Flue gas treatment system

A technology of flue gas treatment system and treatment section, which is applied in the field of waste heat boiler and industrial kiln flue gas treatment. It can solve the problems of high operating cost, high hardness of dust particles, and restrictions on the development of enterprises, so as to save desulfurization agent and occupy an area. Less, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

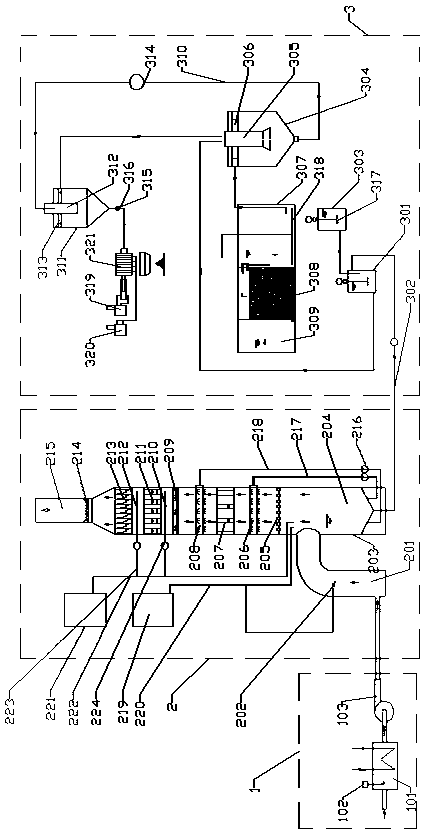

[0035] Accompanying drawing is the specific embodiment of the present invention. Such as figure 1 As shown, this kind of flue gas treatment system includes waste heat recovery section 1, washing and absorption section 2 and washing and absorption liquid treatment section 3, wherein:

[0036] The waste heat recovery section 1 includes a heat exchanger 101, which is used to lower the temperature of the exhaust gas from greater than 200°C to less than 150°C, and the recovered heat is used to produce hot water or steam for heating or other comprehensive utilization of flue gas after treatment. Install a soot blower 102 on the heat exchanger 101. The soot blower 102 is used to clean the heat exchange surface of the heat exchanger 101 to prevent fouling. The outlet end of the heat exchanger 101 is connected to a centrifugal fan 103 to improve exhaust The pressure is greater than 2000Pa to overcome the resistance of downstream equipment and facilities.

[0037] The washing and abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com