Warping sheet type low-temperature gas heat exchange condensation water collecting device

A water collection device and low-temperature gas technology, which is applied in the field of warp-type low-temperature gas heat exchange condensation water collection device, can solve the problems of deep purification of flue gas and insufficient moisture content reduction, unfavorable environmental protection requirements, and impact on the surrounding environment, etc., to achieve No secondary pollution, plume control, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

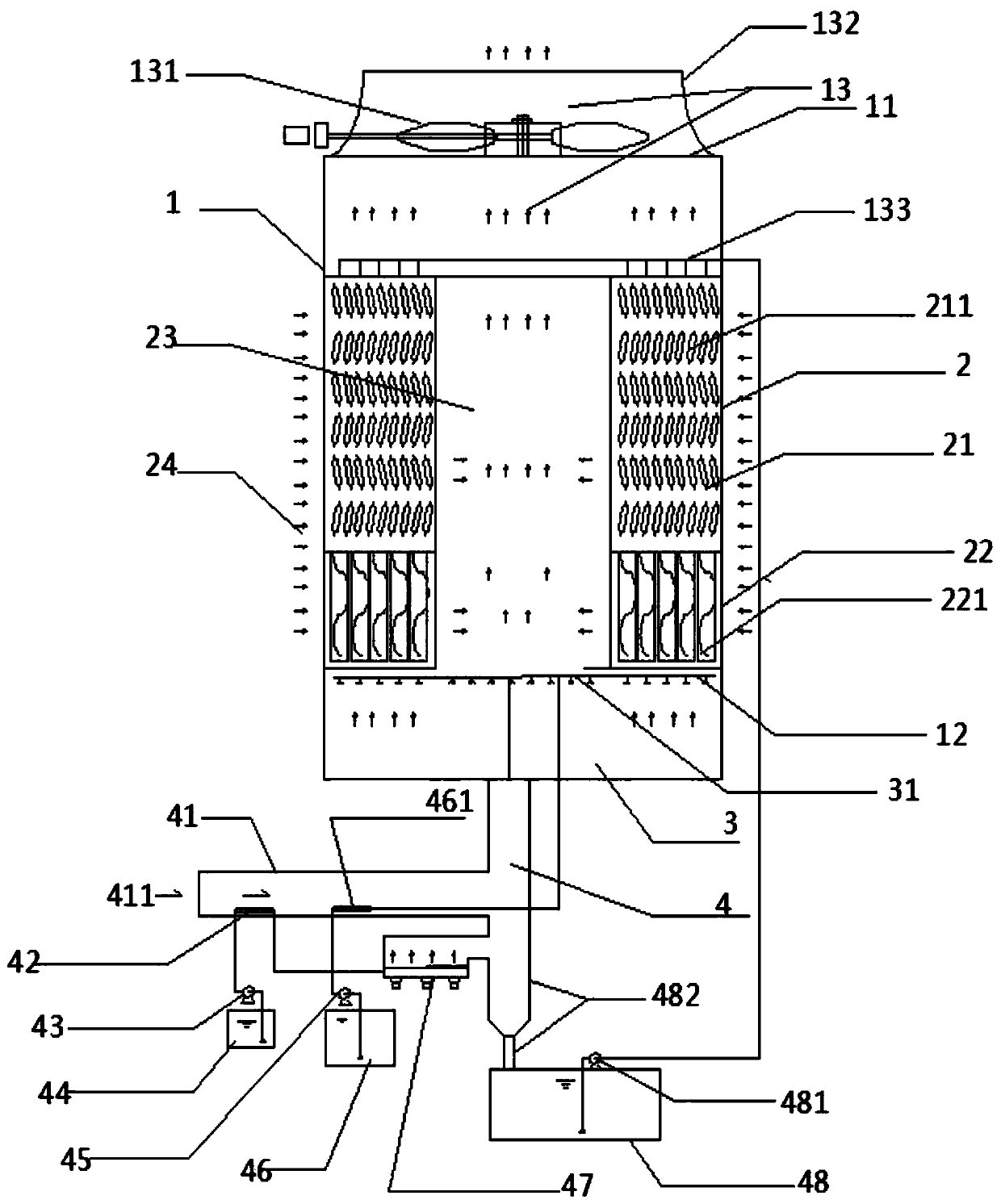

[0028] see figure 1 , figure 2 , the chip-type low-temperature gas heat exchange condensation water collection device includes a heat exchange device and a water collection device. The heat exchange device includes at least two heat exchange boxes 2, and the heat exchange boxes 2 can be arranged in pairs; The heat box 2 is arranged on both sides, and a natural air outlet 23 is formed between the two heat exchange boxes. The heat exchange box 2 is divided into an upper half 21 and a lower half 22 of the heat exchange box; the upper half of the heat exchange box 21 includes at least two rows of square fin heat exchangers 211, and each row of heat exchangers 211 includes at least two fin heat exchangers 211; the lower part of the heat exchanger 22 includes circular fin heat exchangers. A heat exchanger 221; the upper half 21 of the heat exchange box is fixedly connected to the lower half 22 of the heat exchange box;

[0029] The upper part of the heat exchange box 2 is provide...

Embodiment 2

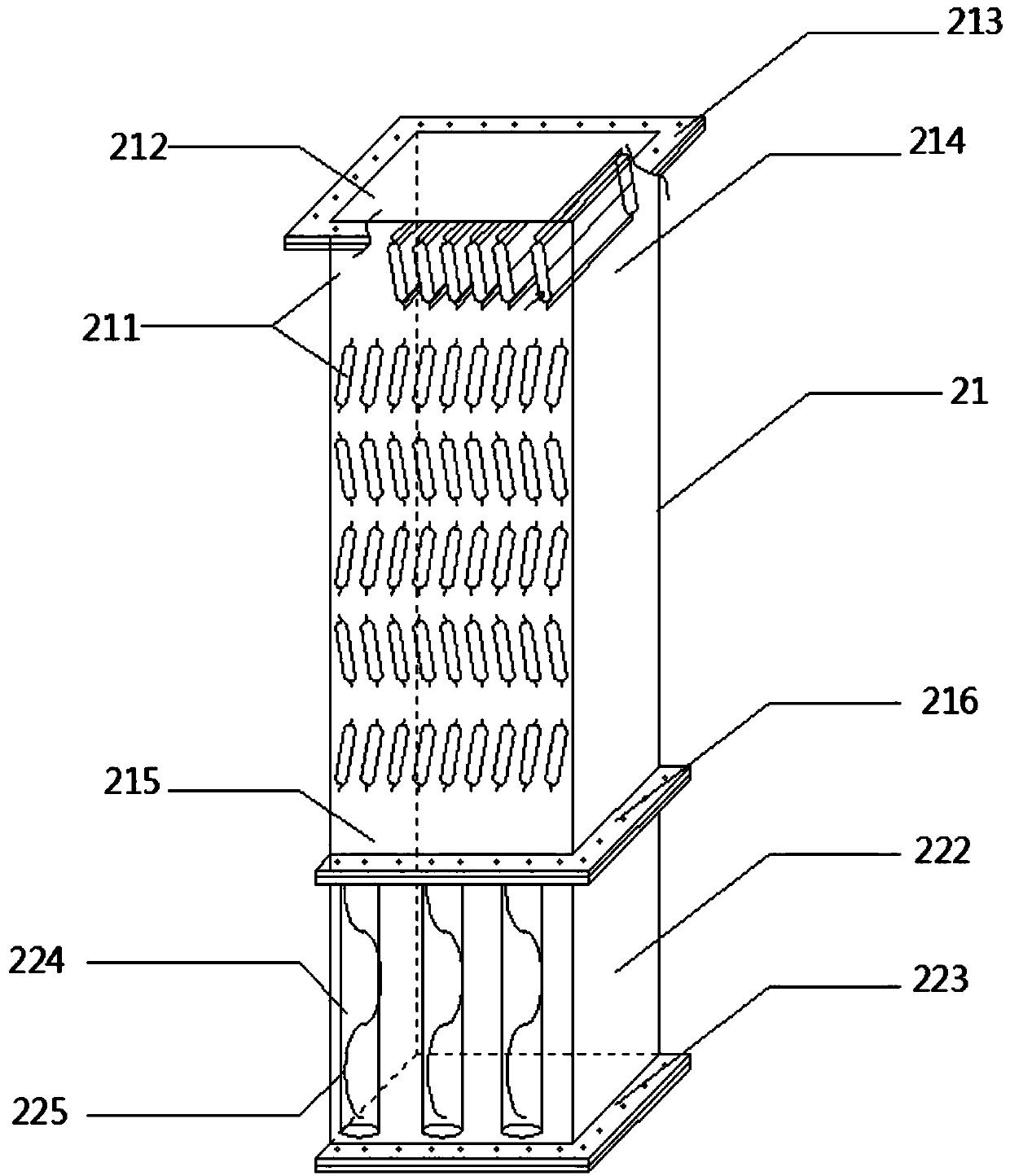

[0052] see figure 2 , image 3 , the difference from the above-mentioned embodiment is that a steel plate 212 is arranged on the top of the heat exchange box 2 in the present invention, and the steel plate 212 is connected to the heat exchange box 2 through a flange 213 .

[0053] The bottom end of the upper part 21 of the heat exchange box is connected to the lower part 22 of the heat exchange box through a flange 216 . The side of the upper part 21 of the heat exchange box includes a side steel plate 214 .

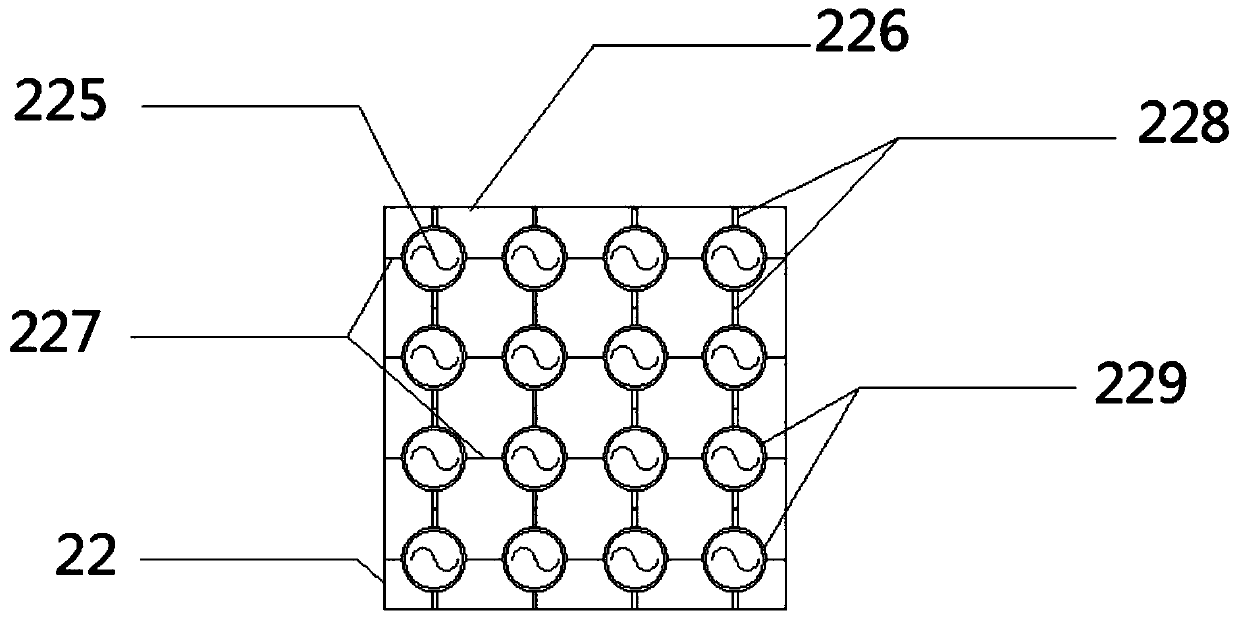

[0054] The lower part 22 of the heat exchange box includes a circular finned heat exchanger 221. The circular finned heat exchanger 221 includes an outer frame 226, and a connecting piece 227 and at least two heat exchangers are arranged in the outer frame 226. The heat pipe 229 is also provided with a warp stainless steel pipe 224; the connector 227 is connected with the outer frame 226 and the heat exchange tube 229, and the heat exchange tubes 229 are connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com