Patents

Literature

90results about How to "Realize waste heat recovery and utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

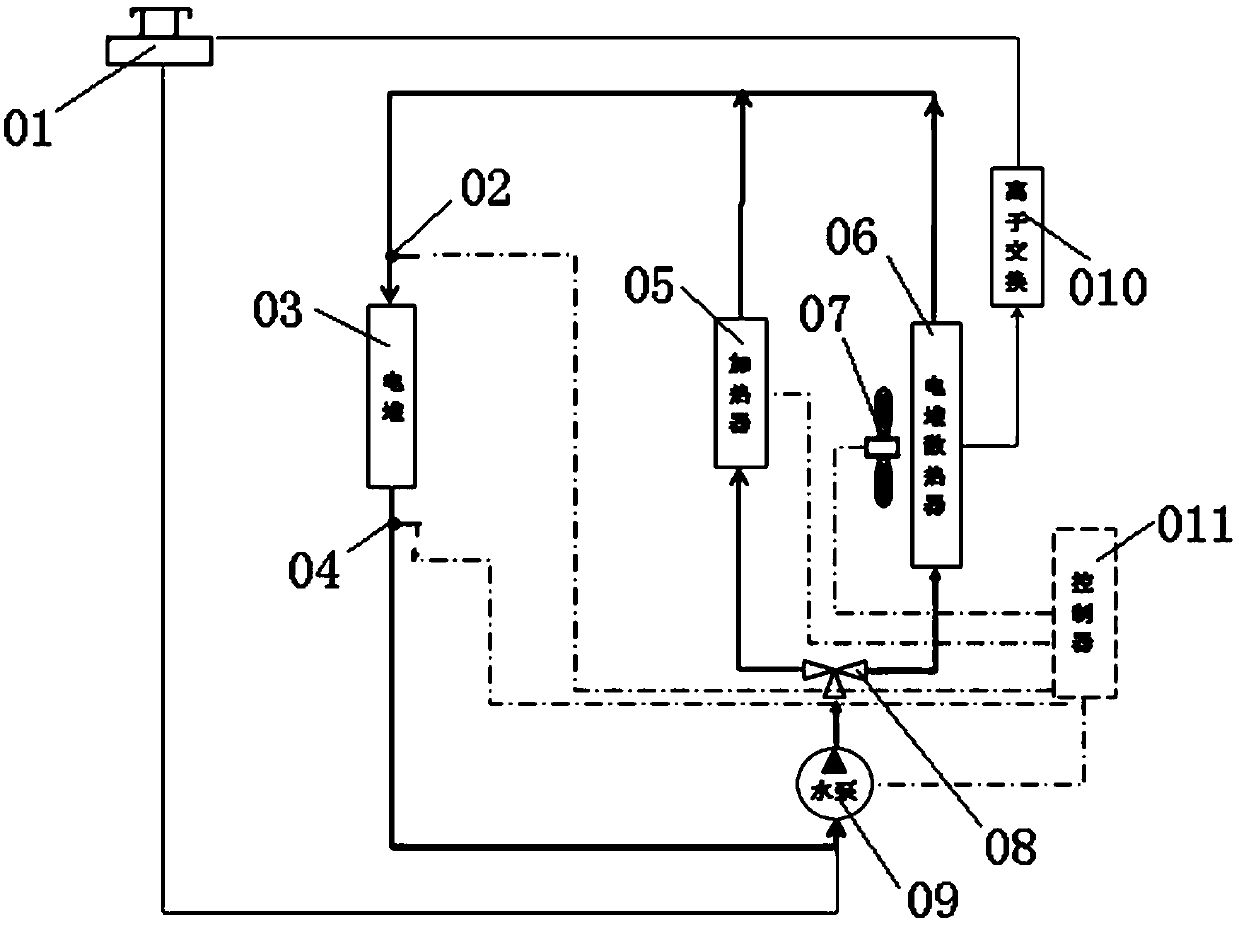

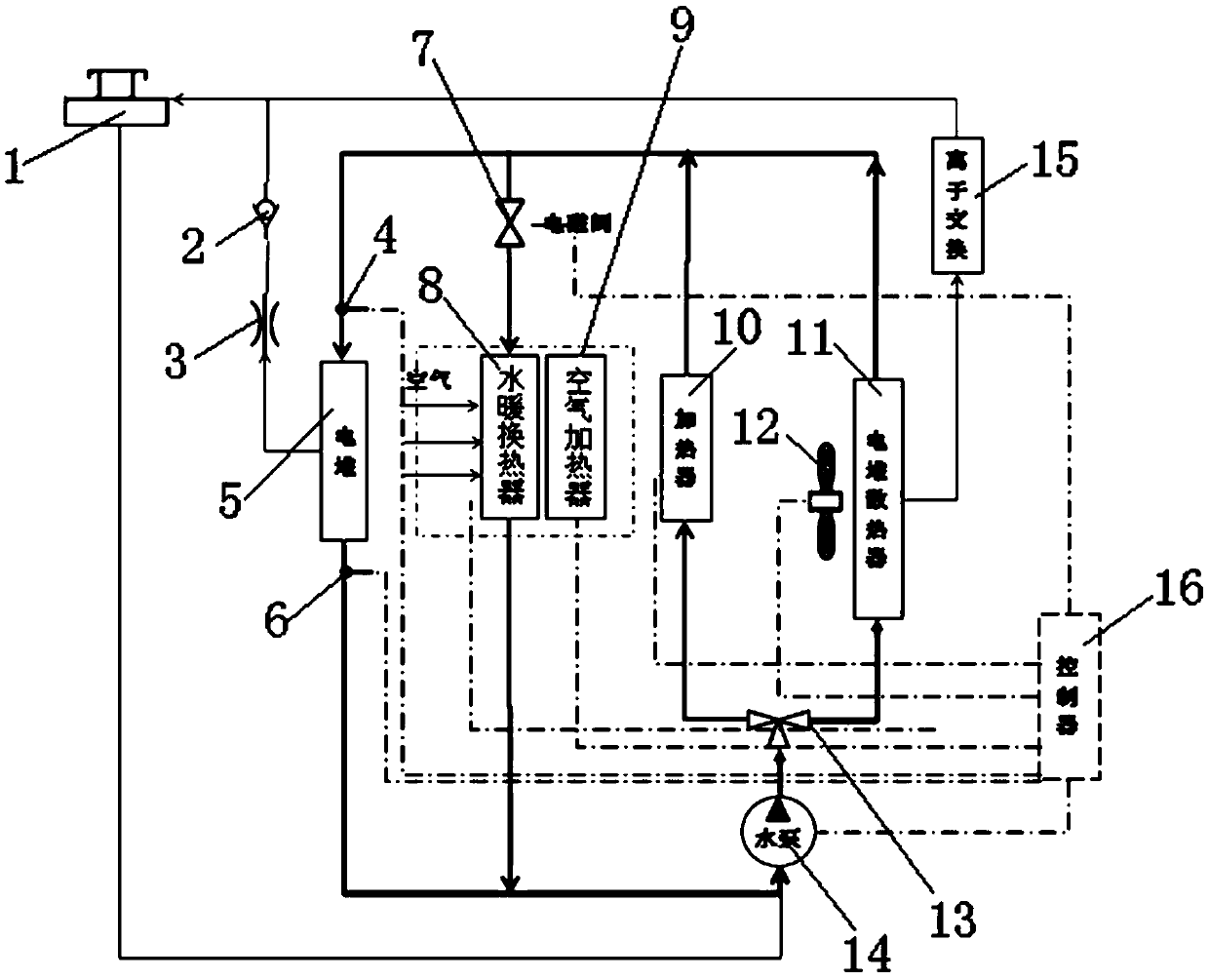

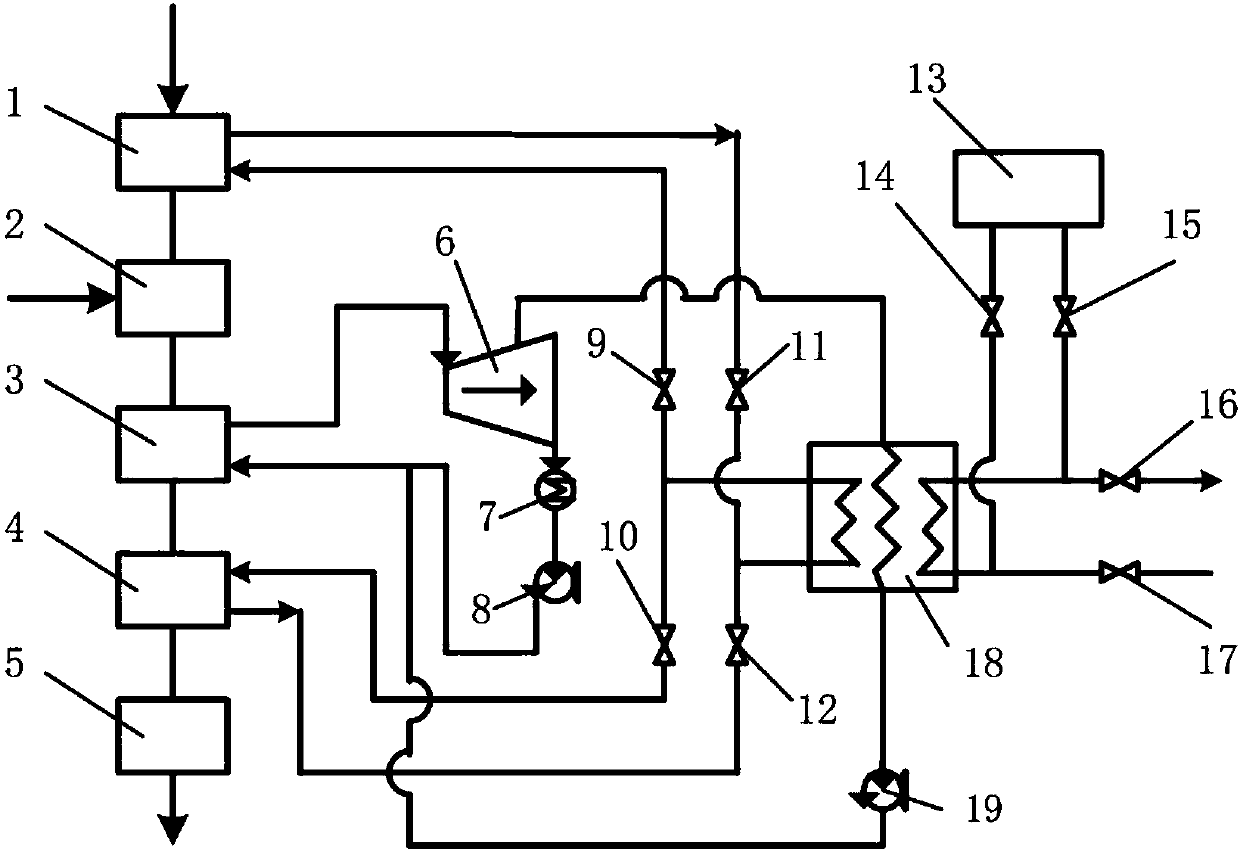

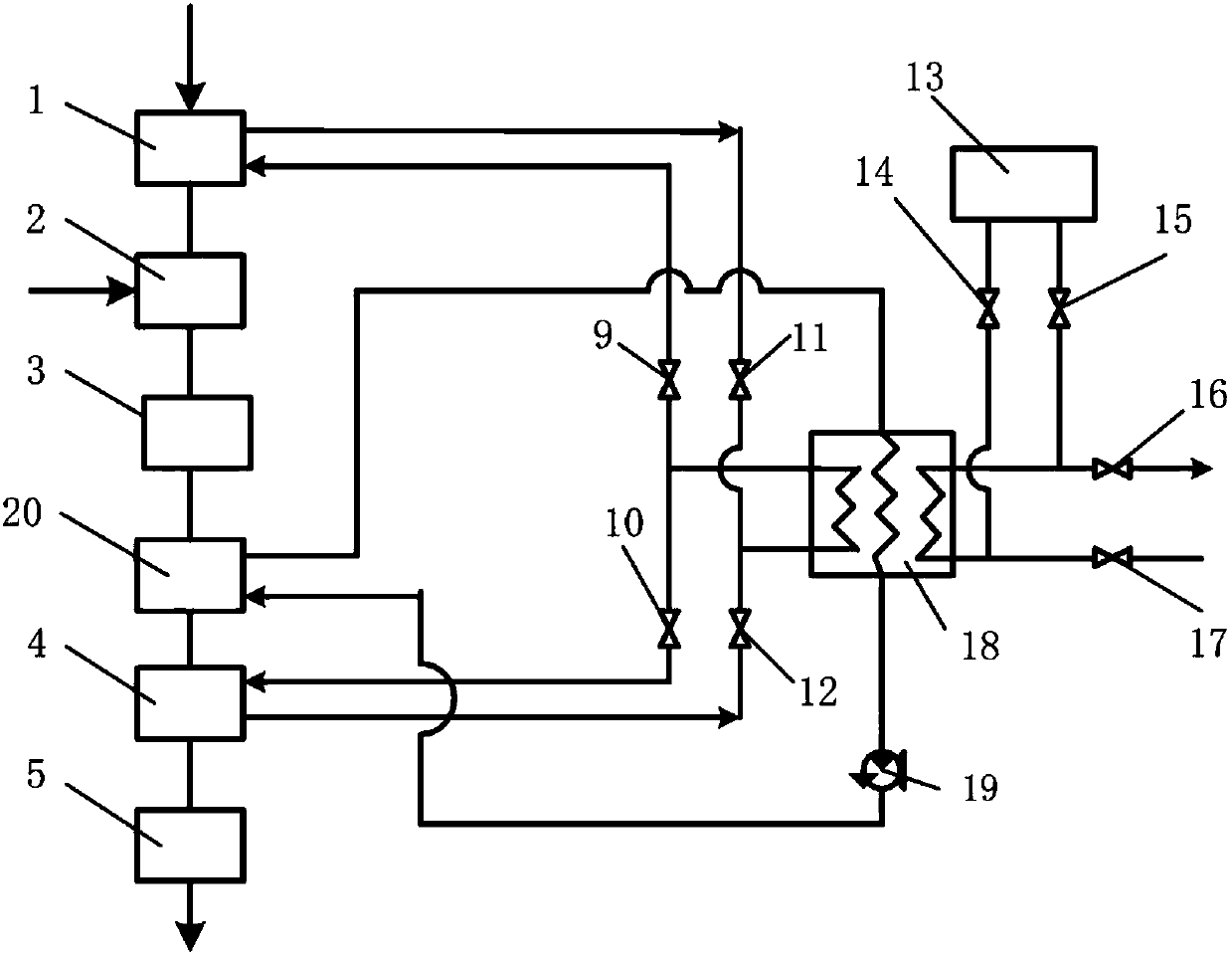

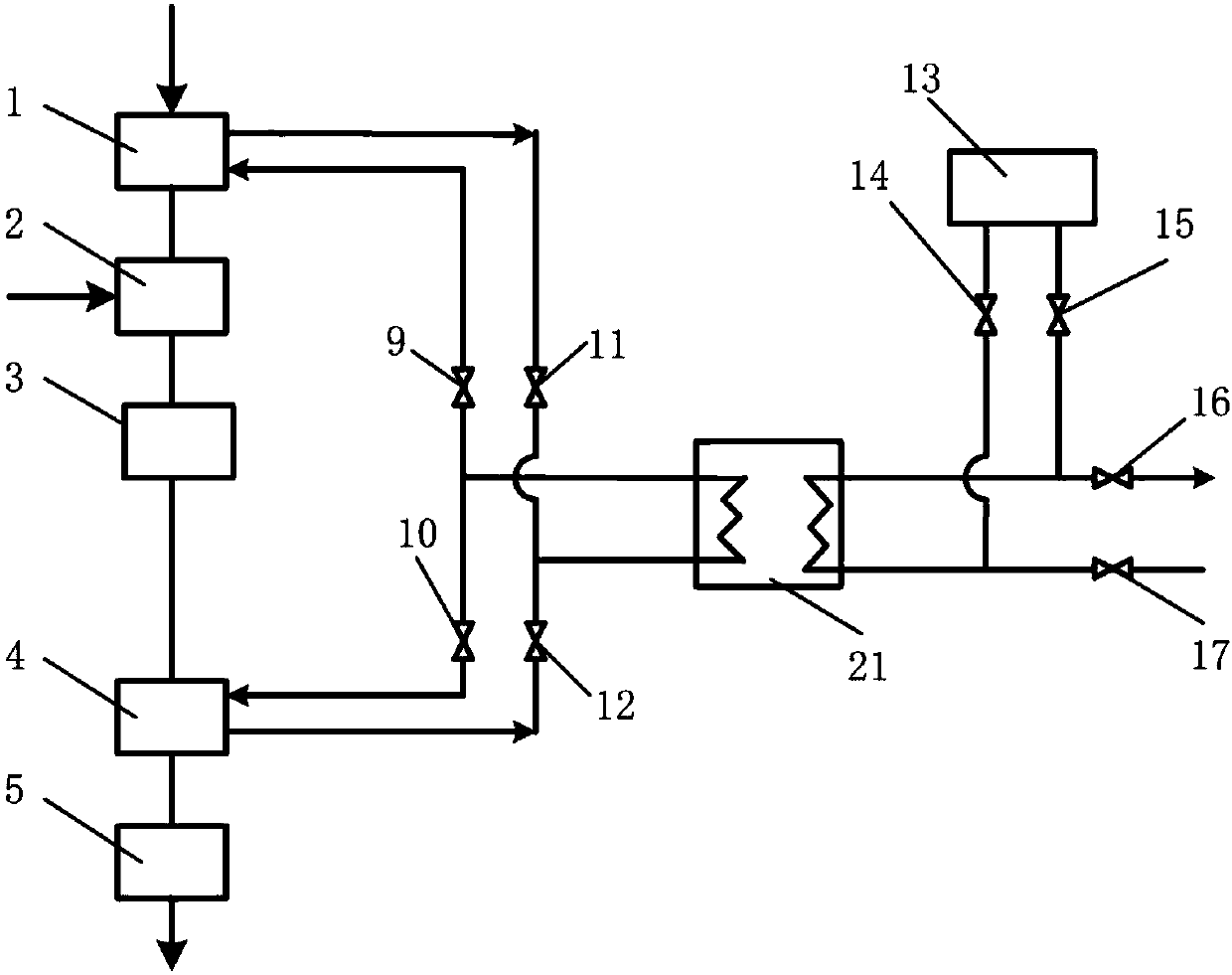

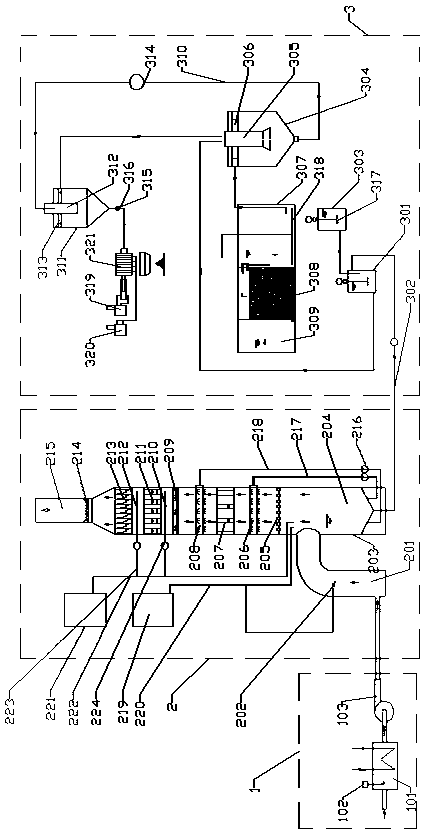

Thermal management system and control method for hydrogen fuel cell vehicle

ActiveCN109532565AStart fastImprove adaptabilityAir-treating devicesVehicle heating/cooling devicesSolenoid valveHydrogen fuel cell

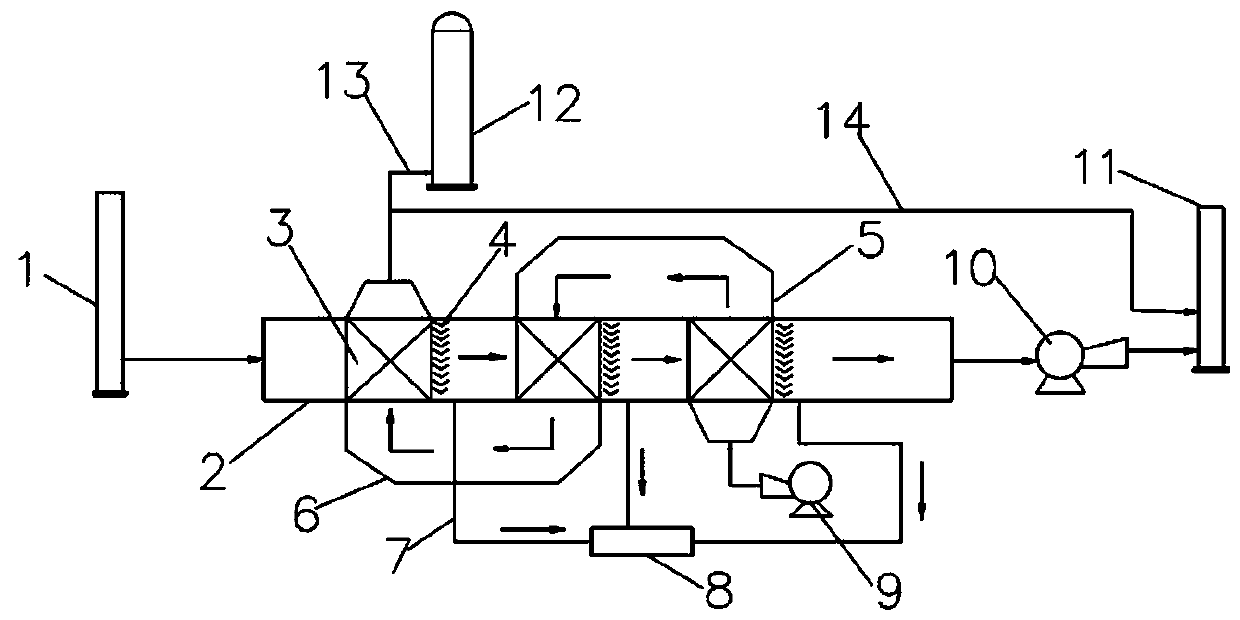

The invention relates to a thermal management system and control method for a hydrogen fuel cell vehicle. The method includes an expansion kettle, a water pump, an electronic thermostat, a fuel cell radiator, a solenoid valve, a fuel cell stack and an ion exchanger. In order to overcome the restriction that an existing fuel cell stack can not be started under the condition of too low ambient temperature, an auxiliary water heating scheme is designed in a small circulation branch to achieve the fast start-up of the fuel cell stack at low temperature and improve the adaptability of the fuel cellstack to the low temperature environment. The waste heat recovery and utilization of the fuel cell stack can be achieved by adding an auxiliary air-conditioning water heating and heat exchange systemin a water system. The electricity demand of an air heater is reduced, the electric energy of the whole vehicle is saved, and the endurance range of vehicles in winter is increased. Through the design improvement of a degassing device for the fuel cell stack, the degassing problem of the fuel cell stack water system in the process of filling and operation is solved, and the reliability of the fuel cell heat management system is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

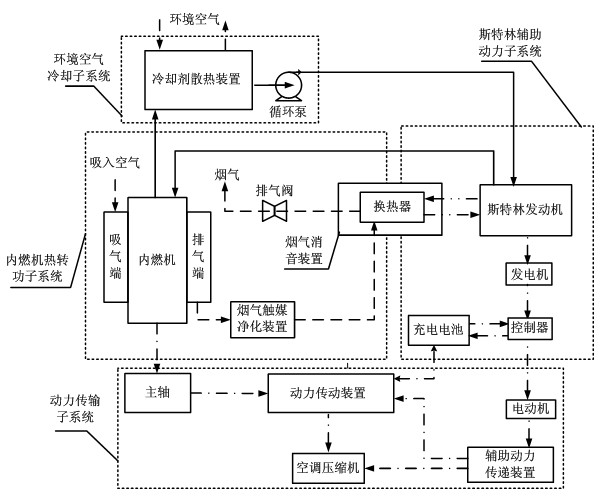

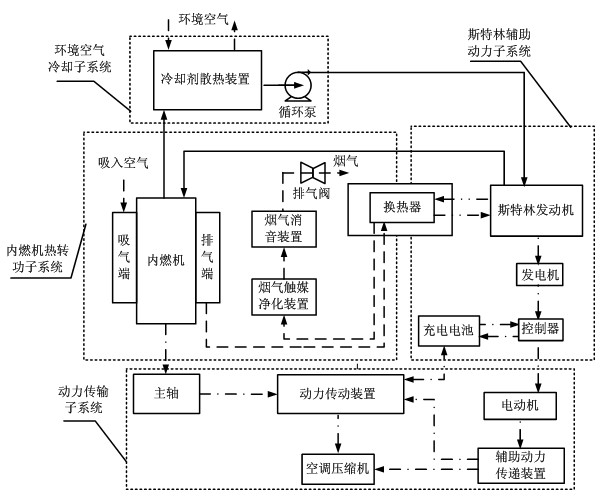

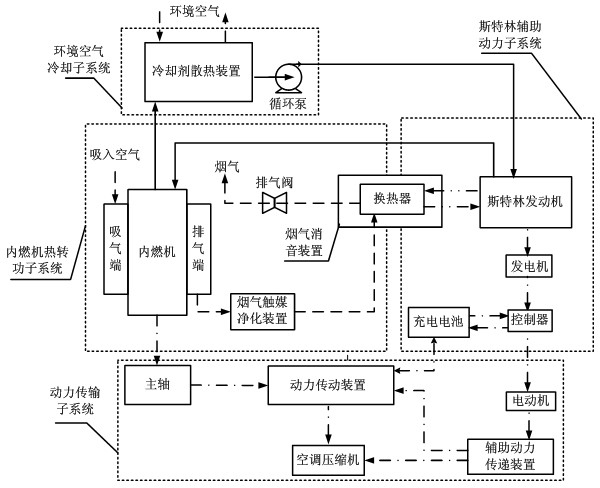

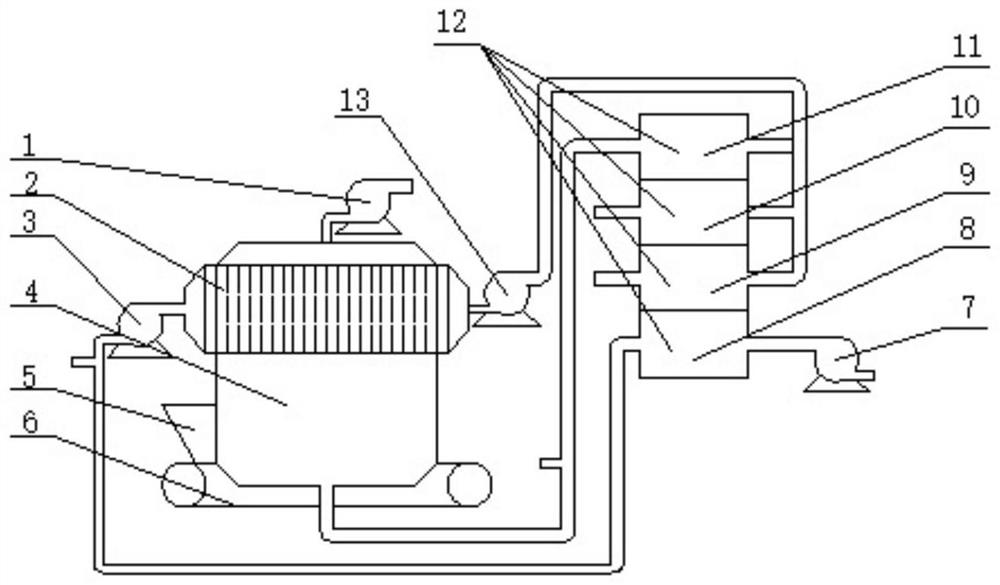

Hybrid dynamic system with combined cycle of internal combustion engine-stirling engine

InactiveCN102434310AImprove fuel efficiencyIncrease output powerInternal combustion piston enginesExhaust apparatusStirling engineElectric generator

The invention discloses a hybrid dynamic system with combined cycle of internal combustion engine-stirling engine, belonging to the fields like energy source and power, wherein the system comprises a stirling auxiliary power subsystem; the subsystem comprises a heat exchanger, a stirling engine, a generator connected with the stirling engine and a controller connected with the generator. One end of the controller is connected with a rechargeable battery and other end thereof is connected with an electric motor. The heat exchanger is configured in a smoke silencer of the internal combustion engine heat-power transferring subsystem, or placed before a smoke catalyst purifying device. The internal combustion engine heat-power transferring subsystem and the stirling auxiliary power subsystem share one coolant heat radiator. The hybrid dynamic system has characteristics of a simple and contract structure, a high fuel use ratio and so on. The hybrid dynamic system can also enhance the output power of the internal combustion engine and improve the energy saving and emission reduction performances for vehicles.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

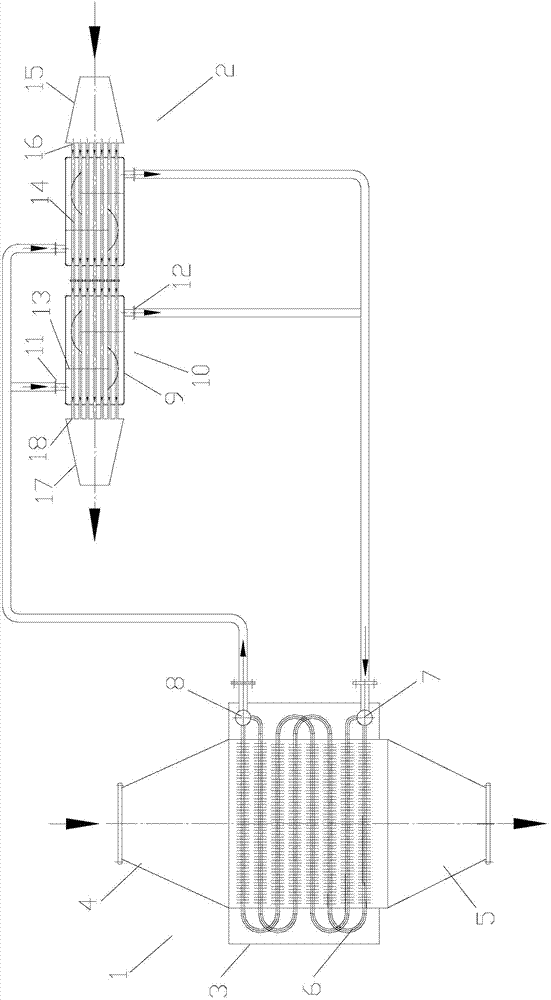

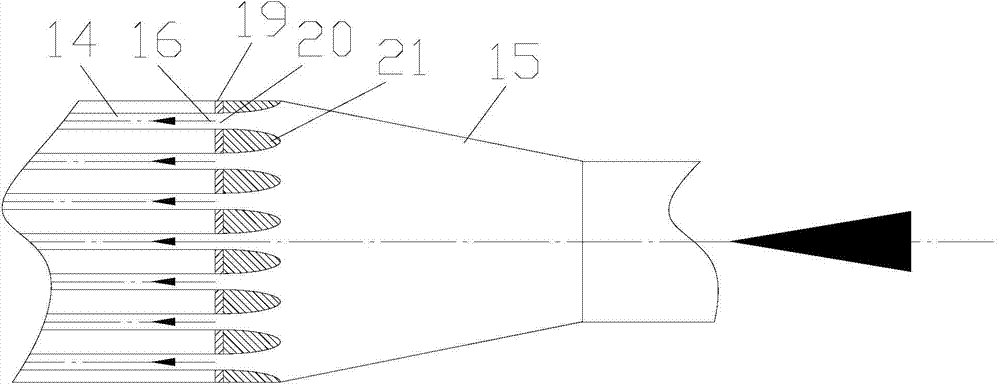

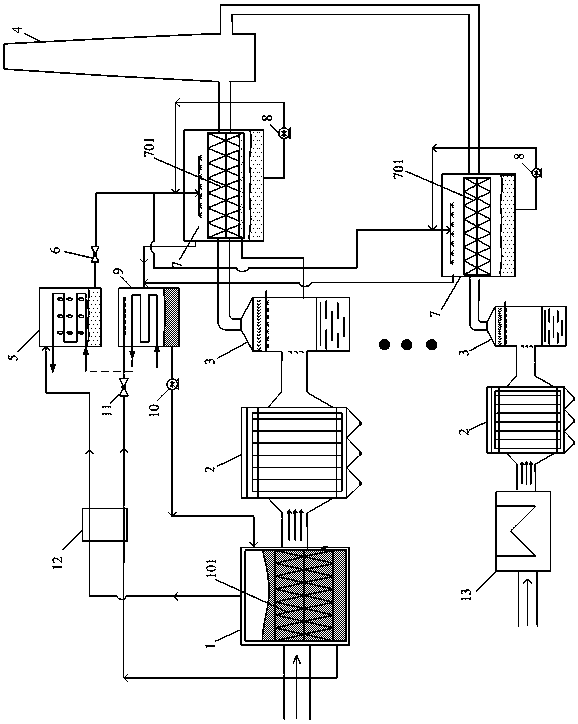

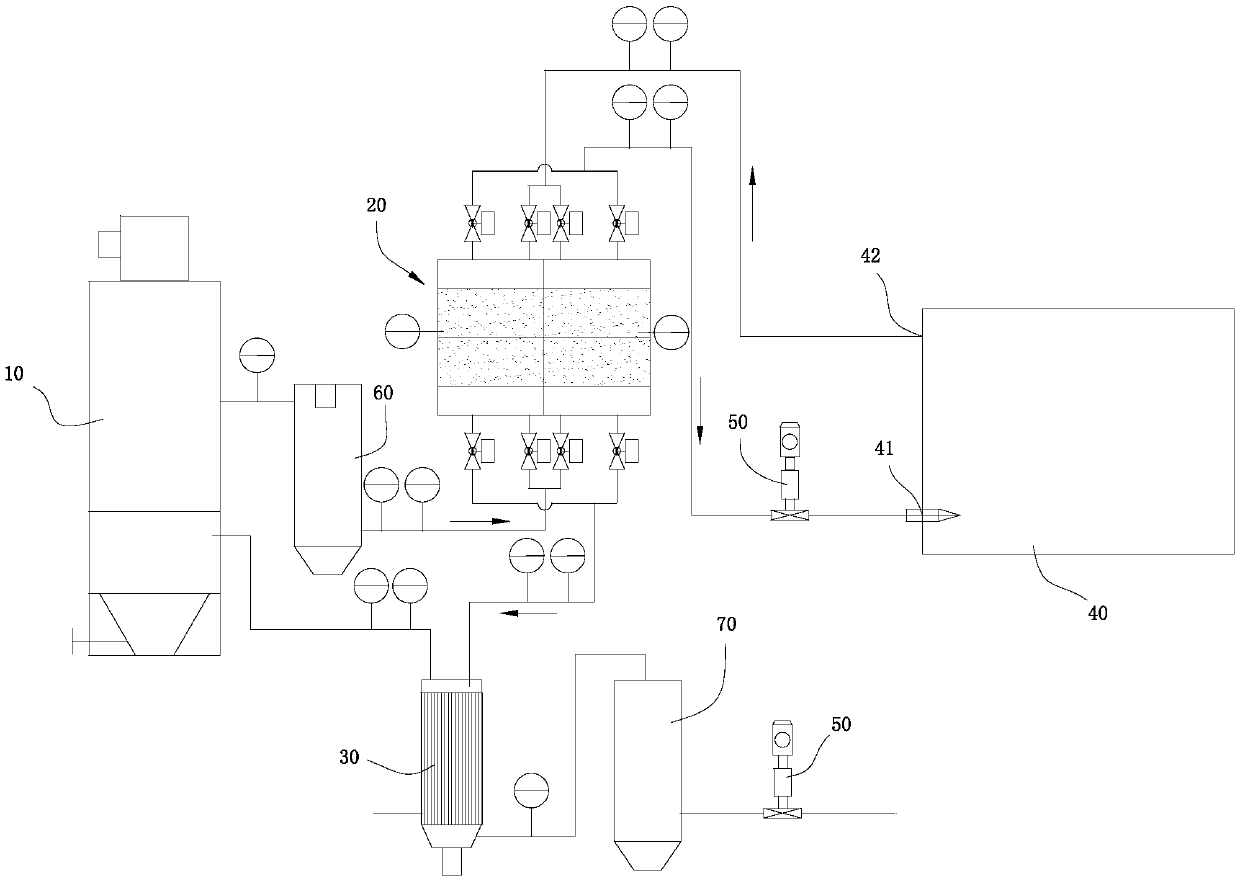

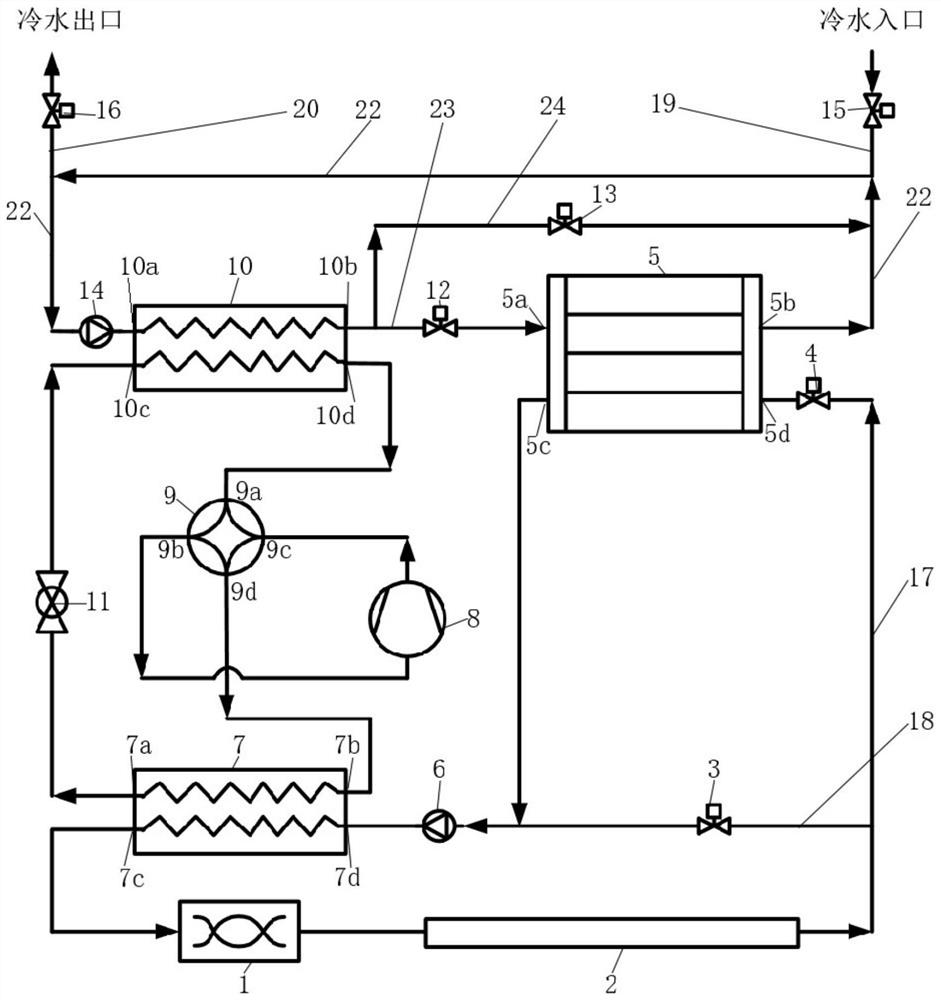

Combined system and method of flue gas waste heat recovery and inlet-gas cooling of gas turbine cycle

ActiveCN107905897ARealize waste heat recovery and utilizationImprove economyGas turbine plantsCombined combustion mitigationCooling towerCogeneration

The invention belongs to the technical field of cogeneration and waste heat utilization and particularly relates to a combined system and method of flue gas waste heat recovery and inlet-gas cooling of a gas turbine cycle. The combined system comprises an inlet-gas cooler, a flue gas-water heat exchanger, a refrigeration device and a cooling tower. The refrigeration device is connected with the inlet-gas cooler through a first chilled water cycle pipeline, connected with the flue gas-water heat exchanger through a second chilled water cycle pipeline, connected with the cooling tower through afirst cooling pipe cycle pipeline and connected with a heating network pipeline through a second cooling water cycle pipeline. Inlet-gas cooling and flue gas waste heat recovery and utilization of a gas turbine are achieved, output force of the gas turbine in summer can reach the rated load, the energy utilization efficiency of the gas turbine combined cycle is improved, the defects that the gas engine is poor in inlet-gas cooling investment economical efficiency and limited in cooling effect are completely overcome, and the economical efficiency of a whole unit is improved.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST

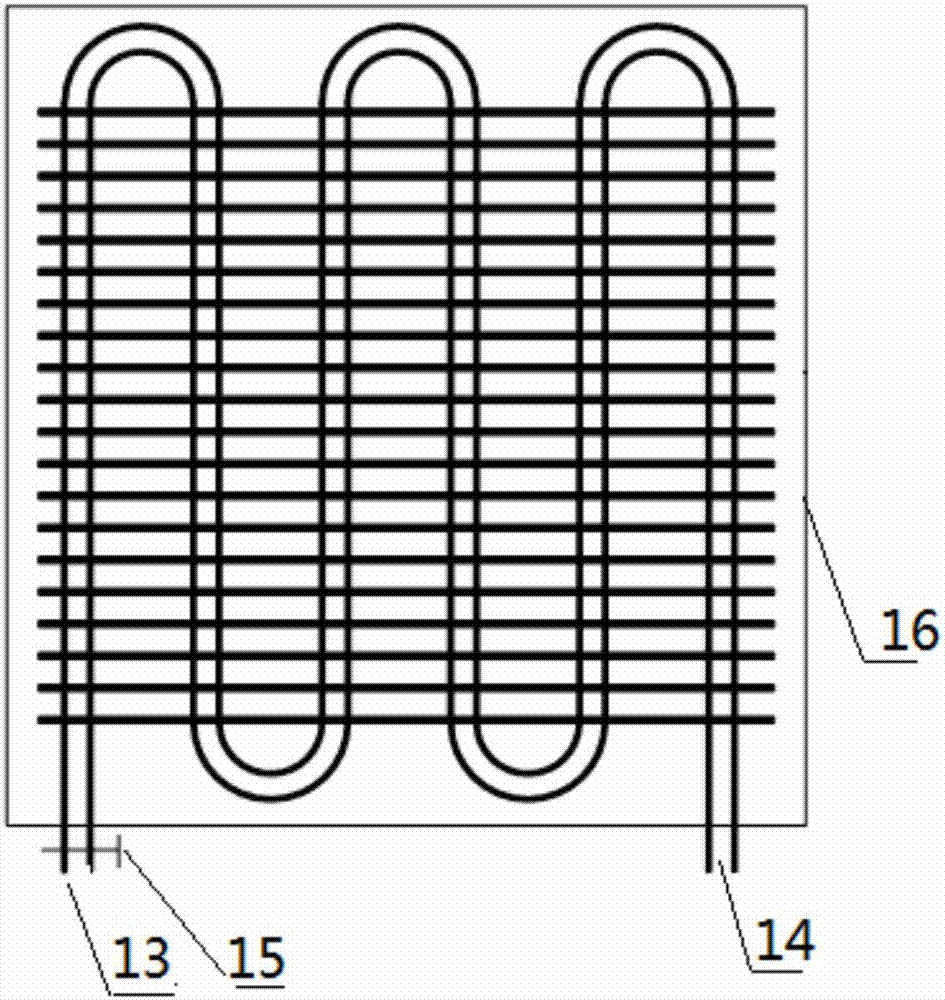

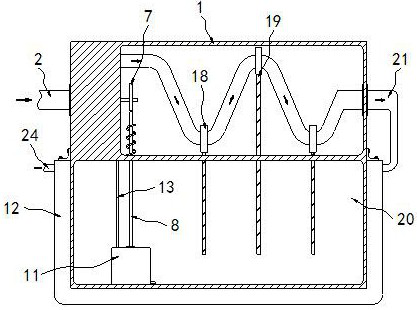

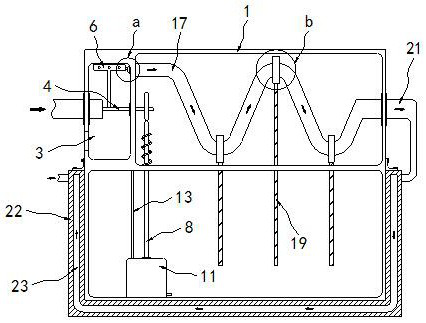

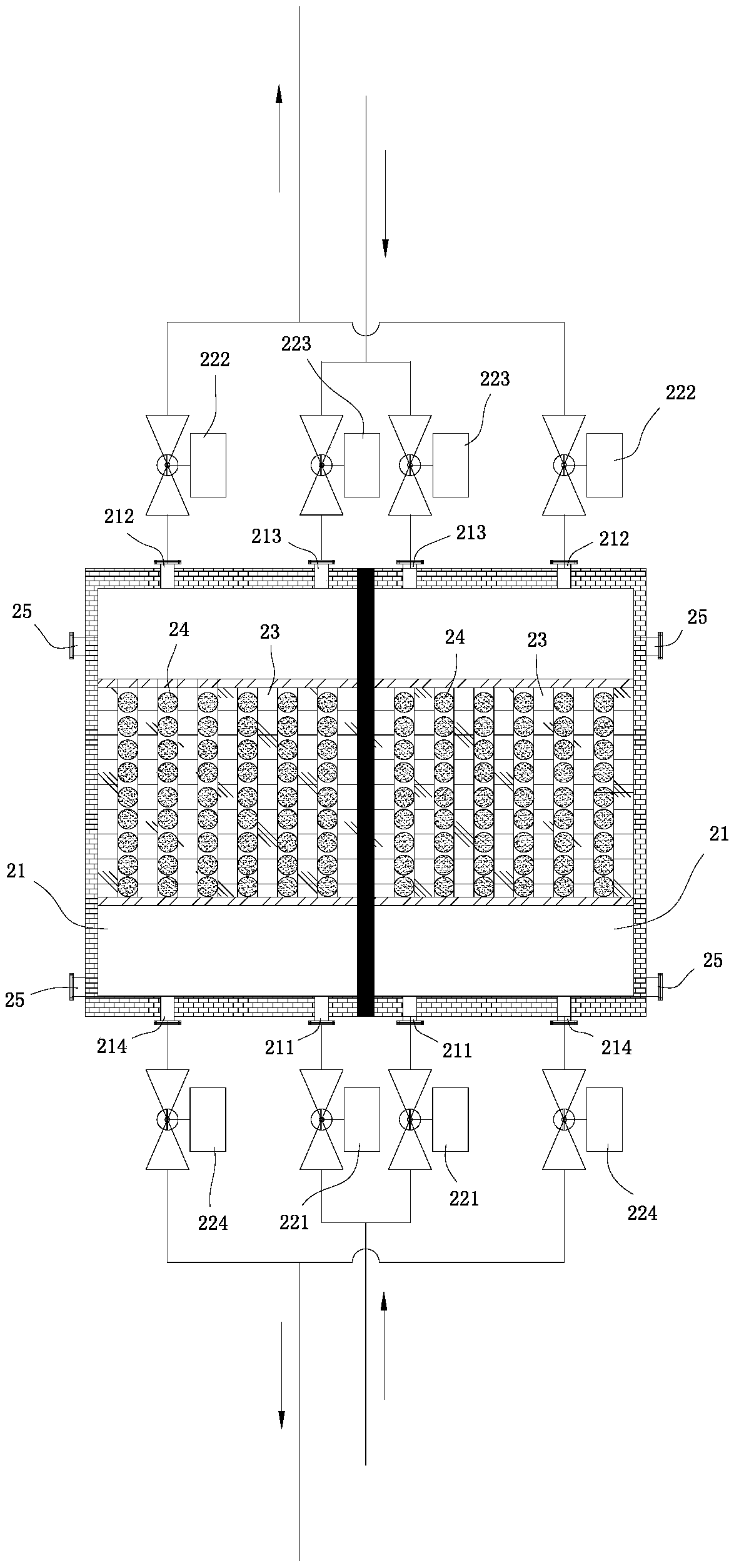

Blast furnace cinder flushing exhaust steam white smoke elimination and waste heat recovery system

InactiveCN110819747AHas whitening effectRealize waste heat recovery and utilizationIncreasing energy efficiencyWaste heat treatmentEngineeringMechanics

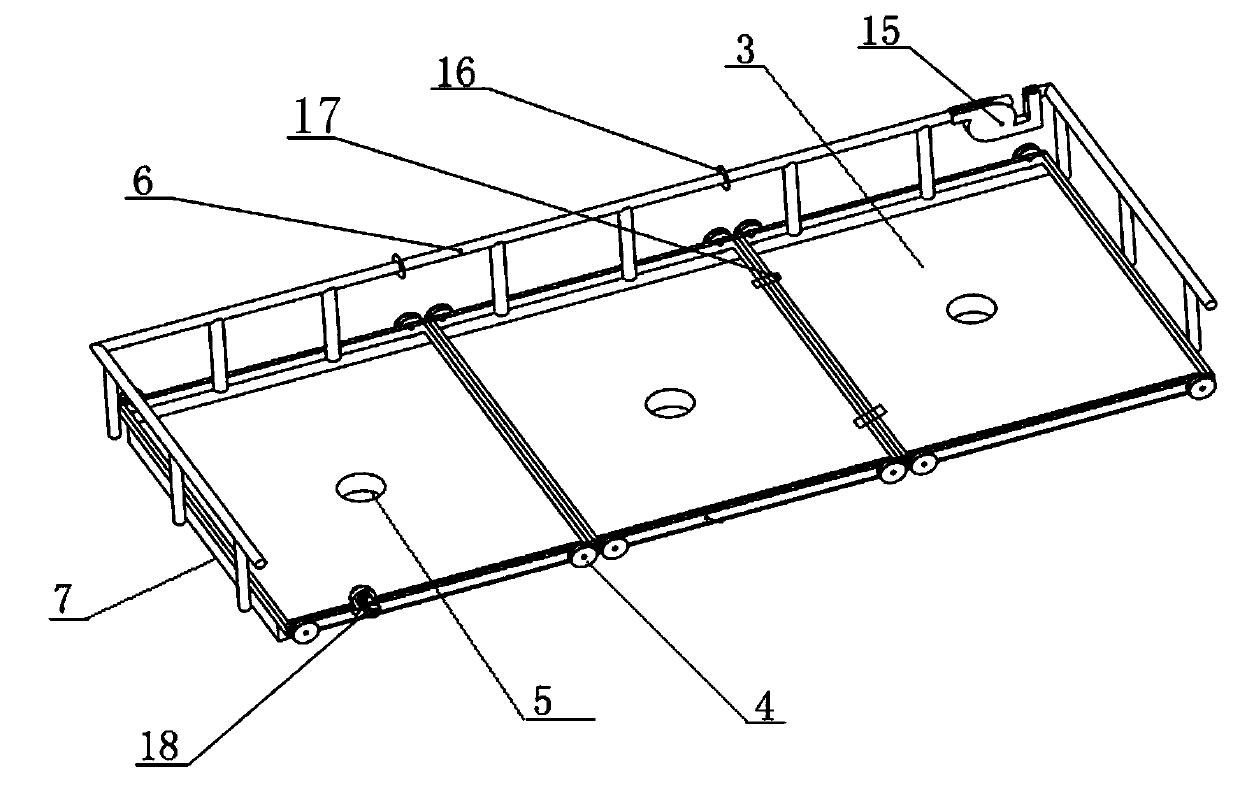

The invention discloses a blast furnace cinder flushing exhaust steam white smoke elimination and waste heat recovery system. The system comprises a blast furnace cinder flushing water exhaust steam diffusion tower, an exhaust steam channel and air channels, wherein the blast furnace cinder flushing water exhaust steam diffusion tower is used for discharging exhaust steam, the exhaust steam channel comprises an input end and an output end, the input end communicates with an exhaust port formed in the cinder flushing water exhaust steam diffusion tower, the output end is provided with an exhaust steam induced draft fan, the exhaust steam induced draft fan is used for providing steam extraction power for the exhaust steam, one ends of the air channels are connected to external air sources, the other ends of the air channels are connected to hot air conduits, the air channels penetrate through the exhaust steam channel repeatedly in a wriggling mode, heat exchangers are arranged at the joints between the air channels and the exhaust steam channel, a plurality of water baffle plates which are arranged in the vertical direction are arranged on the side, facing the output end, of each heat exchanger, the adjacent water baffle plates are staggered to form gaps to form a comb-shaped structure, a plurality of flow outlet holes are formed in the bottom wall part, below the water baffle plates, of the exhaust steam channel, the flow outlet holes communicate with a water pipe, and the water pipe is used for discharging condensed water. The blast furnace cinder flushing exhaust steam white plume elimination and waste heat recovery system has the effect of white smoke elimination, and also has the advantages of being capable of recovering the condensed water and realizing recycling of waste heat.

Owner:SGIS SONGSHAN CO LTD

Annular kiln with movable flat top

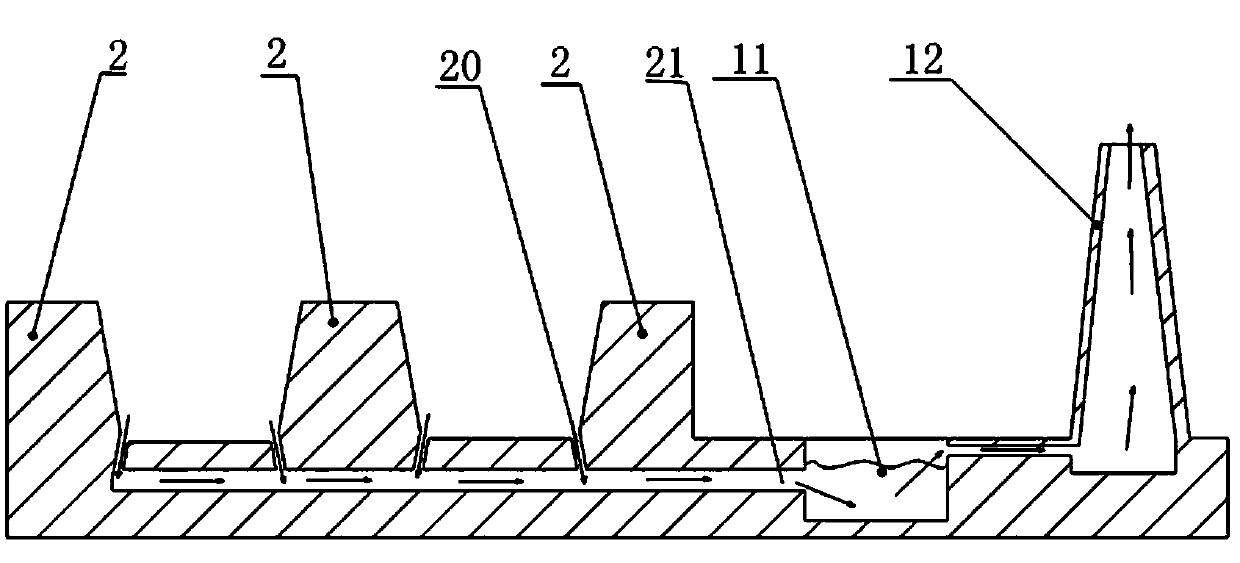

InactiveCN103499213AIncrease productionFlexible splicing and lengtheningFurnace crowns/roofsWaste heat treatmentBrickLap joint

The invention discloses an annular kiln with a movable flat top. The annular kiln with the movable flat top comprises a kiln body, a kiln crown and kiln walls arranged on the two sides. Compared with the prior art, the annular kiln with the movable flat top is characterized in that the kiln crown is the movable flat top, wherein the movable flat top is formed by detachably connecting a plurality of steel structural frames which are in lap joint with one another; each steel structural frame is provided with idler wheels, wherein the idler wheels are matched with tracks arranged at the upper ends of the kiln walls; the lower end face of the movable kiln crown is provided with an insulating layer; a hot gas recycling pipeline is arranged on the kiln crown. The annular kiln with the movable flat top has the advantages of saving money, and being convenient to place, high in degree of mechanization, capable of lowering labor intensity for workers and improving work efficiency, good in heat preservation effect when green bricks are fired, high in rate of finished products, rapid in cooling speed, easy to cool for brick taking, convenient to maintain, and particularly suitable for overall transformation of an existing old kiln.

Owner:黄五三 +3

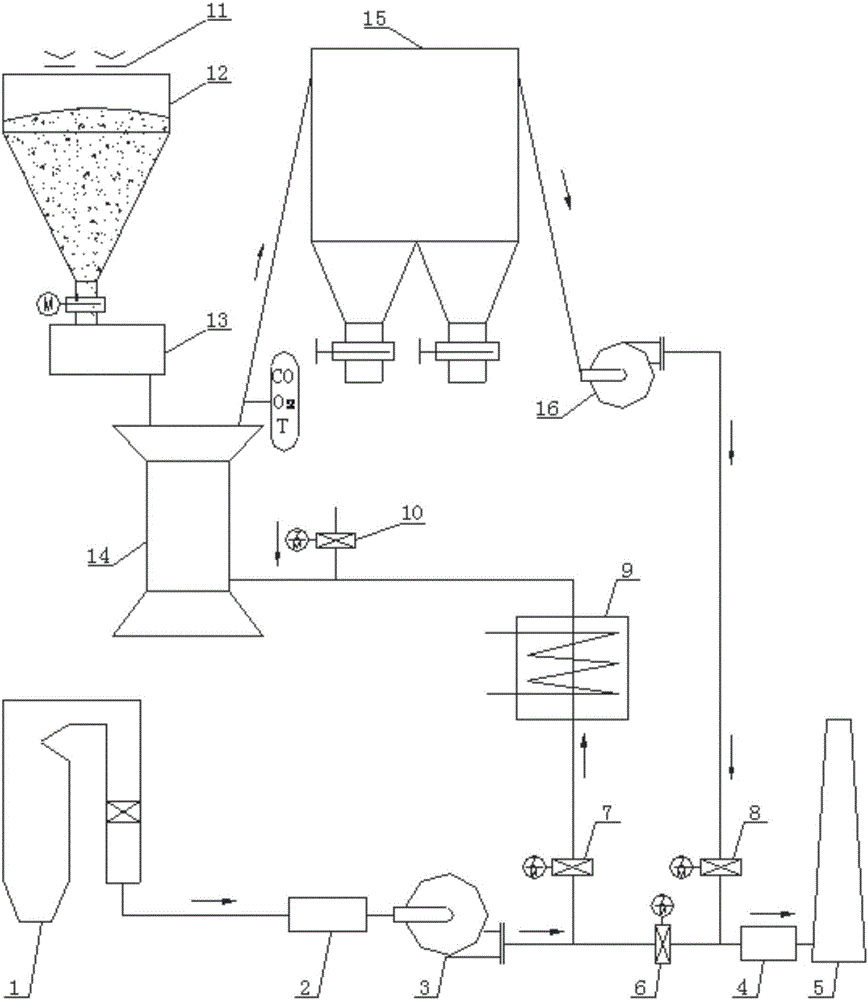

Energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system

InactiveCN106196134AImprove explosion-proof performanceImprove securitySolid fuel pretreatmentDrying gas arrangementsFlue gasCoal dust

An energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system comprises a belt coal feeder, a raw coal bunker, a coal feeder, a coal mill and a powder recovery bunker, wherein the dry air inlet of the coal mill communicates with the outlet of a first induced draft fan which is used for inputting high-temperature flue gas at the tail part of a boiler to the coal mill; an inert gas input passage is arranged in front of the dry air inlet of the coal mill; a first control valve is mounted on the inert gas input passage; the outlet of the coal mill communicates with the inlet of the powder recover bunker; a gas temperature detector and a gas concentration detector are mounted behind the outlet of the coal mill and connected with an alarm controller; a pulverized coal collection device is arranged in the powder recovery bunker; a second induced draft fan is mounted behind the flue gas outlet of the powder recovery bunker; and the outlet of the second induced draft fan communicates with the inlet of a flue gas desulfurization device or a chimney. The energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system is a special production line for providing coal dust fuels for the pulverized coal boiler, the security of the pulverized coal preparation system can be guaranteed while the waste heat of flue gas at the tail part of the boiler is effectively utilized, energy saving and consumption reduction are realized and the environment is protected.

Owner:SHANDONG HUANNENG DESIGN INST

Street lamp cooling device of waste heat drive Stirling engine

InactiveCN108278580ALower working temperatureHigh heat fluxLighting heating/cooling arrangementsPump installationsImpellerEngineering

The invention discloses a street lamp cooling device of a waste heat drive Stirling engine. Waste heat generated during work of a high-power LED street lamp is used for driving the Stirling engine soas to provide power for a fan impeller of a cooling fan of the Stirling engine, after the cooling fan of the Stirling engine works, heat emitting of a heat pipe radiator of the LED streetlamp is reinforced, and the aim of emitting heat through heat is achieved.

Owner:四川博领教育科技有限公司

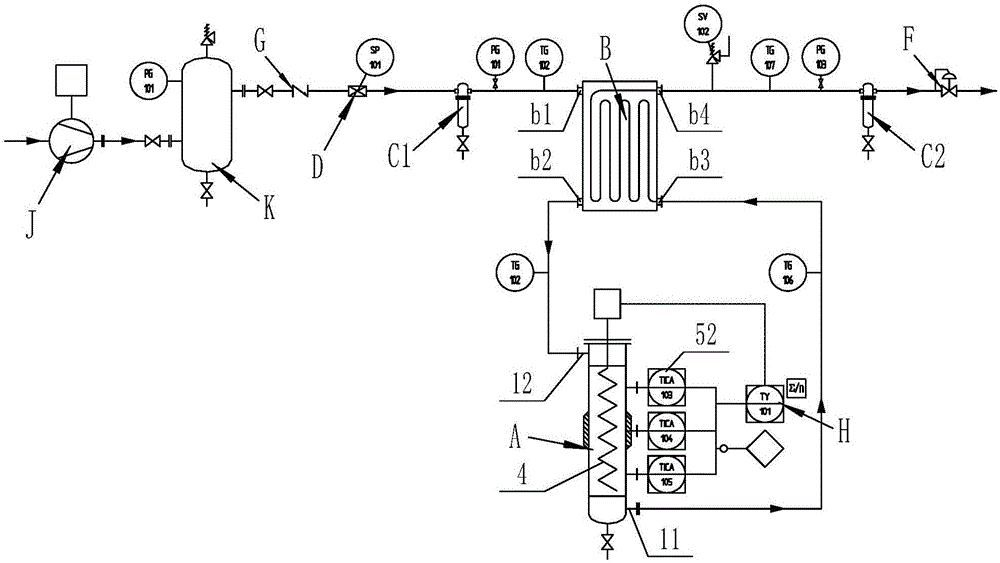

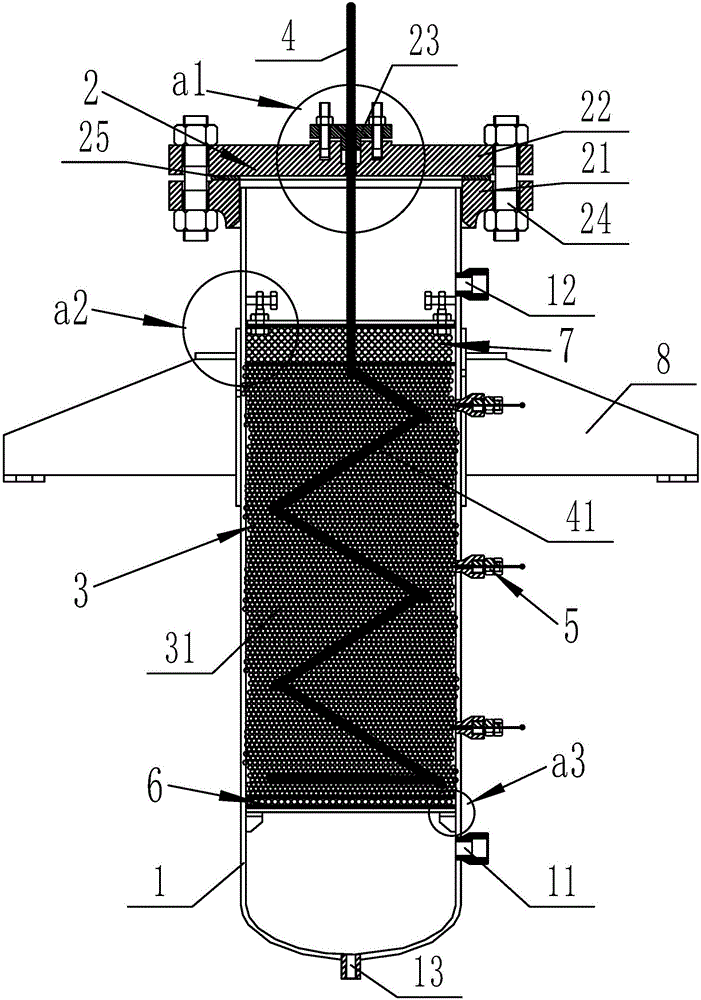

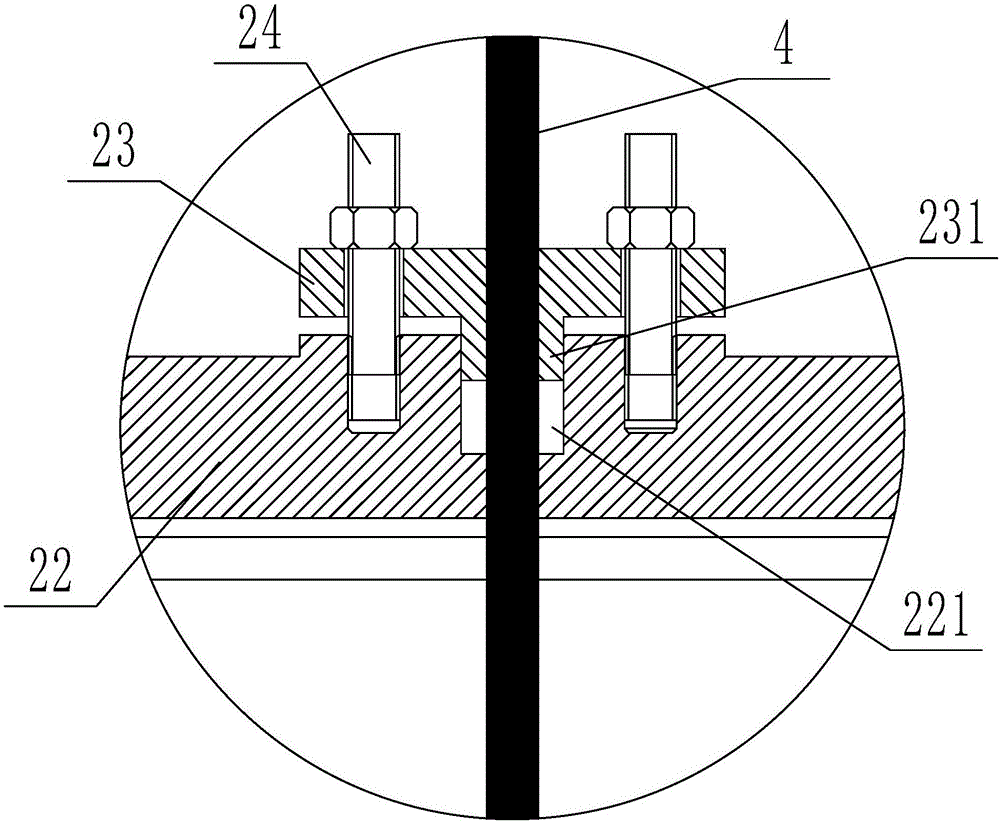

Compressed air purification system and using method thereof

PendingCN106268304AMeet strict requirements for cleanlinessWill not polluteDispersed particle filtrationTransportation and packagingOil freeSewage

The invention discloses a compressed air purification system and a using method thereof. The compressed air purification system comprises a preheating heat exchanger and a reactor. A preheating air inlet, a preheating air outlet, a heat exchange air inlet and a heat exchange air outlet are formed in the preheating heat exchanger. The reactor comprises a cylinder and a barrel cover assembly buckled on the cylinder. The middle section inside the cylinder is a reaction region for filling of a catalyst. A reactor air inlet is formed in the portion, above the reaction region, of the cylinder. A reactor air outlet is formed in the portion, below the reaction region, of the cylinder. A sewage draining exit is arranged at the bottom of the cylinder, and a heating pipe is arranged on the cylinder. The reactor air inlet is connected with the preheating air outlet through a pipeline. The reactor air outlet is connected with the heat exchange air inlet through a pipeline. The purification system is simple and reliable in structure, oil-free compressed air can be rapidly and reliably obtained through purification, the using method is simple, manual operations are greatly reduced, the equipment investment is lowered greatly, and the high practicability and market value are achieved.

Owner:CHONGQING BAOSI FLAMMABLE GAS ENG CO LTD

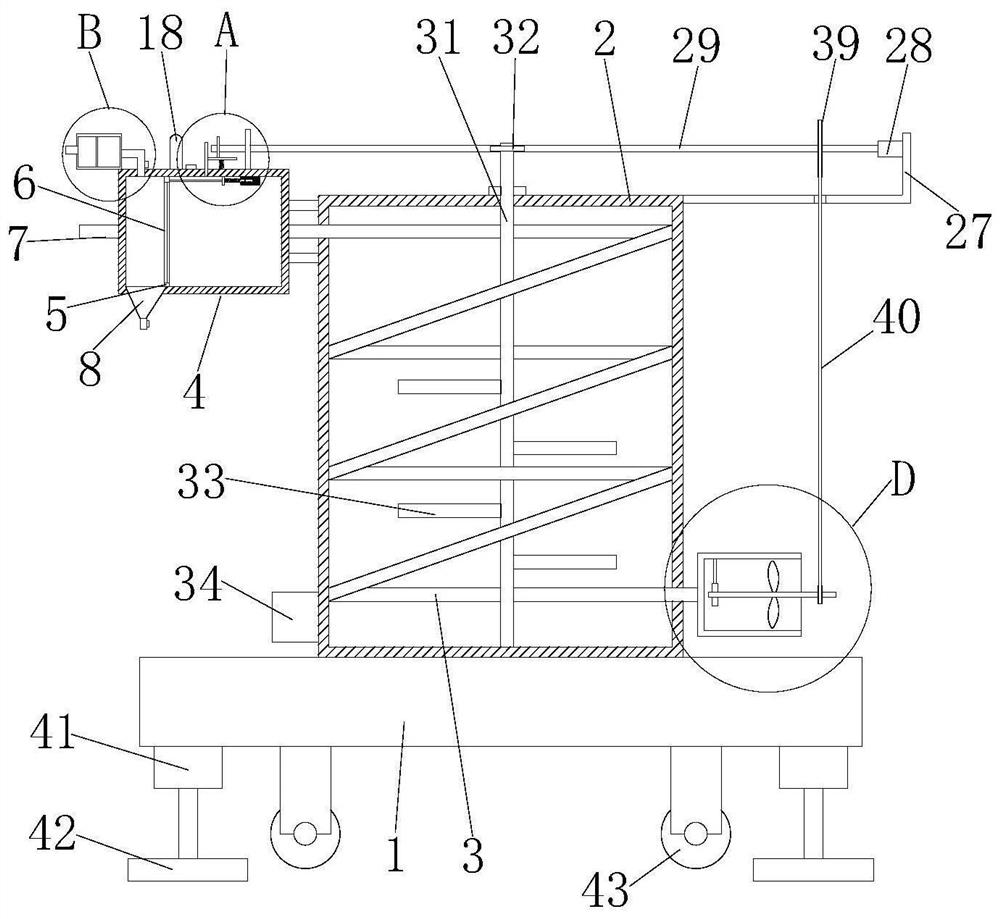

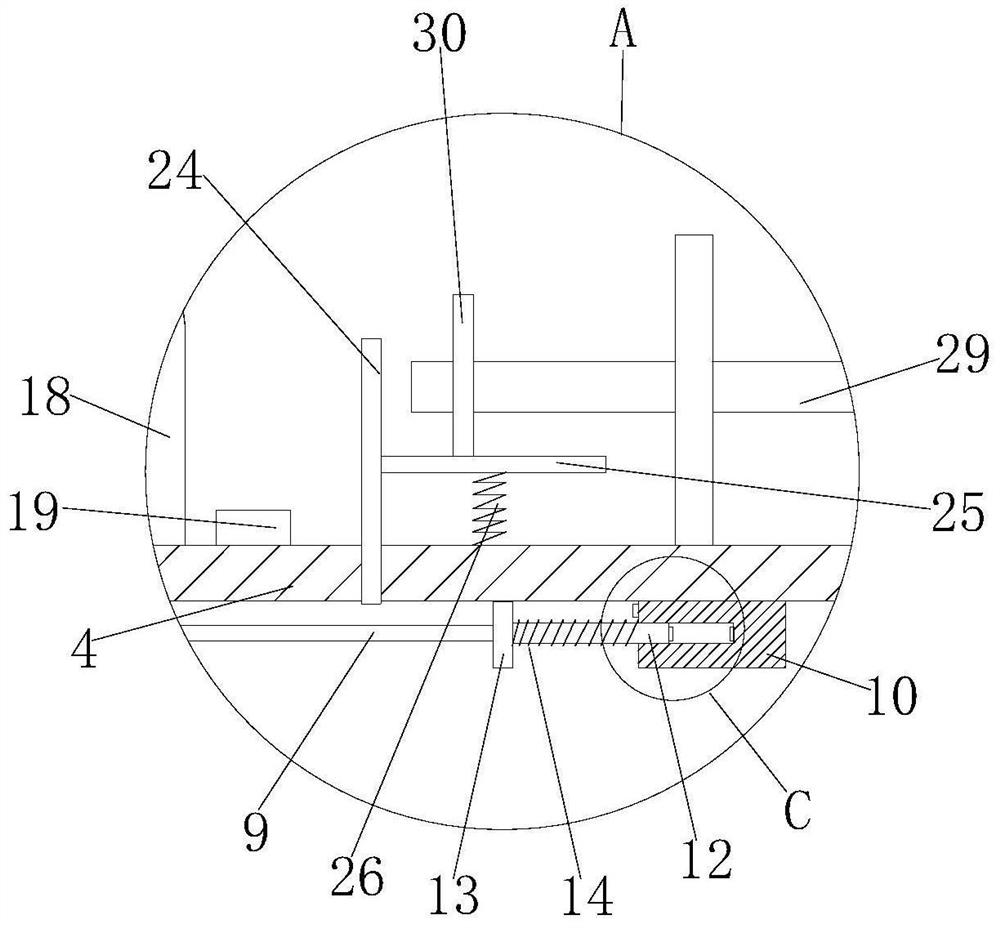

Waste heat recovery system for environment-friendly coating mechanical equipment

InactiveCN111750703ARealize waste heat recovery and utilizationSimple structureDispersed particle filtrationTransportation and packagingProcess engineeringMechanical devices

The invention belongs to the technical field of waste heat recovery of environment-friendly machinery, and particularly relates to a waste heat recovery system for environment-friendly coating mechanical equipment. The waste heat recovery system aims at solving the problems that waste gas in an existing drying chamber is discharged into the atmosphere at a high temperature, so that atmospheric environment pollution is caused, and a large amount of heat energy is wasted. According to the technical scheme, the waste heat recovery system comprises a conveying plate. A box body is mounted at the top of the conveying plate, a spiral coil is arranged on the inner wall of the box body, and a treatment box is fixedly mounted at one end of the spiral coil. A sliding frame is slidably mounted in thetreatment box, a filter screen is fixedly mounted in the sliding frame, and a collecting hopper fixedly communicates with the bottom of the treatment box. A valve is arranged in the collecting hopper, and an air inlet pipe is fixedly mounted on one side of the treatment box. One side of a contact plate is fixedly mounted on one side of the sliding frame, and a fixed seat is fixedly mounted on theinner wall of the top of the treatment box. By the waste heat recovery system, waste heat can be recycled, waste gas can be treated, an alarm can be given and pressure can be relieved when the filterscreen is blocked, the structure is simple, and use is convenient.

Owner:王小珍

Regenerative energy-saving gas cooker

InactiveCN104964312AHigh thermal efficiencyRealize waste heat recovery and utilizationDomestic stoves or rangesCombustion processCombustion chamberPlate fin heat exchanger

The invention discloses a regenerative energy-saving gas cooker. The regenerative energy-saving gas cooker comprises a gas cooker main body, a burner, a sealing pot ring, a smoke recovery ring and a heat pipe heat exchanger, wherein the gas cooker main body is provided with a closed heat recovery chamber and a combustion chamber which is arranged at one side of the closed heat recovery chamber and provided with an upper opening; the burner is arranged in the combustion chamber of the gas cooker main body; the sealing pot ring is arranged on the upper opening of the combustion chamber of the gas cooker main body in a sealing manner, so that a closed space is formed in the combustion chamber; the smoke recovery ring is a hollow structural body with a plurality of air inlet holes and a smoke discharging opening and arranged outside the burner in the combustion chamber of the gas cooker main body; the heat pipe heat exchanger is arranged in the closed heat recovery chamber of the gas cooker main body, and is provided with an air inlet, a hot air outlet pipe, a smoke return pipe and a smoke discharging pipe and communicated with the burner and the smoke recovery ring. By adopting the regenerative energy-saving gas cooker, recovery of smoke heat and preheating of combustion-supporting air can be realized by virtue of the heat pip heat exchanger, the waste of waste heat can be avoided, and the heat efficiency can be improved.

Owner:SHANDONG JIANZHU UNIV

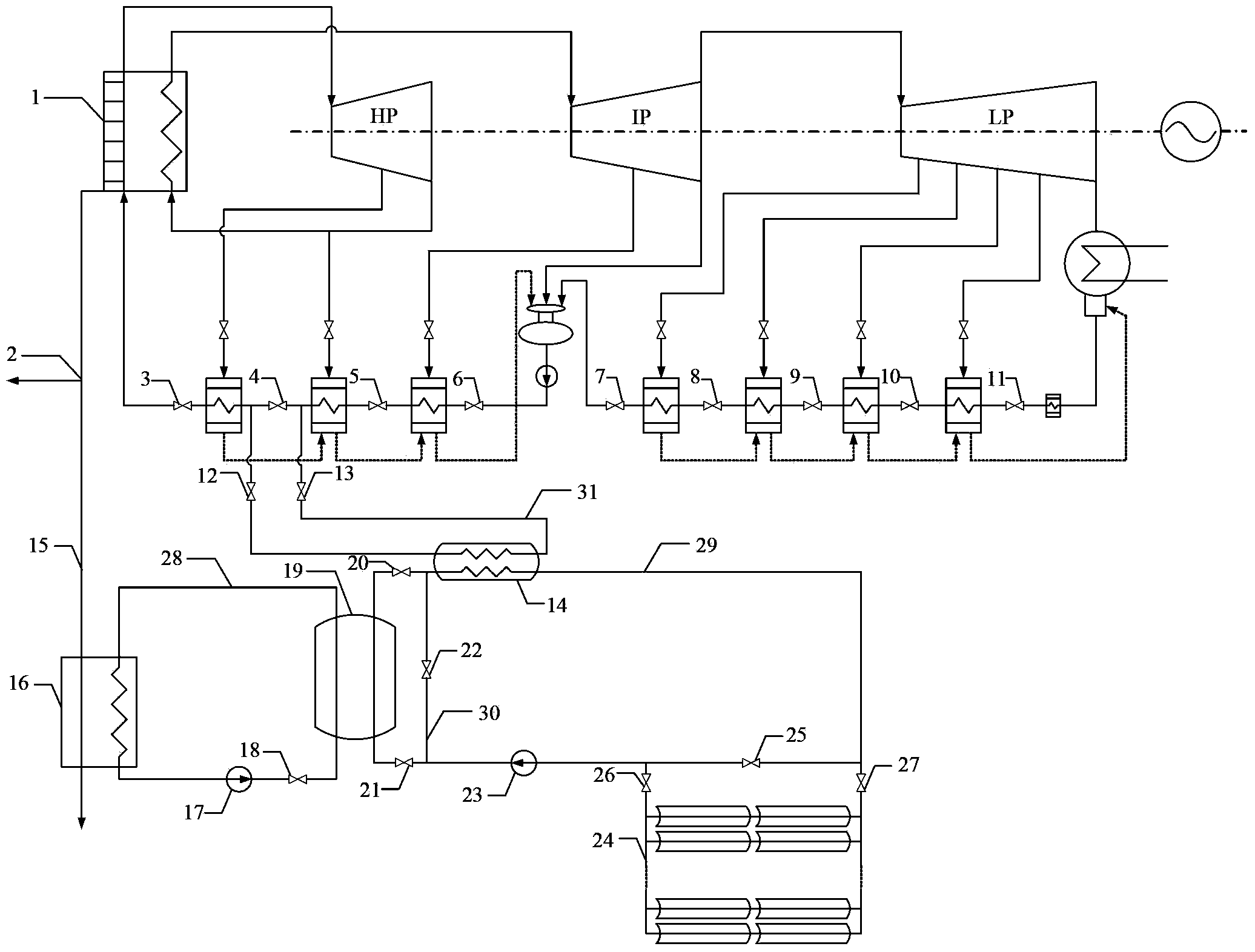

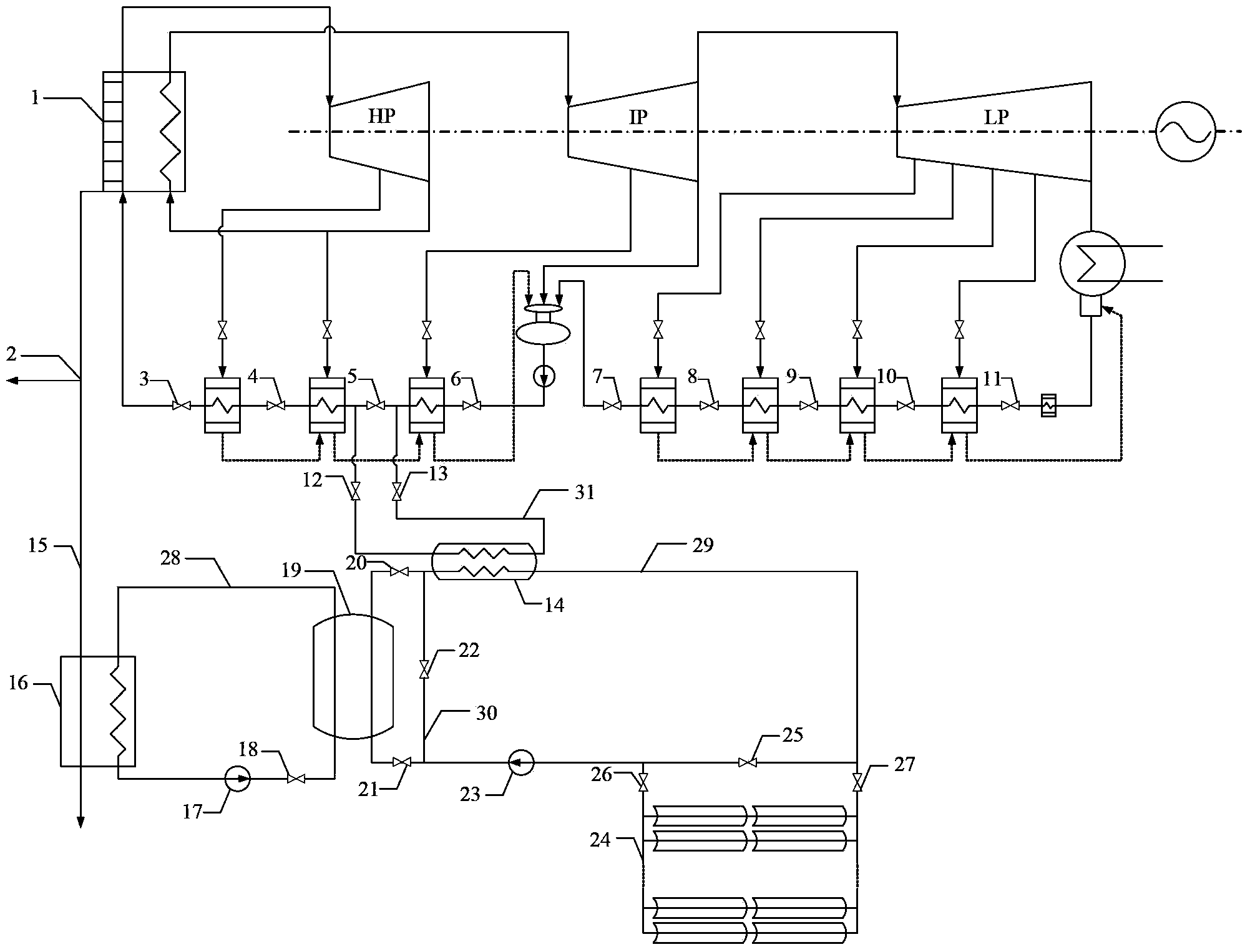

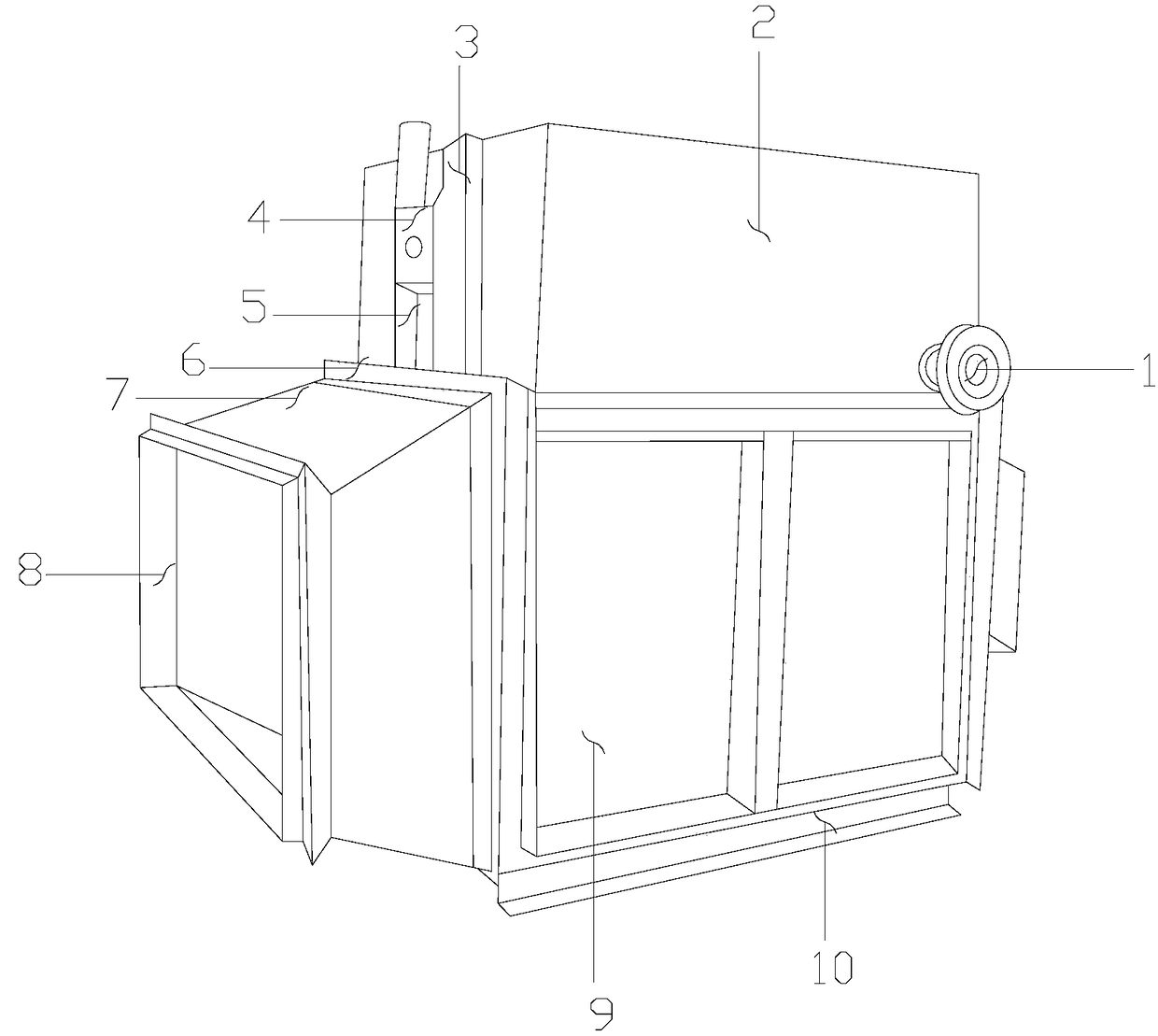

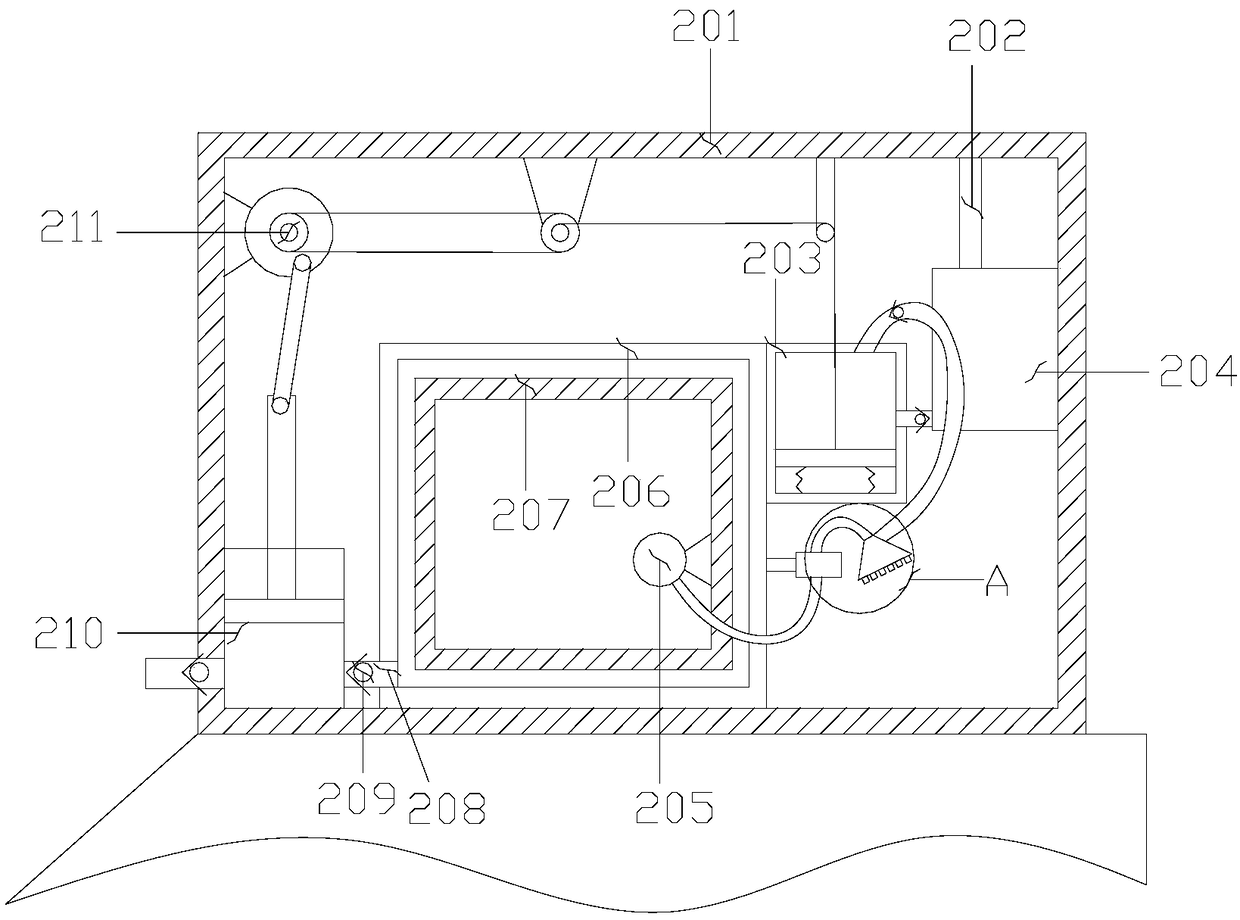

System for assisting coal-burning boiler to generate power by utilizing solar energy and waste heat of ash residue

InactiveCN103410580ARealize waste heat recovery and utilizationReduce areaFrom solar energyEnergy industryManufacturing technologySlag

The invention discloses a system for assisting a coal-burning boiler to generate power by utilizing solar energy and the waste heat of ash slag in the technical field of design and manufacture of power generation equipment of the coal-burning boiler. The system comprises the coal-burning boiler, a solar heat-collecting field, a solid waste-heat recovery device, a heat storage device and an oil-water heat exchanger, wherein the solid waste-heat recovery device is connected with the coal-burning boiler by a slag discharging channel; the heat storage device and the solid waste-heat recovery device are connected in series by a first oil-pipe loop; the oil-water heat exchanger and the heat storage device are connected in series by a second oil-pipe loop; two circulation pipelines of the solar heat-collecting field are connected into the second oil-pipe loop in parallel; the oil-water heat exchanger is provided with a water feeding pipeline; the water feeding pipeline is connected with a water pipe between any two adjacent heaters of the coal-burning boiler in parallel to form a water feeding loop. The system disclosed by the invention has the advantages that the recovery and the utilization of waste heat of a power generation unit are realized, the operation stability of the system is guaranteed and the discharging amount of pollutants in the production process of a power plant is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

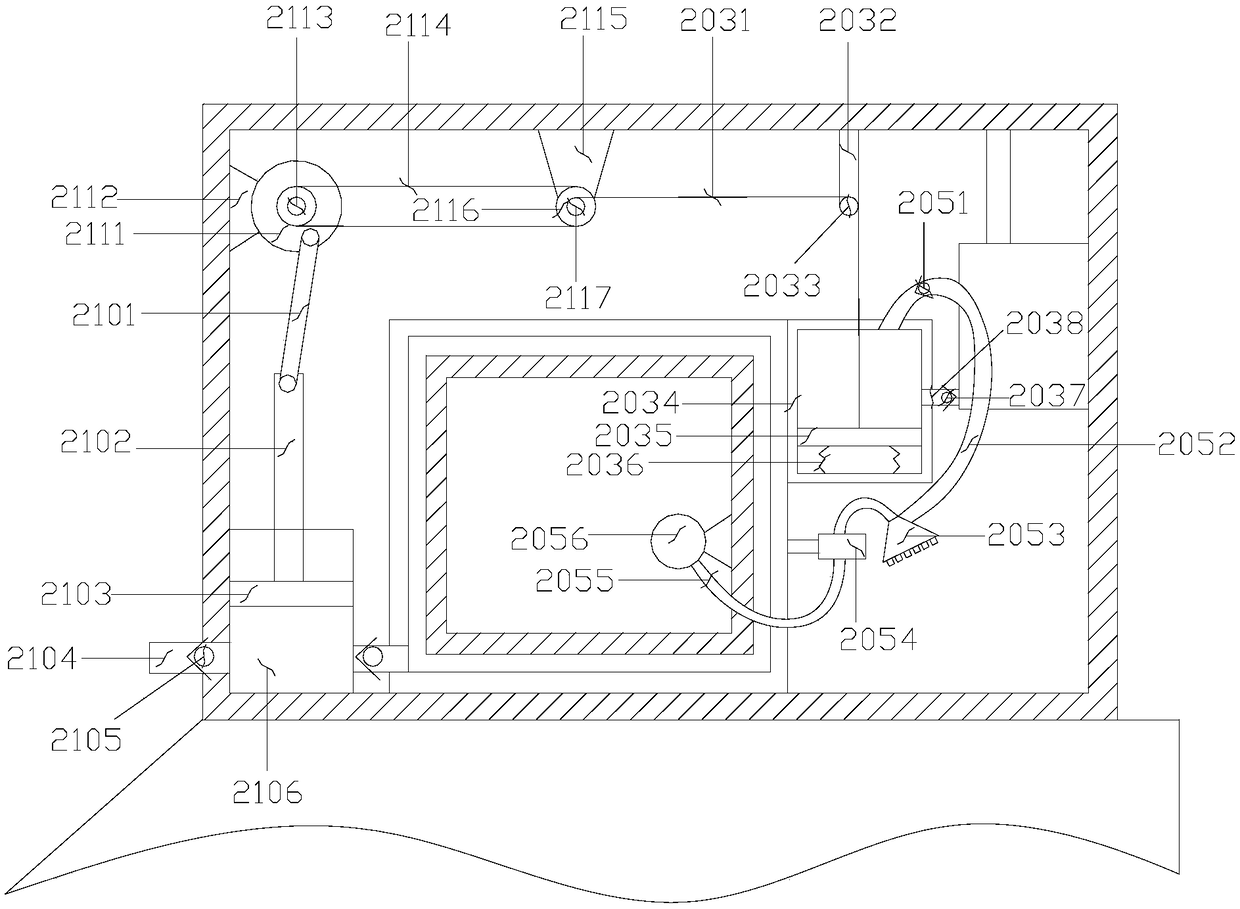

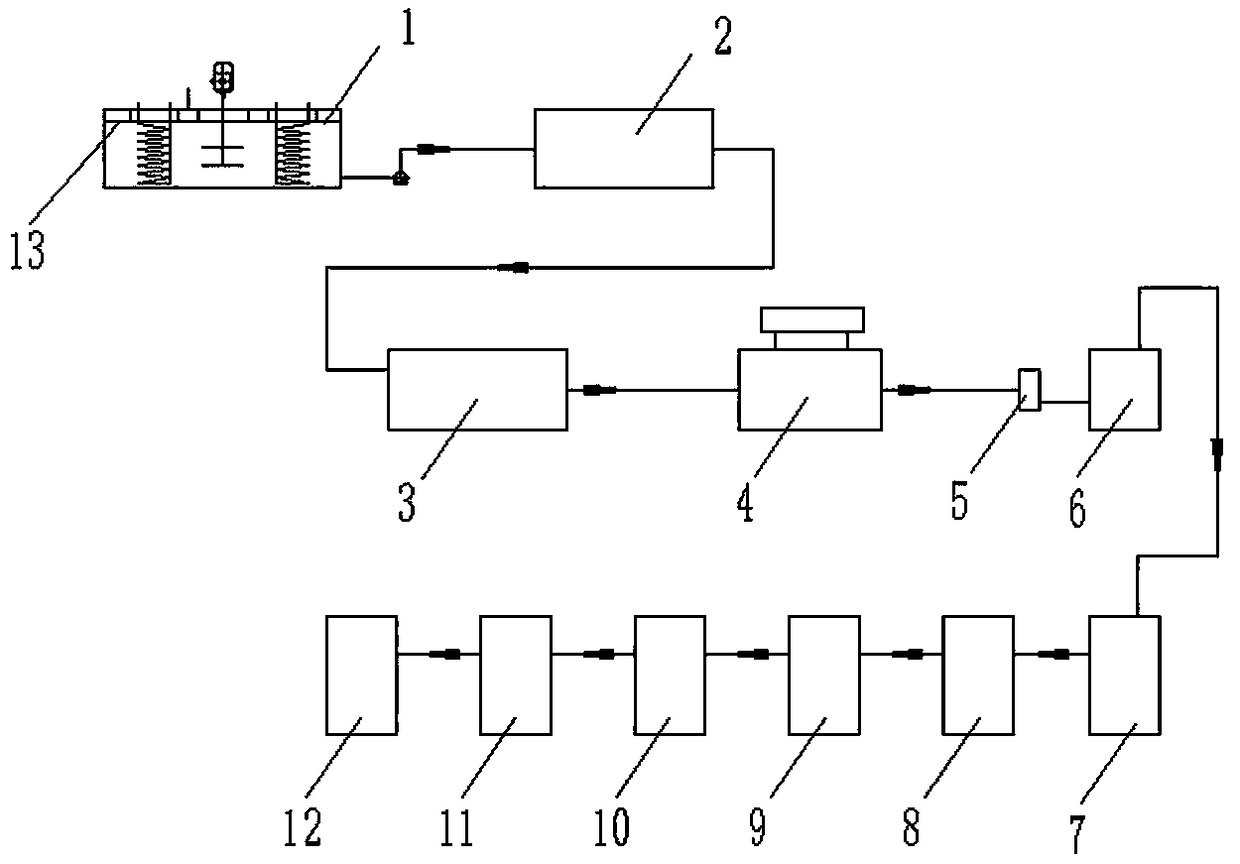

Waste heat recovery and utilization device of microwave equipment for tobacco processing

InactiveCN108613580AHarm reductionRealize waste heat recovery and utilizationIndirect heat exchangersHeatWaste heat recovery unitMicrowave

The invention discloses a waste heat recovery and utilization device of microwave equipment for tobacco processing. The device structurally comprises a combined heat and power generation rotary disc,a waste heat efficient evaporation mechanism, a supporting frame plate, a thermoelectricity heat exchanger, a condensing pipe column, a generator connecting framework, a generator box body, a waste heat generation trough connecting port, a combined heat and power generation box and an absorber base, wherein the waste heat efficient evaporation mechanism is fixedly welded to the upper end of the combined heat and power generation box and is firmly connected through bolts; and the generator connecting framework is fixedly welded to the left side of the combined heat and power generation box andis firmly connected through bolts. By means of the waste heat recovery and utilization device, a pressing plate moves up and down, when the pressing plate moves downwards, disinfectant in a small water tank enters a disinfection box through a liquid inlet pipe; when the pressing plate moves upwards, the disinfectant enters a multi-hole pipe through a liquid outlet pipe and is sprayed out through the multi-hole pipe; and accordingly, substances needing to be disinfected can be subjected to high-temperature disinfection, then waste heat recovery and utilization are achieved, harm of pathogenic bacteria is reduced, and the practical property of the equipment is effectively improved.

Owner:谢桂林

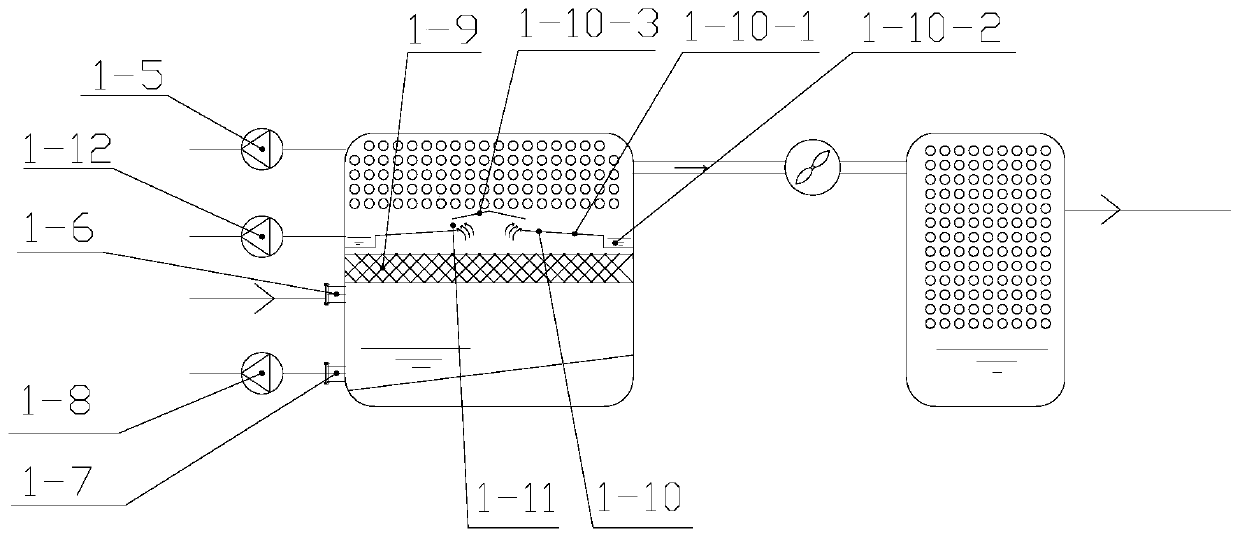

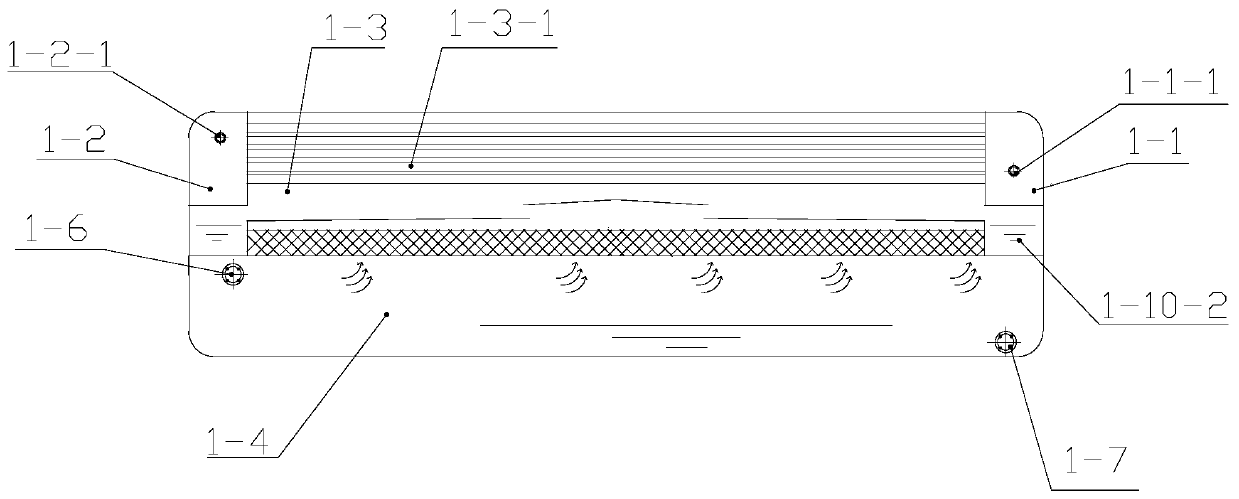

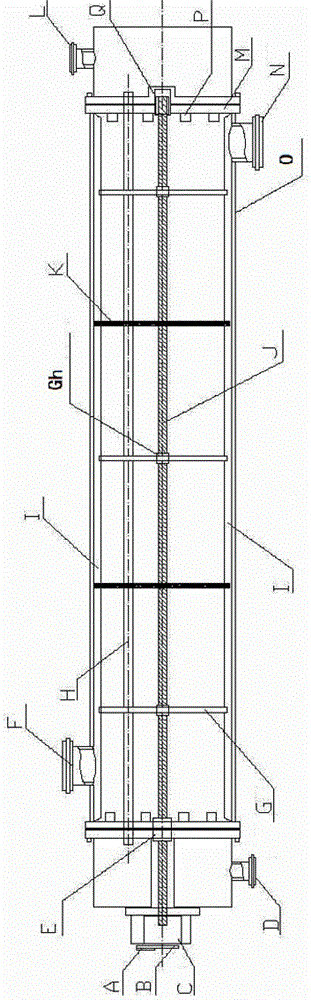

Heat pipe type smoke pulverized coal heating device

InactiveCN104764338ASave energyRealize waste heat recovery and utilizationEnergy industryIncreasing energy efficiencyWaste heat recovery unitProcess engineering

The invention relates to a heat pipe type smoke pulverized coal heating device which comprises a smoke waste heat recovery unit and a pulverized coal heating unit. The smoke waste heat recovery unit comprises a first housing, a smoke inlet is formed in the top of the first housing, a smoke outlet is formed in the bottom of the first housing, and a group of first transverse heat exchange pipes are supported in the first housing and provided with first working medium inlets and first working medium outlets. The pulverized coal heating unit comprises a heat exchange cavity provided with a second housing, the second housing is provided with a second working medium inlet and a second working medium outlet, the first working medium inlets are communicated with the second working medium outlet, and the second working medium inlet is communicated with the first working medium outlets through pipes. A group of second transverse heat exchange pipes are arranged in the second housing and provided with pulverized coal inlets communicated with distributors in a sealed mode and pulverized coal outlets communicated with collectors in a sealed mode. The heat pipe type smoke pulverized coal heating device can recover waste heat of high-temperature smoke, is used for heating pulverized coal and facilitates energy saving.

Owner:NANJING HUADIAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

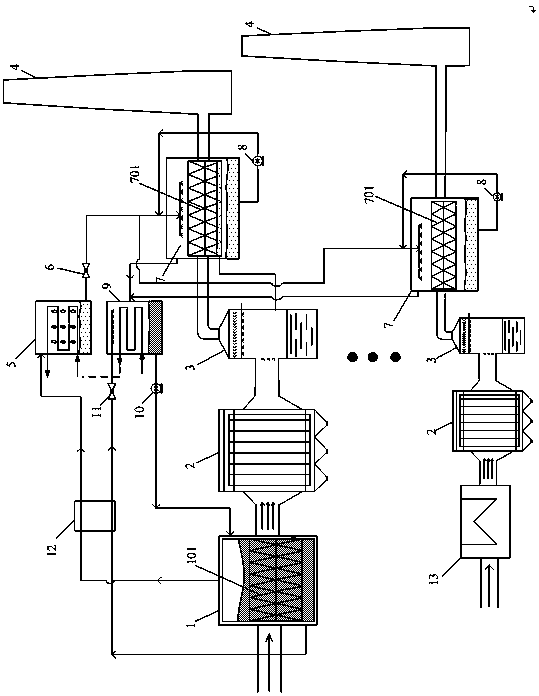

Boiler wet flue gas condensing, water-collecting and fog-clearing system utilizing power station waste heat to refrigerate

InactiveCN110068023ARealize waste heat recovery and utilizationImprove operational efficiencyHeat pumpsBoiler absorbersWater savingPower station

The invention discloses a boiler wet flue gas condensing, water-collecting and fog-clearing system utilizing power station waste heat to refrigerate. The wet flue gas condensing, water-collecting andfog-clearing system comprises a plurality of boiler unit flue gas treatment systems, wherein one boiler unit flue gas treatment system is a main boiler unit flue gas treatment system, and comprises awaste heat generator, a dust collector, a desulfurization tower, an evaporator and a chimney which are sequentially connected, and further comprises a condenser and a heat absorber; the rest of the boiler unit flue gas treatment systems are secondary boiler unit flue gas treatment systems, and each secondary boiler unit flue gas treatment system comprises a waste heat exchanger, a dust collector,a desulfurization tower, an evaporator and a chimney which are sequentially connected. The boiler wet flue gas condensing, water-collecting and fog-clearing system achieves water-collecting and fog-clearing of flue gas of multiple units while realizing sufficient utilization of flue gas waste heat, and realizes certain water-saving earnings and environment-friendly benefits.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

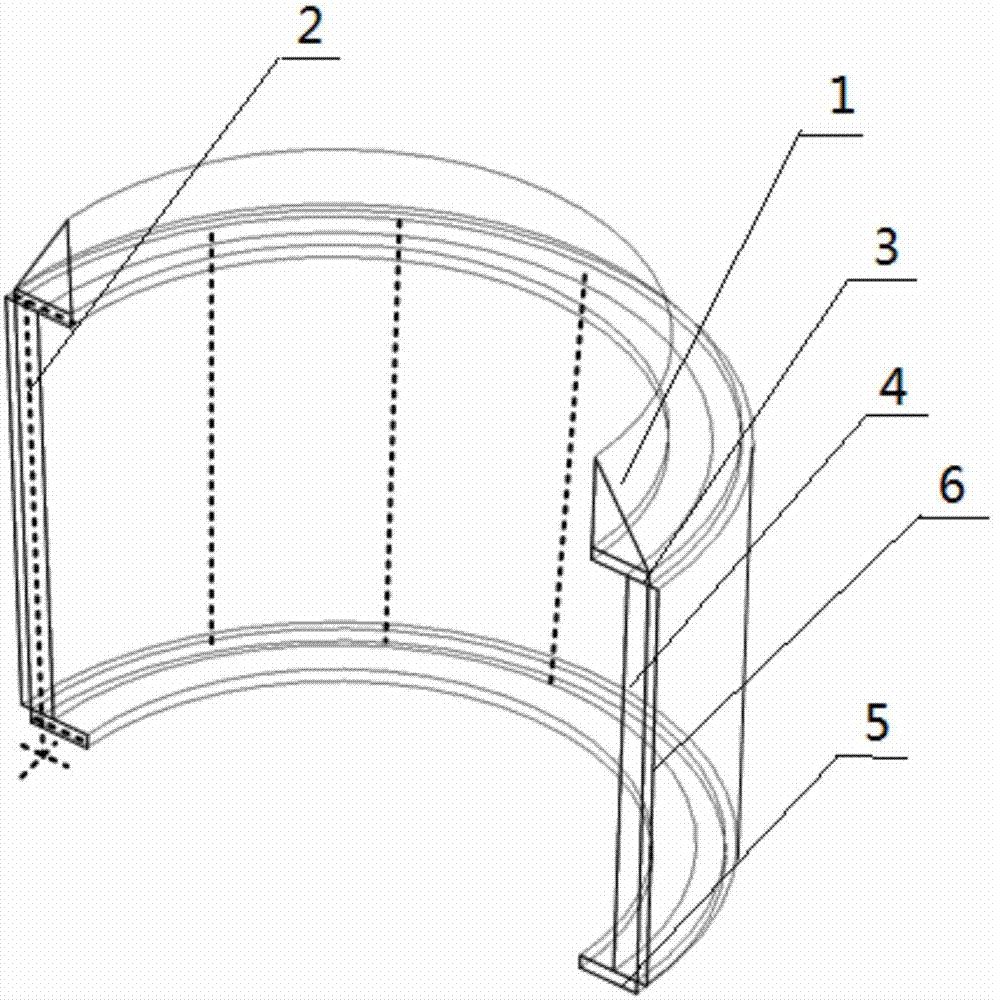

Thermoelectric generation device using steel ladle surface waste heat

ActiveCN106899236ASolve the problem that waste heat cannot be usedSimple structureGenerators/motorsWaste heat recovery unitEngineering

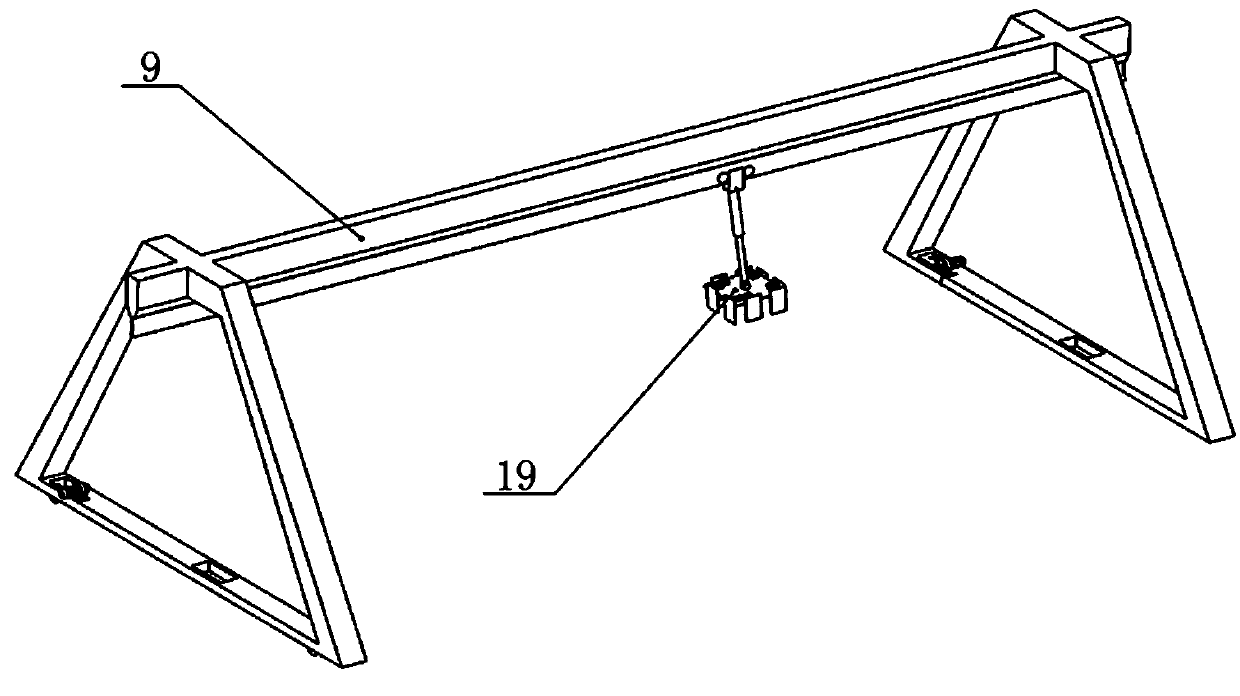

The invention discloses a thermoelectric generation device using steel ladle surface waste heat. The device comprises a protective cover, a skeleton, an upper heat insulating plate, a thermoelectric system, a lower heat insulating plate and a cooling system. The skeleton is a semi-cylindrical support; the protective cover is welded on the skeleton; the upper heat insulating plate, the thermoelectric system and the lower heat insulating plate are fixed on the skeleton by bolts to form a semi-cylindrical shape; the cooling system is arranged outside the thermoelectric system; and the device is composed of two semicircular cylinders. The technical scheme of the invention has the characteristics of simple structure, small size, no mechanical movement and no noise, so that the waste heat recovery and utilization in the limited space can be realized.

Owner:NORTHEASTERN UNIV

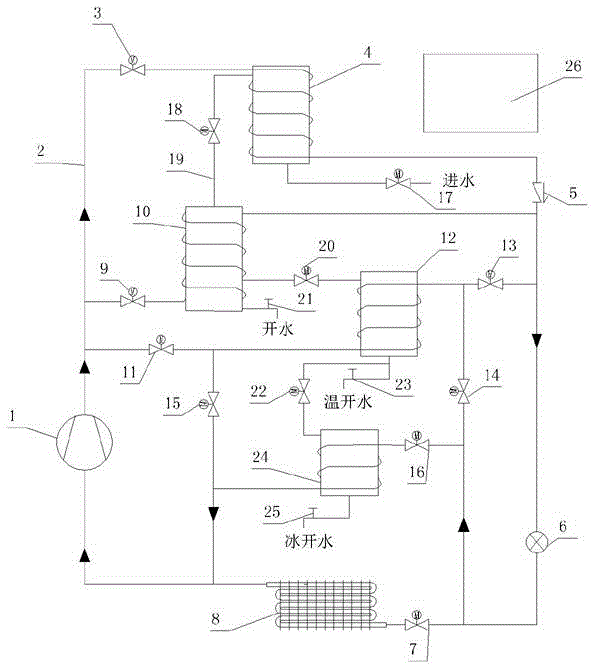

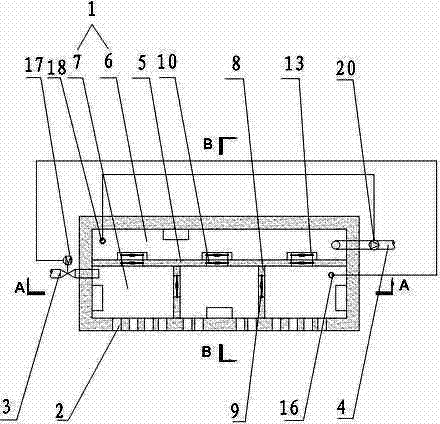

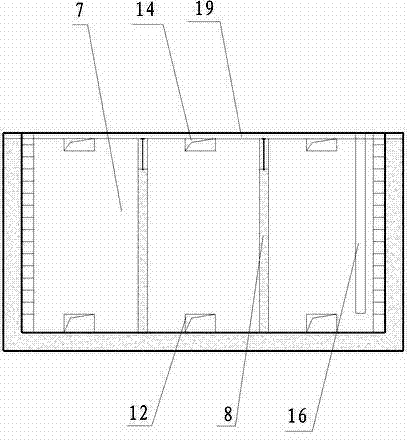

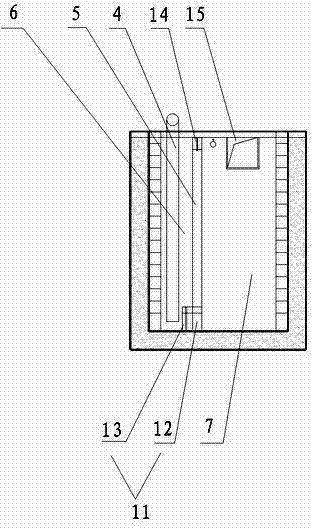

Multi-function heat-pump boiled water device

ActiveCN104019545ARealize waste heat recovery and utilizationReduce power consumptionFluid heatersDomestic cooling apparatusElectric heatingMultiple function

The invention discloses a multi-function heat-pump boiled water device which comprises a control system, a heat pump system and a water system, wherein the water system comprises a water boiler, a high-temperature boiled water tank, a medium-temperature boiled water tank and an ice boiled water tank, which are sequentially connected in series through water system pipelines; the heat pump system comprises a compressor, a throttle mechanism and a hot source heat exchanger, which are connected through heat pump system pipelines. The multi-function heat-pump boiled water device has the benefits that the heat-pump boiled water device can simultaneously provide boiled water, warm water and ice water, is sanitary and healthy, meets diversified demands of different clients, and is particularly suitable for places such as markets, wine shops, drink shops, airports, stations, factories and enterprises needing abundant boiled water; water boiling, temperature rising and temperature lowering are completed through the same one set of heat pump system, and waste heat recovery is realized well; compared with the traditional electric heating water boiler, the power consumption can be reduced by about 70 percent, energy conservation and emission reduction are realized; the heat-pump boiled water device conforms to a new concept of national energy-conservation industrial policy and social energy conservation and environmental protection.

Owner:江苏乐普四方科技有限公司

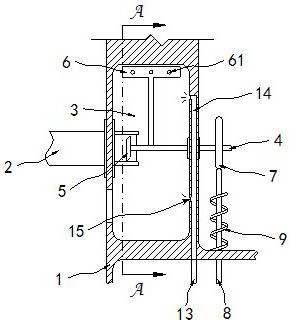

A water seal drain

The invention discloses a water lute drainer which comprises a pool, water inlet pipes, a water replenishing pipe and a drain pipe. The water lute drainer is characterized in that a main partition wall is arranged in the pool so as to separate the pool into a drain tank and a water seal body which are not communicated, and the water replenishing pipe passes through the pool so as to be communicated with the interior of the water seal body; the drain pipe passes through the pool so as to be communicated with the drain tank, the water seal body comprises multiple water seal pools, and water seal partition walls are used for separating the adjacent water seal pools into separate units which are not communicated; multiple water inlet pipes pass through the side wall of the pool and are communicated with each water seal pool, and the top of each water seal partition wall is provided with a water overflowing device; and the main partition wall is provided with multiple drainage devices which are communicated with the water seal pools and the drain tank, and the height of the water overflowing device is lower than that of the drainage devices. The water lute drainer provided by the invention has the advantages that multiple water seal pools share a set of equipment, the structures of the multiple drainage devices are simplified, and the occupied space is obviously reduced.

Owner:CISDI ENG CO LTD

Graphitization furnace surplus energy utilization method based on forced cooling

InactiveCN103900390AIncrease production capacityReduce CooldownCarbon compoundsEnergy inputEngineeringElectricity generation

The invention relates to a graphitization furnace surplus energy utilization method based on forced cooling. The cooling mode of a graphitization furnace is changed into forced cooling from natural cooling, waste heat obtained in the cooling process of a graphitization product is converted into steam through heat-carrying gas, electricity generation and heat supply are carried out, a cooling coil is arranged inside a furnace body, an air inlet of the cooling coil is connected with an air inlet collecting pipe, the air inlet collecting pipe is connected with a waste heat boiler through a cooling fan, an air outlet of the cooling coil is connected with an air outlet collecting pipe, the air outlet collecting pipe is connected with the waste heat boiler, and the steam enters a turbine system for electricity generation and heat supply. Each graphitization furnace production line comprises a plurality of independent furnace bodies, wherein in the cooling process, single furnace body is cooled intermittently, however, it is ensured that the furnace bodies of the whole production line are cooled at any time point, high-temperature gas always enters the waste heat boiler, and a turbine generator set can continuously work. According to the novel graphitization furnace cooling technology, the capacity of the graphitization product is remarkably improved, the comprehensive energy consumption is reduced, and the graphitization production technology is greatly improved.

Owner:张茂勇

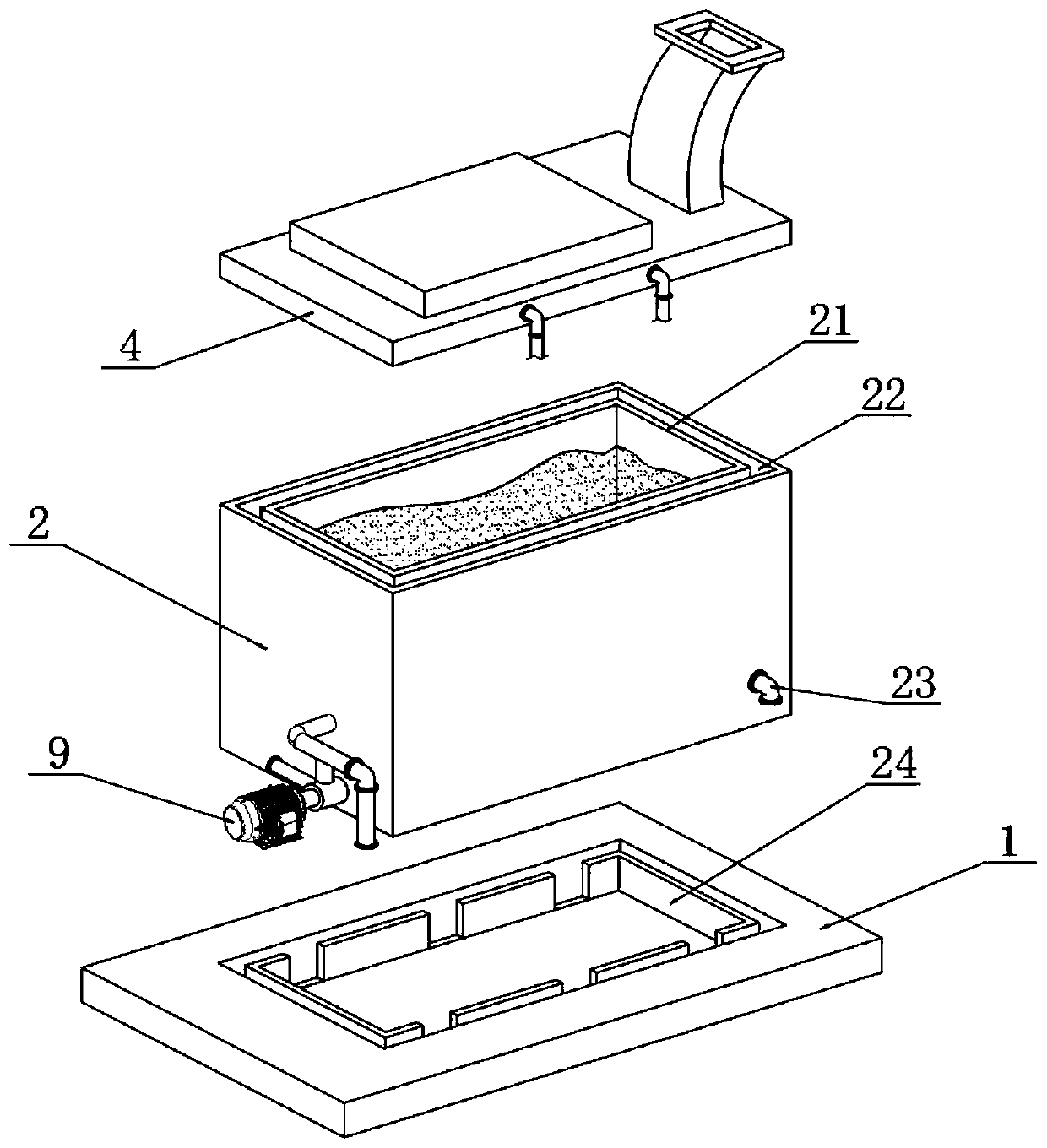

Rapid water-cooling and air-cooling system for metallurgy

InactiveCN111020080AEasy injectionRealize the cooling effectProcess efficiency improvementMetallurgical slagEngineering

The invention relates to the technical field of metallurgy. The invention discloses a rapid water-cooling and air-cooling system for metallurgy. The system comprises a base, a slag box is arranged atthe upper end of the base; a box cover is arranged at the top end of the slag box; an air box is arranged at the upper end of the box cover; a slag inlet is formed in one side, close to the air box, of the upper end of the box cover; and the side face, close to the box cover, of the output end of the compressor communicates with a liquid inlet pipe. A liquid outlet pipe communicates with the side,close to the liquid inlet pipe, of one side face of the box cover, one end of the liquid outlet pipe is connected with a metallurgical furnace, an inner furnace is arranged in the metallurgical furnace, a preheating cavity is formed between the metallurgical furnace and the inner furnace, and a first circulating pipe is arranged in the preheating cavity. The rapid water-cooling and air-cooling system is simple and convenient to operate, water cooling and air cooling are integrally matched, dual cooling is achieved, the rapid cooling efficiency of high-temperature metallurgical slag can be further improved, and meanwhile the high-temperature recycling efficiency generated by the high-temperature metallurgical slag is achieved.

Owner:WUHU DINGHAN REMFR TECH

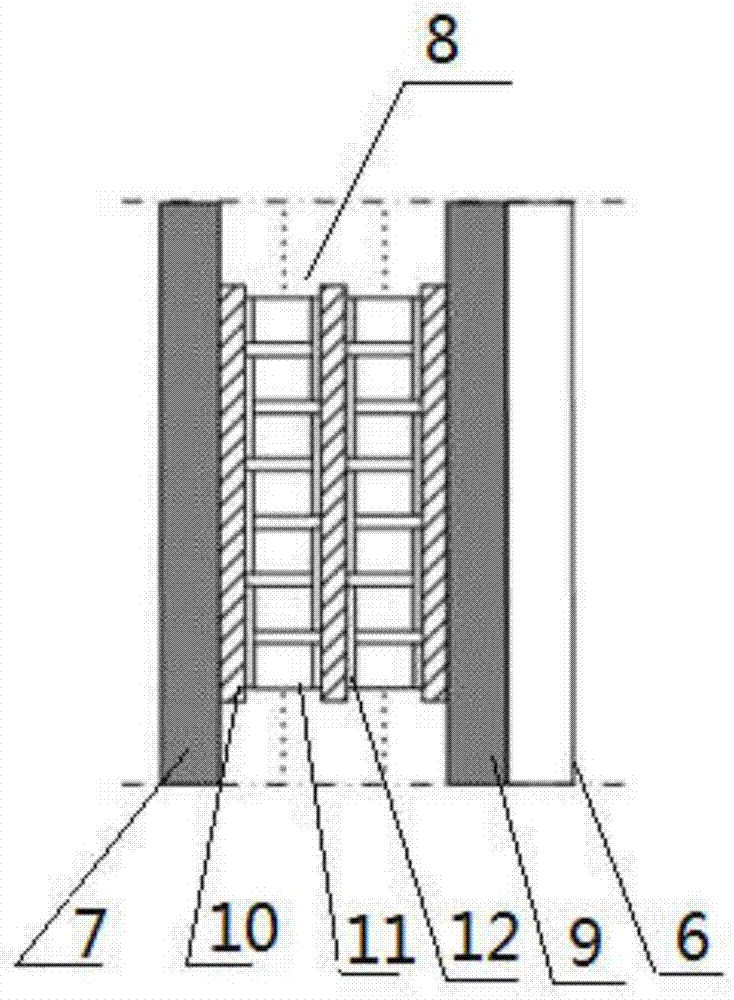

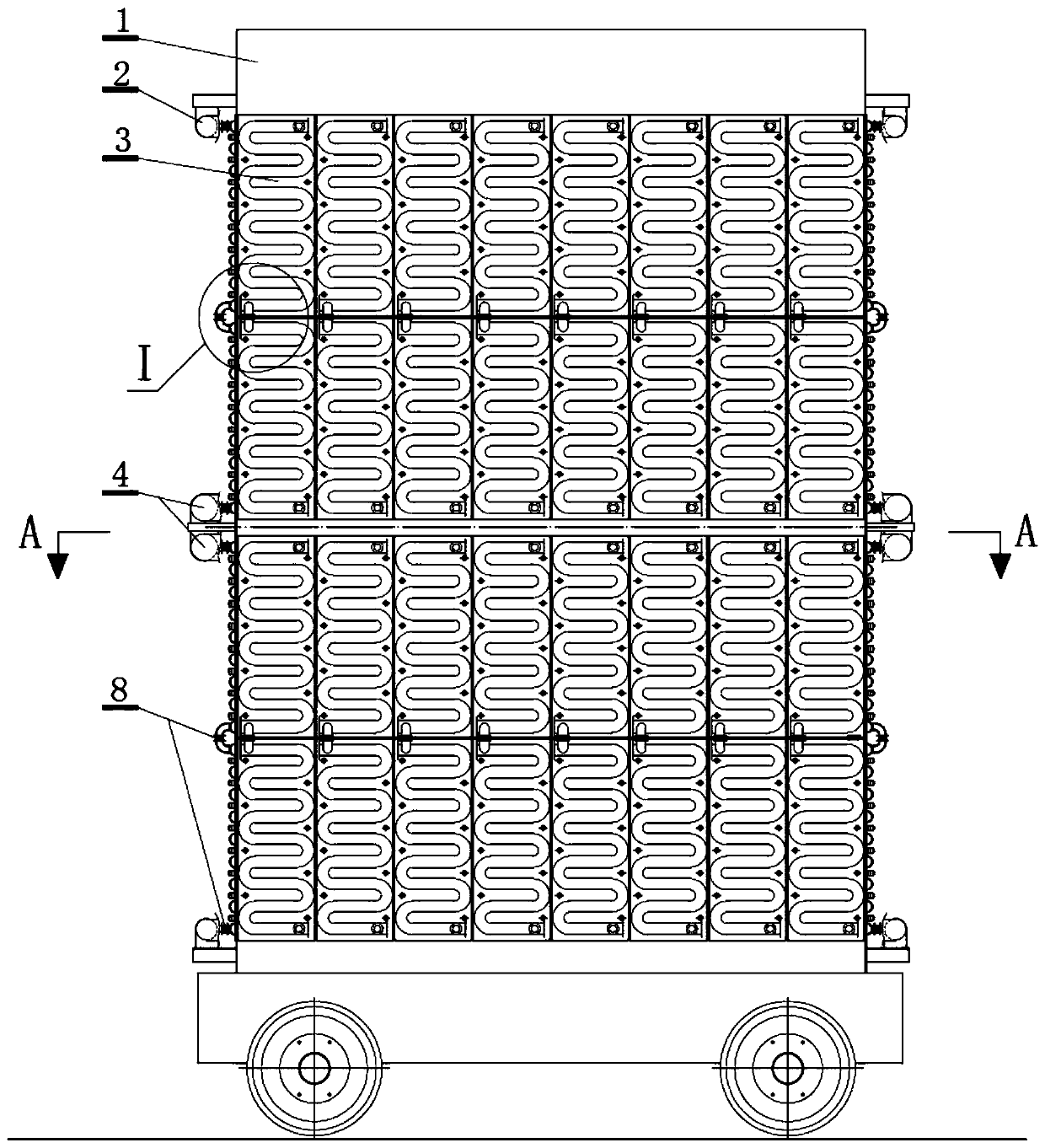

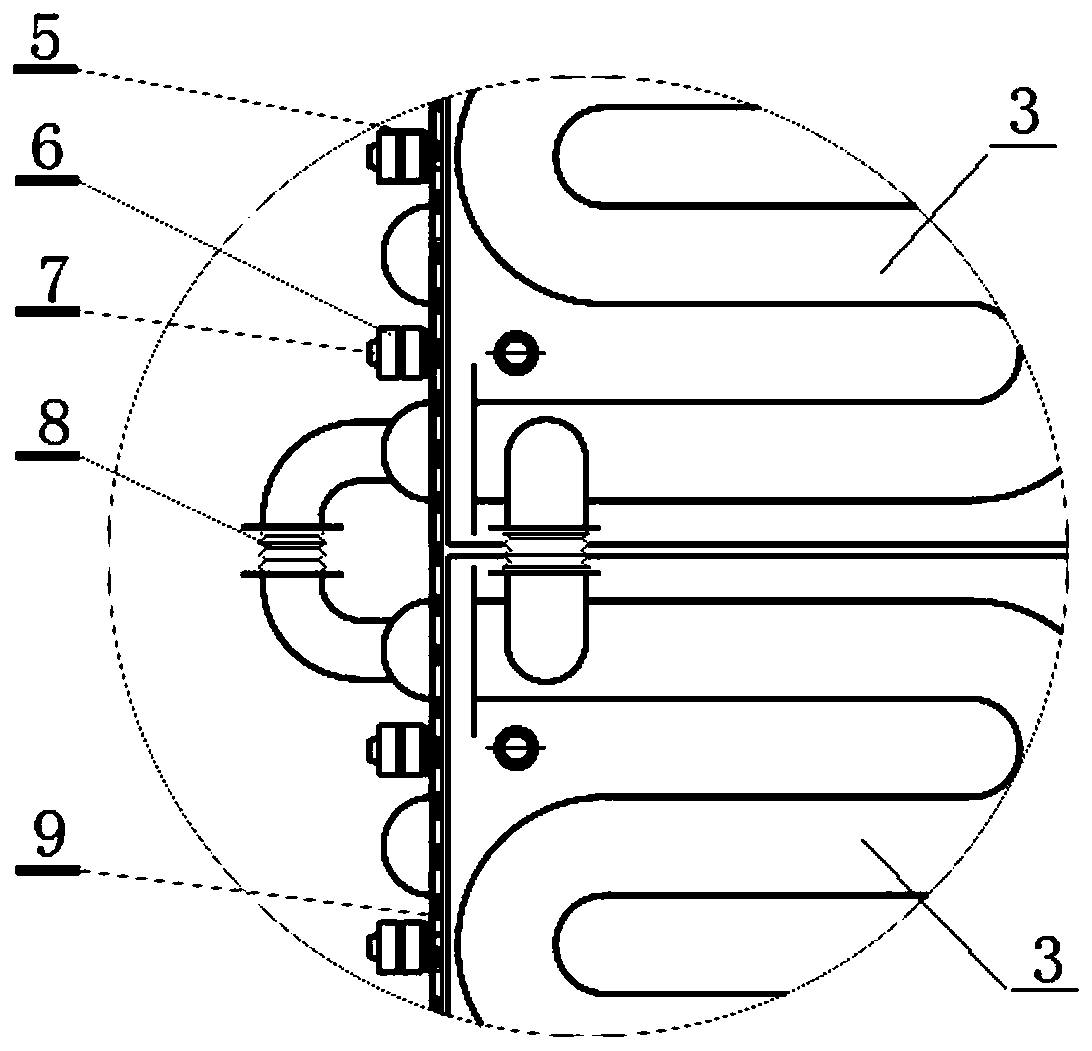

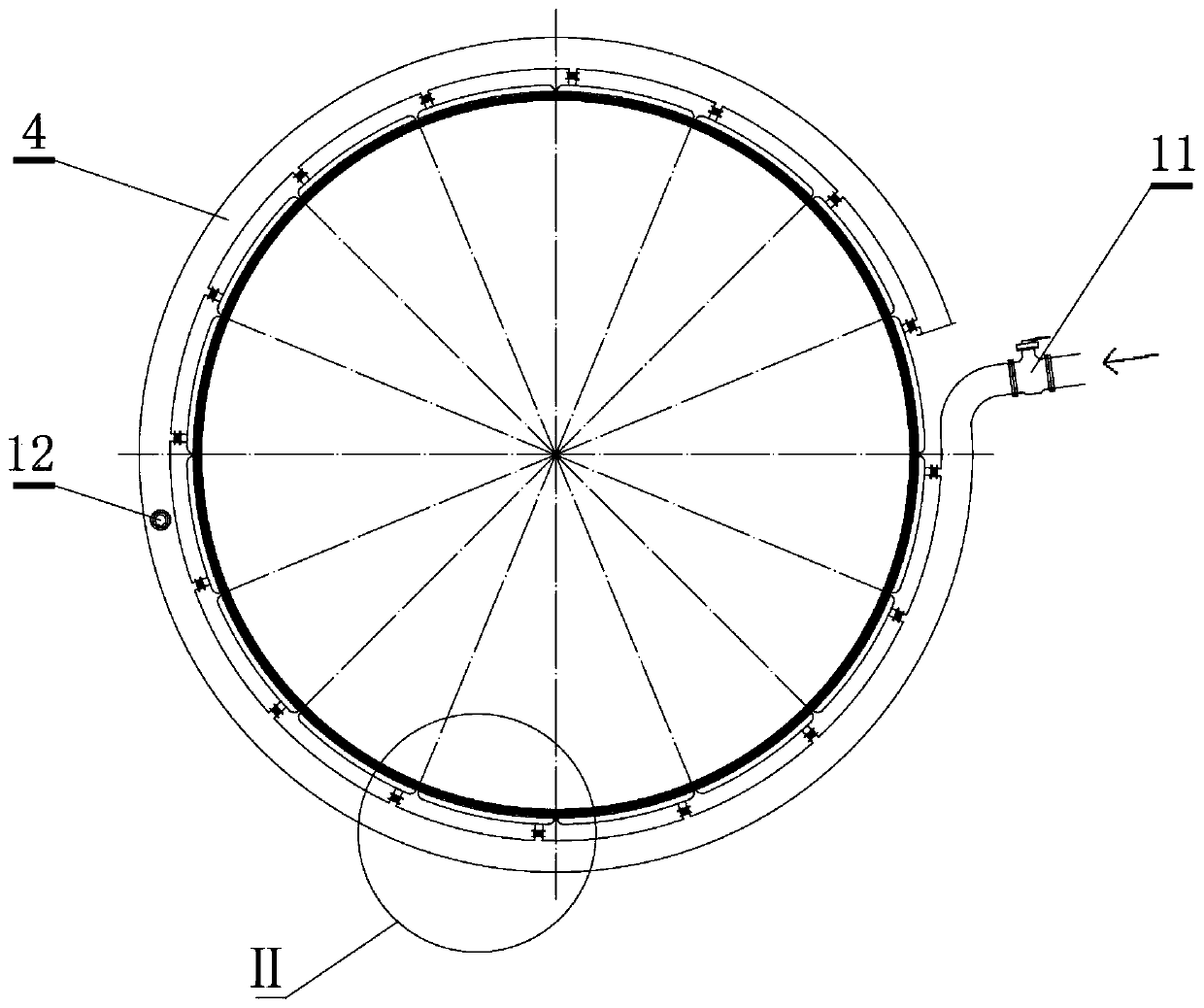

Electric melting magnesium furnace shell cooling device and method

PendingCN110763019AImprove interchangeabilityEasy to install on siteFurnace cooling arrangementsIncreasing energy efficiencyEngineeringMaterials science

The invention relates to an electric melting magnesium furnace shell cooling device and method. The device comprises an upper furnace shell cooling device and a lower furnace shell cooling device. Theupper furnace shell cooling device and the lower furnace shell cooling device are respectively composed of a plurality of independent cooling units. Each cooling unit is connected with a water inletmain pipe through a corresponding water inlet branch pipe, and is connected with a water outlet pipe through a corresponding water outlet branch pipe. The cooling units are fixedly connected with a plurality of bolts welded to a furnace shell through nuts and disc-shaped springs. Spaces between the cooling units and the furnace shell are filled with flexible heat conduction pads. The device is composed of the plurality of cooling units with a unified structure, and the cooling units and the furnace shell are detachably connected, so that not only can the furnace shell be effectively protected,but also the mounting and maintenance are very convenient; and the upper furnace shell cooling device and the lower furnace shell cooling device are put into operation at different phases according to the temperature rise characteristic in the electric melting magnesium production process, so that energy is saved, and synergistic effects are realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Dual-purpose flue gas waste heat utilization system of heat supply unit

PendingCN113757708AAvoid enteringAvoid cloggingLighting and heating apparatusCombustion technology mitigationWater storageThermodynamics

The invention discloses a dual-purpose flue gas waste heat utilization system of a heat supply unit. The dual-purpose flue gas waste heat utilization system is provided with a box body, a movable shaft, a scraping plate, a fixed box, a filter screen and a connecting pipe, wherein an air inlet is formed in one side of the box body; the movable shaft is movably arranged in a dust removal cavity, and a paddle plate is fixed at one end of the movable shaft; the scraping plate is arranged on the side face of the movable shaft, and the other end of the movable shaft is sleeved with a cam; the fixed box is fixed on the box body on the outer side of a valve plate, and a water inlet pipe penetrates through the side surface of the fixed box; the filter screen is fixed to the inner wall of the dust removal cavity, and one end of a conveying pipe is fixed to the outer side of the dust removal cavity; and one end of the connecting pipe is fixedly connected with the other end of the conveying pipe. According to the dual-purpose flue gas waste heat utilization system of the heat supply unit, a large amount of smoke dust in flue gas can be purified, the smoke dust is prevented from entering the water storage cavity, pipeline blockage can be avoided, and meanwhile the heat recovery efficiency can be improved while the sealing performance of the waste heat recovery device is guaranteed.

Owner:徐四保

Sewage and wastewater source steam compression dry heat pump unit

PendingCN111595063ARealize waste heat recovery and utilizationFacilitate waste heat recovery and utilizationHeat pumpsWastewaterProcess engineering

The invention discloses a sewage and wastewater source steam compression dry heat pump unit, and belongs to the technical field of waste heat utilization. The problem that an existing compression typeheat pump cannot utilize industrial sewage and wastewater to serve as a waste heat source is solved by the sewage and wastewater source steam compression dry heat pump unit. An evaporator further comprises a first heat exchange chamber located on the upper portion and a flash evaporation chamber arranged below the first heat exchange chamber in a communicating mode. A working medium inlet chamberand a working medium outflow chamber are formed in the two ends of the first heat exchange chamber in a communicating mode respectively. A vacuum pump is arranged on the upper portion of the evaporator in a communicating mode, and the interiors of the first heat exchange chamber and the flash evaporation chamber are vacuumized through the vacuum pump. A plurality of first heat exchange tubes arearranged in the first heat exchange chamber, and the working medium inlet chamber communicates with the working medium outflow chamber through the first heat exchange tubes. Sewage and wastewater enter the flash evaporation chamber to be subjected to flash evaporation through a sewage and wastewater inlet pipe in a communicating mode, steam which is obtained after flash evaporation is accomplishedmoves upwards to enter the first heat exchange chamber and exchanges heat with working media in the first heat exchange tubes, and the sewage and the wastewater obtained after flash evaporation are discharged from the evaporator through a sewage and wastewater receding pipe.

Owner:HIT HARBIN INST OF TECH KINT TECH

Hot-air grain drying system for deep waste heat recovery

PendingCN113375434AReduce drynessAvoid cloggingFood processingClimate change adaptationEnvironmental engineeringHearth

The invention discloses a hot-air grain drying system for deep waste heat recovery. A fire grate is arranged below a hearth, a charging hopper connected with the fire grate is arranged on the side wall of the hearth, a heat exchanger is arranged on the upper portion of the hearth, an induced draft fan communicates with an inner cavity of the hearth, a cooling fan communicates with a drying tower, the drying tower communicates with an air cooler through a pipeline, and the air cooler communicates with the heat exchanger; and the heat exchanger communicates with a hot-air blower, and the outlet of the hot-air blower communicates with the drying tower. The system has the following benefits: air which is discharged from a low-temperature drying section of the drying tower and contains a large amount of water vapor and impurities is creatively and directly fed into the hearth to participate in combustion, the impurities are basically burnt out, and due to the fact that deep waste heat recovery is designed for the heat exchanger, the water vapor can be condensed in the heat exchanger, condensation heat is released, so that the total amount of recovered waste heat is greatly increased; and although the temperature of air exhausted from a cooling section of the drying tower is low, the content of the water vapor and the impurities is low, the air can be directly used as a drying medium to enter the heat exchanger after being slightly filtered, and waste heat recovery and utilization are realized with low equipment investment.

Owner:沈阳沈工建筑节能清洁能源技术研究院有限公司

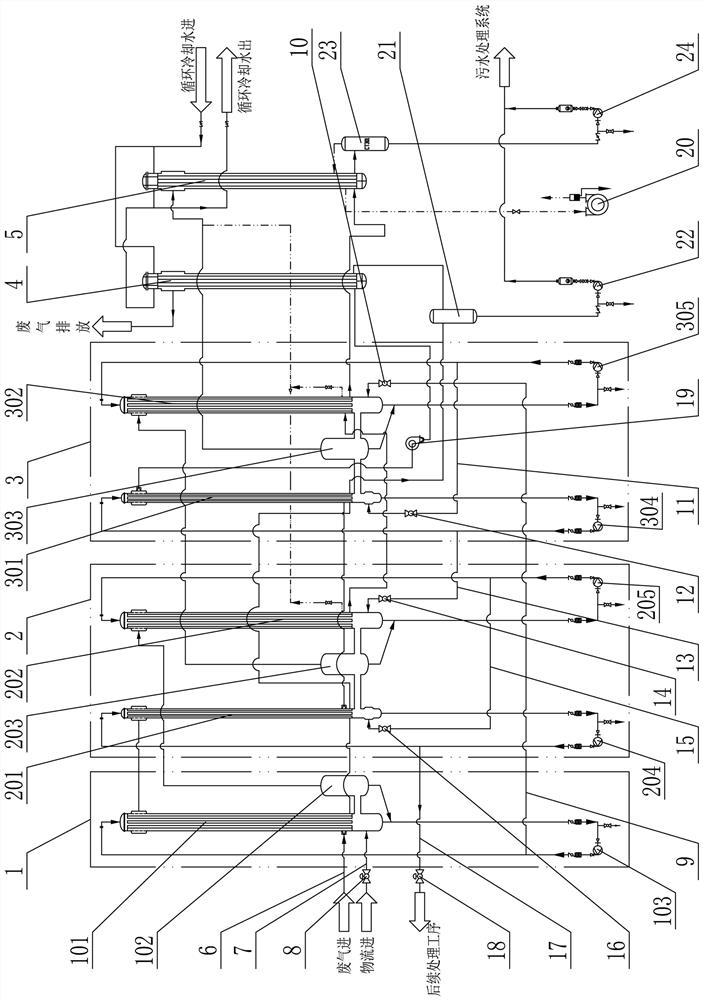

An integrated system for biomass gas purification and combustion tail gas waste heat recovery

ActiveCN104073297BImprove gasification efficiencyIncrease temperatureDispersed particle filtrationEnergy inputBiomass smokeTar

The invention discloses an integrated system for purifying biomass fuel gas and recycling combustion tail gas waste heat. The integrated system comprises a biomass gasifier, a filter, a heat exchanger and a combustion device, wherein the filter comprises two parallel filter cavities; a fuel gas inlet and a smoke gas outlet are formed in one end of each of the two filter cavities respectively; a fuel gas outlet and a smoke gas inlet are respectively formed in the other end of each of the two filter cavities correspondingly; the two independent filter cavities are arranged to respectively perform alternate treatment on the biomass fuel gas and biomass smoke gas; most of dust of the biomass fuel gas can be filtered when the biomass fuel gas passes through the filter cavities; tar can be cracked into combustible gas under the condition of high temperature so as to improve the gasification efficiency of the biomass fuel gas; when the high-temperature biomass smoke gas passes through the filter cavities, the filter can be heated to ensure that the high-temperature biomass smoke gas is in a high-temperature state, so that the cracking conditions of the biomass fuel gas can be provided; meanwhile, the temperature of the biomass fuel gas also can be increased so as to improve the combustion efficiency; finally, the biomass smoke gas is subjected to heat exchange treatment by virtue of the heat exchanger to fully recycle the waste heat of the biomass smoke gas.

Owner:GUANGDONG ZHENGPENG BIOMASS ENERGY TECH

Vinasse filtrate evaporation and concentration system for vinasse protein production feed

ActiveCN112843761AReduce consumptionReduce manufacturing costFeeding-stuffFood processingFiltrationExhaust fumes

The invention provides a vinasse filtrate evaporation and concentration system for producing feed by vinasse protein, and the system comprises a first-effect evaporator, a second-effect evaporator and a third-effect evaporator; the first-effect evaporator is used for carrying out first-time evaporation and concentration on the vinasse filtrate by utilizing waste gas of a filter residue tube bundle dryer; a heater B of the triple-effect evaporator is used for carrying out second-time evaporation and concentration on the vinasse filtration liquid by utilizing steam separated by the double-effect evaporator, and a heater A of the triple-effect evaporator is used for carrying out third-time evaporation and concentration on the vinasse filtration liquid by utilizing waste gas flowing out of a heater A of the double-effect evaporator; a heater B of the second-effect evaporator is used for carrying out fourth-time evaporation and concentration on the vinasse filtration liquid by utilizing steam separated by the first-effect evaporator; and a heater A of the second-effect evaporator is used for carrying out fifth-time evaporation and concentration on the vinasse filtration liquid by utilizing waste gas flowing out of the first-effect evaporator. High-temperature waste gas generated by filter residues in the drying process of the tube bundle drying machine is used as a heat source, filtrate is evaporated and concentrated, steam does not need to be generated, energy consumption is reduced, and the production cost is reduced.

Owner:郑州博大浓缩干燥设备有限公司

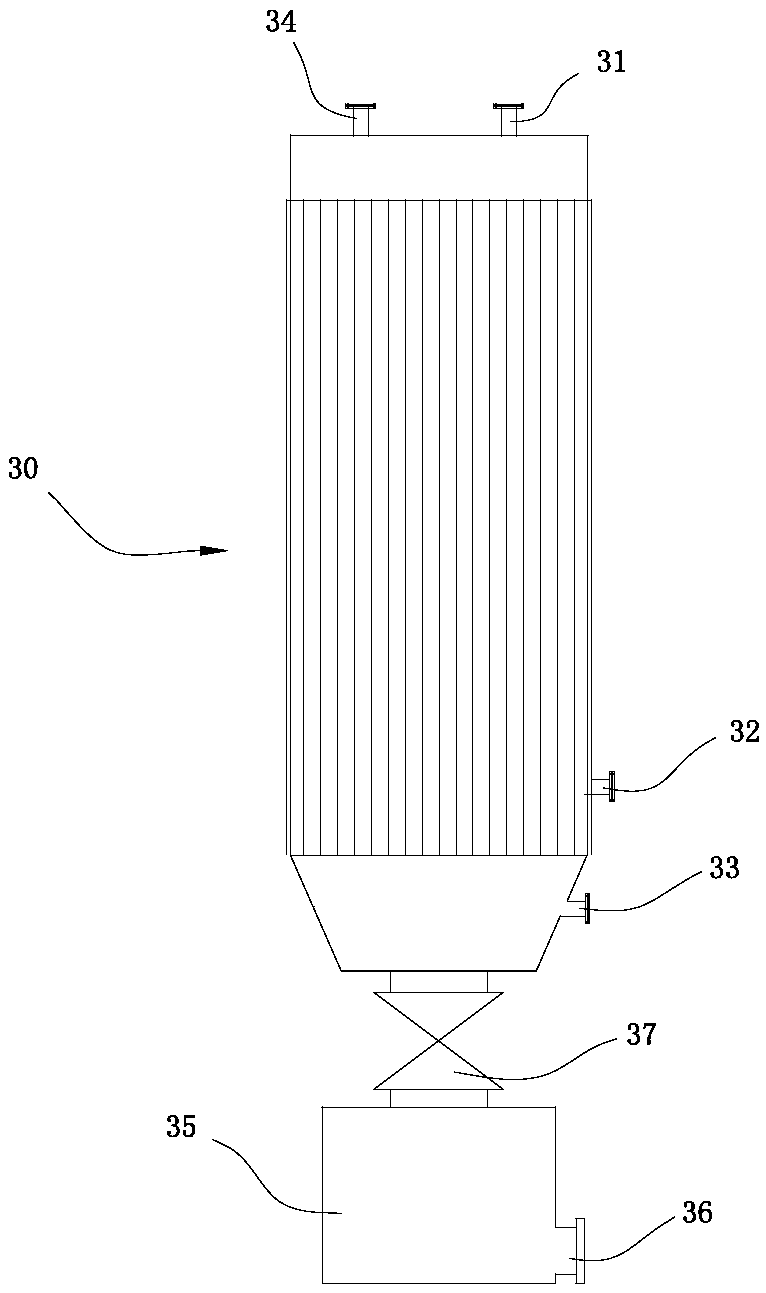

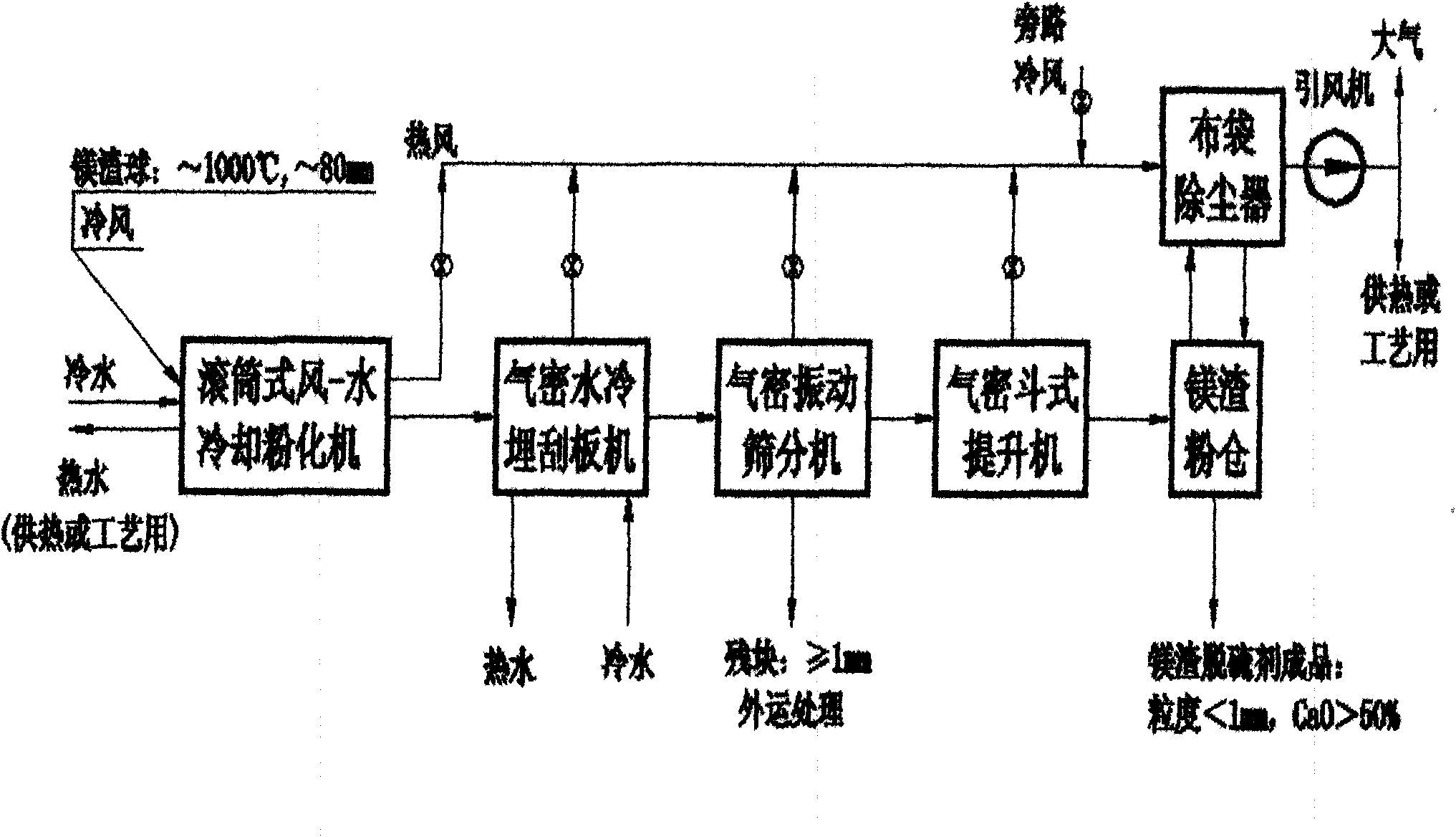

Process method for converting metal magnesium slag into desulphurizer of boiler

InactiveCN101791622BImprove cooling efficiencyEasy to handleSolid waste disposalDispersed particle separationSlagCrusher

Owner:山西猗顿生态环保股份有限公司

Flue gas treatment system

PendingCN110180366AHigh desulfurization and dust removal efficiencyReduce resistanceCombination devicesGas treatmentLiquid wasteWaste treatment

The invention relates to the technical field of flue gas treatment of heat recovery boilers and industry kiln stoves, and specially discloses a flue gas treatment system. The flue gas treatment systemcomprises a waste heat recovery section, a washing absorption section and a washing absorption liquid treatment section, wherein the waste heat recovery section is used for cooling flue gas; the washing absorption section is used for washing and absorbing waste gas; the washing absorption liquid treatment section is used for performing environment-friendly treatment on waste liquid subjected to washing. The system disclosed by the invention integrates waste heat reuse, washing absorption and waste liquid treatment; after the treatment, waste gas and waste heat recycle is realized, energy consumption is reduced, emission concentration of sulfur dioxide is less than 20 mg / Nm<3>, emission concentration of dust is less than 5 mg / Nm<3>, waste water COD is lower than 50 mg / L, SS (suspended solid) is lower than 30 mg / L, PH maintains at around 7, and effects of governing air pollutants and water pollutants are realized.

Owner:COAL IND JINAN DESIGN & RES

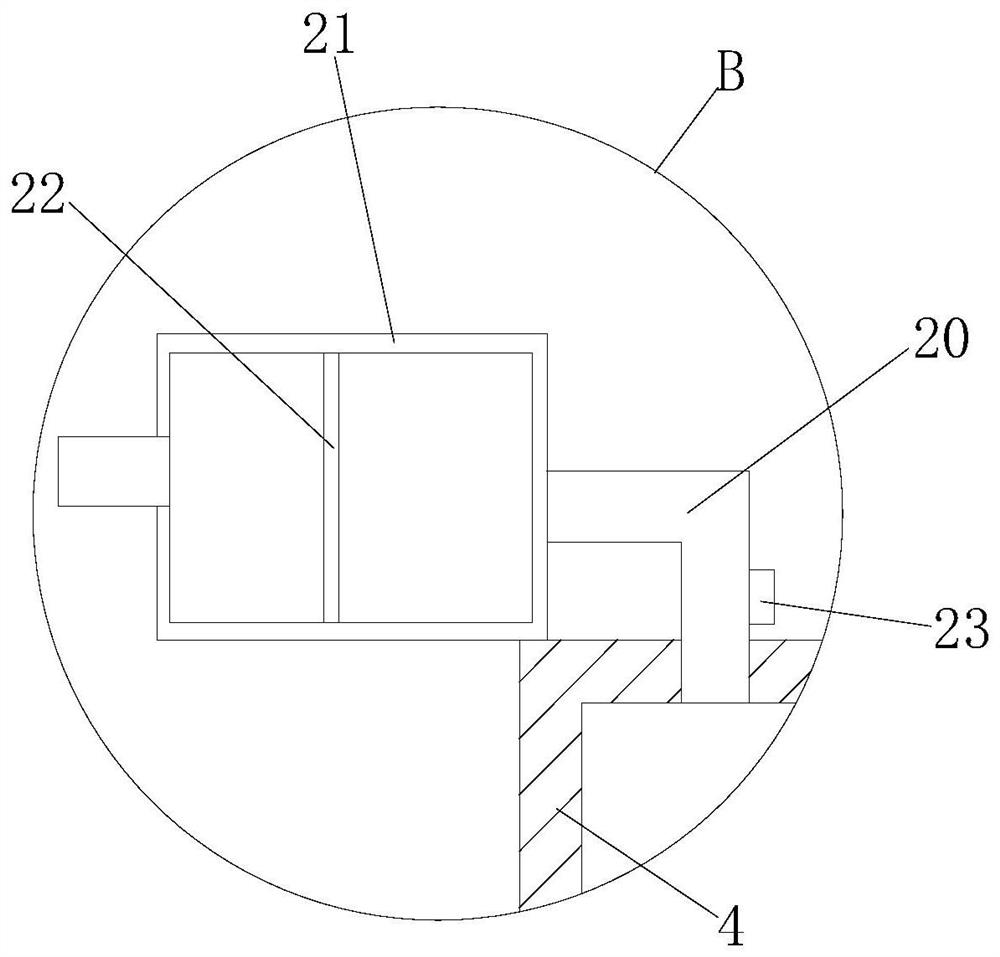

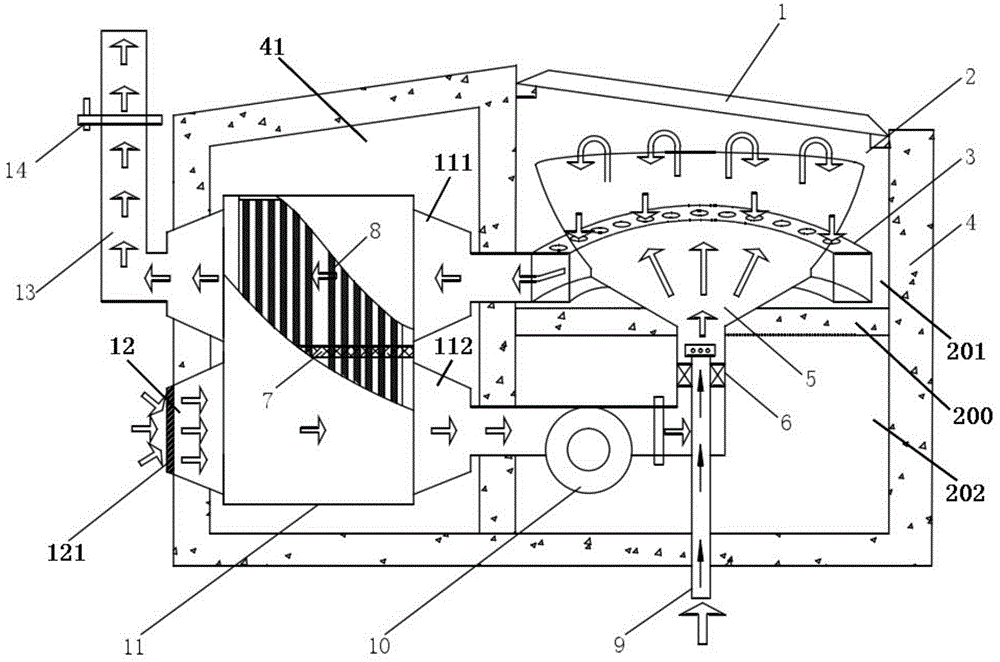

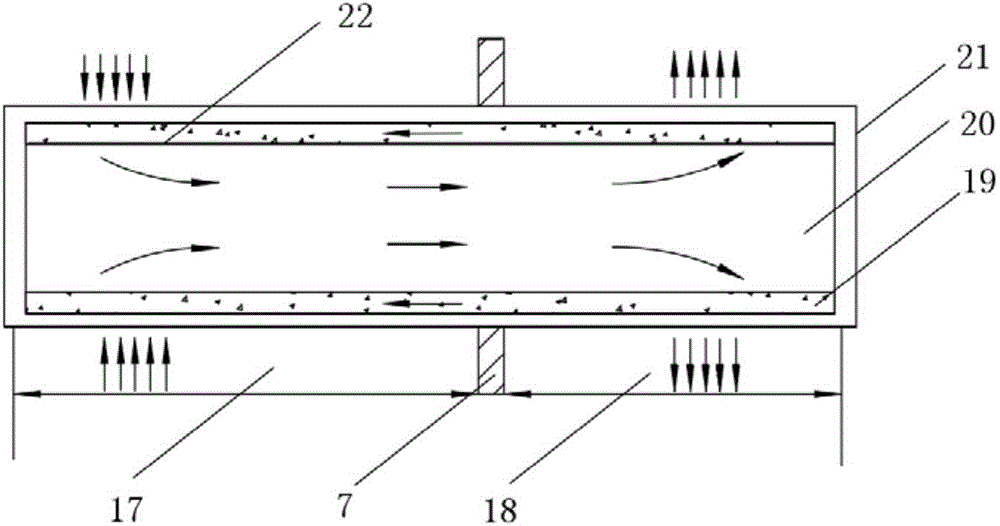

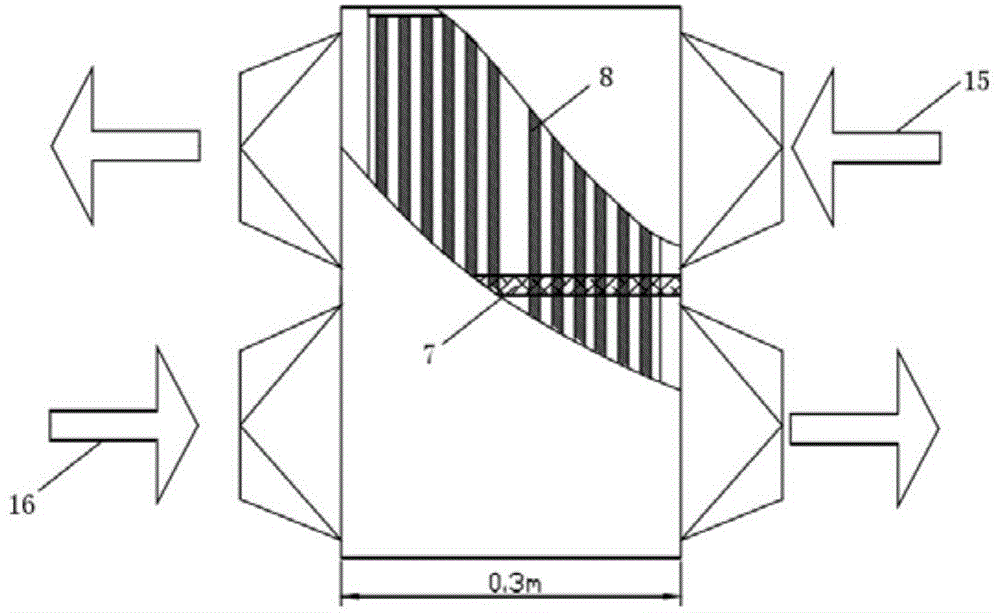

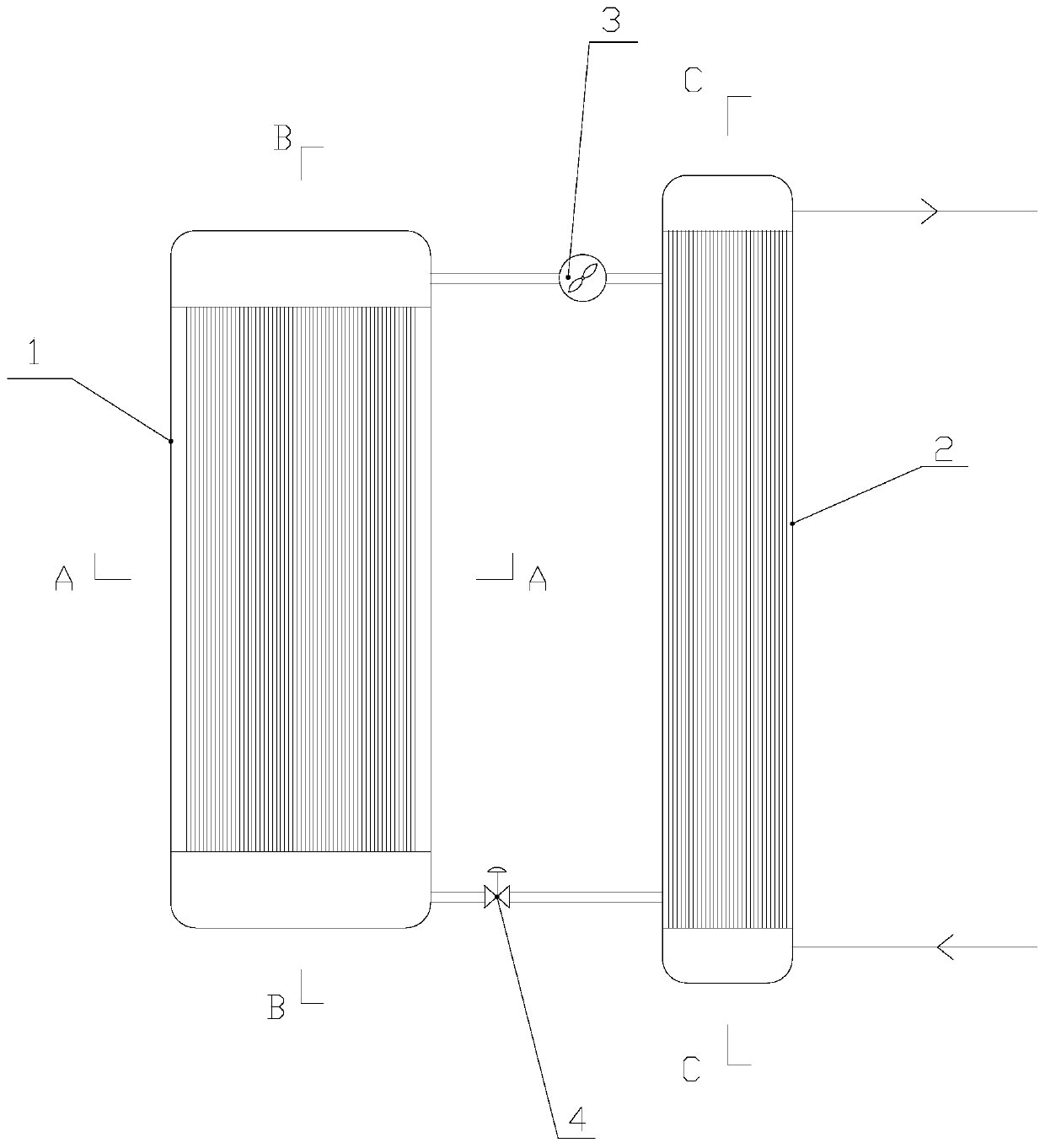

An energy storage constant temperature water system suitable for high temperature and high load thermal printers

ActiveCN112208219BGood thermal controlImprove stabilityRecuperative heat exchangersPrintingTemperature controlComputer printing

The invention relates to an energy-storage constant-temperature water system suitable for high-temperature and high-load thermal printers, which controls the constant temperature of the thermal print head and recycles the waste heat generated during its work. The constant-temperature water circuit ensures constant temperature of the constant-temperature water Refrigerant circuit, and the chilled water circuit on the evaporator side that recycles the cooling capacity of the refrigerant or discharges the heat of the refrigerant. The invention recycles and utilizes a large amount of waste heat generated by the thermal print head when the thermal printer is working, and also recycles and utilizes the cold generated on the evaporator side when heating the constant temperature water, reduces the total energy consumption of the thermal printer, and improves the energy consumption. The utilization rate of the thermal printer improves the stability of the constant temperature water temperature of the thermal printer, and ensures that the thermal printer can also work normally under the condition of continuous long-term operation.

Owner:SOUTHEAST UNIV

Process and system for preparing acid by combining sulfur and exhaust gas obtained in viscose exhaust gas TRS (total reduced sulfur) recovery

The invention relates a process for preparing acid by combining sulfur and exhaust gas obtained in viscose exhaust gas TRS (total reduced sulfur) recovery. According to the process, the defects of theexisting exhaust gas acid preparation system that the stable operation is affected by the defect of a raw material post, and the cost is too high, are made up; meanwhile, sulfur produced by a viscoseexhaust gas TRS recovery technology is effectively utilized, the problem TRS cannot be processed by a conventional technology as the TRS contains more complex iron impurities is solved, therefore, the development of a circular economy technology of a company is achieved.

Owner:宜宾海翔化工有限责任公司

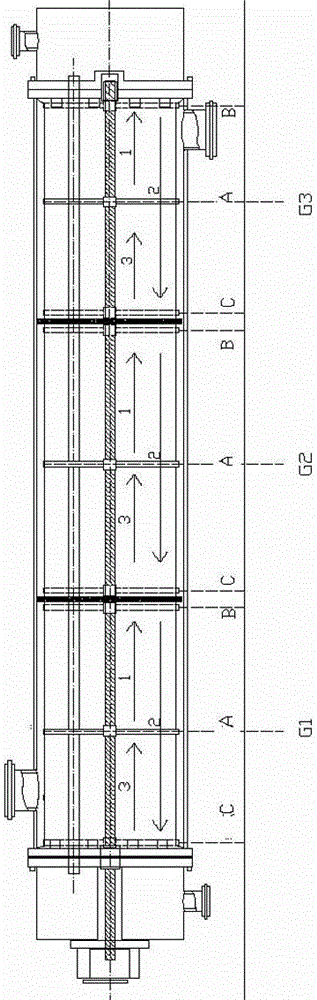

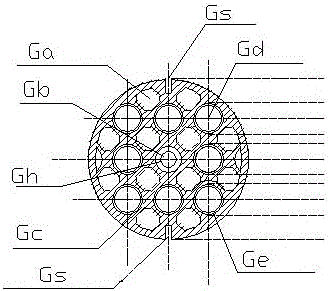

Housing-and-tube heat exchanging device

InactiveCN106568345AGuaranteed heat exchange effectRealize waste heat recovery and utilizationChemical industryStationary tubular conduit assembliesSoftened waterSewage

The invention relates to a housing-and-tube heat exchanging device. The technical scheme is that a plurality of groups of heat exchanging tubes arranged in an inner cavity of a housing; two ends of the heat exchanging tubes are fixed connected through tube plates; a waste water inlet and a softened water outlet are formed in one end of the housing, and a softened water inlet and a waste water outlet are formed in one end of the housing; the softened water outlet, the heat exchanging tubes and the softened water inlet communicate with each other; and the waste water inlet, the inner cavity of the housing and the waste water outlet communicate with each other. The technical problem that it is difficult to completely clean the conventional housing-and-tube heat exchanging devices can be solved; the heat exchanging efficiency of the heat exchanger can be improved; and the service life of the heat exchanger is prolonged.

Owner:BEIJING RUNHUA WATER SUPPLY EQUIP FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com