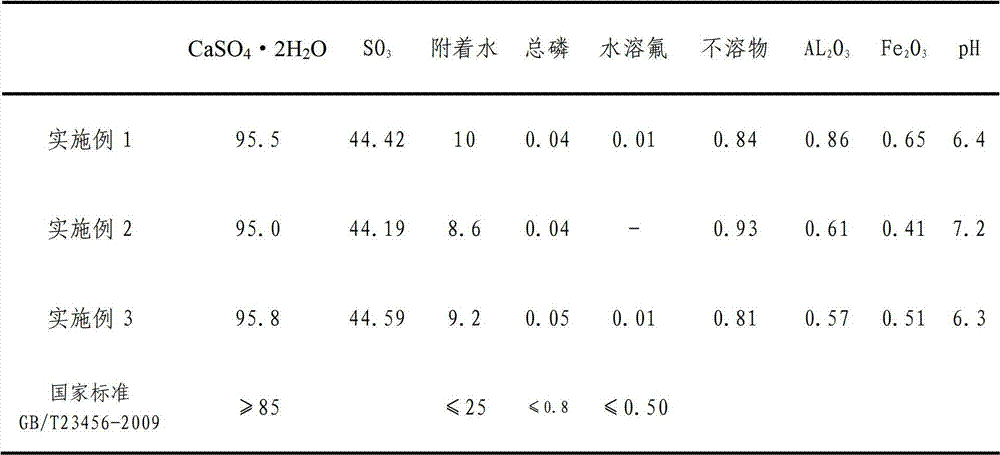

Phosphogypsum composite pretreatment technique

The invention discloses a phosphogypsum composite pretreatment technique which comprises the following steps: directly taking phosphogypsum slag from a slag discharge port of a chemical industry enterprise, passing through a 30-mesh vibrating screen for separation, and meanwhile flushing the phosphogypsum slag with industrial wastewater of the chemical industry enterprise to remove hard mineral impurities; adding an alkaline calcium-increase liquid which accounts for 1-2 wt% of phosphogypsum into the phosphogypsum slurry obtained by flushing so as to regulate the pH value to 7+ / -1, sending into a stratification filter tank, stirring, standing, and removing a surface layer organic substance film and soluble impurities; and sending the stratified and purified phosphogypsum slurry into a vacuum filter to carry out vacuum filtration, thereby obtaining filter residues and a filtrate. According to the technique, the phosphogypsum slag at the discharge port of the chemical industry enterprise is directly utilized to extract the high-purity low-impurity high-grade phosphogypsum, thereby saving the stock place and lowering the transportation cost; and the raw material is from three wastes and does not generate secondary pollution, the intermediate product hard mineral impurities can be directly used commercially, and water can be used circularly, thereby greatly enhancing the comprehensive utilization ratio of the phosphogypsum and implementing organic unification of environmental, economical and social benefits.

Owner:广西凯浩环保材料股份有限公司

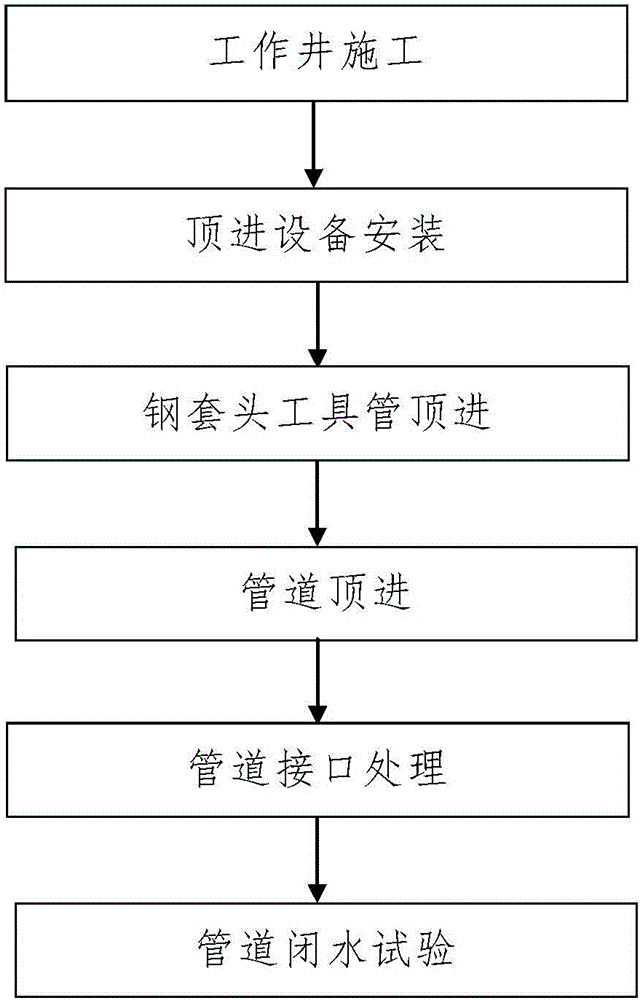

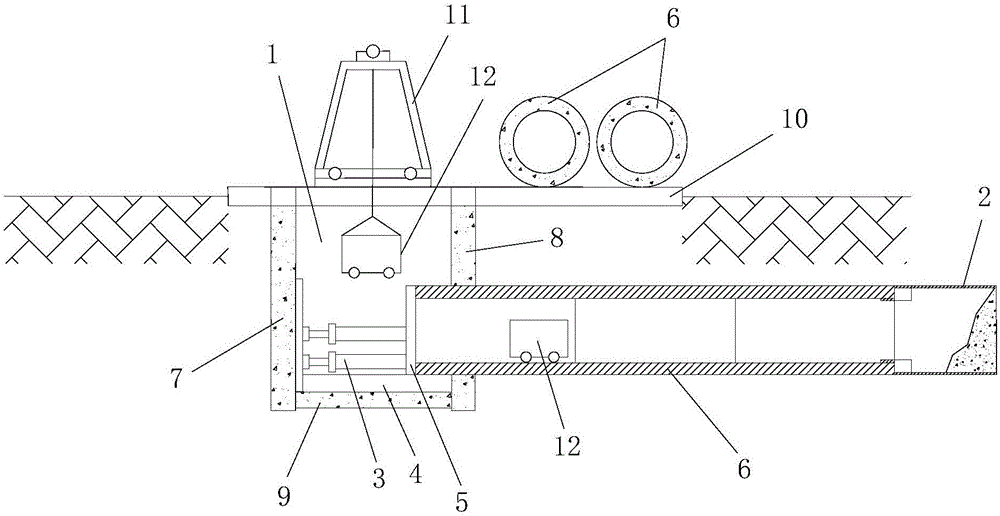

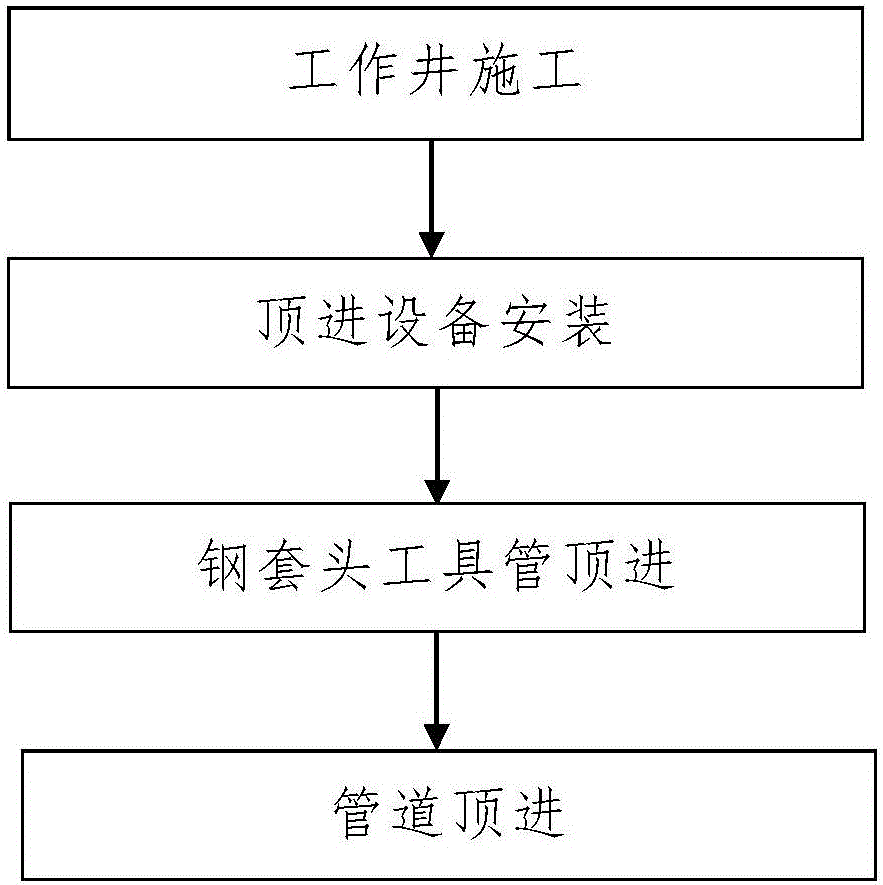

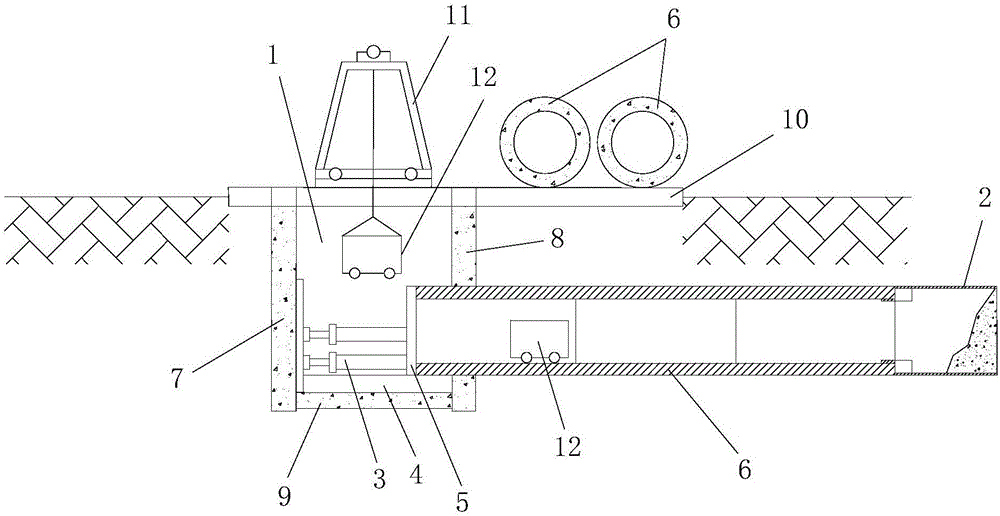

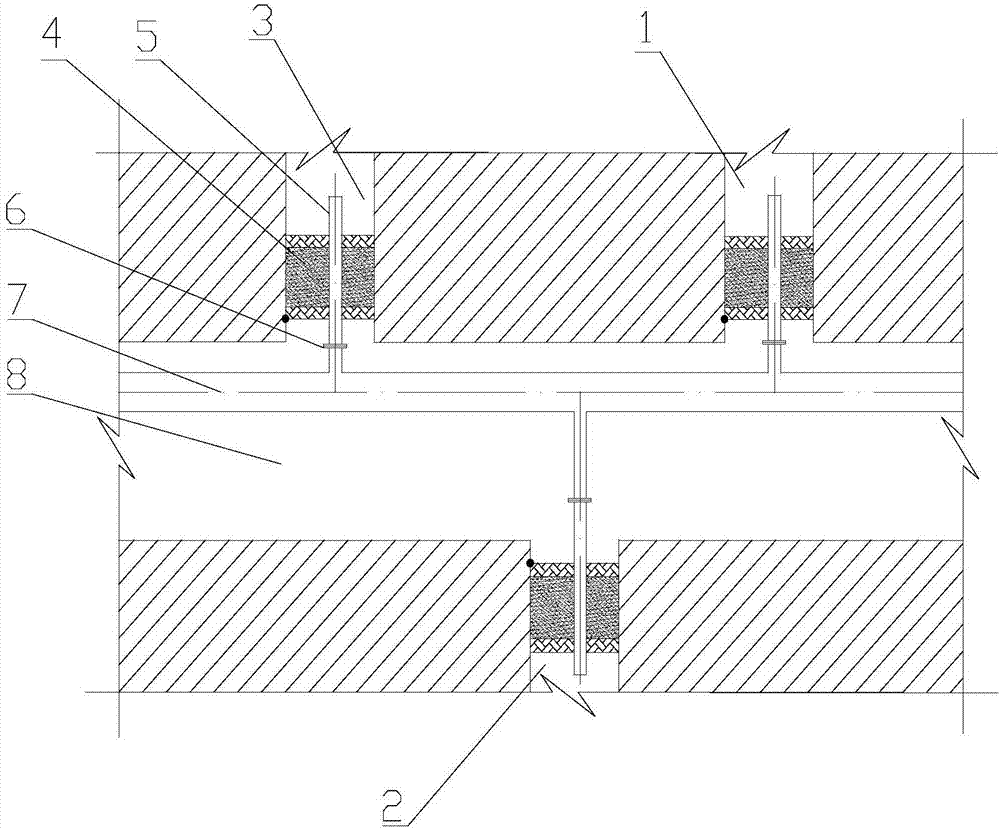

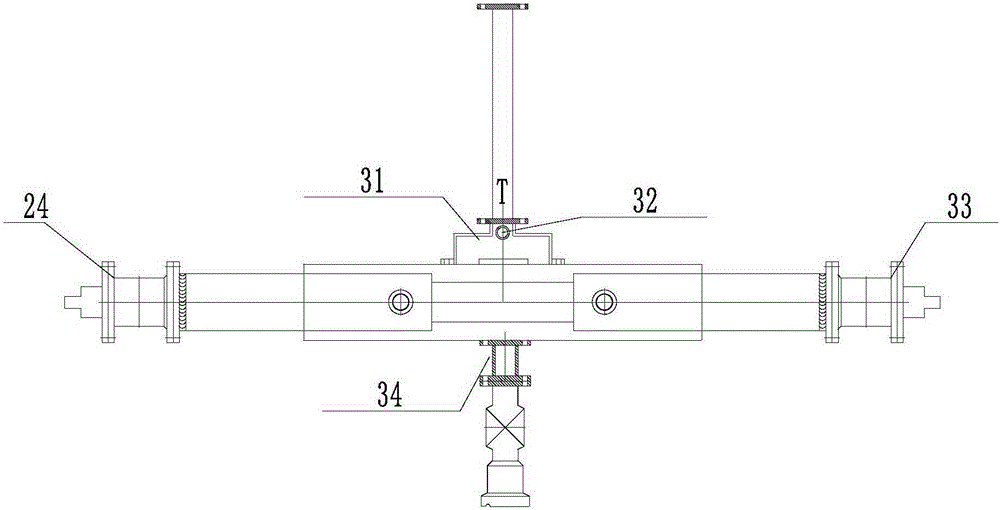

Pipe-jacking construction method for mealy sand stratum

ActiveCN106369223AThe method steps are simpleReasonable designPipe laying and repairEngineeringUnderground pipeline

The invention discloses a pipe-jacking construction method for a mealy sand stratum. The pipe-jacking construction method for the mealy sand stratum comprises the steps that firstly, a working well is constructed, specifically, the working well used for jacking a constructed underground pipeline is constructed, the constructed underground pipeline is formed by splicing a plurality of pipeline assembly sections from front to back, and a steel bushing head tool pipe comprises a steel sleeve, a supporting ring mounted on the inner side of the rear end of the steel sleeve, and an insertion opening fixed to the supporting ring; secondly, jacking equipment is mounted, specifically, the jacking equipment is mounted at the bottom of the inner side of the working well; thirdly, the steel bushing head tool pipe is jacked through the process that the steel bushing head tool pipe is hoisted in place, the steel bushing head tool pipe is jacked, and manual intra-pipe earth cutting is conducted; fourthly, the pipeline is jacked, specifically, the multiple pipeline assembly sections of the constructed underground pipeline are jacked from front to back; fifthly, a pipeline port is treated; and sixthly, a closed water test for the pipeline is conducted. According to the pipe-jacking construction method for the mealy sand stratum, the steps are simple, the design is reasonable, construction is easy and convenient, and the using effect is good; and a pipe-jacking construction process of the mealy sand stratum can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:中铁二十局集团第五工程有限公司

Tobacco mulching cultivation method

InactiveCN103168591AImprove permeabilityImprove biological activityFertilising methodsHorticultureAmmonium nitrateMoisture

The invention discloses a tobacco mulching cultivation method. The nitrogen application rate is 52.5 kg / hm<2>, the ratio of basal fertilizer and top-dressing is 7:3, N:P2O5:K2O is equal to 1:1:3, the basal application materials include 3000 kg / hm<2> of decomposed sesame cake fertilizer, 60 kg / hm<2> of ammonium nitrate, 80 kg / hm<2> of phosphatic fertilizer, 191.4 kg / hm<2> of potassium sulfate, 37.5 kg / hm<2> of zinc sulfate, and 22.5 kg / hm<2> of boric acid, the topdressing materials in the rosette stage include 37 kg / hm<2> of potassium sulfate and 84 kg / hm<2> of potassium nitrate. In the process of transplanting, 15 kg / hm<2> of potassium nitrate is applied in a nest mode, a plastic film is covered, the plastic film is uncovered in the former half period of June, and 7500 kg / hm<2> of wheat straws are covered after earth up until harvest is finished. The tobacco mulching cultivation method is capable of keeping appropriate soil moisture and heat conditions in the growth period of tobacco, enables the tobacco to form a layering and well-developed frame-shaped root system, and is favorable for coordination of water, fertilizer, air and heat of soil.

Owner:HENAN AGRICULTURAL UNIVERSITY

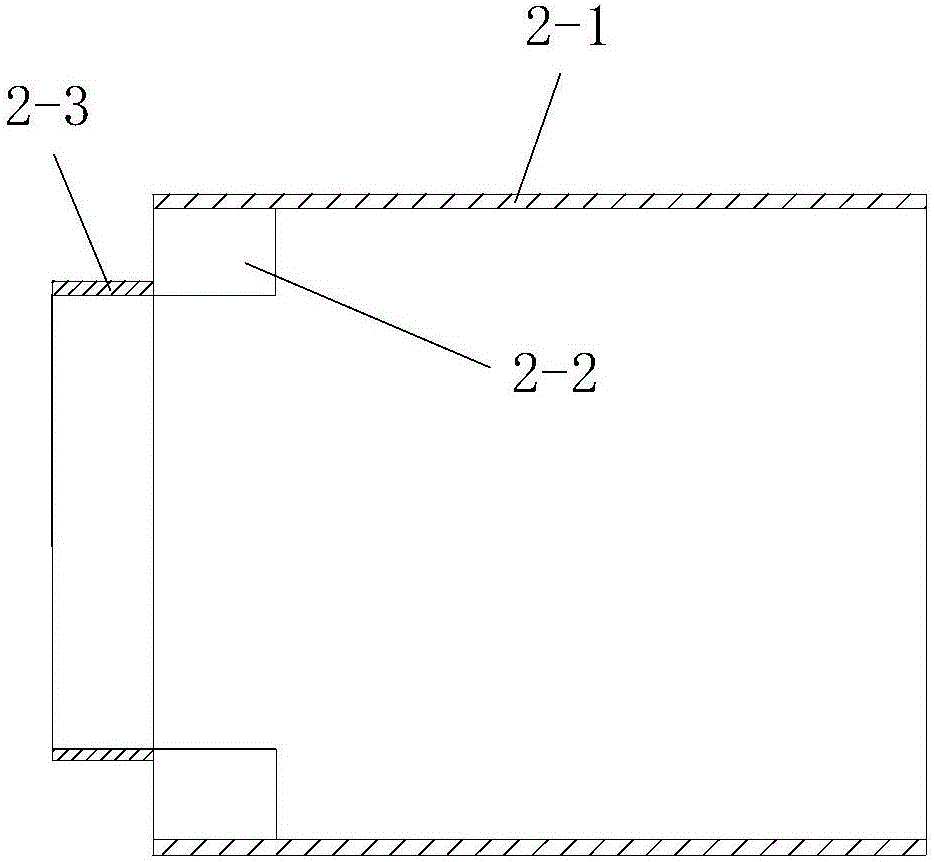

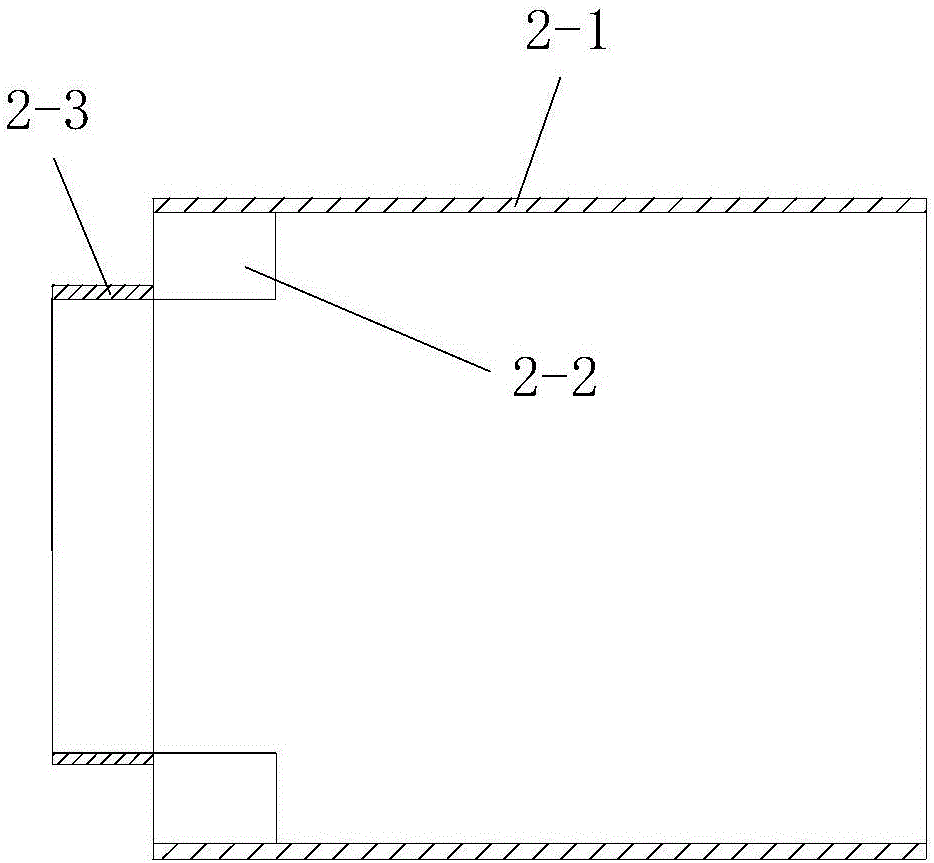

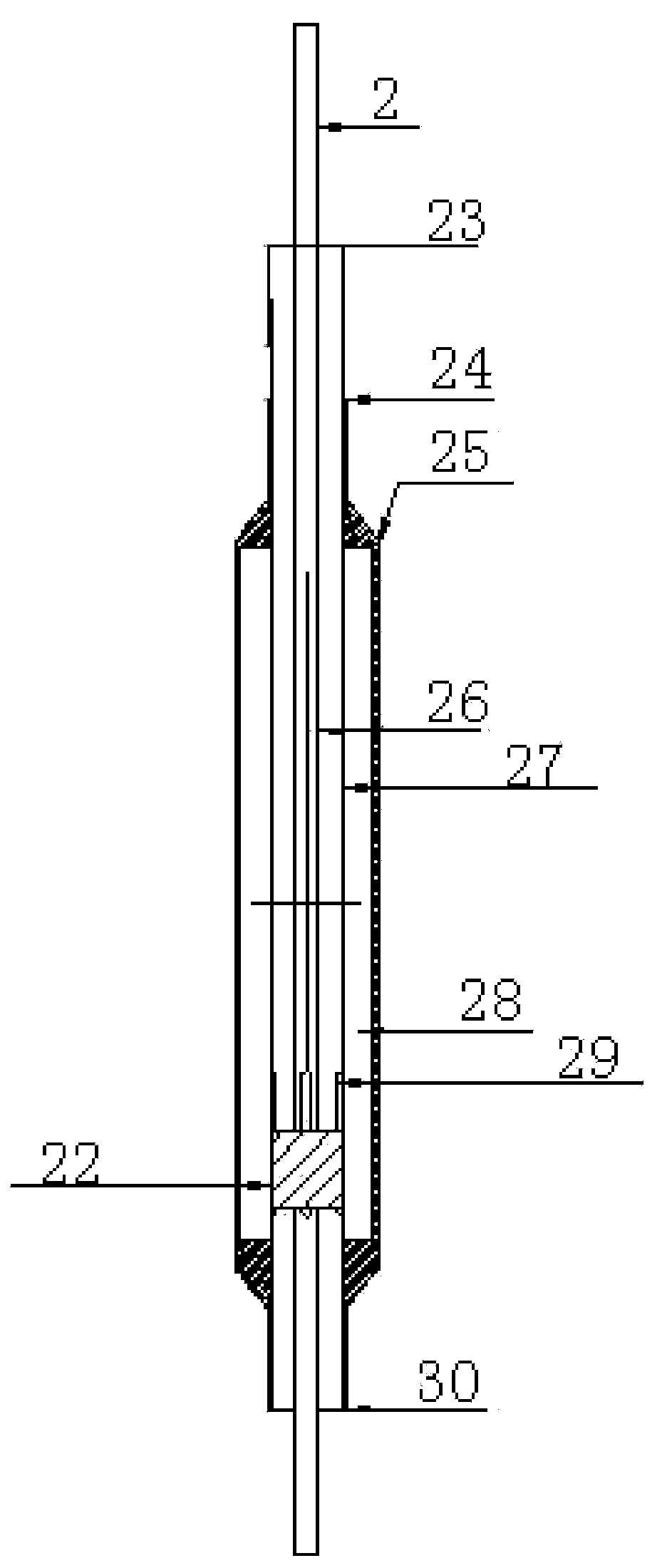

Silty soil stratum pipe-jacking jacking construction method based on tool pipe with steel sleeve head

ActiveCN106402490AThe method steps are simpleReasonable designPipe laying and repairStructural engineeringEngineering

The invention discloses a silty soil stratum pipe-jacking jacking construction method based on a tool pipe with a steel sleeve head. The method includes the steps that firstly, a work well is constructed, wherein the work well used for jacking a construction underground pipeline is constructed, the construction underground pipeline is formed by splicing a plurality of pipeline splicing joints, the tool pipe with the steel sleeve head comprises the steel sleeve pipe, a supporting ring installed on the inner side of the rear end of the steel sleeve pipe and an inserting port fixed to the supporting ring, the wall thickness of the steel sleeve pipe is 0.8-1.2 cm, and the length of the steel sleeve pipe is 80-120 cm; secondly, a jacking device is installed; thirdly, the tool pipe with the steel sleeve head is jacked, wherein the tool pipe with the steel sleeve head is hoisted in place, the tool pipe with the steel sleeve head is jacked, and a soil is manually excavated in the pipe; and fourthly, pipeline jacking is performed, wherein the pipeline splicing joints in the construction underground pipelines are jacked correspondingly from front to back. The method is simple in step, reasonable in design, easy and convenient to construct, good in using effect, capable of easily, conveniently and fast completing the silty soil stratum pipe-jacking jacking construction process and safe and reliable in construction process.

Owner:中铁二十局集团第五工程有限公司

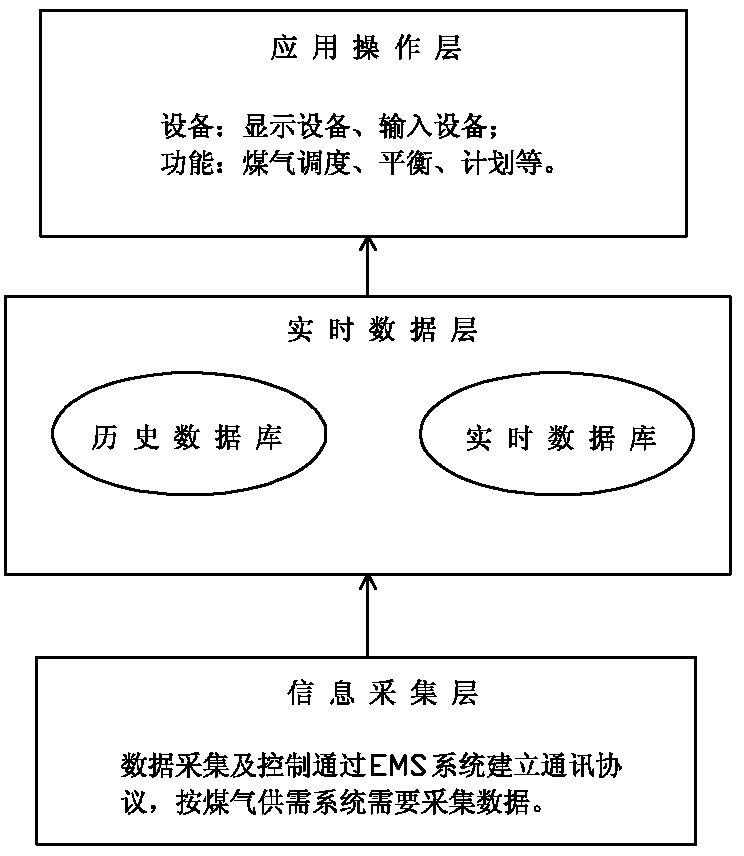

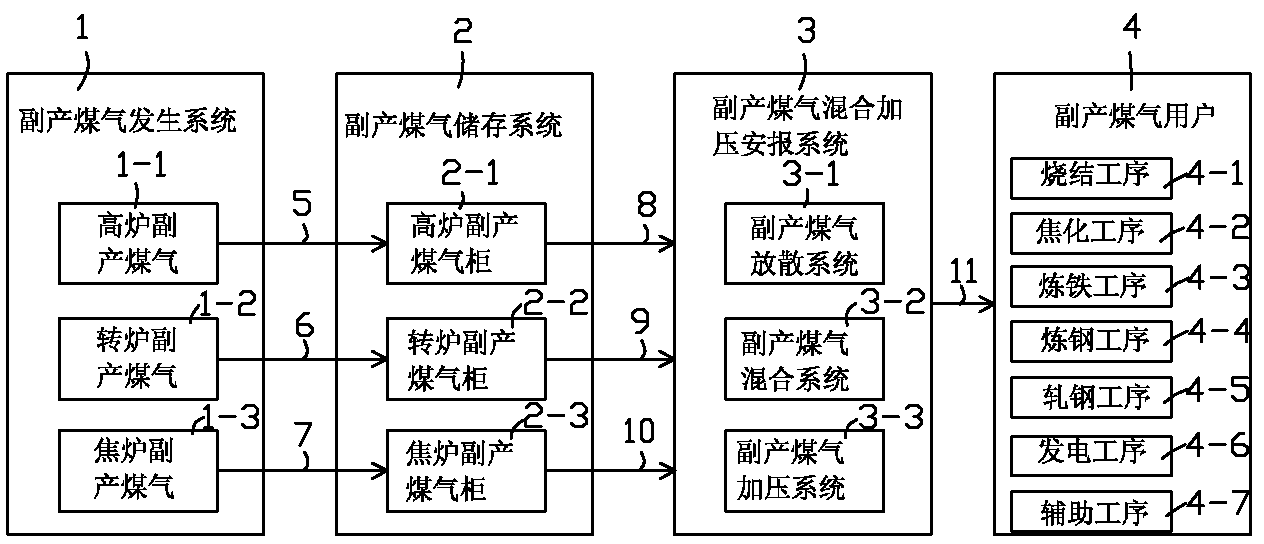

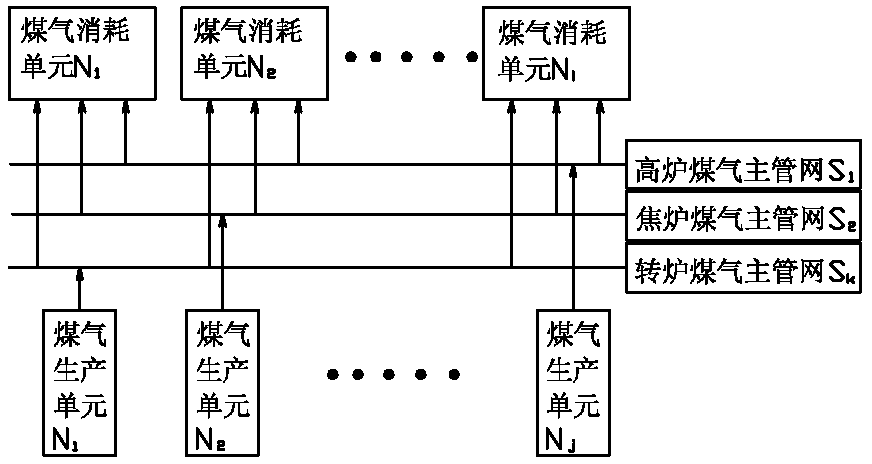

Method for offline analyzing and online scheduling of byproduct gas of metallurgy industry

ActiveCN102915006AImprove productivityImprove operational efficiencyTotal factory controlProgramme total factory controlMathematical modelDesign load

The invention relates to a method for offline analyzing and online scheduling of byproduct gas of a metallurgy industry. A data collection server is connected with a gas producing and marketing project control system and can be used for carrying out the online scheduling on a byproduct gas supply and demand system of the metallurgy industry according to data provided by a system through a pipe network mathematical model, a gas supply and demand system prediction model and a gas supply and demand system optimal scheduling model. According to the method for the offline analyzing and the online scheduling of the byproduct gas of the metallurgy industry, the production rates of energy devices of iron and steel enterprises are greatly increased, and the condition that gas appliances work under a design load can be ensured, so that the operation efficiencies of the gas appliances are improved; the gas spreading can be effectively reduced, a secondary gas energy resource can be adequately adopted, and the reasonable operation of the producing economy can be guaranteed; the predicting and processing schemes can be timely, quickly and precisely made, and the influence caused by faults can be controlled at a lowest limit; the scheduling theory basis can be provided for a scheduler, the subjective blindness of the scheduling can be reduced, and a scheduling command can be timely and accurately issued; and important data parameters for leaderships to make decision to straighten the production of the iron and steel enterprises.

Owner:BEIJING ZHINENG XIANGYING ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH CO LTD

Cheap nutritional biological deodorization packing and preparation method thereof

InactiveCN104692763AHigh strengthLarge specific surface ratioSolid waste managementDispersed particle separationWood ashNutrition

The invention provides cheap nutritional biological deodorization packing and a preparation method thereof. The deodorization packing is prepared from the following materials: coal ash, zeolite powder, lime, gypsum, cement, sodium hydroxide, sodium silicate, wood ash, bagasse ash and waste molasses. The packing is high in strength, high in breathability and stable in performance, has rich nutrition and can provide enough nutrient substances for microbes, so that the problems that organic carriers are low in strength and the like can be solved, and the problem that growth of deodorizing bacteria is influenced because inorganic packing is short of nutrition can be solved. The packing is long in service life, and the forming speed of a biological deodorization film is high. In addition, the nutritional biological deodorization packing prepared by the invention is low in cost and changes wastes into valuable materials, the pollution is reduced, and the environmental benefits, economical benefits and social benefits can be simultaneously realized.

Owner:SUN YAT SEN UNIV

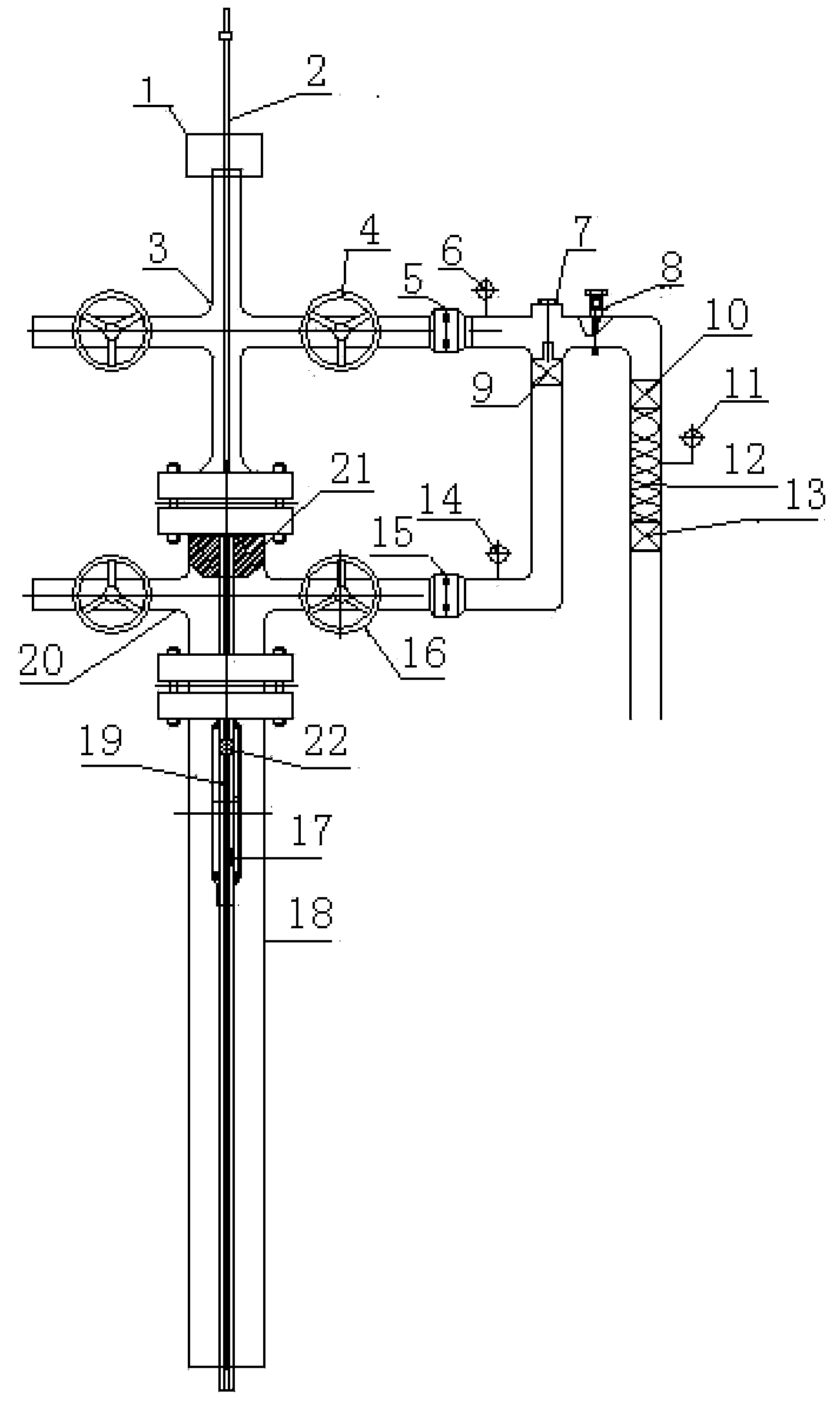

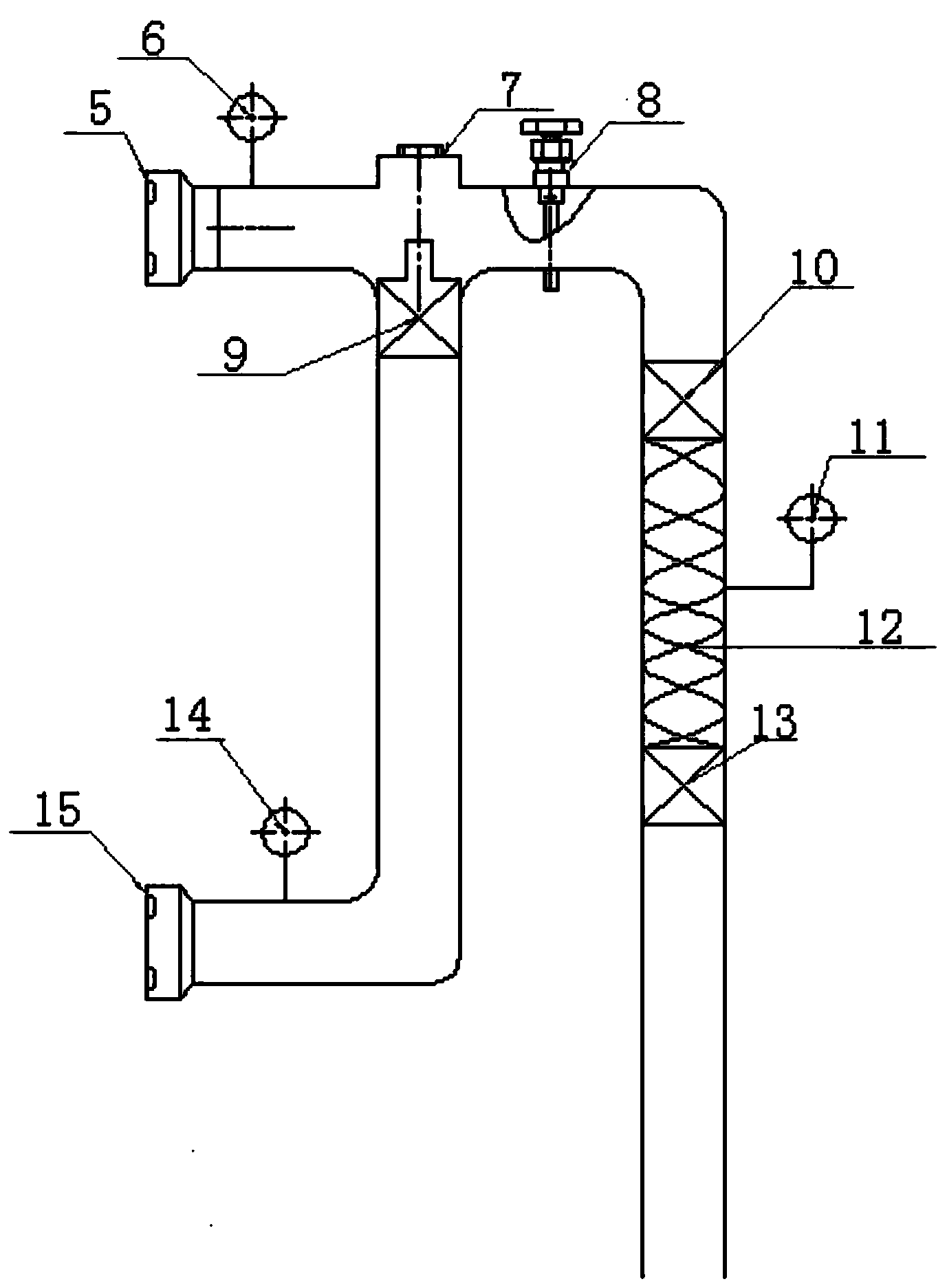

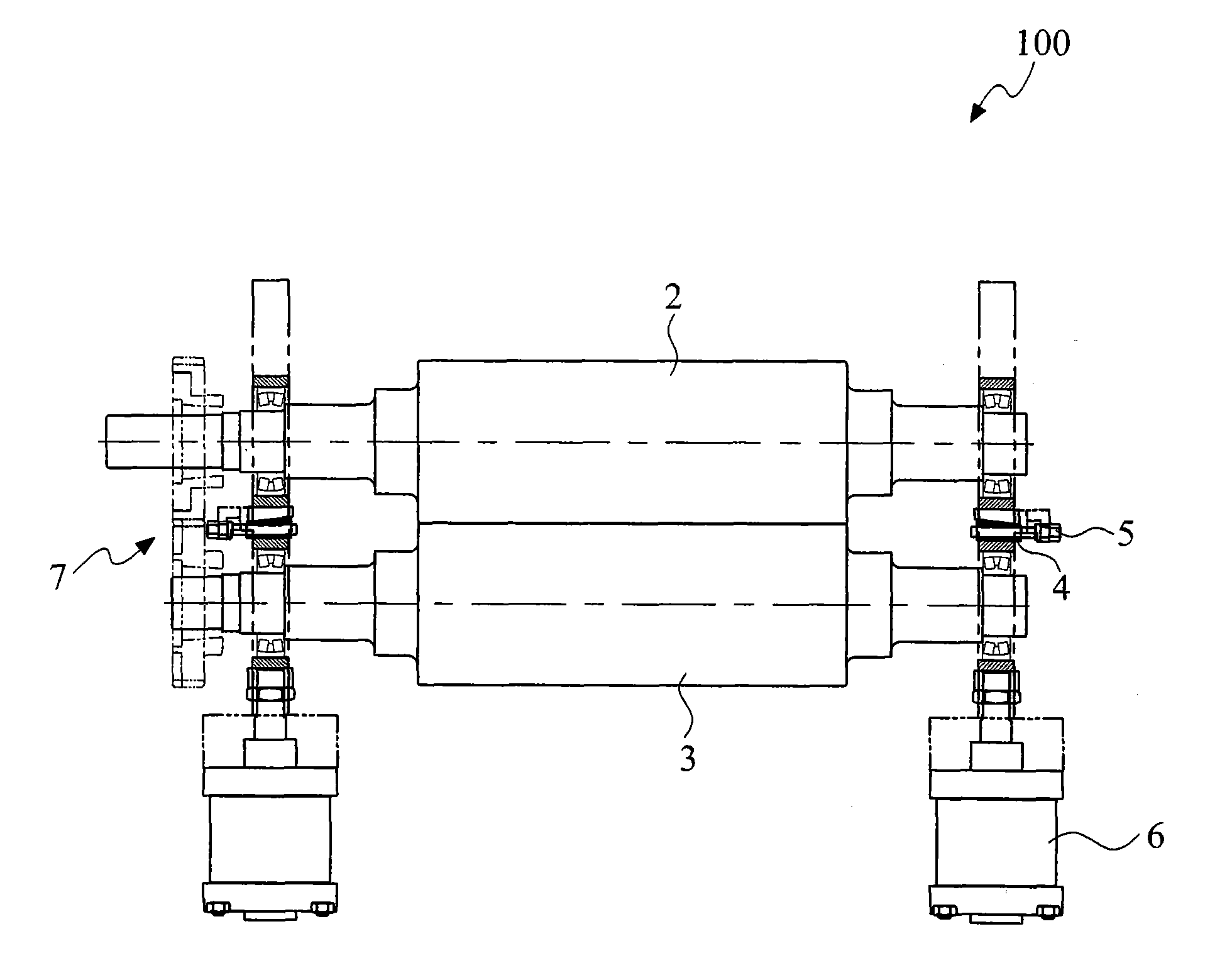

Combined-type oil well casing gas recovery device

InactiveCN104074494AAchieve production management goalsAvoid pollutionFluid removalWorking fluidTubing hanger

The invention discloses a combined-type oil well casing gas recovery device. The ground part is a combined-type tee assembly, one end of a tee is connected with an oil pipe gate at the front end of a small cross, another end of the tee is connected with a casing gate at the front end of a large cross, and the third end of the tee is provided with a liquid discharge check valve and a stop valve. The underground part comprises an oil-gas mixing pump assembly, the upper end of an outer working barrel is connected with an oil pipe hanger in the large cross of a wellhead, the lower end of the outer working barrel is connected with an oil well production tubular column, and a piston with the upper end being connected with a polish rod and the lower end being connected with a sucker rod is arranged in an inner working barrel. An oil storage chamber is arranged between the outer working barrel of a mixing pump and the inner working barrel of the mixing pump. A strip-shaped liquid inlet is formed in the lateral wall of the inner working barrel. The liquid discharge check valve is opened during upstroke to discharge liquid and closed automatically during down-stroke. A gas exhaust check valve is opened to exhaust gas during down-stroke and closed automatically during upstroke. The combined-type oil well casing gas recovery device can solve the phenomena of descending of the working fluid level of an oil well, productivity reduction and gas locking caused due to the fact that oil well casing gas builds the pressure for a long time.

Owner:檀长江

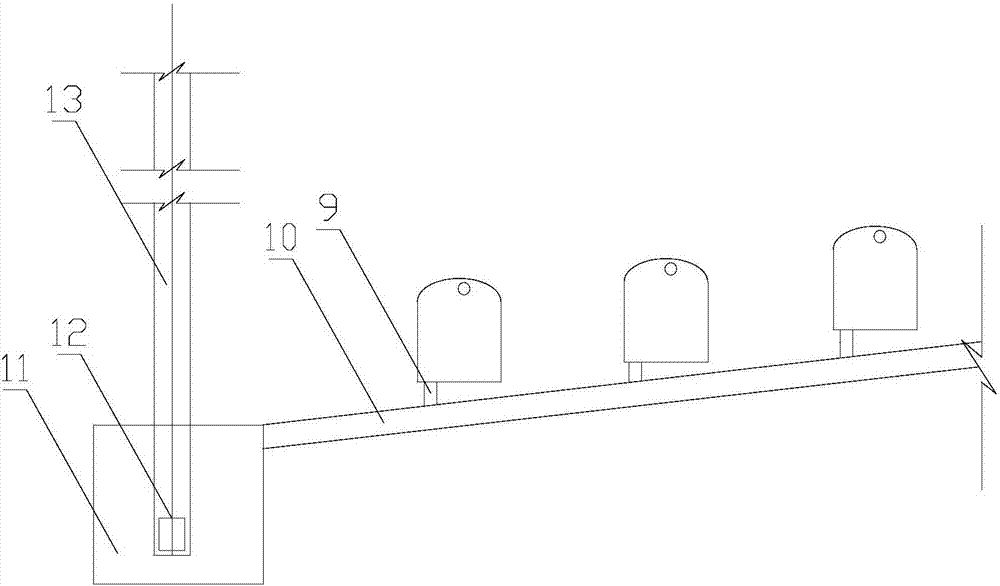

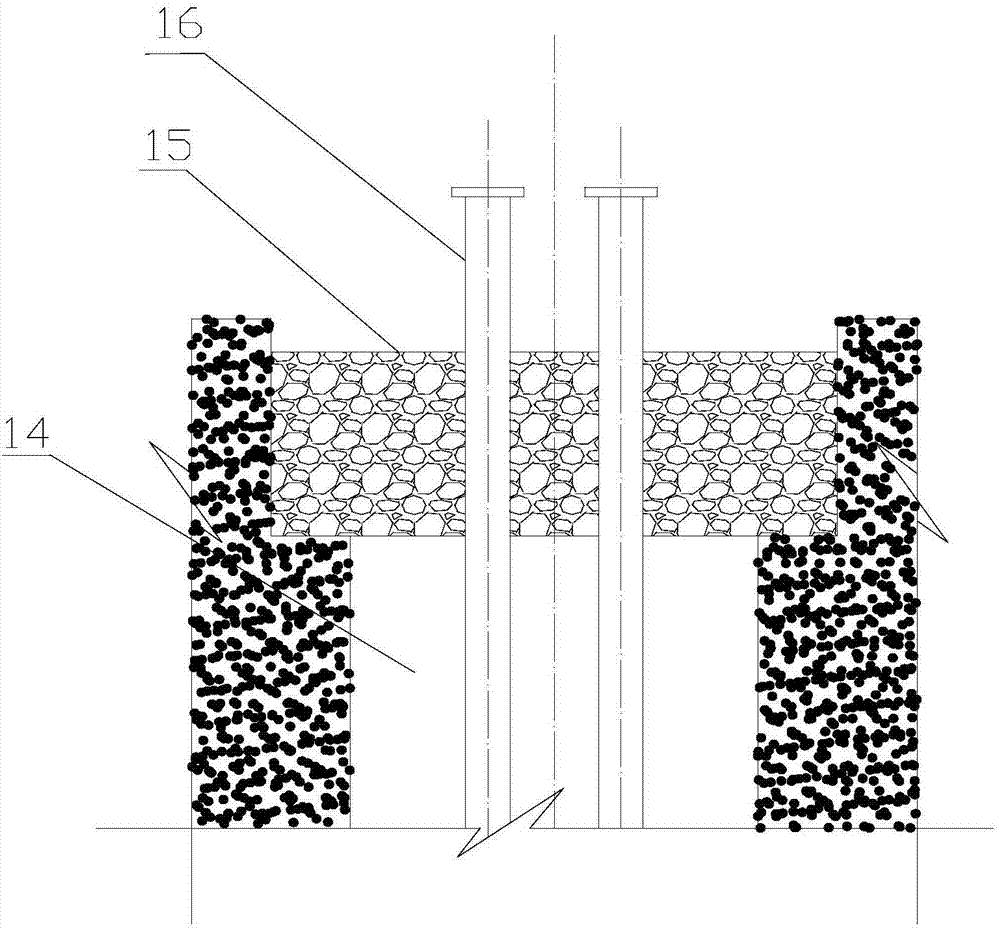

Novel process for abandoned mine downhole gas control

ActiveCN107035401ARealize economic benefitsGood environmental benefitsMining devicesDrainageRebarWellhead

The invention provides a novel process for abandoned mine downhole gas control. The novel process comprises the steps that (1) before an abandoned coal mine is closed, downhole branched roadways are blocked, and steel pipe holes are reserved in the upper portions of blocking walls to enable the interior to communicate with the exterior; (2) the reserved steel pipe holes of the multiple downhole branched roadway blocking walls are connected with a downhole gas pumping and discharging main system to conduct gas pumping and discharging; (3) blocked roadway drainage water communicates with main roadway drainage water, a water storage bin is built at a low downhole position, a water suction pump and a water pipe are mounted to pump and drain downhole gushing water to the ground, and the normal pumping and drainage effect of the downhole gushing water can be achieved after the coal mine is closed; (4) a main pithead and a vice pithead of the abandoned mine are closed, a footrill and an inclined shaft are filled with laying material rock walls and loess, steel pipes are embedded into the footrill and the inclined shaft, a main pithead and a vice pithead of a vertical shaft are blocked through reinforced concrete cover plates, and meanwhile, steel pipes are embedded into the main pithead and the vice pithead of the vertical shaft to enable the interiors of the pitheads to communicate with the exteriors of the pitheads; and (5) downhole gas is discharged and extracted through ground gas discharging and extraction equipment. The novel process can achieve the purposes of abandoned mine downhole gas comprehensive control and utilization.

Owner:CECEP NINGXIA NEW ENERGY RESOURCES LTD

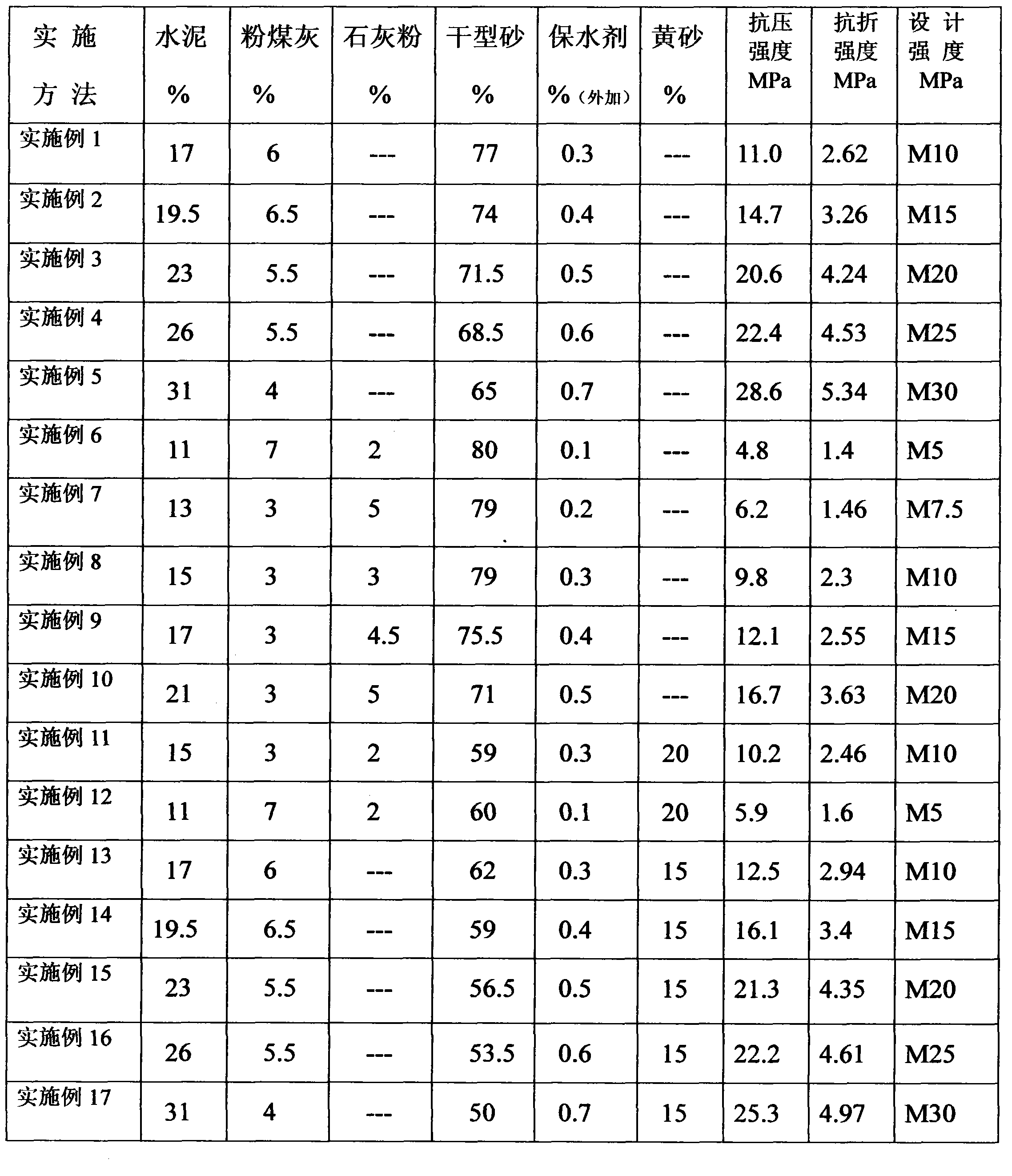

Waste foundry sand dry-mixed mortar

The invention relates to a waste foundry sand dry-mixed mortar, belonging to the technical field of circular economy and building material mortar. The waste foundry sand dry-mixed mortar is characterized in that the production raw materials of the dry-mixed mortar are based on waste foundry sand with the following mass ratio: 11-31% of cement, 3-7% of dry coal ash, 0-5% of dry lime powder, 50-80% of dry waste foundry sand, 0-20% of yellow sand (with particle diameter between 2.36mm and 1.18mm), and 0.1-0.6% of water retaining agent (additionally added). The varieties of the dry-mixed mortar prepared according to the invention comprise various types of dry-mixed masonry mortar, dry-mixed plastering mortar, dry-mixed terrace mortar and the like which all meet the requirements of national standard GB / T25181 Ready Mixed Mortar. The waste foundry sand dry-mixed mortar is beneficial for the harmless treatment and resource utilization of the waste foundry sand, and opens up a brand-new resource regeneration way of the waste foundry sand.

Owner:秦大春

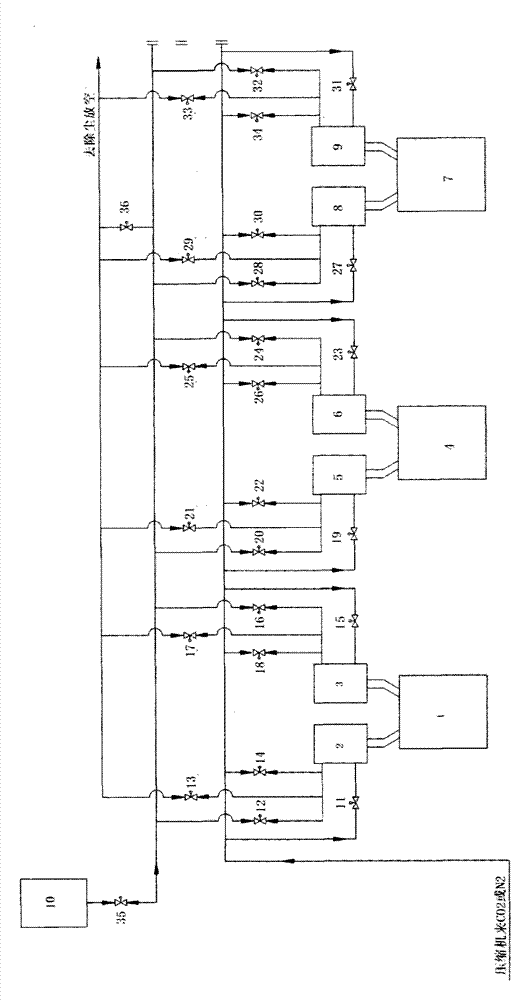

Method for implementing mutual pressurization/depressurization among pressurized gasification furnace coal locks

InactiveCN102925216ASimple methodLess investmentCombustible gas productionGas compressorProcess engineering

The invention discloses a method for implementing mutual pressurization / depressurization among pressurized gasification furnace coal locks. The coal lock is provided with a pressurization / depressurization pipeline, a final pressurization pipeline, a gas seal pipeline and an evacuation pipeline; and each pipeline is correspondingly provided with a pressurization / depressurization control valve, a final pressurization control valve, a gas seal control valve and an evacuation control valve. The control valves on the pipelines are opened and closed to implement mutual pressurization / depressurization among the coal locks; and the insufficient pressure after mutual pressurization of the coal locks is implemented by supplementing inert gas for pressurization. No coal lock gas compressor is arranged, and the evacuated gas is inert gas. The method disclosed by the invention can avoid the adverse effect on the whole coal gasification production system and the environmental pollution when crude gas is used as the coal lock pressurization gas; and the method can effectively save the energy, and lower the equipment investment and the maintenance and operating cost.

Owner:YUNNAN COAL CHEM IND GROUP +2

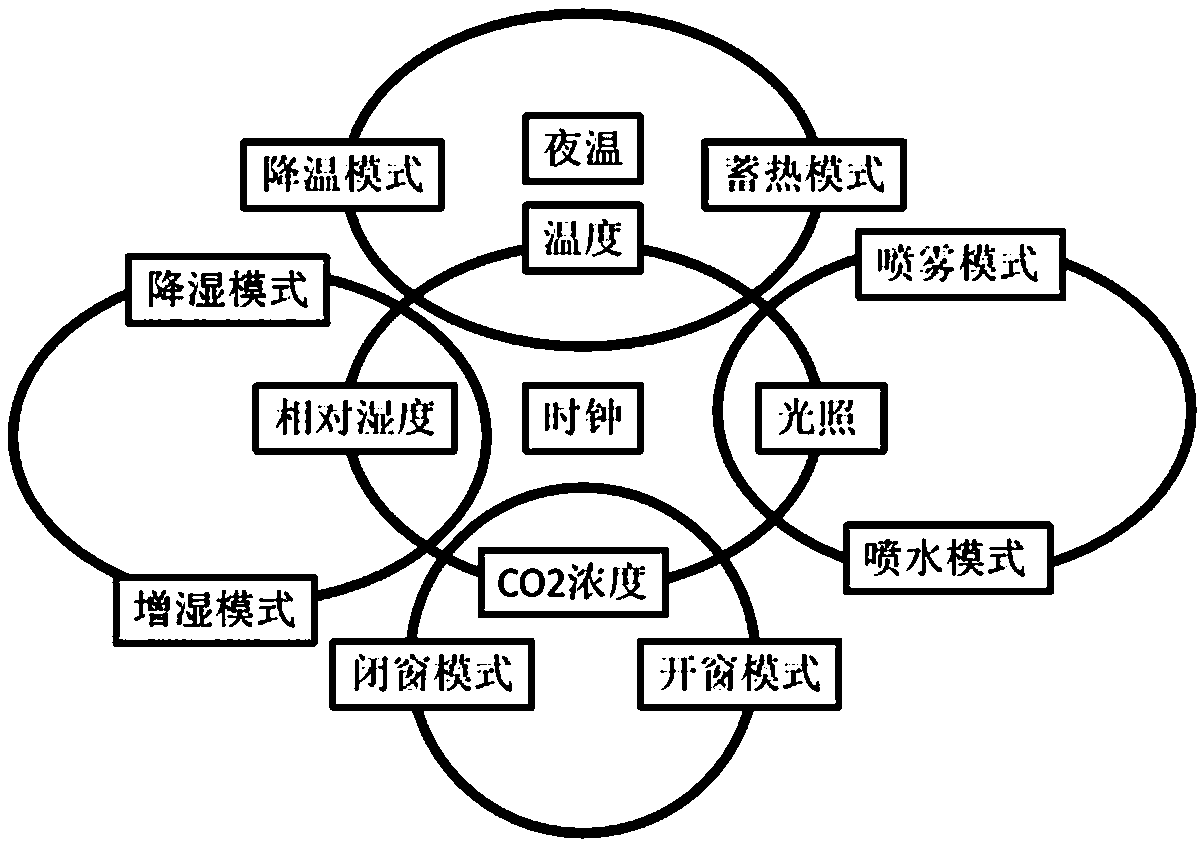

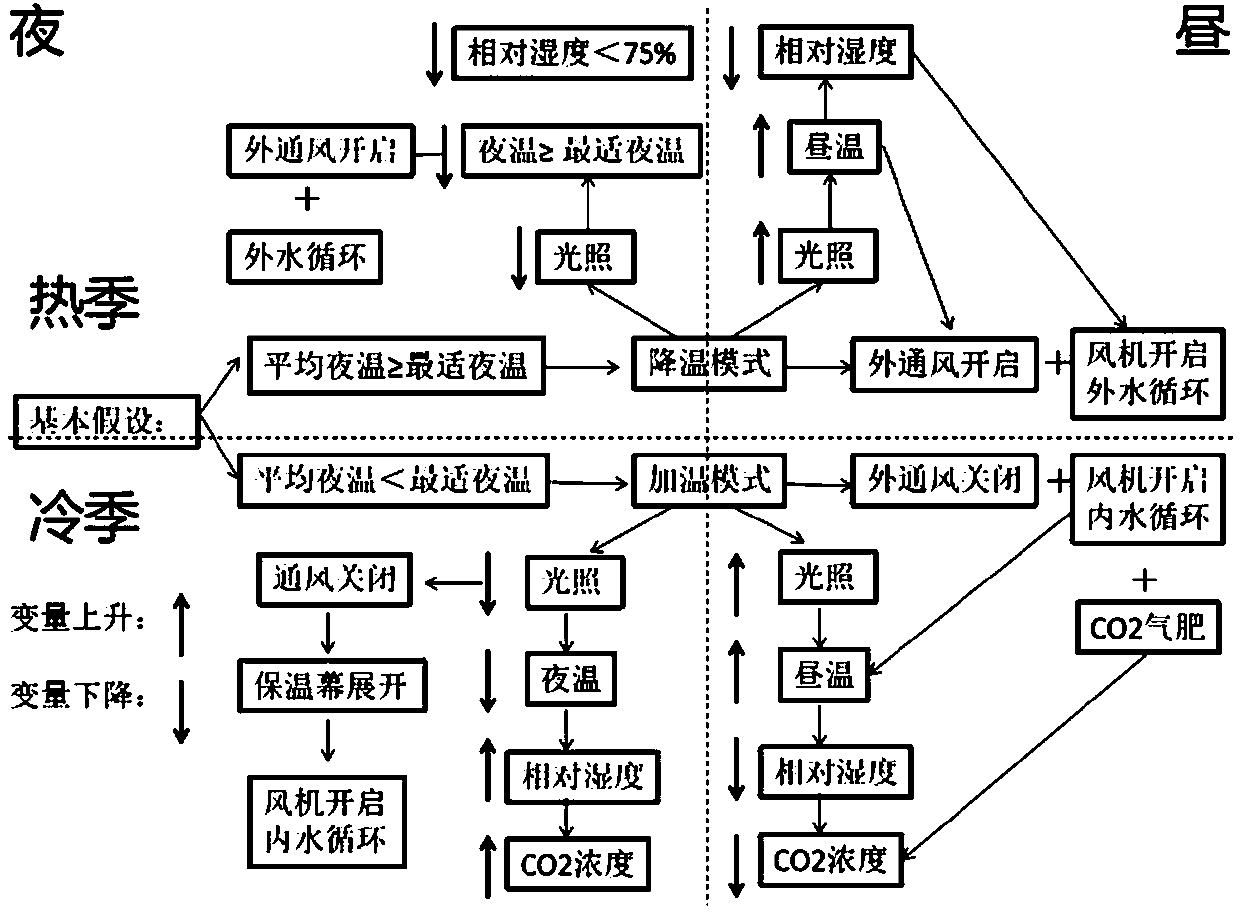

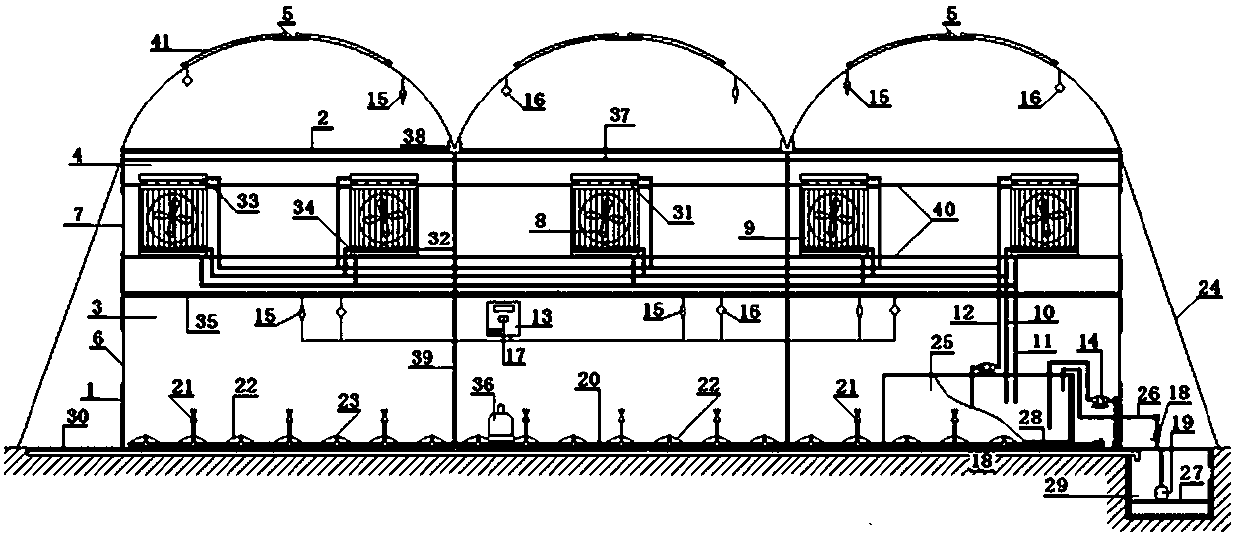

Intelligent greenhouse and environmental control method of using greenhouse effect for heat collection and fan coils for heat exchange

ActiveCN110178600AIncrease temperatureIncrease effective accumulated temperatureClimate change adaptationGreenhouse cultivationCold seasonAir volume

The invention discloses an intelligent greenhouse and environmental control method of using the greenhouse effect for heat collection and fan coils for heat exchange. The greenhouse is a multi-unit combined light-transmissive greenhouse with a highly overhead structure and comprises fan coil devices which are arranged at the middle-upper portions of the greenhouse, wherein each fan coil device integrating a heat exchanger and a wet curtain comprises a high-air-volume low-air-pressure fan and is provided with an inner water circulation pipe and an outer water circulation pipe, and the fan coildevices are connected to a heat storage pool through one water supply and return pipe. Two curtain layers are arranged above and below the devices respectively. An intelligent control system is designed, the greenhouse is closed for keeping warm in the cold season, the fans are started, internal water circulation of the coils is enabled, the solar heat is accumulated into water during daytime, andcrops are supplemented with CO2 gas fertilizer; the solar heat in the water is released into the air during nighttime. The greenhouse is opened for ventilation in the hot season, the fans are started, and external water circulation is enabled; the ventilation cooling effect is improved through evaporation and heat absorption on the surfaces of the heat exchangers. The problem that the cost is toohigh when existing methods are adopted for regulating the greenhouse environment is solved in an environment-friendly low-carbon mode, the remarkable effects of increasing the production, improving the quality, reducing the consumption of drugs and saving water are achieved, and transformation and upgrading of facility agricultural production modes are facilitated.

Owner:云南旭滇农业技术有限公司

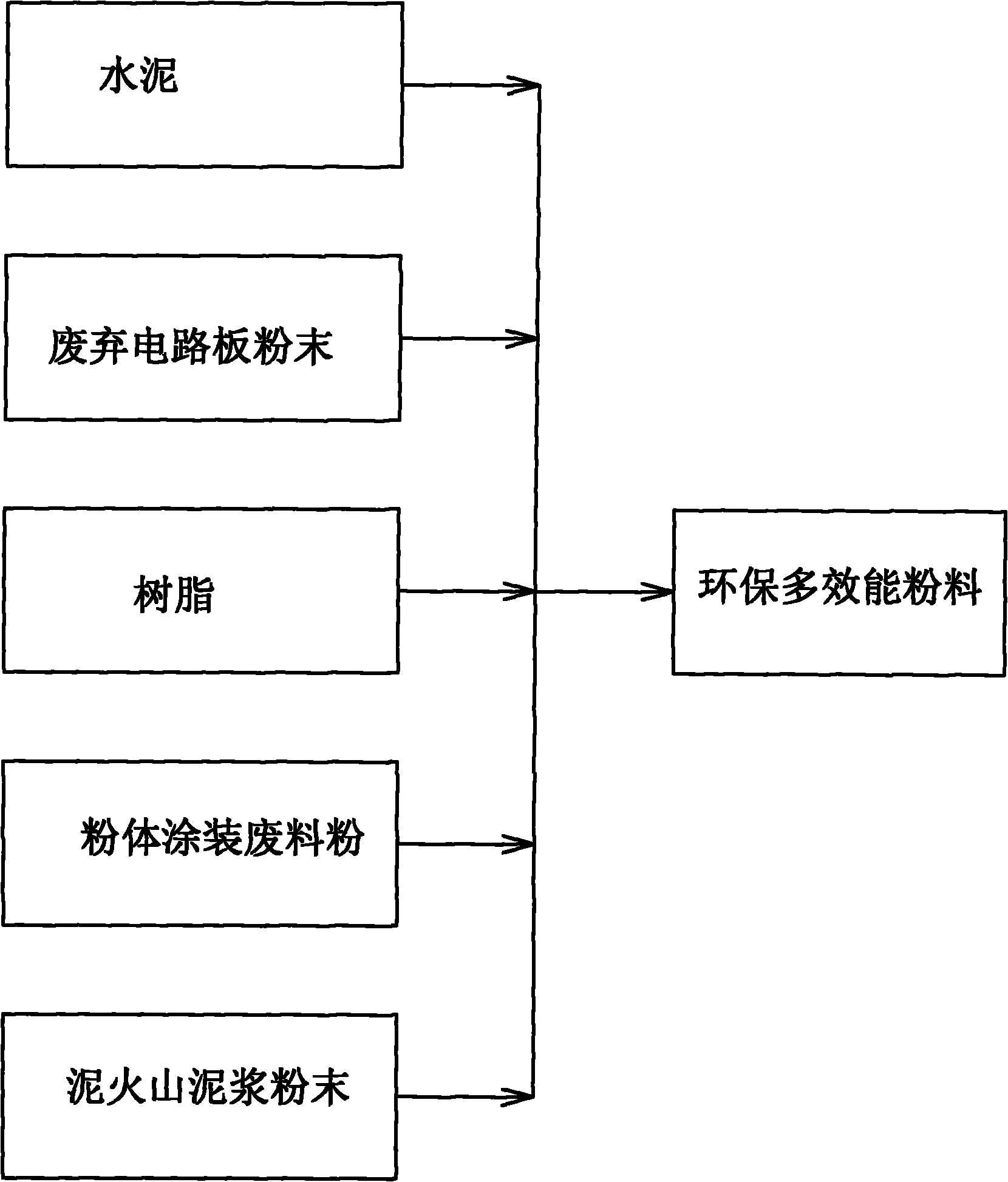

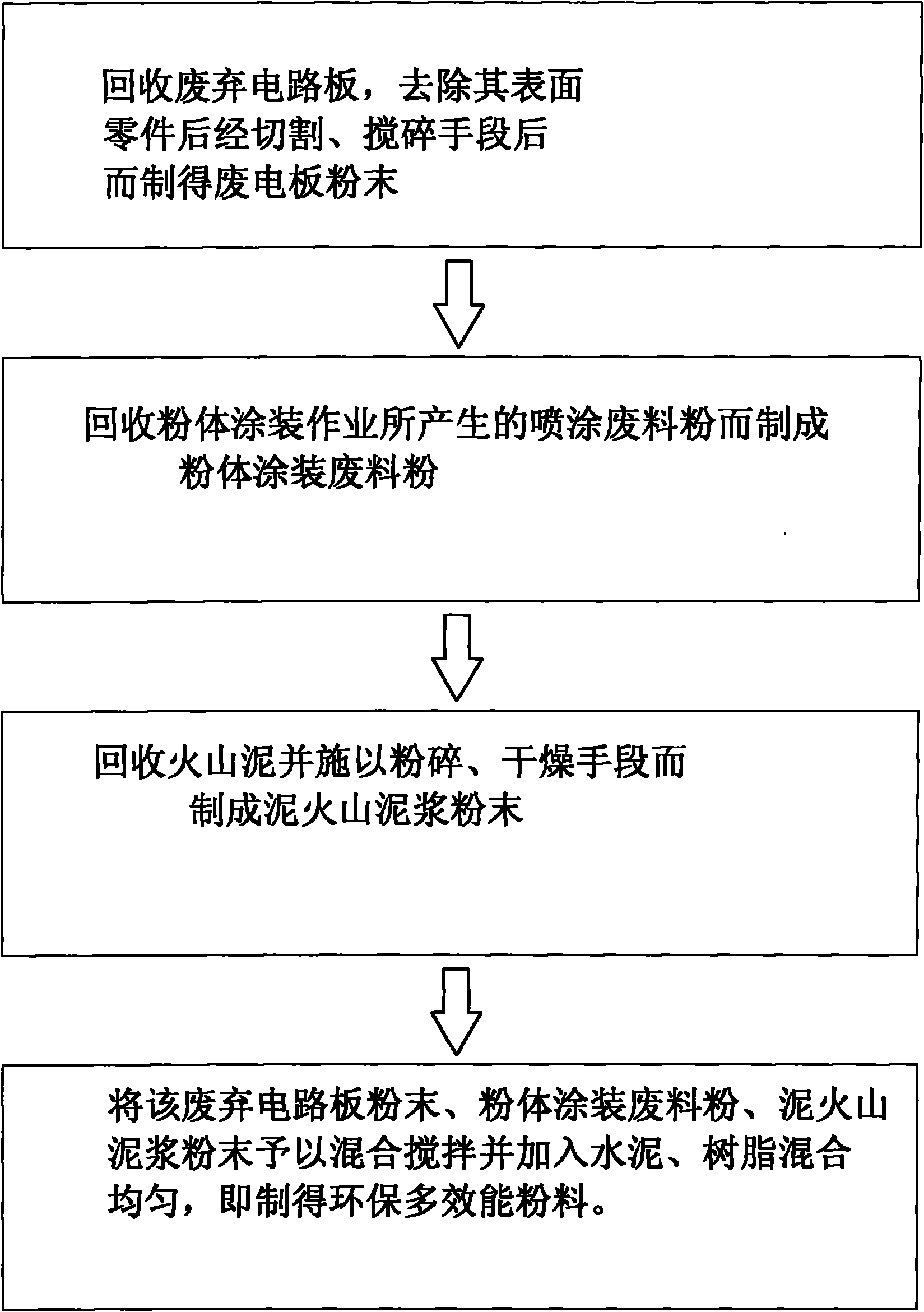

Environmental-protection and multiple-effect powder composite and production method thereof

InactiveCN101805152AGood physical propertiesThe industry has good economic benefitsSolid waste managementSlurryPolyresin

The invention discloses an environmental-protection and multiple-effect powder composite and a production method thereof. The environmental-protection and multiple-effect powder composite is prepared by mixing cement, waste circuit board powder, resin, powder coating waste powder and mud volcano powder. The method for producing the environmental-protection and multiple-effect powder composite comprises the following steps of: recycling the waste circuit boards, removing the parts on the surface, cutting, crushing and separating to produce the waste circuit board powder; recycling the spraying waste powder generated in the powder coating operation to produce powder coating waste powder; recycling mud volcano slurry, crushing and drying to produce mud volcano powder; mixing the waste circuit board powder, the powder coating waste powder and the mud volcano powder together, adding the cement and resin, and uniformly mixing to obtain the environmental-protection and multiple-effect powder. The invention is widely applied to the places with the need of using environmental-protection and multiple-effect powder compositions and provides a good production method for producers.

Owner:王武添 +7

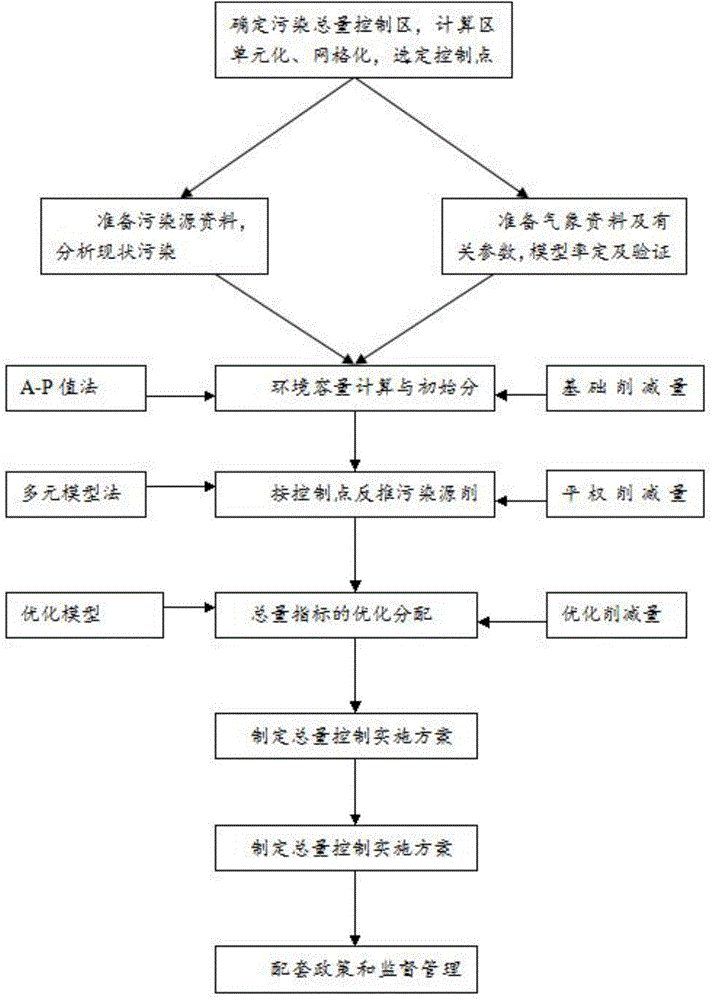

Step-by-step method for controlling total amount of air pollution

The invention discloses a step-by-step method for controlling the total amount of air pollution. The method includes: performing basic reduction quantity calculation of pollution sources; calculating affirmative reduction quantity with a multi-source model method; performing optimal allocation of total amount controlled load. An A-P value method and the multi-source model method are integrated, an optimal allocation model is introduced, and a method system which is reasonable in technology and economically feasible is formed.

Owner:SICHUAN UNIV

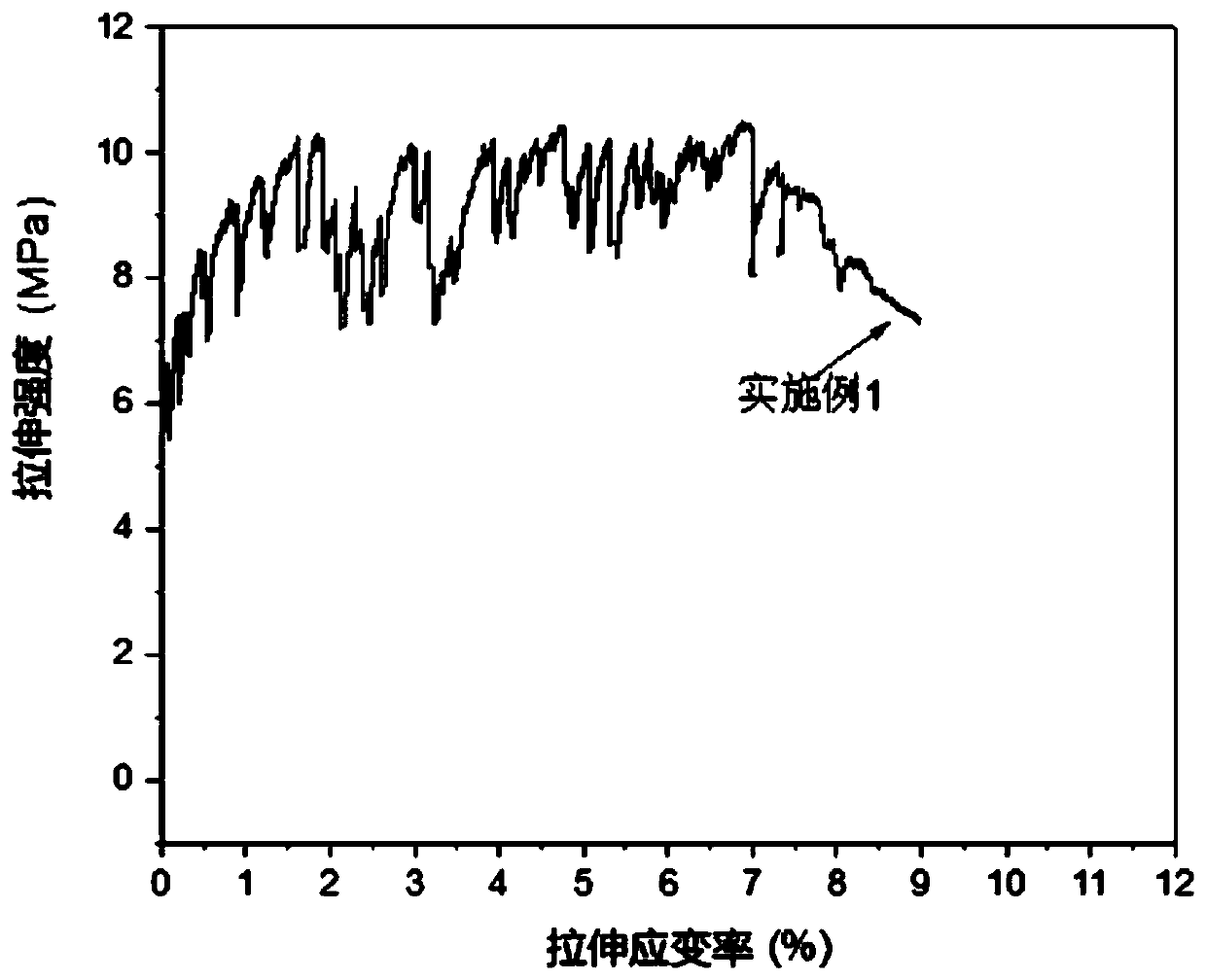

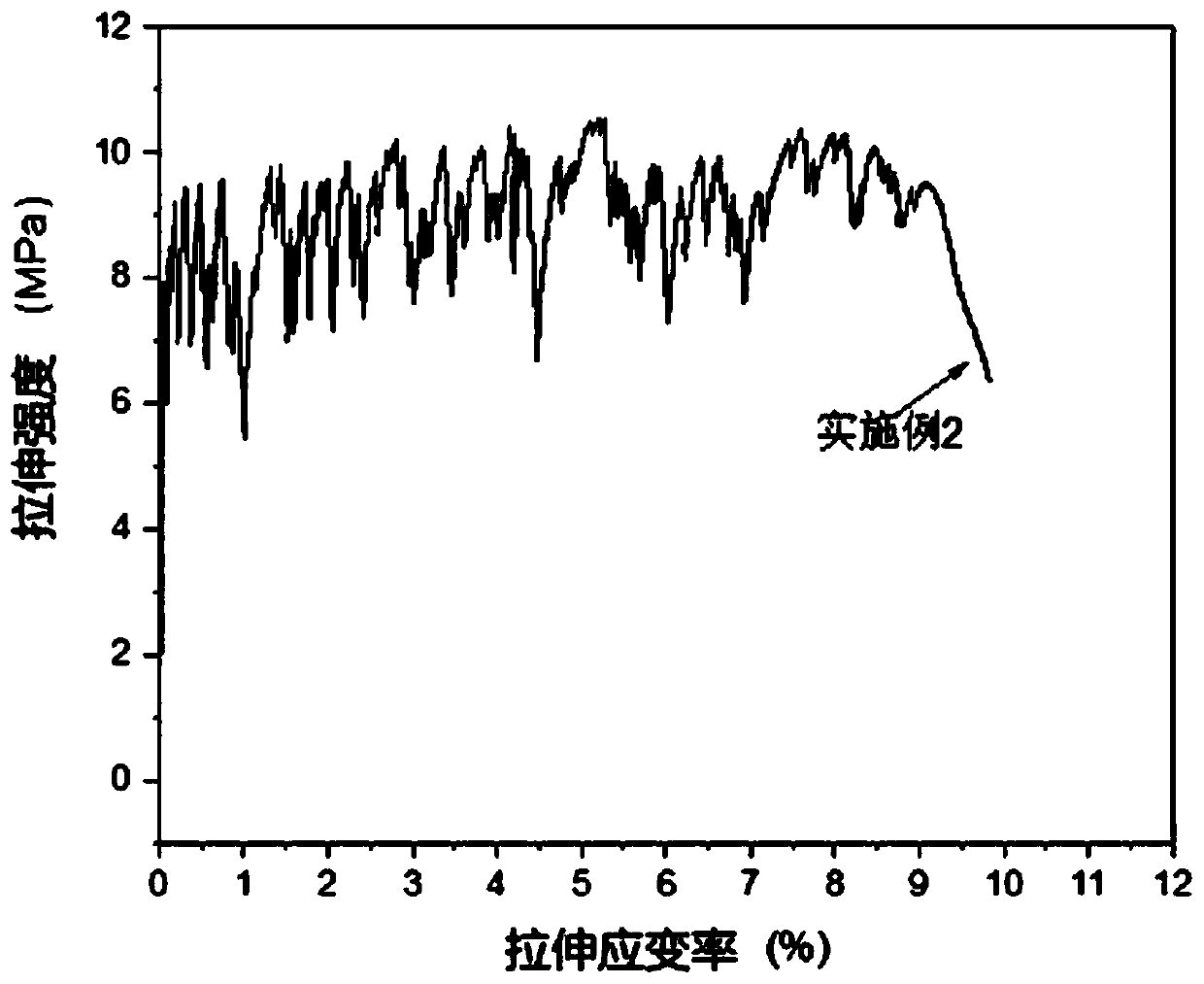

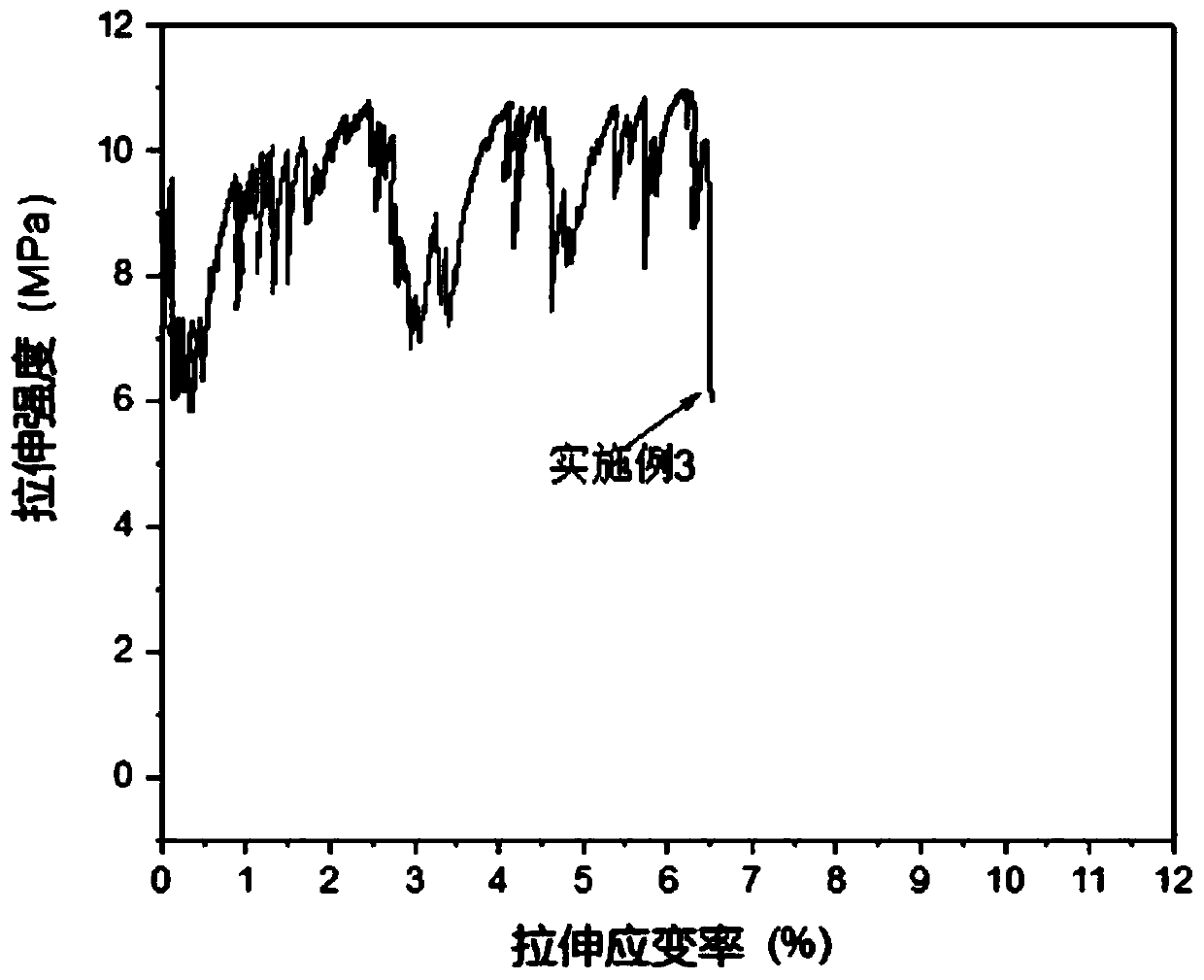

Ultrahigh-strength and high-ductility marine concrete material and preparation method thereof

The invention discloses an ultrahigh-strength and high-ductility marine concrete material and a preparation method thereof. The marine concrete material is a cement-based composite material. The cement-based composite material uses seawater, marine gravels and cement as raw materials which are subjected to mixing treatment to obtain the marine concrete material with compressive strength of larger than 150 MPa and ductility of larger than 6% under uniaxial tensile load. According to the invention, by adoption of the seawater to replace fresh water as mixing water, sea sand or coral sand to replace fine quartz sand or river sand as an aggregate and ultra-high-molecular-weight synthetic fiber as a micro-energy dissipative component, an ultra-high strength and high-ductility marine concrete material with the compressive strength exceeding 150 MPa and the ductility of larger than 6% under uniaxial tensile load can be prepared; thus, problems like shortage of fresh water and deterioration of the ecological environment can be alleviated; meanwhile, great technical benefits, economic benefits and environmental protection benefits brought by marine resourceful utilization can be realized.

Owner:SOUTHEAST UNIV

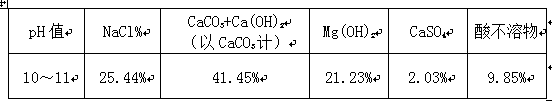

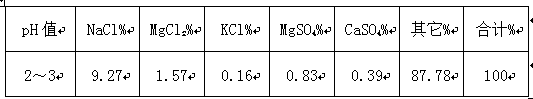

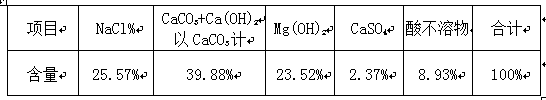

Method and device for purifying bromine-extracting waste liquid

PendingCN108529788AReduce turbidityDo not change the effective compositionWater treatment parameter controlSludge treatmentLiquid wasteSaline water

The invention discloses a method and a device for purifying bromine-extracting waste liquid. Waste salt sludge generated in the process of refining saline through a chemical process is selected and used for adjusting pH value of the bromine-extracting waste liquid, and turbidity of the bromine-extracting waste liquid is lowered through secondary coagulation process and air flotation process; the method and the device can be used for purifying high-acidity high-salinity bromine-extracting waste liquid, acid corrosiveness of the waste liquid is lowered remarkably, up-to-standard emission is realized, and no acidic pollution is caused to surrounding environment; various suspended matters can be removed effectively, the bromine-extracting waste liquid after being purified is quite clear, the turbidity is lowered remarkably, and 90% of ingredients like silicon and iron in the bromine-extracting waste liquid can be removed without changing original active composition in the same; through purifying treatment, quality of the bromine-extracting waste liquid is improved greatly, the method and the device can be directly used for salt drying in the sun, vacuum salt making and other process using saline, are low in purifying cost and simple in raw material obtaining way, realize treatment of waste by waste and have remarkable environment protection benefit.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for hydration preparation of autoclaved fly ash-lime brick from PO saponification waste residues, garbage power plant slag and fly ash

The invention discloses a method for hydration preparation of an autoclaved fly ash-lime brick from PO saponification waste residues, garbage power plant slag and fly ash. The method comprises 1, preparing building blocks with the size of 70mm*50mm*20mm from 100g of concrete, 2, breaking and screening garbage power plant slag and selecting slag with particle sizes of 2-3mm as a concrete aggregate, 3, dissolving additive accessory materials such as sodium silicate as an activator, sodium sulfate and triethanolamine as early strength agents and sodium abietate as a dispersant through a certain amount of water, adding PO saponification waste residues into the solution, orderly adding garbage power plant slag, PO42.5 cement and fly ash into the solution and fully stirring the mixture to obtain slurry, 4, taking out the slurry and carrying out repeated compaction to obtain fly ash building blocks, 5, standing to maintain the fly ash building blocks obtained by the step 4 for 24h, and 6, steaming the fly ash building blocks through an autoclaved reaction kettle with water in the bottom layer at a temperature of 165-195 DEG C for 5-9h, carrying out natural cooling to the room temperature and discharging the products. The autoclaved fly ash-lime brick realizes change of waste into valuables.

Owner:福建洋屿环保科技股份有限公司

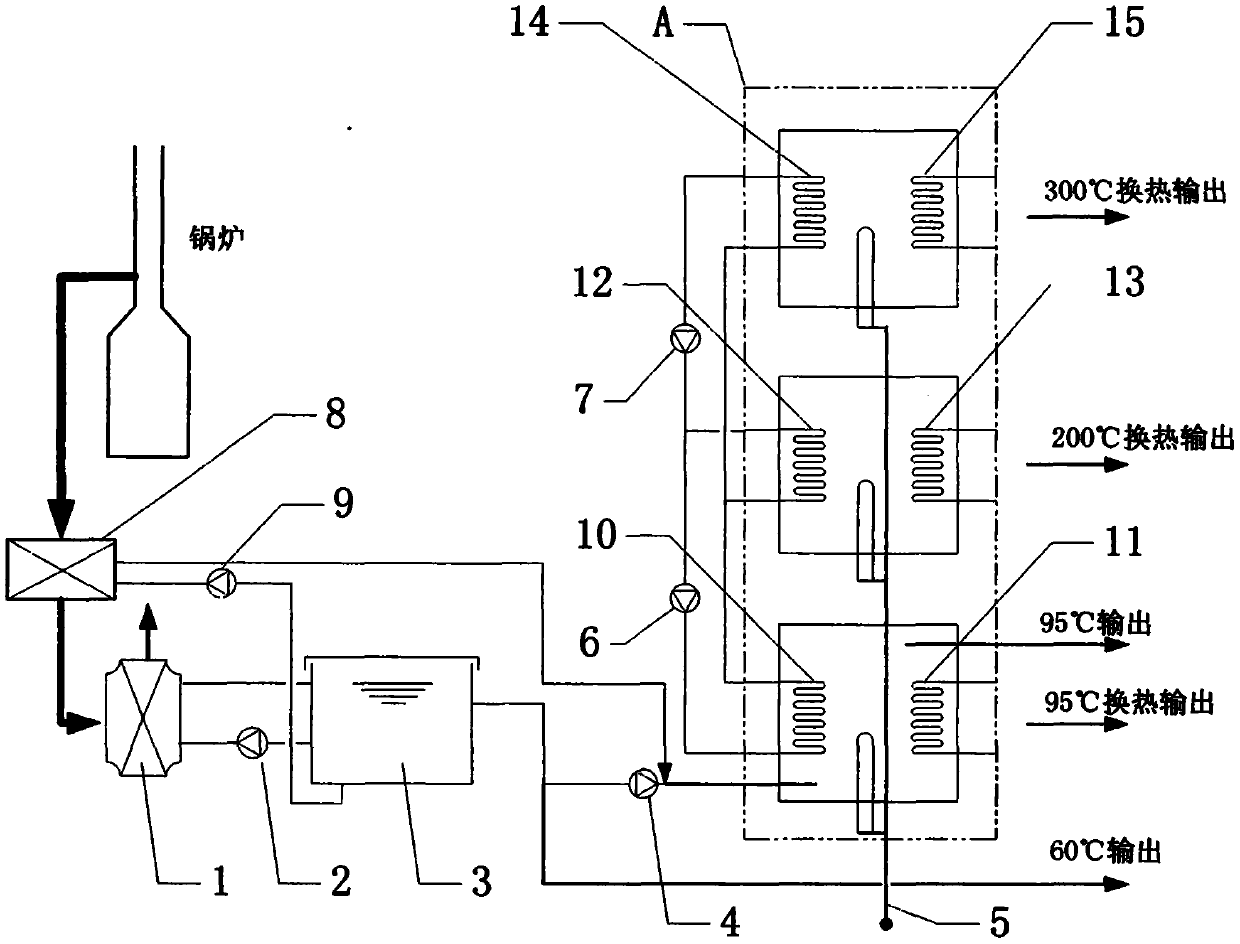

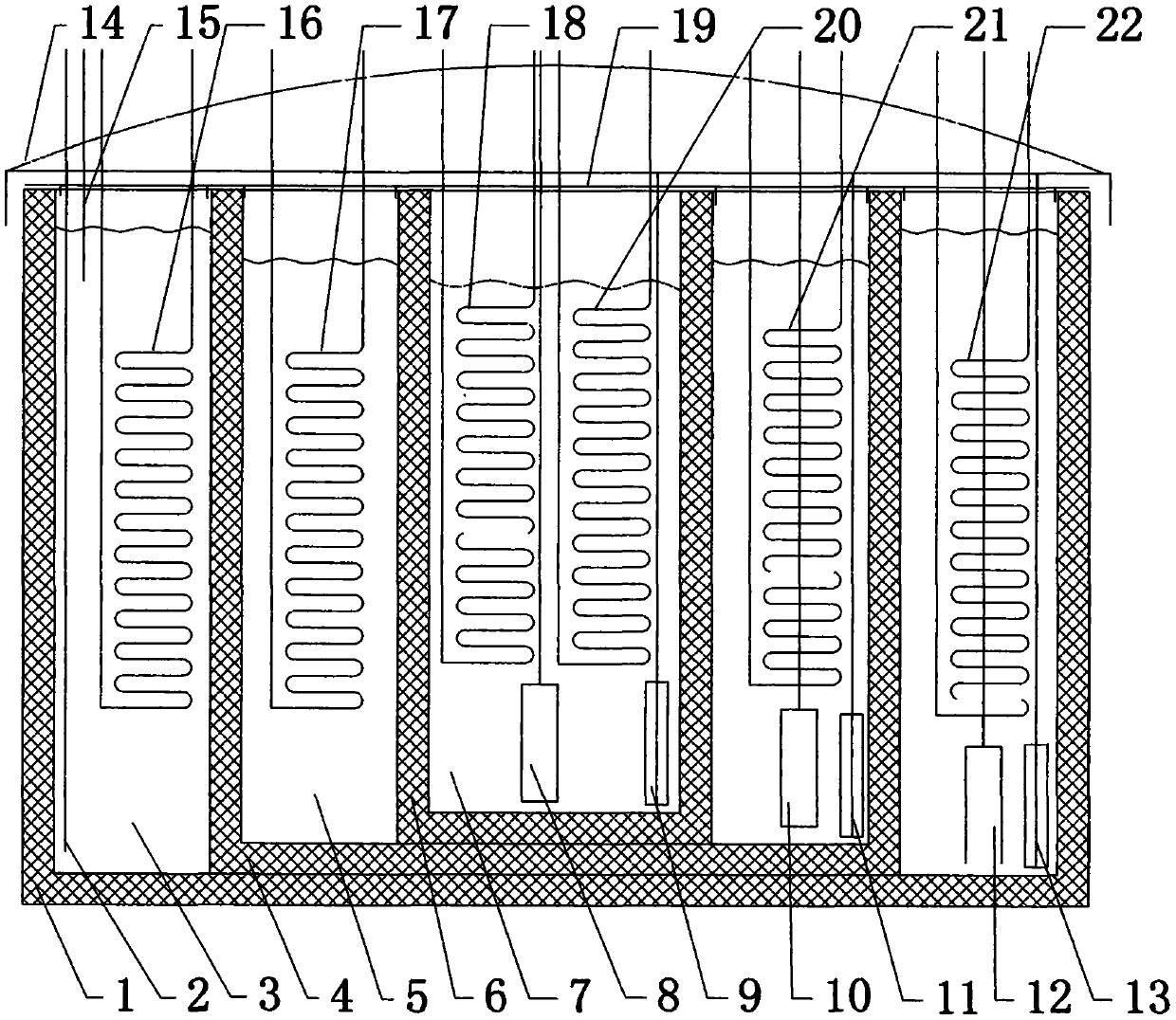

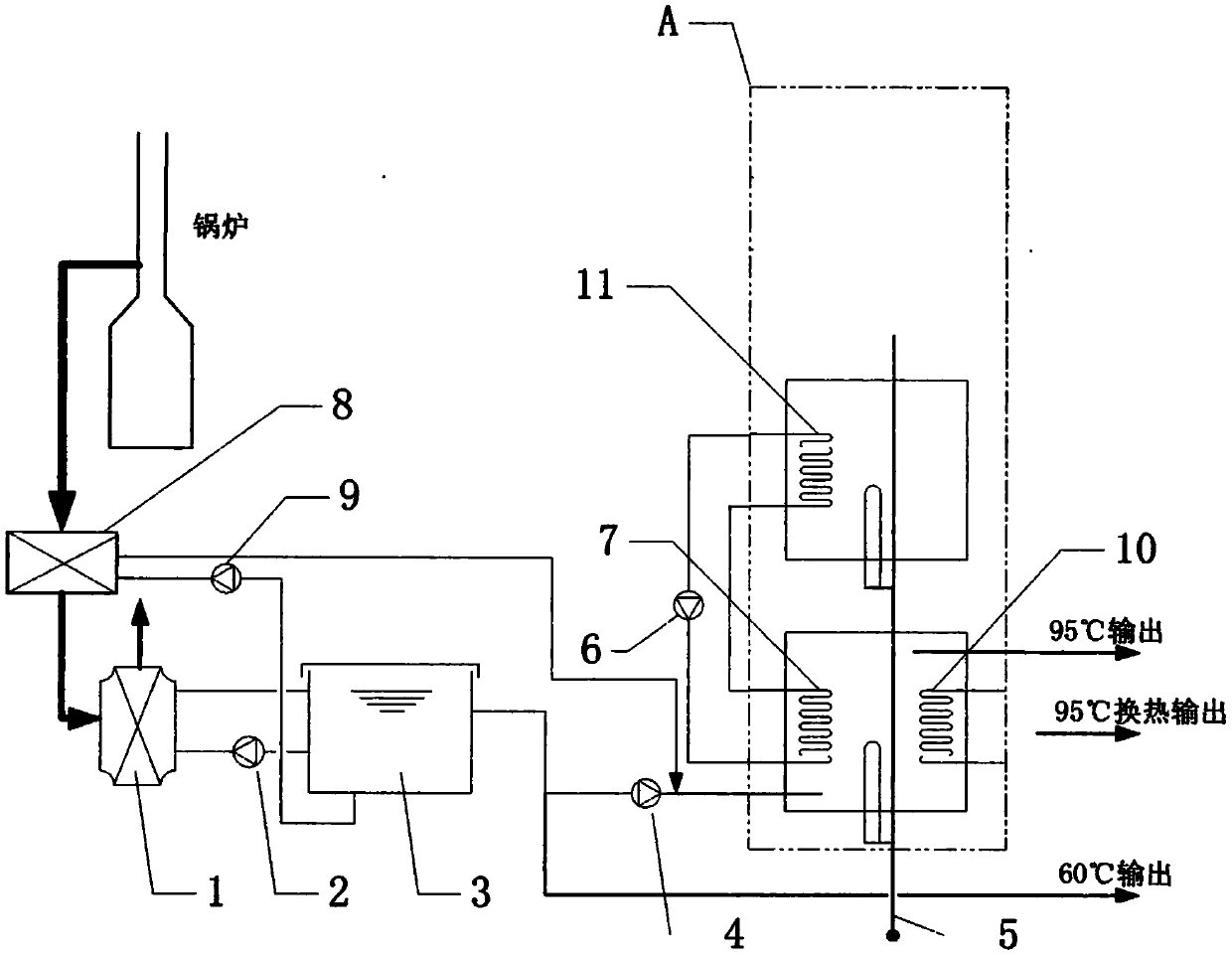

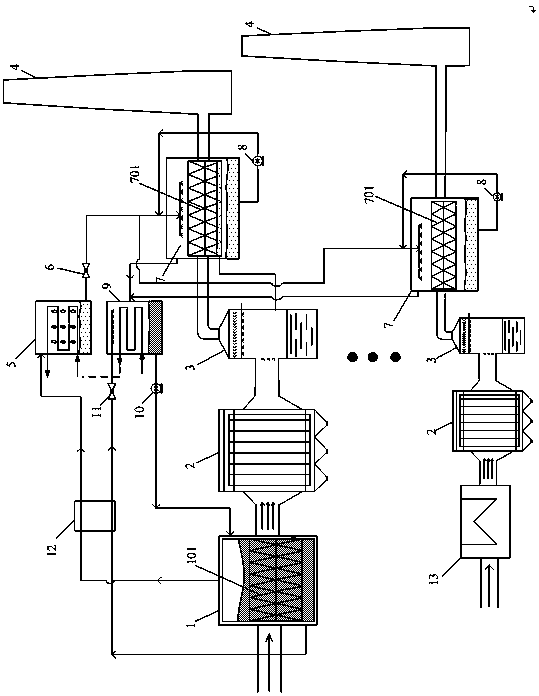

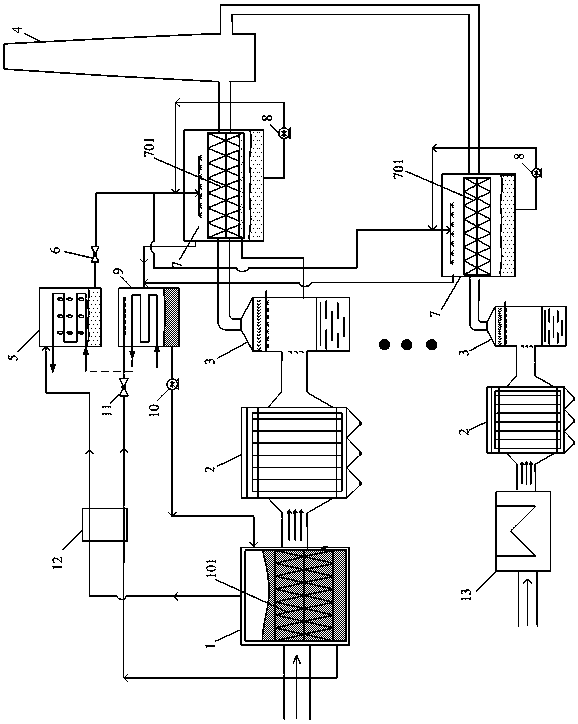

Integrated heat supply system for flue gas source heat pump waste heat recovery, flue gas white smoke removal and off-peak electricity phase change energy storage gradient temperature rise

PendingCN110529870AMeet individual heat transfer needsImprove energy efficiency ratioHeat recovery systemsHeat storage plantsThermal energyHeat pump

The invention discloses an integrated heat supply system for flue gas source heat pump waste heat recovery, flue gas white smoke removal and off-peak electricity phase change energy storage gradient temperature rise, and relates to the field of boiler flue gas white smoke removal, heat energy recycling and phase change energy storage. The objective of the invention is to solve the problem that white smoke is formed at a chimney opening in wet smoke exhausted by a boiler, visual pollution is generated, haze weather is intensified, and existing fused salt heat storage technology cannot meet theindustrial production requirement. The smoke source heat pump and the sleeve tank phase change energy storage device are creatively combined to generate a good effect. The flue gas source heat pump ofthe system can achieve complete recycling of natural gas heat energy, and the phenomenon of white smoke emission is eliminated. The sleeve tank phase change energy storage device raises 60 DEG C hotwater generated by the flue gas source heat pump into 95 DEG C hot water and 120-180 DEG C steam through the off-peak electricity energy storage warming system and supplies the hot water and the steamback to the boiler heat supply system, and environmental benefits and energy-saving benefits of eliminating chimney white smoke, reducing boiler natural gas consumption and reducing energy consumption cost are achieved.

Owner:李育勤

Asphalt mixture additive and preparation method thereof

ActiveCN104559258APerformance is easy to controlImprove road performanceBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt mixture additive and a preparation method thereof. The asphalt mixture additive comprises the following components in parts by mass: 10-20 parts of a polymer, 5-10 parts of a cross linker, 10-20 parts of padding, 0.5-2 parts of a smog inhibitor, 1-2 parts of a plasticizer, 0.1-1 part of an antioxidant and 50-70 parts of matrix asphalt, wherein the matrix asphalt is one of Shell 70#, Shell 90#, SK70# or SK90#. Compared with the prior art, the asphalt mixture additive has the advantages that the anti-rutting performance and water damage resistance of an asphalt mixture can be significantly improved, the low-temperature cracking resistance and ageing resistance of asphalt concrete can be effectively improved, and the service life of asphalt roads is prolonged; meanwhile, the asphalt mixture additive can substitute about 15-25% of asphalt raw materials in the asphalt mixture, so that the production temperature is reduced to 140 DEG C, then the smoking phenomenon in the production and spreading processes is effectively reduced, and the asphalt mixture additive is energy-saving and environment-friendly; and the production method is simple, low in cost and suitable for industrialized production.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

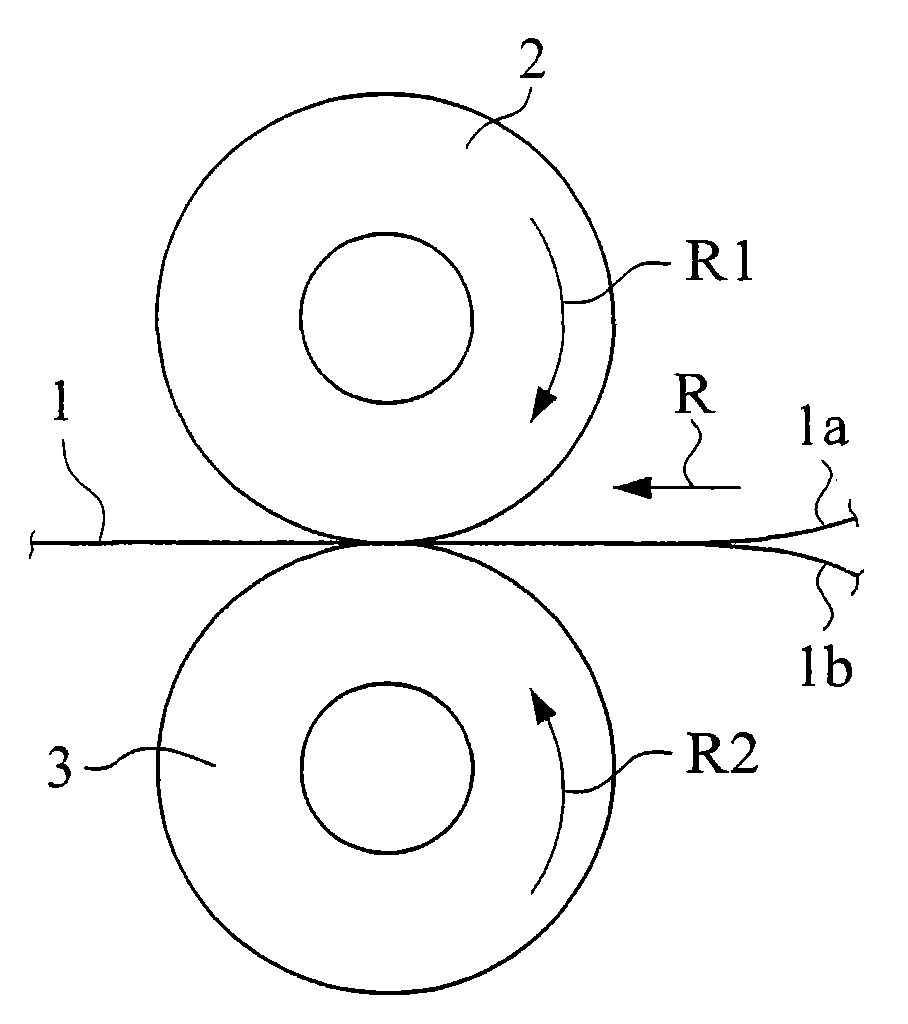

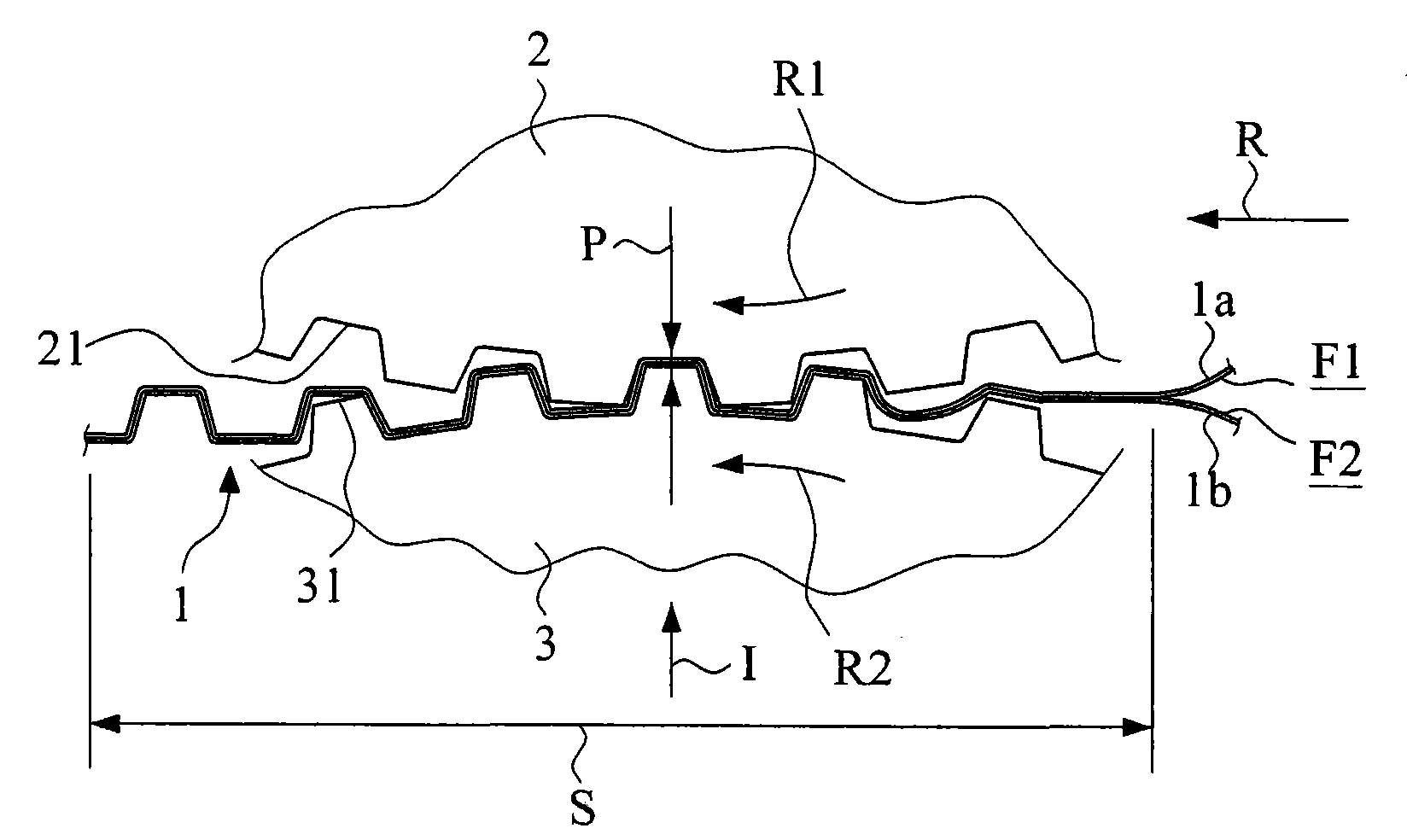

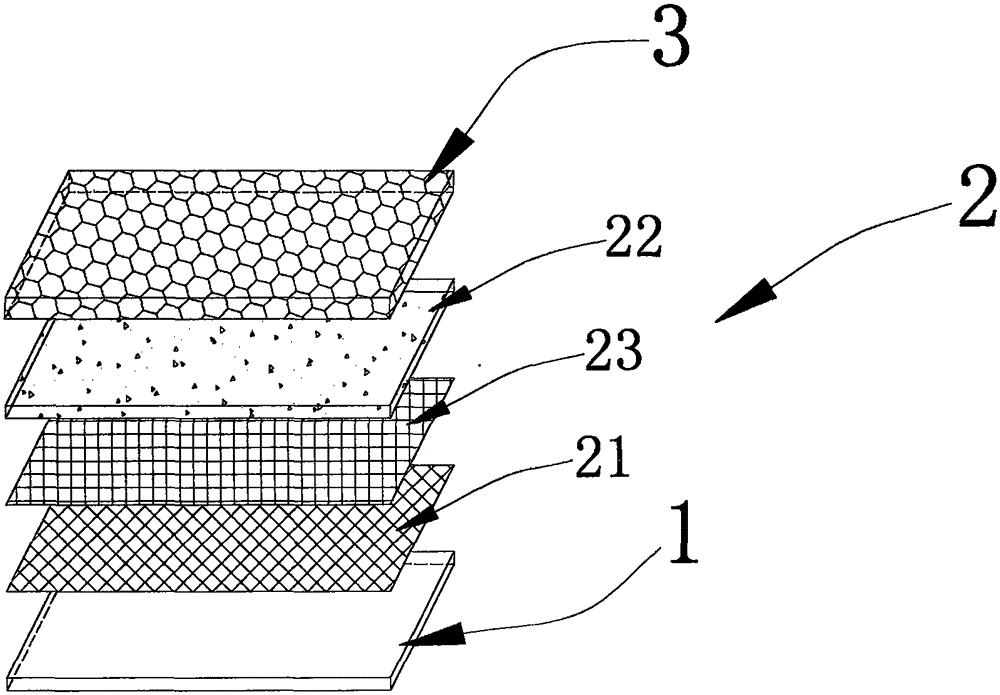

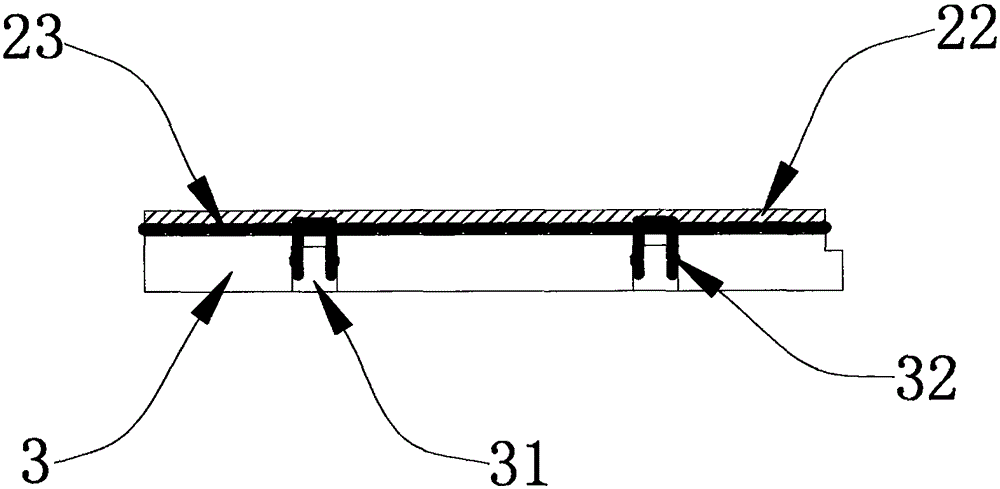

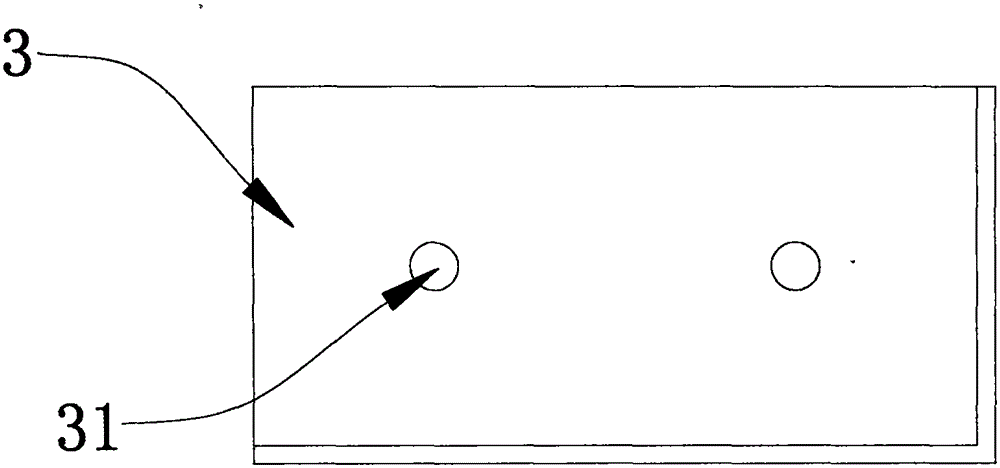

Multi-layer tissue paper with compression adhesive structure

ActiveCN101988280AImprove stabilityRaise the desire to buy the productSpecial paperPaper/cardboardAdhesiveTissue paper

The invention discloses multi-layer tissue paper with a compression adhesive structure, which comprises first tissue paper and at least one second tissue paper, wherein the first tissue paper comprises a first overlaying surface, the second tissue paper comprises a second overlaying surface, the first overlaying surface and the second overlaying surface are at least partially mutually overlaid, and an overlaying region is defined between the first tissue paper and the second tissue paper. The first tissue paper forms a plurality of first compression parts protruded from the molding direction after the overlaying region between the first tissue paper and the second tissue paper is rolled by rolling force, the second tissue paper forms a plurality of second compression parts which correspond to the first compression parts and are the same with the molding direction, and all the first compression parts and at least one part regions of the corresponding second compression parts form a compression point by rolling and adhesion, thereby realizing compression and adhesion of the first tissue paper and the second tissue paper and simultaneously impressing patterns.

Owner:CHAN LI MACHINERY

Aluminum passivating agent

InactiveCN104593759AAchieve environmental benefitsGood performanceMetallic material coating processesAluminiumRaw material

The invention discloses an aluminum passivating agent. According to the key points of the technical scheme, the aluminum passivating agent comprises the following raw materials in percentage by mass: 3-5wt% of fluorozirconic acid, 2-5wt% of fluorotitanic acid, 5-8wt% of silica sol, 1-2wt% of citric acid, 1-3wt% of tartaric acid, 2-3wt% of acetic acid, 4-5wt% of ammonia water and the balance of purified water. The invention aims at providing the aluminum passivating agent which is free of heavy metals and can effectively prevent dust from adhering on the surface of die-cast aluminum after a conversion film is formed.

Owner:杭州美立尔表面处理技术有限公司

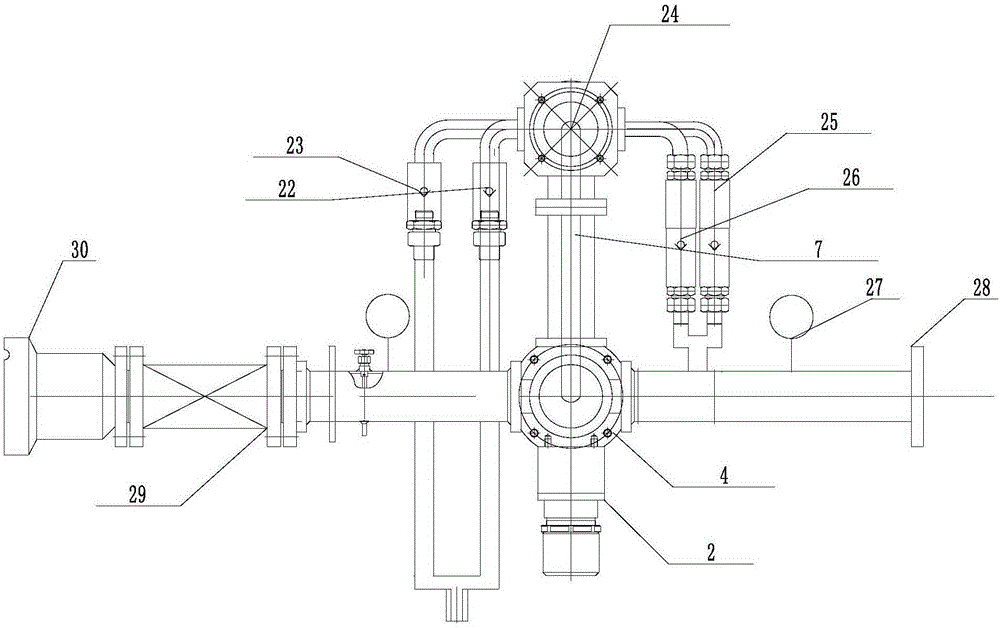

Self-controlled oil well casing gas recycling device

ActiveCN105178919AAchieve production management goalsAvoid pollutionFluid removalConnection typeHydraulic cylinder

The invention discloses a self-controlled oil well casing gas recycling device. A liquid feeding tee joint and a stroke push rod sealer are respectively connected to the front end and the rear end of a series-connection type piston pull rod hydraulic cylinder; a push rod reversing rocker arm rack is connected between the stroke push rod sealer and a reversing valve left end and right end reversing push rod sealer; liquid feeding and draining manifolds (A and B) are arranged at the lower end of the hydraulic cylinder; upper portions of two gas feeding one-way valves are connected with a gas feeding hole of the hydraulic cylinder; lower portions of the two gas feeding one-way valves are connected with a casing gate of a wellhead Christmas tree; upper portions of two gas discharging one-way valves are connected with a gas discharging hole of the hydraulic cylinder; lower portions of the two gas discharging one-way valves are connected with a liquid draining tee manifold connected to a T port of a reversing valve; a liquid feeding one-way valve of a liquid inlet of a P port of the reversing valve is connected with a production liquid draining gate of the wellhead Christmas tree; and the liquid draining tee manifold at the position of a liquid draining manifold of the T port of the reversing valve is connected with a production main line. Problems that oil well casing gas builds the pressure for a long time, an oil well working fluid level is reduced, capacity is reduced, and gas locking is caused are solved.

Owner:檀长江

Method for preparing autoclaved fly ash brick through hydration with PO saponification waste residue, garbage power plant slag and coal-fired power plant fly ash

InactiveCN105948635ASolve the problem of comprehensive utilization of resourcesSolve the home problemSolid waste managementCeramic shaping apparatusSlagFlexural strength

The invention discloses a method for preparing an autoclaved fly ash brick through hydration with PO saponification waste residue, garbage power plant slag and coal-fired power plant fly ash. The method is characterized in comprising the following steps: (1) 100g of concrete is prepared into a building block with a size of 70mm*50mm*20mm; (2) garbage power plant slag is crushed; slag particles with sizes of 2-3mm are selected as an aggregate of the concrete; (3) water is added for dissolving additive auxiliary materials including an activating agent Na2SiO3, early strength agents Na2SO4 and triethanolamine, and a dispersing agent sodium rosinate; the PO saponification waste residue is added; the garbage power plant slag, PO42.5 cement and coal-fired power plant fly ash are sequentially added; the mixture is well mixed, such that a slurry is prepared; (4) the slurry obtained in the step (3) is fetched and pressed into building blocks; (5) the building blocks obtained in the step (4) are allowed to stand for curing for 24h; (6) the building blocks obtained in the step (5) are steamed in an autoclave reactor, wherein the temperature is controlled at 230-250 DEG C and autoclave is carried out for 5-9h; the material is discharged after natural cooling; and (7) compression strength tests and flexural strength tests are carried out. According to the invention, the above three solid waste resources are used or preparing the autoclaved fly ash bricks, such that waste is turned valuable.

Owner:福建洋屿环保科技股份有限公司

Preparation method of low heavy metal-leached ecological cement

The invention discloses a preparation method of low heavy metal-leached ecological cement. The method comprises the following steps: based on limestone, sludge, coal ash, aeolian sand, ferromanganese slag and a catalyst as raw materials, coarsely grinding the limestone and the sludge while carrying out pretreatment on the ferromanganese slag in a grinding manner, and then grinding with other components into required specific surface area after calcining at high temperature. On one hand, wastes such as the aeolian sand, the coal ash, the ferromanganese slag and the like are effectively utilized, and the problems of environmental pollution and land occupation caused by stacking of the wastes are solved; on the other hand, leaching of heavy metals is inhibited by cement solidification reaction of the sludge. Therefore, the secondary pollution is reduced; the wastes are recycled; the production cost of the cement is reduced; the application prospect integrated with environmental benefits, social benefits and economic benefits is achieved.

Owner:湖北京兰水泥集团有限公司

Boiler wet flue gas condensing, water-collecting and fog-clearing system utilizing power station waste heat to refrigerate

InactiveCN110068023ARealize waste heat recovery and utilizationImprove operational efficiencyHeat pumpsBoiler absorbersWater savingPower station

The invention discloses a boiler wet flue gas condensing, water-collecting and fog-clearing system utilizing power station waste heat to refrigerate. The wet flue gas condensing, water-collecting andfog-clearing system comprises a plurality of boiler unit flue gas treatment systems, wherein one boiler unit flue gas treatment system is a main boiler unit flue gas treatment system, and comprises awaste heat generator, a dust collector, a desulfurization tower, an evaporator and a chimney which are sequentially connected, and further comprises a condenser and a heat absorber; the rest of the boiler unit flue gas treatment systems are secondary boiler unit flue gas treatment systems, and each secondary boiler unit flue gas treatment system comprises a waste heat exchanger, a dust collector,a desulfurization tower, an evaporator and a chimney which are sequentially connected. The boiler wet flue gas condensing, water-collecting and fog-clearing system achieves water-collecting and fog-clearing of flue gas of multiple units while realizing sufficient utilization of flue gas waste heat, and realizes certain water-saving earnings and environment-friendly benefits.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

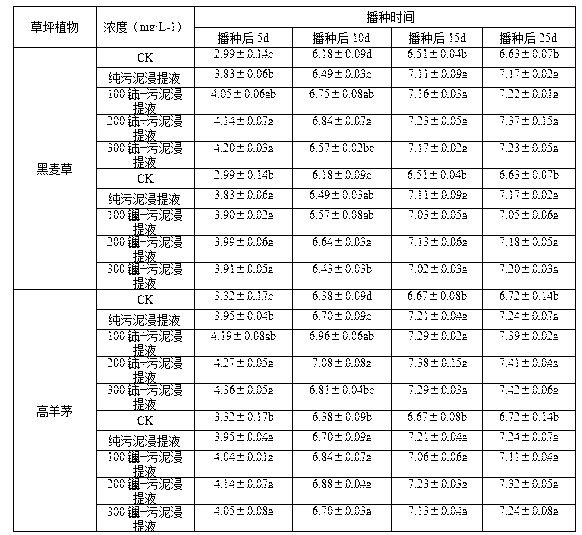

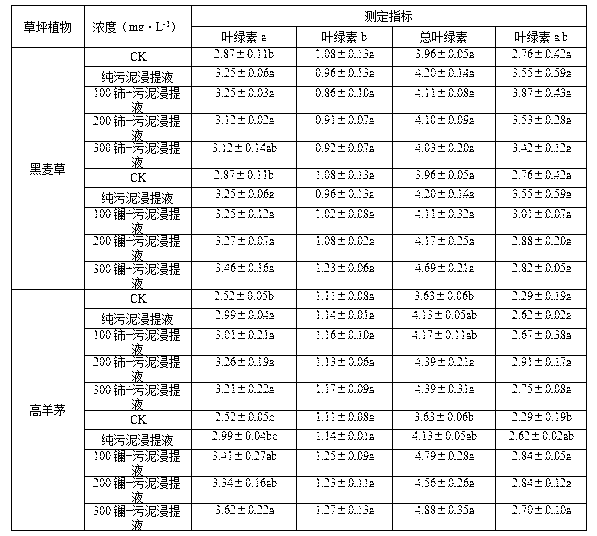

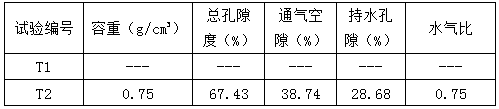

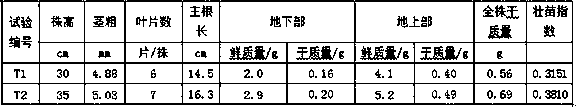

Method for regulating growth of festuca arundinacea in hot summer environment by sludge mixed seed soaking solution

InactiveCN103262860AImprove vitality indexReduce manufacturing costBiocidePlant growth regulatorsSoil scienceFestuca arundinacea

The invention discloses a method for regulating growth of festuca arundinacea in a hot summer environment by a sludge mixed seed soaking solution, which comprises the following steps: the sludge / rare-earth mixed seed soaking solution is composed of a sludge leaching solution and a rare-earth solution in a weight ratio of 1:1, wherein the sludge leaching solution is prepared by mixing sludge and distilled water in a weight ratio of 1:2, standing for 24 hours and filtering; and the rare-earth solution is a water solution containing 200-400 mg.L<-1> Ce(NO3)3.6H2O or La(NO3)3.6H2O. The experimental result indicates that the sludge mixed seed soaking solution can induce the accumulation of the seedling in-vivo proline, and can maintain the proline on a high level in the strong light and heat activation process, thereby enhancing the growth property of the festuca arundinacea in the field under high-temperature conditions in summer.

Owner:TIANJIN NORMAL UNIVERSITY

Method for making organic fertilizer by using packed compost technology

InactiveCN108329166AIncrease productionIncrease profitBio-organic fraction processingExcrement fertilisersEconomic benefitsNitrogen source

The invention discloses a method for making an organic fertilizer by using a packed compost technology. The method is characterized in that cow manure is taken as a nitrogen source, mushroom residue is taken as a carbon source, cow manure and mushroom residue are uniformly mixed to obtain a mixture, a decomposed microbe inocula is uniformly spread or sprayed in the mixture, a compost is uniformlystirred, the compost is subjected to high-temperature aerobic fermentation, and the temperature of the compost is kept at 50-60 DEG C for fermentation; the compost is subjected to turning for one timeevery day when the temperature exceeds 60 DEG C, and turning for one time every two days when the temperature is 50-60 DEG C, cooling is carried out after fermentation for several days, when the temperature of the compost is reduced to 50 DEG C, packaging processing is carried out, and no turning is carried out after packaging processing; and when the compost temperature is cooled to the ambienttemperature, the fermentation is finished. The packed compost technology has the advantages of simple process, economic performance, and less land occupation, uses limited land occupation for massiveproduction, and can greatly increase the efficiency and economic benefit of organic fertilizer production manufacturers.

Owner:TANGSHAN HAIAO ORGANIC FERTILIZER CO LTD

Heat preservation and decoration integrated ecological stone and preparation method thereof

InactiveCN105155799AImprove plasticitySolve the problems of long construction period, high comprehensive cost and poor safetyCovering/liningsMetal layered productsFiberAdhesive

The invention discloses a heat preservation and decoration integrated ecological stone which comprises a facing layer, a middle layer and a heat preservation layer, wherein the middle layer is located between the facing layer and the heat preservation layer; the middle layer consists of an alkali-resistant fiber mesh fabric, a polymer cement mortar adhesive and a hot galvanized wire mesh; and circular grooves are formed in the heat preservation layer and U-shaped buckles are matched with the grooves. The heat preservation and decoration integrated ecological stone has the benefits as follows: the product integrates the heat preservation effect and the decoration effect; one-time forming can meet requirements of the heat preservation function and the decoration function, so that the artificial ecological stone not only has grain and line effects of natural stones but also can achieve the heat preservation function, and the construction cost and the construction procedures are greatly reduced; and in order to guarantee the fastness and the stability of a product when the product is stuck onto the wall, a traditional anchor sticking method is improved technologically, two cylindrical grooves and U-shaped stainless steel buckles passing through the cylindrical grooves are designed on a heat preservation material, and the construction safety is guaranteed.

Owner:河北大自然石材有限公司

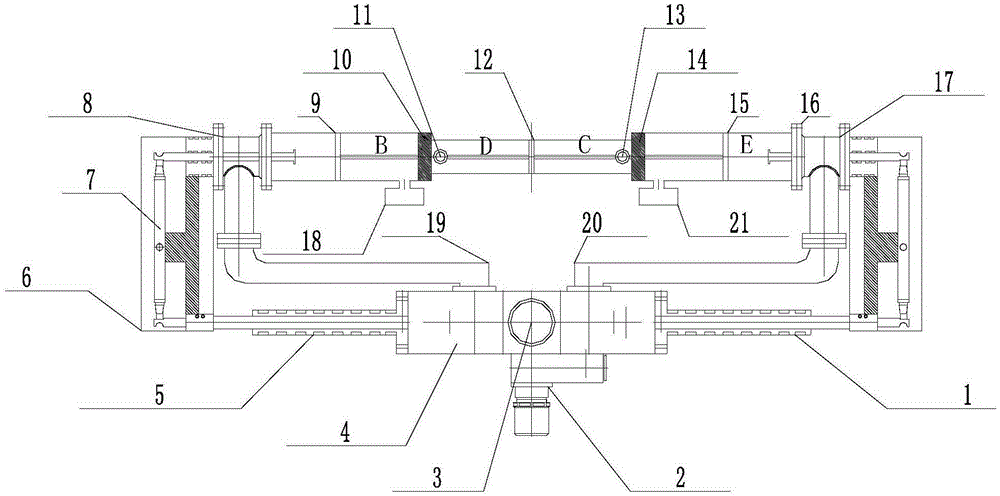

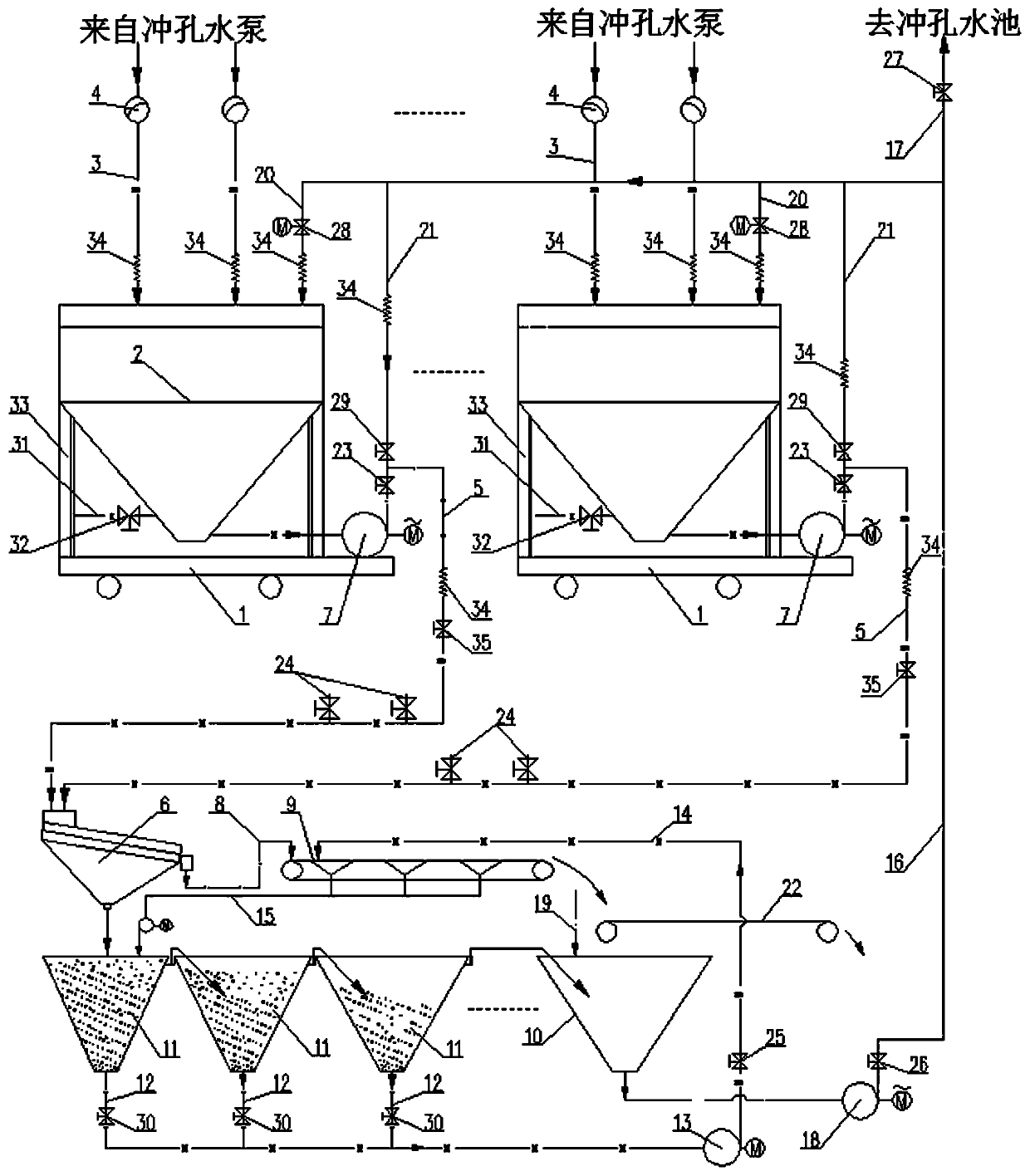

Slurry long-distance hydraulic conveying and solid-liquid separation device and separation process

The invention discloses a slurry long-distance hydraulic conveying and solid-liquid separation device and a separation process, the slurry long-distance hydraulic conveying and solid-liquid separationdevice is used for long-distance conveying and solid-liquid separation of coal-water slurry generated by hydraulic punching of gas drainage holes in a coal mine gas end-located drainage roadway. Eachcollecting and conveying unit comprises a moving trolley with a collection barrel fixed on the top surface, the collection barrel can receive slurry of a plurality of gas drainage holes, and the bottom end of the collection barrel is connected with a fine particle grading screen through a slime water pipeline with a slurry pump; oversize products of the fine particle grading screen enter a vacuumbelt filter, screen underflow of the fine particle grading screen enter enters a settling concentration tank, and the underflow of each settling concentration tank is conveyed to the vacuum belt filter; filtrate of the vacuum belt filter returns to the settling concentration tank, the overflow of the settling concentration tank enters a circulating water tank, the bottom end of the circulating water tank is connected with a circulating water main pipeline with a water pump, and the tail end of the circulating water main pipeline is respectively connected with a punching water tank, each collecting barrel and each slime water pipeline. The slurry long-distance hydraulic conveying and solid-liquid separation device can realize long-distance transportation of the slurry, solid-liquid separation and recycling of water for hydraulic punching.

Owner:ZHONGYUN INTERNATIONAL ENGINEERING CO LTD

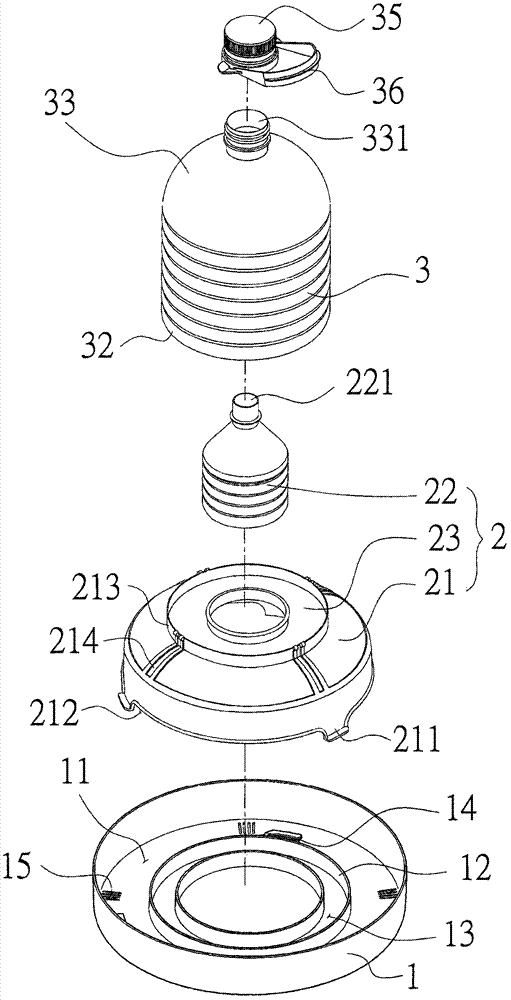

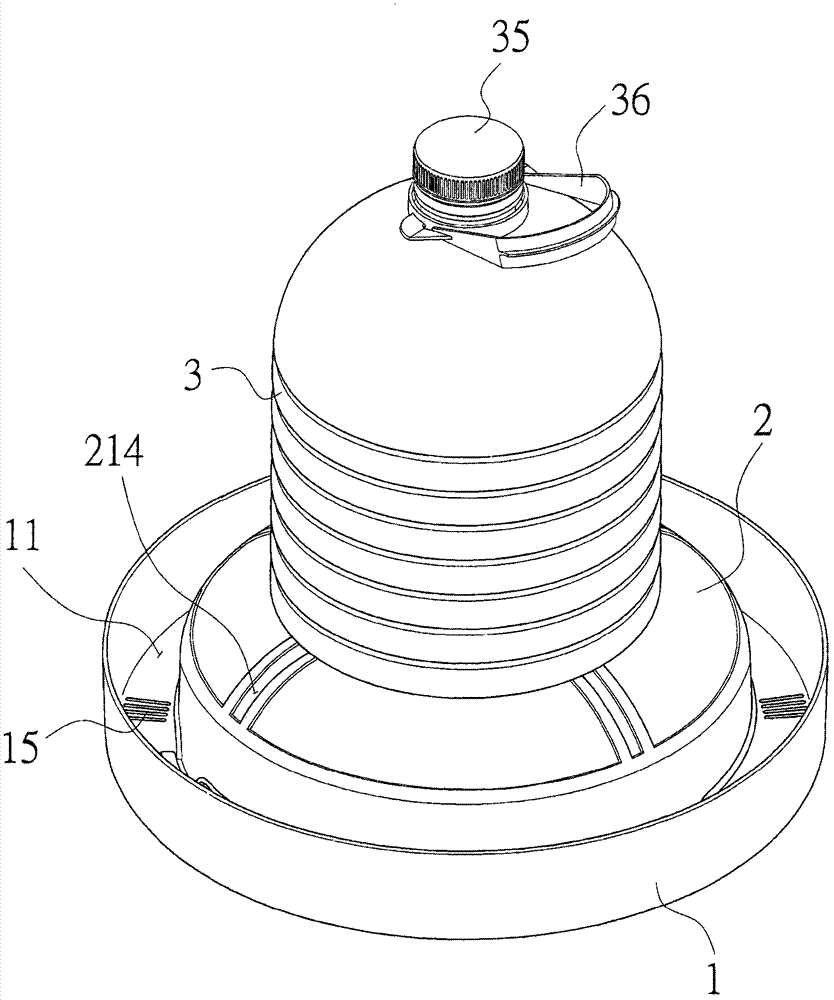

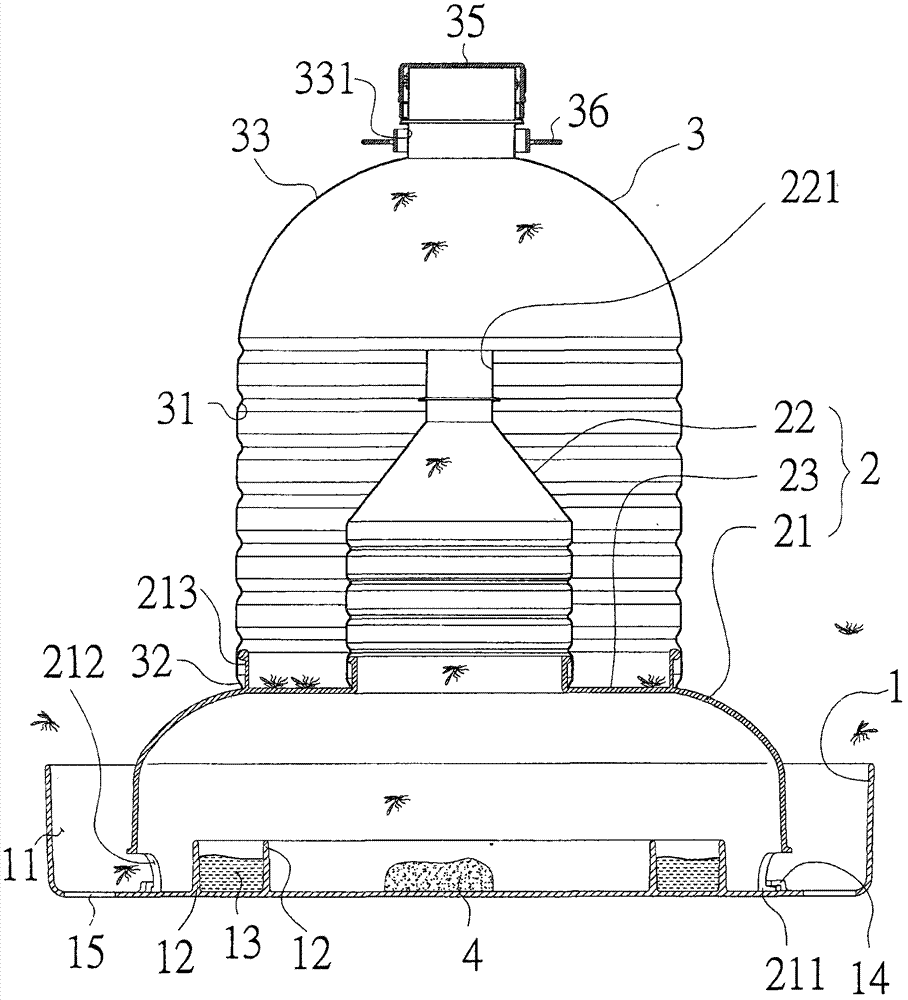

Winged insect trapping device

InactiveCN102783466AEfficient captureEffectively eliminateInsect catchers and killersTrappingEngineering

The invention provides a winged insect trapping device. An arched cover body of an insect collecting unit is arranged on a base, an inlet is arranged on the peripheral side of the arched cover body, the upper end of the arched cover body is provided with a restraining contracted tube body, the arched cover body is in hollow communication with the restraining contracted tube body, the restraining contracted tube body upward extends to the upper portion to form a restraining contracted outlet, and a blocking piece is arranged on the outer side of the upper end of the arched cover body in a surrounding mode so as to form an insect collecting region between the blocking piece and the restraining contracted tube body. The winged insect trapping device is further provided with a light-transmitting cover for covering the restraining contracted tube body of the insect collecting unit, the insect collecting region and the position of the blocking piece. Therefore, an inductor capable of releasing acidic matter is arranged in the arched cover body of the insect collecting unit, the characteristic that mosquitoes, flies and other winged insects like the acidic matter and fly towards the light is utilized to absorb and enable the mosquitoes, the flies and other winged insects to fly into the arched cover body of the insect collecting unit, the mosquitoes, and then the flies and other winged insects fly towards the bright and closed light-transmitting cover and die off on their own in the light-transmitting cover under sun exposure due to food shortage, thereby achieving the actual effect of effectively catching and killing the mosquitoes, and then the flies and other winged insects.

Owner:顾飞龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com