Low emission technology and complete set of equipment for pollutant in flue gas from garbage power generating boiler

A boiler flue gas and garbage power generation technology, applied in the field of pollutant absorption, can solve the problems that ultra-low emissions cannot be achieved, and it is difficult to meet EU emission standards, etc., and achieve the effects of scientific device design, wide trial use, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

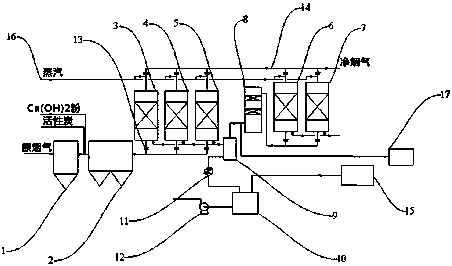

[0024] Such as figure 1 As shown, a complete set of pollutants in waste-to-energy boiler flue gas, SDA reactor 1, bag filter 2, first adsorption tank 3, regeneration tank 4, first backup tank 5 and gas-liquid separator 9, oxidation decomposition The tower 8, the second adsorption tank 6 and the second standby tank 7 are connected through pipelines successively, the liquid outlet after the separation of the gas-liquid separator 9 is connected to the neutralization tank 10, and the ozone is also connected between the oxidation decomposition tower 8 and the gas-liquid separator 9 Generator 17.

[0025] According to a specific embodiment of the present invention, after semi-dry desul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com