Integrated wet flue gas desulphurization and dust removal device and method

A technology of wet flue gas desulfurization and desulfurization equipment, applied in chemical instruments and methods, separation methods, external electrostatic separators, etc., can solve the problems of high energy consumption, low efficiency of flue gas desulfurization and dust removal, and low utilization rate of wastewater. Achieve the effects of saving investment, improving efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

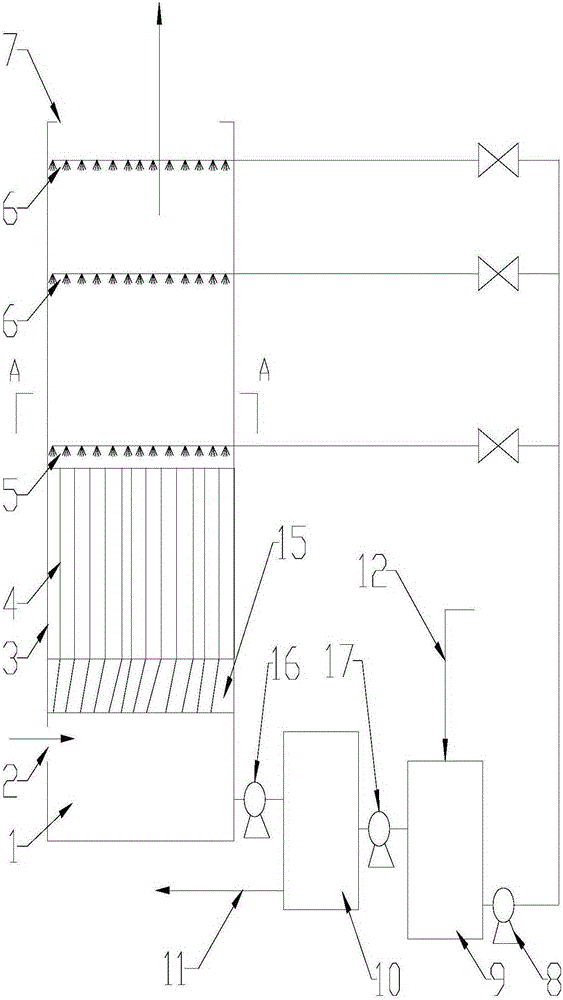

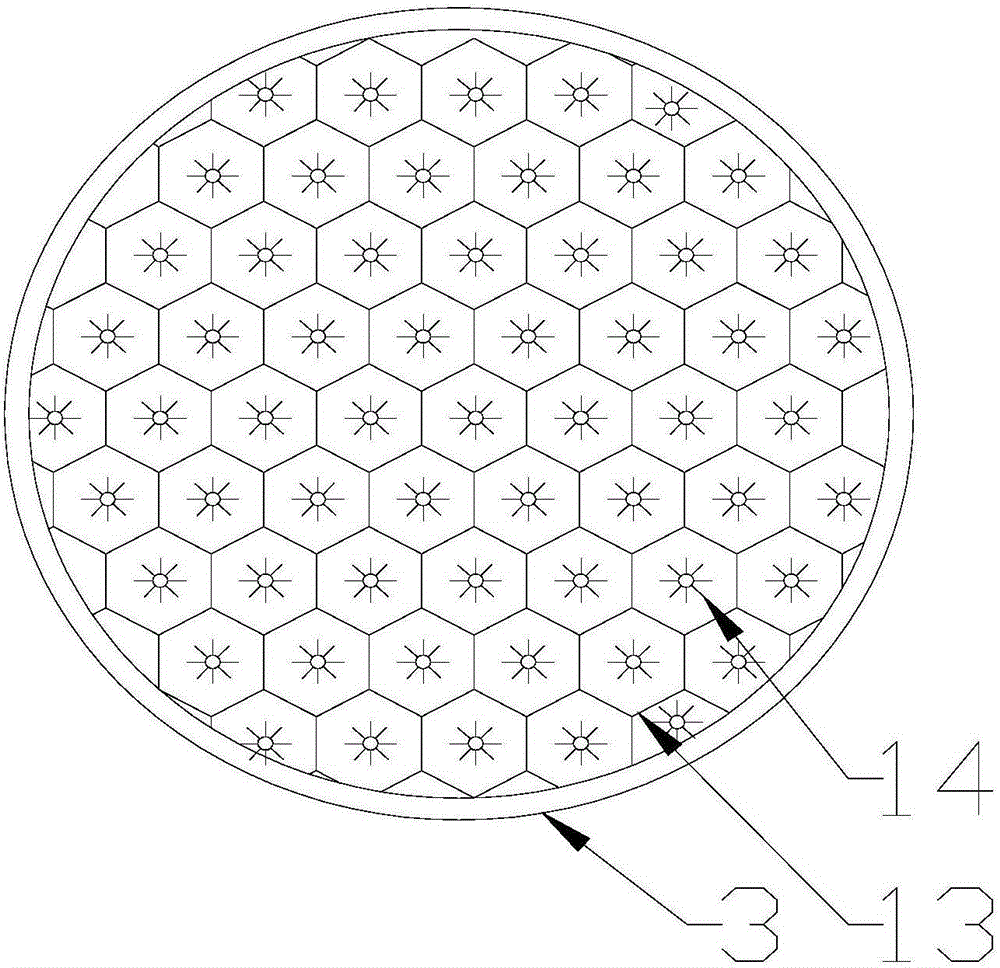

[0016] Depend on figure 1 combine figure 2 As shown, the upper part of the integrated wet flue gas desulfurization and dust removal device is alkaline desulfurization, and the lower part is tubular electrostatic precipitator. The device includes a cylinder 3, which is an upright cylinder with flue gas on one side of the bottom Inlet channel 2, the bottom space of cylinder body 3 in the lower part of the flue gas inlet channel 2 is a buffer pool 1, and the upper part of the flue gas inlet channel 2 is an air flow uniform distribution plate 15, which has a uniform flow for the flue gas flow Effect, the flue gas after flow equalization is beneficial to electrostatic dust removal and lye sulfur removal, the upper part of the air flow uniform distribution plate 15 is the electrostatic dust removal area 4, and a number of honeycomb inner hexagonal anode tubes 13 are suspended i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com