Patents

Literature

52results about How to "High desulfurization and dust removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive treatment method of sulfur-containing flue gas

ActiveCN101637685BImprove purification qualityAchieving zero emissionsCombination devicesUsing liquid separation agentChemical industryFlue gas

Owner:CHENGDU DEMEI ENG TECH

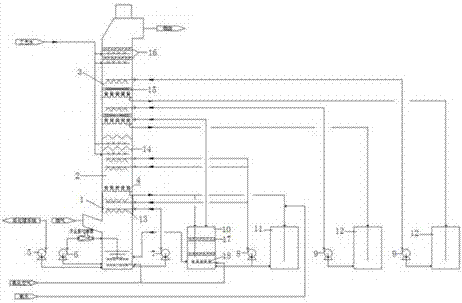

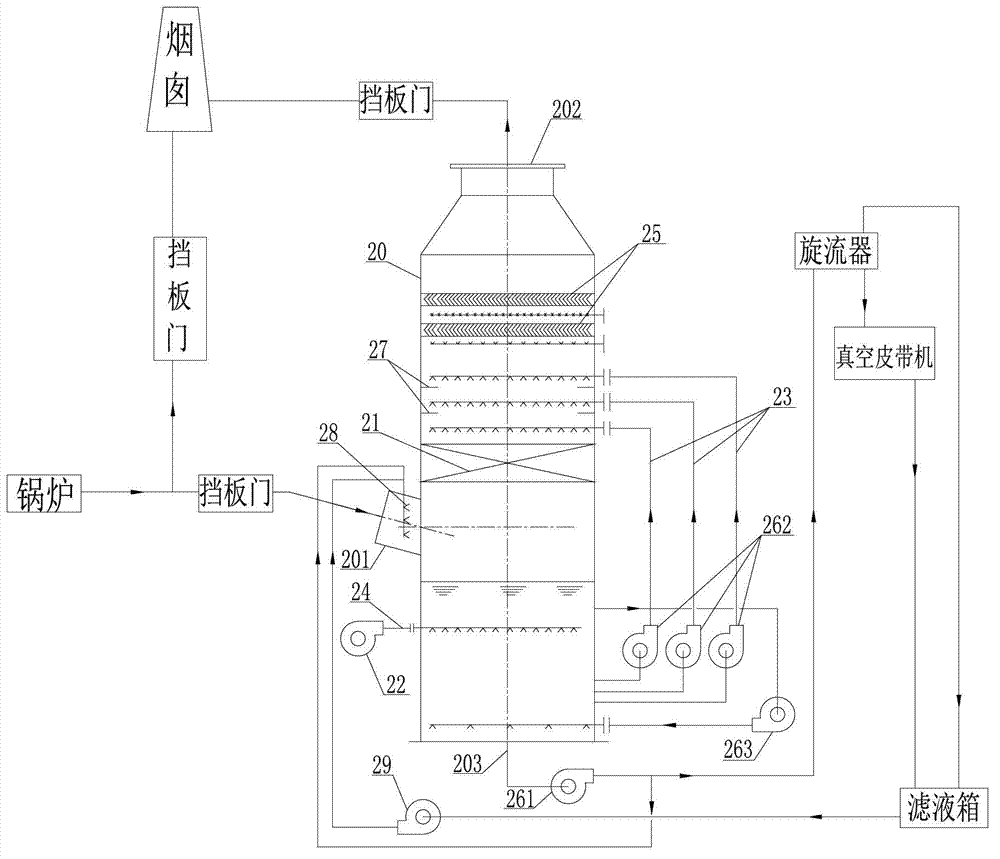

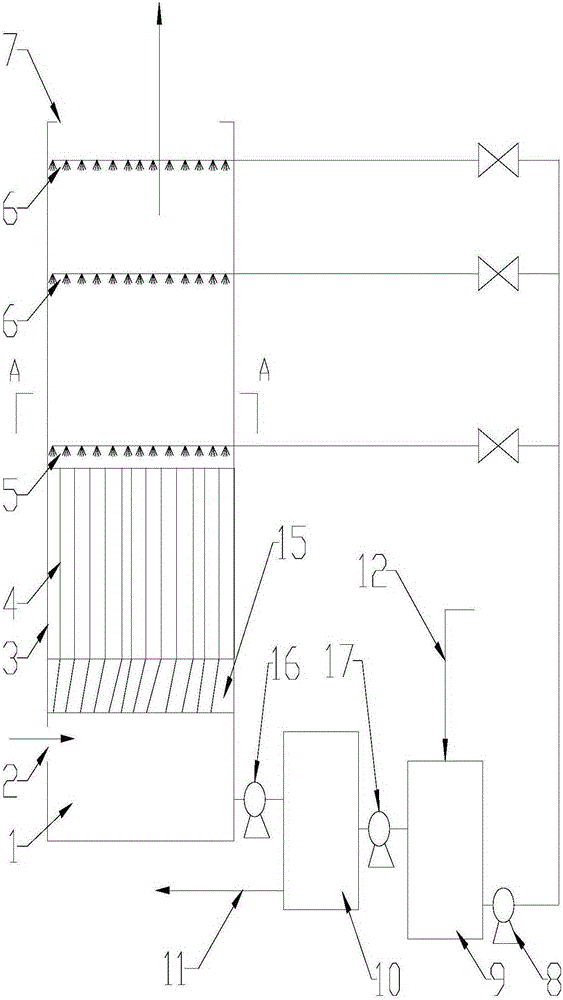

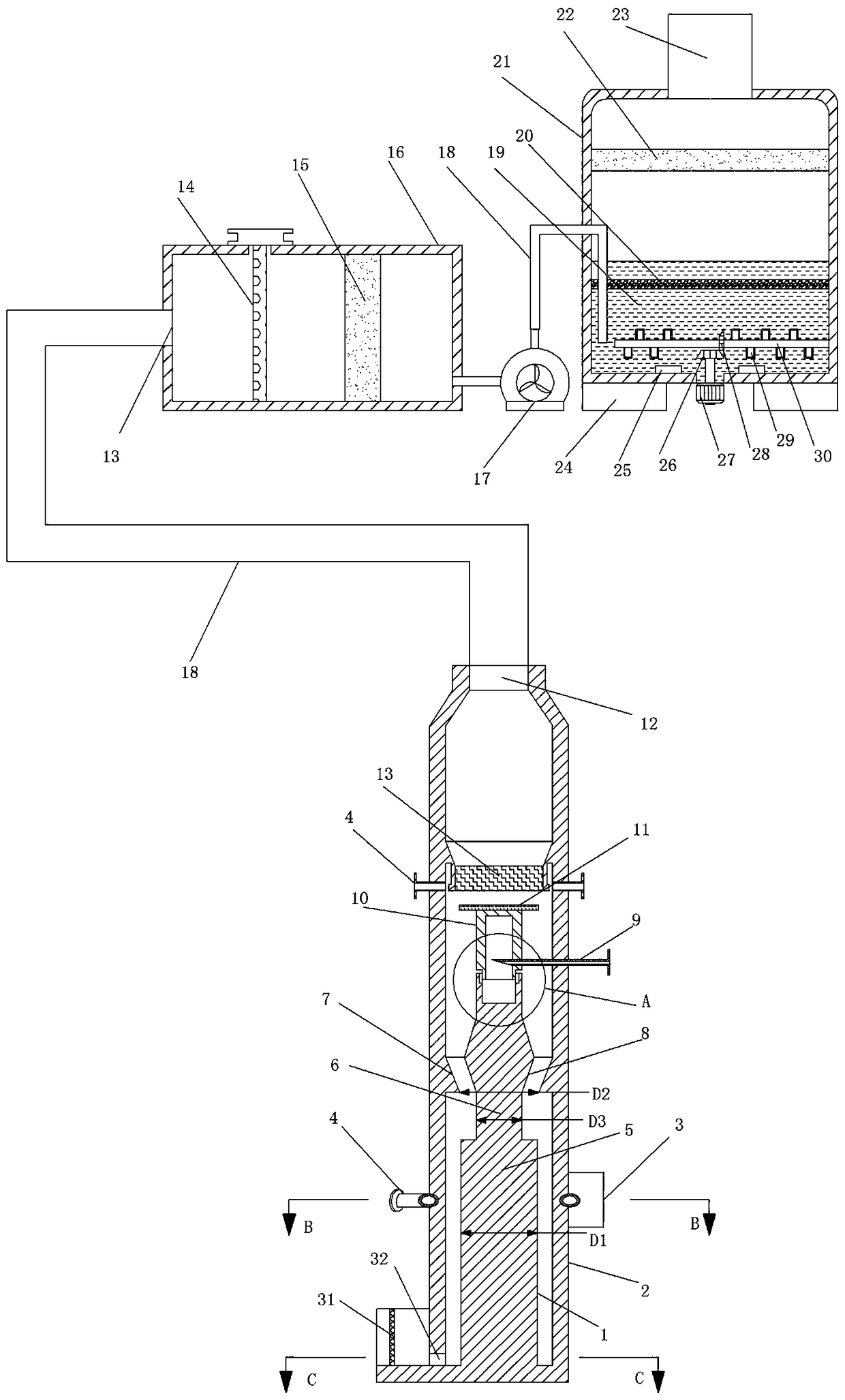

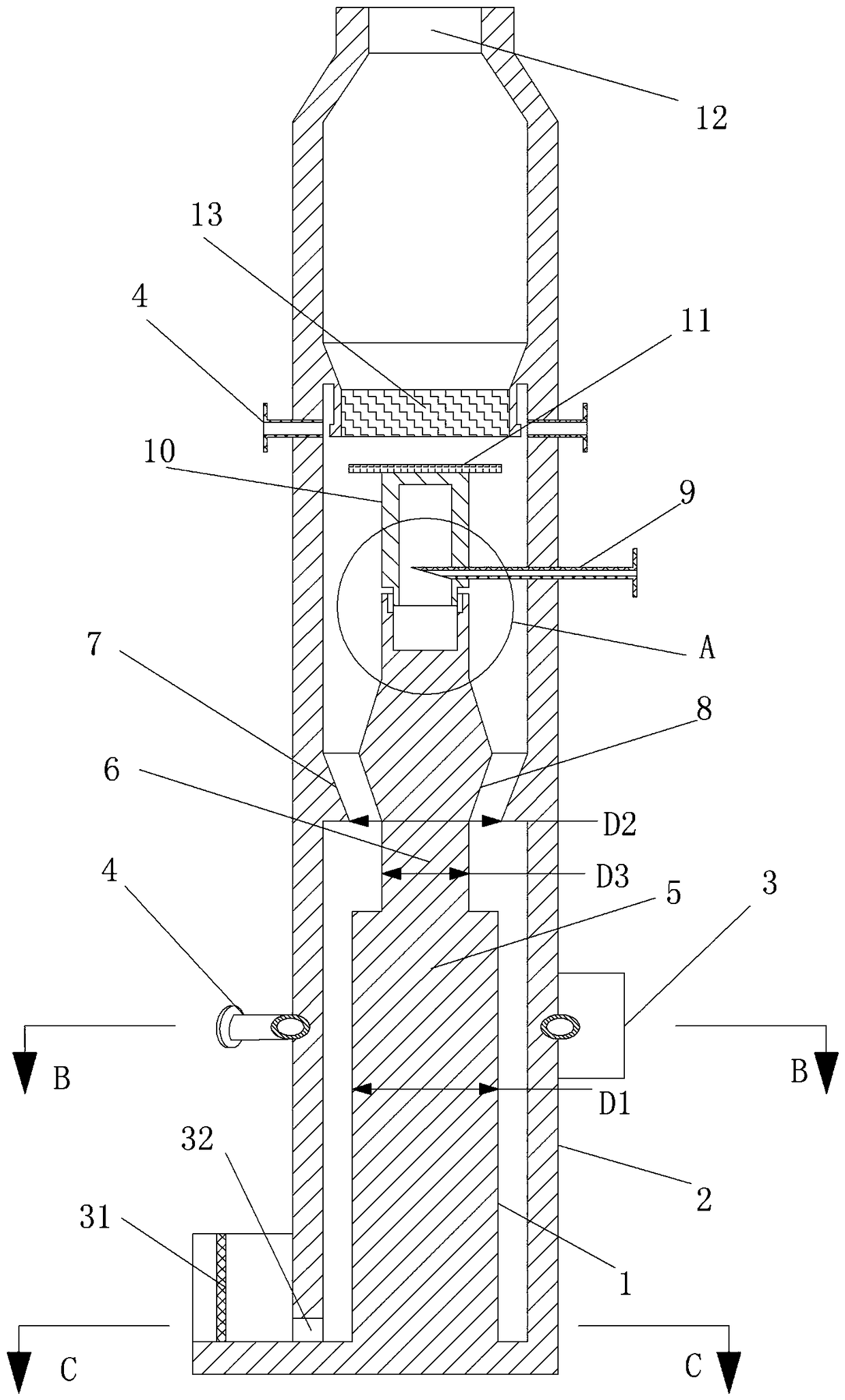

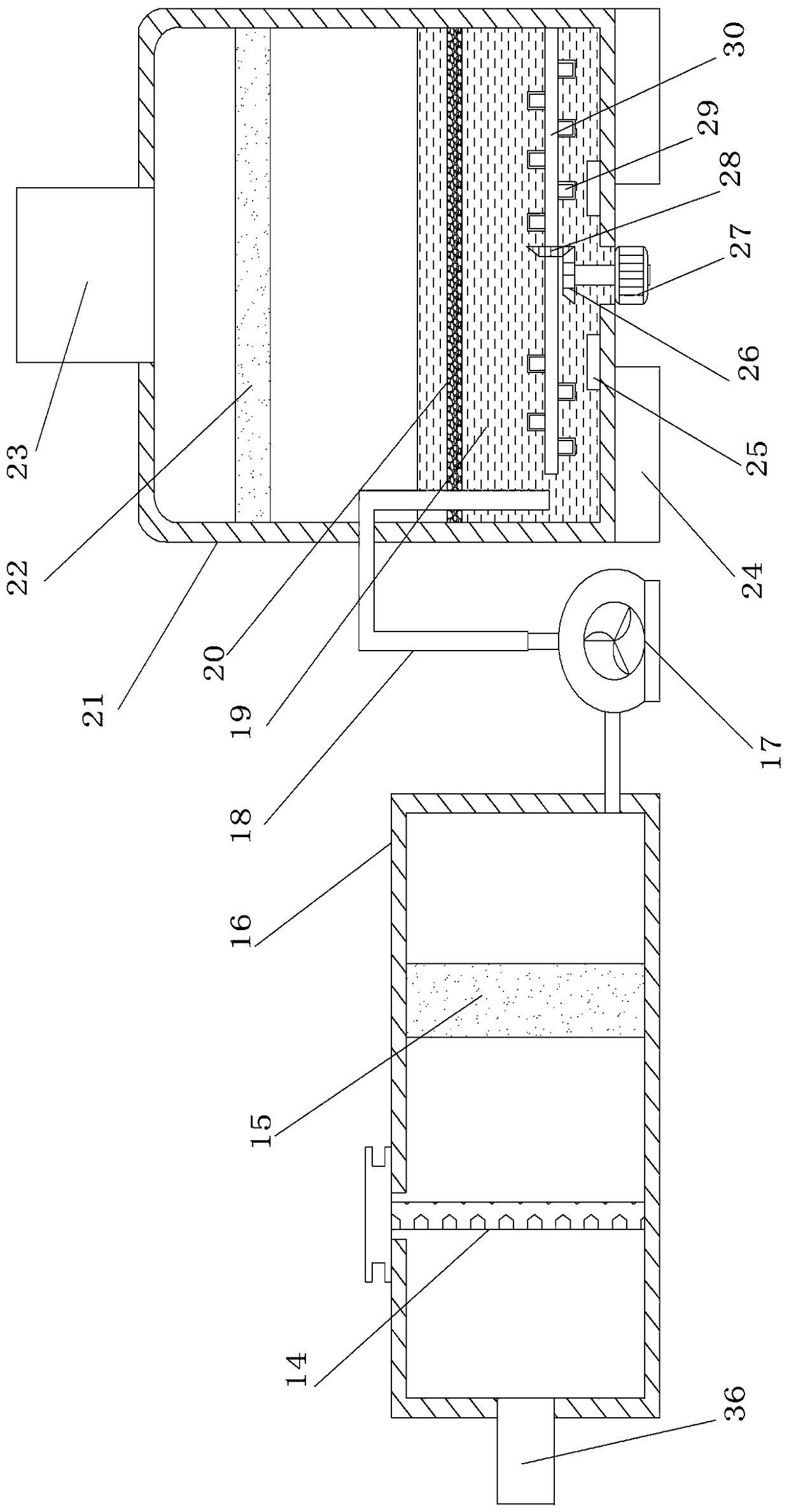

DDC (Desulfurization-Dedusting-Cleansing) process and device for flue gas multi-pollutant ultra-low ammonia emission

InactiveCN106925090AIncrease oxidation rateHigh removal rateCombination devicesGas treatmentMulti pollutantTower

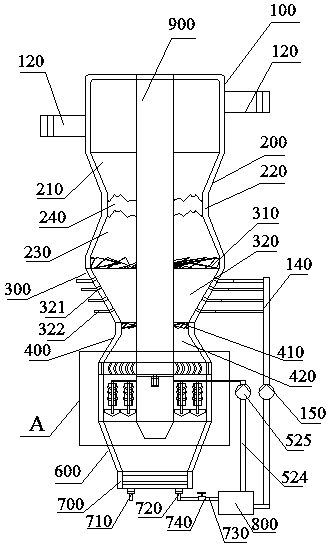

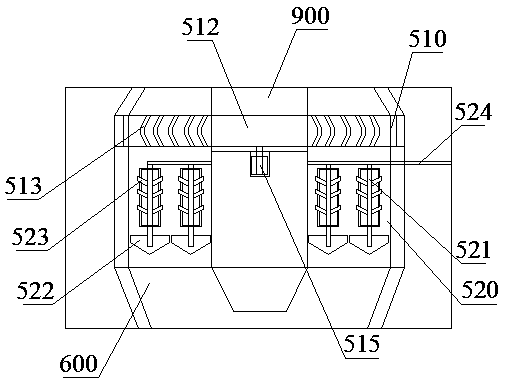

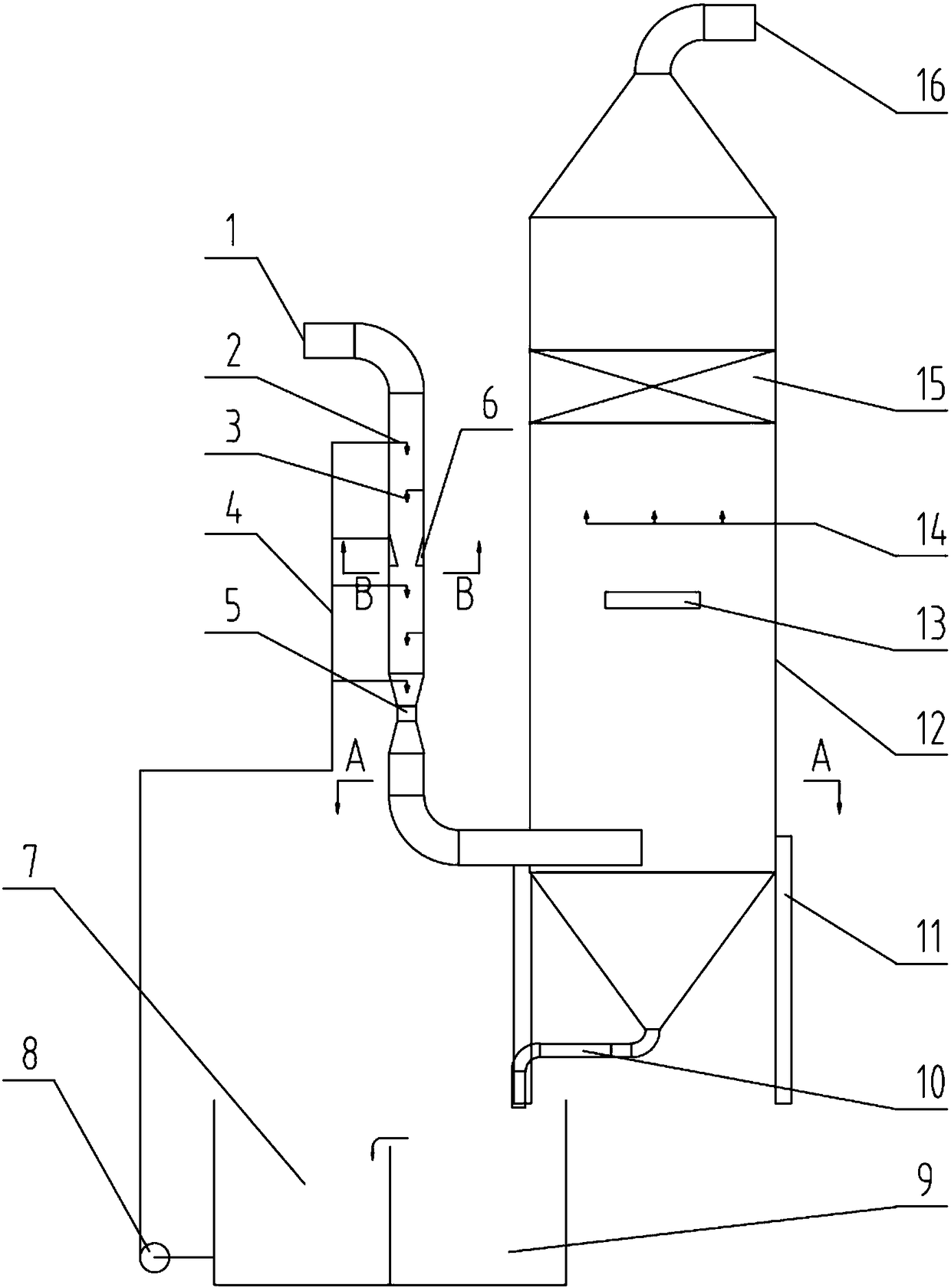

The invention discloses a DDC (Desulfurization-Dedusting-Cleansing) process and device for flue gas multi-pollutant ultra-low ammonia emission. Flue gas is sequentially treated in the following steps to be changed into purified flue gas and then discharged: on a concentration section, spraying the flue gas by an ammonium sulfate solution so as to produce mist and concentrated solution; on an absorber section, spraying mist by an ammonium sulfite solution, absorbing SO2 in the mist, and producing desulfurized mist and absorption liquid; on a purifying, dedusting and demisting section, washing and electrically decontaminating the desulfurized mist, and producing purified flue gas and scrubbing solution. According to the flowing direction of the flue gas, a core tower of the device is divided into three function areas which are isolated from one another by virtue of tower plates, and the different function areas are mutually communicated through cyclone demisting riser caps on the tower plates. The three function areas respectively form three independent circulation loops with an external tank through pumps and pipelines. The device is scientific in design, compact in arrangement and high in desulfurization and dedusting efficiency, and formation of aerosol and a tailing drop phenomenon of the flue gas can be eliminated. The process and the device disclosed by the invention can realize long-term stable operation, realize ultra-low emission and have excellent practicality and wide applicability.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

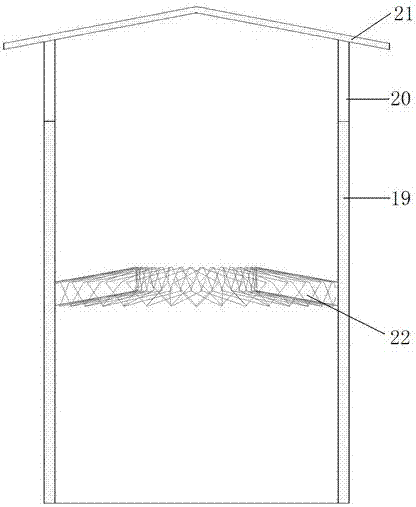

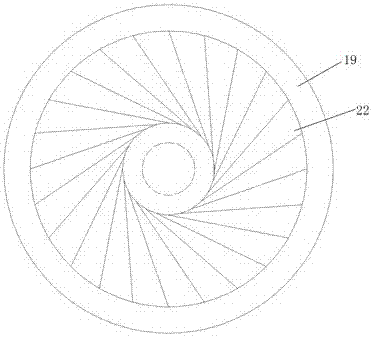

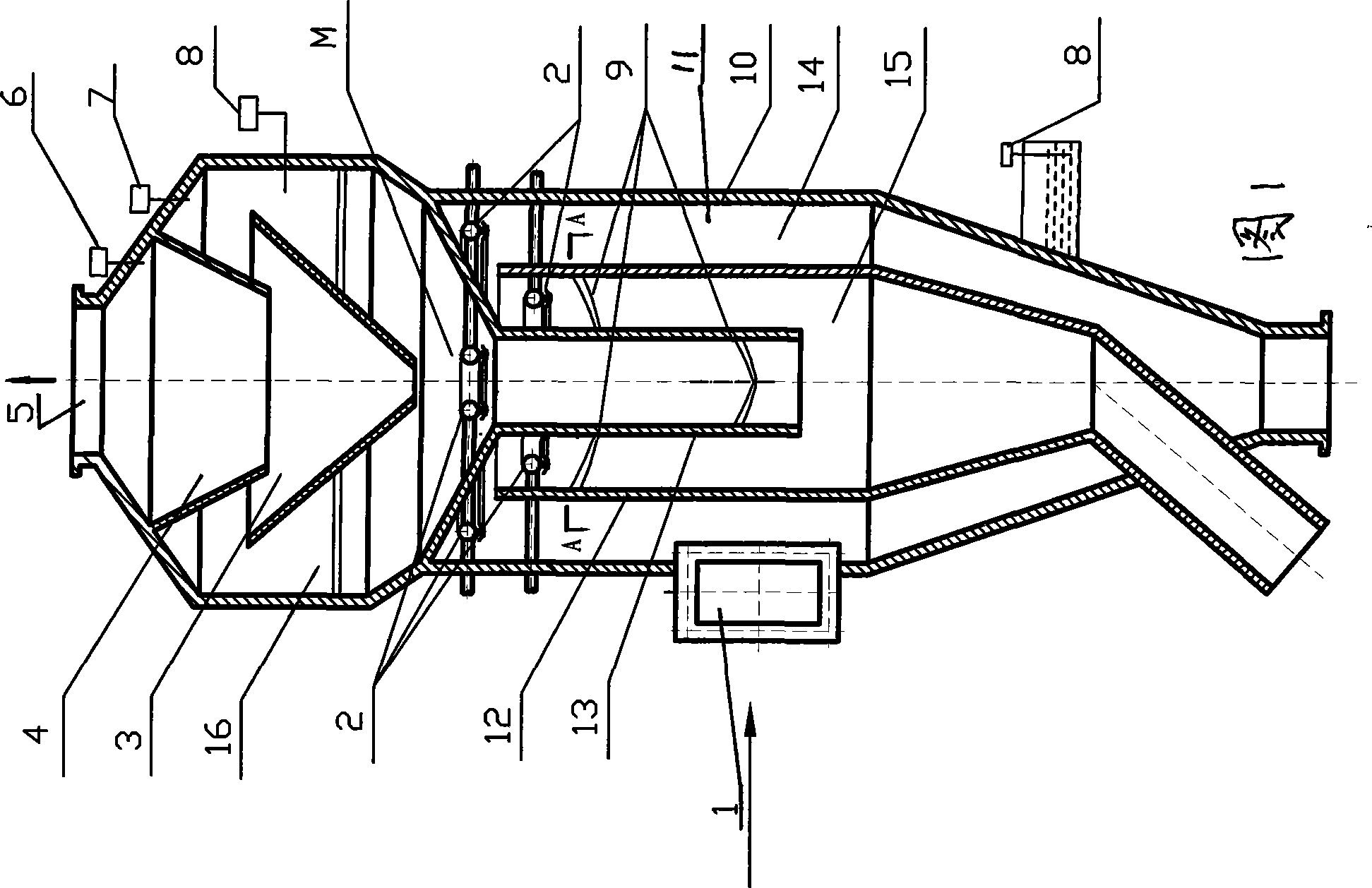

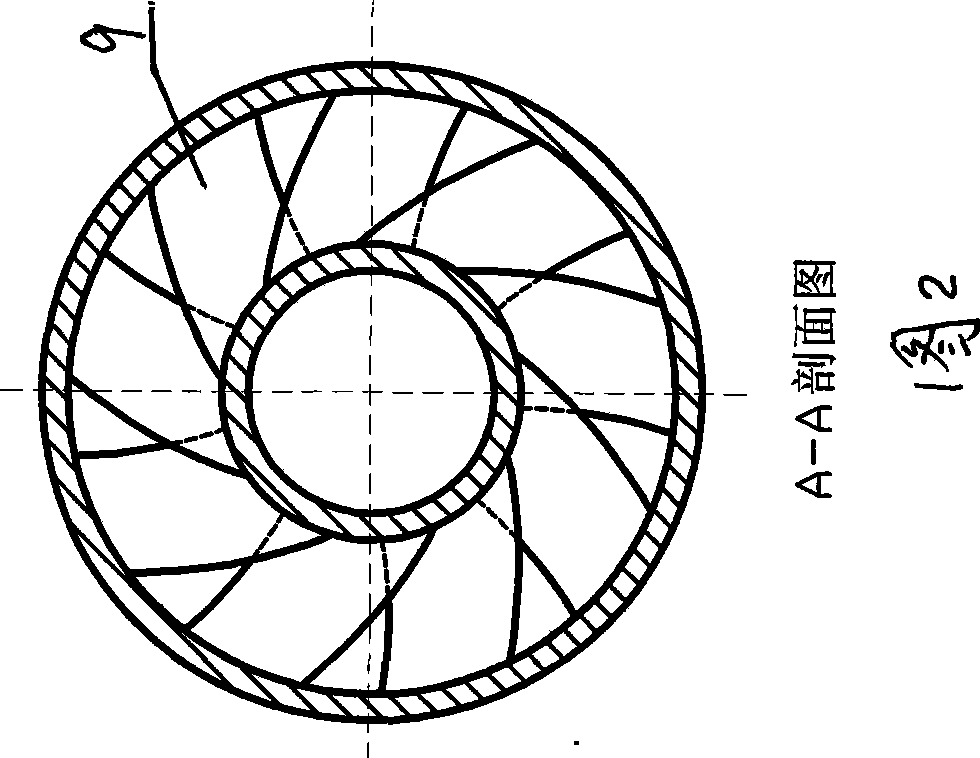

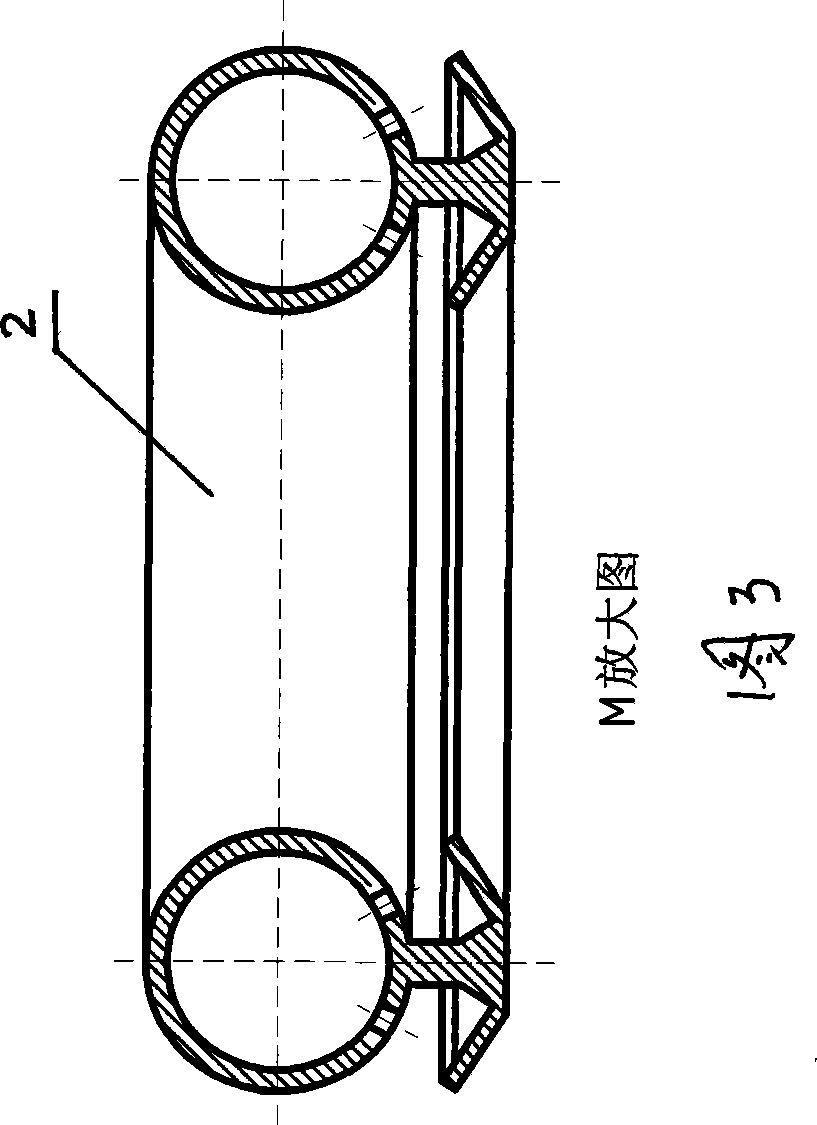

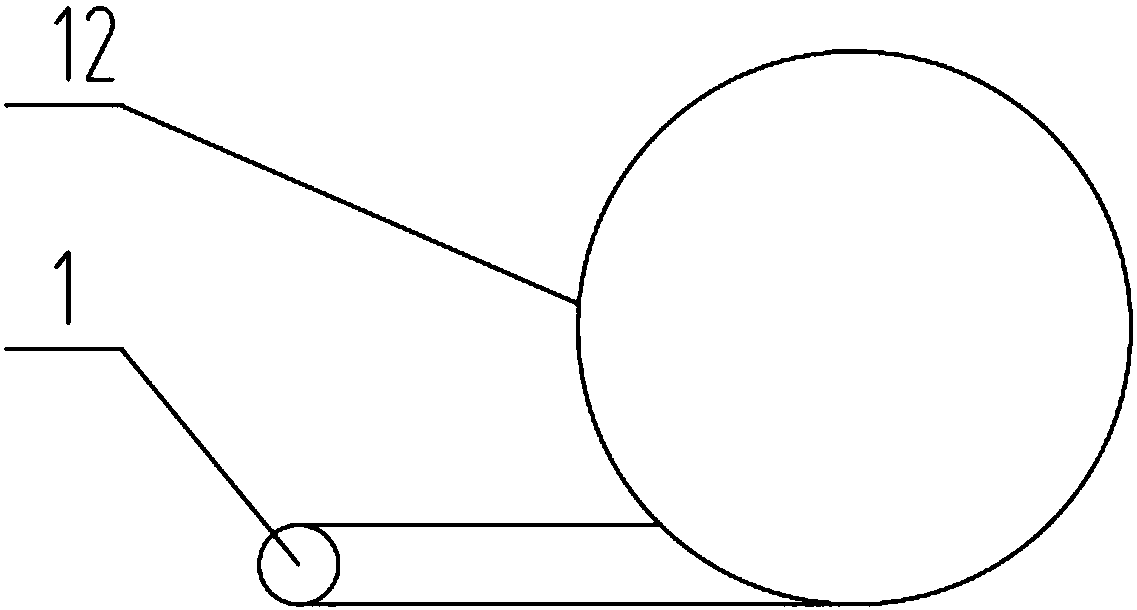

Turbulent ball type turbocharging compound desulfurization dust removal tower

ActiveCN102805999AIncrease contact timeFully contactedUsing liquid separation agentBall typeEngineering

The invention relates to a turbulent ball type turbocharging compound desulfurization dust removal tower, which belongs to the technical field of gas purification and comprises a spraying tower body, a gas inlet, a smoke outlet, a slurry discharger, a slurry discharge pump, a Roots blower, multilayer spraying pipes, an annular separation plate, a circulation pump, a demister, a disturbance pump and a plurality of turbulent ball type turbocharging acceleration smoke gas desulfurization dust removal devices, wherein the turbulent ball type turbocharging acceleration smoke gas desulfurization dust removal devices are arranged in the tower and respectively comprise a casing, a pipeline, upper and lower porous end plates, a turbulent ball and a plurality of blades, the pipeline is fixedly arranged in the center of the casing, the upper and lower porous end plates are respectively arranged at the upper end and the middle part of the casing, the turbulent ball is filled in the space between the upper and lower porous end plates, the blades are arranged between the porous end plates and the pipeline, the upper end of each blade is connected with the inner wall of the casing, the lower end of each blade is connected with the outer wall of the pipeline, and the lower end of the casing is connected with a smoke shielding cover. The turbulent ball type turbocharging compound desulfurization dust removal tower has the advantages that the full gas and liquid contact can be realized under the conditions of the shortest time, the smallest space and the lowest liquid-gas ratio, the high-speed mass transfer is carried out, and the high dust removal and desulfurization efficiency can be improved at the minimum energy consumption.

Owner:北京威肯泛联能源科技有限公司

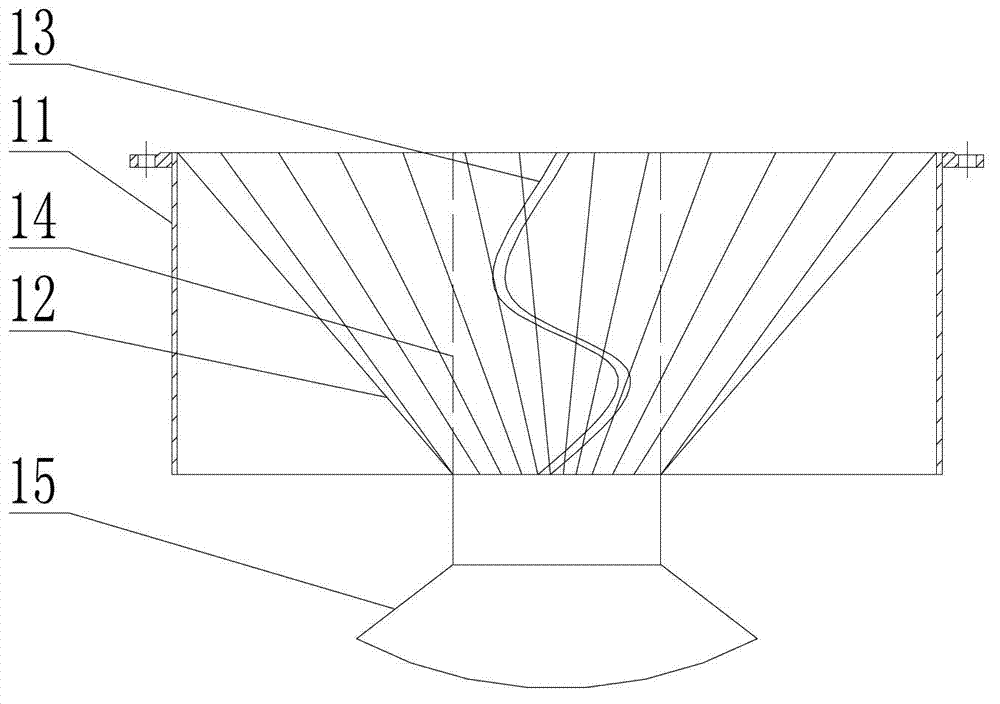

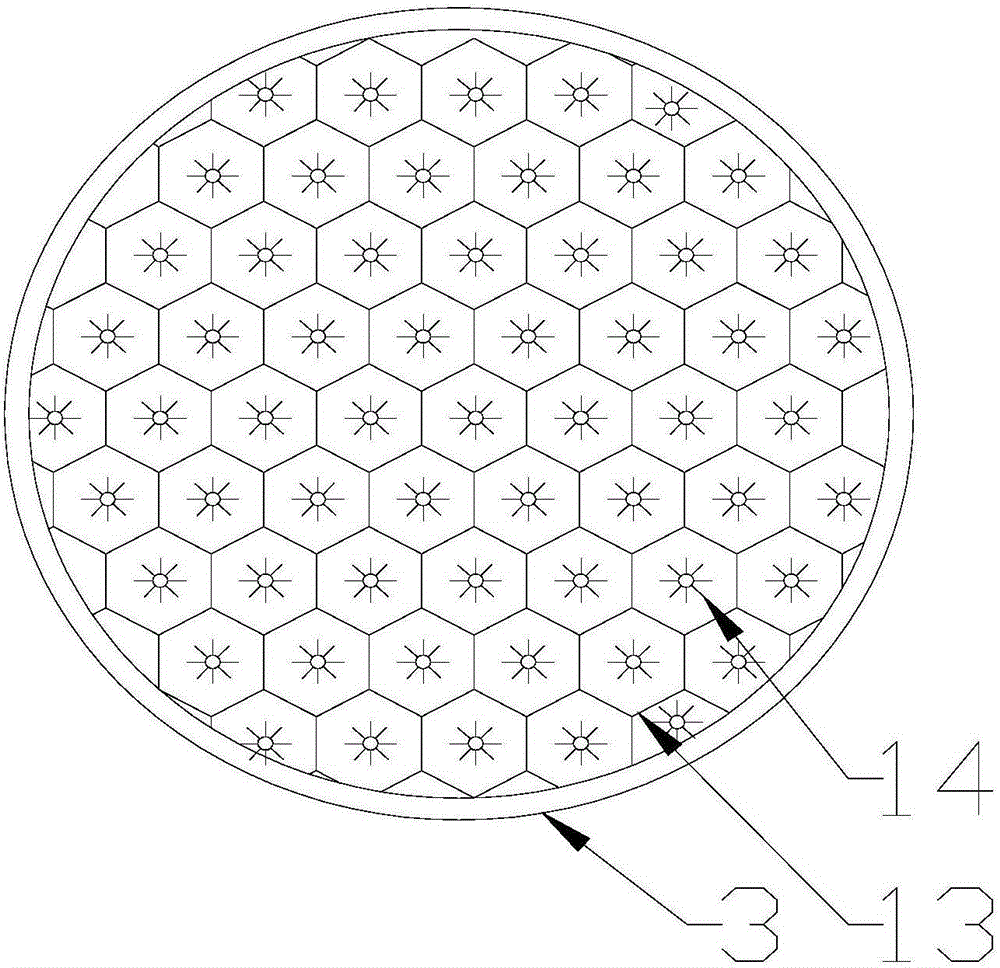

Desulfurization and dedusting absorption tower with porous current equalizer

ActiveCN105617852AHigh desulfurization and dust removal efficiencyEvenly distributedGas treatmentUsing liquid separation agentFlue gasContact time

The invention discloses a desulfurization and dedusting absorption tower with a porous current equalizer. The desulfurization and dedusting absorption tower comprises a tower body, at least one sprayer and at least one porous current equalizer, wherein the tower body is provided with a flue gas inlet and a flue gas outlet; the sprayer is arranged in the tower body, is positioned between the flue gas inlet and the flue gas outlet and is used for spraying slurry; the porous current equalizer comprises a porous current equalizing plate, is arranged in the tower body and is positioned above the flue gas inlet and above the sprayer, and a plurality of airflow holes for flue gas as well as the slurry to pass through are formed in the porous current equalizing plate; when the desulfurization and dedusting absorption tower is in use, the upper surface of the porous current equalizing plate receives the slurry sprayed by the sprayer and forms a slurry holding layer; when the flue gas passes through the slurry holding layer, a bubbling phenomena occurs, so that the contact area and the contact time between the flue gas and the slurry in the slurry holding layer are effectively increased, the slurry can fully absorb sulfides in the flue gas as well as dust, and further, the desulfurization and dedusting efficiency of the desulfurization and dedusting absorption tower is effectively improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

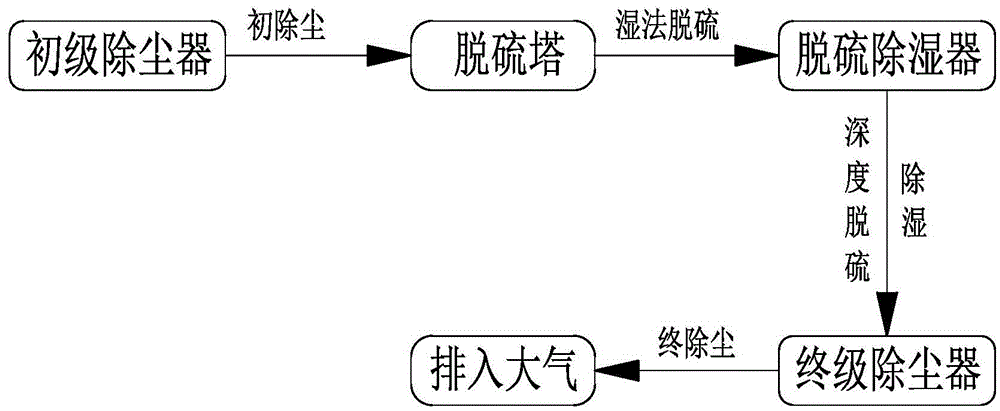

Deep purification method and device of flue gas after wet-process desulfurization

ActiveCN105642104AHigh desulfurization and dust removal efficiencyProcess stabilityCombination devicesGas treatmentChemistryCalcium hydroxide

Owner:潍坊天洁环保科技有限公司

Integrated wet flue gas desulphurization and dust removal device and method

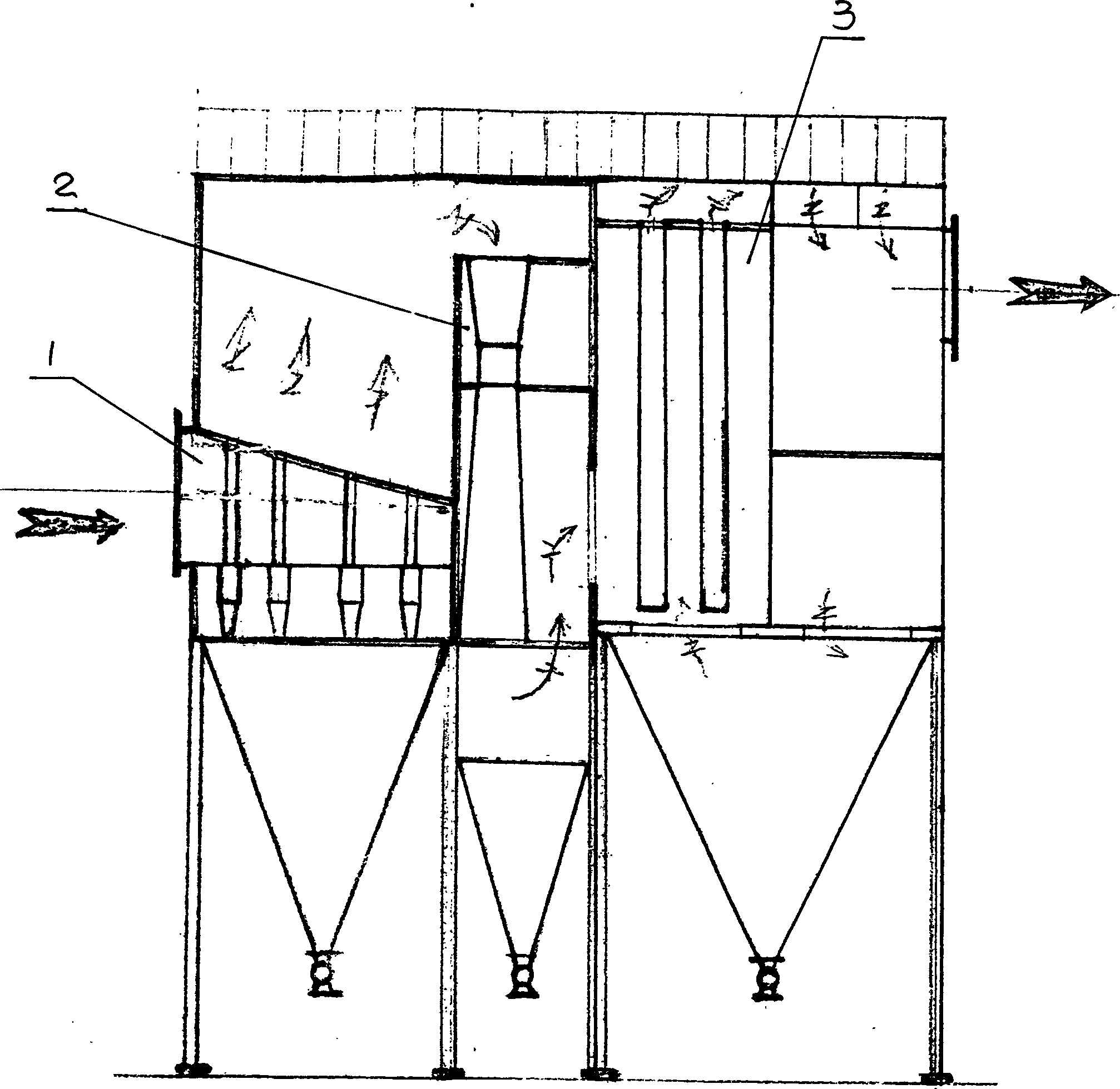

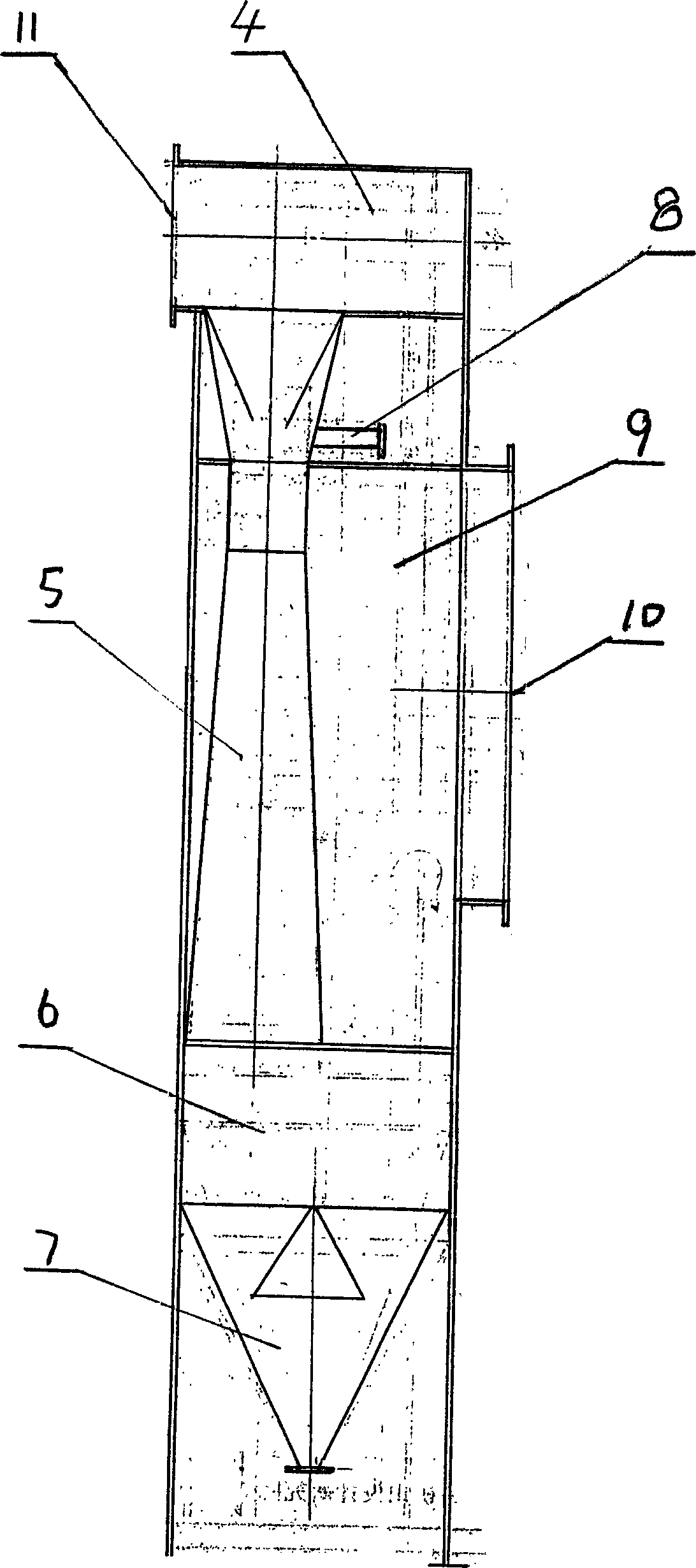

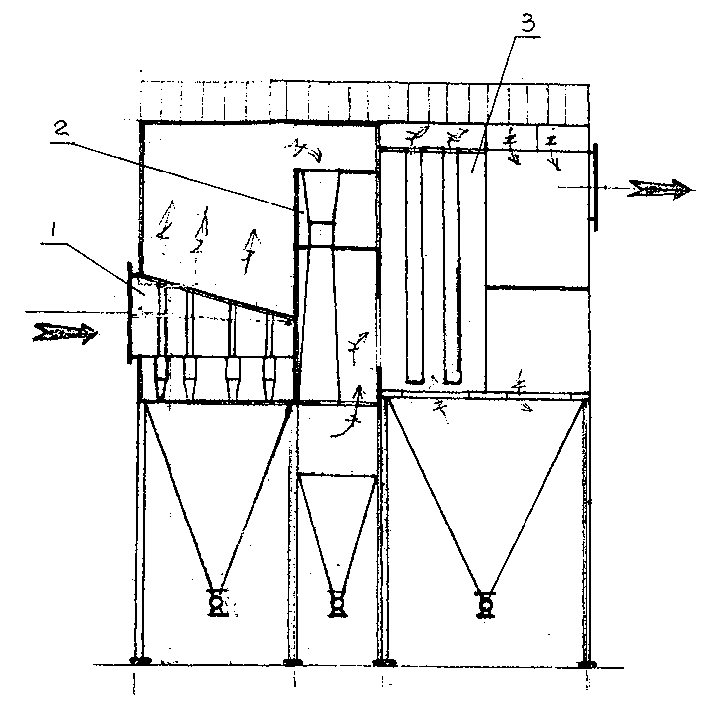

InactiveCN105214465AReduce processingReduce emission concentrationDispersed particle separationExternal electric electrostatic seperatorInlet channelFlue gas

The invention provides an integrated wet flue gas desulphurization and dust removal device and method. The integrated wet flue gas desulphurization and dust removal device is formed by combining an alkaline desulphurization device on the upper portion and a tubular electrostatic precipitation device on the lower portion, and comprises a cylinder. A flue gas inlet channel is formed in one side of the bottom of the cylinder, a buffer pond is arranged in the bottom space of the cylinder, a gas uniform distribution plate is arranged above the flue gas inlet channel, an electrostatic precipitation area is arranged above the gas uniform distribution plate, upper spray pipes and a lower spray pipe are connected with an outlet of a booster pump through pipelines, an inlet of the booster pump is connected with the bottom of a neutralization pond, an alkali liquor addition pipeline is arranged at the top of the neutralization pond, the top of the neutralization pond is connected with an outlet pipeline of a booster pump b, an inlet pipeline of the booster pump b is connected with the middle of a sedimentation pond, the bottom of the sedimentation pond is connected with a waste liquor outlet through a pipeline, the top of the sedimentation pond is connected with an outlet of a booster pump a, and an inlet pipeline of the booster pump a is connected with the bottom of the buffer pond. The device and method mainly solve the problems that the efficiency of desulphurization and dust removal of tail flue gas of industrial boilers is low, energy consumption is high, and the utilization rate of waste water is low.

Owner:李继凤

Combined two-stage flue gas desulfurization and dust-eliminating process

InactiveCN1454699ASimple processBest matchCombination devicesUsing liquid separation agentSulfurEngineering

The invention refers to a compound double-grade smoke desulfurizing and dust eliminating process which can desulfurize sulfur and eliminate dust effectively. It is made up of the first, the second and the third parts: the first part is ceramics multi-pipe dust catcher or electrostatic dust catcher, it carries on the first grade dust eliminating, it eliminates 90-99% dust in the smoke; the second part is venturi drying and absorbing tower, the sulfur in smoke reacts with desulfurizing liquid and is absorbed, realizes the first grade desulfurizing; the third part is bag desulfurizing and dust catcher, it eliminates the resultant in desulfurizing reaction and carries on secondary dust eliminating to the tiny particles in smoke.

Owner:樊金鑫

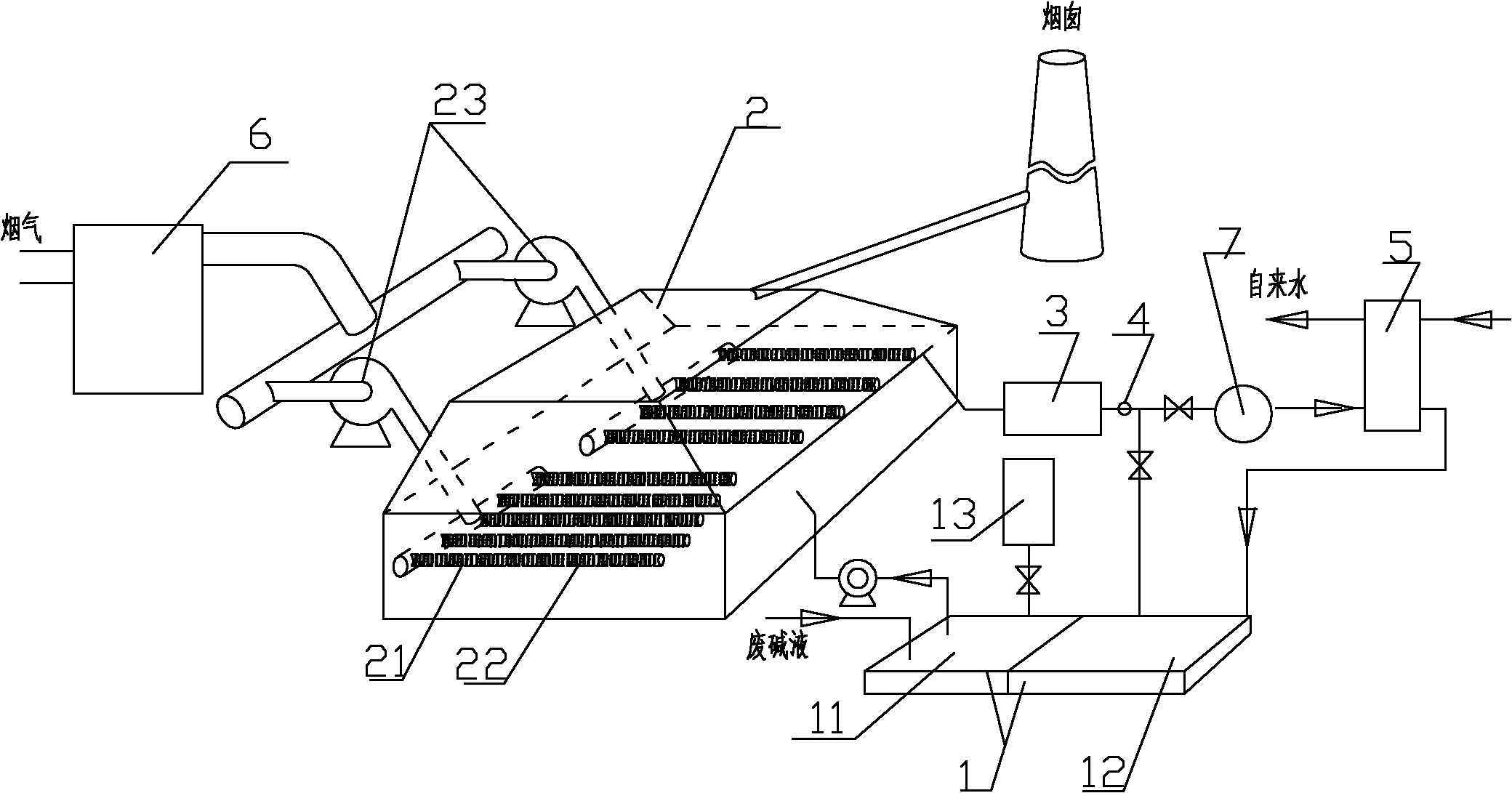

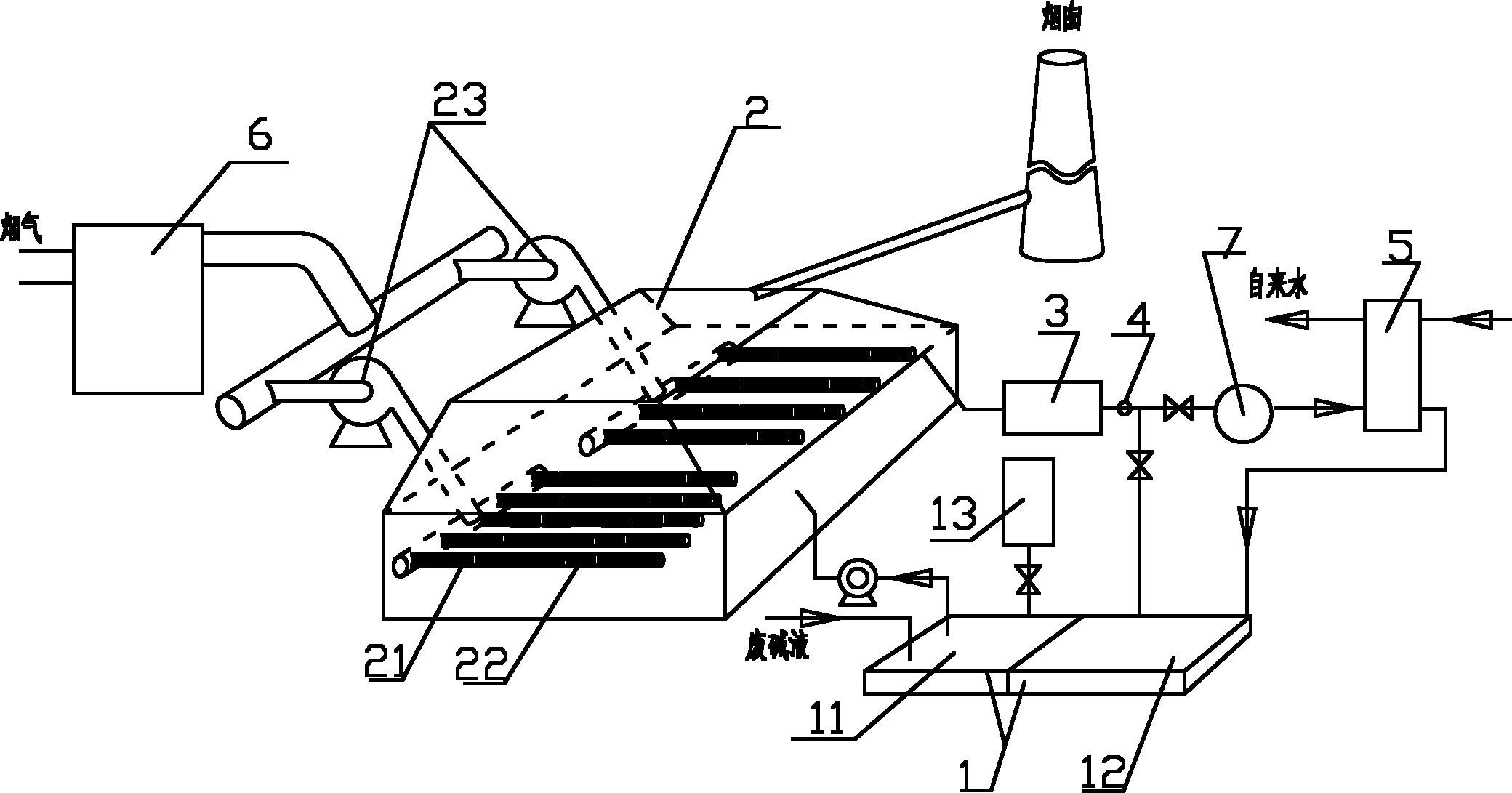

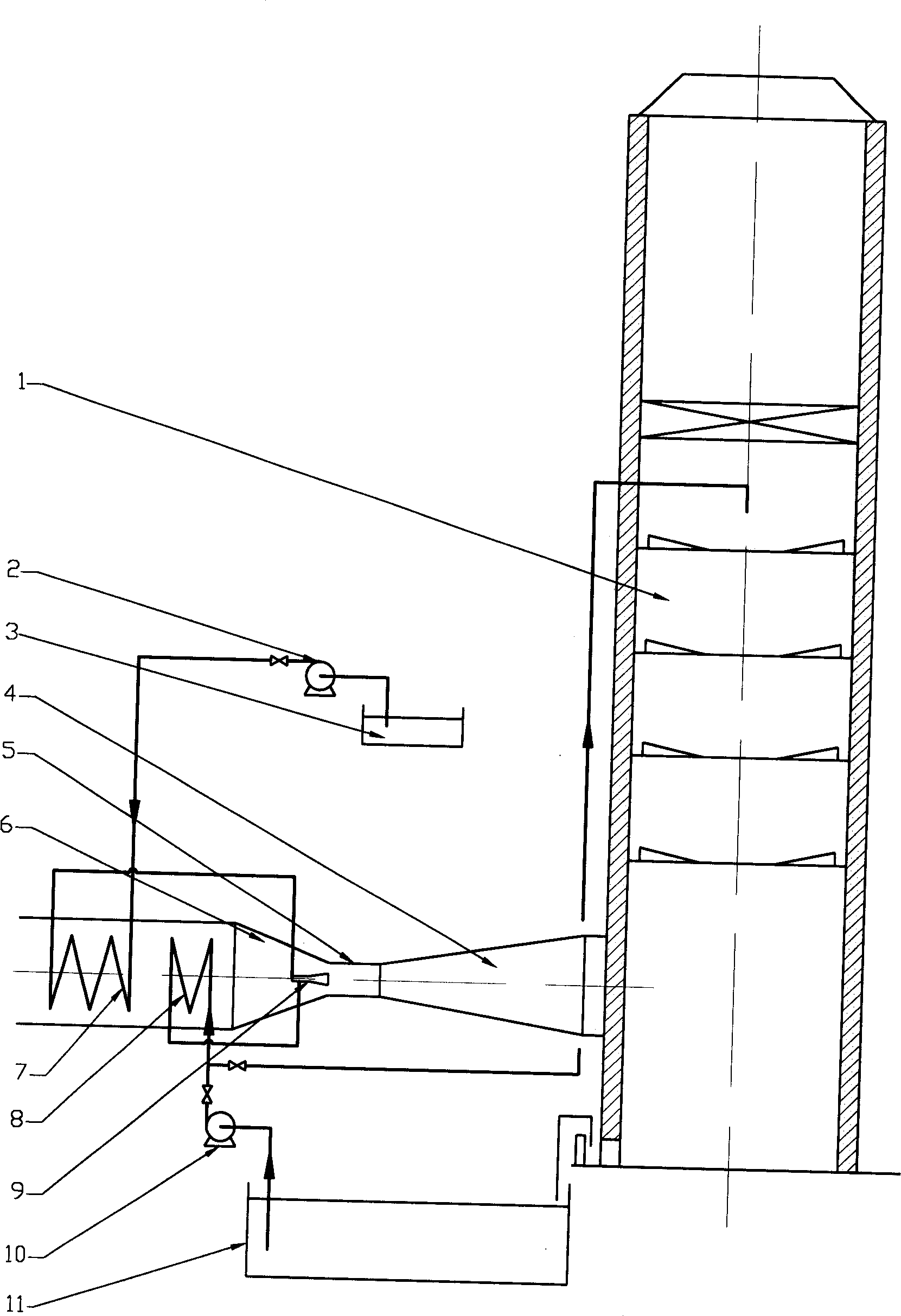

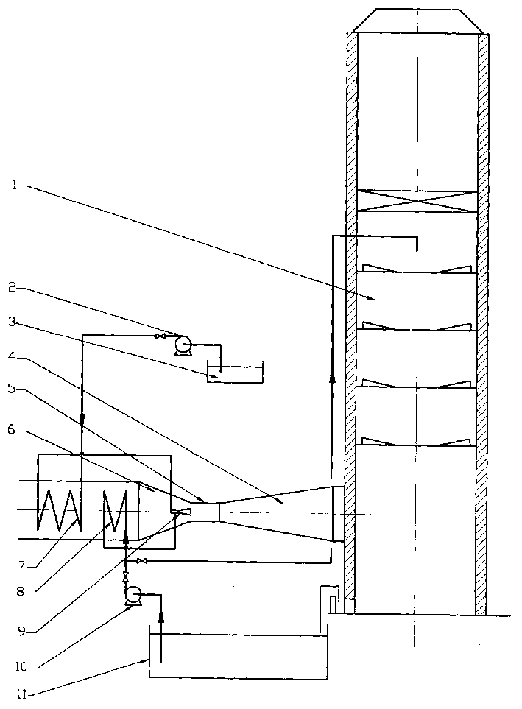

Method and system for combined treatment of boiler smoke and alkaline waste water and waste heat utilization

ActiveCN102172467AGuaranteed coverageHigh desulfurization and dust removal efficiencyUsing liquid separation agentExhaust gasFlue-gas desulfurization

The invention discloses a method and system for combined treatment of boiler smoke and alkaline waste water and waste heat utilization. The method belongs to a waste water and exhaust gas processing method. Firstly, alkaline waste water is sent into an alkali liquor pool so as to evenly stir water quality and water amount; then, the obtained mixture is sent into an integral desulfuration dust collector; the waste water discharged from the desulfuration dust collector is sent to a water-water heat exchanger or is directly sent to an effluent pool after being detected by a temperature sensor; meanwhile, boiler smoke is sent to the integral desulfuration dust collector for desulfuration and dust collection after being subjected to waste heat recovery. Different from the traditional smoke desulfuration and dust collection method, the method provided by the invention has the advantages that an aeration mode is adopted to cause the smoke and the waste water to intensively contact, thereby overcoming the problems of big capital construction investment and high operation cost or low desulfuration efficiency of the traditional method; meanwhile, smoke desulfuration, dust collection, smoke waste heat recovery and waste water waste heat recovery are cooperatively controlled; and low-grade waste heat is effectively recovered while the high-efficiency desulfuration and dust collection effect is guaranteed.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Desulfurized dust collector with multiple water films

InactiveCN101376082AReasonable structureHigh desulfurization and dust removal efficiencyCombination devicesDust collectorWaste management

Owner:NORTHEAST DIANLI UNIVERSITY

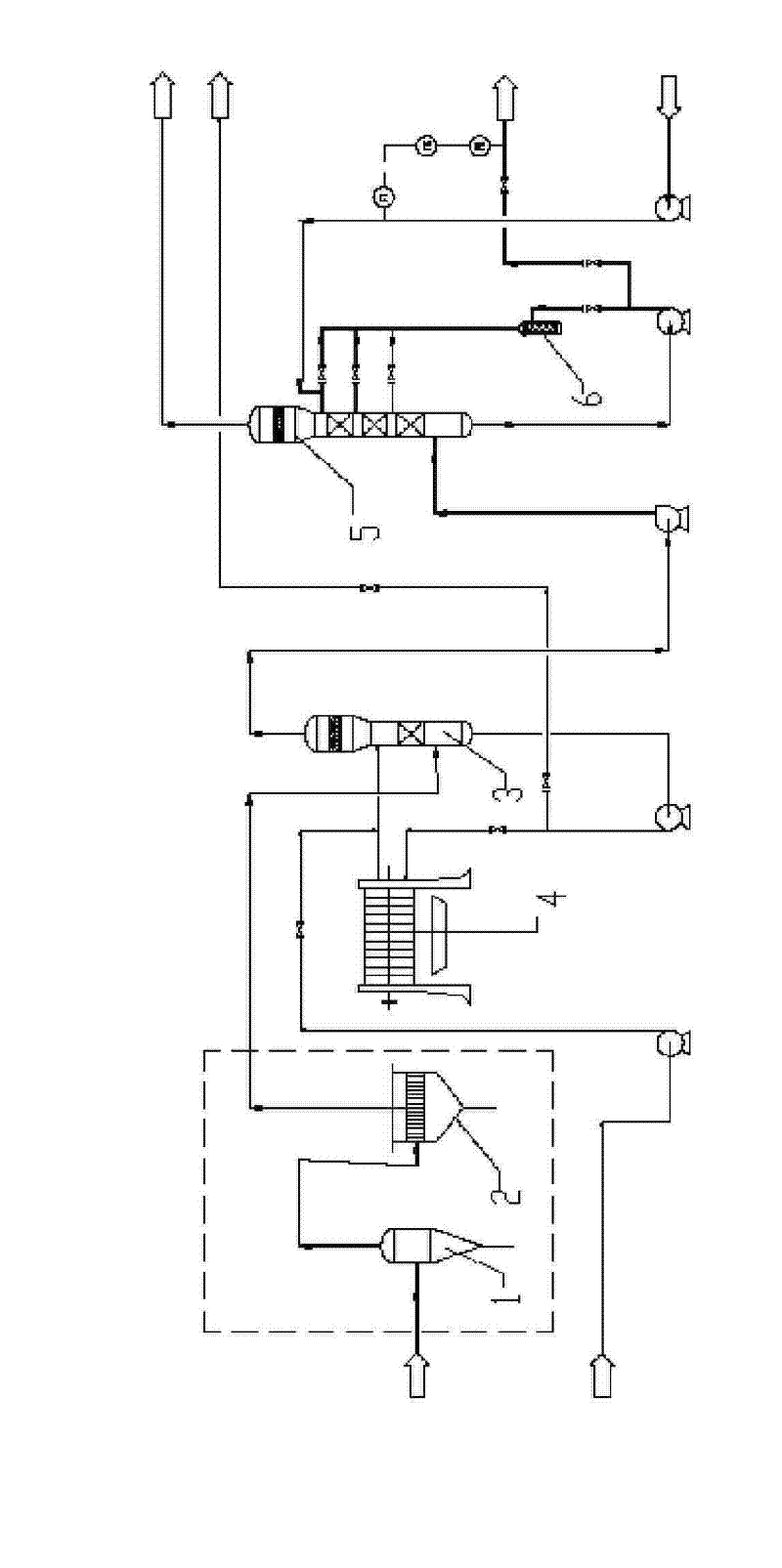

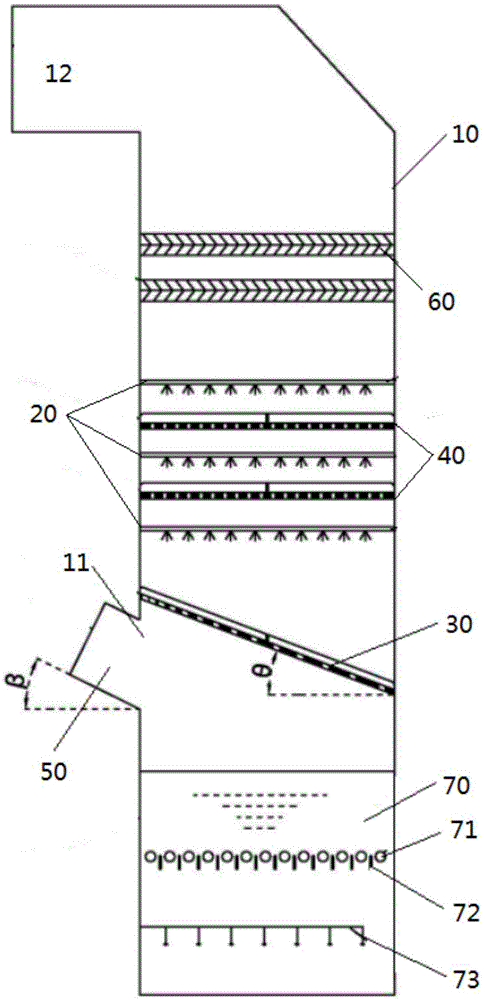

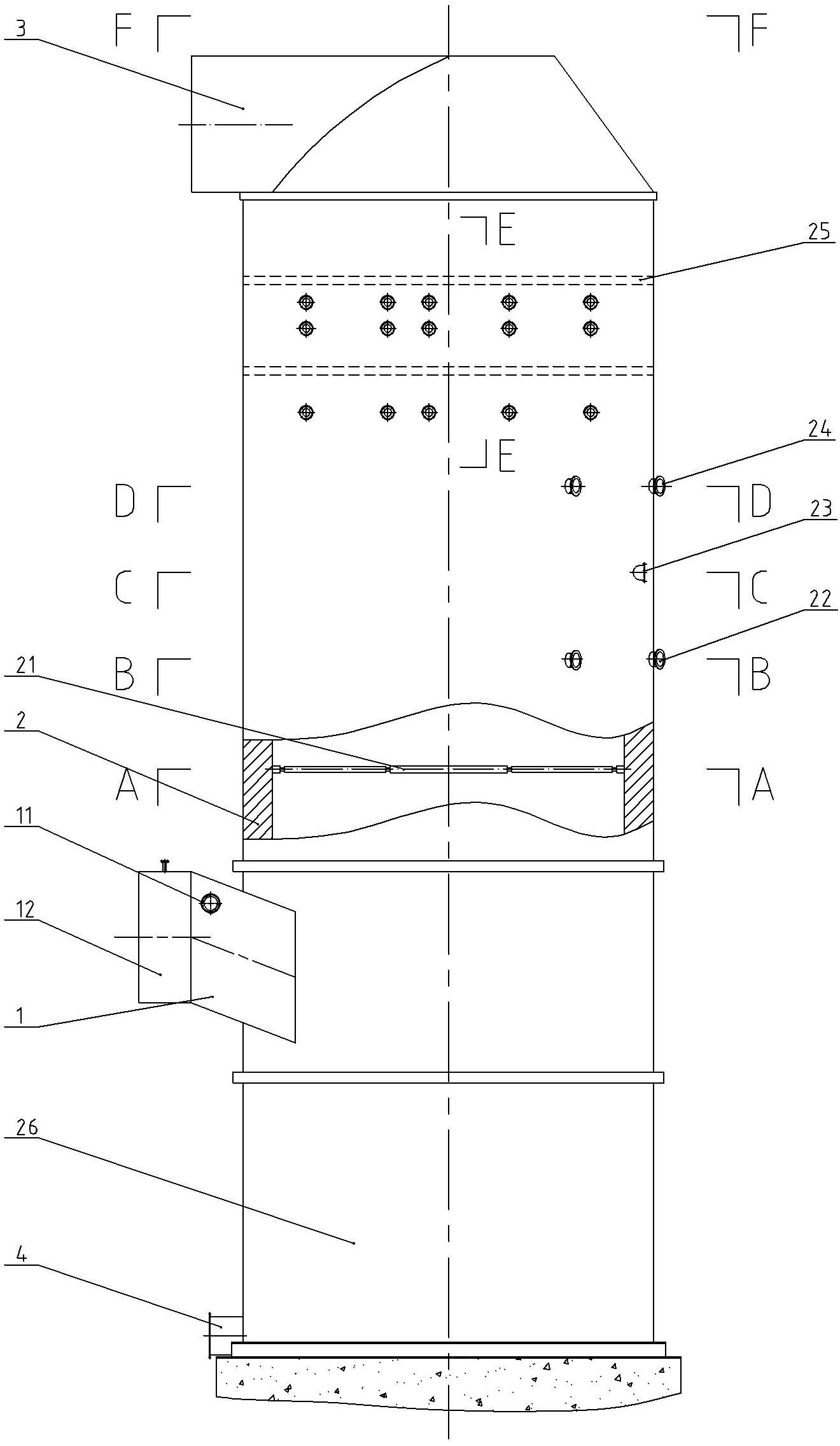

Single-tower six-section stepped purification desulfurization dust-removal and ultralow-emission integrated device

PendingCN106000043AReduce dust contentLow costCombination devicesGas treatmentPhysical chemistryDust control

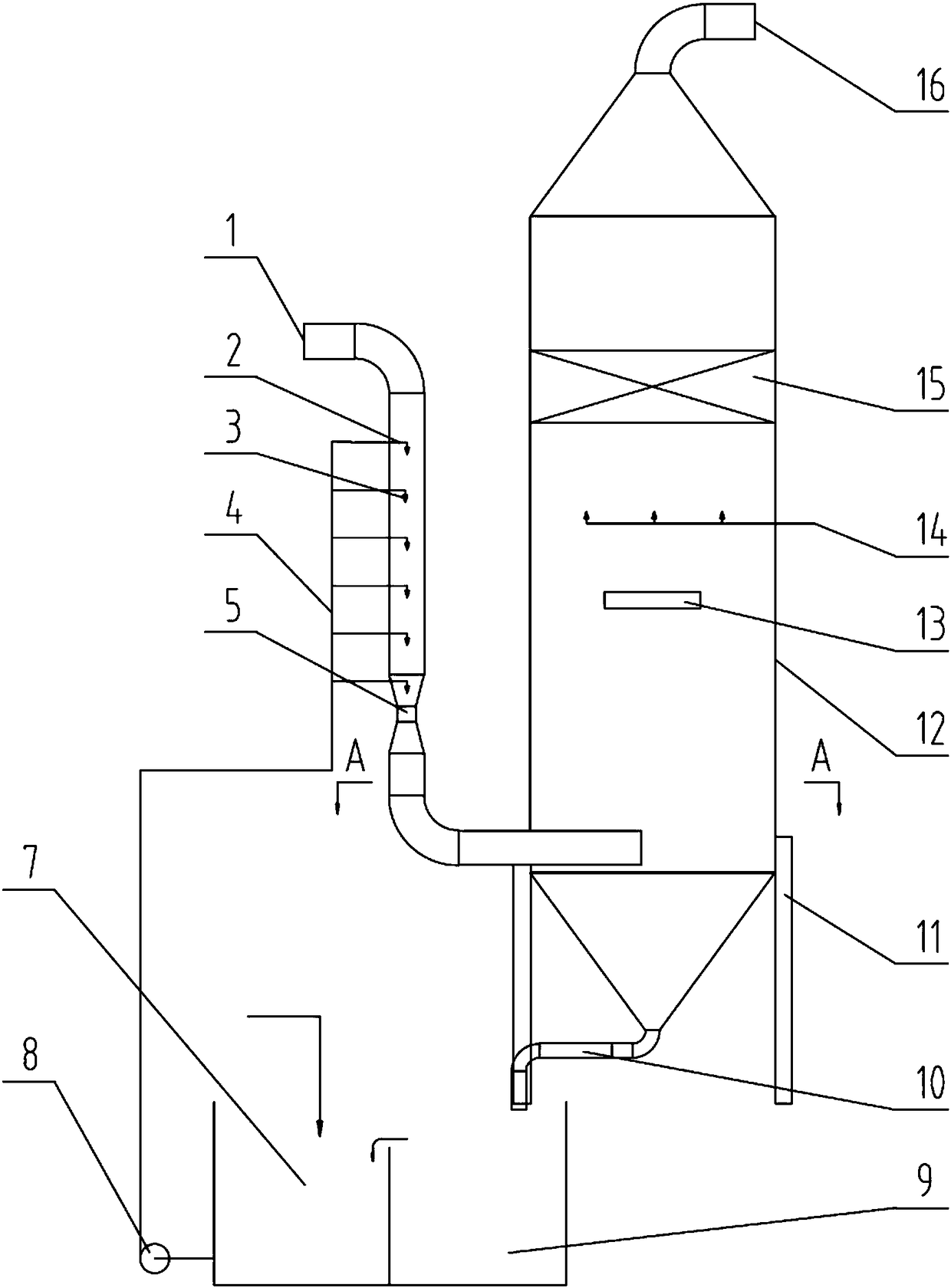

The invention discloses a single-tower six-section stepped purification desulfurization dust-removal and ultralow-emission integrated device, and belongs to the field of environmental protection; the device is composed of an oxidation section, a concentration section, an absorption section, a purification water-washing section, a demisting section, a separation plate and a wet electric section. The upper part of the oxidation section of the device achieves gas communication with the concentration section through a pipeline, and liquid separation is achieved by the separation plate; the upper part of the concentration section of the device achieves gas communication and liquid separation with the absorption section through a liquid collecting tank; the upper part of the absorption section of the device achieves gas communication and liquid separation with the purification section through a liquid collecting tank; the demisting section of the device is located at the upper part of the purification section; the wet electric section of the device is located at the upper part of the demisting section. A reaction in the single-tower six-section stepped purification desulfurization dust-removal and ultralow-emission integrated device is a gas-liquid reaction, the reaction speed is fast, the reaction is completed, and the desulfurization efficiency is high. The system realizes the requirement of ultralow emission, and is simple and concise in structure, easy to implement, low in cost, and favorable for wide popularization and utilization.

Owner:张波

High-efficiency smoke desulfurizing, dedusting and purifying device

PendingCN108554151AWell mixedComplete contact reactionCombination devicesGas treatmentActivated carbonParticulates

The invention relates to a high-efficiency smoke desulfurizing, dedusting and purifying device. The device comprises a desulfurization tower, a dedusting box and a purifying box, smoke enters the desulfurization tower, the smoke and a chemical liquid flow in the desulfurization tower in the same direction and undergo a desulfurization reaction and rotation in order to achieve preliminary dedusting, radial interlacing mixing is performed on a stop channel, and a fluid infusion is obtained in the central area of the tower, so full air and liquid mixing, complete contact reaction and good desulfurizing and dedusting effects are achieved; the arrangement of a filter plate and an activated carbon adsorption layer makes waste gas filtered and adsorbed and some large particulate impurities in air filtered out, the waste gas in the dedusting box is conveyed into the purifying box through an exhaust fan and a conveying tube, the contact between an air filter screen and the chemical liquid makes the waste gas in full contact with the chemical liquid at the bottom of the inner chamber of the purifying box in order to chemically react the waste gas, and a stirrer in the purifying box can stir the chemical liquid to improve the reaction efficiency of the waste gas and the chemical liquid and improve the waste gas purifying effect.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

Combined desulphurization and dedusting apparatus and method for wet flue gas

InactiveCN105195004ALess investmentReduce processingCombination devicesExternal electric electrostatic seperatorHigh energyElectrostatic precipitator

The invention provides a combined desulphurization and dedusting apparatus and method for wet flue gas. The upper part of the apparatus executes tubular electrostatic dust collection, and the lower part of the apparatus executes alkaline desulphurization. The apparatus comprises a drum; one side of the bottom of drum is provided with a flue gas inlet channel; bottom space of the drum is a buffer pool; the upper part of the flue gas inlet channel is provided with two lower sprinkler pipes; an air flow uniform distribution plate is arranged above the lower sprinkler pipes; the upper part of the air flow uniform distribution plate is an electrostatic dust collection zone; the lower sprinkler pipes and an upper sprinkler pipe are respectively connected with outlets of booster pumps through pipelines; inlets of the booster pumps are connected with the bottom of a neutralizing pool; the top of the neutralizing pool is provided with an alkali lye adding pipeline and connected with an outlet pipeline of a booster pump b; an inlet pipeline of the booster pump b is connected with the central part of a sedimentation basin; the bottom of the sedimentation basin is connected with a waste liquid outlet through a pipeline; the top of the sedimentation basin is connected with the outlet of a booster pump a; and an inlet pipeline of the booster pump a is connected with the bottom of the buffer pool. The combined desulphurization and dedusting apparatus and method mainly overcome the problems of low efficiency, high energy consumption, low utilization rate of waste water and the like of desulphurization and dedusting of tail flue gas of an industrial boiler.

Owner:李继凤

SO2 and dust comprehensive treatment absorber

ActiveCN105413421AImprove bindingIncrease contact areaGas treatmentUsing liquid separation agentSufficient timeTrapping

The invention discloses an SO2 and dust comprehensive treatment absorber and belongs to the technical field of desulfurization and dust removal. The absorber is a mixed liquid 8-11 in pH comprising a protein ion membrane liquid and an alkaline liquid; the protein ion membrane liquid is a liquid membrane carrying negative and positive ions that is formed by adding an amphoteric surfactant and a foam stabilizer in a protein fermentation broth. The protein ion membrane liquid forms small-diameter bubbles during spray atomization, greatly increasing specific surface area (thousands of times in this increase), that is to say the area of contact between SO2 and an absorber liquid is increased, better facilitating the trapping of dust and SO2 in smoke; therefore, mass transfer contact residence time of an absorbed gas between gas and liquid phases is much longer than the retention time of the gas in the liquid phase to react with the alkaline liquid, and reaction is given sufficient time, that is to say the reaction time of SO2 with the absorber liquid is prolonged.

Owner:HEZE XINDING ENVIRONMENTAL ENG EQUIP

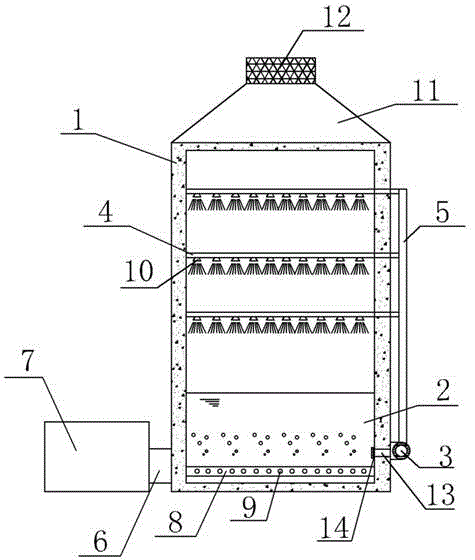

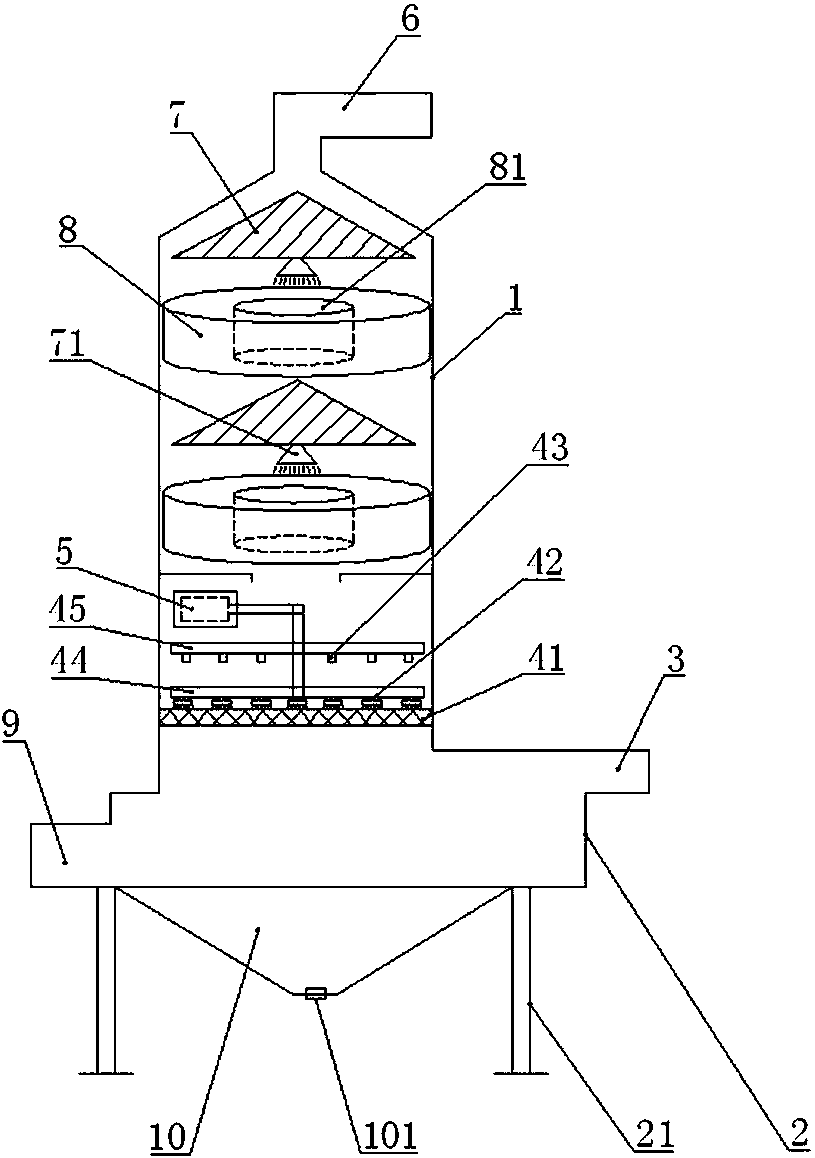

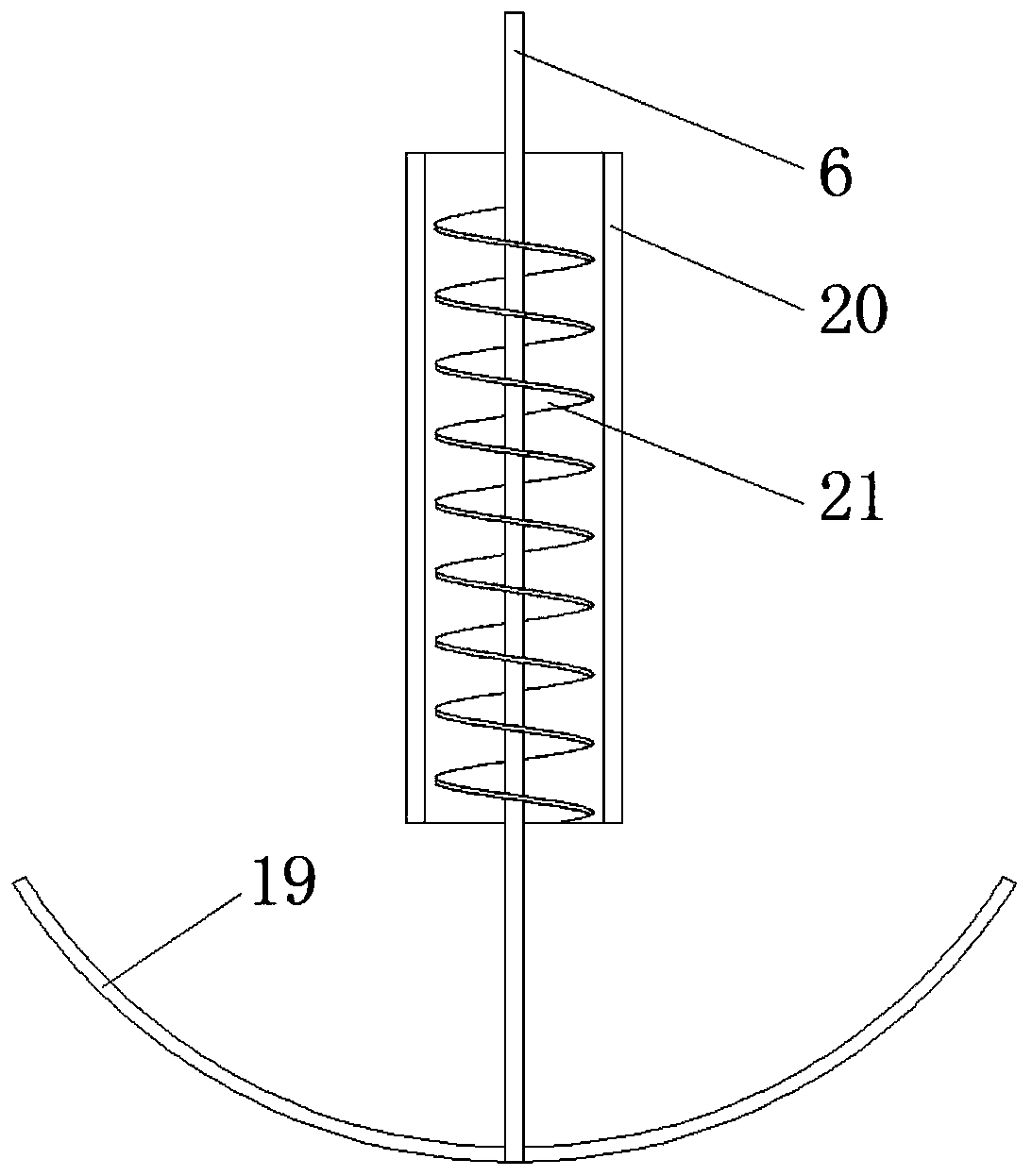

Small-sized multilayer dust removal and desulfurization device

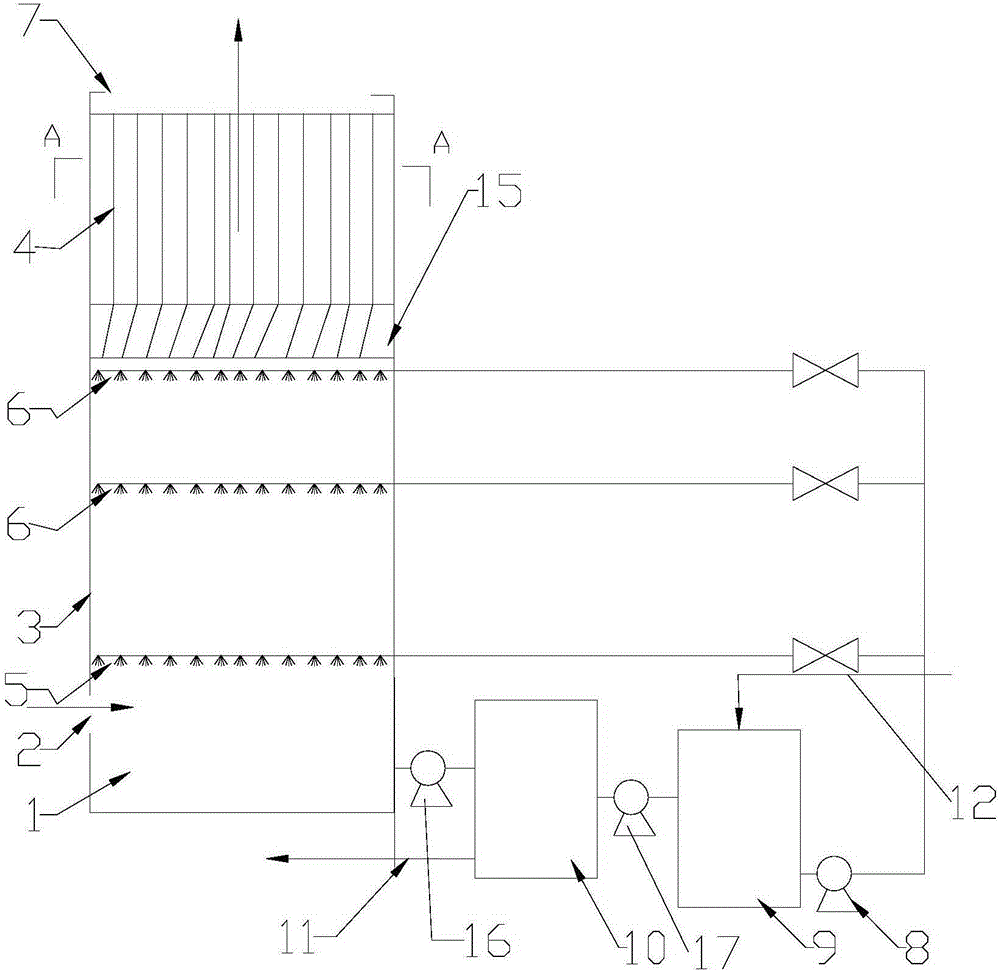

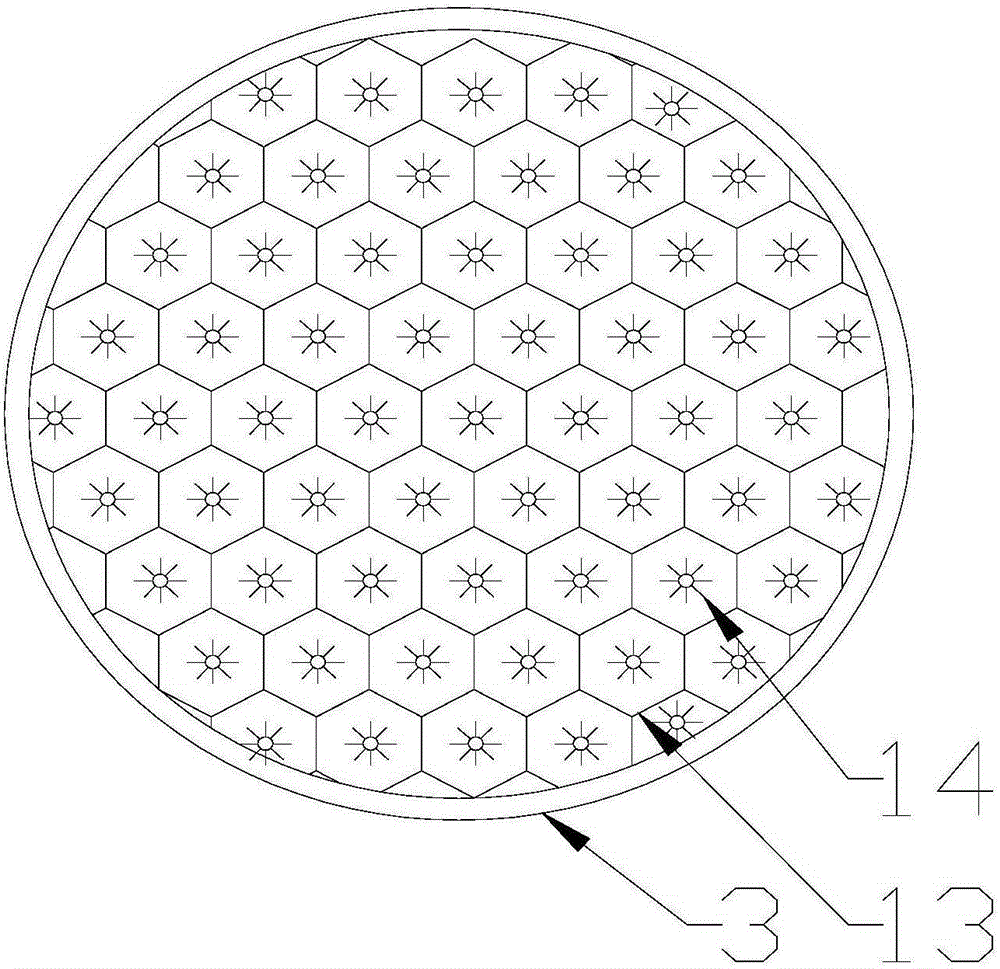

InactiveCN105964081ASuitable for handlingCompact structureGas treatmentUsing liquid separation agentWater bathsFlue gas

The invention discloses a small-sized multilayer dust removal and desulfurization device which comprises a tank body, wherein a water bath is arranged at the inner bottom of the tank body; multiple spraying layers are arranged in the tank body; an air inlet pipe is arranged on the outer wall of the tank body; a spiral air compressor is arranged at one end of the air inlet pipe, and the other end of the air inlet pipe is communicated with an aerator pipe arranged at the bottom of the water bath to press dusty sulfur-containing flue gas into the water bath; a water inlet pipe is also arranged on the outer wall of the tank body; one end of the water inlet pipe is communicated with the bottom of the water bath, and the other end of the water inlet pipe is communicated with a lifting pump arranged on the outer wall of the tank body; the lifting pump is communicated with the spraying layers through a pipeline arranged on the outer wall of the tank body, so that an alkaline desulfurization solution in the water bath is delivered into the spraying layers for spraying operation through the lifting pump; a tapered flow guide cover is arranged at the top of the tank body; a ring-shaped exhaust opening is formed in the upper part of the tapered flow guide cover. The device is compact and simple in structure, relatively high in desulfurization efficiency and convenient in post-maintenance.

Owner:成都市沃发特科技有限公司

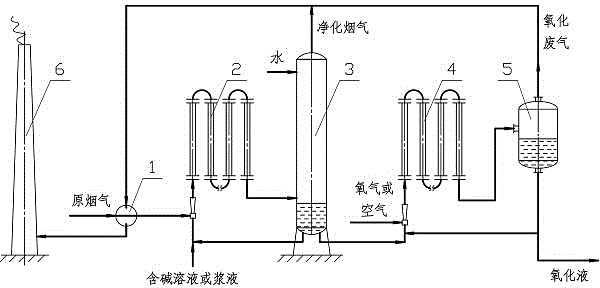

Alkali-water desulphurization dust removal technology

InactiveCN105983307AFully contactedIncrease mass transfer driving forceUsing liquid separation agentSulfateSpray nozzle

The invention relates to an alkali-water desulphurization dust removal technology, and relates to a wet-method environment-friendly treatment technology for sulfur-containing smoke. The alkali-water desulphurization dust removal technology comprises the following steps: performing primary desulphurization dust removal by taking a sulfur-containing solution as a first desulphurization agent, performing the secondary desulphurization dust removal by adopting the water as a second desulphurization agent, performing the primary desulphurization dust removal in a tubular reaction device, and performing the secondary desulphurization dust removal in a tower-type device; and enabling the desulphurized dust-removed sulphite-containing mixed solution to enter an independent tubular oxidation reactor, and performing the oxidation reaction to obtain a sulfate mixed solution. By adopting the alkali-water desulphurization dust removal technology, the technical defects of the traditional wet-method desulphurization technology that a spray nozzle is blocked by scales formed on the inner wall and components in the desulphurization tower can be overcome, and the long-term operation of the device can be guaranteed; the equipment investment is low, the operation expense is low, the operation flexibility is high, the absorption, neutralization and oxidation are thoroughly carried out, and the desulphurization efficiency is high.

Owner:吴剑华

Energy-saving high effective desulfurizing and dust control method and equipment using remaining heat

InactiveCN1467015AHigh desulfurization and dust removal efficiencyLow running costUsing liquid separation agentDust controlProcess engineering

An energy-saving efficient desulfurizing and dusting method and apparatus using afterheat is disclosed. Said method features that the residual of high-temp fume is used to heat water to become steam, which is then sprayed out at high speed by the nozzle of Venturi tube to provide power for forcing the fume to pass through said apparatus. Said apparatus is composed of Ventiru tube and desulfurizing-dusting tower. In the contraction segment of venturi tube, there are primary heat exchanger, secondary heat exchanger and nozzle. Its advantages are low cost and high efficiency of 90% of desulfurizing and 99.5% for dusting.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

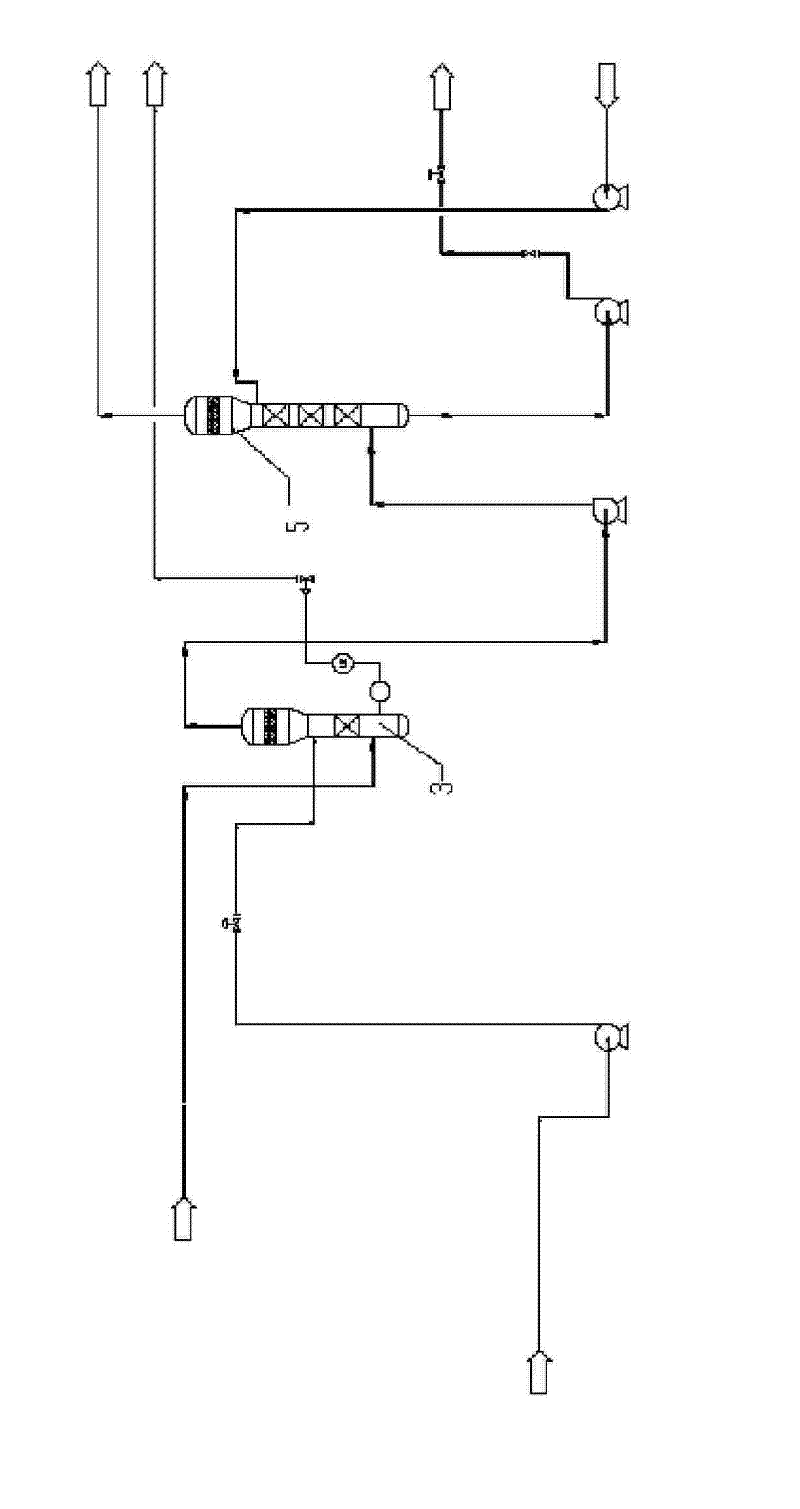

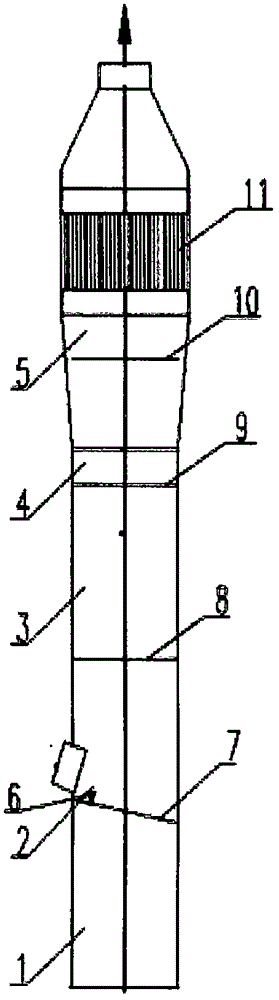

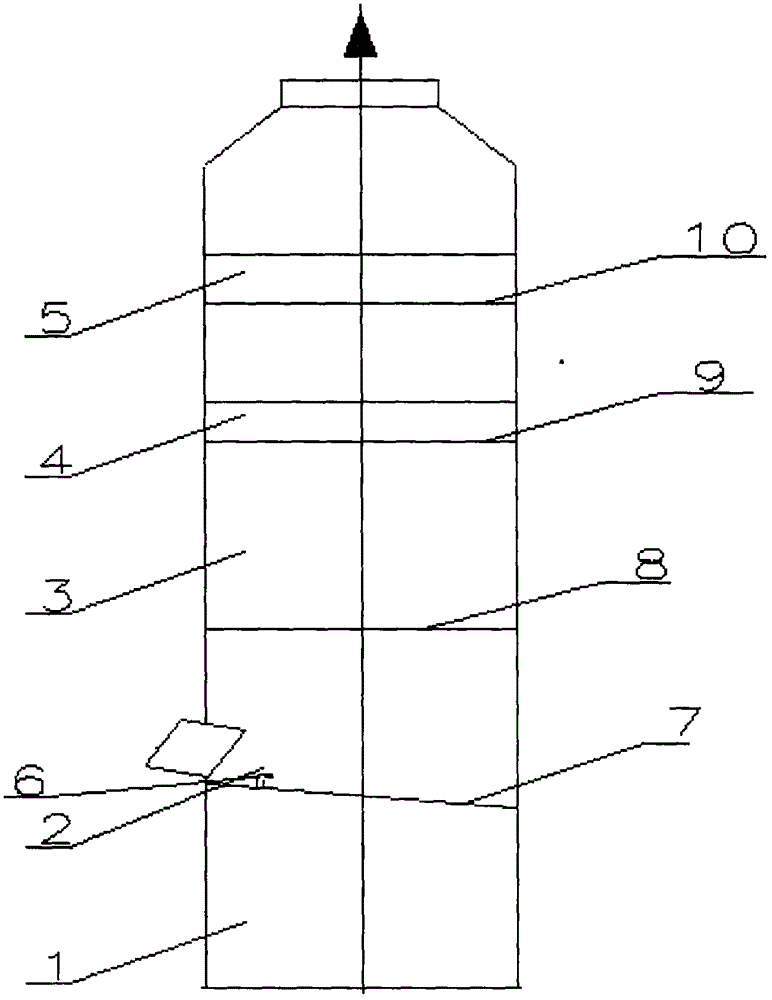

Single-tower five-section gradient purification, sulfur removal and dust removal ultra-low emission integrated device

PendingCN105854566AReduce dust contentLow costGas treatmentUsing liquid separation agentDust controlEnvironmental engineering

The invention discloses a single-tower five-section gradient purification, sulfur removal and dust removal ultra-low emission integrated device and belongs to the field of environmental protection. The device is composed of an oxidation section, a concentration section, an absorption section, a purification washing section and a defogging section. The upper portion of the oxidation section of the device and the concentration section achieve gas communication through a pipeline, and liquid isolation is achieved through a partition plate. The upper portion of the concentration section of the device and the absorption section achieve gas communication and liquid isolation through a liquid collecting tank. The upper portion of the absorption section of the device and the purification section achieve gas communication and liquid isolation through a liquid collecting tank. A reaction gas-liquid reaction is conducted in the single-tower five-section gradient purification, sulfur removal and dust removal ultra-low emission integrated device, the reaction speed is high, the reaction is complete, and the sulfur removal efficiency is high. The system meets the ultra-low emission requirements, and is simple in structure, easy to achieve, low in cost and beneficial for wide utilization and popularization.

Owner:张波

Desulfuration and dust collection method based on reverse spray type semidry method for flue gas of sintering machine

InactiveCN102085451BPut an end to the problem of easy bed collapseIncrease profitCombination devicesMetallurgyBaghouse

The invention discloses a desulfuration and dust collection method based on a reverse spray type semidry method for flue gas of a sintering machine. The desulfuration and dust collection method comprises the steps of cooling, desulfuration by virtue of a desulfurizer and dust collection by virtue of a cloth bag, wherein the flue gas is reversely sprayed by a flue before the desulfurizer, and slaked lime is sprayed to the flue gas so as to perform primary desulfuration and cool the flue gas. In the desulfurizer, the flue gas is further desulfurized and cooled. Then desulfuration ash is sprayedto the flue gas through a flue at the bottom of the desulfurizer so as to perform desulfurization. The desulfurized flue gas enters an efficient bag-type dust collector for further desulfuration and dust collection of the flue gas. The desulfuration and dust collection method disclosed by the invention has the advantages of relatively low investment, high desulfuration and dust collection efficiency and the like, and is free from influence of the properties, temperature and flow of the flue gas and suitable for the flue gas desulfuration and dust collection systems of various sintering machines.

Owner:秦皇岛双轮环保科技股份有限公司

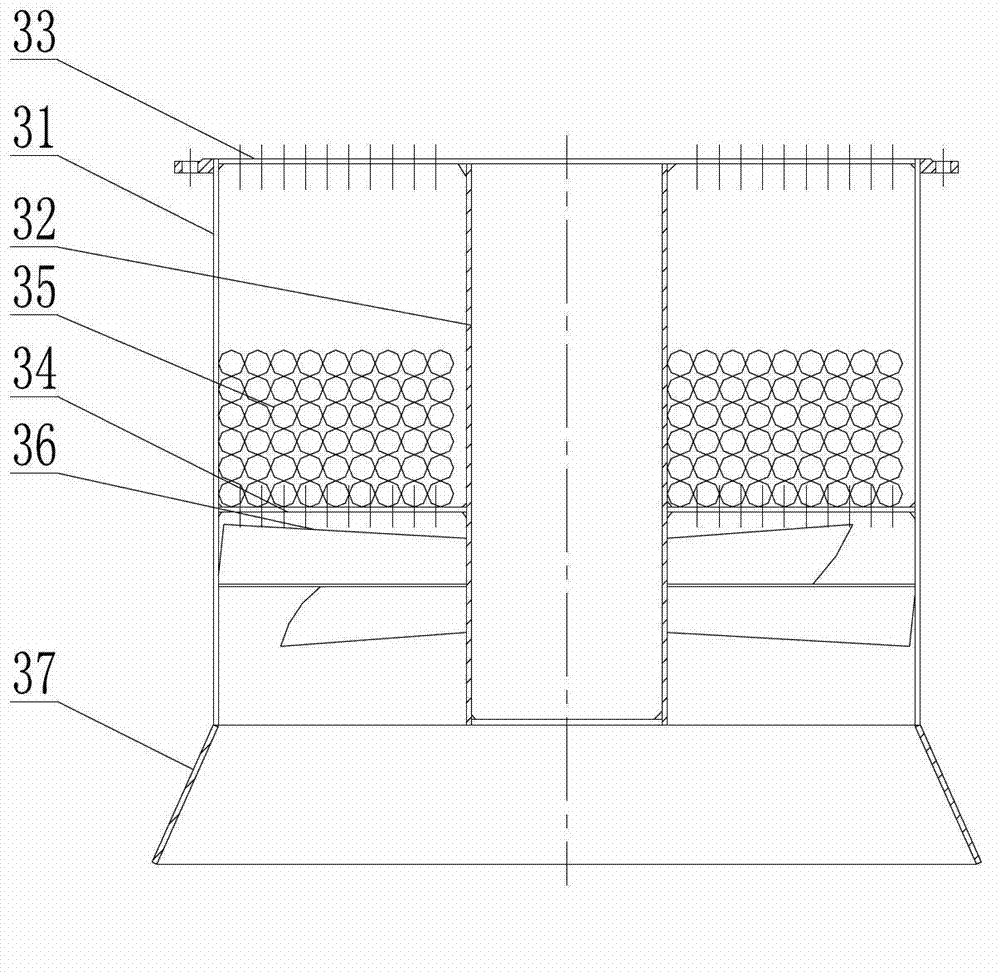

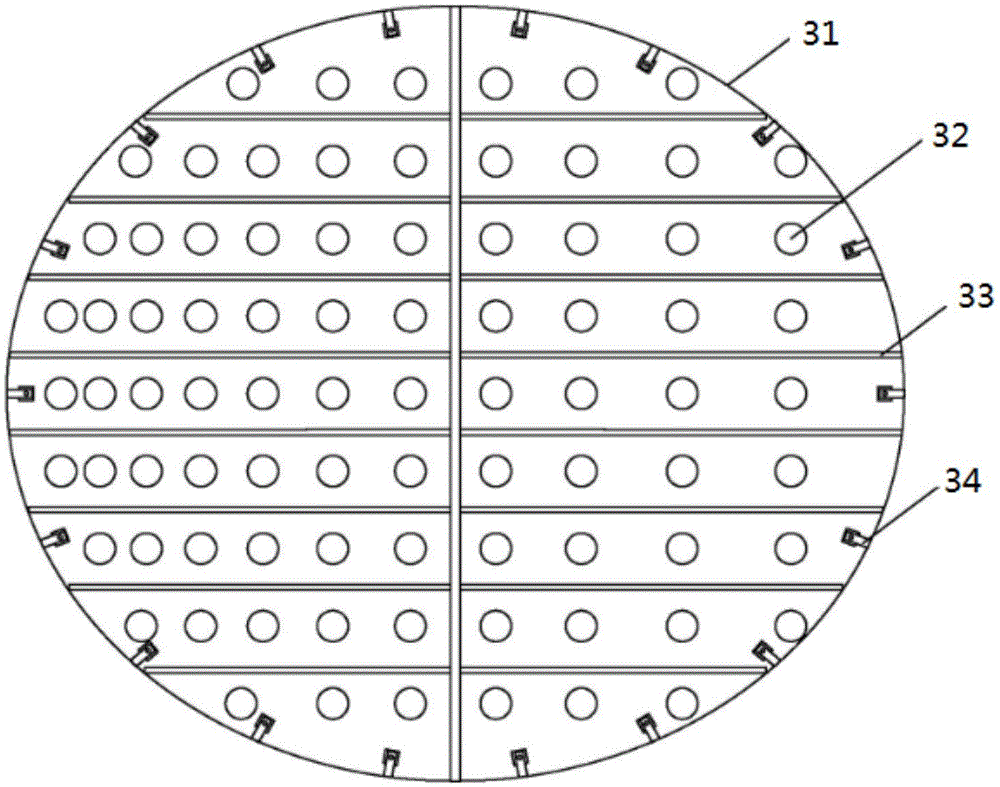

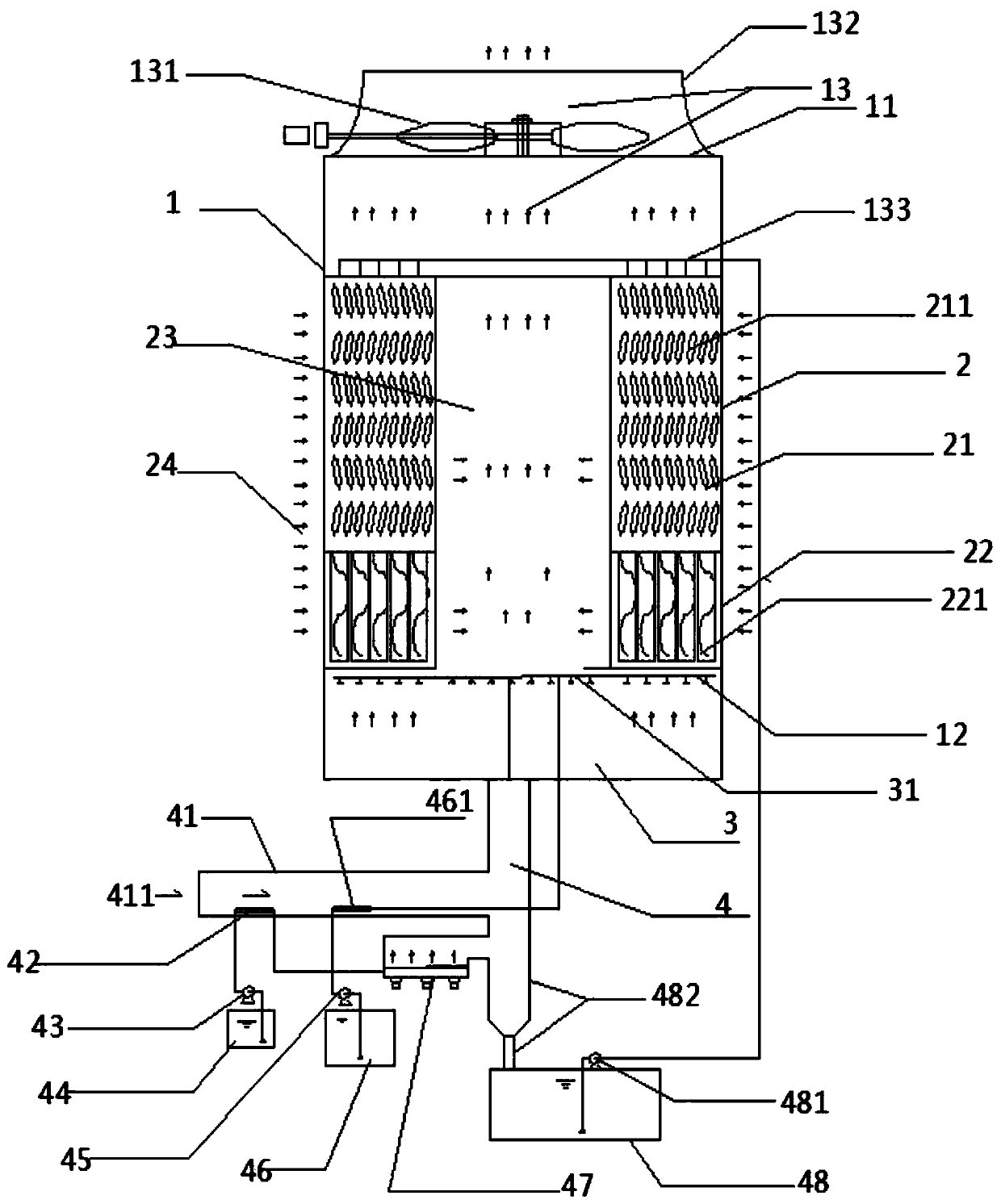

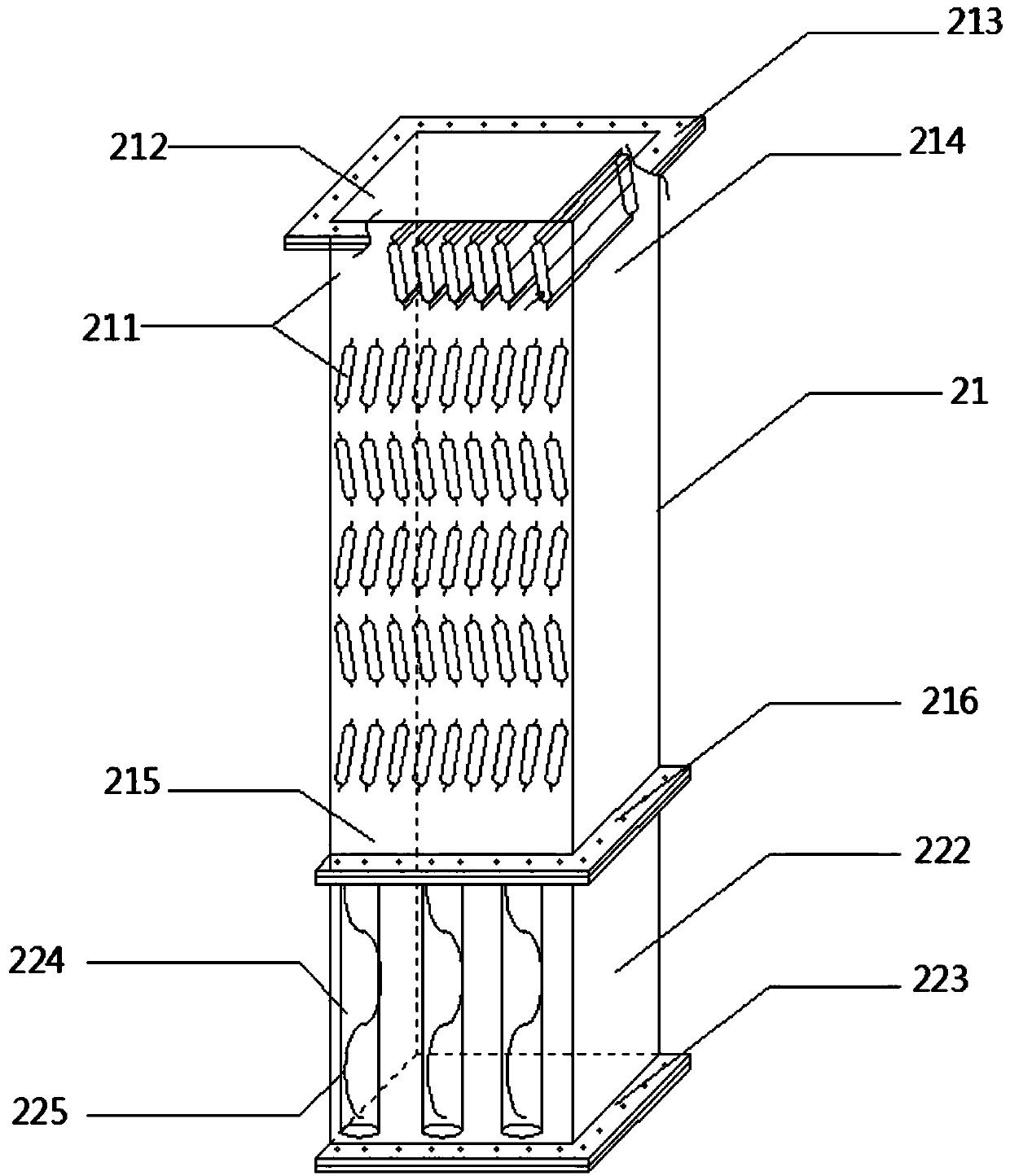

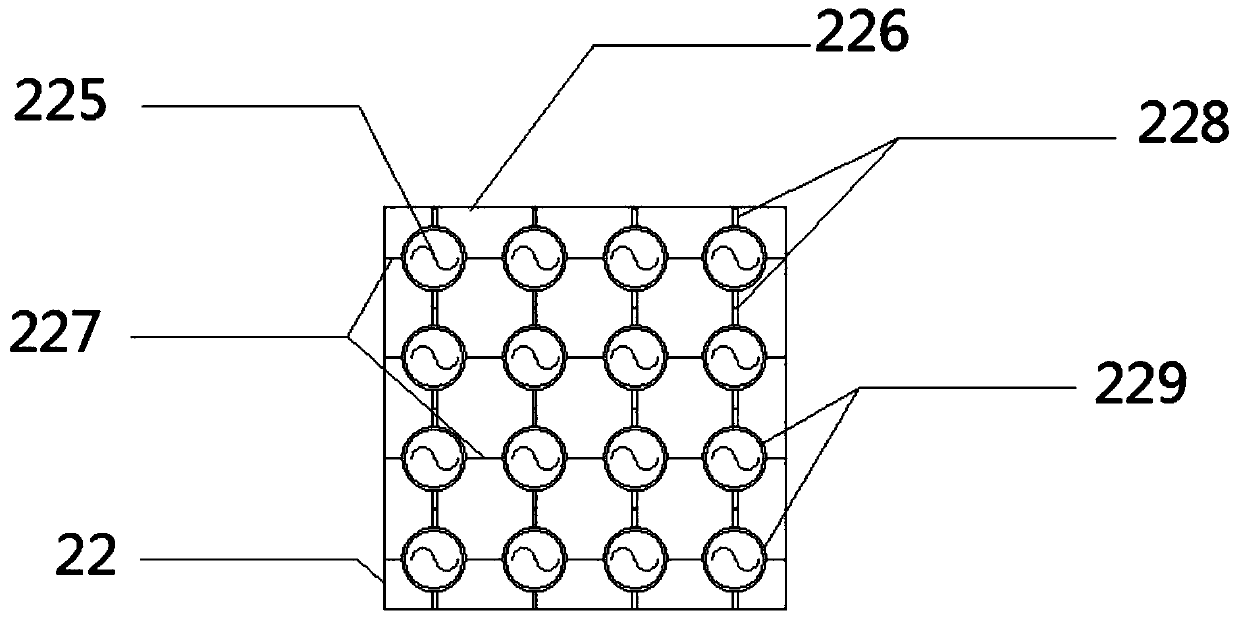

Warping sheet type low-temperature gas heat exchange condensation water collecting device

PendingCN109631653AWhite mist disappearsIncrease moisture contentUsing liquid separation agentIndirect heat exchangersRecuperatorEngineering

The invention discloses a warping sheet type low-temperature gas heat exchange condensation water collecting device. A heat exchange device and a water collecting device body are included. The heat exchange device comprises at least two heat exchange boxes arranged on the two sides, and each heat exchange box is divided into an upper part and a lower part. Each heat exchange box upper half part comprises at least two rows of square warping sheet type heat exchangers. Each heat exchanger lower half part comprises circular warping sheet type heat exchangers. The heat exchange box upper parts andthe heat exchange box lower parts are fixedly connected. A draught fan is arranged at the upper portions of the heat exchange boxes, the lower ends of the heat exchange boxes are connected with a smoke air guiding pipe, the smoke air guiding pipe is connected with an alkali liquor storage tank and an ultrasonic atomizer, and the ultrasonic atomizer is connected with the water collecting device body through a water collecting pipe. The water collecting device body comprises a condensation water collecting and storing box, and the condensation water collecting and storing box is connected withthe heat exchange boxes through a cleaning pipeline. The warping sheet type low-temperature gas heat exchange condensation water collecting device is provided and can achieve smoke plume treatment, water collecting dehumidification, high desulfuration and dust removal efficiency and convenient installation, and secondary pollution is not generated.

Owner:北京鑫晟环能科技发展有限公司

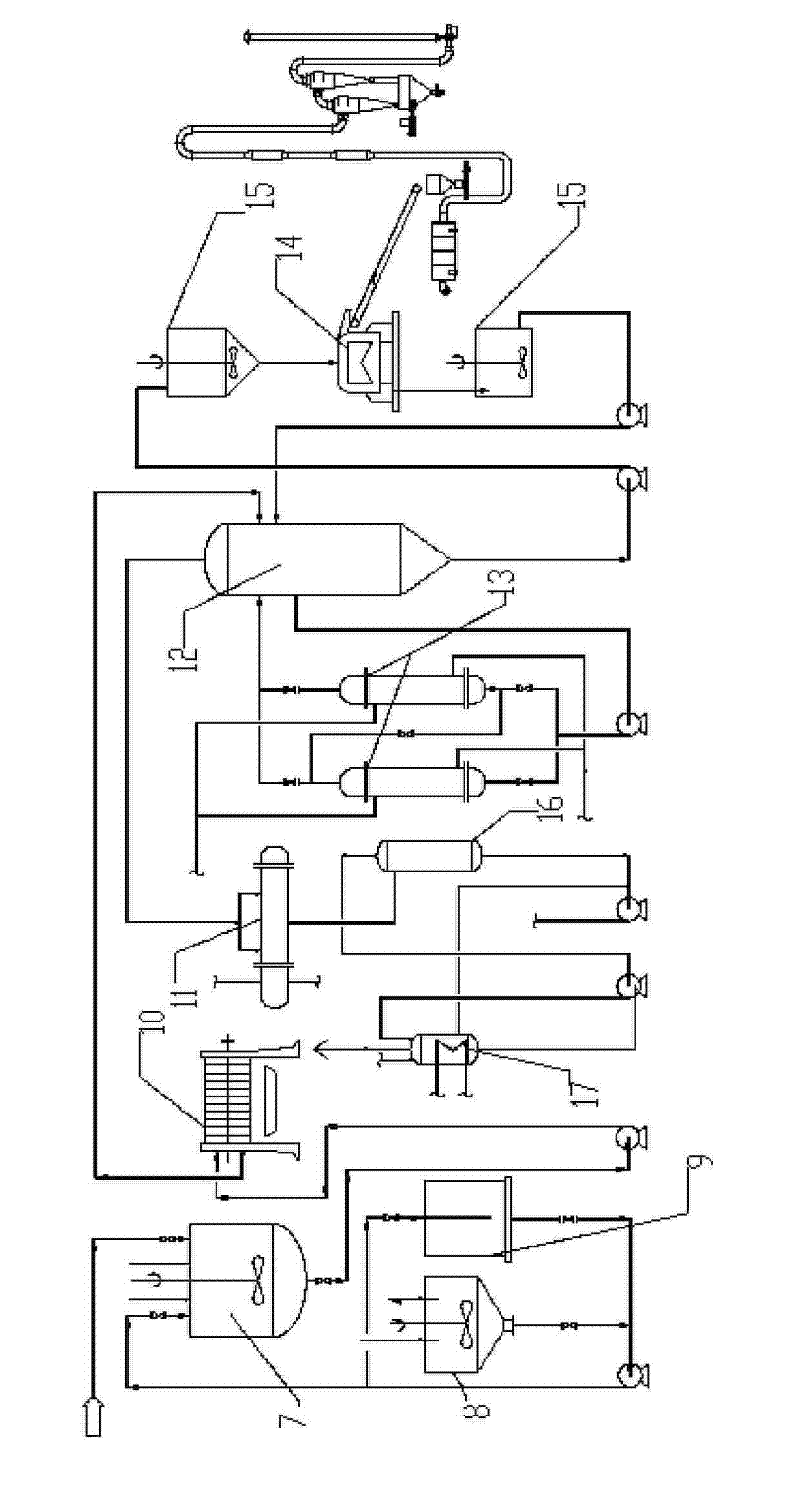

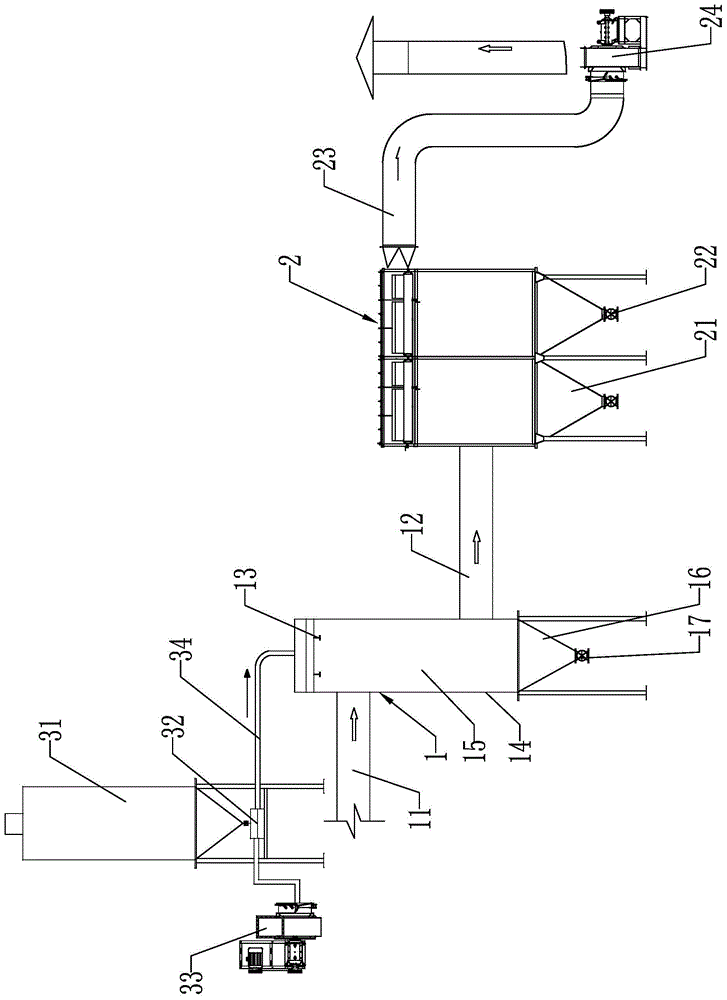

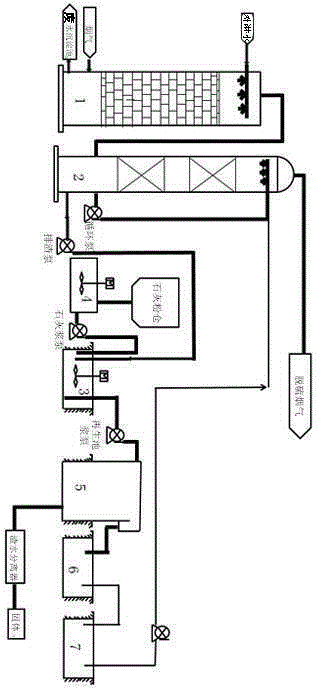

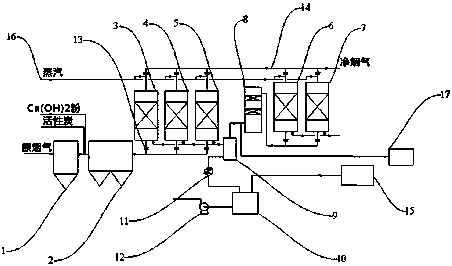

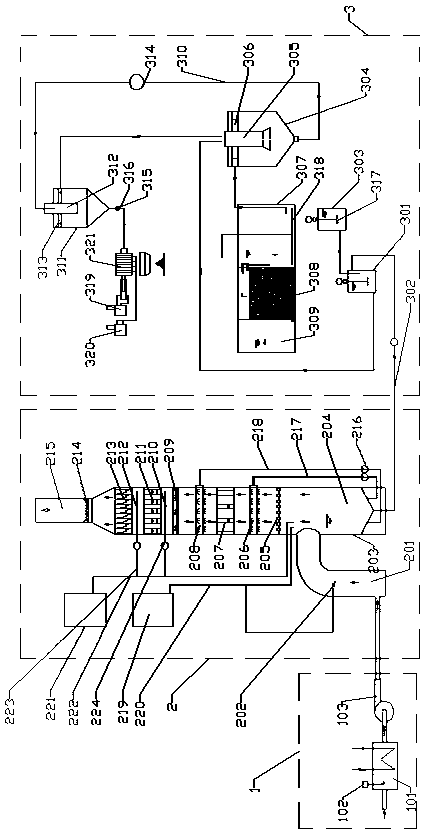

Low emission technology and complete set of equipment for pollutant in flue gas from garbage power generating boiler

PendingCN107638801ADesign scienceCompact layoutDispersed particle separationDecompositionEmission standard

The invention discloses an ultra-low emission technology and a complete set of equipment for pollutants in flue gas from a garbage power generating boiler. An SDA reactor, a bag-type dust collector, afirst adsorption tank, a regeneration tank and a gas-liquid separator are sequentially connected, the gas-liquid separator is connected with a neutralization tank and an oxidation decomposition towercorrespondingly, the oxidation decomposition tower is connected with a second adsorption tank, flue gas enters the SDA reactor, dry injection is conducted, the bag-type dust collector absorbs a largeamount of acid and adsorbs dust in the flue gas, and obtained gas enters into the first adsorption tank, the regeneration tank continues to absorb heavy metals, dioxins and oxidized NOx in the flue gas, and adsorption and regeneration are alternately performed. Regenerated gas enters the gas-liquid separator to separate gas and liquid, and the obtained liquid flows into the neutralization tank and reacts with sodium alkali or ammonia water in the neutralization tank, the gas enters the oxidation decomposition tower and enters the second adsorption tank after oxidation, purified smoke obtainedby two-stage adsorption is emitted, regenerated gas after the second stage adsorption also returns to the gas-liquid separator for secondary oxidation and absorption until emission standards and ultra-low emission requirements are met.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

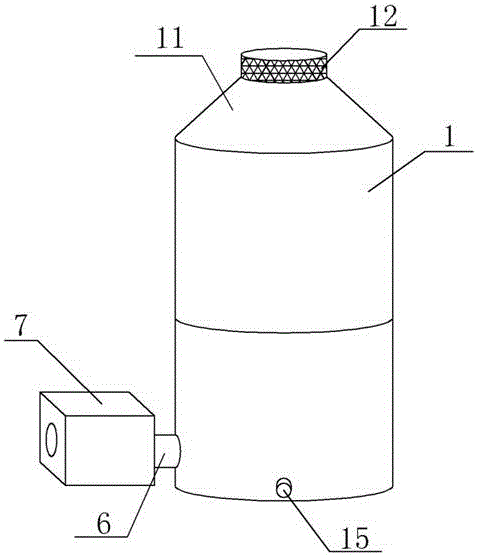

Desulfurization dust remover capable of removing oil mist

InactiveCN108499296AReduce differential pressureExtended service lifeCombination devicesGas treatmentSprayerDust collector

The invention discloses a desulfurization dust remover capable of removing oil mist. The dust remover comprises a dust removing device and a bracket body. A smoke inlet is formed in the bracket body,and the bracket body is of a hollow structure; a filter net is arranged inside the dust removing device, a plurality of brushes are arranged on the filter net, and the brushes are placed on a first ring bracket; a second ring bracket is arranged on the upper side of the first ring bracket, and a plurality of nozzles are arranged on the second ring bracket; hollow partition plates and solid partition plates are also installed inside the dust removing device, and the solid partition plates are arranged above the hollow partition plates; through holes are formed in the hollow partition plates, and sprayers are arranged at the lower sides of the solid partition plates; an exhaust port is formed in the top of the dust removing device; an overflow tank is arranged on the bracket body; the dust remover is further provided with a storage chamber, and the storage chamber is formed in the lower side of the bracket body. The dust remover has the advantages that the oil mist and greasy dirt can beremoved and cleaned in the basic function of a conventional dust collector, the smoke is repeatedly sprayed, and the dust remover has high desulfurization and dust removal efficiency.

Owner:成都市美铭环保科技有限公司

Desulfuration and dust collection method based on reverse spray type semidry method for flue gas of sintering machine

InactiveCN102085451APut an end to the problem of easy bed collapseIncrease profitCombination devicesMetallurgyBaghouse

The invention discloses a desulfuration and dust collection method based on a reverse spray type semidry method for flue gas of a sintering machine. The desulfuration and dust collection method comprises the steps of cooling, desulfuration by virtue of a desulfurizer and dust collection by virtue of a cloth bag, wherein the flue gas is reversely sprayed by a flue before the desulfurizer, and slaked lime is sprayed to the flue gas so as to perform primary desulfuration and cool the flue gas. In the desulfurizer, the flue gas is further desulfurized and cooled. Then desulfuration ash is sprayedto the flue gas through a flue at the bottom of the desulfurizer so as to perform desulfurization. The desulfurized flue gas enters an efficient bag-type dust collector for further desulfuration and dust collection of the flue gas. The desulfuration and dust collection method disclosed by the invention has the advantages of relatively low investment, high desulfuration and dust collection efficiency and the like, and is free from influence of the properties, temperature and flow of the flue gas and suitable for the flue gas desulfuration and dust collection systems of various sintering machines.

Owner:秦皇岛双轮环保科技股份有限公司

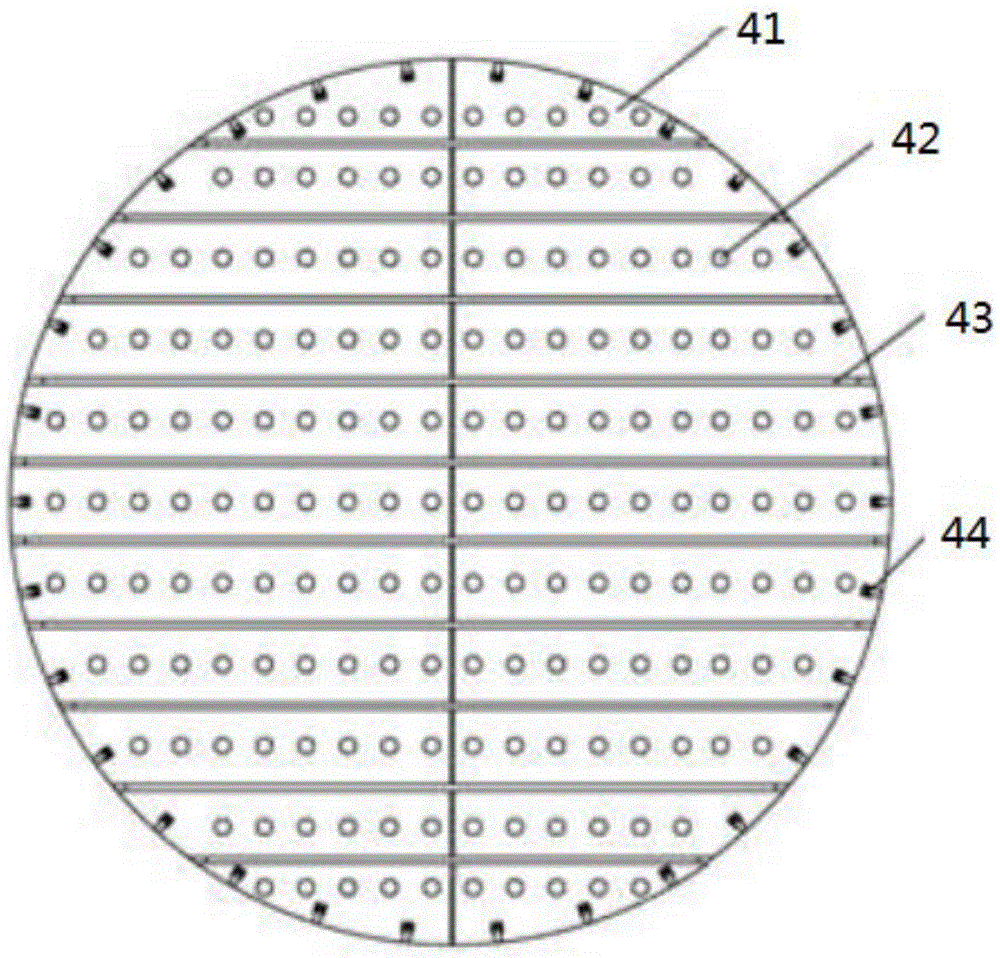

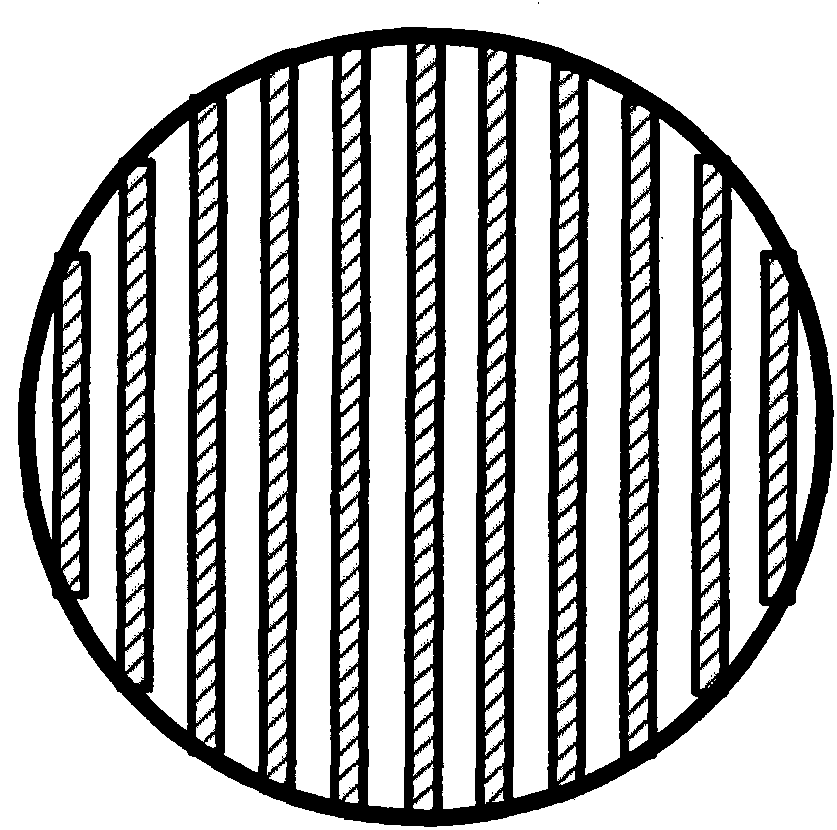

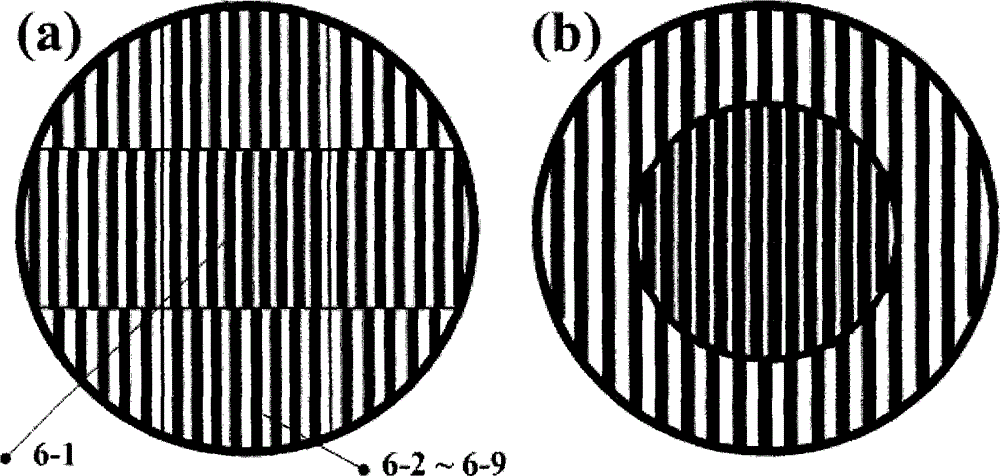

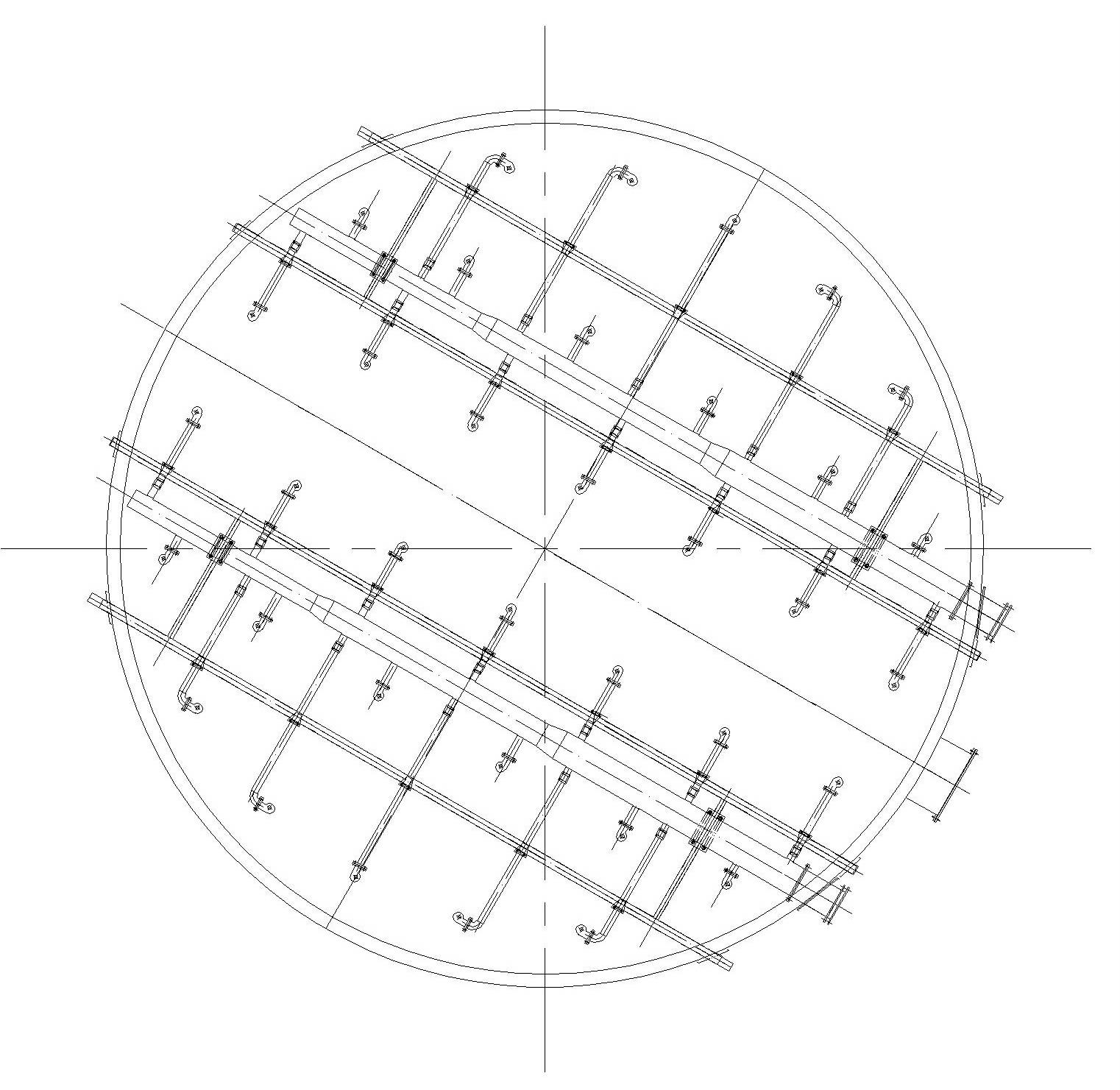

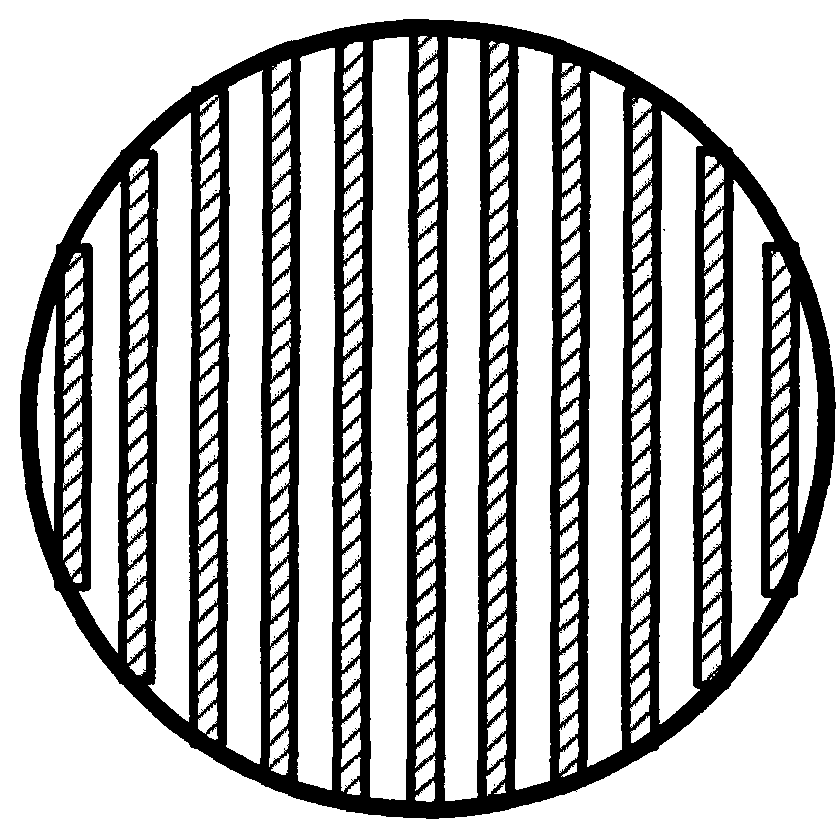

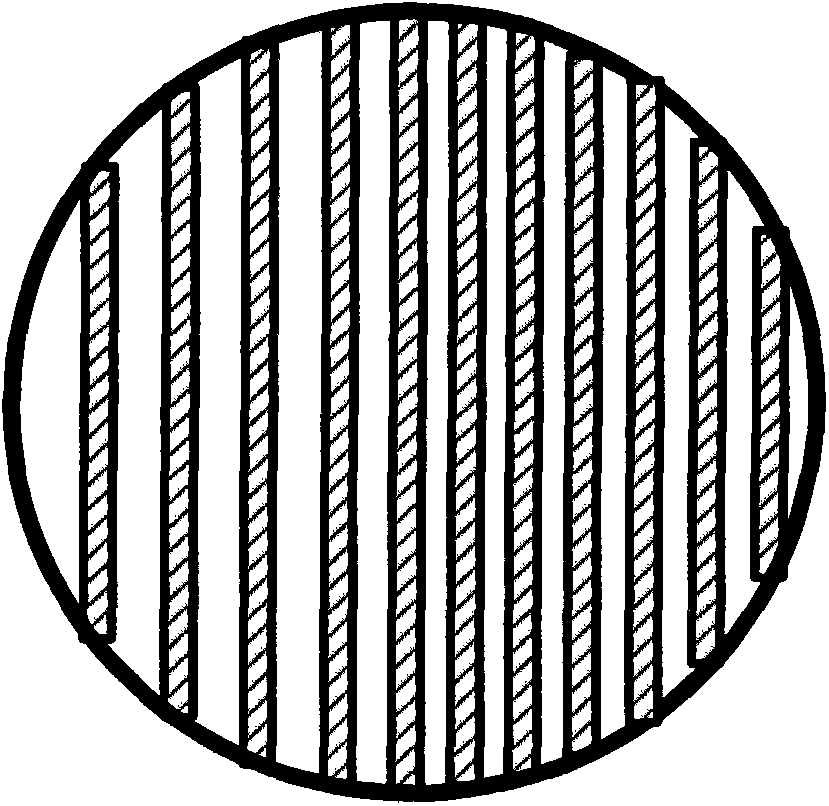

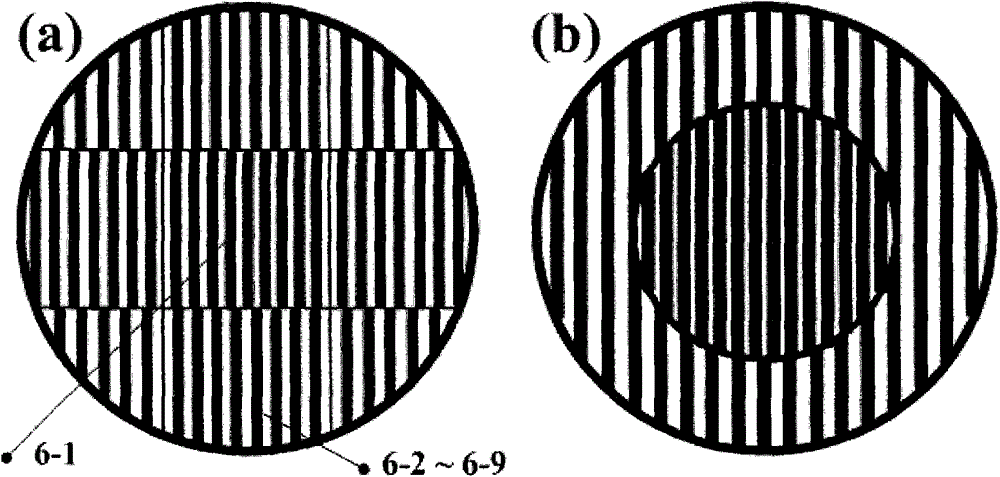

Venturi rod layer with non-uniform rod distances

ActiveCN103908855AGuaranteed contact effectEfficient mass transferUsing liquid separation agentSpray towerEngineering

The invention discloses a Venturi rod layer with non-uniform rod distances. The Venturi rod layer is characterized in that: the Venturi rod layer comprises at least more than one non-uniformly distributed corrosion-resisting metal or nonmetal solid rod or hollow pipe assembly, and the distance among the rod assembly or the pipe assembly is determined by the gas flow distribution in the zone where the rod assembly or the pipe assembly are installed. The Venturi rod layer is disposed between a gas feeding section of a spraying tower and a first spraying device and / or in a gas adsorption section. The Venturi rod layer provided by the invention can give better play to the Venturi effect generated when gas flows through converging-diverging paths among rods, and therefore (1) "homogenization" adjustment of gas bias current in the gas feeding section of the spraying tower and / or low-gas-velocity distribution of the high side wall in the center of the tower are achieved so that the gas flowing through the rod layer approximates to "plug flow", thus increasing the gas-liquid contacting efficiency; (2) a highly-turbulent liquid thin layer is formed on the surface of the rod layer so that efficient bubbling mass transfer of "gas in liquid" can be achieved when the gas is flowing through the rod layer zone, thus significantly increasing the mass transfer efficiency; and (3) "self-cleaning" of the rods can be achieved by high-speed washing and turbulence of gas flow among rod gaps.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

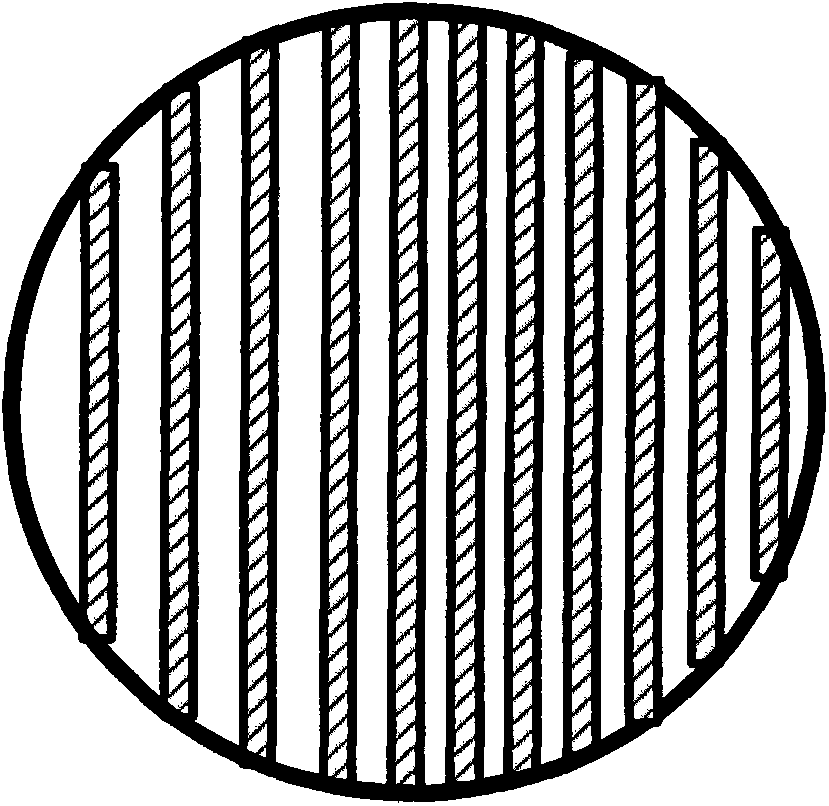

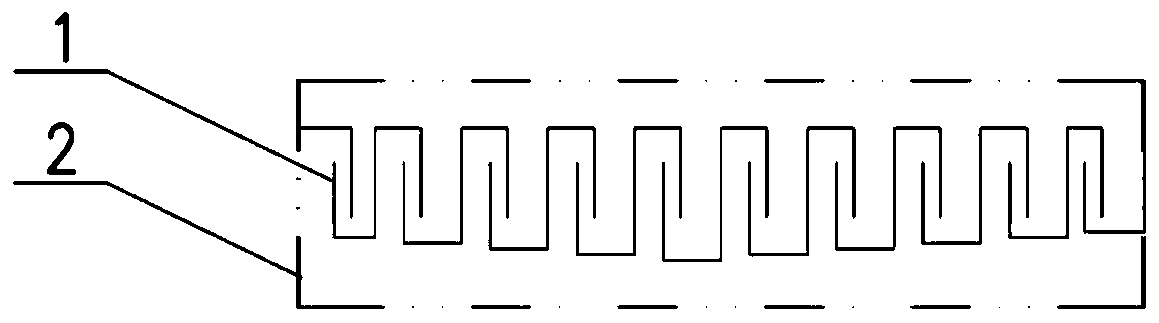

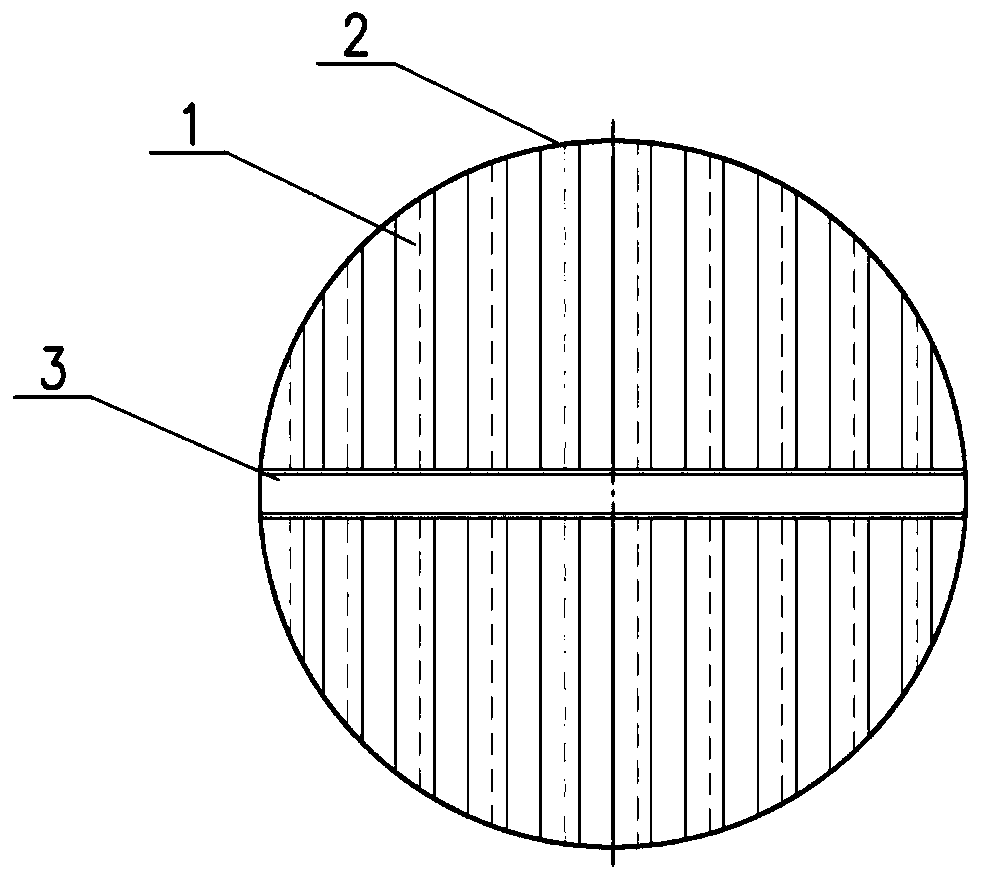

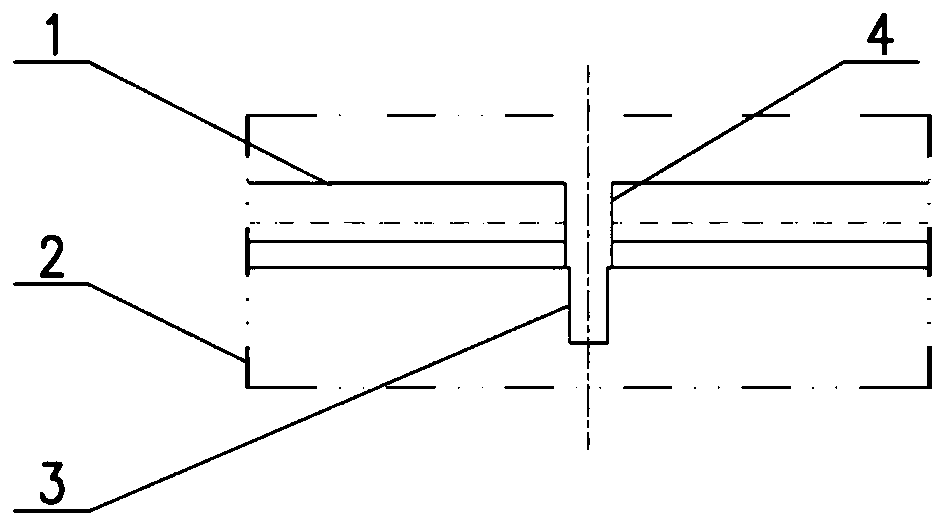

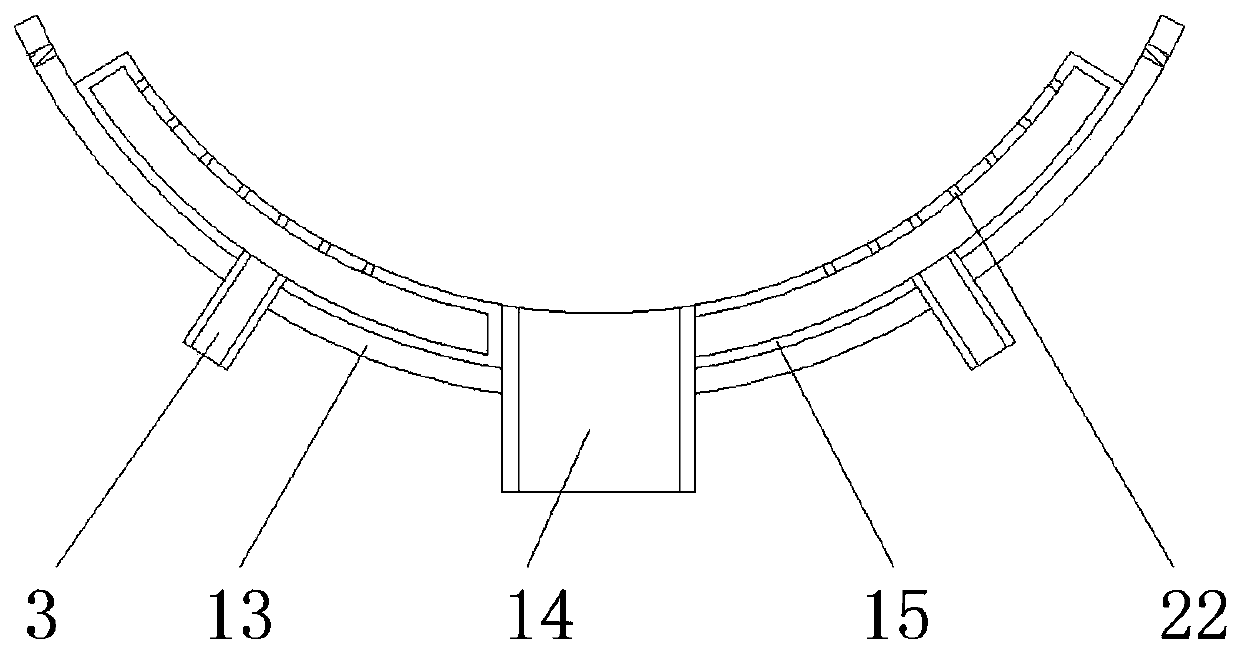

S-shaped strip-shaped bubble cap desulfurization tower tray device with gradually changed height

PendingCN111298630AHigh desulfurization and dust removal efficiencyNo overflowDispersed particle separationFlue gasDust control

The invention discloses an S-shaped strip-shaped bubble cap desulfurization tower tray device with gradually changed height, which comprises at least one U-shaped support piece and a tower tray. The U-shaped support piece is fixedly arranged in an absorption tower, and the U-shaped support piece is provided with a U-shaped groove. The tower tray is vertically arranged above the U-shaped support piece, the tower tray is formed by arranging a plurality of strip-shaped plate bodies with transverse S-shaped sections in parallel, the S-shaped end parts of the adjacent plate bodies are mutually staggered and arranged at intervals, and the intervals form a middle channel. Gas sealing plates are arranged at the ends of the plate bodies and located on the two sides of a flue gas inlet. The S-shapedtops of the strip-shaped plate bodies are flush with one another. T he S-shape heights of the strip-shaped plate bodies which are sequentially arranged from the inner wall of the tower tray to the center of the tower tray are gradually increased. The tower tray device has the beneficial effects that overflowing caused by the fact that the liquid level of local slurry exceeds the upper edges of the S-shaped end parts is avoided; and gas and liquid in the tower tray are uniformly mixed, so that the overall desulfurization and dust removal efficiency of the tower tray is effectively improved, and discharge of granular heavy metals is reduced.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

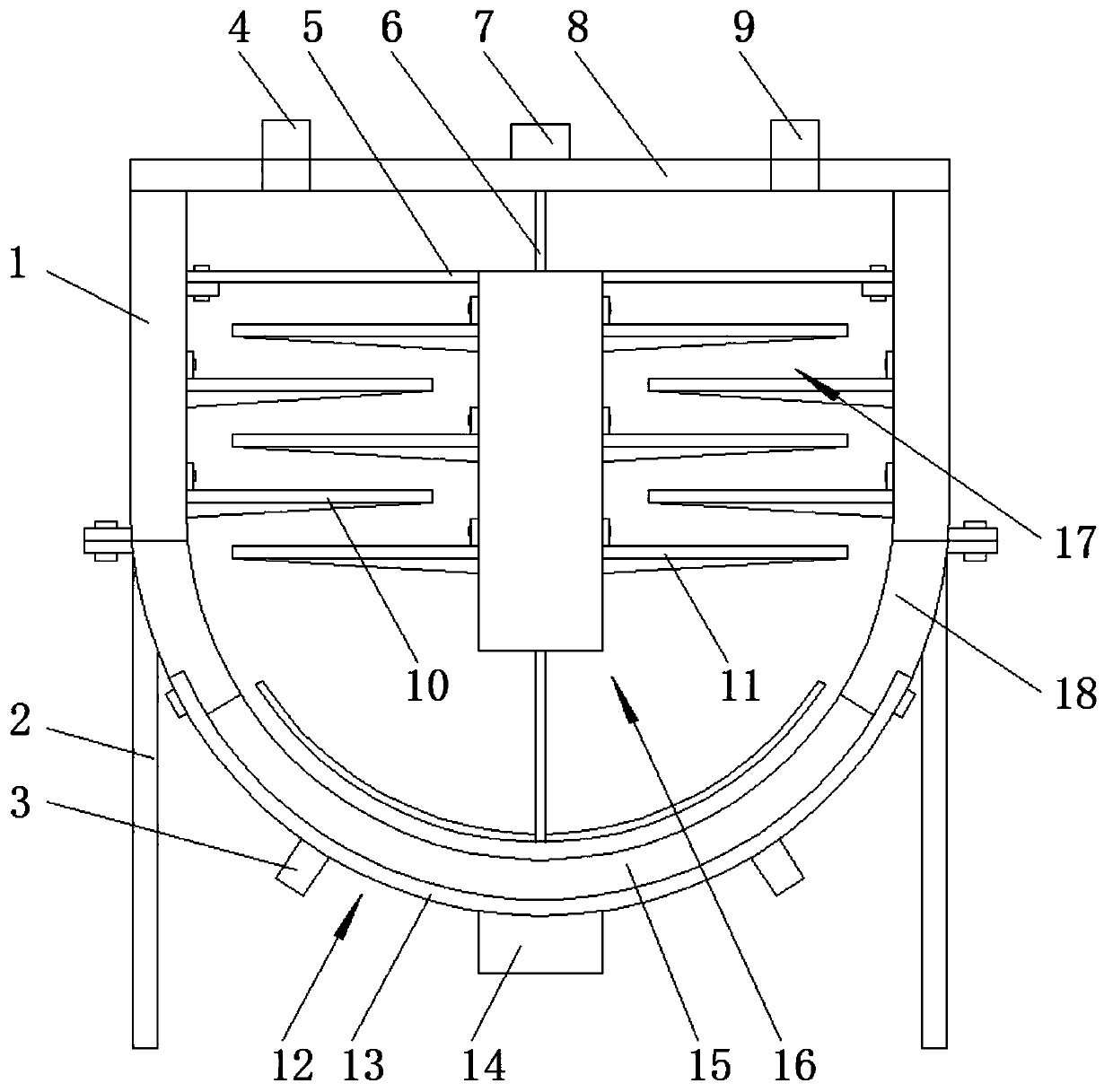

Flue gas dust removal and desulfurization device

InactiveCN110327765AImprove the quality of dedusting and desulfurizationReasonable structural designGas treatmentUsing liquid separation agentFlue gasPropeller

The invention discloses a flue gas dust removal and desulfurization device which comprises a top cover, a circulating cylinder, a bottom cover, a gas inlet assembly, a lifting assembly and a bafflingassembly. A top cover is buckled at the top end of the vertically arranged circulating cylinder; the bottom end of the circulating cylinder is connected with a bottom cover through a bolt; an air inlet assembly is detachably installed in the center of the bottom cover and comprises an air distribution plate which is arranged in the bottom cover and provided with a plurality of air outlet holes. Aone-way valve is arranged in each air outlet hole; a lifting assembly is mounted in the circulating cylinder above the air distribution plate and comprises a rotating shaft and a lifting cylinder, wherein the rotating shaft is internally and rotatably arranged and is provided with lifting propeller blades; the lifting cylinder sleeves the rotating shaft; the top end of the rotating shaft penetrates through the top cover and is fixedly connected with a motor shaft, fixed to the top end face of the top cover, of a motor. A baffle assembly is mounted on the inner side wall of the circulating cylinder on the peripheral side of the lifting assembly. The device has the advantages of reasonable structural design, practicability, reliability and the like, and can be widely popularized and used.

Owner:杭州汇东环境工程有限公司

Flue gas treatment system

PendingCN110180366AHigh desulfurization and dust removal efficiencyReduce resistanceCombination devicesGas treatmentLiquid wasteWaste treatment

The invention relates to the technical field of flue gas treatment of heat recovery boilers and industry kiln stoves, and specially discloses a flue gas treatment system. The flue gas treatment systemcomprises a waste heat recovery section, a washing absorption section and a washing absorption liquid treatment section, wherein the waste heat recovery section is used for cooling flue gas; the washing absorption section is used for washing and absorbing waste gas; the washing absorption liquid treatment section is used for performing environment-friendly treatment on waste liquid subjected to washing. The system disclosed by the invention integrates waste heat reuse, washing absorption and waste liquid treatment; after the treatment, waste gas and waste heat recycle is realized, energy consumption is reduced, emission concentration of sulfur dioxide is less than 20 mg / Nm<3>, emission concentration of dust is less than 5 mg / Nm<3>, waste water COD is lower than 50 mg / L, SS (suspended solid) is lower than 30 mg / L, PH maintains at around 7, and effects of governing air pollutants and water pollutants are realized.

Owner:COAL IND JINAN DESIGN & RES

Efficient turbulence atomization mixing desulfurization and dust removal process based on rotational flow

ActiveCN111097249AHigh densityExtension of timeCombination devicesGas treatmentParticulatesEngineering

The invention discloses an efficient turbulence atomization mixing desulfurization and dust removal process based on rotational flow, which comprises the following steps: after smoke dust flows downwards and passes through a reducing section, particles and gas components in the smoke dust are compressed and collided, and the density is increased; after the smoke dust enters a stable section, the particles are collided due to the curved surface structures of an arc-shaped concave section, an arc-shaped convex section and an inclined surface section; desulfurization slurry in the slurry pool issprayed into the spray cooling area through a first liquid feeding pipe and a first nozzle, so as to spray particles to form a gas-liquid mixture; the second rotational flow plate and the first rotational flow plate are opposite in rotational flow direction, upward rotational flow is formed, more contacts with desulfurization slurry are made multiple times and the slurry continuously flows downwards to enter a rotational flow diverging area, so the contact time of sulfide and the desulfurization slurry is greatly prolonged, and the sedimentation efficiency is further improved. The desulfurization and dust removal process is high in desulfurization and dust removal efficiency, the dust emission concentration is detected to be smaller than 3.8 mg / m < 3 > and the sulfur dioxide emission concentration is detected to be smaller than 25 mg / m < 3 > after 0.1 ton of normal-pressure coal-fired boiler smoke dust is processed.

Owner:新疆海天祥瑞环保工程有限公司

Multi-stage spray venturi desulfurization and dust removal apparatus and method thereof

PendingCN109107342ASimple structureSmall footprintGas treatmentUsing liquid separation agentFlue gasSpray nozzle

The invention relates to a desulfurization and dust removal integrated apparatus, particularly to a multi-stage spray venturi desulfurization and dust removal apparatus and a method thereof. The multi-stage spray venturi desulfurization and dust removal apparatus comprises flue gas pipes connected to both ends of a venture pipe, a desulfurizing agent conveying pipe, a desulfurization and dust removal tower with a clean flue gas outlet at the top portion, and a precipitation pool, wherein the desulfurizing agent conveying pipe is connected to a desulfurizing agent storage pool through a desulfurization and dust removal conveying pump, the flue gas pipe is tangentially connected to the bottom portion of the desulfurization and dust removal tower, a plurality of spray baffles are arranged inthe flue gas pipe connected to the inlet section of the venturi pipe, the bottom ends of the spray baffles are provided with atomizing spraying nozzles, the inlet ends of the spray baffles are connected to the desulfurizing agent conveying pipe, the bottom portion of the desulfurization and dust removal tower is provided with a liquid outlet pipe, the liquid outlet pipe is connected above the precipitation pool, and any one of the spray baffles and the adjacent spray baffle are arranged in the flue gas pipe in a staggered manner. Compared to the apparatus in the prior art, the apparatus of theinvention has advantages of simple structure, small occupation area, short flue gas channel, long gas flow stroke, convenient maintenance, low investment, high desulfurization and dust removal efficiency and the like.

Owner:广西广逸环保科技有限公司

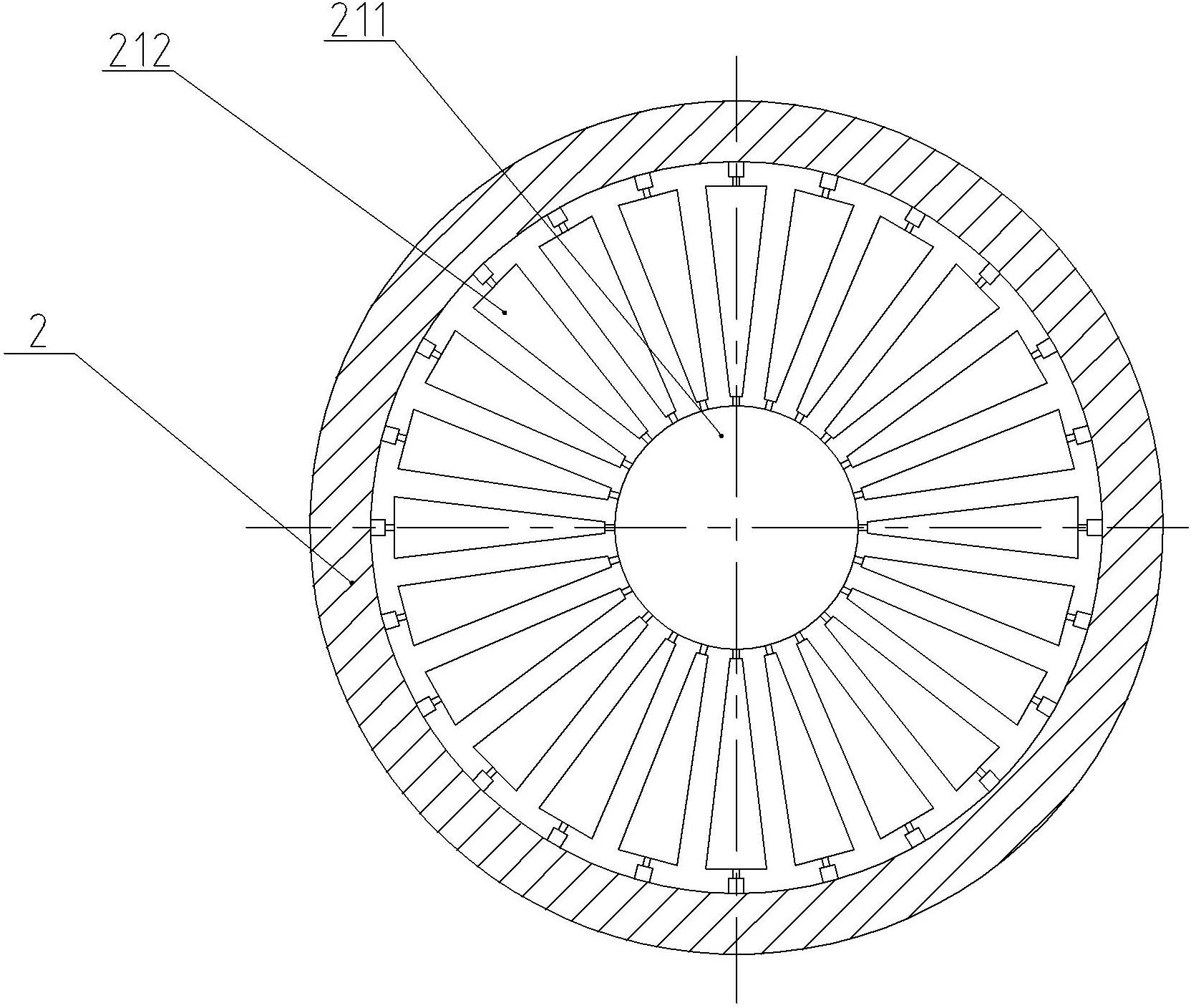

Pneumatic flow dividing, spraying and desulfurizing equipment

InactiveCN102228780ASimple processIncrease kinetic energyCombination devicesUsing liquid separation agentIsosceles trapezoidFlue gas

The invention discloses pneumatic flow dividing, spraying and desulfurizing equipment. The pneumatic flow dividing, spraying and desulfurizing equipment comprises a gas inlet chamber, a tower body and a gas discharging opening, wherein three layers of spraying devices and a dehydrating and demisting device are arranged in the tower body; a pneumatic flow dividing device is arranged between an outlet of the gas inlet chamber and a first-layer spraying device, and consists of a central column and a plurality of isosceles trapezoid-shaped metal sheets, one ends of the metal sheets are welded to the central column through connecting pieces, the other ends of the metal sheets are fixed on the inner wall of the tower body through the connecting pieces, included angles between the metal sheets and the horizontal direction are between 22 DEG and 30 DEG, and the circumference consisting of the whole metal sheets has a ventilation rate of about 40%, so that the rotary ascending velocity of flue gas flow is increased, kinetic energy of the flue gas flow is increased, ascending flue gas flow can hold absorption liquid sprayed down from the upper side, and the strong mass transfer time between a gas phase and a liquid phase is extended, thus SO2 and dust particles in flue gas can be well reacted and adsorbed, and the high desulfurizing and dust removing efficiency is realized; meanwhile, according to the pneumatic flow dividing, spraying and desulfurizing equipment disclosed by the invention, an absorption liquid circulating system has the advantages of low energy consumption and low operation cost.

Owner:HUNAN JIAYU ENVIRONMENT PROTECTION EQUIP

A Venturi rod layer with non-uniform rod spacing

ActiveCN103908855BGuaranteed contact effectEfficient mass transferUsing liquid separation agentThin layerSpray tower

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com