Small-sized multilayer dust removal and desulfurization device

A desulfurization device, multi-layer technology, applied in the field of small multi-layer dust removal and desulfurization devices, can solve the problems of large footprint, environmental pollution, short service life, etc., and achieve improved desulfurization and dust removal efficiency, high desulfurization and dust removal efficiency, structure simple compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

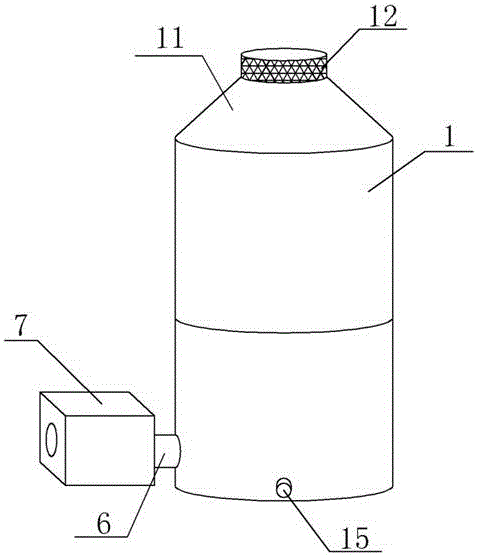

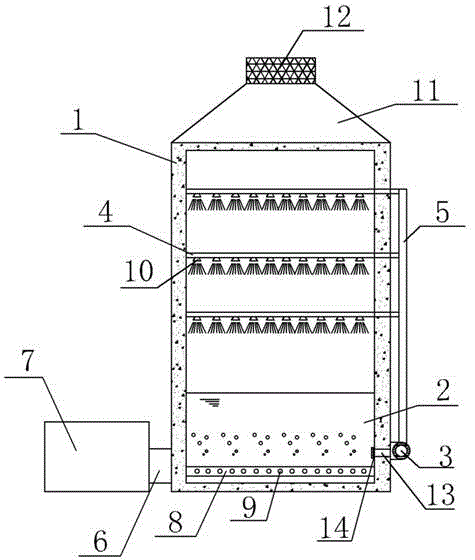

[0025] Such as figure 1 and figure 2 Shown is a preferred solution of the present invention, a small-scale multi-layer dedusting and desulfurization device, the inner bottom of the tank body 1 is provided with a water bath 2, the lower part of the outer wall of the tank body 1 is provided with a lift pump 3, and the inside of the tank body 1 is provided with three Layer spray layer 4, the lower part of the outer wall of the tank body 1 is also provided with a water inlet pipe 13 communicating with the water bath 2, and the lift pump 3 is connected to the water inlet pipe 13 and sprayed with each layer through the pipeline 5 arranged on the outer wall of the tank body 1. The layers 4 are all connected; the spray layer 4 is set in three layers, and the whole device firstly performs the first step of desulfurization and dust removal through the water bath 2, so that the gas enters the tank body 1 and is directly surrounded by liquid, which increases the contact between the gas-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com