Efficient turbulence atomization mixing desulfurization and dust removal process based on rotational flow

A technology for desulfurization and dust removal, desulfurization and dust removal equipment, applied in the direction of combined devices, chemical instruments and methods, gas treatment, etc., can solve the problem that the gas phase components and liquid phase components cannot be fully contacted, the gas-liquid contact time cannot be effectively increased, and the smoke and dust cannot be sprayed Settlement and other problems, to achieve the effect of improving spray settlement efficiency, increasing contact area and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

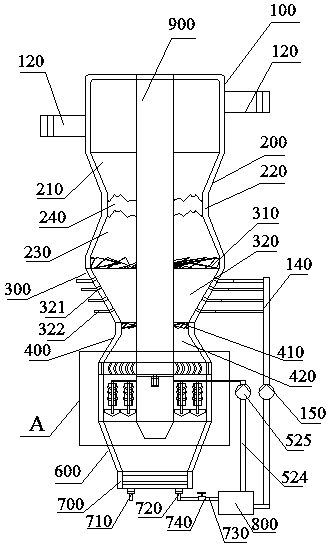

[0037] see Figure 1-8 As shown, this embodiment provides a swirl-based high-efficiency turbulent atomization mixed desulfurization and dust removal process, including the following steps:

[0038] S1. The smoke and dust enter the intake area 100 through the buffer pipe 130 and the intake pipe 120, and after flowing downward through the tapered section 210, the particles and gas components in the smoke and dust are compressed and collided, and the density increases. After entering the stable section 220, due to The arc-shaped concave section 242, the arc-shaped convex section 243, and the inclined-plane section 244 on the deflector are all run through with vertical guide holes 245. On the one hand, the arc-shaped concave section 242, the arc-shaped convex section 243, and the inclined-plane The curved surface structure of the section 244 makes the particles collide, increases the contact area, and after further increasing the contact time and density of the particles, the smok...

Embodiment 2

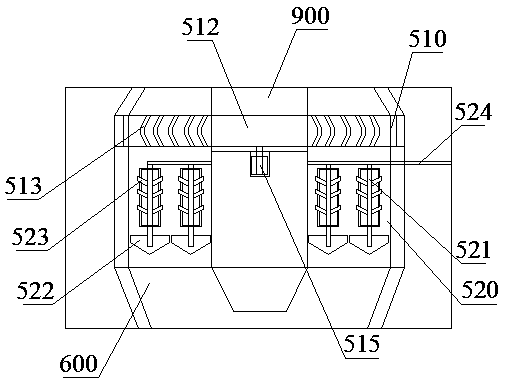

[0043] refer to Figure 1-8 As shown, this embodiment provides a high-efficiency turbulent atomization mixed desulfurization and dust removal equipment, which is suitable for the high-efficiency turbulent flow atomization mixed desulfurization and dust removal process based on swirling flow, including the intake area 100 and the diversion area 200 connected in sequence from top to bottom , the first swirl atomization area 300, the second swirl atomization area 400, the turbulent atomization area 500, the settling area 600, the waste liquid pool 700, the side of the waste liquid pool 700 is provided with a slurry pool 800, the slurry pool 800 Contains desulfurization slurry inside. The desulfurization slurry is selected from sodium hydroxide solution or calcium hydroxide solution with a pH value of 7-8.

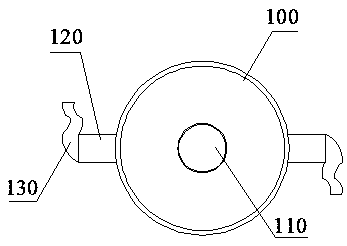

[0044] The air intake area 100 is cylindrical and has an exhaust port 110 on the top, and the bottom of the exhaust port 110 is installed with the air intake area 100, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com