Easy-to-burn honeycomb briquet moulding block

A flammable honeycomb briquette and forming block technology, which is applied in the direction of fuel, solid fuel, peat processing, etc., can solve the problems of unsatisfactory effect, incomplete combustion, difficult ignition, etc., achieve broad market application prospects, low cost, Make easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

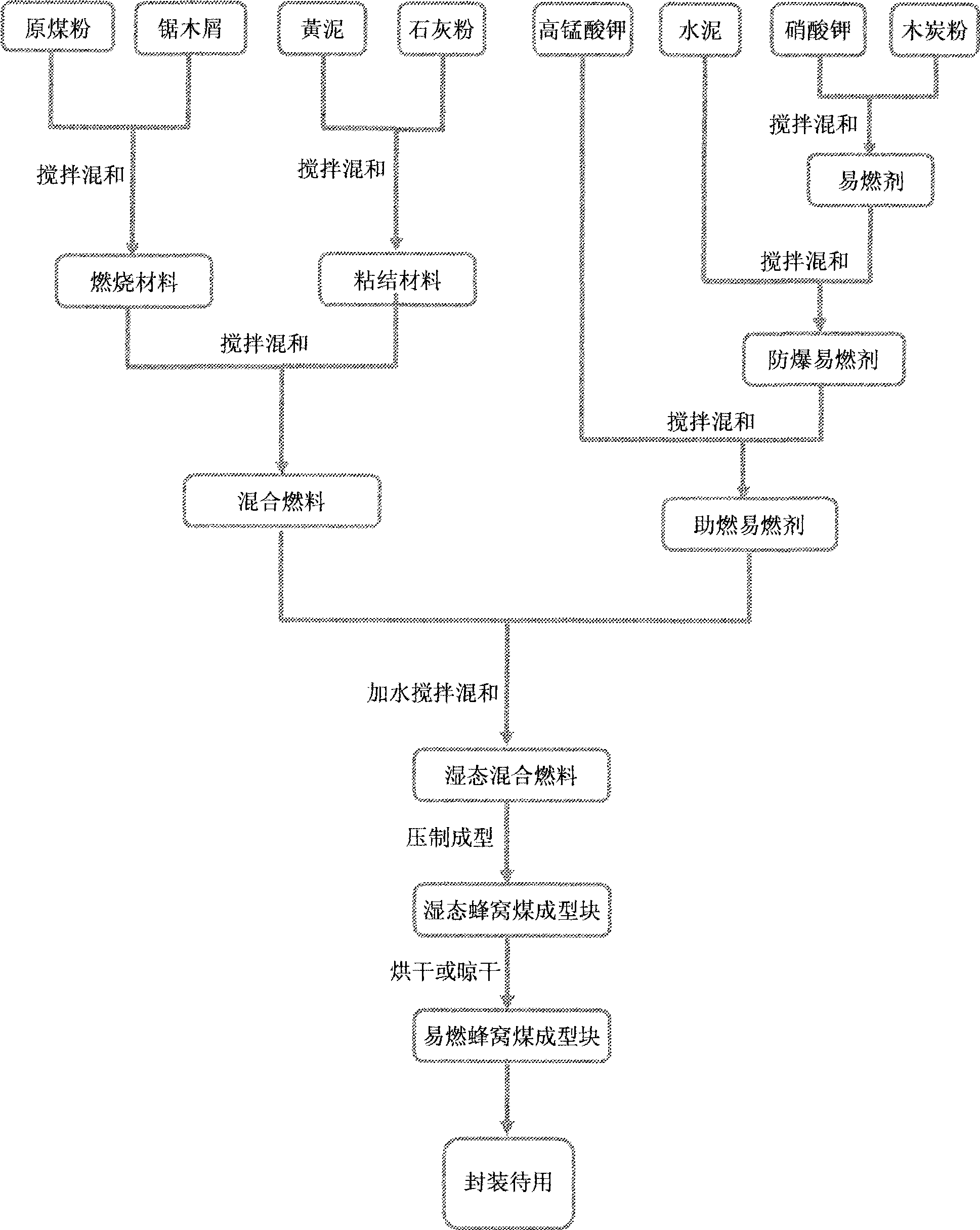

[0018] exist figure 1 Among them, the present invention is made up of 8 kinds of materials of raw coal powder, sawdust, yellow mud or red mud, lime powder, potassium permanganate, cement, potassium nitrate and charcoal powder, and concrete implementation steps are:

[0019] The first step: Through crushing, screening and other processes, 50-60 weight units of raw coal powder with a particle diameter of less than 3 mm are screened out, and they are evenly mixed with sawdust of 15-25 weight units to produce uniform particles and uniform color powdery burning material.

[0020] Step 2: uniformly mix 15-25 weight units of ordinary yellow mud powder or red mud powder with 3-7 weight units of lime powder to form a powdery bonding material.

[0021] The third step: the powdered combustion material generated in the first step is evenly stirred and mixed with the powdered caking material generated in the second step to generate a mixed fuel.

[0022] Step 4: Evenly mix 20-30 weight u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com