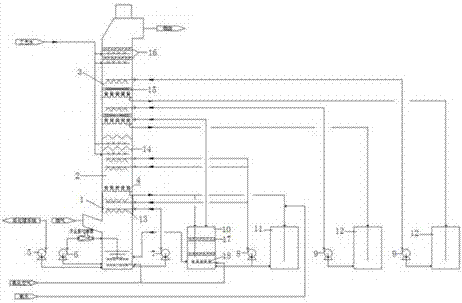

DDC (Desulfurization-Dedusting-Cleansing) process and device for flue gas multi-pollutant ultra-low ammonia emission

A pollutant and flue gas technology, applied in the field of processes and devices, can solve problems such as endangering human health, air pollution, aggravating the greenhouse effect, etc., and achieve the effects of saving investment and operating costs, stable device operation, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

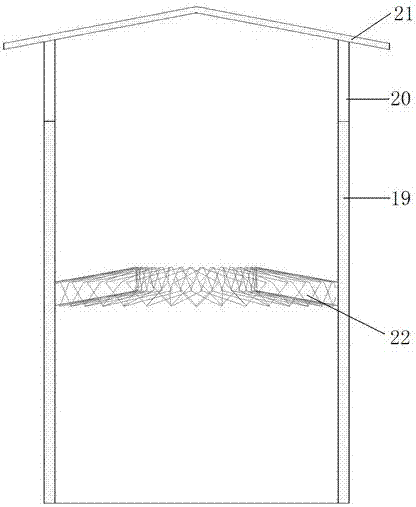

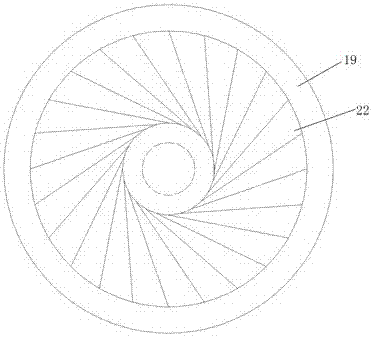

[0038] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0039] The cyclone aerator 18 used in the present invention is purchased from Yixing Chimei Hydraulic Plastics Co., Ltd.

[0040] The reaction of the flue gas multi-pollutant ultra-low emission ammonia method DDC process of the present invention is mainly:

[0041] (NH 4 )2SO 3 + H 2 SO 3 = 2NH 4 HSO 3 + H 2 O(1)

[0042] NH 4 HSO 3 + NH 3 ·H 2 O=(NH 4 ) 2 SO 3 + H 2 O (2)

[0043] Ammonium sulfite absorbs sulfur dioxide to generate ammonium bisulfite, and ammonium bisulfite is added with ammonia to generate absorbent ammonium sulfite.

[0044] The product of ammonia desulfurization is ammonium sulfate, which is a stable salt and does not have the ability to absorb sulfur dioxide. In order to ensure efficient ammonium sulfite oxidation rate and sulfur dioxide absorption rate, the oxidation and absorption process is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com