Patents

Literature

49results about "Working-up peat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

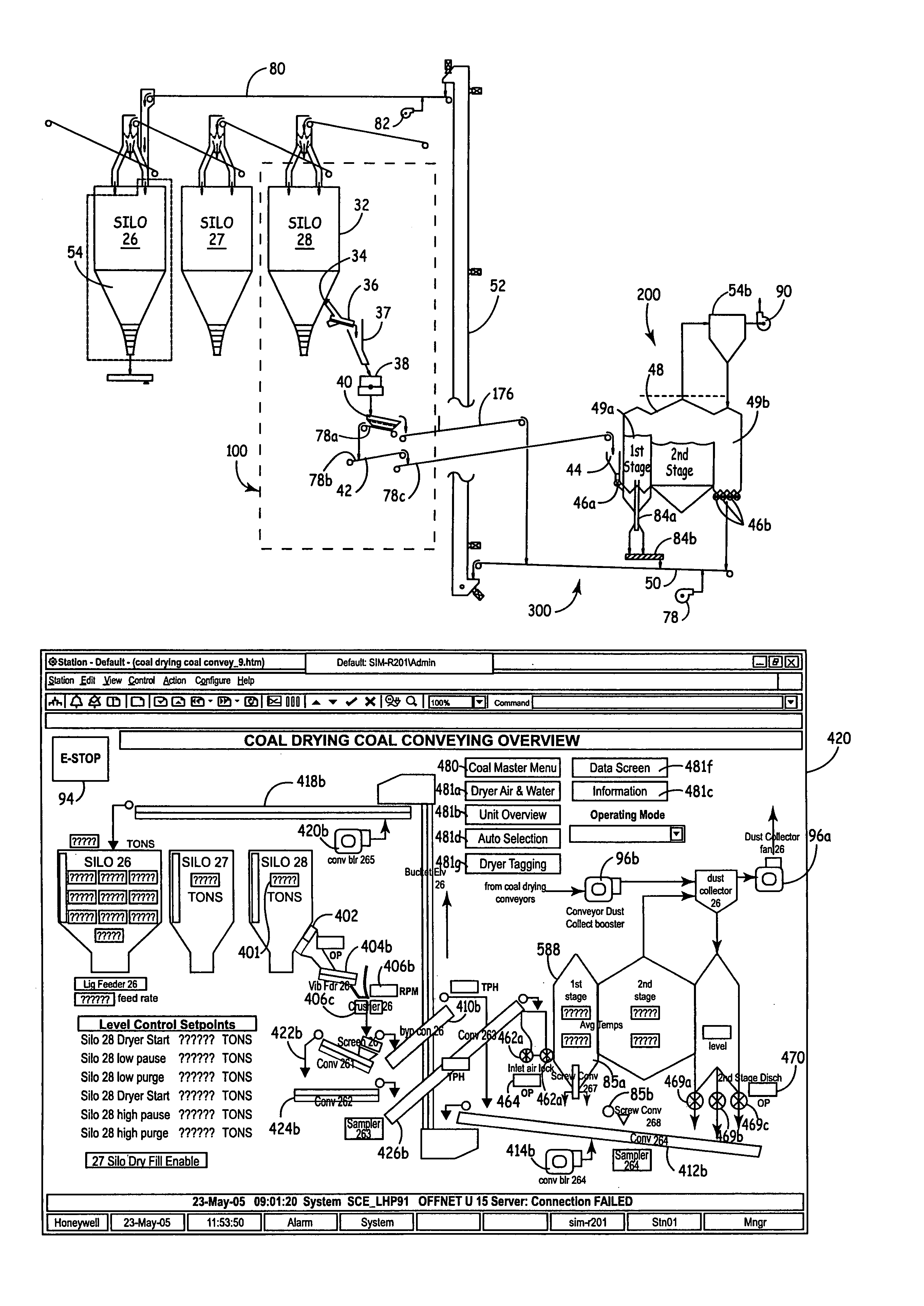

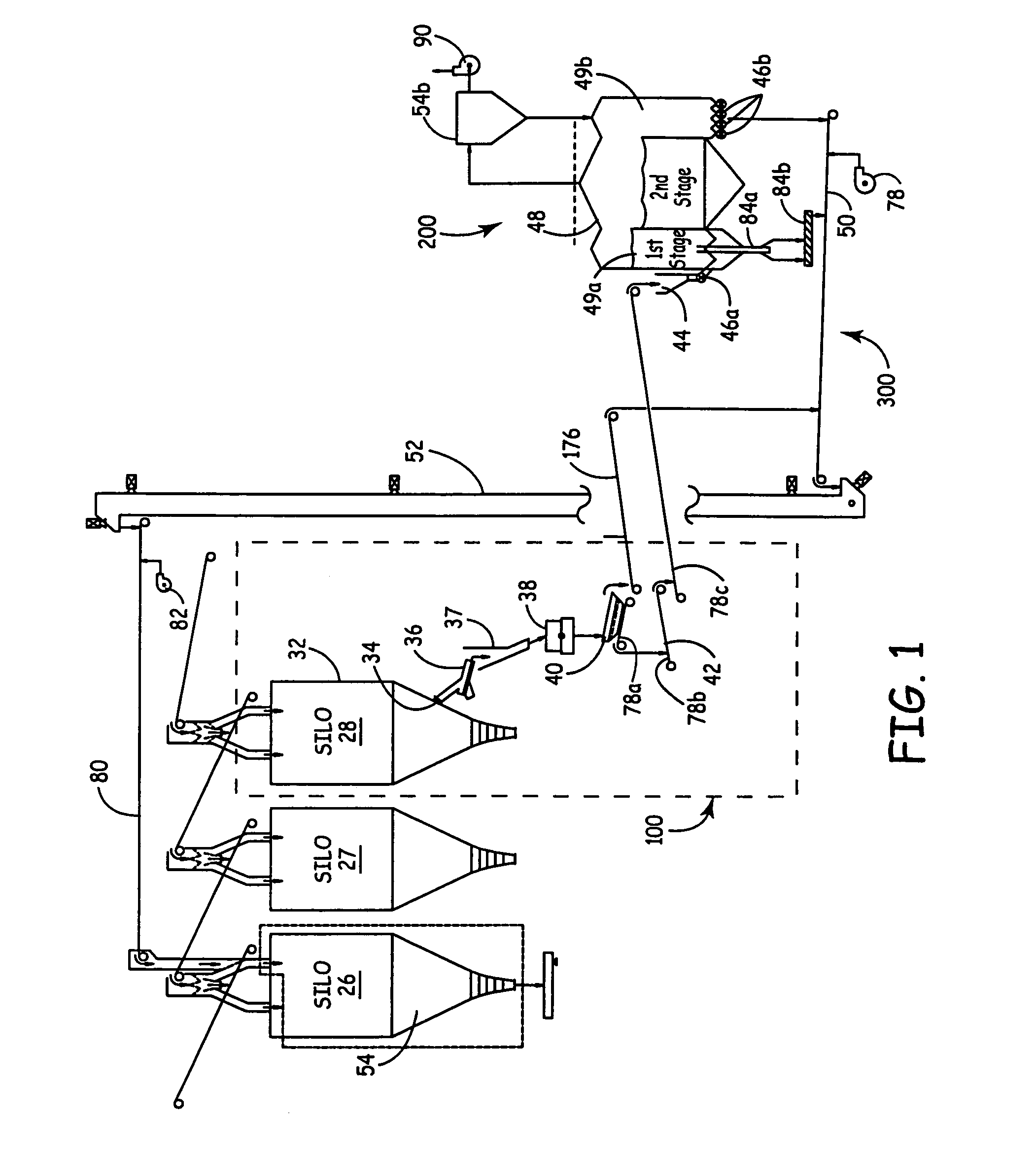

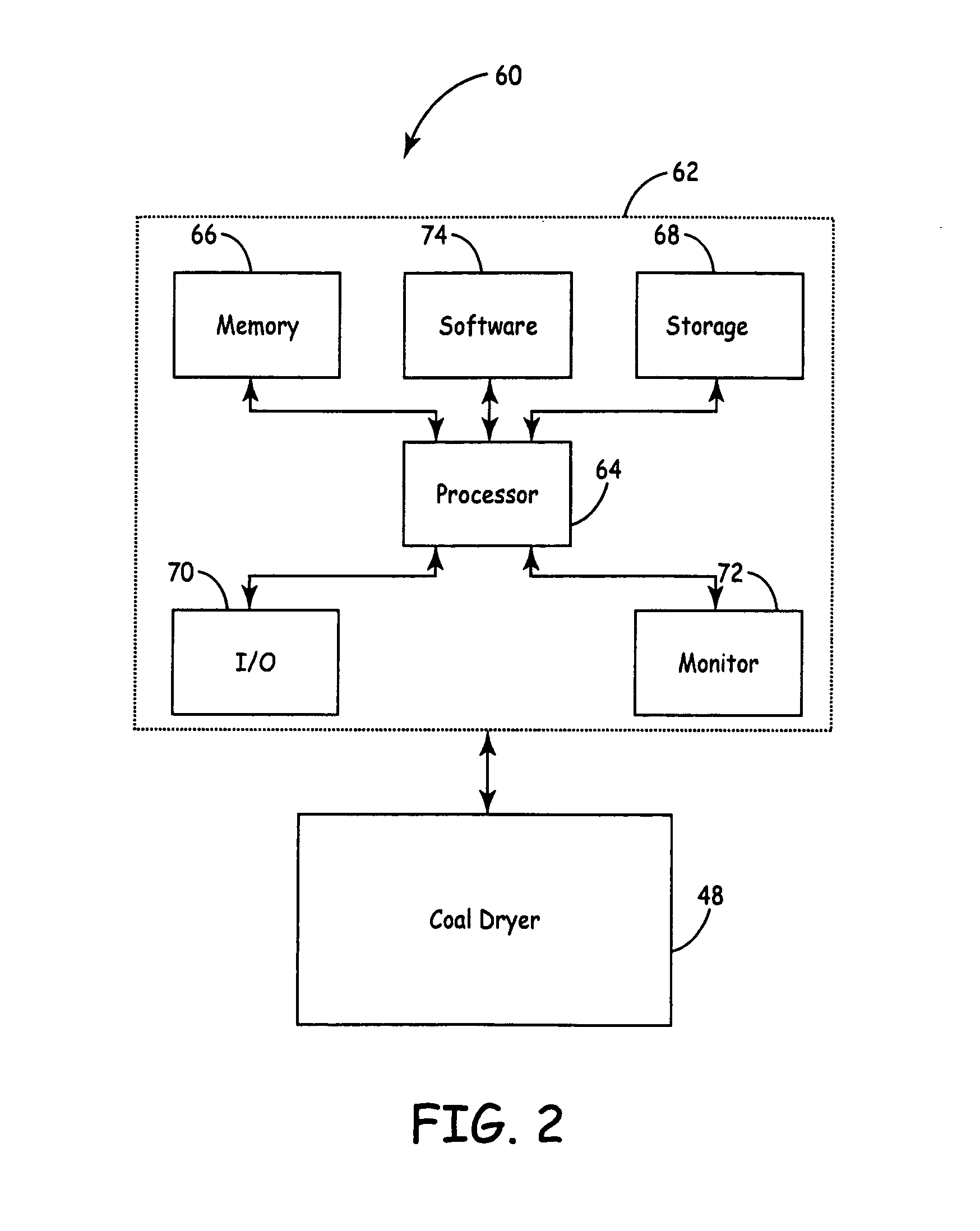

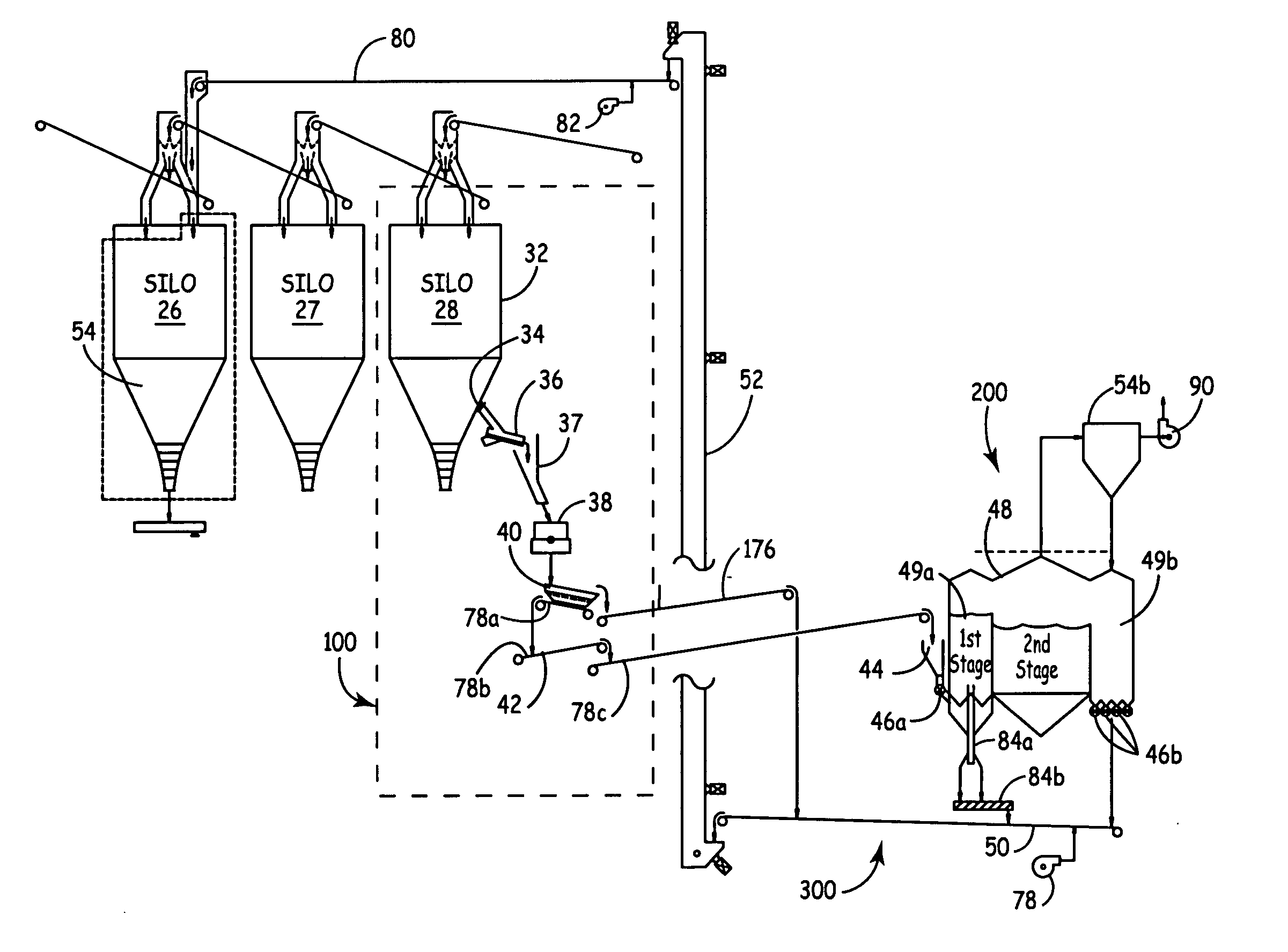

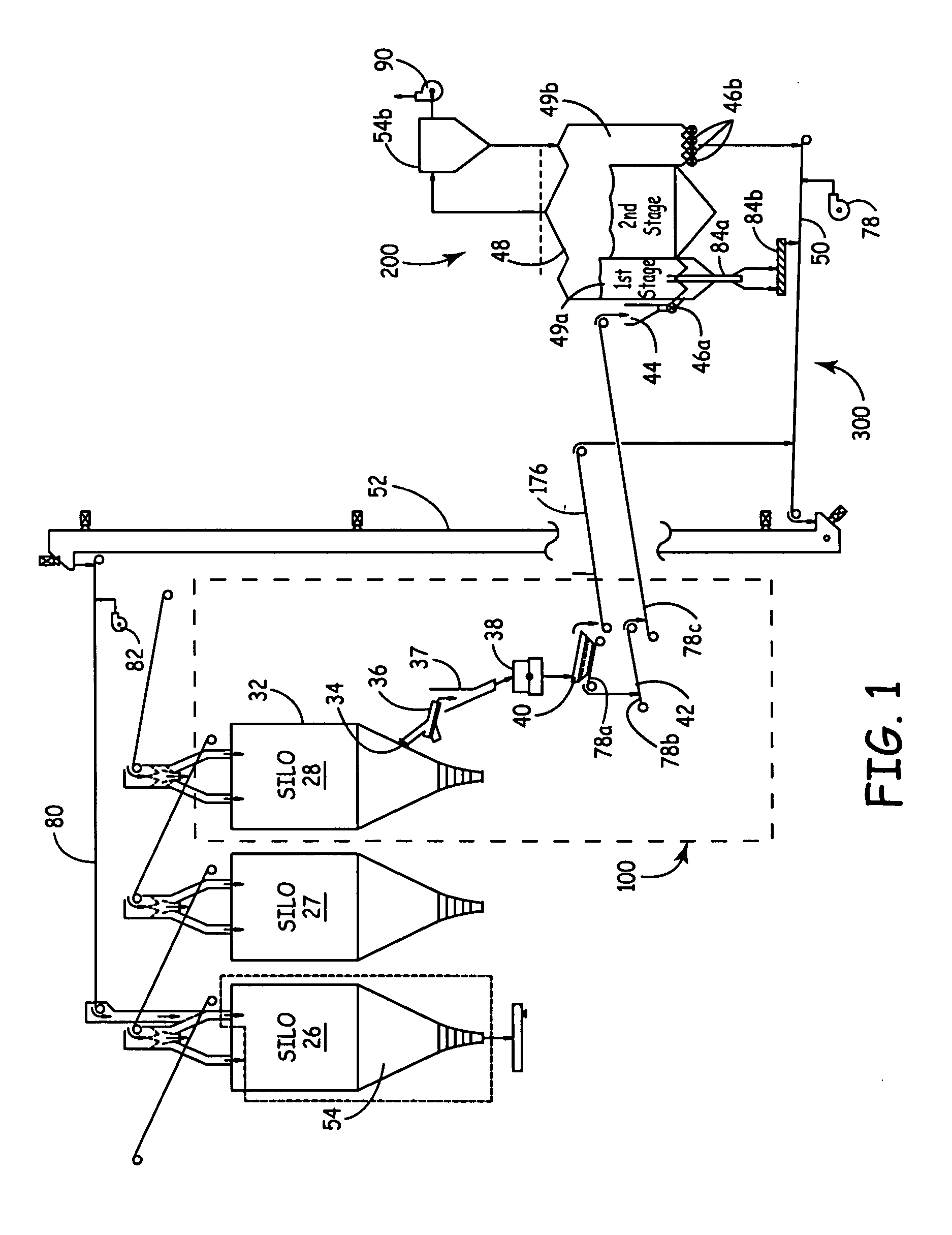

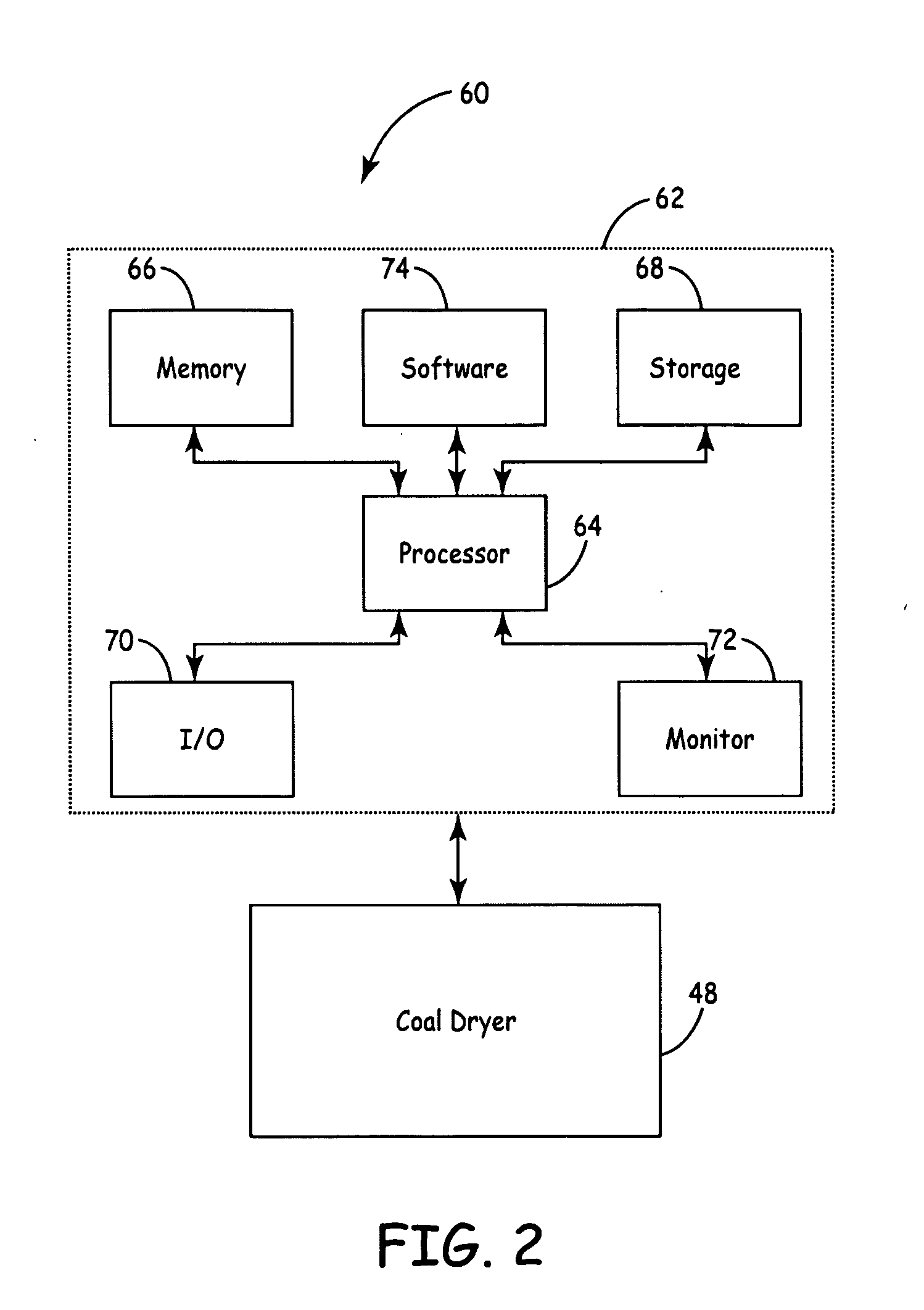

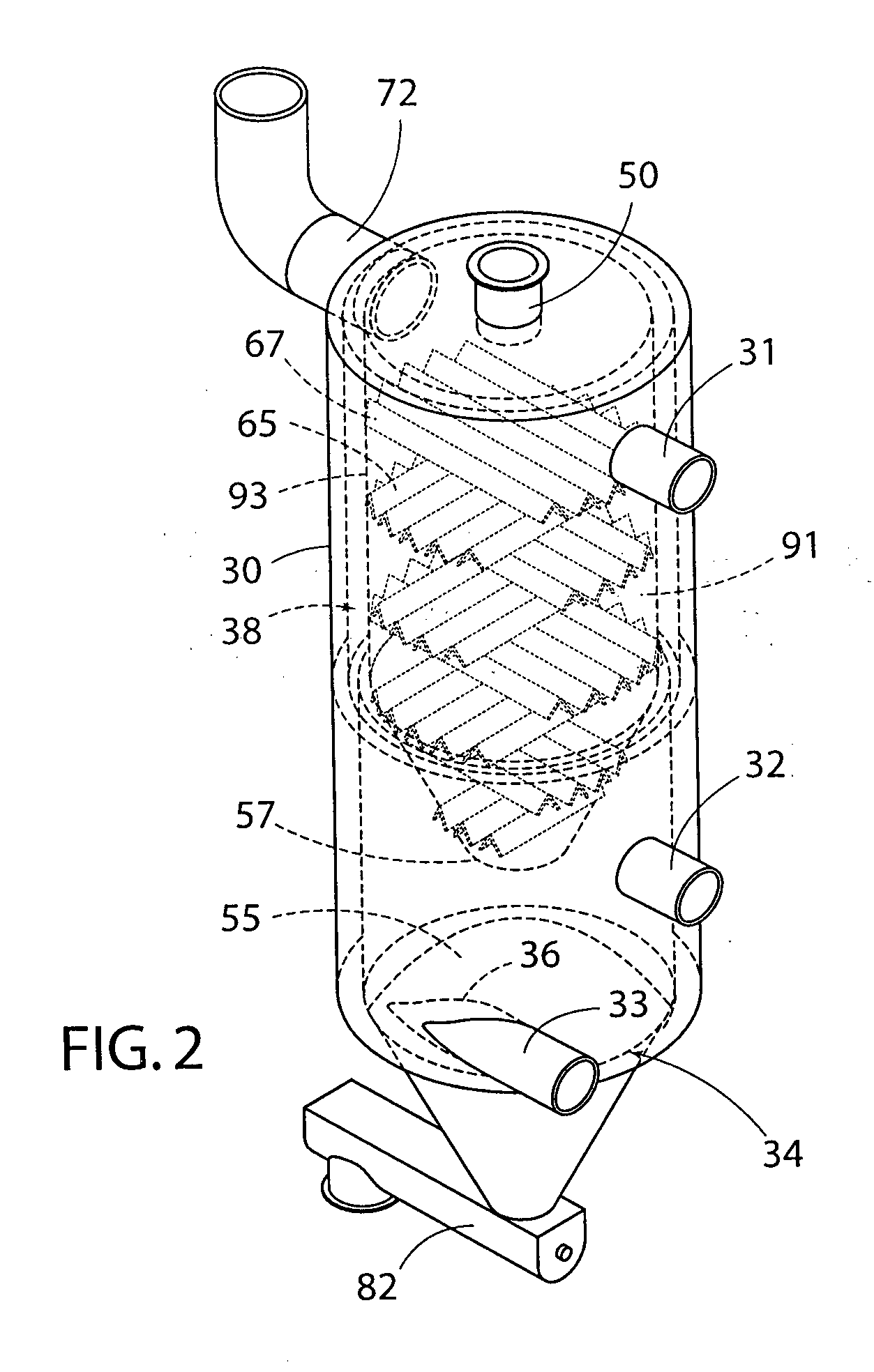

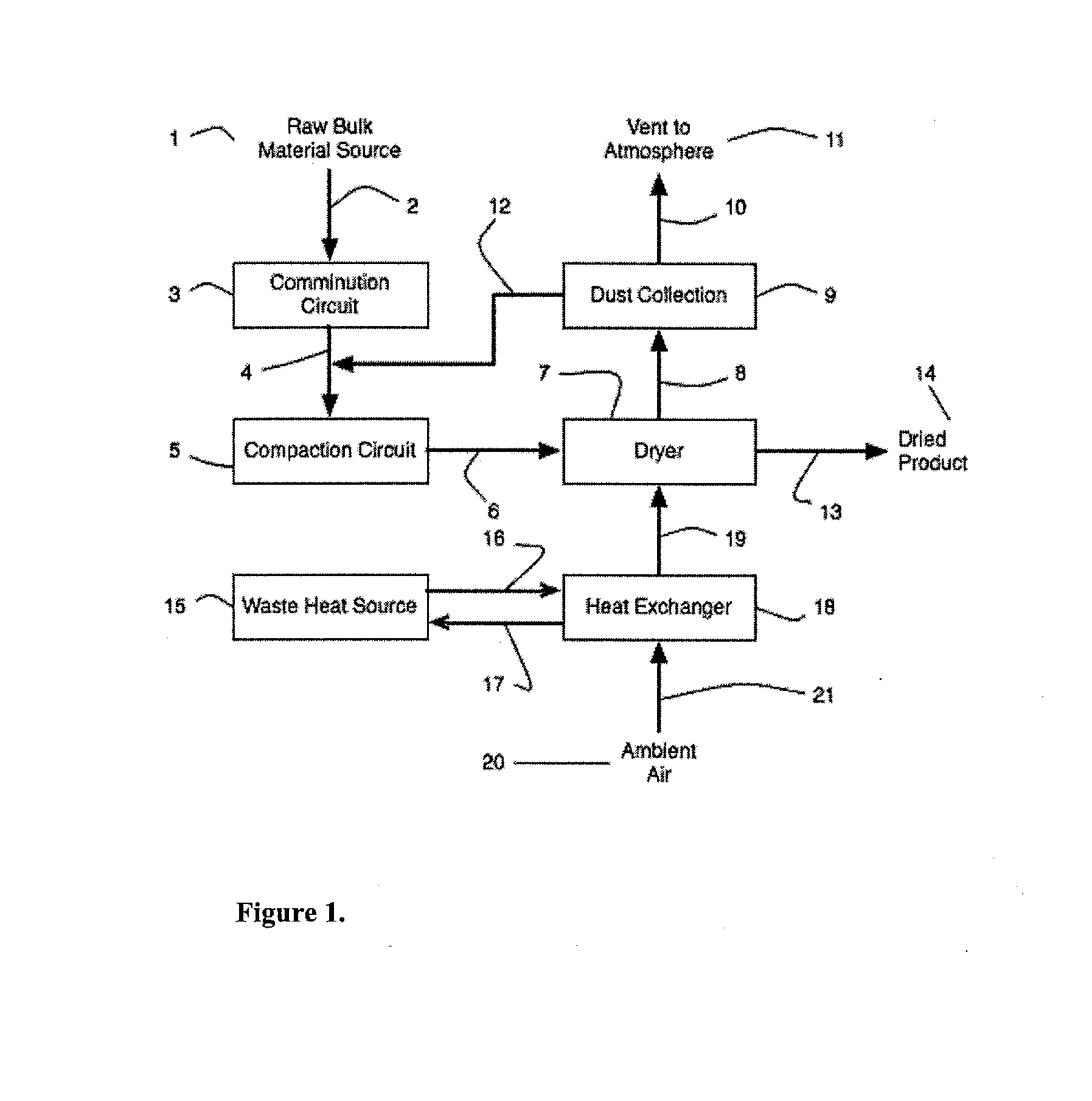

Control system for particulate material drying apparatus and process

ActiveUS7987613B2Easy to controlEasy to monitorDrying using combination processesCombustible gas coke oven heatingParticulatesFluidized bed drying

A control system for controlling the utilization of heated waste streams for fluidizing particulate matter such as coal in a fluidizing bed dryer. The control system includes a number of graphic user interfaces that allow an operator to more easily monitor and / or control the various regulator devices. The control system controls coal handling or transportation, fluid handling or flow, and the discharge of discarded or separated coal from the dryer.

Owner:RAINBOW ENERGY CENT LLC

Control system for particulate material drying apparatus and process

ActiveUS20060112588A1Maximize productionMaximize efficiencyCombustible gas coke oven heatingDrying solid materials with heatParticulatesFluidized bed drying

A control system for controlling the utilization of heated waste streams for fluidizing particulate matter such as coal in a fluidizing bed dryer. The control system includes a number of graphic user interfaces that allow an operator to more easily monitor and / or control the various regulator devices. The control system controls coal handling or transportation, fluid handling or flow, and the discharge of discarded or separated coal from the dryer.

Owner:RAINBOW ENERGY CENT LLC

Method for preparing honeycomb active carbon from coal and coal tar

InactiveCN101503191ASimple ingredientsLow costCarbon compoundsWorking-up peatActivated carbonCarbonization

The invention provides a method for preparing honeycomb-like activated carbon by using coal and coal tar, which takes coal dust and the coal tar as raw materials to prepare the honeycomb-like activated carbon by grinding the coal dust, charge mixture, vacuum pugging, seal aging, vacuum extruding and moilding, drying, carbonization and activation. The method for preparing the honeycomb-like activated carbon only takes the coal tar as cementing agent, so as to overcome the defect that multiple cementing agents are needed to be applied in the technique, thus having the characteristics of simple raw materials, low production cost and easy industrialization. The produced honeycomb-like activated carbon has the characteristics of large geometric area and specific surface area, high mechanical strength and the like, and can be applied for the treatment of waste gas and waste water and catalyst carrier.

Owner:BEIJING UNIV OF CHEM TECH

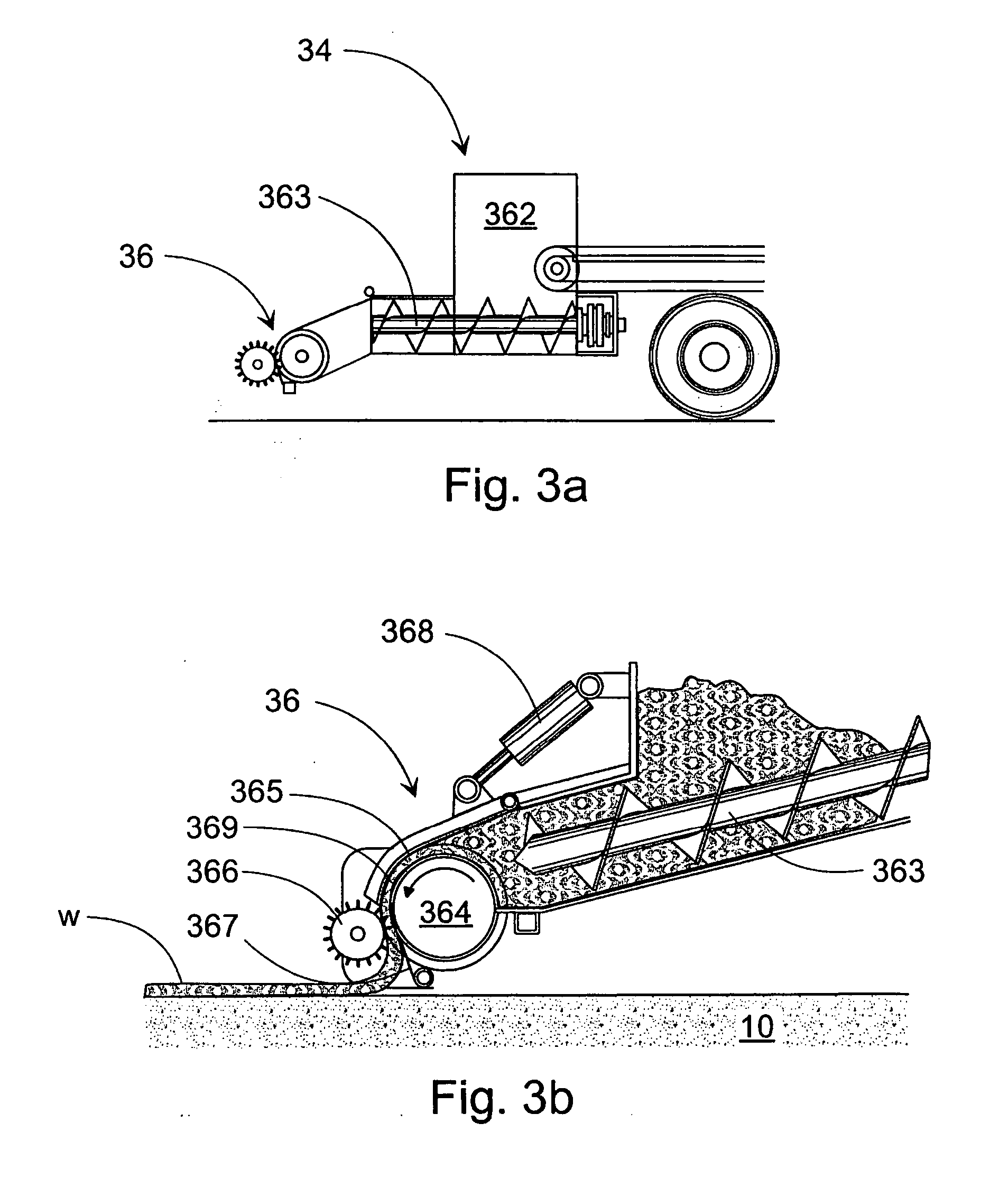

Device for upgrading solid organic materials

A device for upgrading a solid organic material into a resulting product comprises a reactor with an organic material inlet, and a flue gas inlet adapted to introduce flue gas into the reactor, an input driver adapted to continuously transfer the solid organic material to the organic material inlet, an output driver adapted to continuously transfer the solid organic material out of the reactor, a gas flow element operatively connected to the flue gas inlet permitting flue gas to mix with the solid organic material but restricting flow of the solid organic material away from the flue gas inlet, and a rapid cooling device operatively connected to the output driver and adapted to apply a heat transfer liquid directly onto the solid organic material and thereby form the resulting product.

Owner:TOTAL SINERGY INT

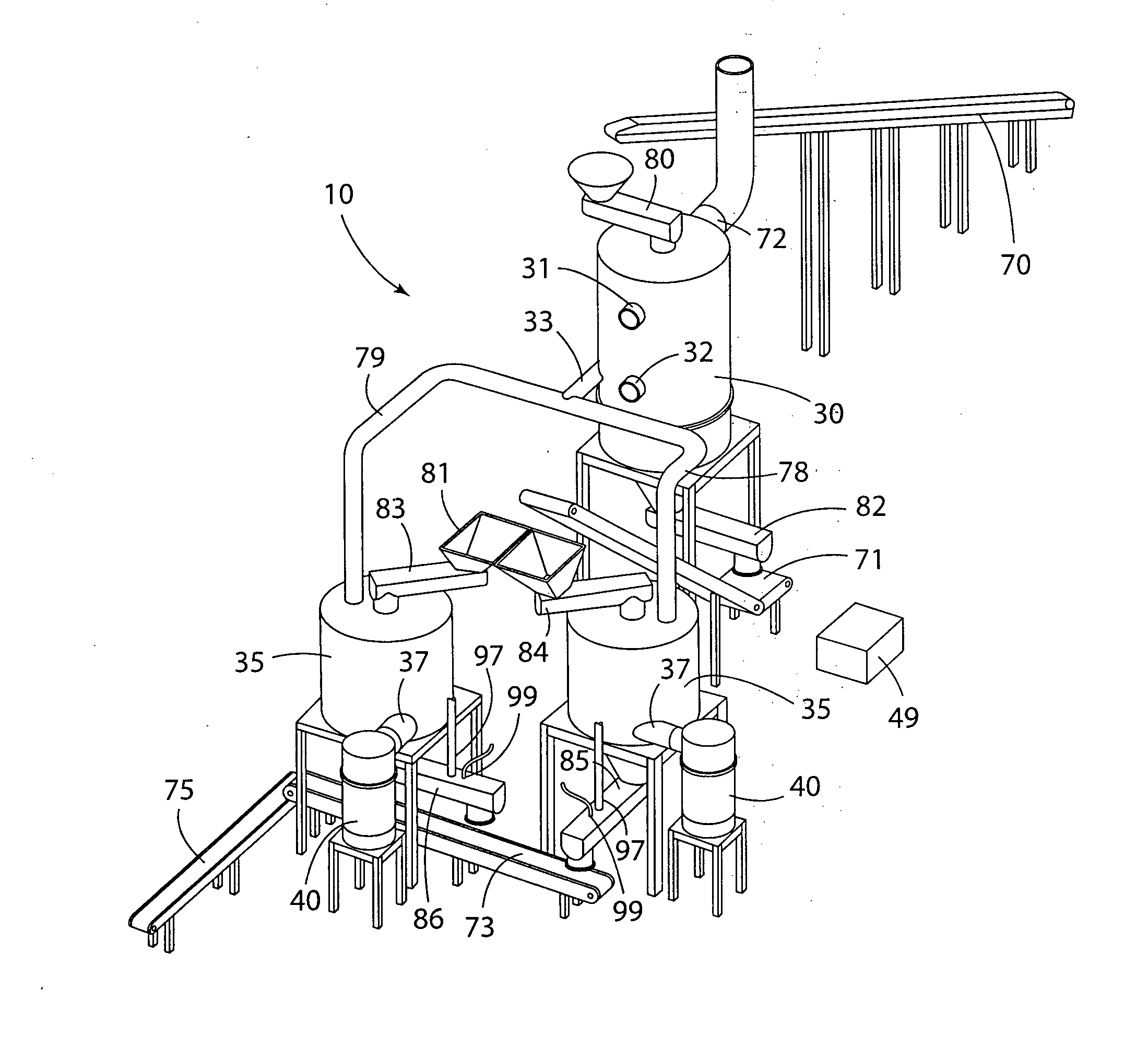

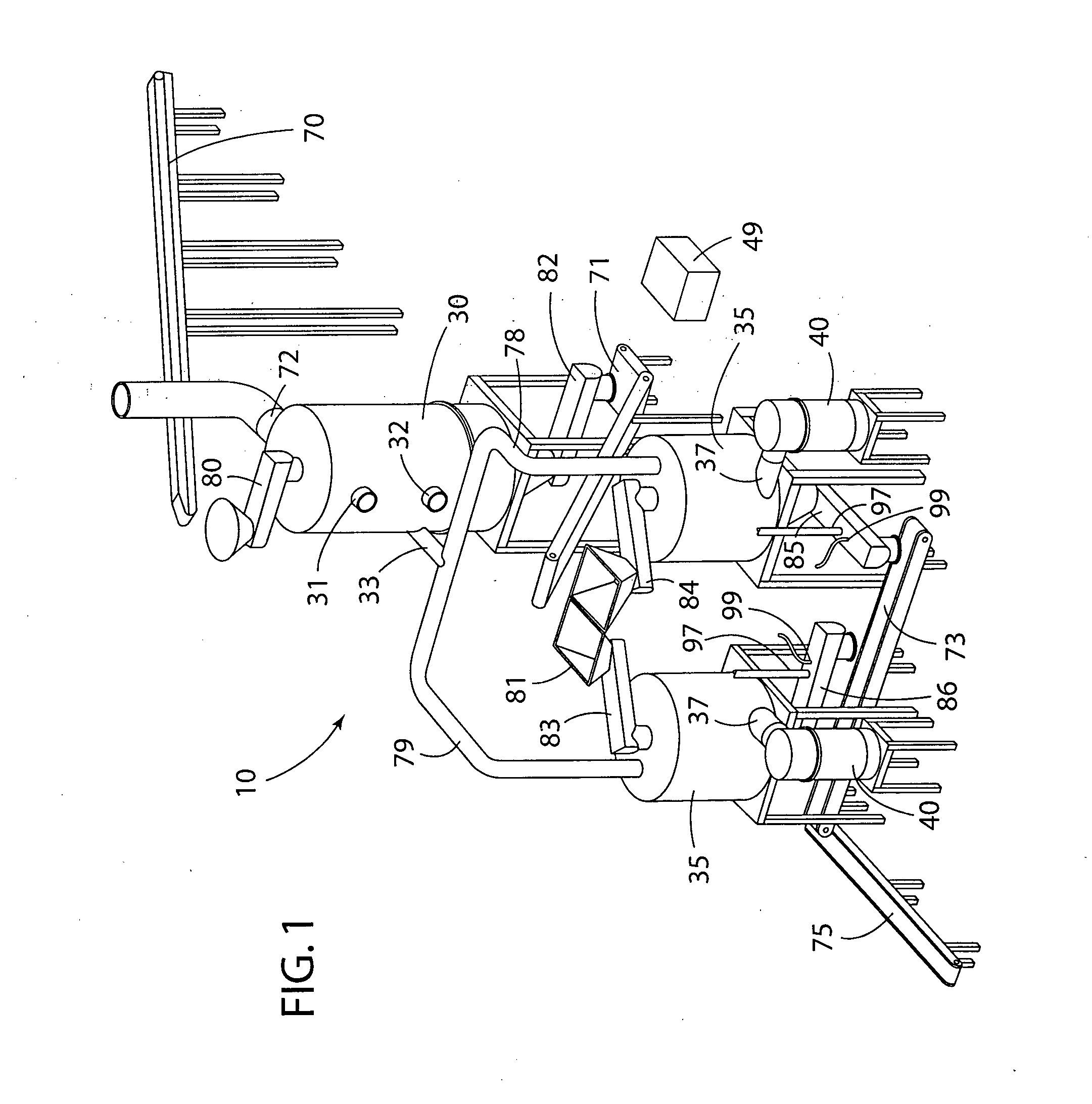

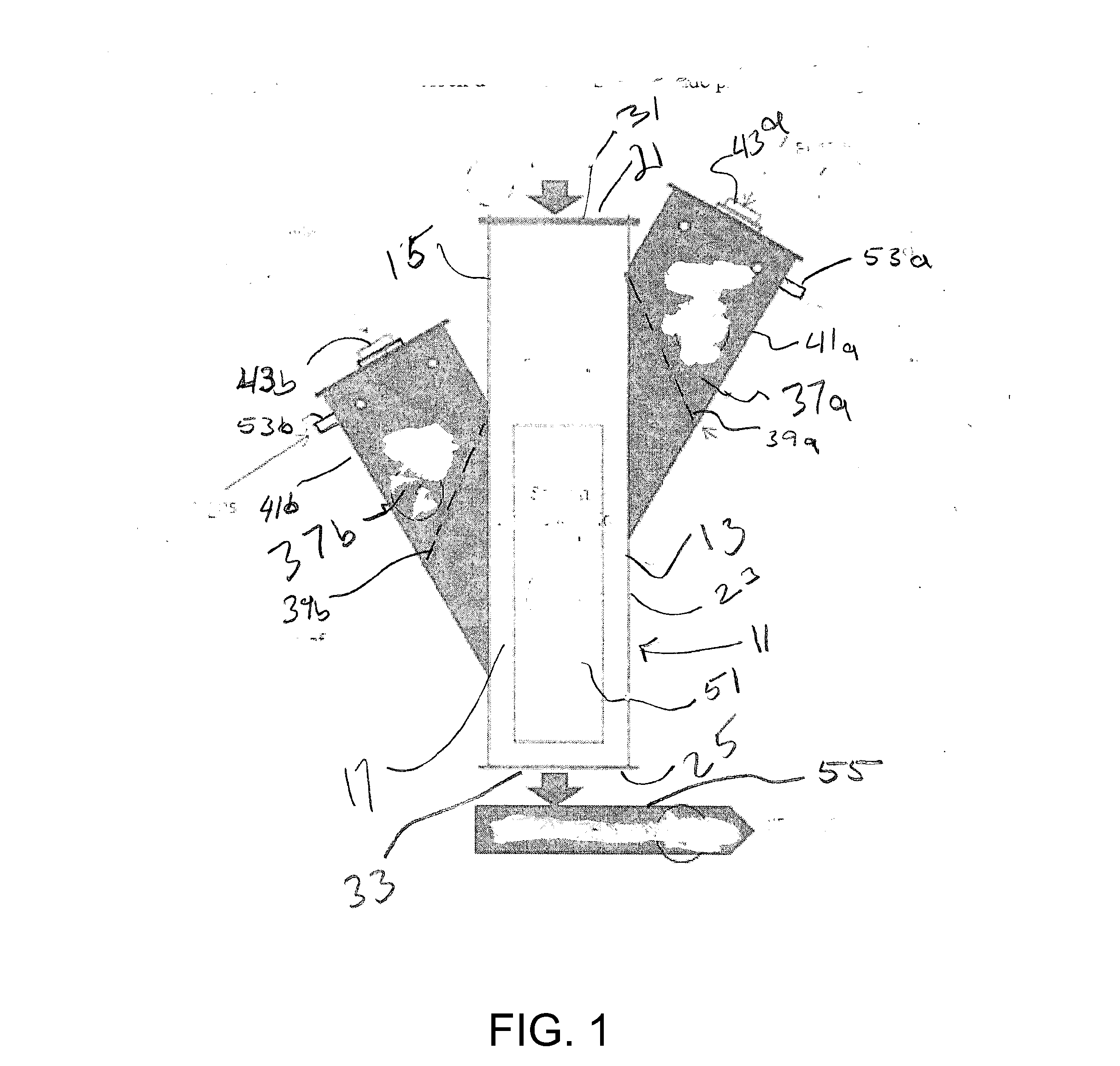

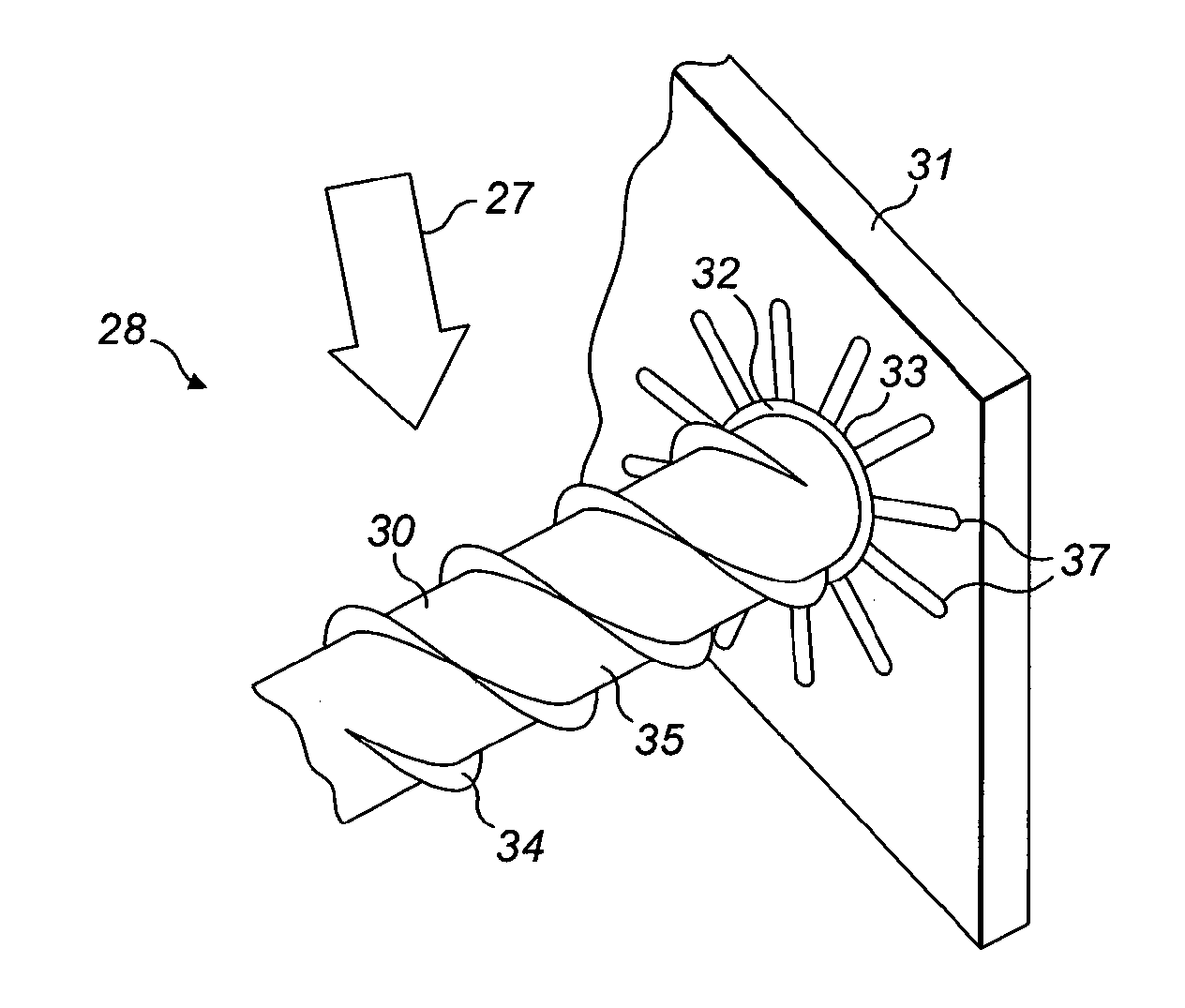

Apparatus and methods for treating solids by electromagnetic radiation

InactiveUS20140352206A1Efficient combustionDegradation of combustionBiofuelsSolid fuelsEngineeringElectromagnetic radiation

Embodiments of the present invention are directed to methods and apparatus for subjecting coarsely divided solid material, such as solid fossil fuels, to microwave radiation using gravity feed through a chamber and protecting irradiating windows by placement outside the angle of repose.

Owner:MICROCOAL INC

Microwave drying and upgrading method of lignite or coal slime

ActiveCN102102043AUniform moisture contentThere will be no ignition of pulverized coal accidentsSolid fuelsWorking-up peatMicrowaveEngineering

The invention discloses a microwave drying and upgrading method of lignite or coal slime. The method is characterized in that coal is preheated and performs thermal dehydration treatment before drying and the waste heat generated by coal in the drying process is utilized to perform the hot press moulding of coal. By adopting the method of the invention to perform the drying and upgrading of lignite or coal slime, the effects of reducing the energy consumption and increasing the quality and the cost of microwave drying can be further reduced; and the method is a brand-new drying and upgrading method of lignite or coal slime.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

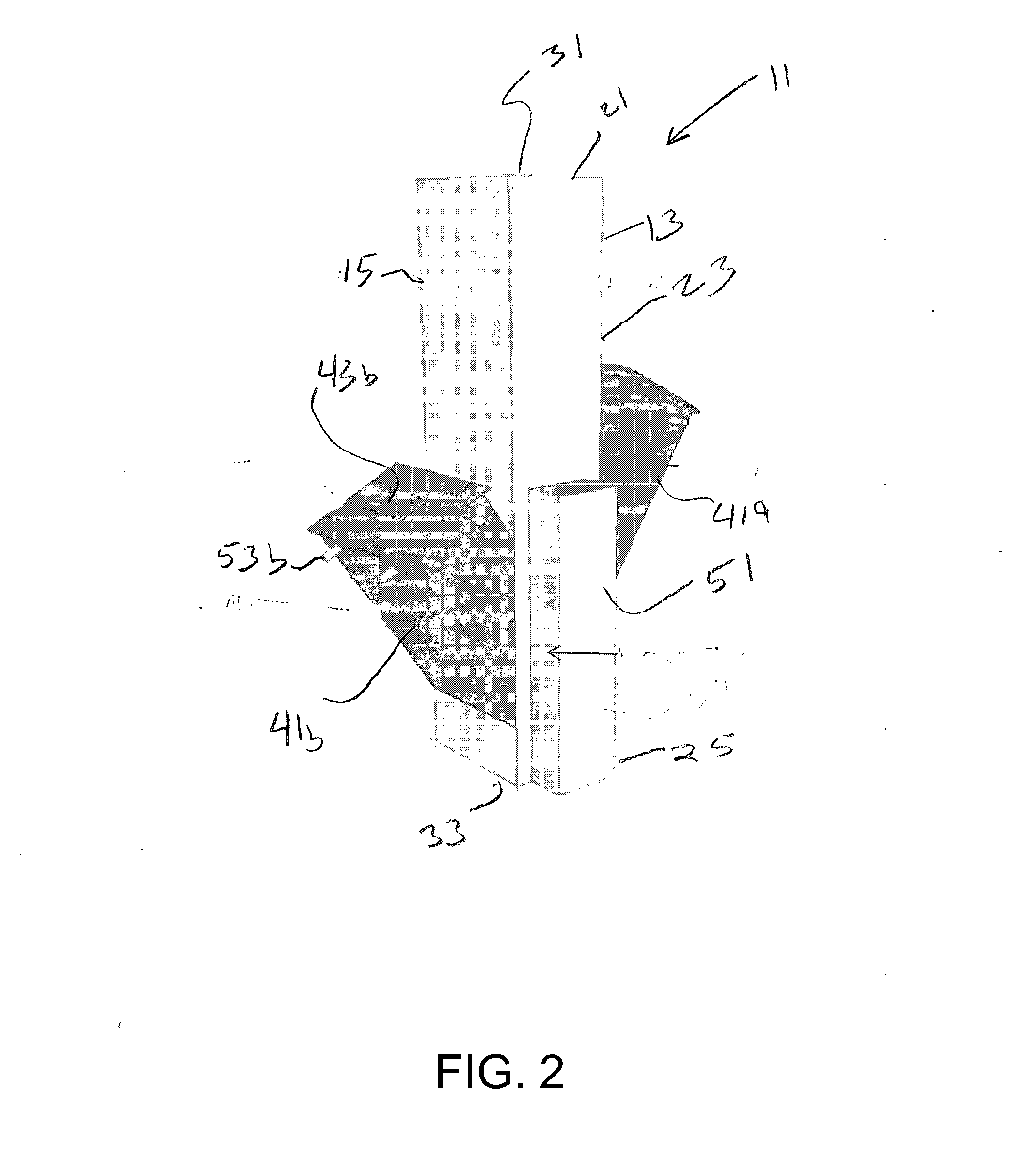

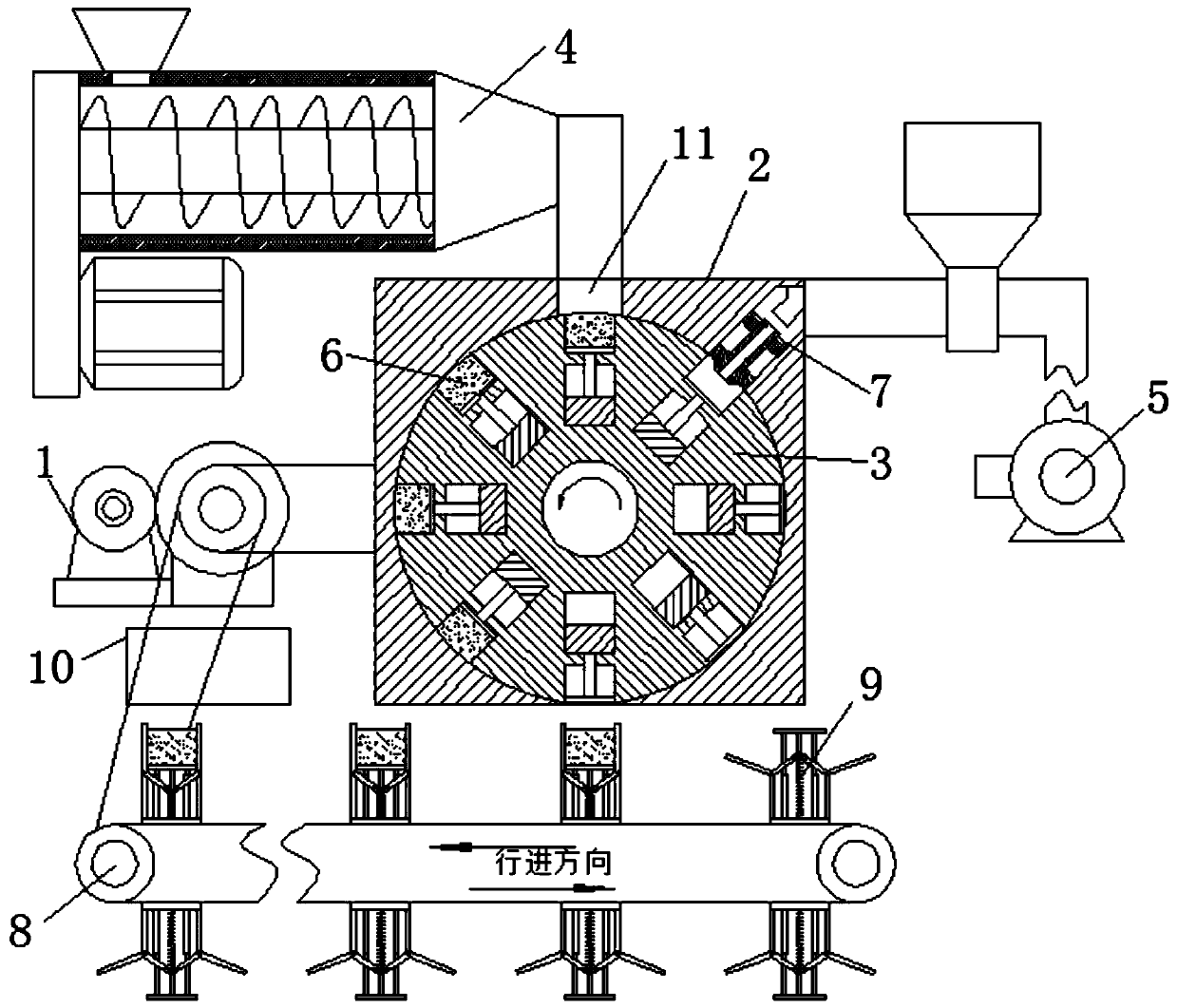

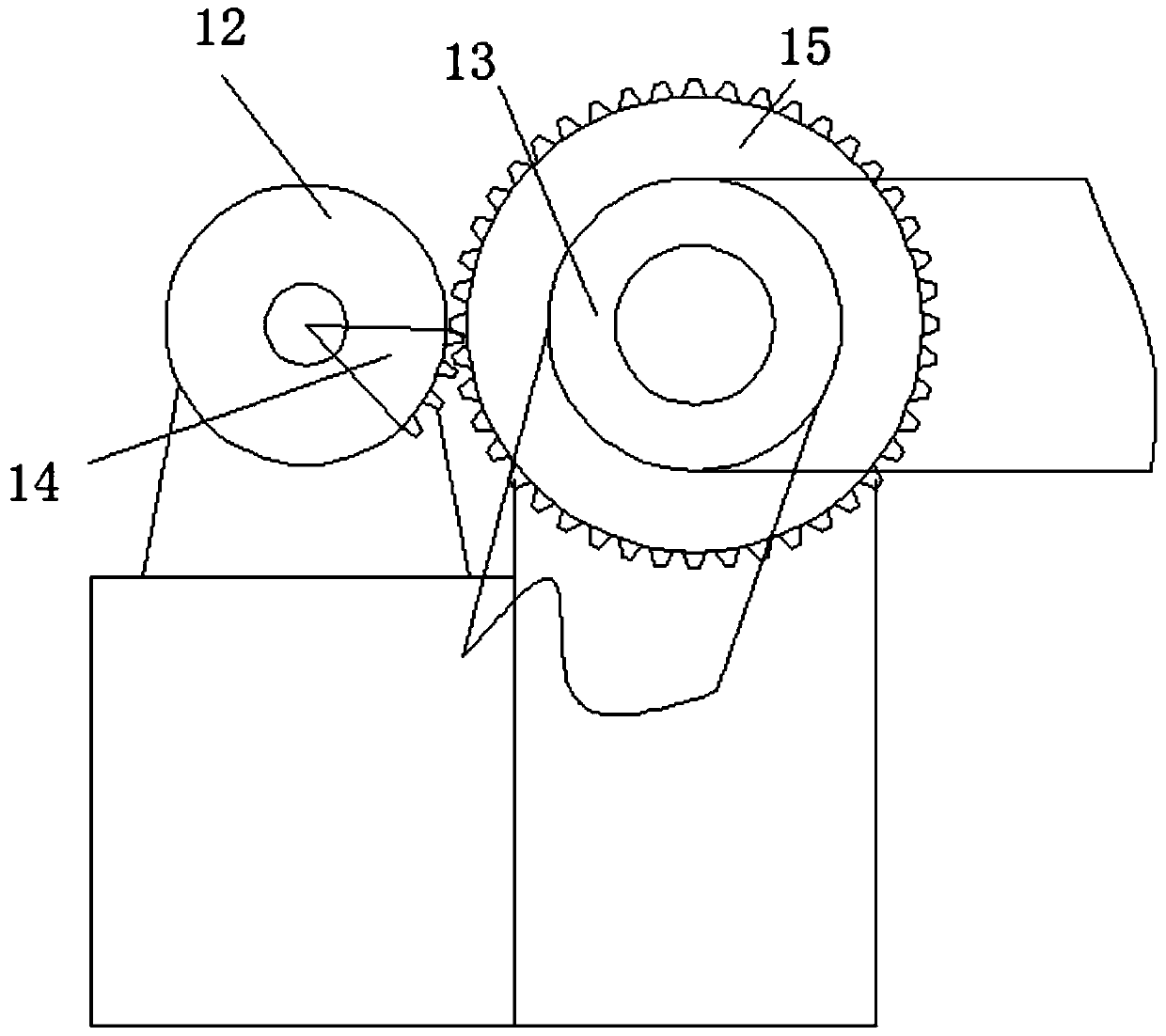

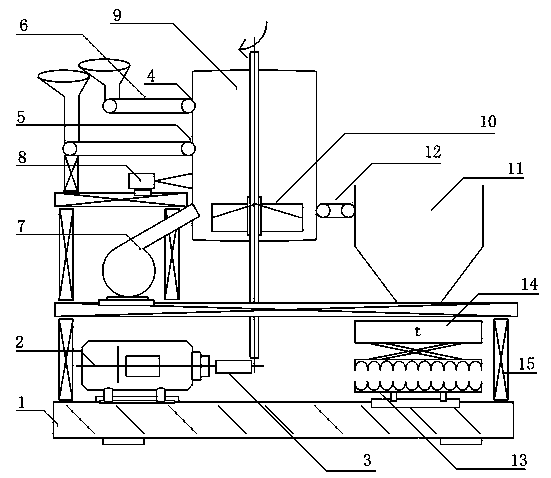

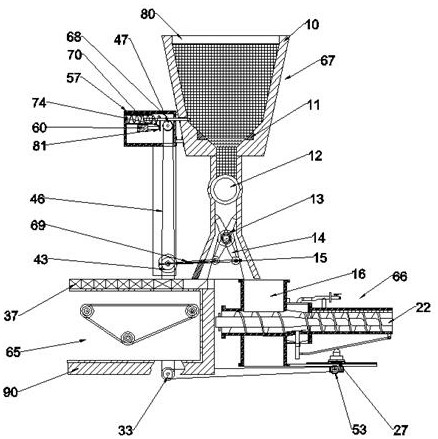

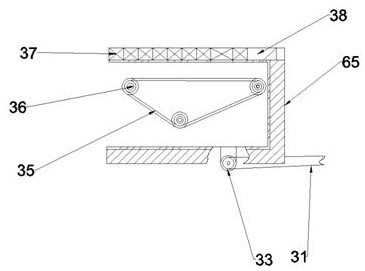

Coal slime forming machine

ActiveCN104927956AReasonable structural designHigh degree of operation automationDrying gas arrangementsSolid fuelsEngineeringFeeding tube

The invention discloses a coal slime forming machine and relates to the technical field of coal treatment technology. The forming machine comprises a power mechanism, a feeding and forming mechanism and a conveying and drying mechanism. The power mechanism comprises a lifting rod moving vertically; the feeding and forming mechanism comprises a feeding tube, and a forming pressure applying die and a forming pressure bearing die which match with each other vertically and mutually; the forming pressure applying die is connected to the bottom of the lifting rod; the conveying and drying mechanism is located at the bottom of the forming pressure bearing die, the conveying belt of the conveying and drying mechanism is provided with a puncture device and a drying device sequentially in the conveying direction of the conveying belt, and the tail of the conveying and drying mechanism is provided with a material collection device. The forming machine is reasonable in structure, the machining efficiency is high, and the automation level is high.

Owner:JIANGSU ZHONGWEI HEAVY IND MACHINERY

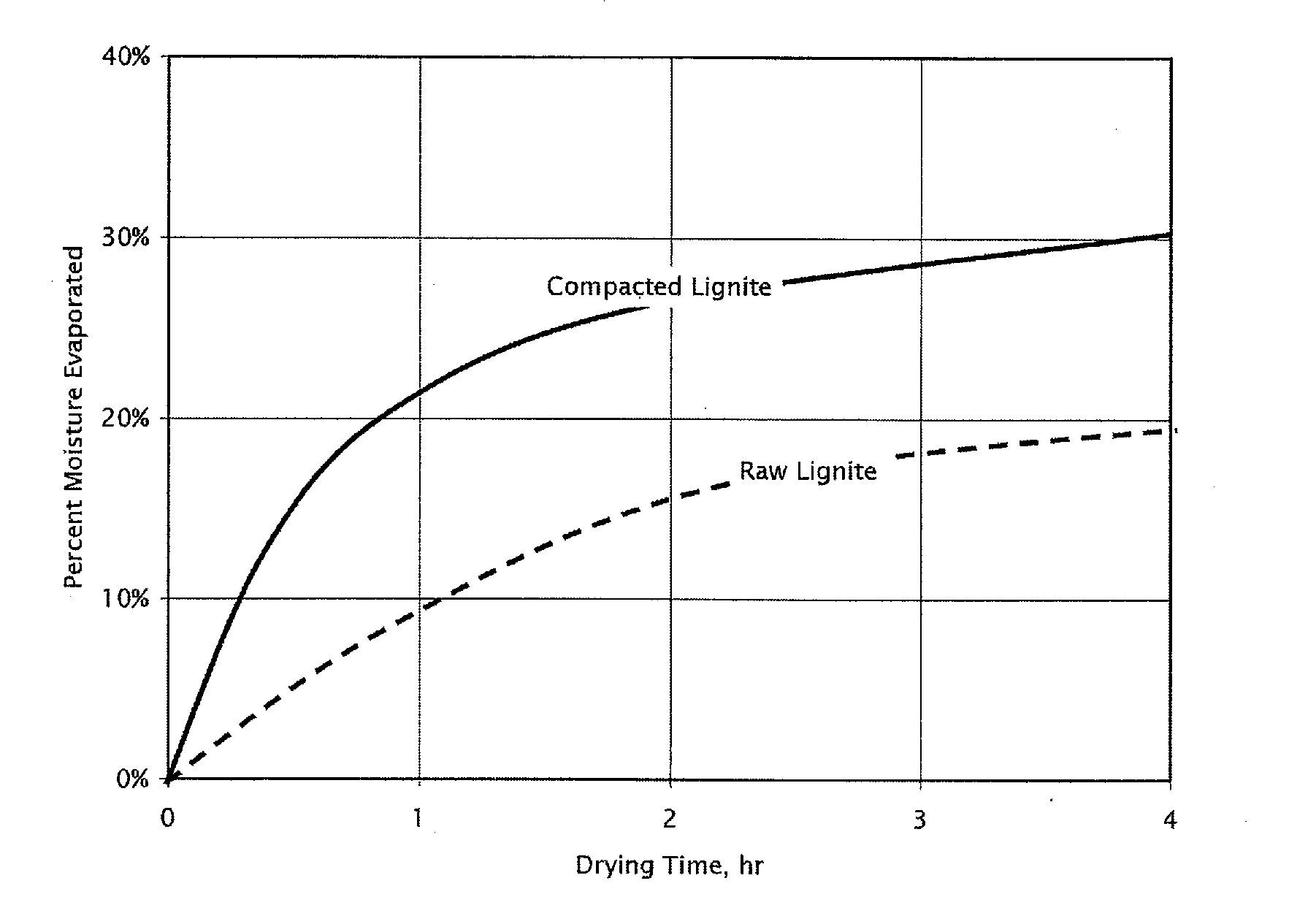

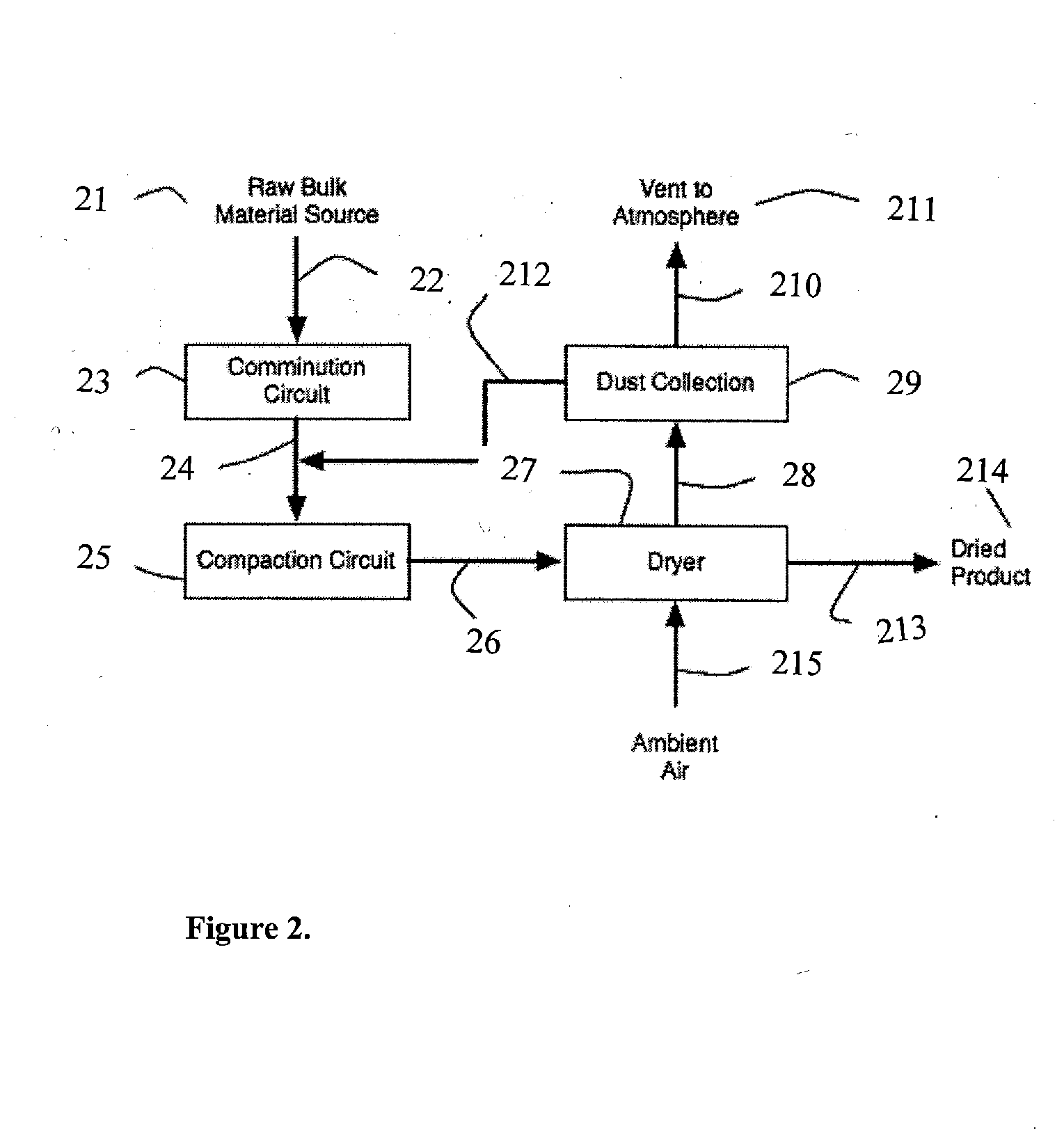

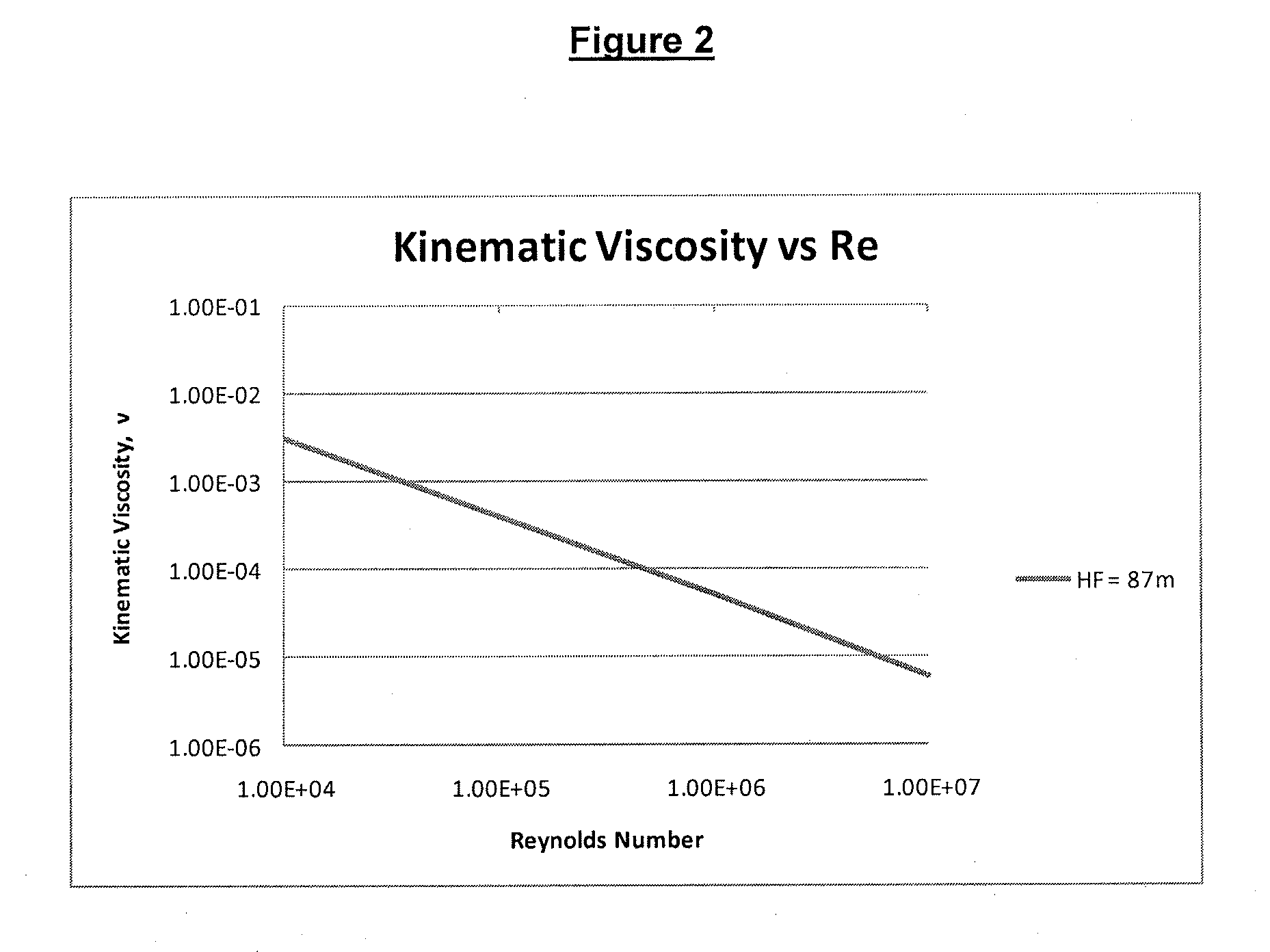

Method To Improve The Efficiency Of Removal Of Liquid Water From Solid Bulk Fuel Materials

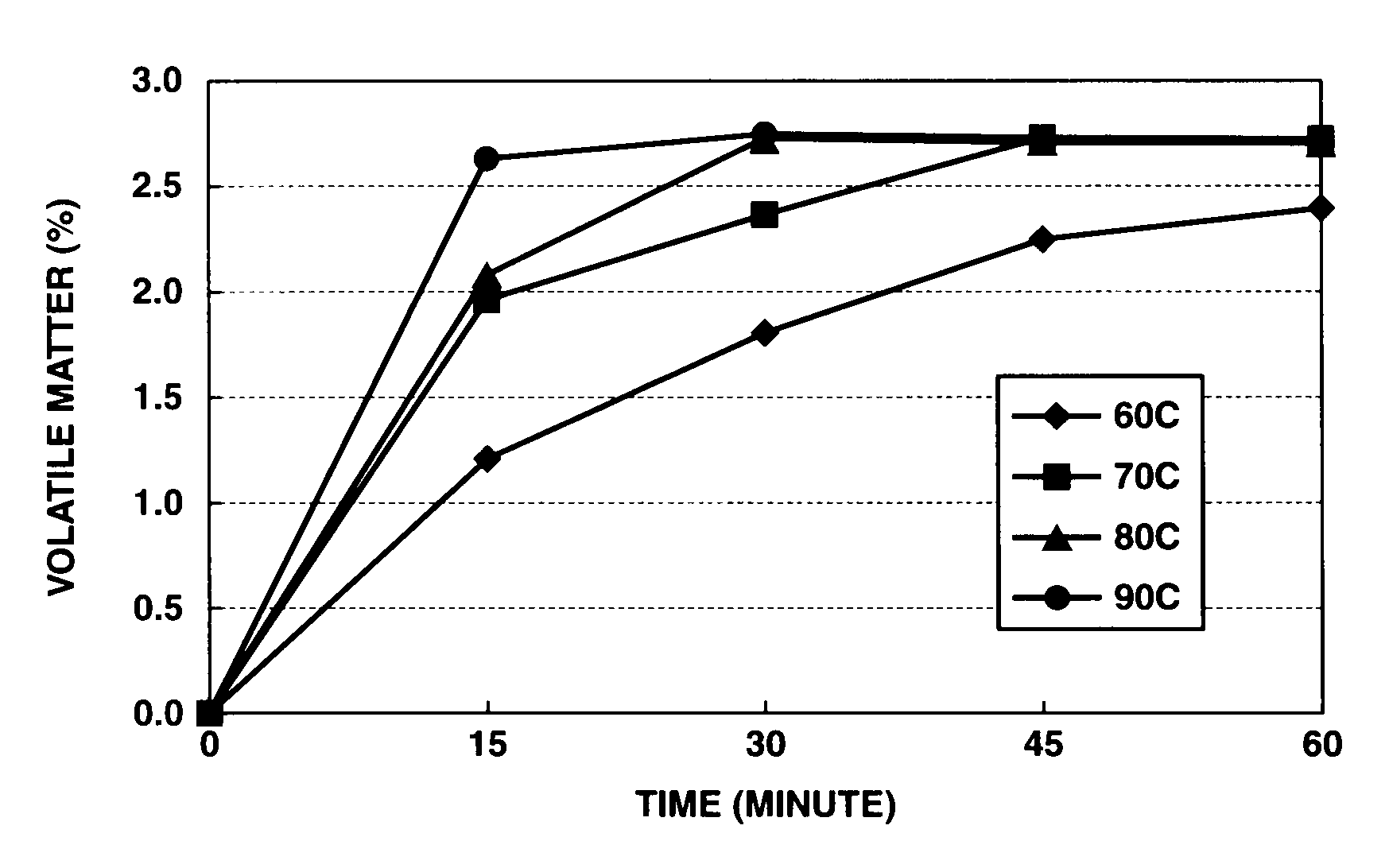

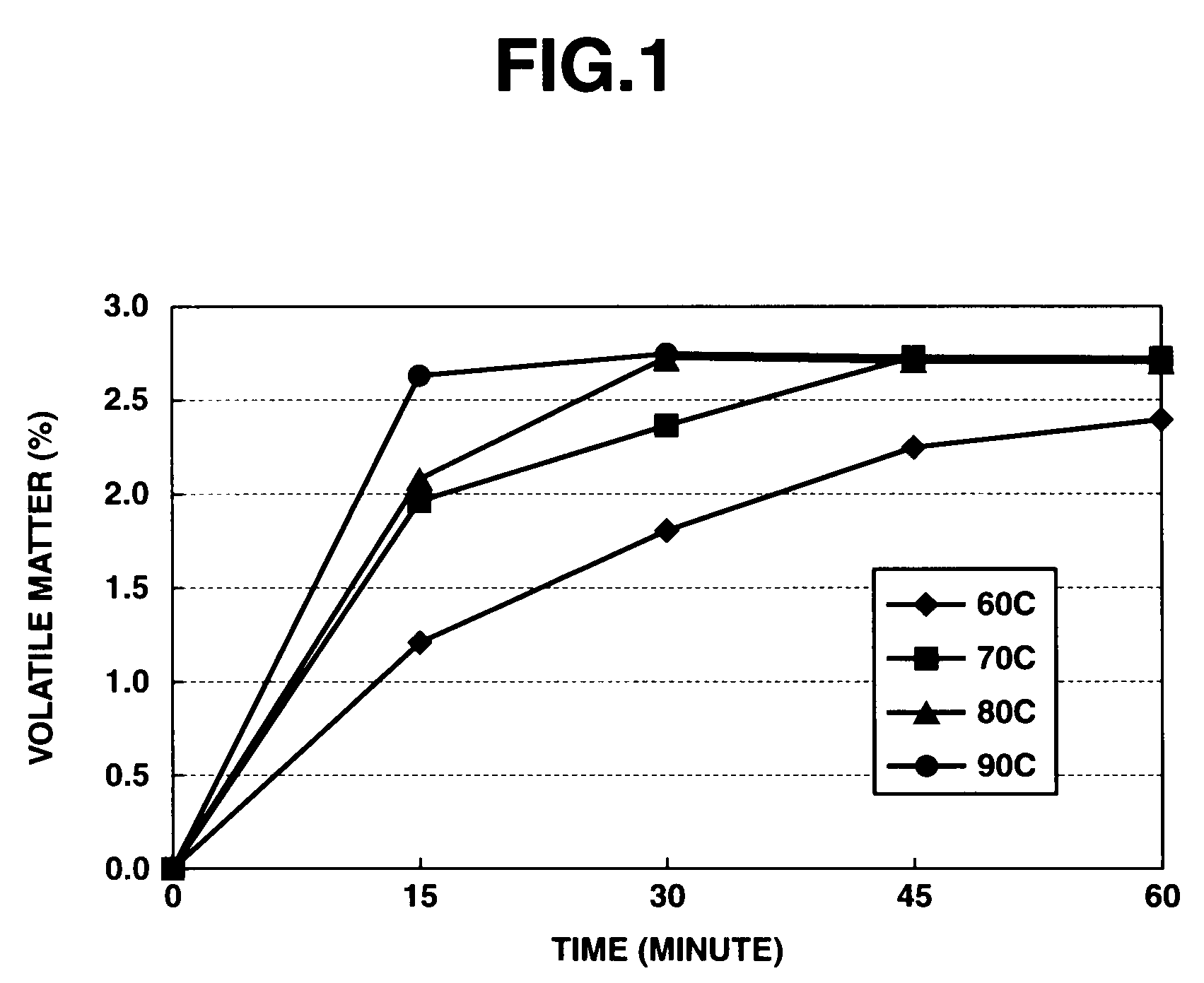

InactiveUS20080222947A1Improve efficiencyLess timeDrying using combination processesDrying solid materials with heatBrown coalWater concentration

The invention provides methods to efficiently reduce the water concentration of raw solid fuels, including low rank coals such as brown coal, lignite, subbituminous coal, and other carbonaceous solids. Efficiently drying these materials at low temperatures significantly reduces greenhouse gas emissions and allows the production of low-rank coals for gasification and liquifaction.

Owner:GTL ENERGY LTD

Method for preparing biomass type coal adhesive from boghead coal and co-producing biomass type coal and organic fertilizer

InactiveCN103173236ARealize high-value utilizationIncrease surface areaBio-organic fraction processingChemical industryAdhesiveWater resistant

The invention discloses a method for preparing a biomass type coal adhesive from boghead coal and co-producing biomass type coal and an organic fertilizer, which comprises the following steps of: crushing boghead coal, adding alkaline liquor to boil, keeping the temperature, standing, and taking supernate as the biomass type coal adhesive; mixing corn straws, coal gangue with soft coal after crushing, adding the biomass type coal adhesive, solid sulphur and a waterproof agent, after uniformly mixing the biomass type coal adhesive, the solid sulphur and the waterproof agent with water, and extruding, forming and drying through a forming machine to obtain biomass type coal; and filtering biomass type coal adhesive preparation residues, adjusting pH, adding cow dung to ferment, and dosing, pelleting and drying to obtain the organic fertilizer. According to the invention, the abundant boghead coal resource in inner Mongolia is utilized for developing cheap adhesive; the biomass type coal, which has the advantages of being low in cost, high in sulphur content, moisture-proof and water-resistant and is applicable to an industrial furnace, is developed by utilizing abundant coal gangue resource and corn straw resource; and residues after preparing the biomass type coal adhesive from boghead coal are used for preparing the organic fertilizer, and therefore, the method disclosed by the invention is capable of saving energy, reducing emission, reducing the production cost of the biomass type coal, and increasing the additional value of boghead coal and the utilization rate of coal gangue.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +2

Method for preparing and conveying coal slurry

The invention relates to a method for preparing and transmitting coal slurry. At present, high pressure piston pumps are adopted for pumping mostly, which has very high requirement on the bearing pressure of equipment and requires quite high operation and maintenance costs. The method is characterized in that: the coal slurry which comes out from a coal washery is broken, removed of impurities and then stirred, black liquor and limestone particles are added during stirring to form coal mud, and then industrial water is added and stirring is continued. The coal mud is transmitted to a boiler and then to a plurality of feeding inlets arranged in the middle part of the boiler by adopting a plurality of low pressure pumps, with the coal slurry flow at each feeding inlet ranging from 5 tons to 7 tons per hour. Pretreatment is carried out on the coal slurry in the method so that the water content of the coal slurry meets the requirement for being suitable to transmission through the pumps; and feeding at the middle part with multiple points is adopted, thus realizing the transmission of the coal slurry at low pressure and low energy consumption, and further being beneficial to the stable burning of the coal slurry in the boiler.

Owner:范家峰 +2

Method for preparation of biogas and combined production of organic fertilizer through processing peat by dilute acid

InactiveCN103275745AEasy to adjustIn line with industrial policyBio-organic fraction processingWaste based fuelRobust least squaresOrganic fertilizer

The present invention refers to 3D rotational X-ray imaging systems for use in computed tomography (CT) and a fast, accurate and mathematically robust calibration method for determining the effective center of rotation (I) in not perfectly isocentric 3D rotational C-arm systems and eliminating substantially circular ring artifacts (RA) which arise when using such a CT scanner system. For this purpose, a C-arm based rotational CT scanner comprising at least one radiation detector (D) having an X-radiation sensitive surface exposed to an X-ray beam emitted by at least one X-ray tube (S), each rotating along a non-ideal circular trajectory (TF, TCD) about an object of interest to be three-dimensionally reconstructed from a set of 2D projection images is used for providing geometrical calibration data by scanning a calibration phantom from a plurality of distinct projection directions and calculating, for each projection direction, the 3D positions of the X-ray tube's focal spot and the X-ray detector's center. For approximating the exact 3D position and angular direction of the axis of rotation about which the at least one X-ray tube and the at least one radiation detector rotate, a circular regression technique using a number of mathematically robust least squares fits is applied.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Spherical alumina particles and production process thereof

Owner:SHOWA DENKO KK

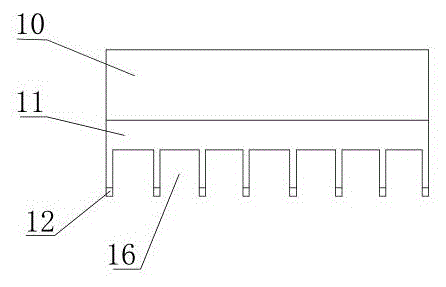

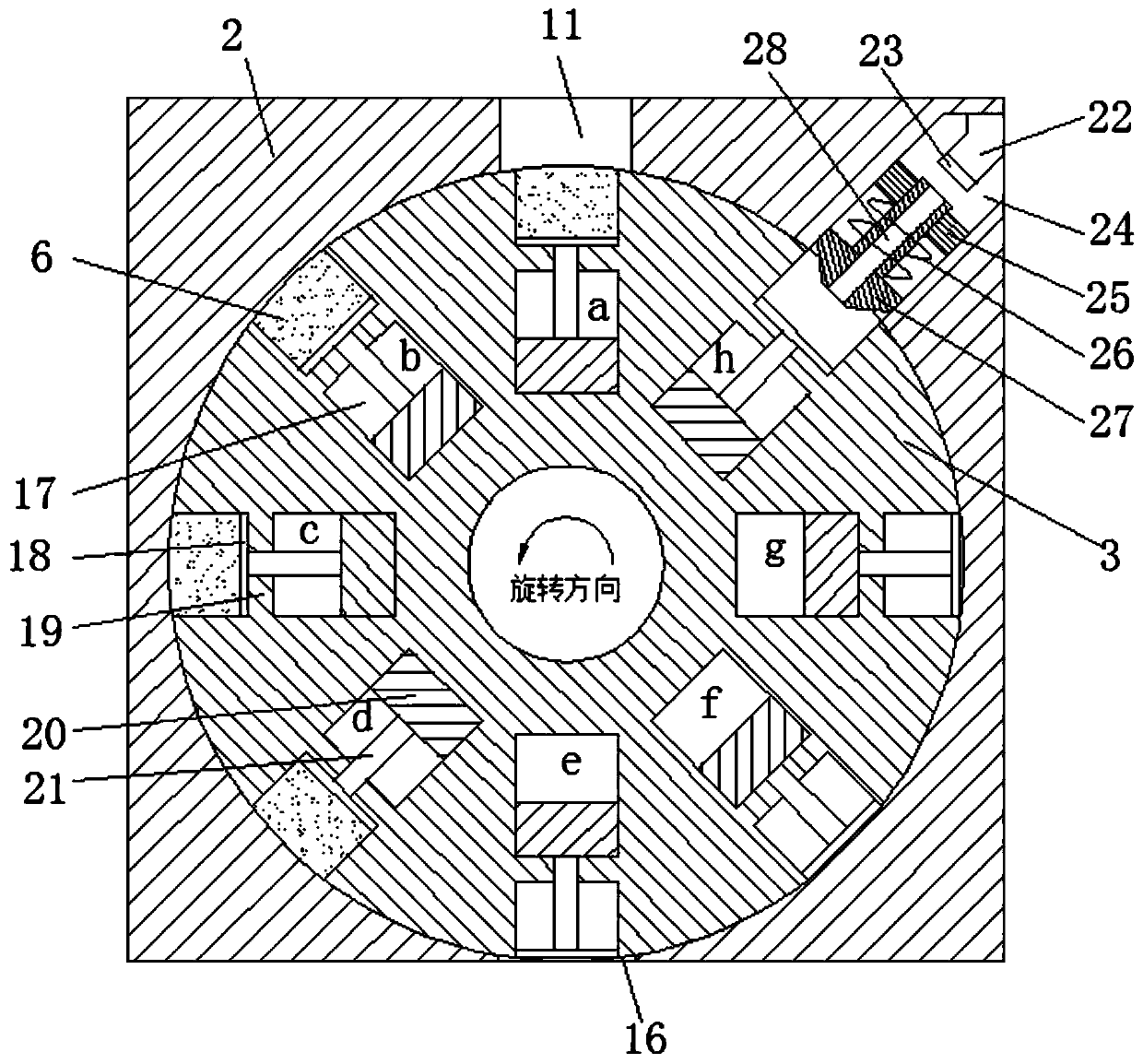

High efficient device for making billet from coal slime and application method thereof

ActiveCN110682581ANo impact damageCompact structureWorking-up peatShaping pressMetallurgyEngineering

The invention relates to the processing field of billet making from coal, in particular to a high efficient device for making billet from coal slime and an application method thereof. The high efficient device for making billet from coal slime comprises a billet making box, a cylindrical cavity is arranged in the inner part of the billet making box, the cavity is internally and rotatably connectedwith a rotating roller, the rotating roller is driven to rotate around a central axis of the cavity in the cavity through a driving mechanism, eight mold grooves are arranged on the roller surface ofthe rotating roller along the circumferential direction at equal intervals and used for making the coal billet, a groove is arranged on the position which is on the rotating roller and corresponds the mold grooves, the groove is provided with counterweight blocks for extruding and discharging the coal billet, the upper and lower side walls of the billet making box are respectively provided with feeding and discharging ports, the feeding port of the billet making box is connected with the discharging end of a screw feeder, the feeding port and the discharging port communicate with the mold grooves in a involution manner, a conveying belt for conveying the formed coal billet is arranged directly below the discharging port, and the conveying belt is connected with the driving mechanism. According to the high efficient device for making the billet from the coal slime and the application method thereof, the device is compact in structure, time-saving and labor-saving, free of impact damageto the mold grooves, and long in service life.

Owner:洪丽雅

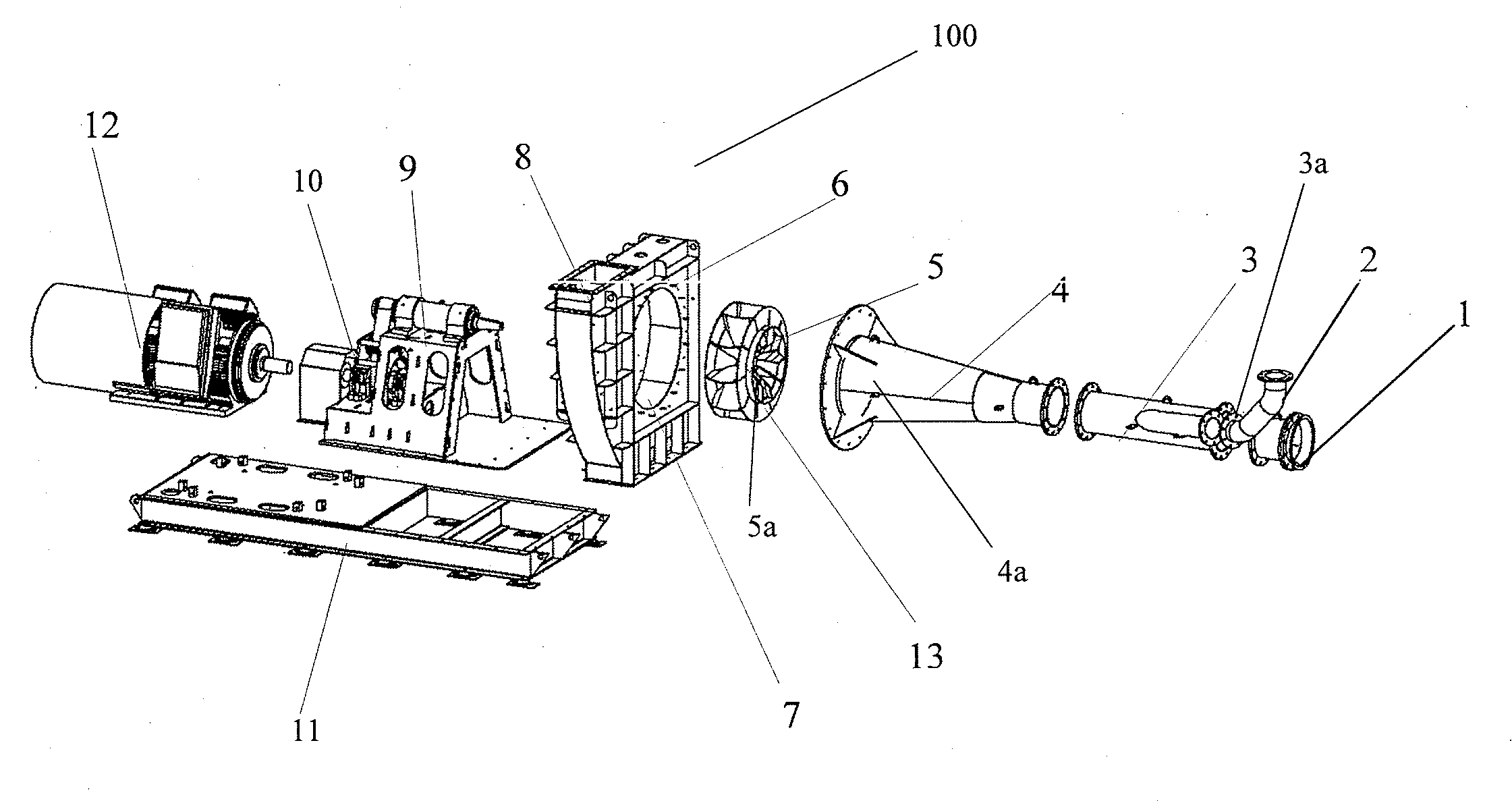

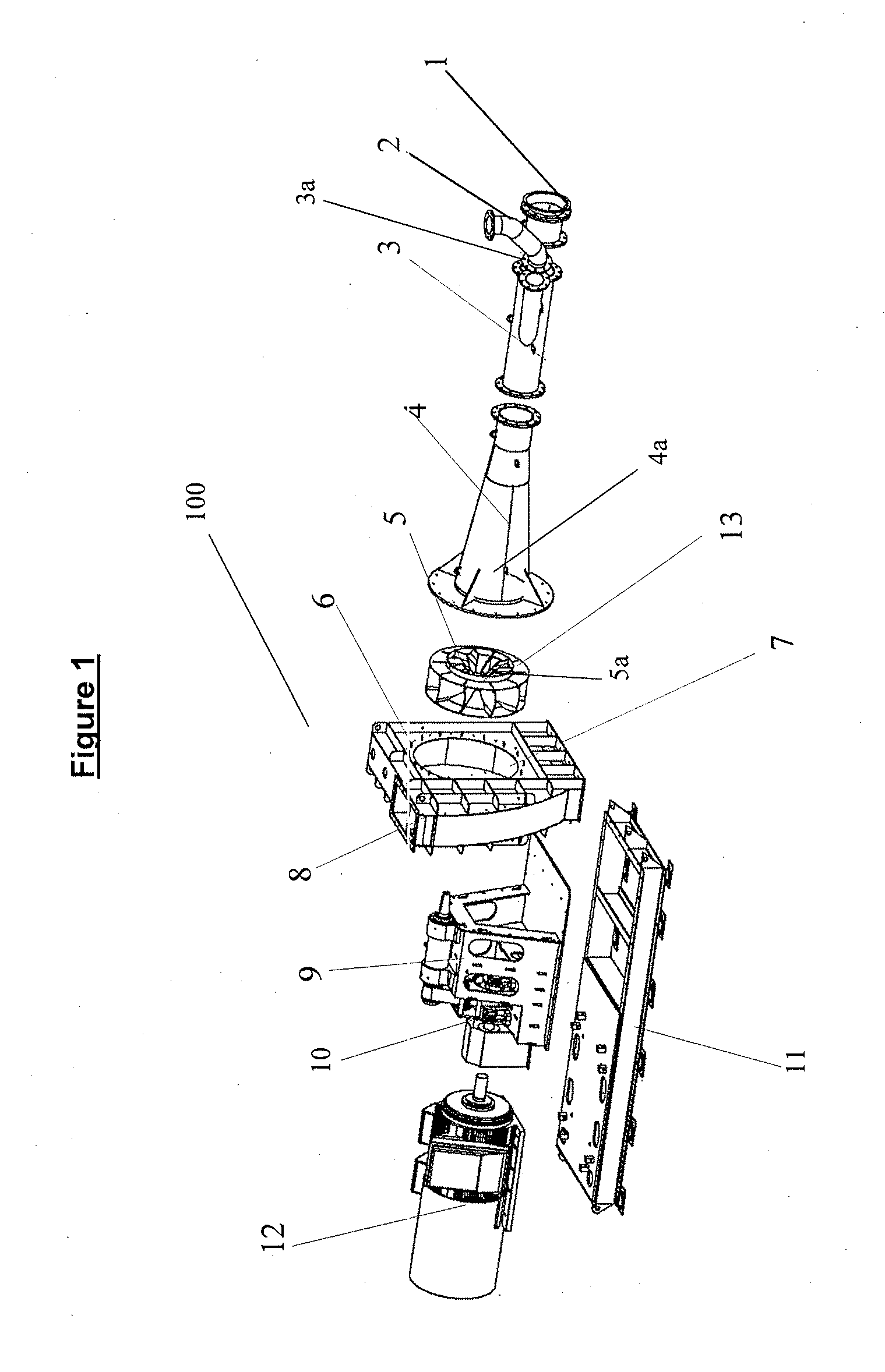

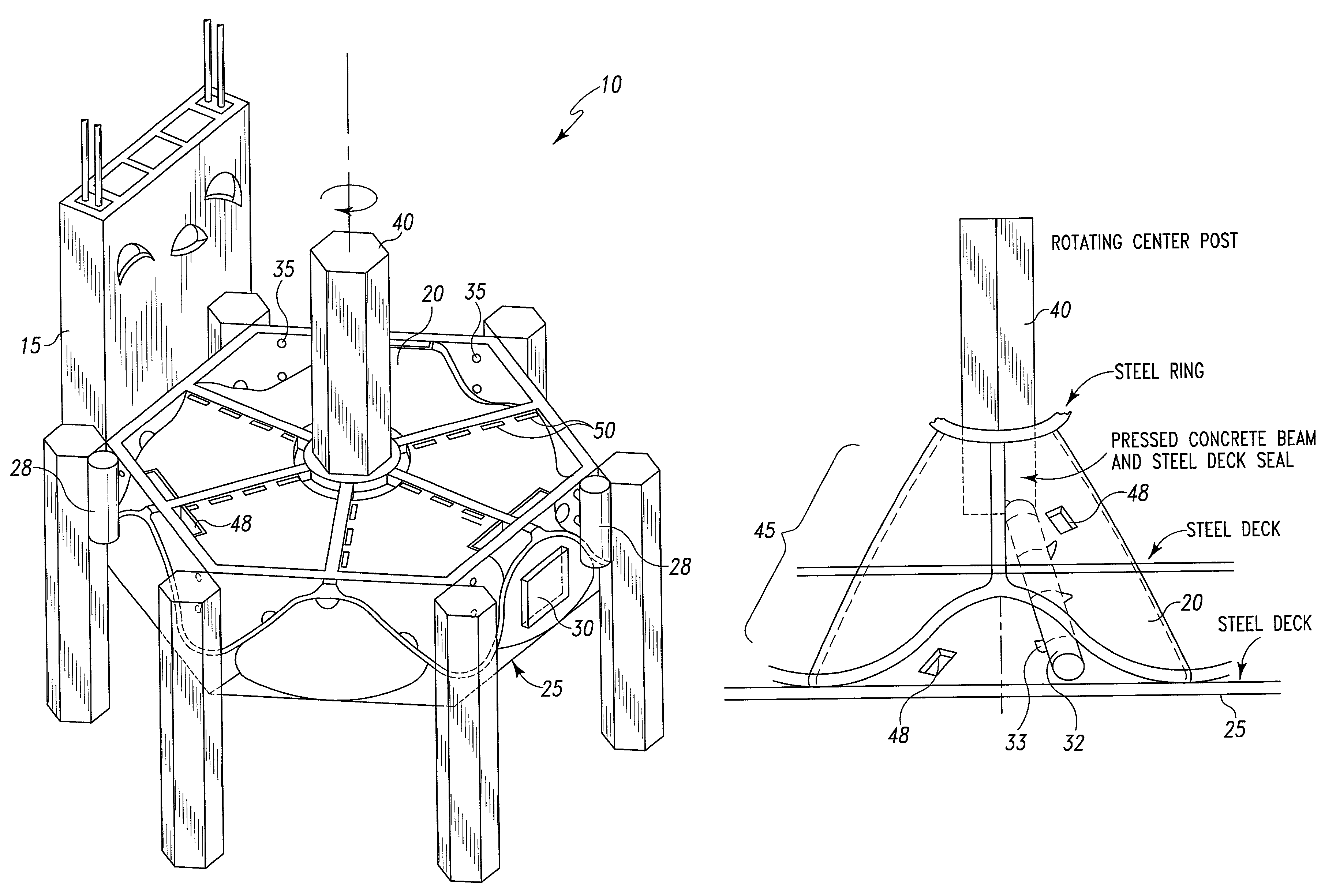

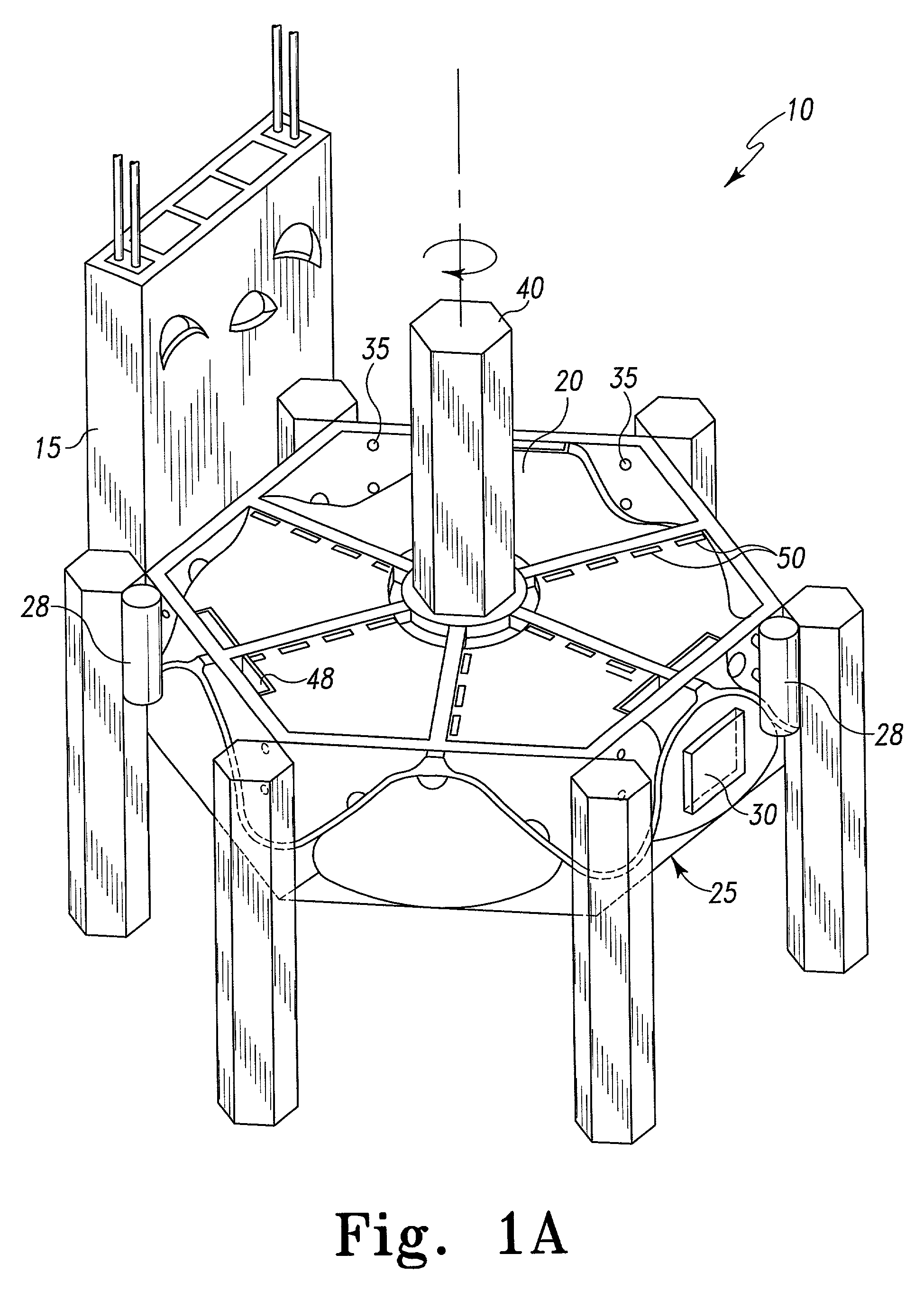

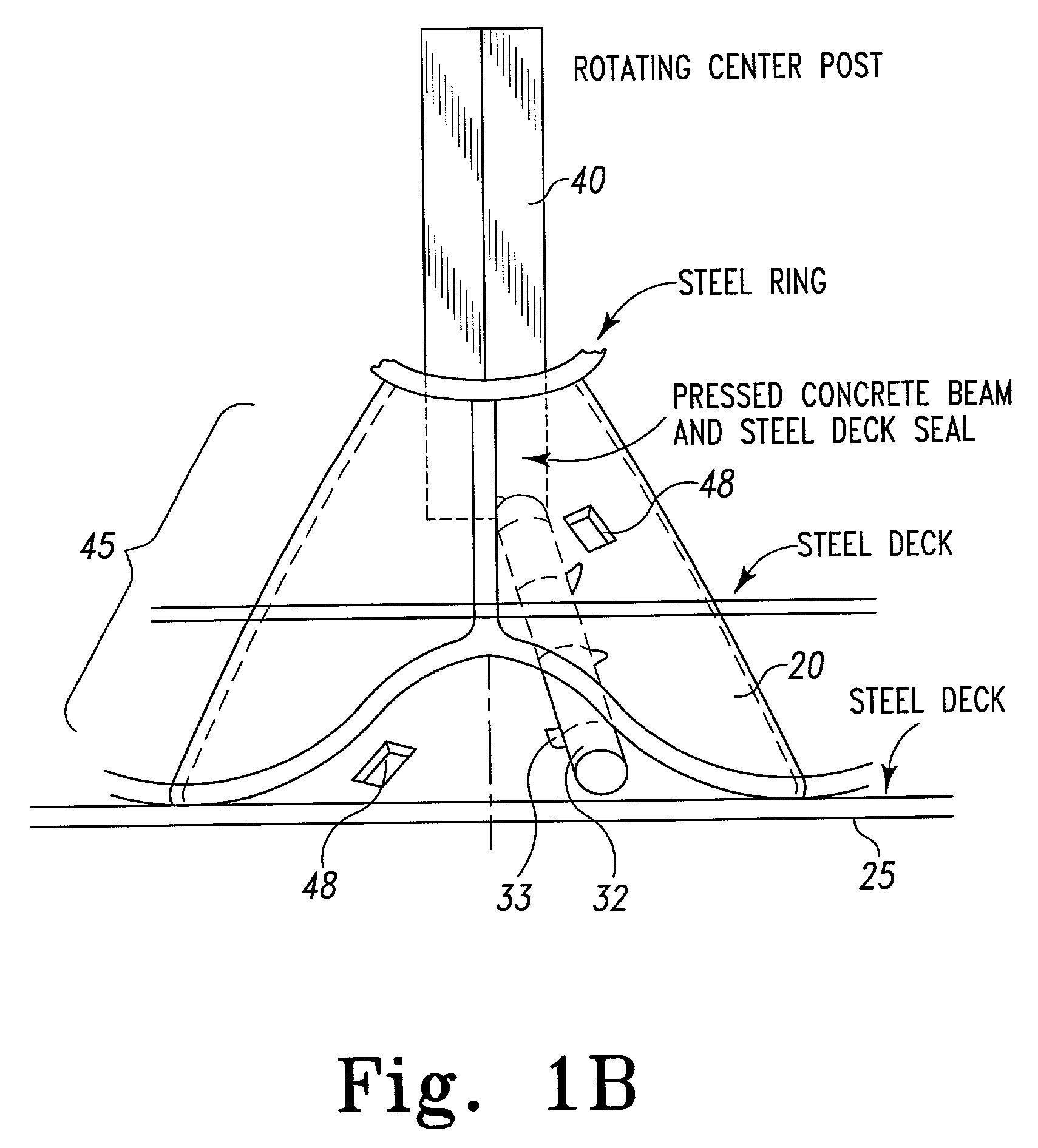

Apparatus and method for size reduction

A method for size reduction of a material comprising the steps of: feeding material through a feed assembly into a cyclone chamber, the cyclone chamber having an elongate cylindrical conduit having a frusto-conical section; adding at least one viscosity modifying agent into the cyclone chamber; and providing a cyclonic fluid stream within the cyclone chamber. The invention also includes an apparatus for carrying out size reduction of a material comprising: a cyclone chamber having an elongate cylindrical conduit having a frusto-conical section; a device for creating a cyclonic fluid stream within the cyclone chamber, such that the frusto-conical section of the cyclone chamber terminates in an opening forming the inlet to the device; an air inlet tube in fluid connection with the cyclone chamber at the opposite end of the frusto-conical section; and a feed assembly for feeding material into the cyclone chamber.

Owner:MUSSE

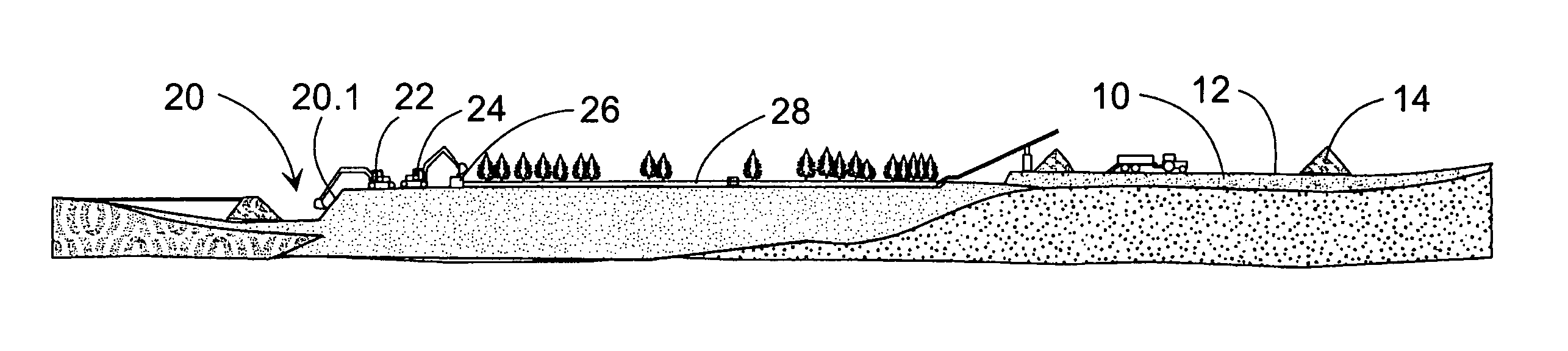

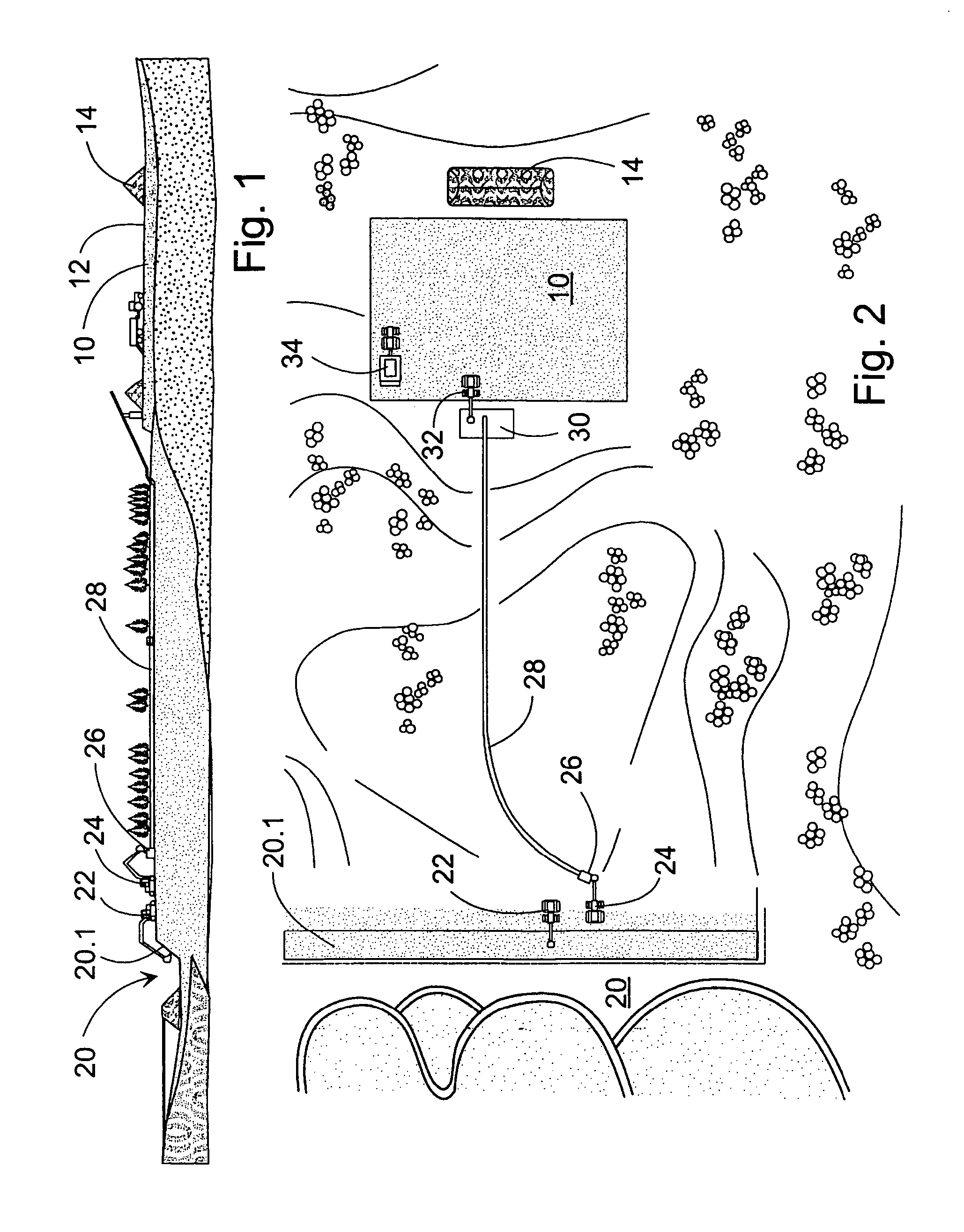

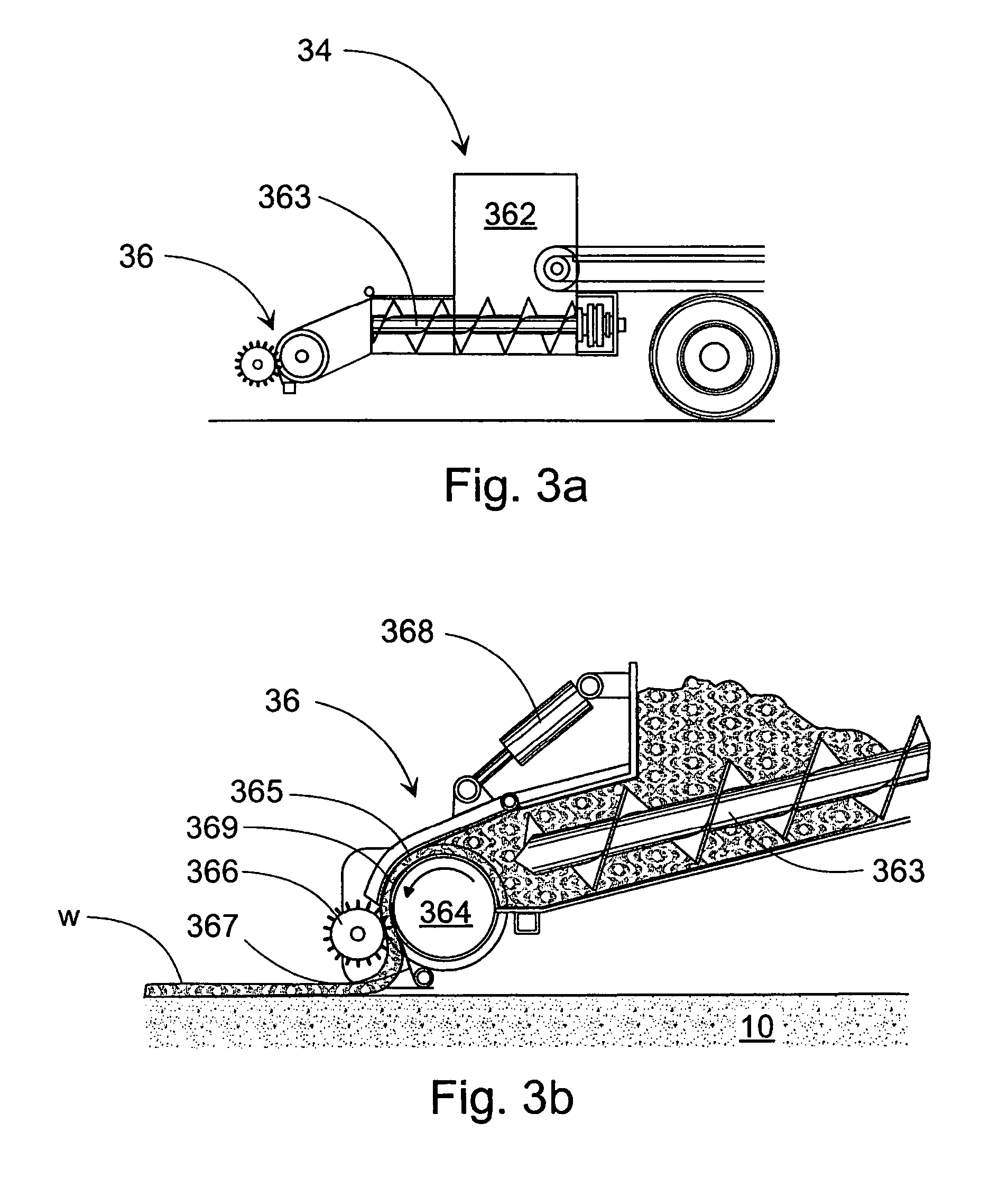

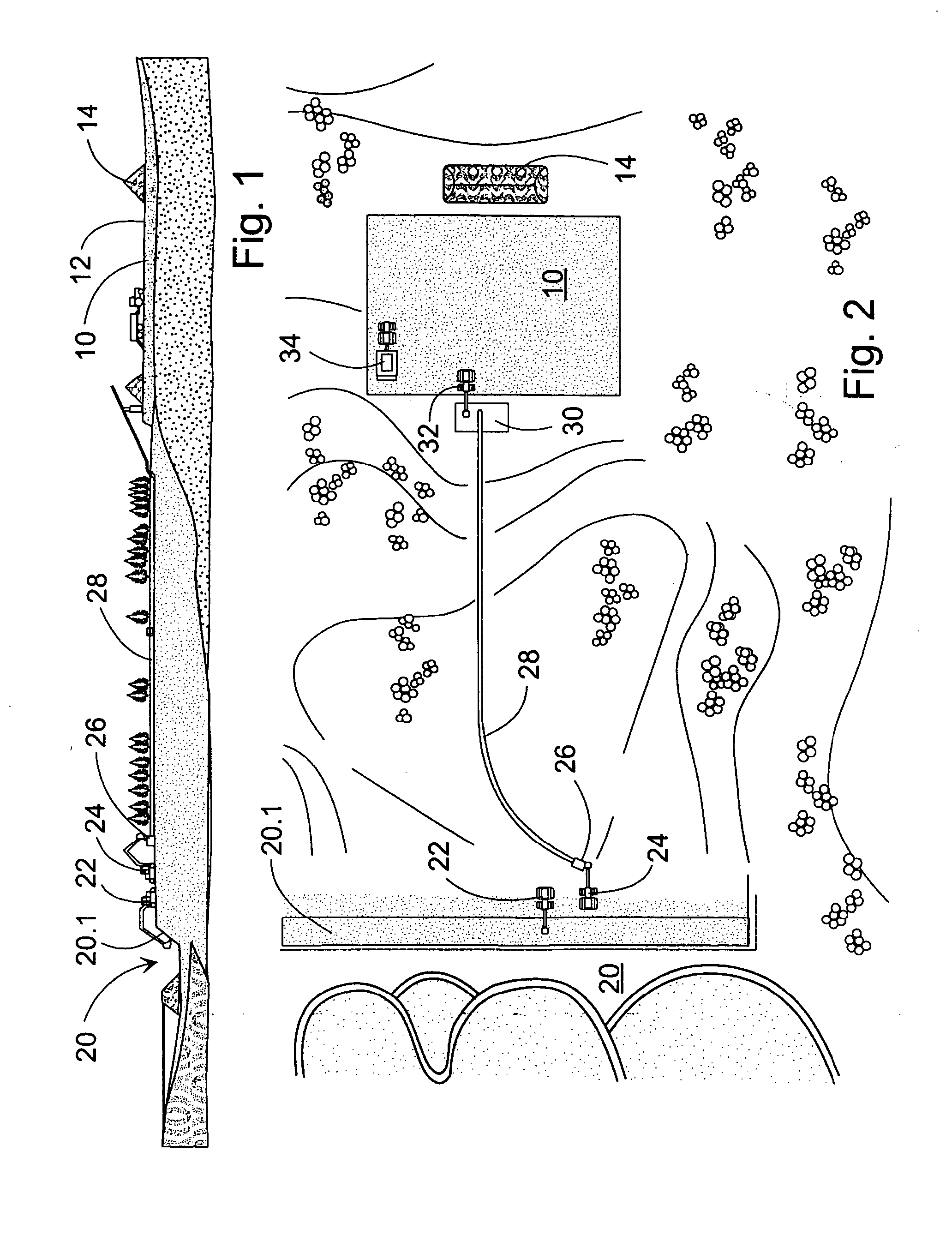

Method and equipment for producing horticultural and fuel peat and a fuel peat product

A method is disclosed for producing horticultural or fuel peat, in whichthe peat is removed from a bog,the removed peat is transferred from the bog to a drying field a distance away, in which the moved peat is dried, mainly by exploiting direct solar energy, so that the peat dries due to the effect of the solar radiation and the wind,after drying, the peat is moved from the drying location to further use or storage.The drying field is a special surfaced field, essentially impermeable to water, created for drying, and the peat is spread on the field as a thin 1-15 cm layer of a high-consistency mass, with a solids content of 8-30%.

Owner:VAPO

Culm and chip mixing method and special equipment thereof

InactiveCN103657499AReduce volumeReduce weightWorking-up peatMixer accessoriesHybrid typeProcessing plants

The invention relates to a culm and chip mixing forming machine and a method for preparing a culm and chip mixing material by using the forming machine. The culm and chip mixing forming machine is mainly composed of a base, a motor, a culm feed port, a chip feed port, a blowing port, a binder adding port, a stirrer, a material storing box, a mould and a compressor. The forming machine provided by the invention has the advantages that the colliery waste culm and the waste chip of a wood processing factory are subjected to deep processing again so that a novel fuel is formed, the use ratios of the coal and the wood are improved, the pollution caused by the industrial waste is reduced, the transportation of the output fuel is convenient, and the flammability is good.

Owner:张京三

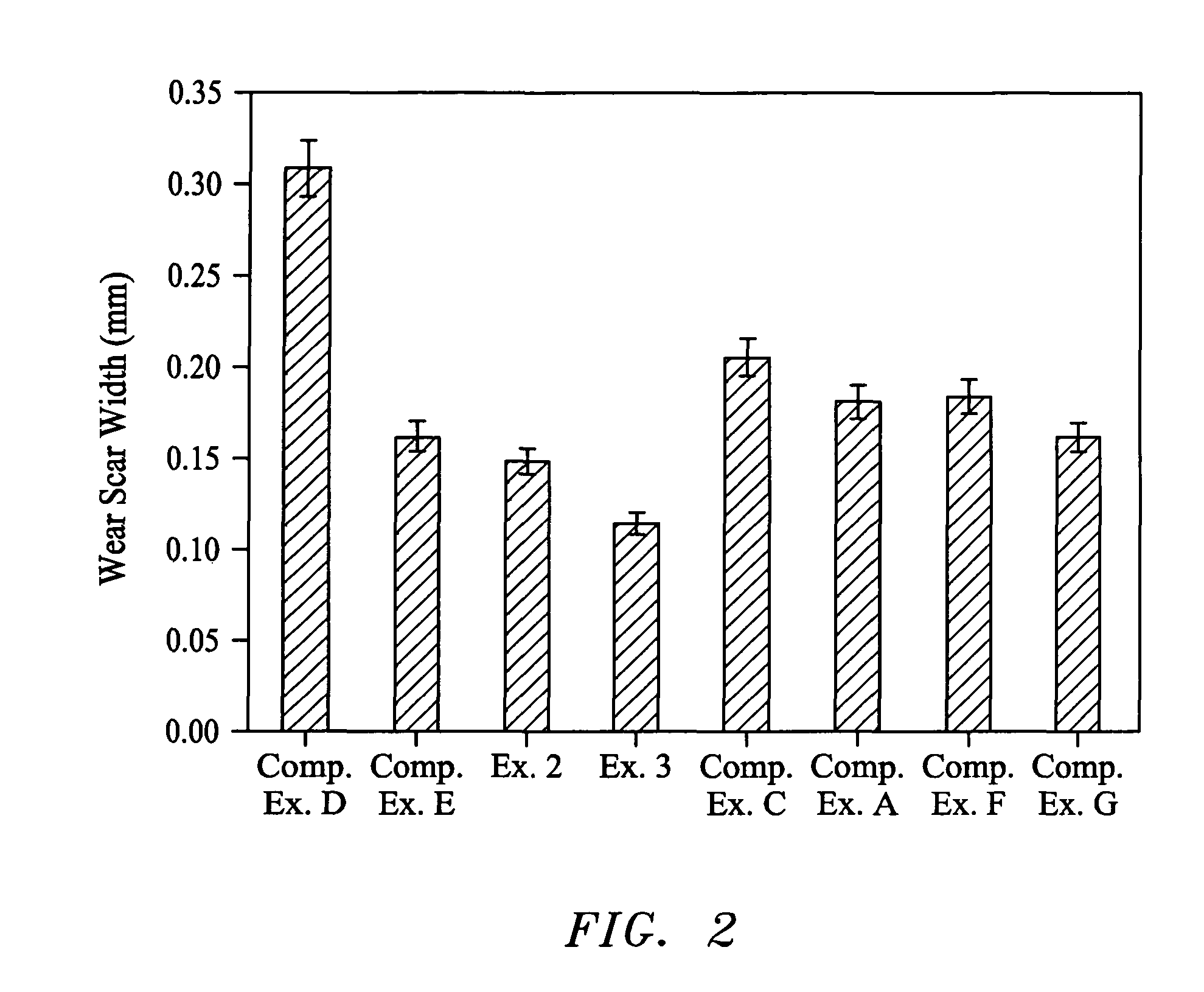

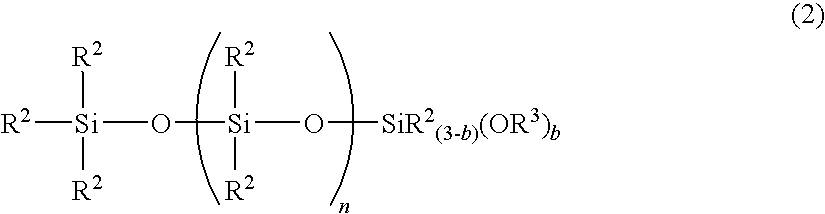

Lubricating oil compositions

InactiveUS8153566B2Reduce wearImproved and relatively comparable wear reducing propertySilicon organic compoundsBearing componentsSilane compoundsHydrolysate

Owner:CHEVRON ORONITE CO LLC

Peat brick manufacture method

The invention discloses a peat brick manufacture method, which comprises the following processing steps of: (1) shale is crashed into shale powder by a rock breaker; (2) peat and water are blended and stirred into a peat slurry; (3) the shale power obtained in the step (1) and the peat slurry obtained in the step (2) are blended and stirred to peat brick raw material; (4) the peat brick raw material is poured into a mould to be molded, dried, and baked to obtain the peat brick. The peat brick manufacture method has the advantages that the raw material is more uniformly stirred; the quality of the finished goods of the brick is increased; the finished brick has the clear outline, can reach the hardness standard of number 200 brick; the method makes waste profitable, reduces the cost and the pollution.

Owner:重庆市文钜机械有限公司

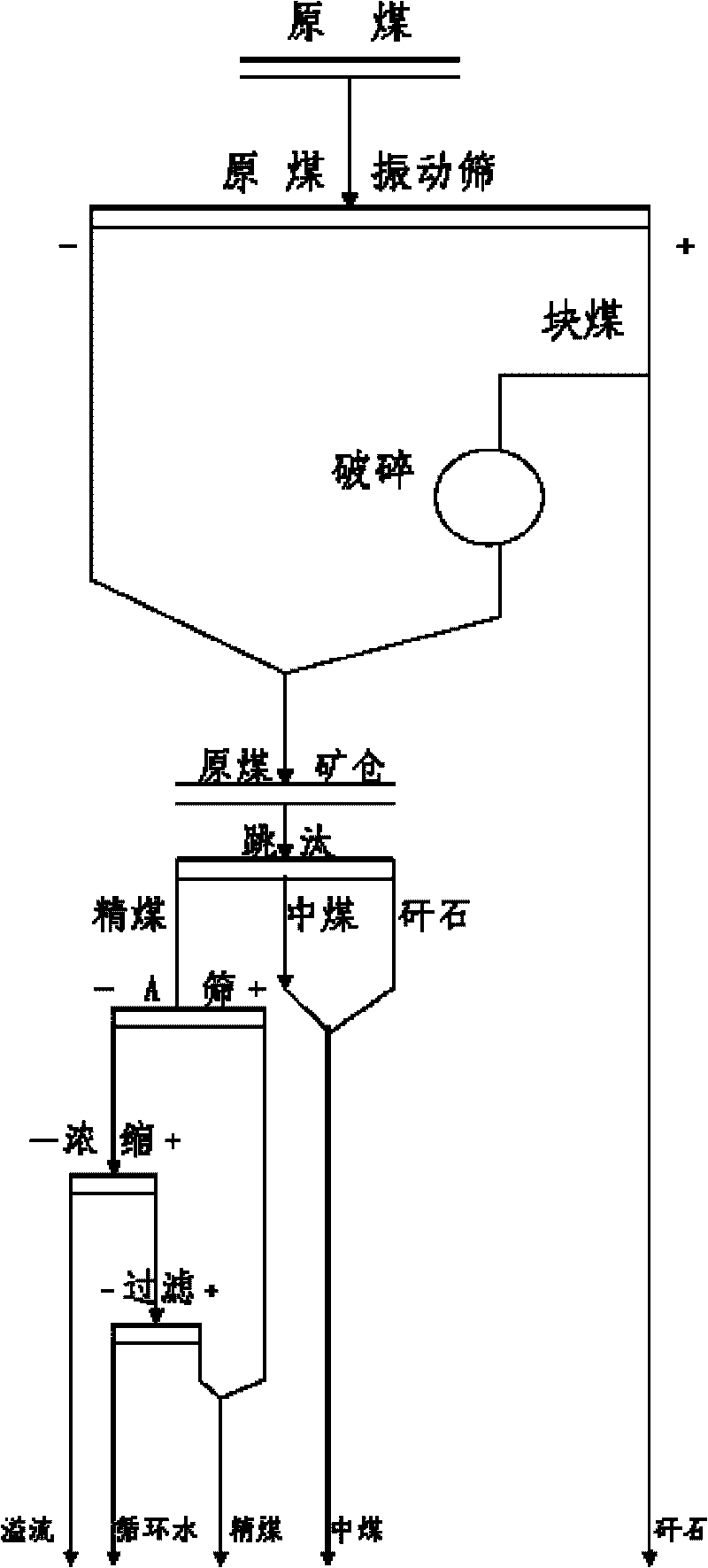

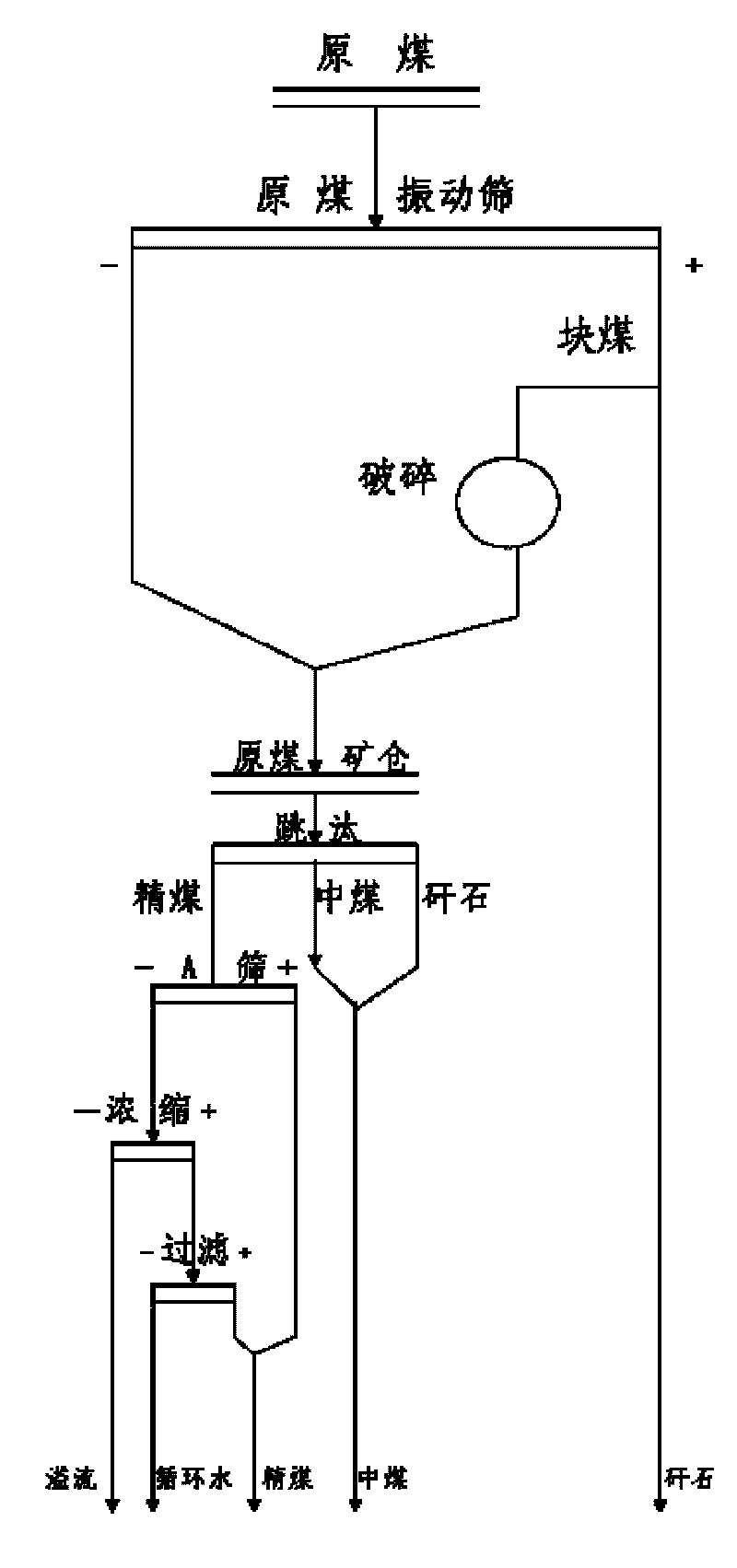

Grading method for recovering refined coal from coal slime

The invention relates to a method for recovering refined coal from coal slime, in particular to a grading method for recovering the refined coal from the coal slime. The method has the technical key points that by using a spiral classifier and the principle that 'sedimentation velocity in the liquid is different due to different particle sizes and specific gravities' of solid particles, the method realizes the separation between relatively high ash component and relatively low ash component by gravity classification; and 25-35% of plus sieve low ash refined coal with larger particle size can be recovered from the relatively high ash component, and 30-40% of minus sieve high ash coal slime with smaller particle size can be removed from the relatively low ash component. Through twice classification, the aim of 'removing the relatively high ash component in the coal slime' can be achieved. The embodiment of the invention can be used for recovering the refined coal from the coal slime, thus achieving the aim of reducing the ash content of the refined coal and meeting the demand of the user.

Owner:ZIBO WANGZHUANG COAL MINE

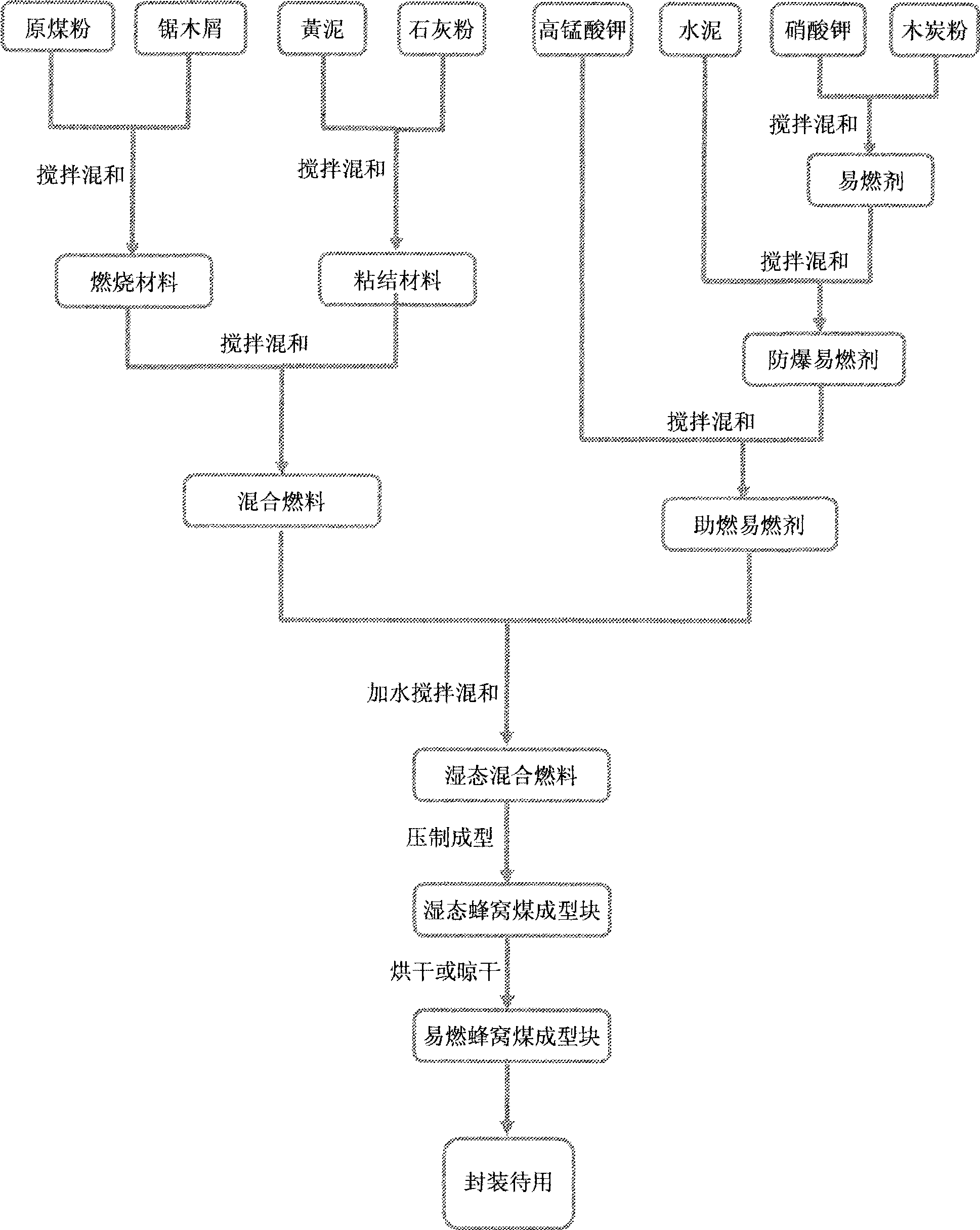

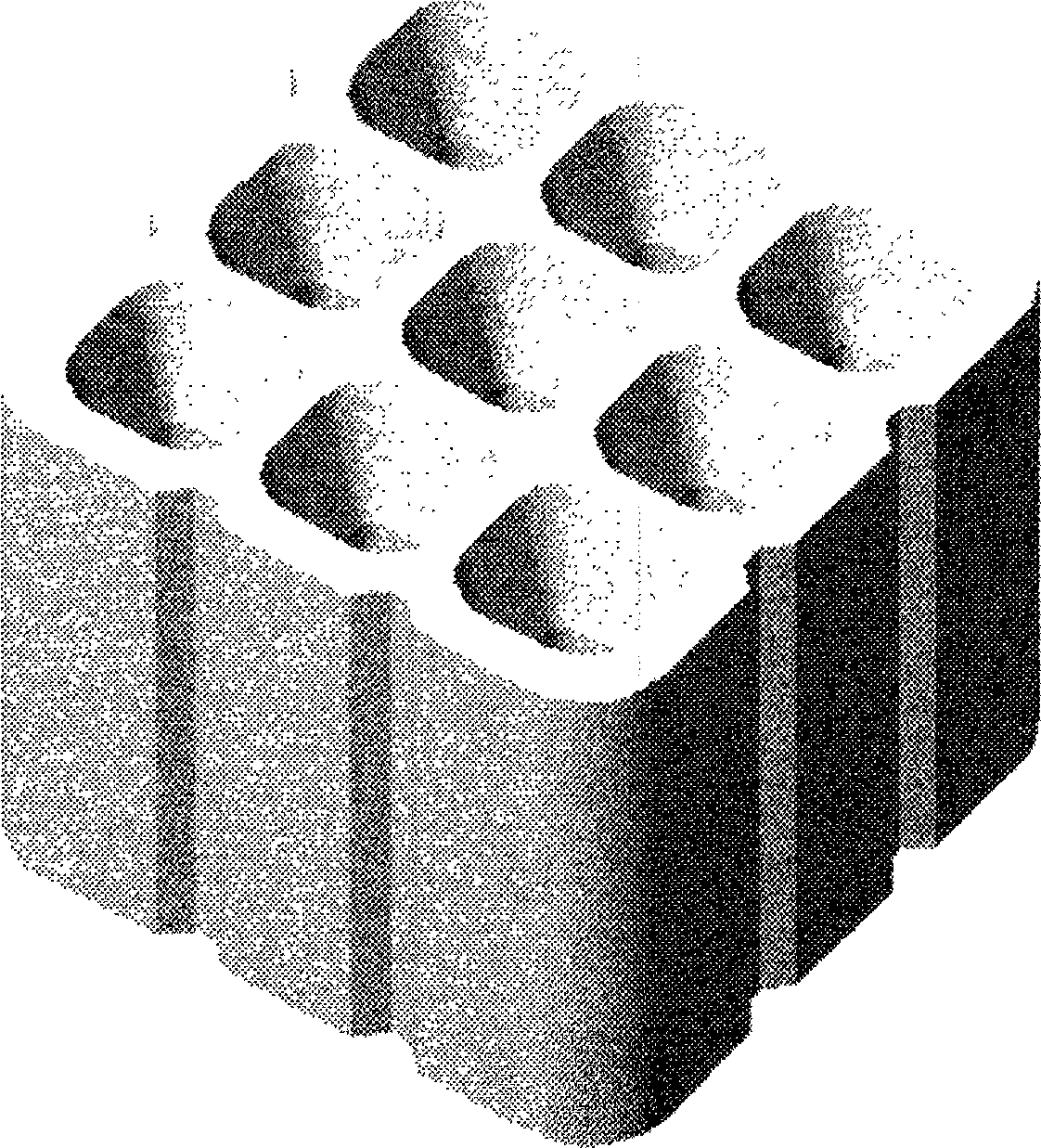

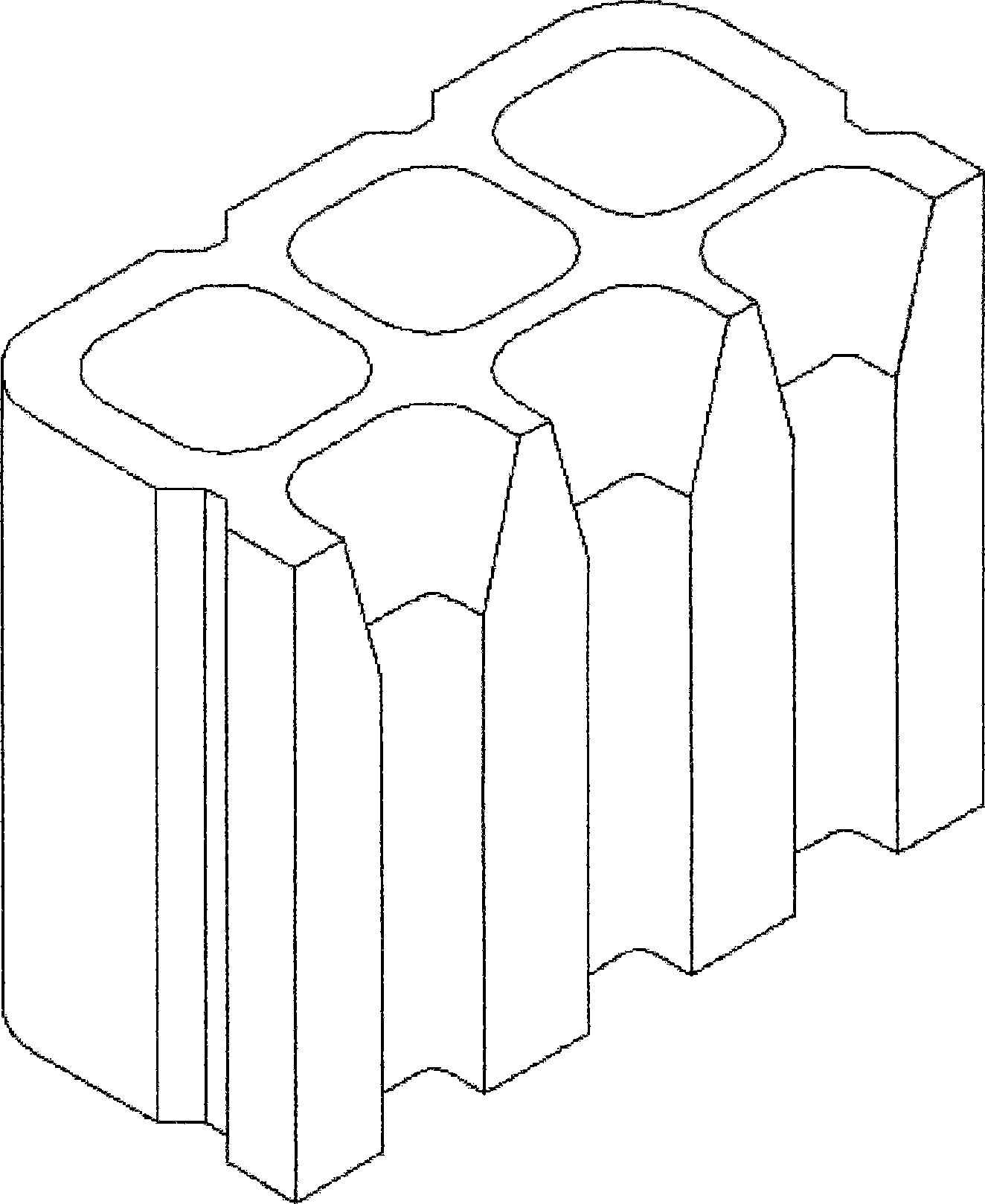

Easy-to-burn honeycomb briquet moulding block

The invention relates to a multi-purpose flammable honeycomb briquette forming block, in particular to a high-efficiency, energy-saving and environmental protection flammable honeycomb briquette forming block for two-dimensional compact array and three-dimensional stack use, and larger-scale combustion operation. The multiple-purpose flammable honeycomb briquette forming block is set out to two aspects of combustion component and outline structure, overall improves the combustion performance of the honeycomb briquette, creates a novel honeycomb briquette forming block, and is characterized by easy combustion, light weight, high efficiency, environmental protection and the like. In addition, the multiple-purpose flammable honeycomb briquette forming block has the advantages of simple material drawing, convenient preparation, low manufacturing cost, wide application scope and market application prospects, and higher economic practical value.

Owner:钟明华

Heat dissipating silicone grease compositions

InactiveUS7786056B2Minimal change of viscosityHeavy loadSilicon organic compoundsSemiconductor/solid-state device detailsPolymer scienceSilicone grease

A silicone grease composition comprising 3-30 wt % of an organopolysiloxane and 60-96.9 wt % of a heat conductive filler is diluted with a least volatile isoparaffin having a boiling point of 260-360° C. Despite a heavy loading of heat conductive filler, the grease composition is easily applicable to heat sinks as a thin uniform coating. The composition is drastically increased in shelf stability at room temperature, easy to handle, and provides for good heat dissipation.

Owner:SHIN ETSU CHEM IND CO LTD

Method and equipment for producing horticultural and fuel peat and a fuel peat product

A method is disclosed for producing horticultural or fuel peat, in which the peat is removed from a bog, the removed peat is transferred from the bog to a drying field a distance away, in which the moved peat is dried, mainly by exploiting direct solar energy, so that the peat dries due to the effect of the solar radiation and the wind, after drying, the peat is moved from the drying location to further use or storage. The drying field is a special surfaced field, essentially impermeable to water, created for drying, and the peat is spread on the field as a thin 1-15 cm layer of a high-consistency mass, with a solids content of 8-30%.

Owner:VAPO

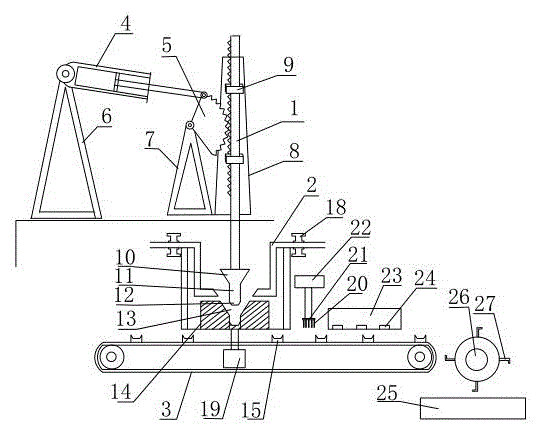

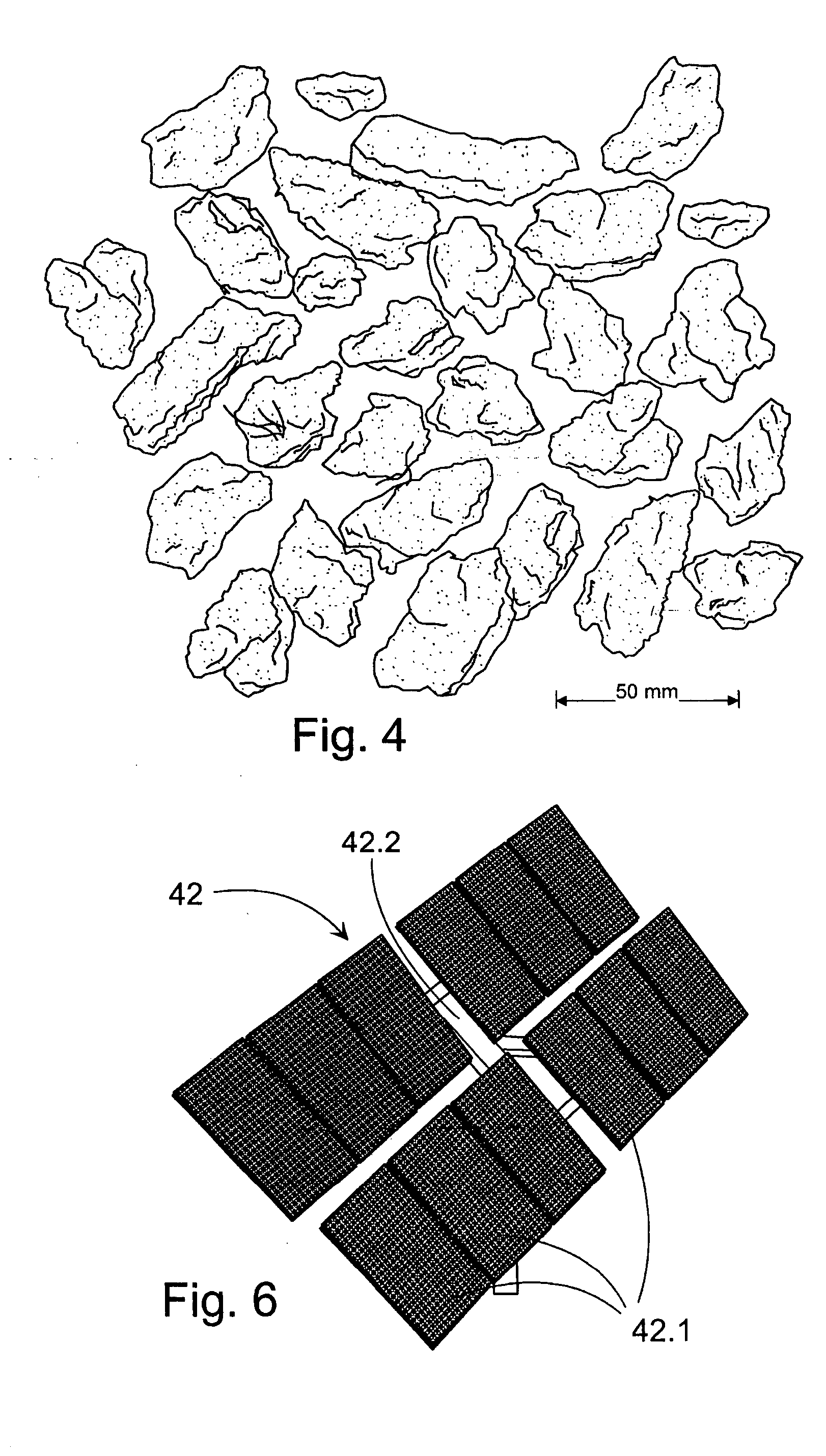

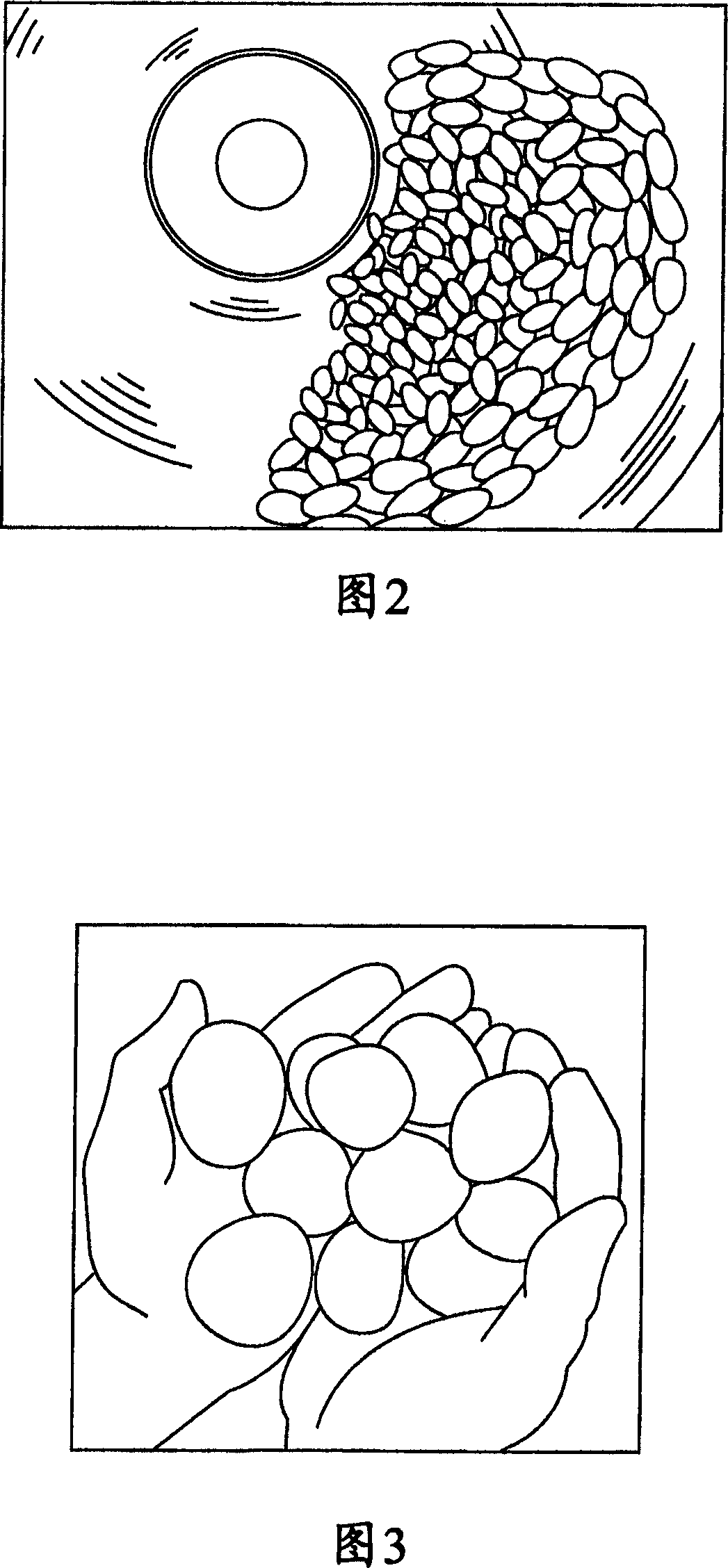

Fuel product and process

InactiveCN1997726AAvoid premixingAvoid processing requirementsSolid fuelsWorking-up peatParticulatesRotating drum

A process for producing fuel pellets is described. The pellets are obtainable from a particulate carbon-based material and a binder, the process comprising the following steps: admixing the material and binder, and agglomerating the so-formed mixture by tumbling. The tumbling action, such as in a rotary drum, serves to agglomerate the particles and bind the mixture into the pellets, usually with a variable size distribution. No mechanical compression force is required, and with the binders used, the process can be carried out at ambient temperature. The process provides a simple but efficient process for using waste carbon-based materials, and forming a useable fuel product, which is easily transportable and efficiently combustible. Rotating drum or pan agglomerators are relatively low cost to build, and are capable of very high tonnage throughputs. Customised products can be produced and the process enhances the economics of ash and sulphur removal in coal upgrade plants.

Owner:SOLSYS

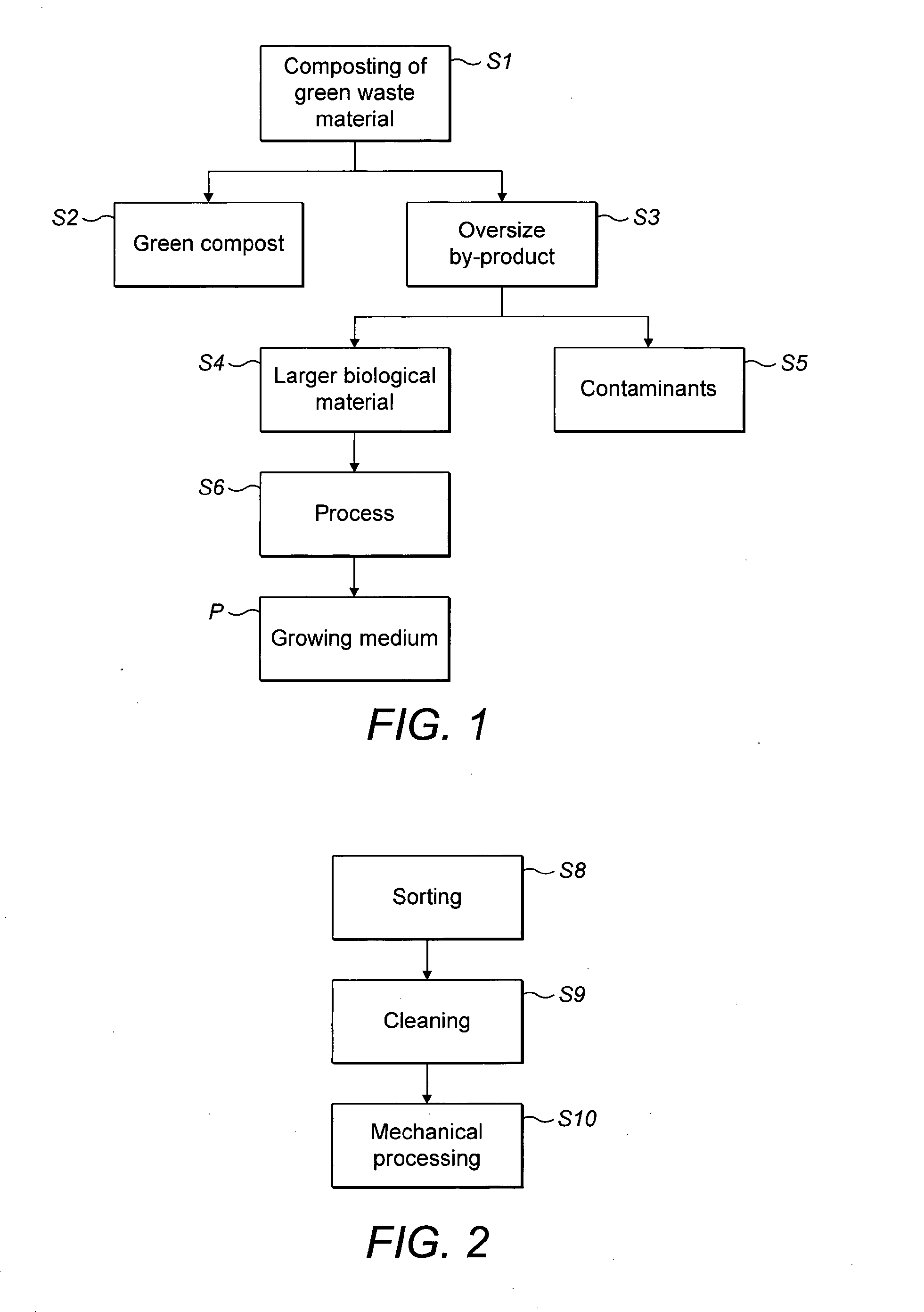

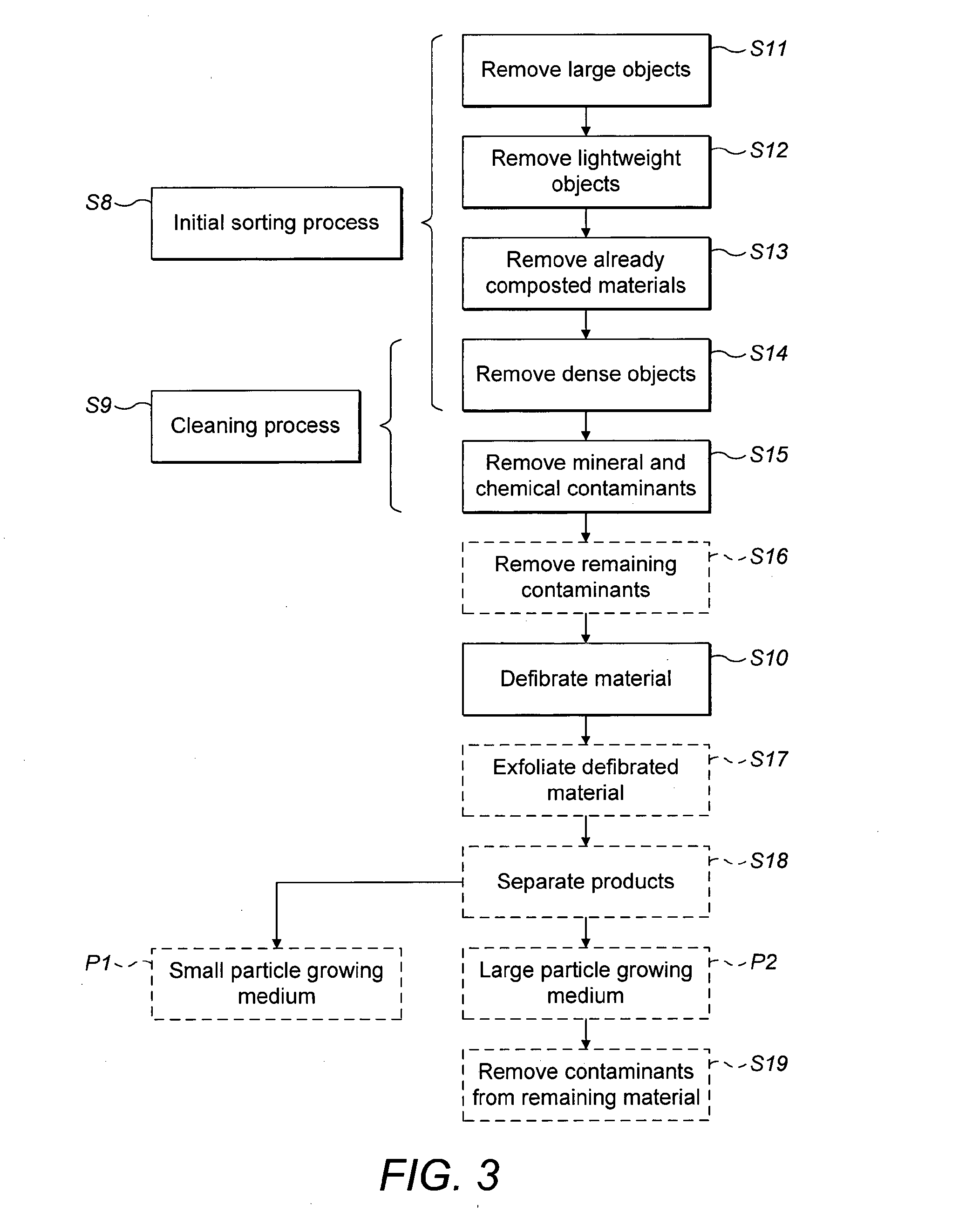

Biomaterial process and apparatus

InactiveUS20160107945A1Increase the proportionBio-organic fraction processingProductsMaterials scienceBy-product

Owner:FREELAND HORTICULTURE

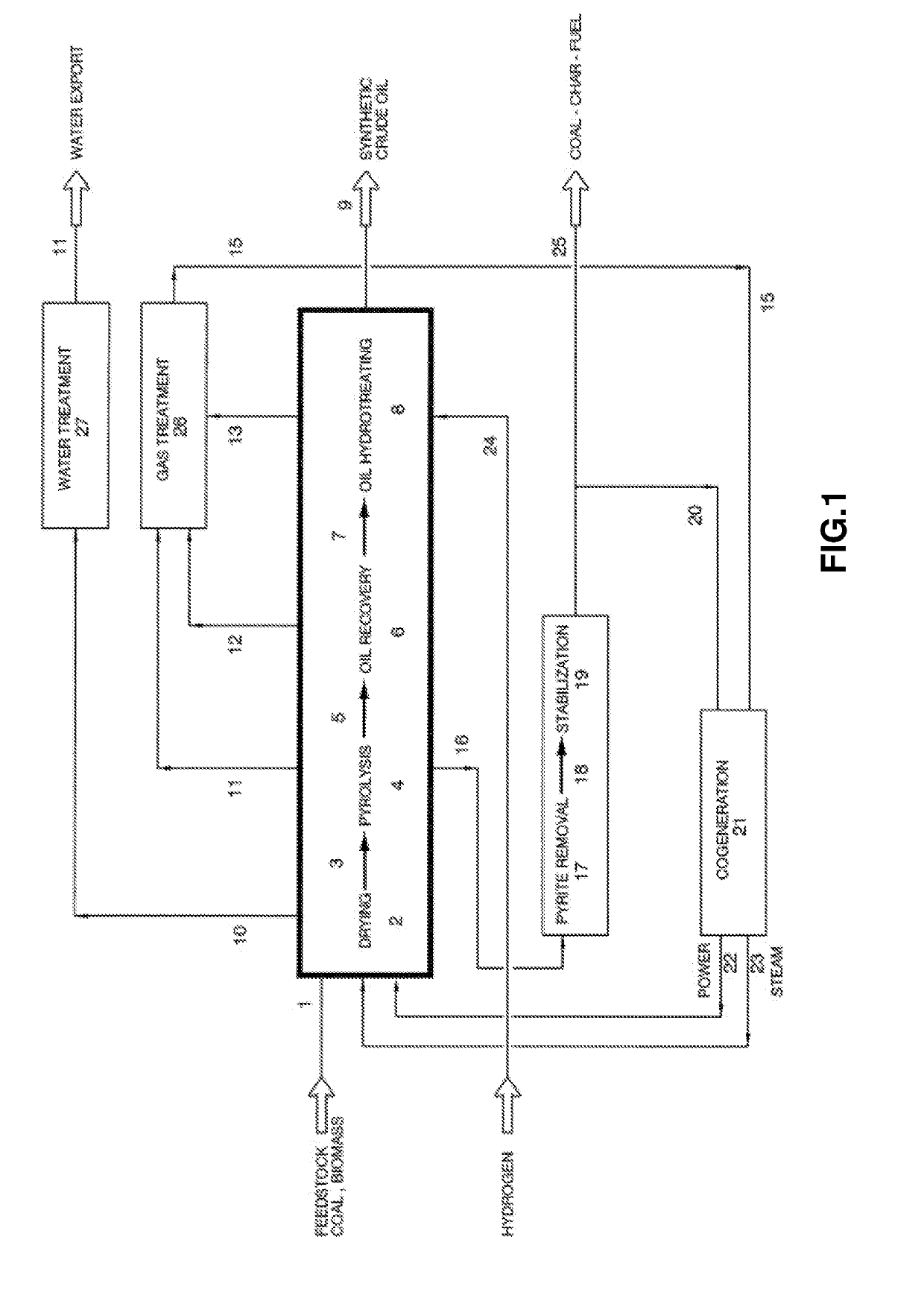

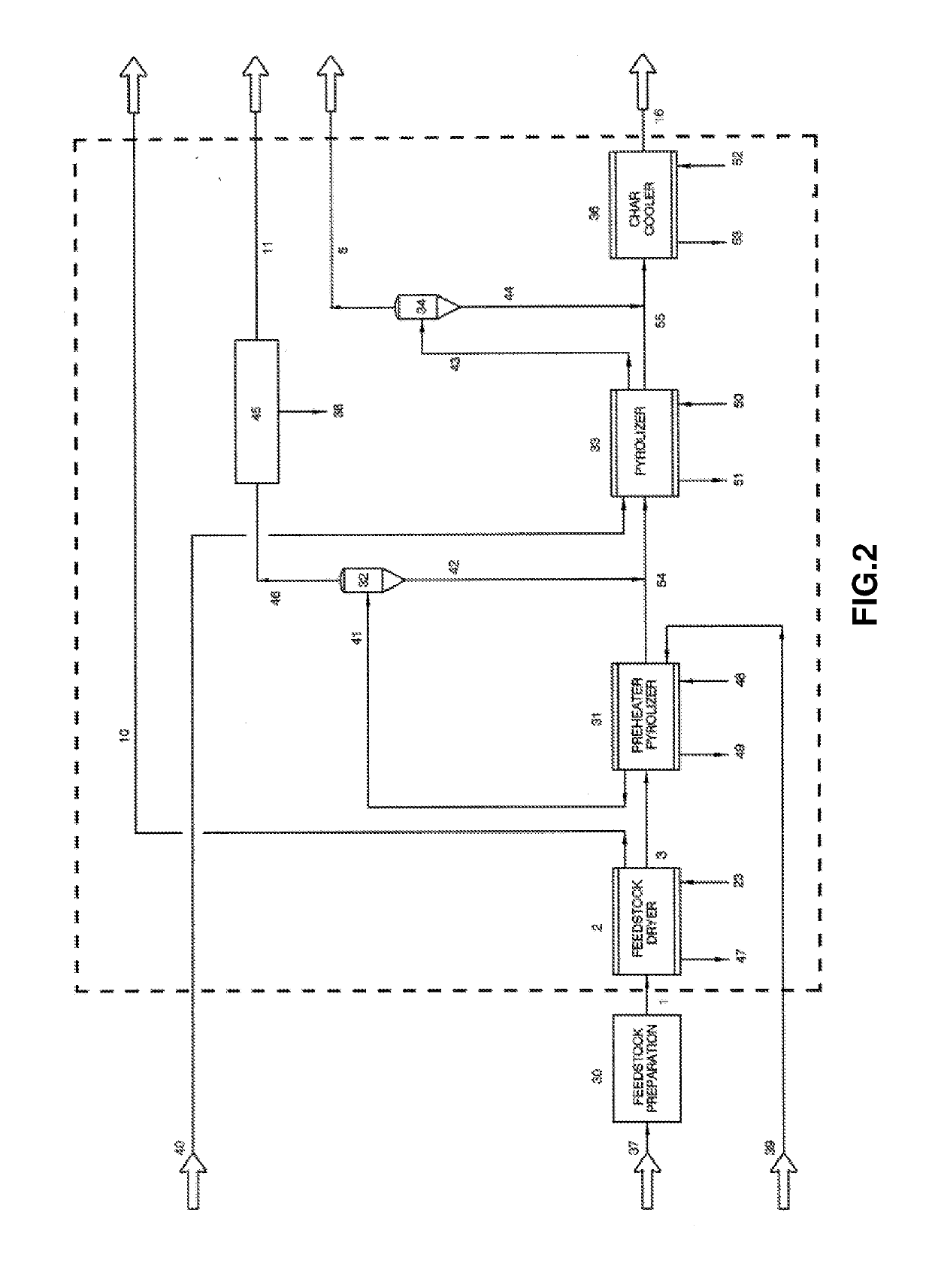

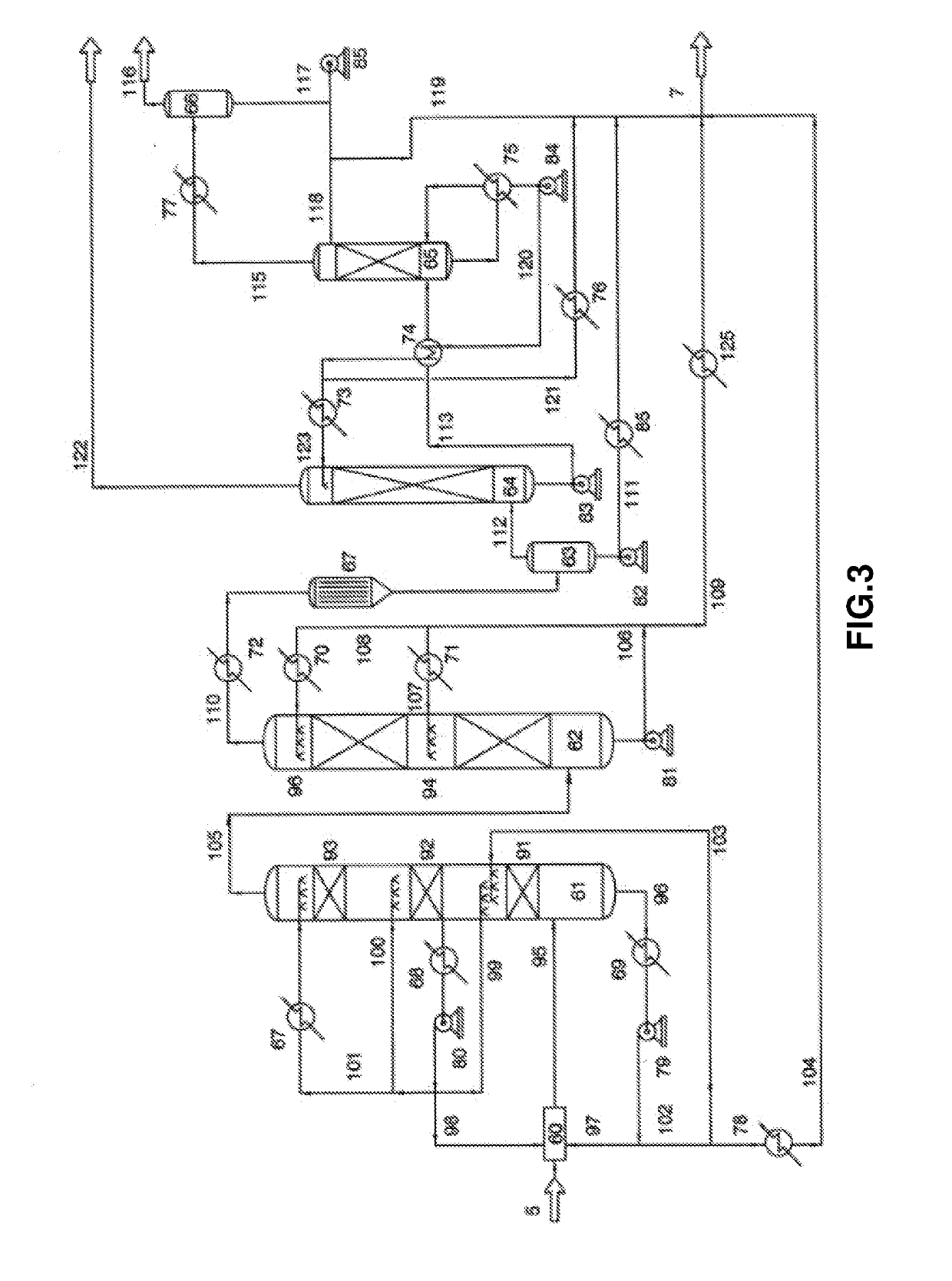

Control, method for pyrolysis process of low-rank-coal

InactiveUS20190292466A1Easy to controlAllow optimizationProgramme controlCoke oven safety devicesAnalysis dataChemical composition

A process control method for the on-line operation in real time of a low-rank-coal pyrolysis process producing a coal-char product, a pyrolysis gas, and a complex multi-component coal-tar-oil. The control method is based on measuring the concentration of selected compounds in the three products, a solid phase, a gas phase and a liquid phase condensed from the gas-phase, using a combination of spectrometric technology including scanning in the infrared, visible, ultraviolet and microwave spectral regions, and analyzing the data based on application of a modified Chi-Square data manipulation fitting technique developed for the specific products and process. This process control method provides a basis for accurate on-line control of the process operating parameters and allows optimization of the coal-char quality as well as the quality and yield of the extracted coal-tar-oil with unique chemical composition derived from low-rank coal in a pyrolysis process. The subject invention is based on the selection of 2-6 key compounds contained in each product to be measured and used as control point, calibration of the process operating conditions to the key compound composition and monitoring the changes in concentration on-line in real time.

Owner:ENGLAND DENNIS CARL +1

Peat drying and dewatering device capable of adjusting treatment mode according to water content

InactiveCN112812803AReduce labor intensityShorten heat treatment timeWorking-up peatHigh humidityPeat

The invention discloses a peat drying and dewatering device capable of adjusting the treatment mode according to the water content. The device comprises a material distributing and detecting mechanism, the material distributing and detecting mechanism comprises a tank body, a vertically-through feeding cavity is formed in the tank body, a pressure sensor is arranged on the inner wall of the feeding cavity, and a valve is arranged in the feeding cavity; according to the peat drying and dewatering device capable of adjusting the treatment mode according to the water content, peat with different water contents can be classified, the classification process is automatic, compared with manual classification, the efficiency is greatly improved, the labor intensity of workers is relieved, and when the peat entering the tank body is in the high water content state, the diversion guide device guides the peat into the extrusion treatment equipment for extrusion treatment, and when the water content of the peat is low, the diversion guide device guides the peat into the hot air drying equipment for treatment, so that unnecessary heat treatment is avoided, the heat treatment time of the high-humidity peat is greatly shortened, the energy consumption is greatly reduced, and the enterprise cost is reduced.

Owner:深圳市南堂欢贸易有限公司

Apparatus and method for size reduction

A method and apparatus for size reduction of a material. The method includes the steps of: feeding material through a feed assembly into a cyclone chamber, the cyclone chamber having an elongate cylindrical conduit having a frusto-conical section; adding at least one viscosity modifying agent into the cyclone chamber; and providing a cyclonic fluid stream within the cyclone chamber. The apparatus includes: a cyclone chamber having an elongate cylindrical conduit having a frusto-conical section; a device for creating a cyclonic fluid stream within the cyclone chamber, such that the frusto-conical section of the cyclone chamber terminates in an opening forming the inlet to the device; an air inlet tube in fluid connection with the cyclone chamber at the opposite end of the frusto-conical section; and a feed assembly for feeding material into the cyclone chamber.

Owner:MUSSE

Formula of novel peat brick

InactiveCN106064933AReduce pollutionReduce manufacturing costWorking-up peatCeramic materials productionBrickPeat

The invention discloses a formula of a novel peat brick. The peat brick is prepared by the following raw materials in parts by weight: 25-30 parts of moulded tailing slime, and 75-70 parts of gangue powder; physical and chemical indices of the moulded tailing slime are as follows: calorific value is 280-320 kilocalorie, and the water content is 12.5-13.5%; the physical and chemical indices of the gangue are as follows: particle size is 1-2.5mm. The formula has the beneficial effects that the coal is directly washed, byproducts are used as raw materials for brickmaking, other auxiliary materials are not added, waste is changed into valuables, environment pollution is reduced, and production cost is reduced.

Owner:四川乔丰新材料科技有限公司

Process for production of low temperature char during production of low temperature tars

An improved process for the production of smokeless (low CO2—CO emitting) boiler fuels which have been obtained by careful temperature control and the addition of waste, trash or other carbonaceous material during carbonization of various coal materials such as tar sands, bituminous coal, peat lignite, and oil shale.

Owner:BENNETT ENGINEERS & ASSOCS OF AUSTIN COLORADO

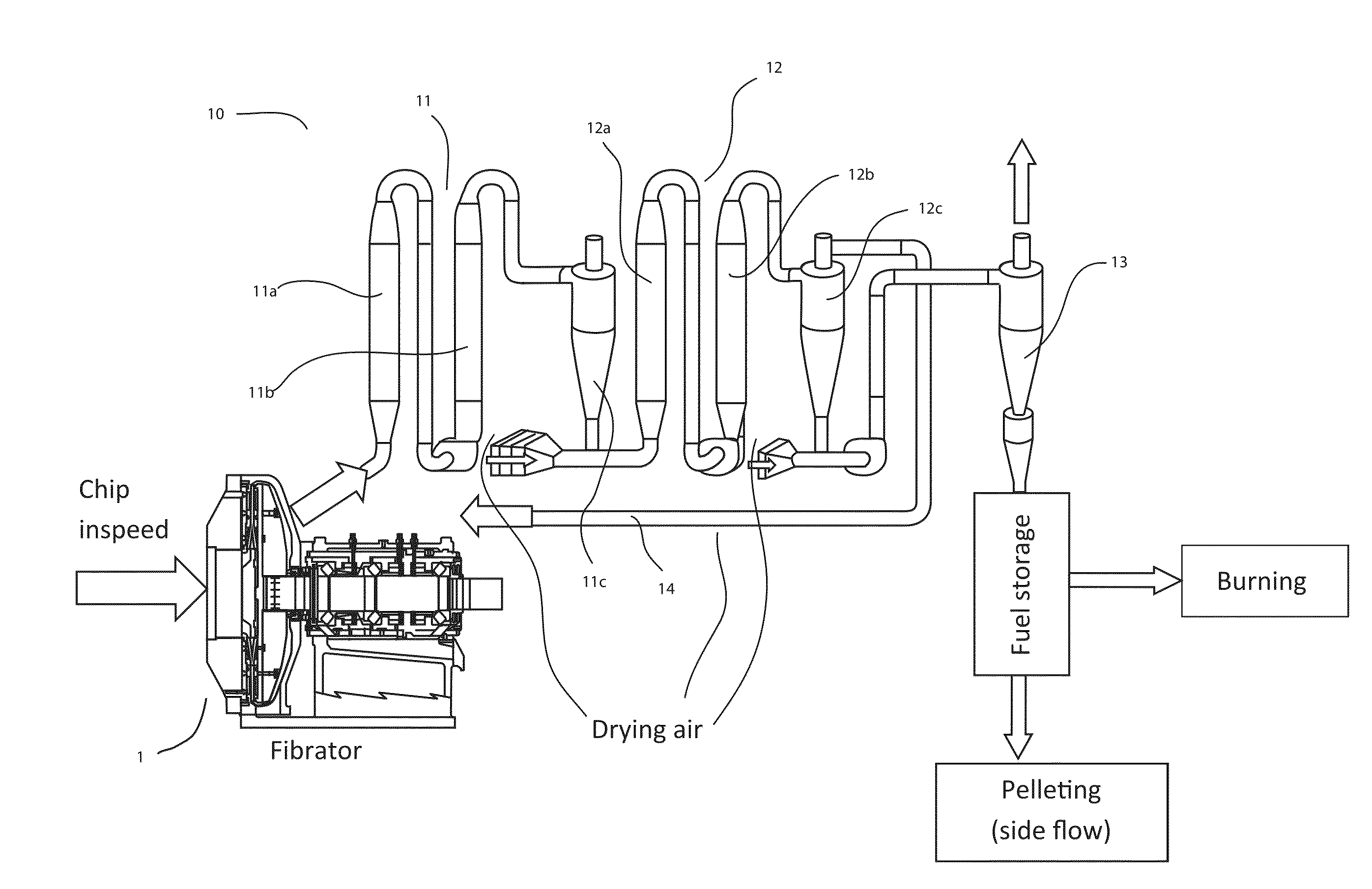

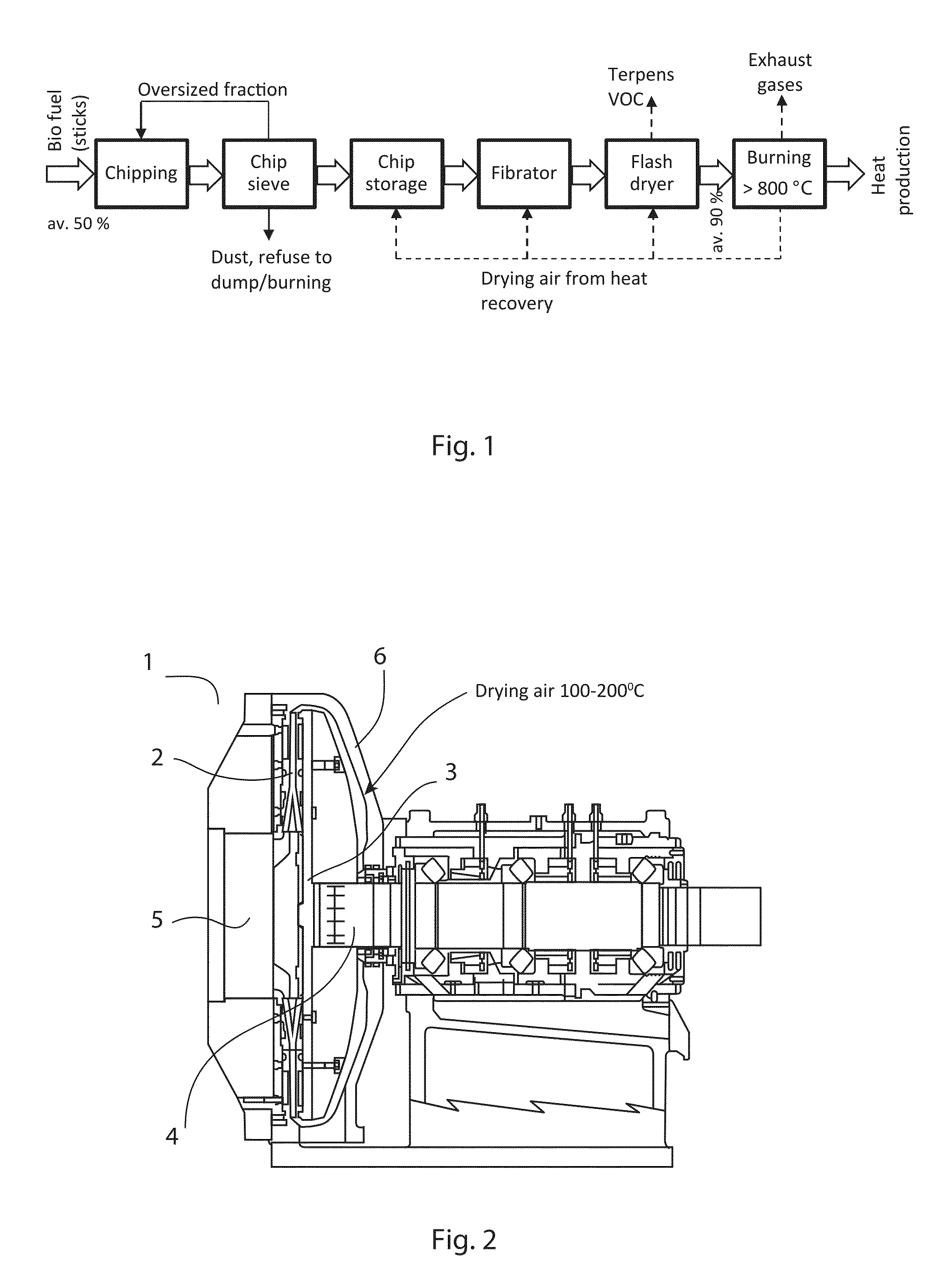

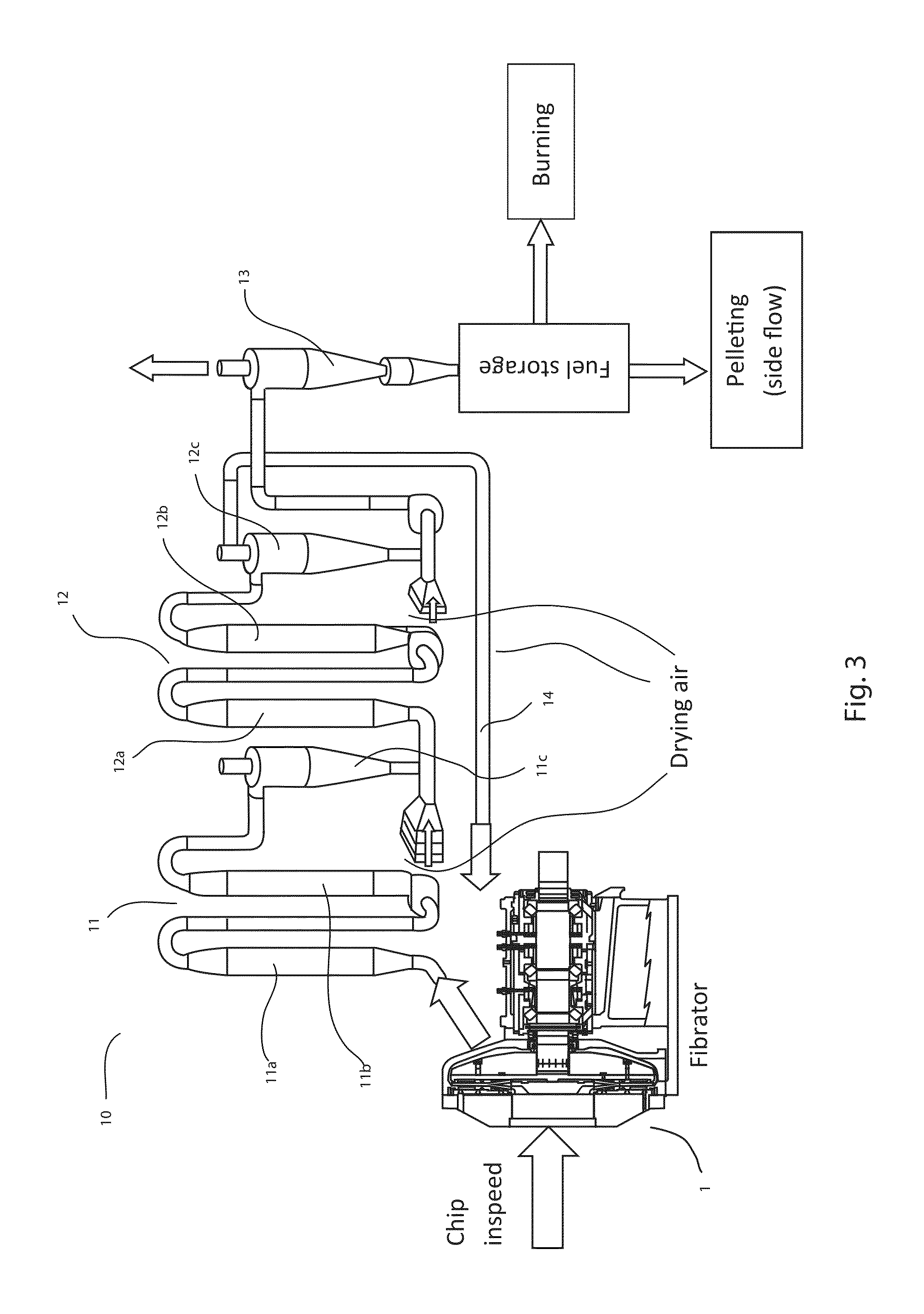

Method for producing biofuel and use of biofuel

InactiveUS20160060557A1Reduce riskReduce carbon dioxide emissionsDrying solid materials with heatBiofuelsBiofuelEngineering

The present invention relates to a method for manufacturing a biofuel from a vegetable-based biomaterial by performing the manufacture in an integrated manner, in such a way that the biomaterial is made finer and dried with the aid of heat brought from a heat-releasing process, when the drying is finally performed after the finer making stage, optionally in such a way that drying is started already in connection with finer making. The invention also relates to a biofuel manufactured in this manner and the use of the fuel in question.

Owner:AALTO UNIV FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com