Patents

Literature

35results about How to "Avoid premixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

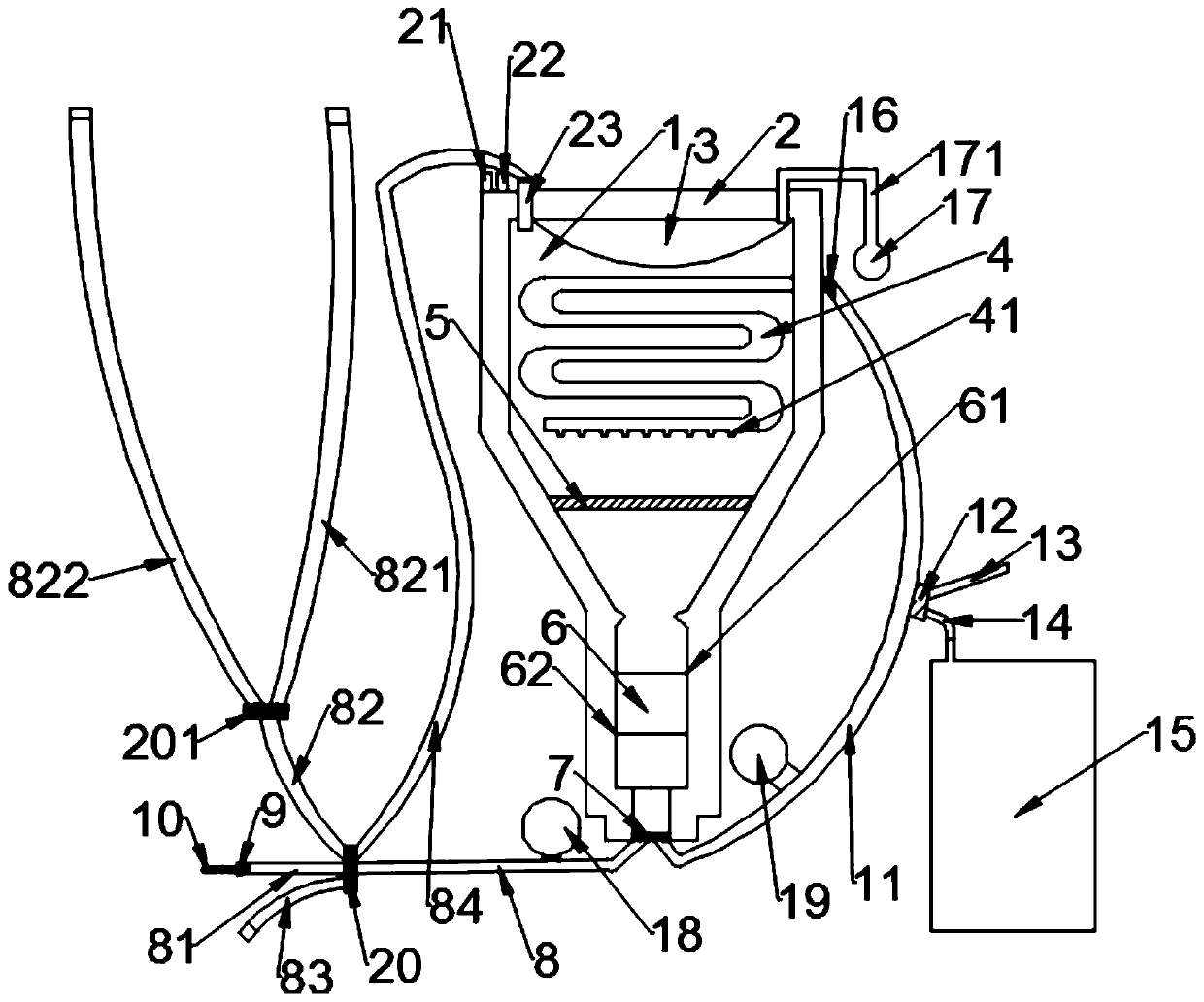

Microfluidic chip, manual centrifuging device and nucleic acid detection method

InactiveCN108043478AEliminate the steps of adding samplesEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsMicrofluidic chipChemistry

The invention relates to a microfluidic chip, a manual centrifuging device and a nucleic acid detection method. The microfluidic chip comprises at least one sample adding layer and a channel layer arranged at the lower side of the sample adding layer, wherein the upper surface of the channel layer is provided with a plurality of test units which are in centered distribution and are used for loading a to-be-tested reagent and transmitting the to-be-tested reagent to a chamber; each test unit comprises at least two chambers which are interconnected through a channel; and a plurality of sample adding holes corresponding to the channel layer are arranged along the central circumference of the sample adding layer for injection of a reagent into one of the chambers of a corresponding test unit.The manual centrifuging device provided by the invention is a portable device which does not rely on an external power supply, integrates nucleic acid extraction, amplification and detection by utilizing a microfluidic chip technology, realizes rapid and convenient nucleic acid analysis, and is used for rapid response and field diagnosis of emergencies like large-scale infectious diseases, food safely affairs and environmental pollution accidents.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

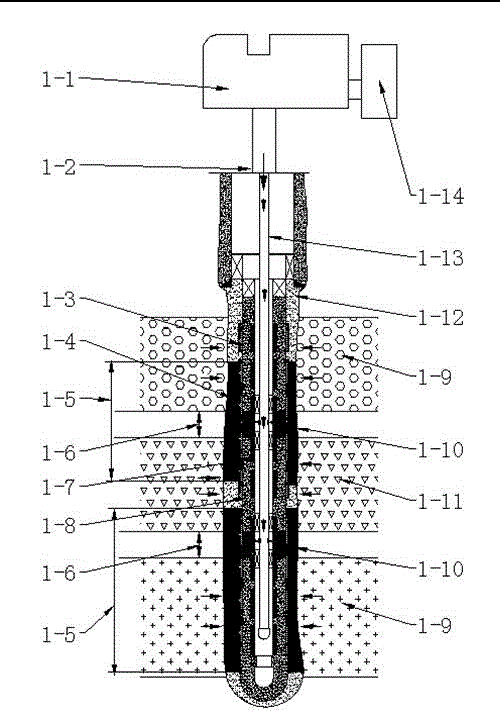

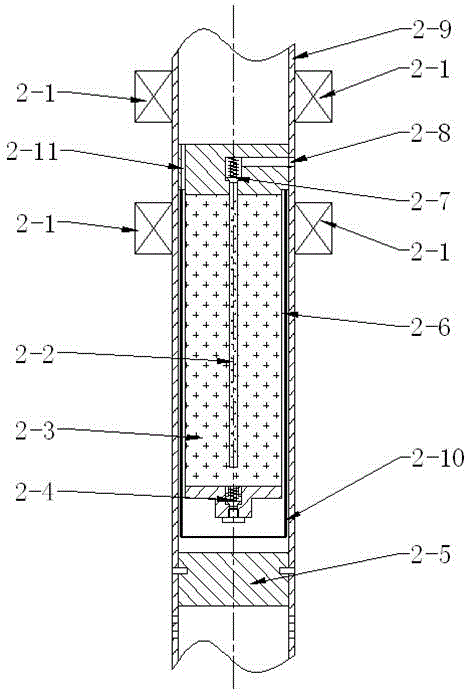

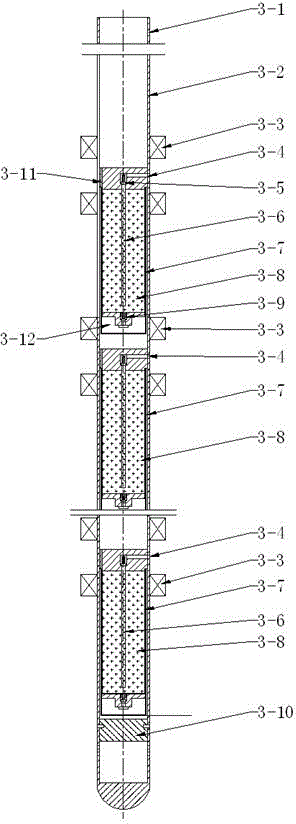

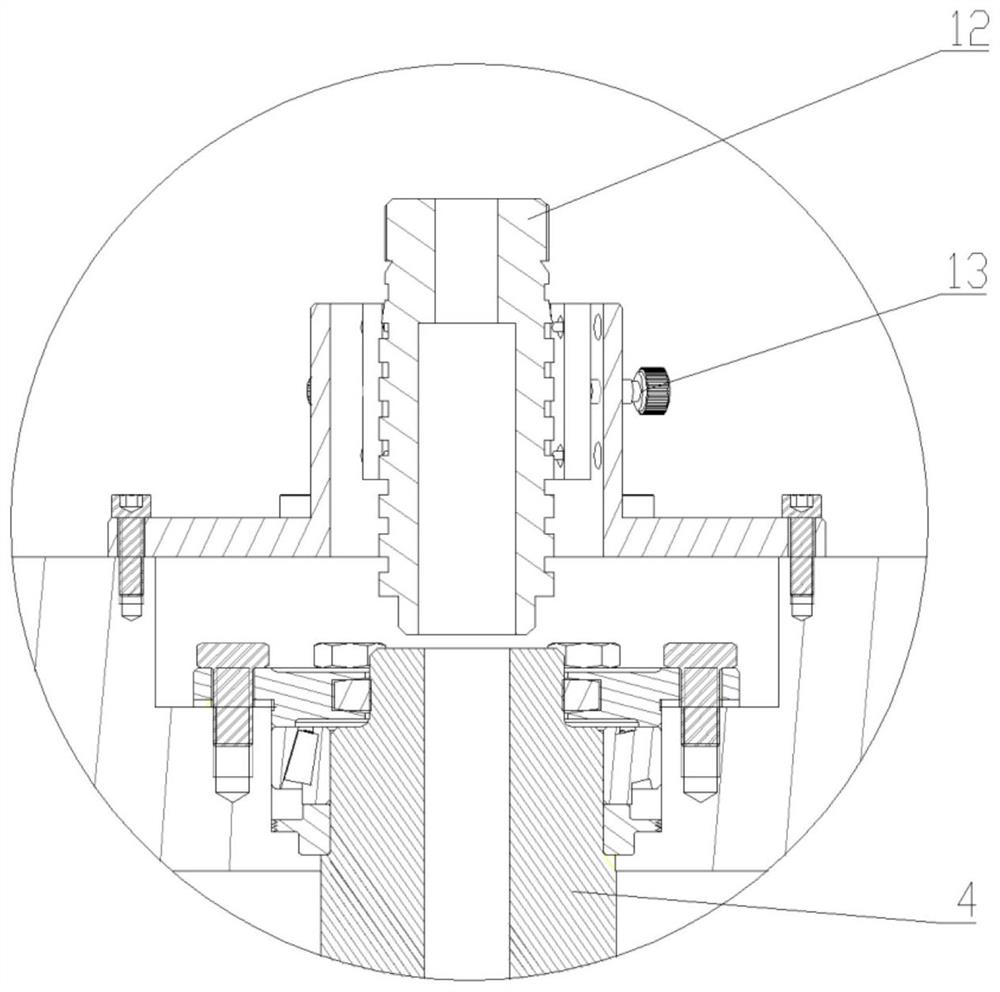

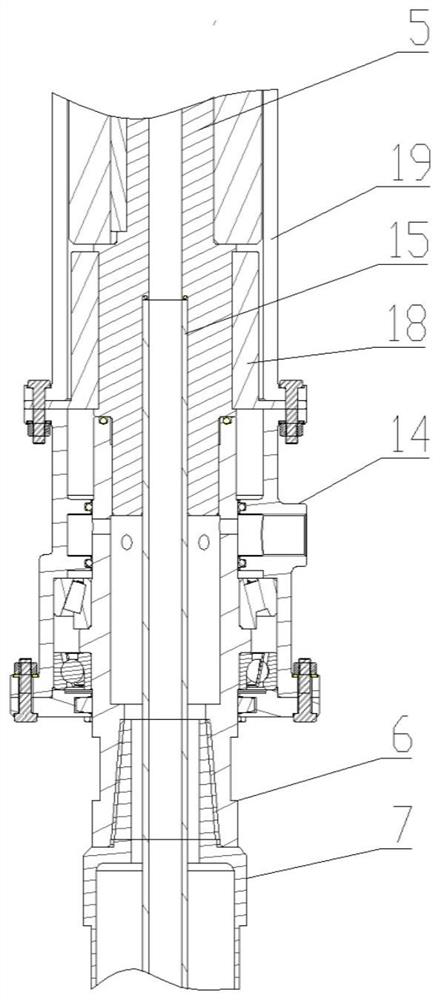

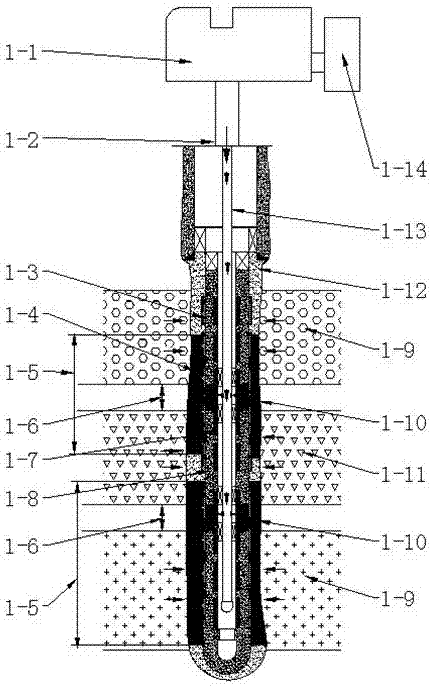

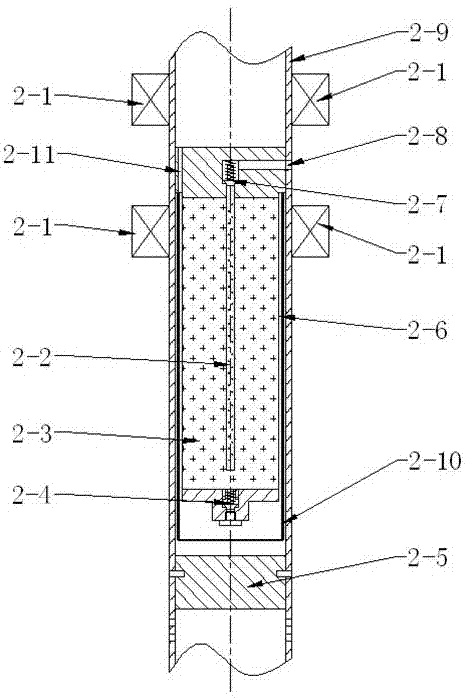

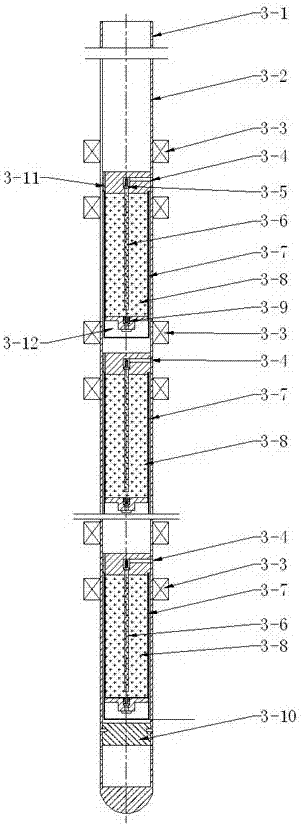

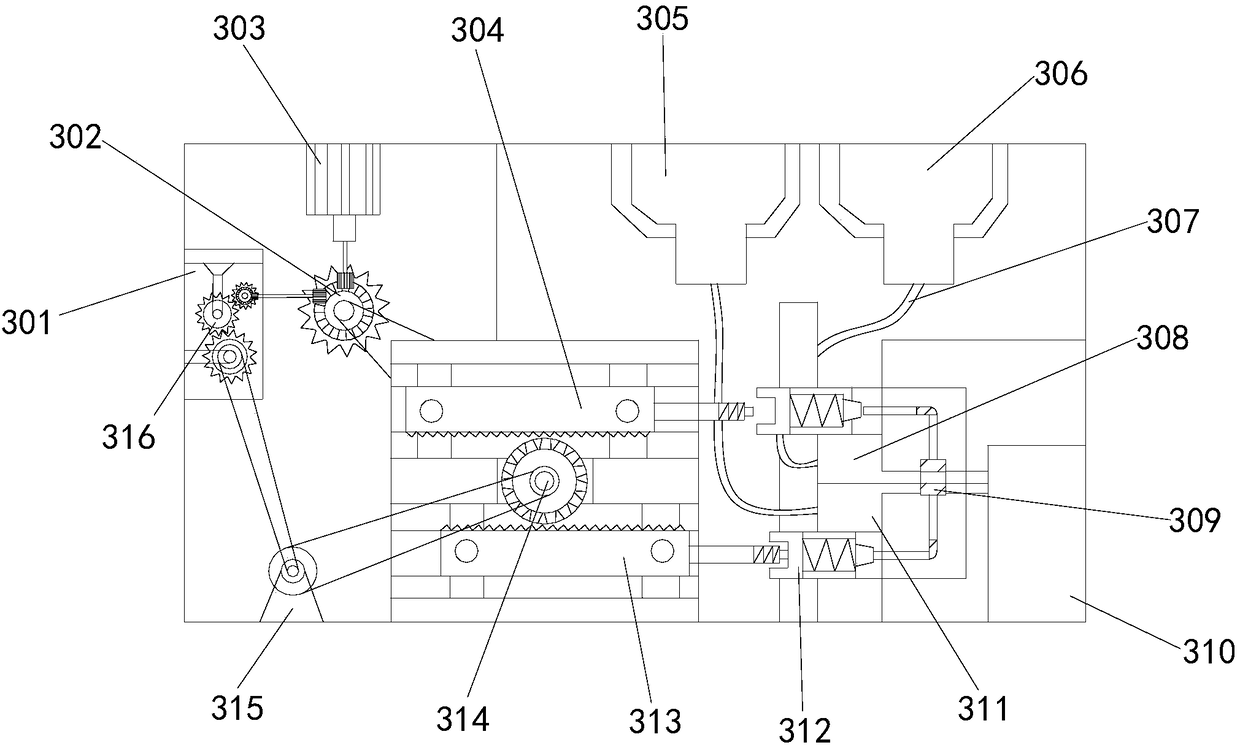

Storage-type precise quantitative oil-gas well down-hole work agent injection system and injection method

ActiveCN104948134AGuaranteed accuracyImprove efficiencyCleaning apparatusFluid removalThermodynamicsInjection well

The invention discloses a storage-type precise quantitative oil-gas well down-hole work agent injection system and injection method. The injection system comprises an injection pipe and a ground pressurization device, the injection pipe is internally provided with one or more injection units, each injection unit comprises a volume-variable work agent storer, pressure is conducted on the volume-variable work agent storers by the ground pressurization device in the injection pipe, and the work agent is squeezed out. The invention discloses an injection method for using the storage-type accurate quantitative oil-gas well down-hole work agent injection system at the same time. The work agent is injected into a down-hole target location in a quantitative mode. According to the injection system, by means of the mode that the work agent can be quantitatively injected into the work agent storers in advance, the work agent can be injected accurately and quantitatively, and the injected volume accuracy of the work agent can be guaranteed. By means of the injection method, the work agent can be injected into the target location accurately and quantitatively, the accuracy of injected volume and the injection location is very good, and the best injection effect is guaranteed.

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

Single-inlet double-oil-way composite atomizing nozzle

ActiveCN114526498AReduce weightIncreased complexityContinuous combustion chamberCombustion chamberInjector nozzle

The invention belongs to the technical field of atomization oil nozzles of gas turbines, and particularly relates to a single-inlet double-oil-way composite atomization nozzle which comprises a nozzle rod body and a cap cover. The nozzle rod body comprises an inner sleeve and an outer sleeve; an auxiliary oil way channel is arranged in the inner sleeve; a gap between the inner sleeve and the outer sleeve forms a main oil path channel; the cap cover is connected to the oil outlet end of the nozzle rod body in a sleeving mode. An air inlet hole, a central hole and a beveled hole are formed in the cap cover; the multiple beveled holes enable air to flow in a rotary annular mode, auxiliary atomization is carried out on fuel oil, and the fuel oil atomization quality is improved. A single oil supply channel is adopted to supply oil to the atomizing nozzle, so that the assembly difficulty is lower, meanwhile, the combustion chamber structure can be simplified, and the weight of the combustion chamber structure can be reduced; a built-in air heat insulation screen and the mutual cooling scheme design of the main oil way channel and the auxiliary oil way channel are adopted, and the problems that in the working process of the combustion chamber, a nozzle is in a high-temperature working environment for a long time, and coking and carbon deposition occur are solved.

Owner:成都中科翼能科技有限公司

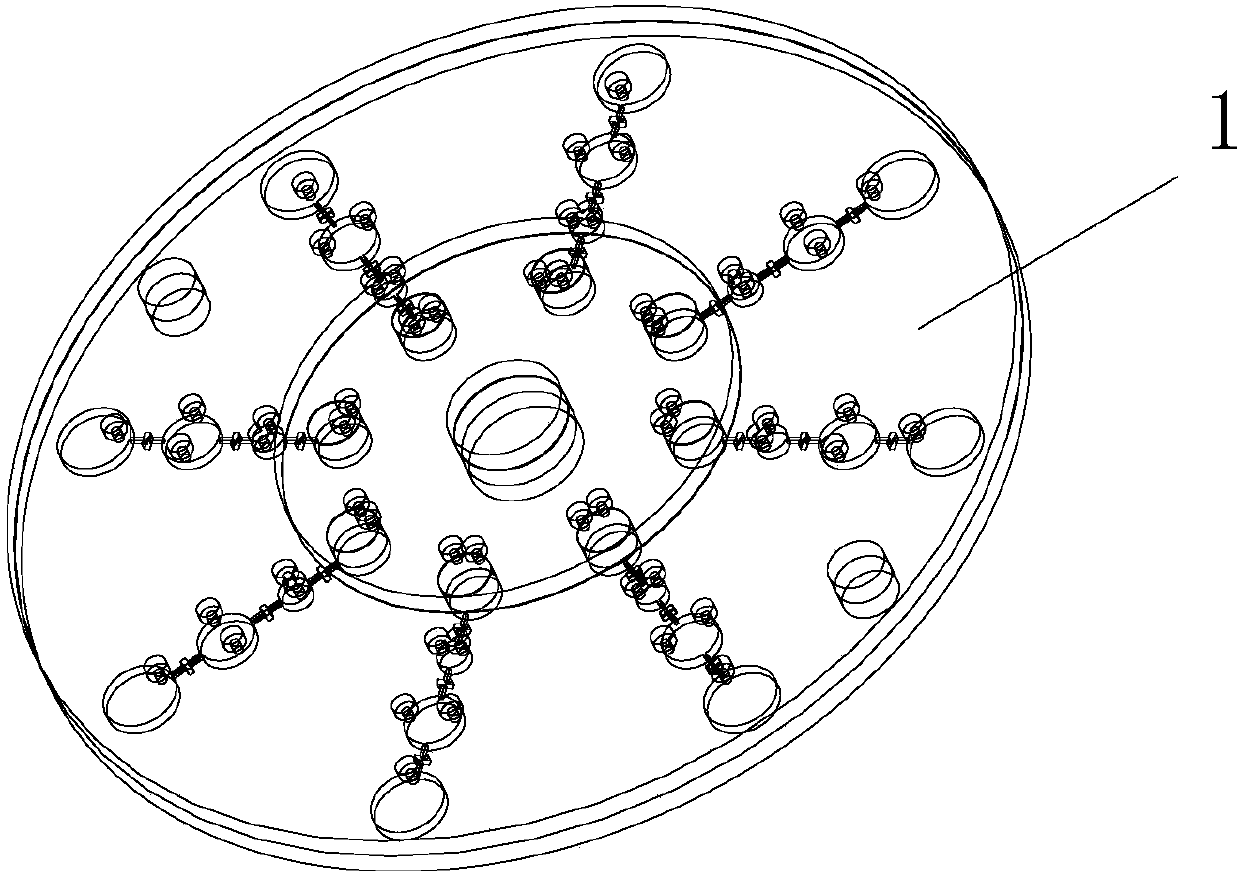

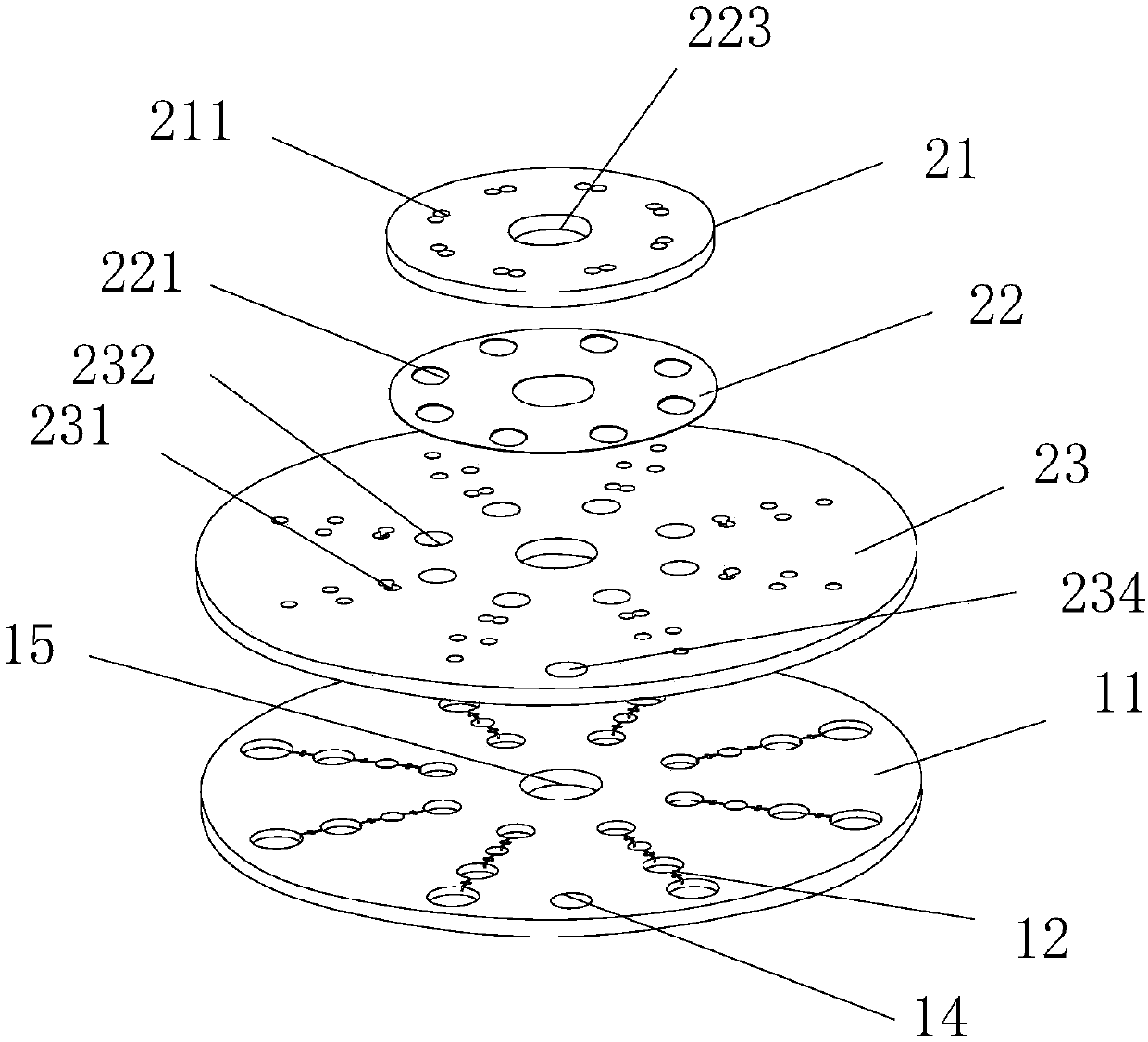

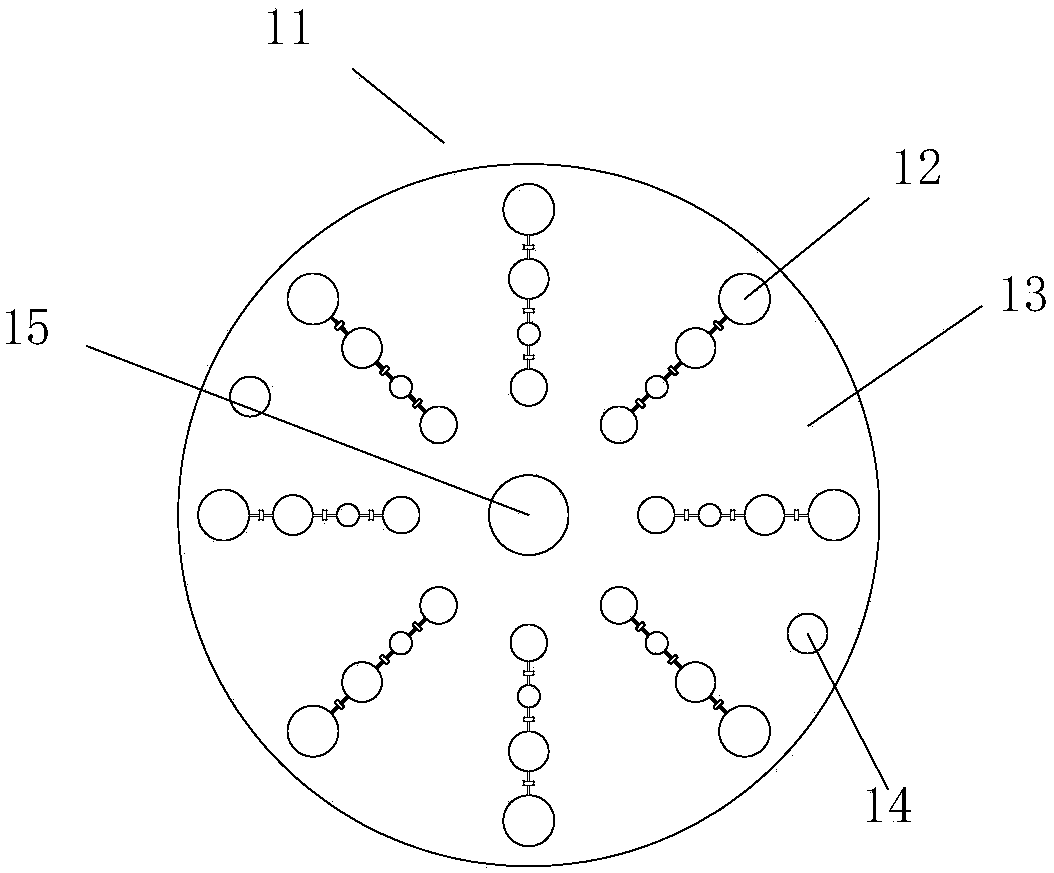

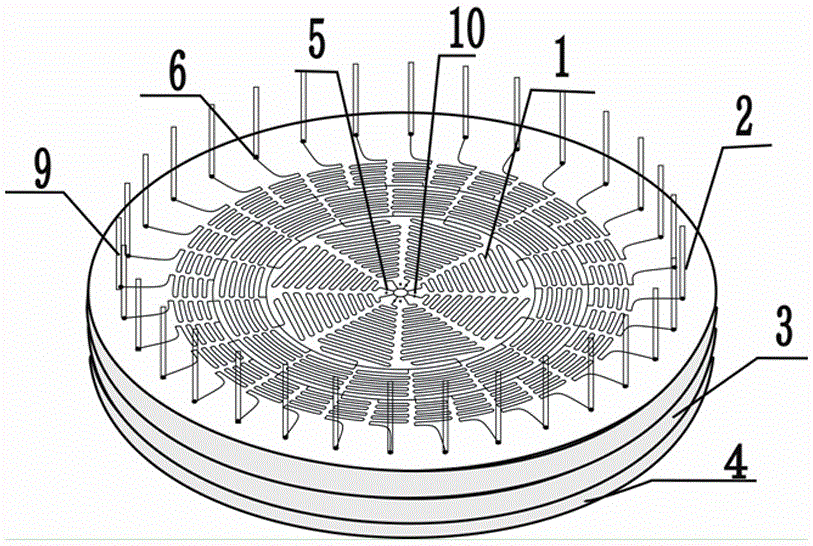

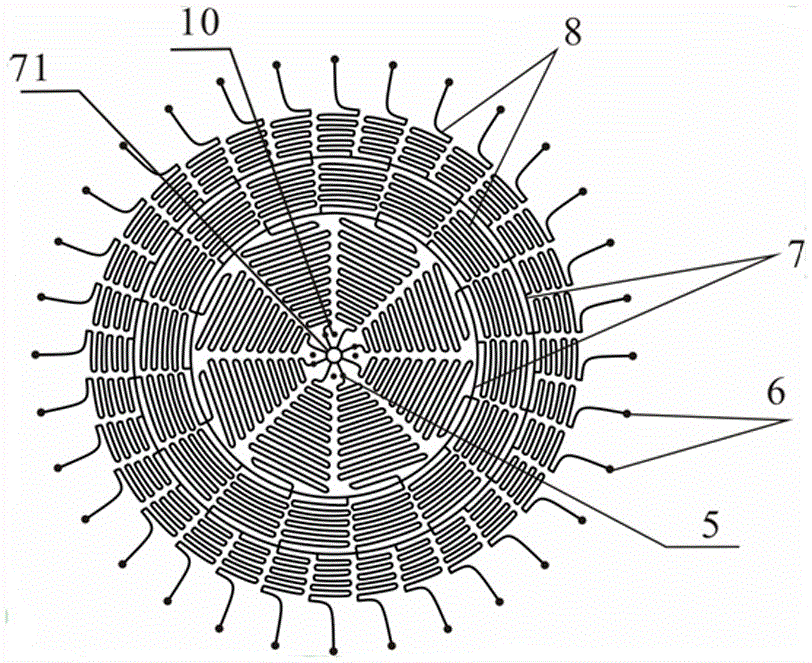

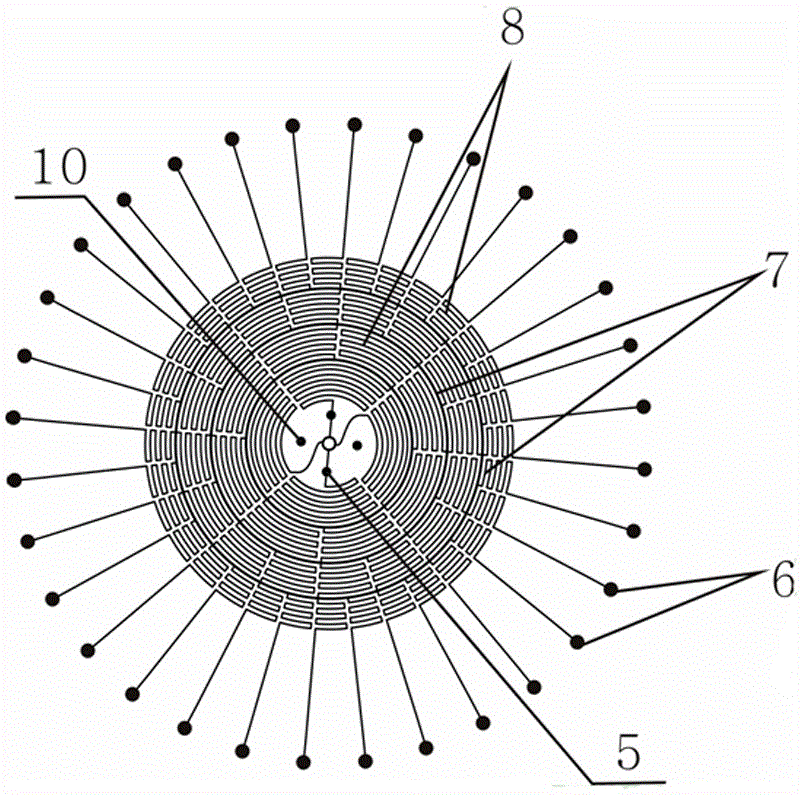

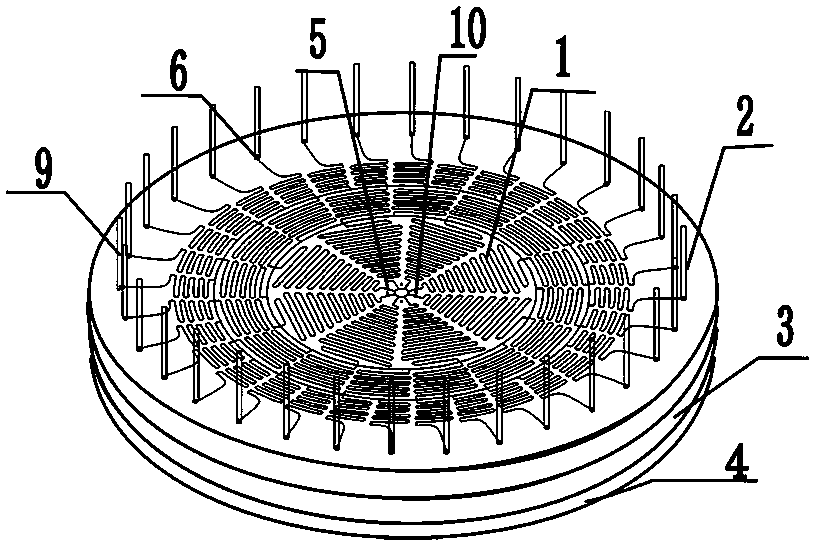

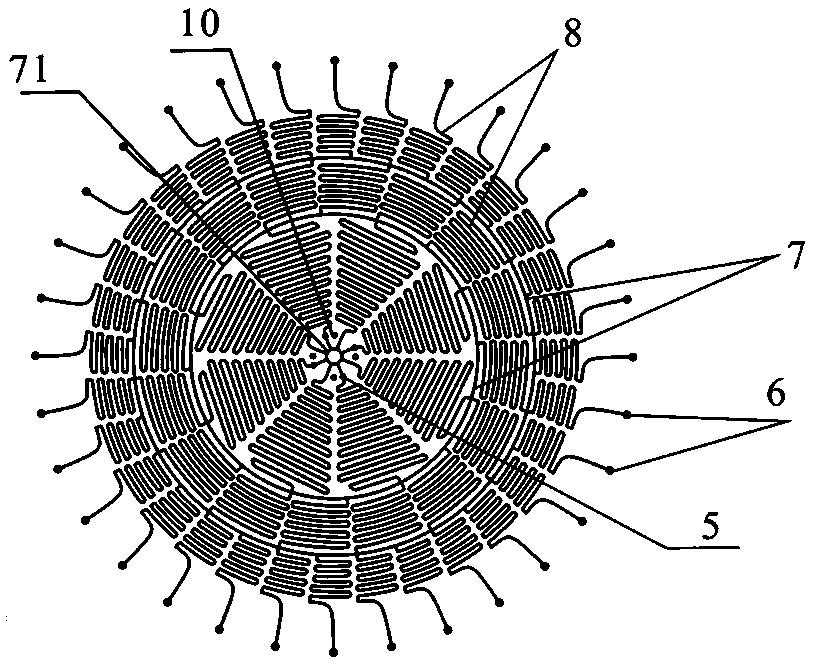

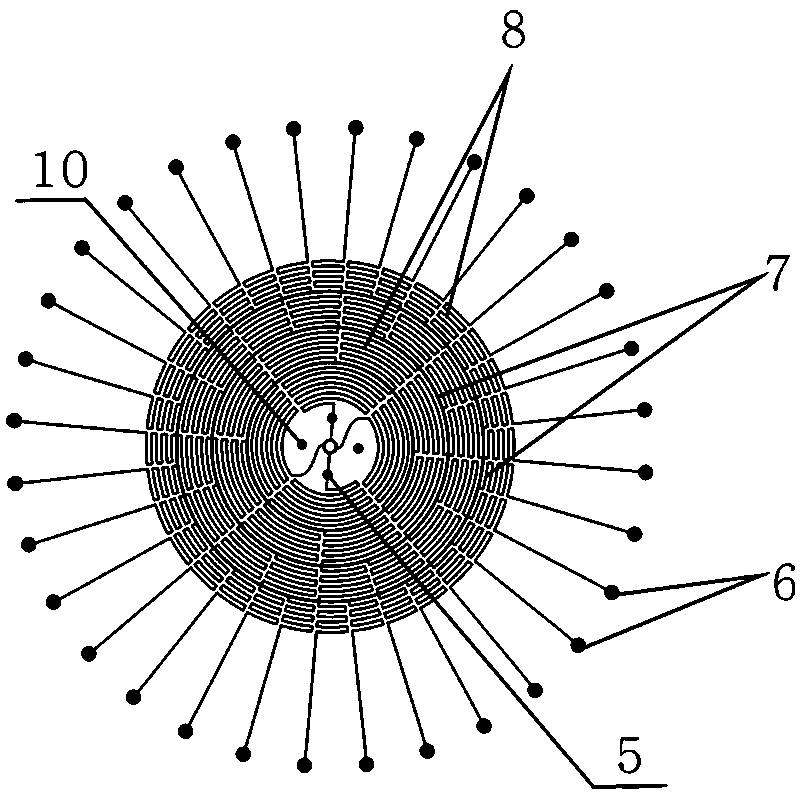

Multi-material gradient mixed liquid drop formation device based on micro-fluidic chip

The invention provides a multi-material gradient mixed liquid drop formation device based on a micro-fluidic chip. The device comprises an upper layer micro-fluidic chip, a middle layer micro-fluidic chip and a lower layer plate chip. Solution entrances, microchannel networks and solution exits are arranged on the upper layer micro-fluidic chip and the middle layer micro-fluidic chip respectively; the microchannel networks of the upper layer micro-fluidic chip and the middle layer micro-fluidic chip are composed of concentric annular channels and radial subchannels with same quantity which are connected in an alternatively distributed mode respectively; the solution entrances of the upper layer micro-fluidic chip and the middle layer micro-fluidic chip are communicated with the first concentric annular channel and the first set of radial subchannels in same-layer chip microchannel networks respectively; the solution exits of the upper layer micro-fluidic chip and the middle layer micro-fluidic chip are communicated with the last set of radial subchannels in the same-layer chip microchannel networks respectively, and the solution exits of the upper layer micro-fluidic chip is communicated with the solution exits of the middle layer micro-fluidic chip and corresponds to the solution exits of the middle layer micro-fluidic chip one to one.

Owner:NORTHEASTERN UNIV

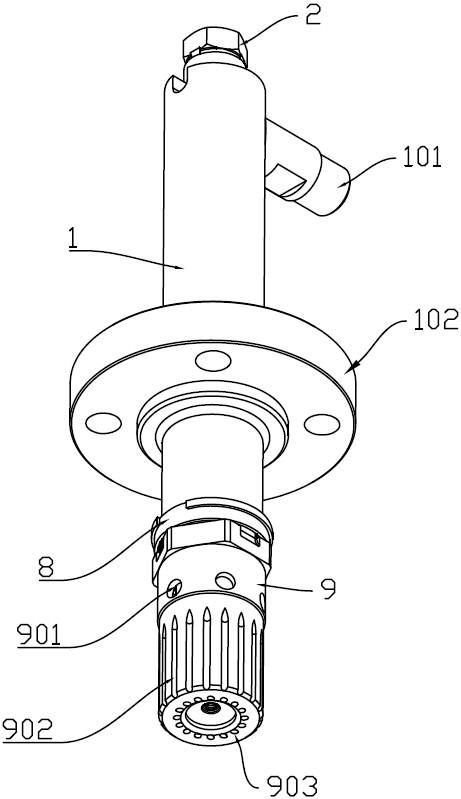

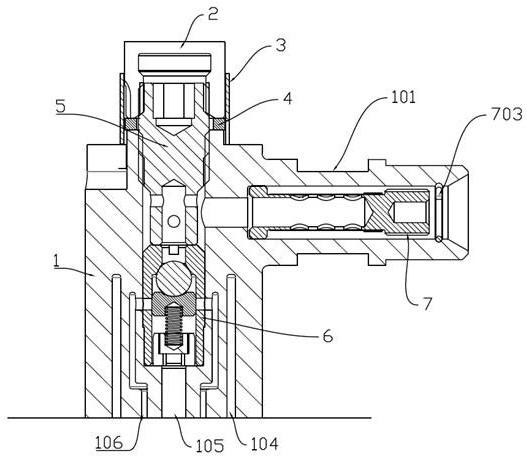

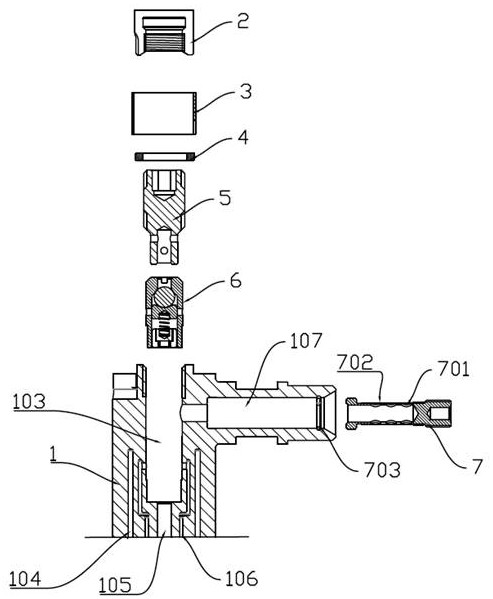

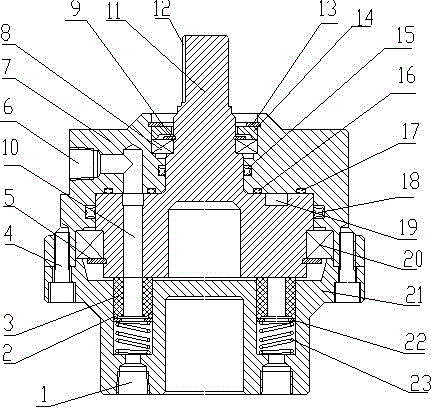

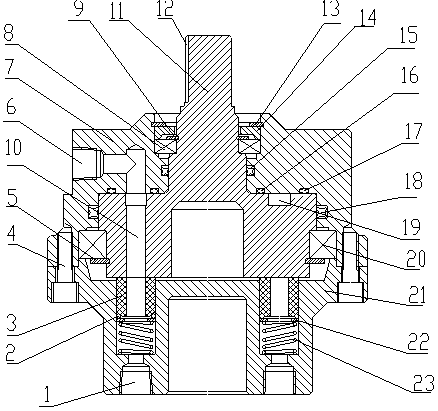

Angle rotary connector capable of entering and exiting same channel by plurality of channels

ActiveCN105987249AGuaranteed tightnessImprove corrosion resistancePipe elementsEngineeringMechanical engineering

The invention discloses an angle rotary connector capable of entering and exiting the same channel by a plurality of channels. The channels are arranged at the outer end of a lower shell body; 4-32 channels are arranged; each channel is internally provided with an annular sealing part, a first O-shaped ring, a spring cushion and a spring in sequence; a rotary shaft is arranged in an upper shell body; a star-shaped sealing ring is arranged under a first bearing between the rotary shaft and the lower shell body; a common channel is arranged on one side of the upper shell body; an annular groove is formed in the horizontal plane of the lower part of the rotary shaft; the annular groove corresponds to the common channel in the vertical direction; a second O-shaped ring is arranged on one side of the annular groove and a third O-shaped ring is arranged on the other side of the annular groove; the annular groove of the rotary shaft is internally provided with a rotary shaft channel and the rotary shaft channel corresponds to the channel; a star-shaped ring is arranged between the rotary shaft above a second bearing and the shell body; a key slot is formed in the outer end of the rotary shaft; and the upper shell body and the lower shell body are fixedly connected through a bolt. The angle rotary connector is simple in structure, is supported by the double bearings and is flexible to rotate and the torque is alleviated. The sealing effect is ensured and the service life is prolonged.

Owner:TENGZHOU TIANXUAN ROTARY UNION

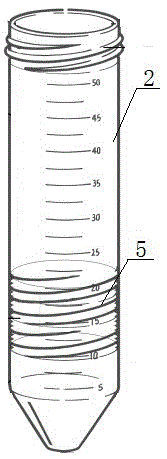

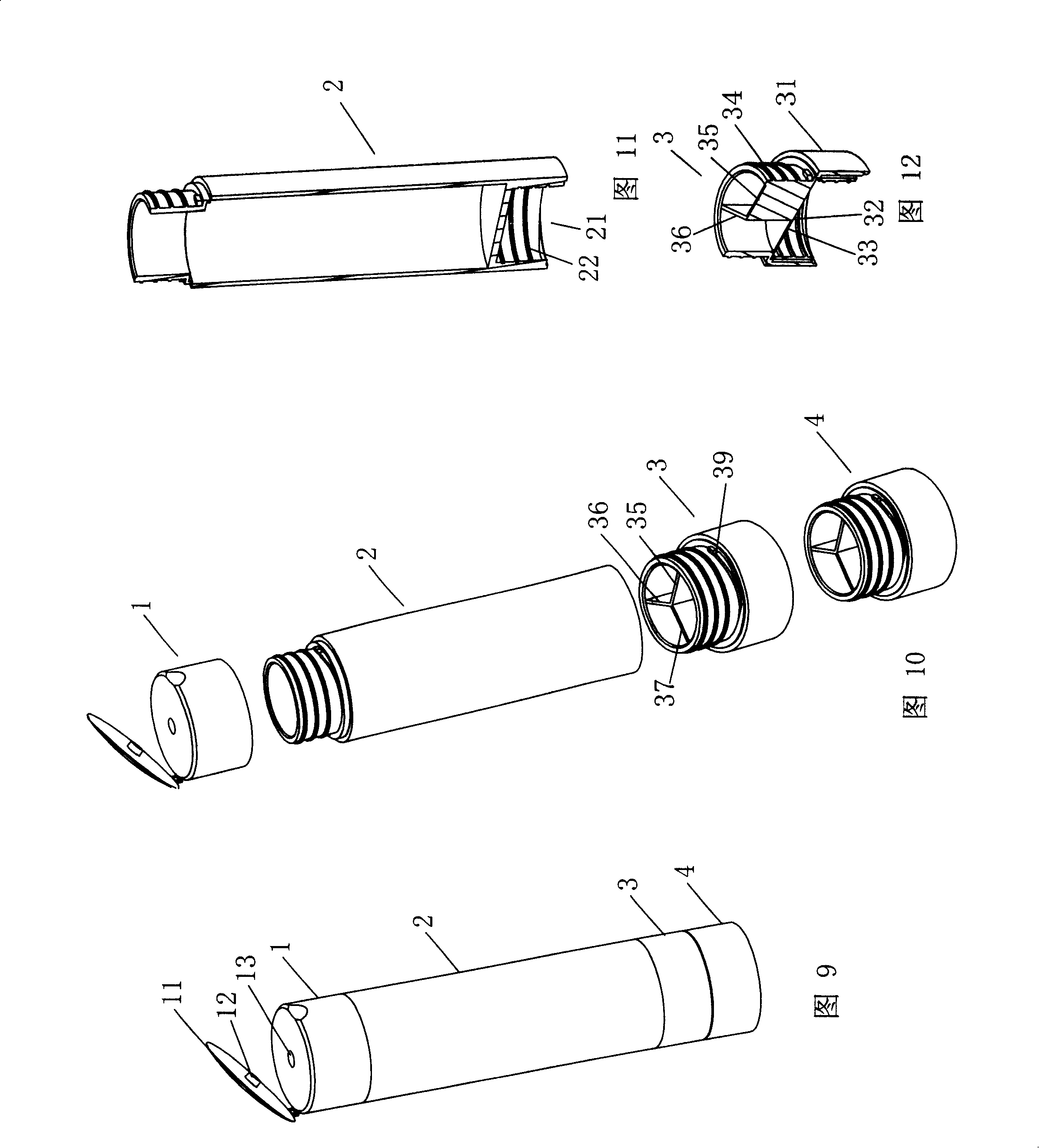

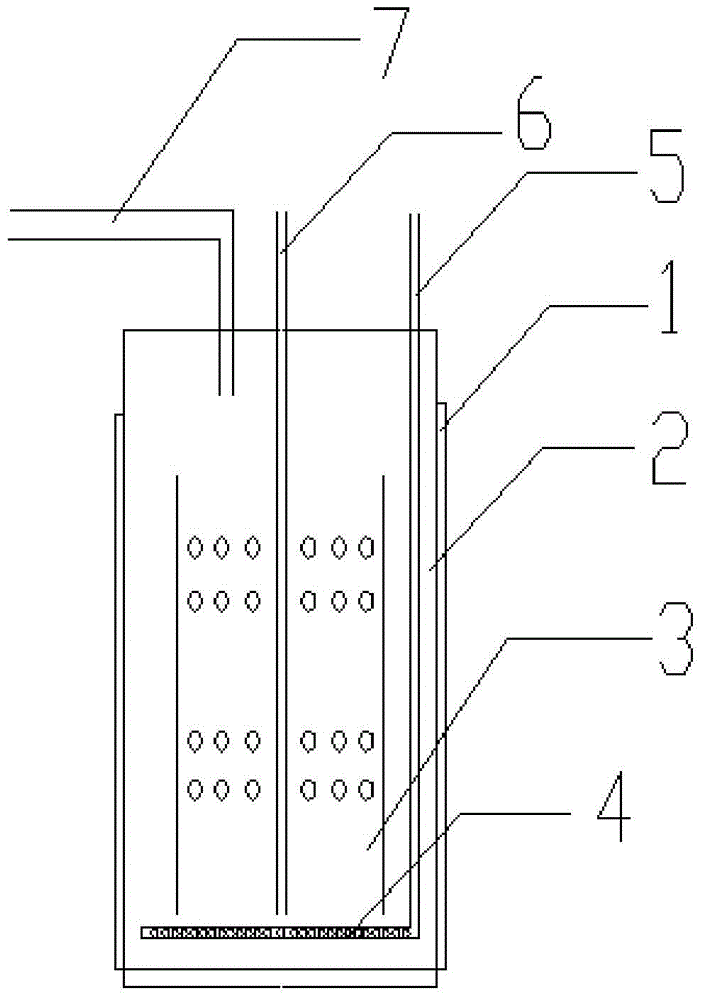

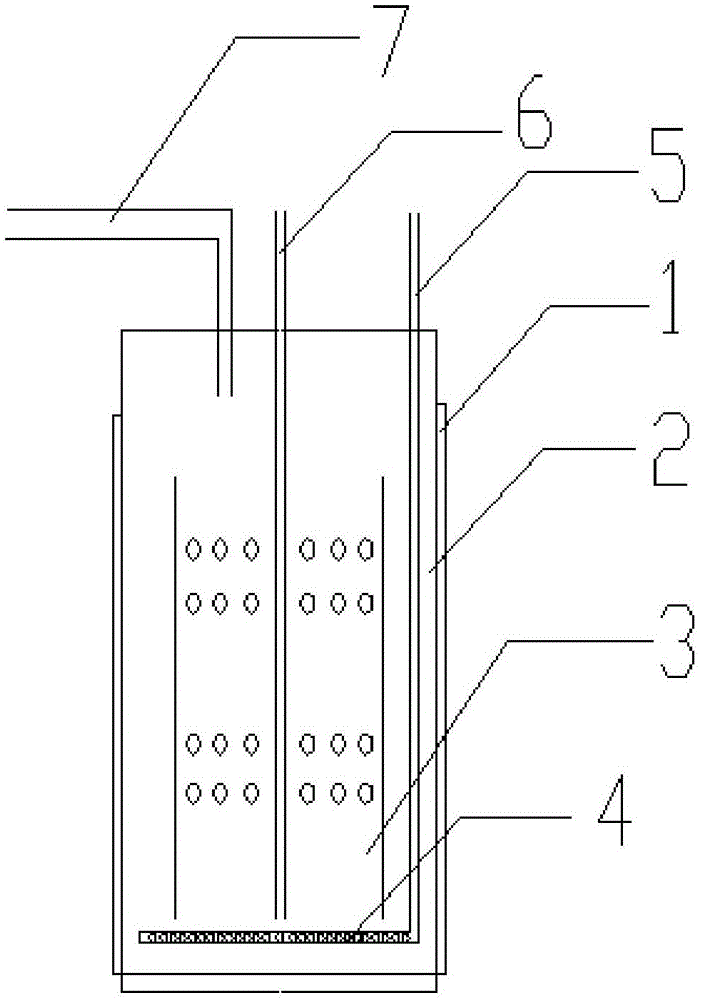

Density gradient centrifugal tube with position-adjustable porous diaphragm and application of centrifugal tube

ActiveCN105567556AAvoid premixingAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCentrifugal separation

The invention provides a density gradient centrifugal tube with a position-adjustable porous diaphragm. The density gradient centrifugal tube comprises a centrifugal tube body, a centrifugal tube cover is arranged at the upper end of the centrifugal tube body, a diaphragm layer is arranged in the centrifugal tube body, an internal thread is formed in the inner wall of the centrifugal tube body, an external thread is formed in the outer wall of the diaphragm layer, the internal thread of the centrifugal tube body is matched with the external thread of the diaphragm layer, and multiple small pores are formed in the diaphragm layer. The centrifugal tube is divided into the portion for containing a separating solution and the portion for being added with a sample to be detected through the diaphragm layer, premixing of the sample and the separating solution is effectively avoided, sample pollution caused during centrifuging and sampling is reduced, and the quality of centrifugal separation is greatly improved; meanwhile, a diaphragm layer rotary knob can be made to adjust the diaphragm layer up and down according to differences of the types and volumes of samples to be treated, so that optimal separation solution volume exists at the lower end of the diaphragm layer, and the application range is widened.

Owner:武汉海吉力生物科技有限公司

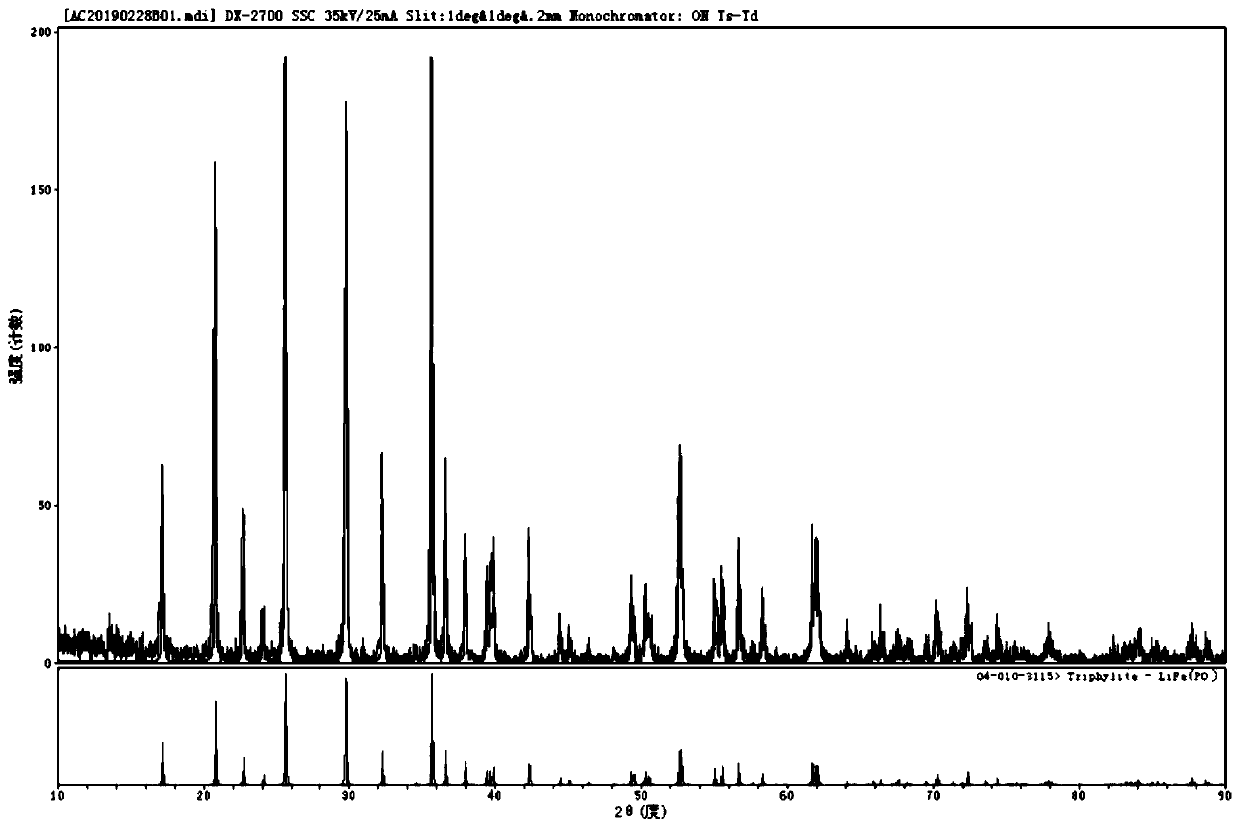

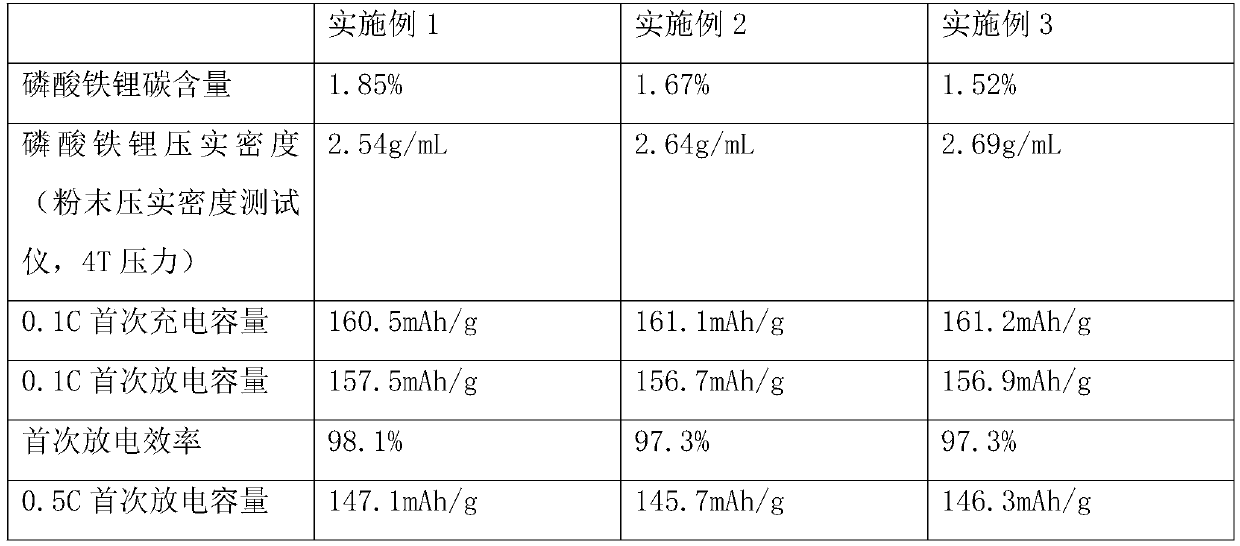

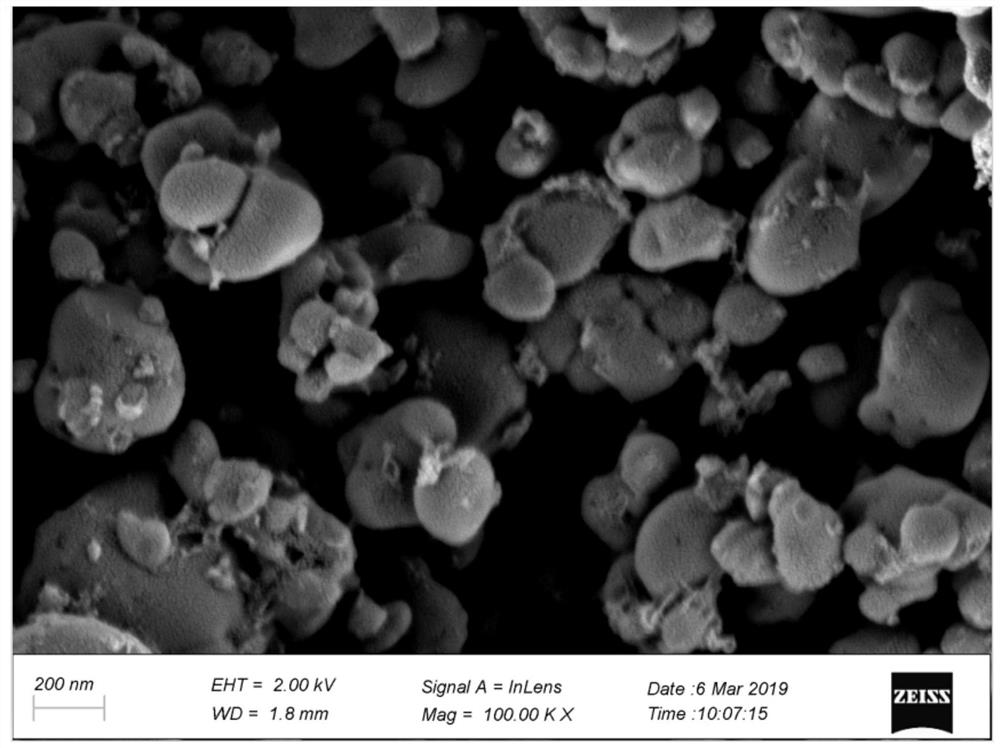

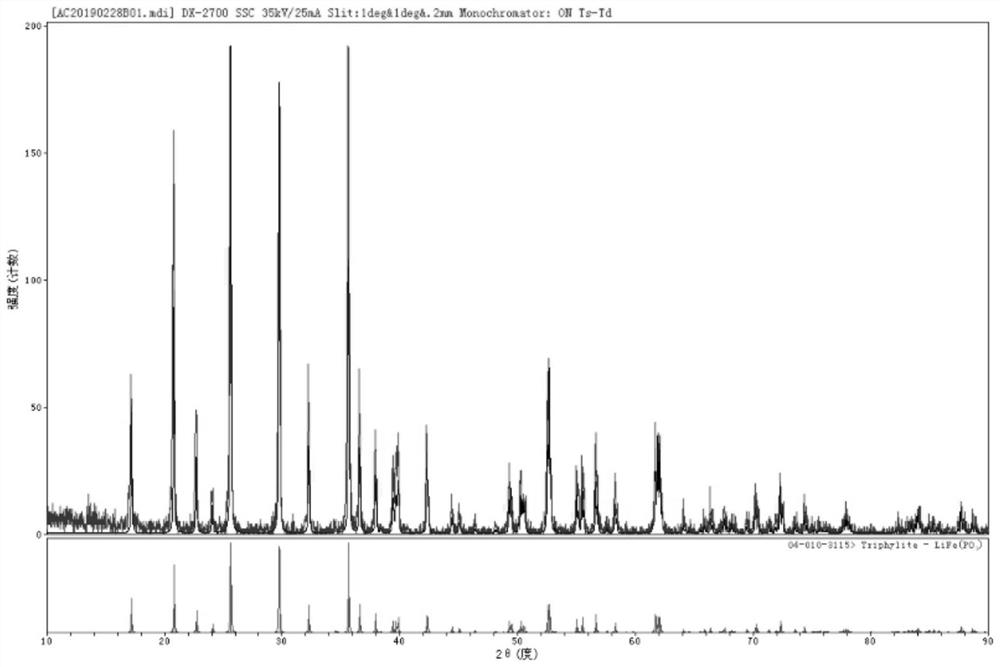

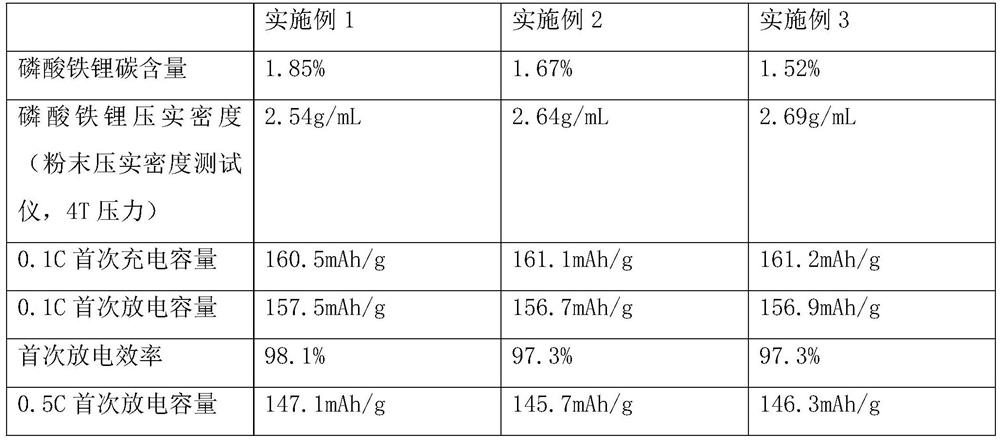

Treatment method of waste lithium iron phosphate

ActiveCN110690429AIncrease compaction densityIncrease capacityCell electrodesWaste accumulators reclaimingO-Phosphoric AcidSulfide compound

The invention discloses a treatment method of waste lithium iron phosphate. The method comprises the following steps of: pretreating a waste lithium iron phosphate material, adding the pretreated material into a phosphoric acid solution, performing reacting and then filtering to obtain a first filtrate and a first filter residue; adding sulfide into the first filtrate for reaction, and then performing filtering to obtain a second filtrate and a second filter residue; adding iron powder into the second filtrate, performing stirring to react, removing iron, adding battery-grade lithium carbonateinto the obtained iron-removed material, and performing stirring to react until no bubbles are generated so as to obtain a reaction material; adding the reaction material into a water-soluble organiccarbon source, performing stirring, dispersing and dissolving, and performing spray drying on the obtained material in a spray dryer to obtain a dried material; and putting the dried material into aroller way furnace, performing calcining, crushing, mixing and screening, removing iron, and carrying out vacuum packaging. According to the method, resource utilization of the waste lithium iron phosphate can be achieved, high-end circulation is achieved, the recovery rate of all elements is high, the waste water generation amount is small, and the obtained lithium iron phosphate is excellent inperformance.

Owner:四川朗晟新能源科技有限公司

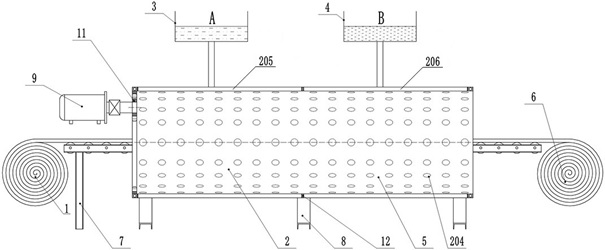

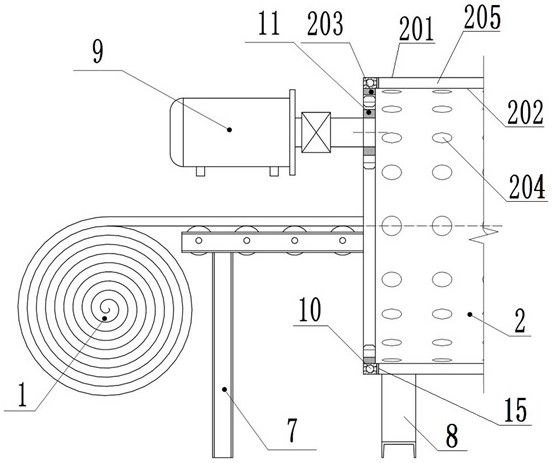

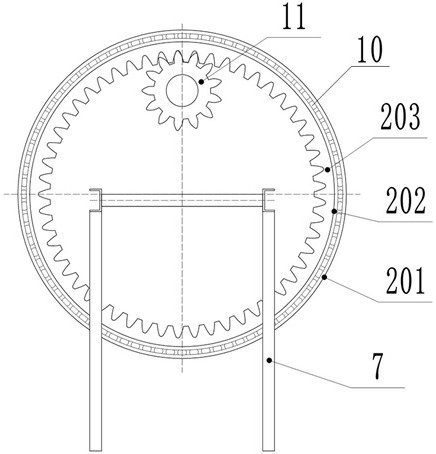

Equipment and method for rapidly preparing gel felt

The invention provides equipment and method for quickly preparing a gel felt. The equipment for quickly preparing the gel felt comprises an outer cylinder, an inner cylinder rotationally arranged in the outer cylinder and provided with an inner cavity for an unfolded fiber felt to penetrate through the inner cylinder, and a driving device which is in transmission connection with the inner cylinder and used for driving the inner cylinder to rotate; the inner cylinder and the outer cylinder are arranged in a spaced mode to form an annular cavity; the two axial ends of the annular cavity are closed; an inlet allowing silica sol, a catalyst or catalytic sol to enter the annular cavity is formed in the outer cylinder; a plurality of communicating holes for communication between the inner cavity of the inner cylinder and the annular cavity are formed in the inner cylinder; and when the inner cylinder rotates, the silica sol, the catalyst or the catalytic sol entering the annular cavity enters the inner cavity of the inner cylinder through the communicating holes and is sprayed to the surfaces of the two sides of the fiber felt under the rotation action of the inner cylinder. The all-directional spraying effect can be achieved, so that it is guaranteed that the silica sol, the catalyst or the catalytic sol is fully and evenly immersed into the fiber felt, and the good heat preservation and heat insulation performance of the gel felt is guaranteed.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

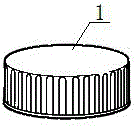

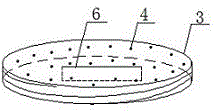

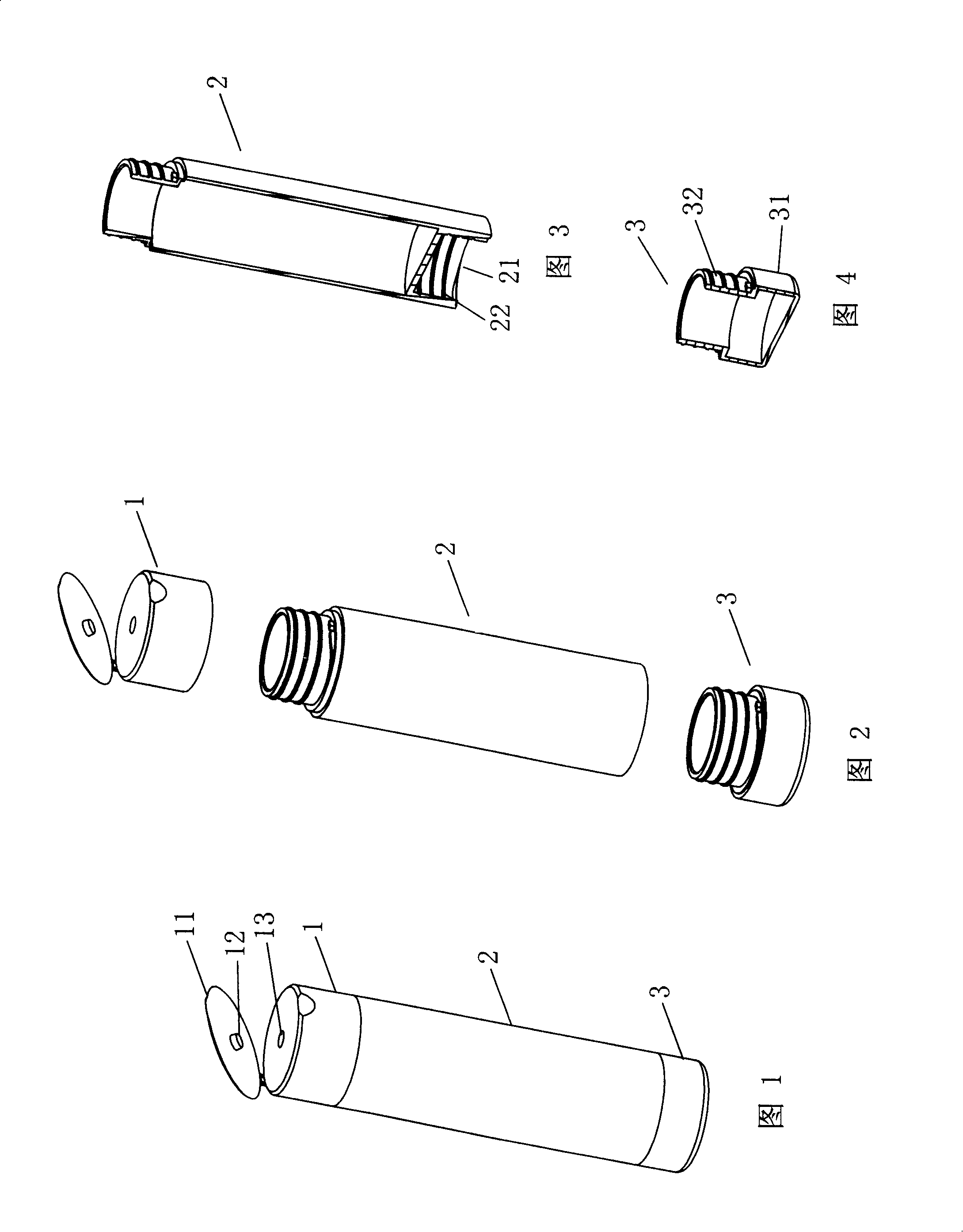

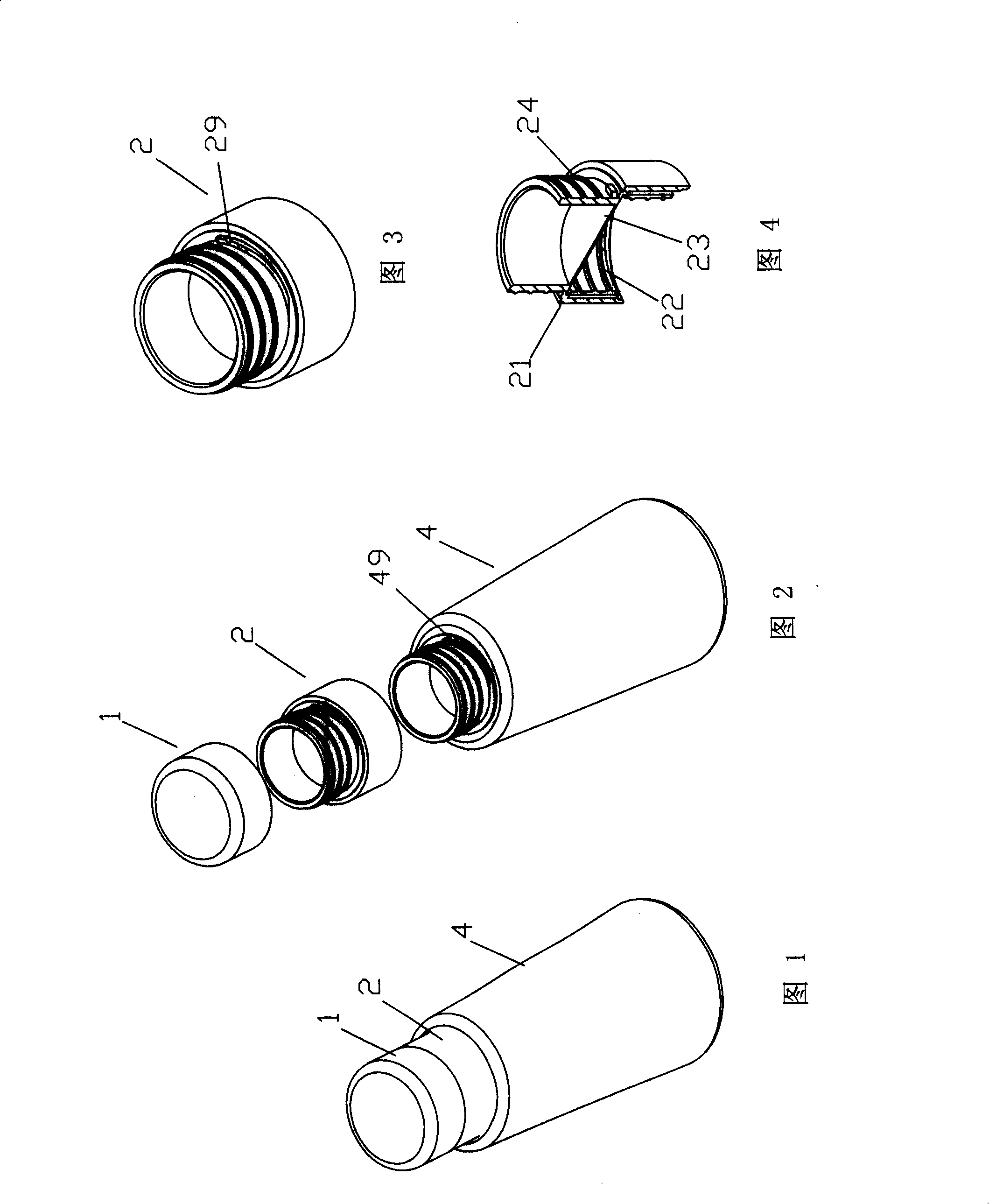

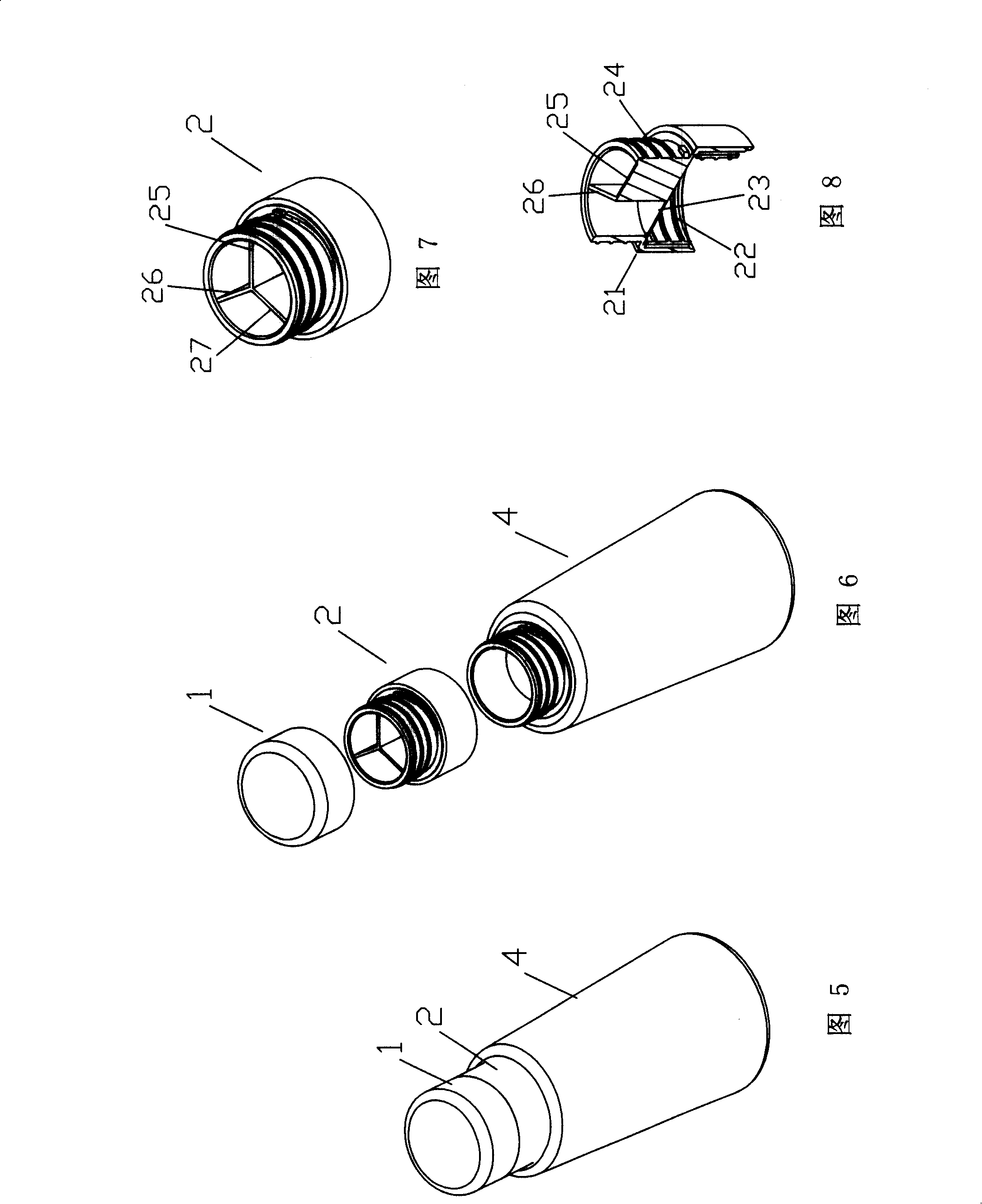

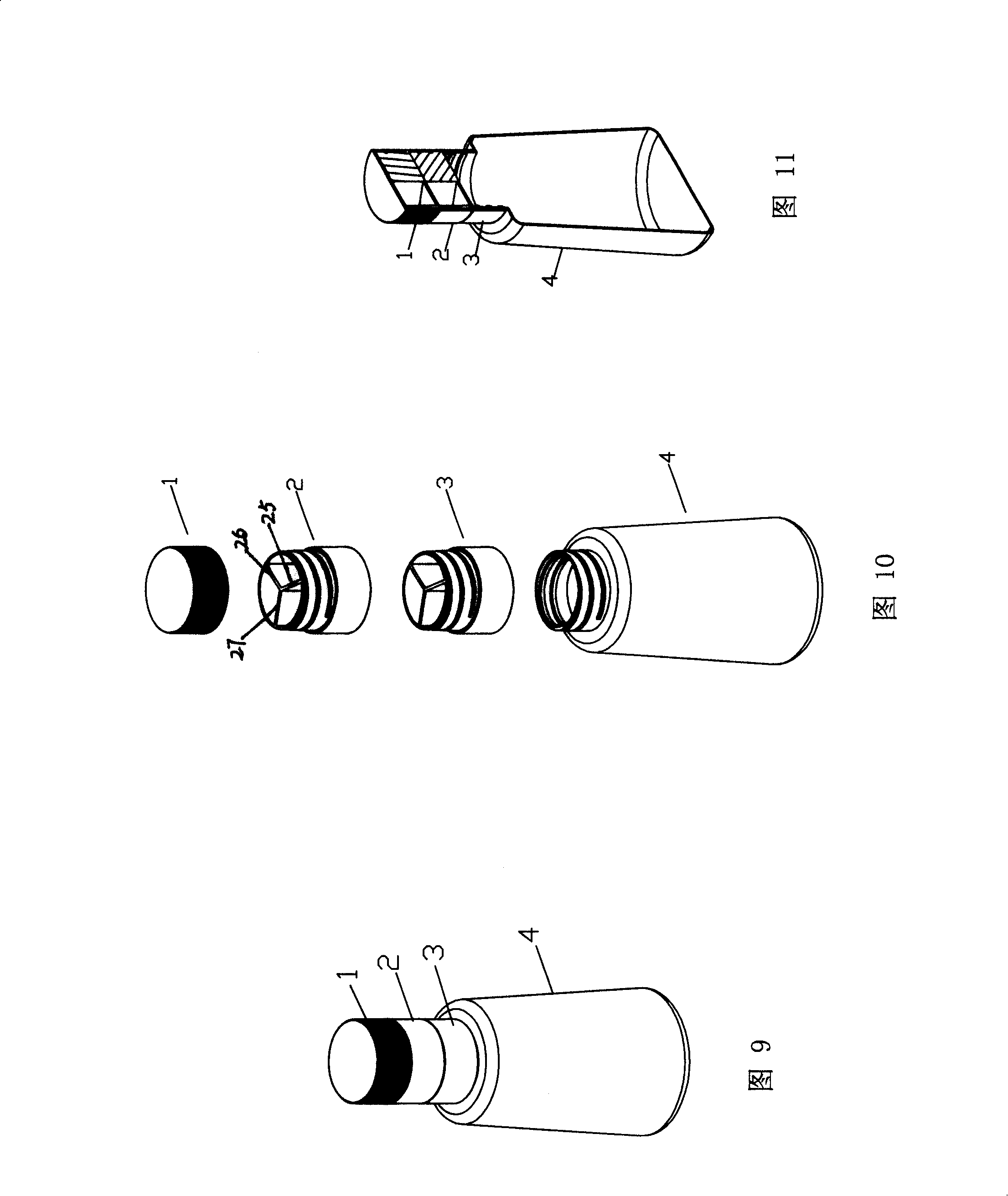

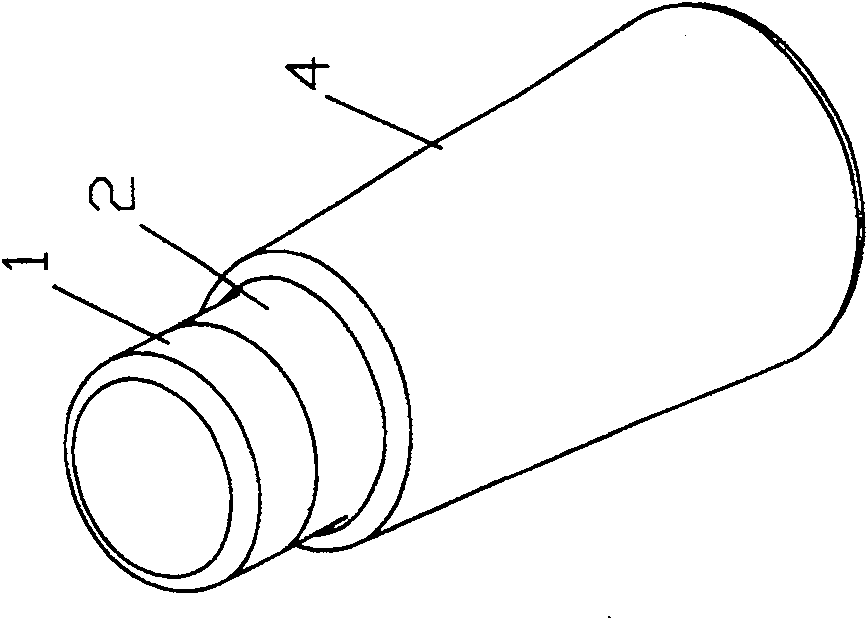

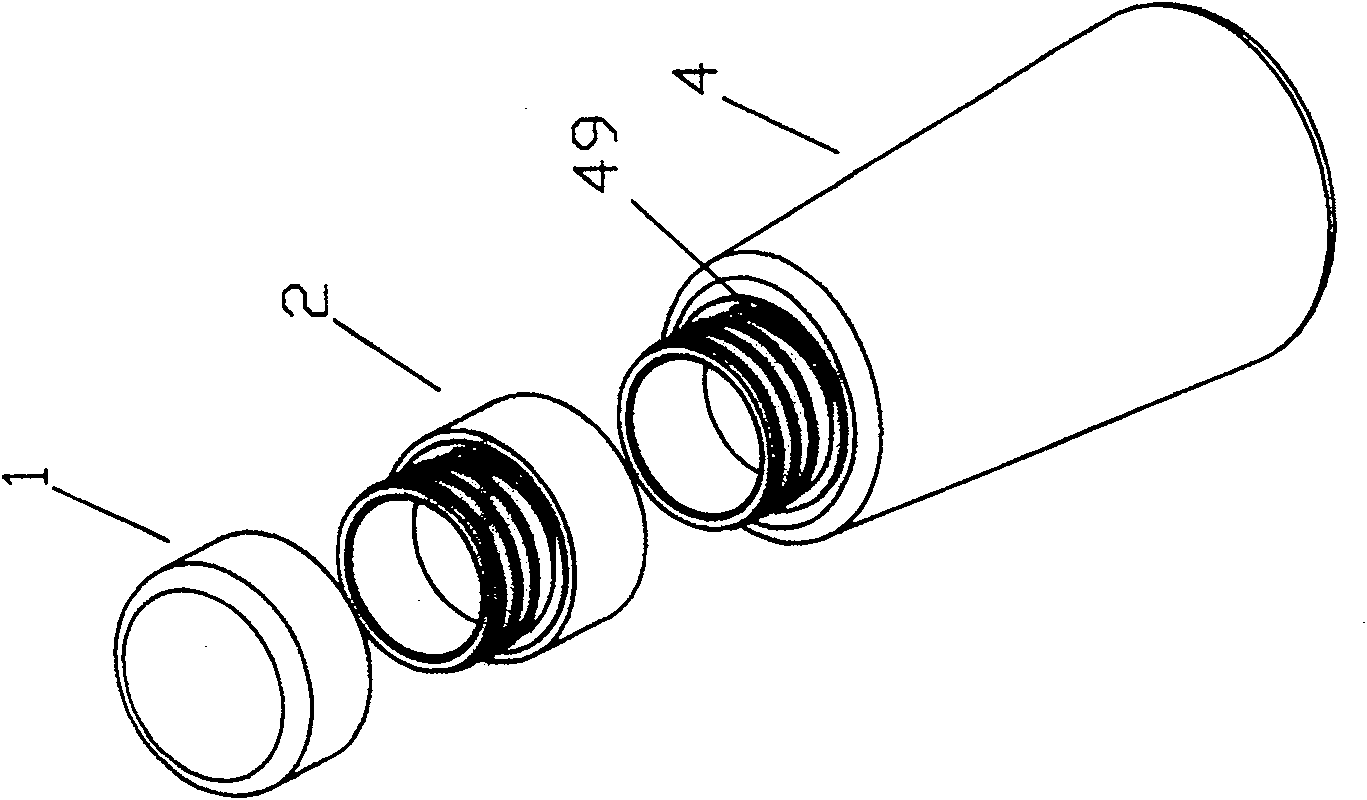

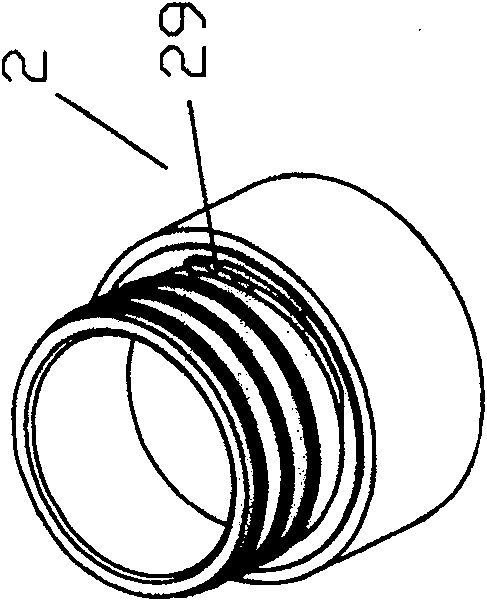

Combined container and solute storing device

InactiveCN101224808AAvoid premixingAvoid failureClosuresRigid containersChemical reactionEngineering

The invention provides a combined type container and a solute storage device, and the combined type container includes a bottle body, a bottle cap and at least one solute storage device arranged at the bottom of the bottle body. The bottle bottom and the uppermost solute storage device and the two neighboring solute storage devices are all connected by thread. The solute storage device contains a tubular main body and a transversal partition board arranged in the tubular main body, the transversal partition board divides the tubular main body into a lower concave cavity and an upper concave cavity used for storing the solute, the inner wall of the lower half of the tubular main body and the outer wall of the upper half all are provided with threads. The combined type container is used for preparing the solute and the solvent that need to be blended and used on the spot, which can not only avoid the phenomenon that the chemical materials are mixed in advance and get useless due to the chemical reaction, but also needs no calculation and weighing operation in the blending, so the preparing procedures are considerably simplified. The solute storage device is combined with the bottle body and the bottle cap by the thread at the bottom, which is beautiful in shape, simple and convenient in use and is convenient for being transported and carried.

Owner:陈红锋

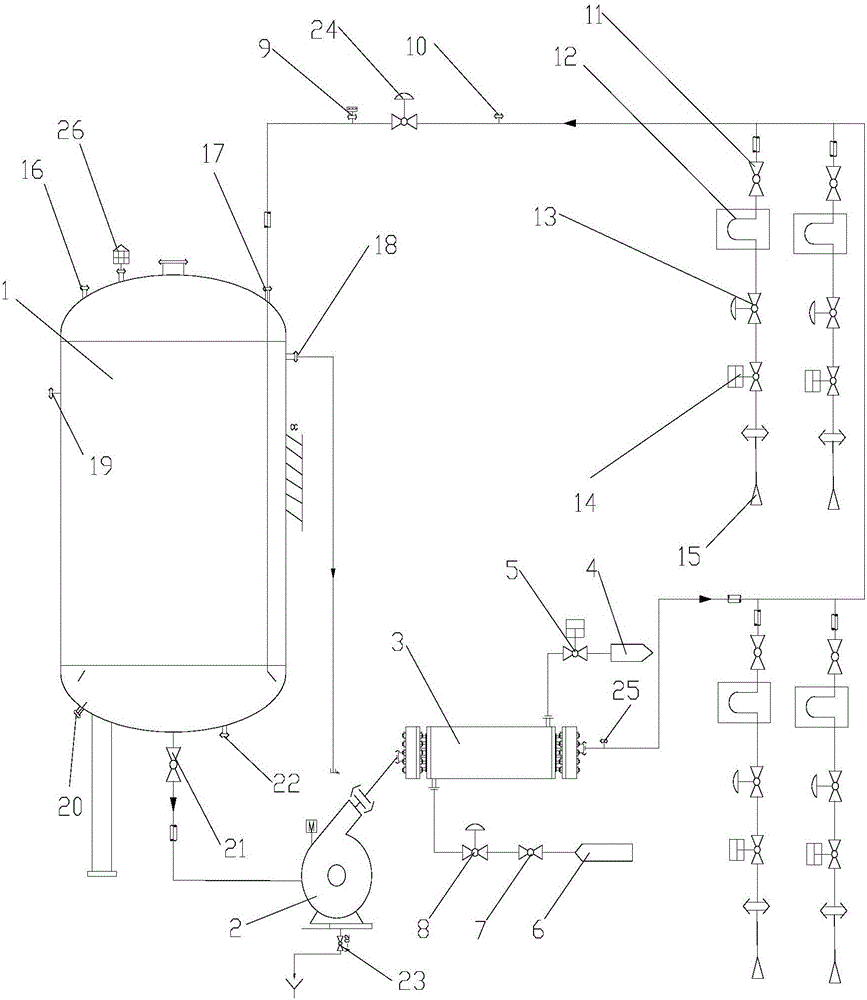

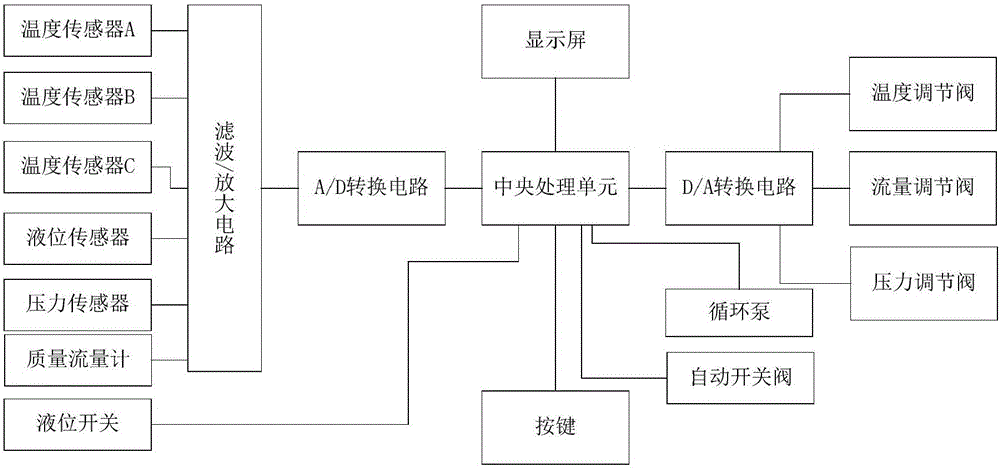

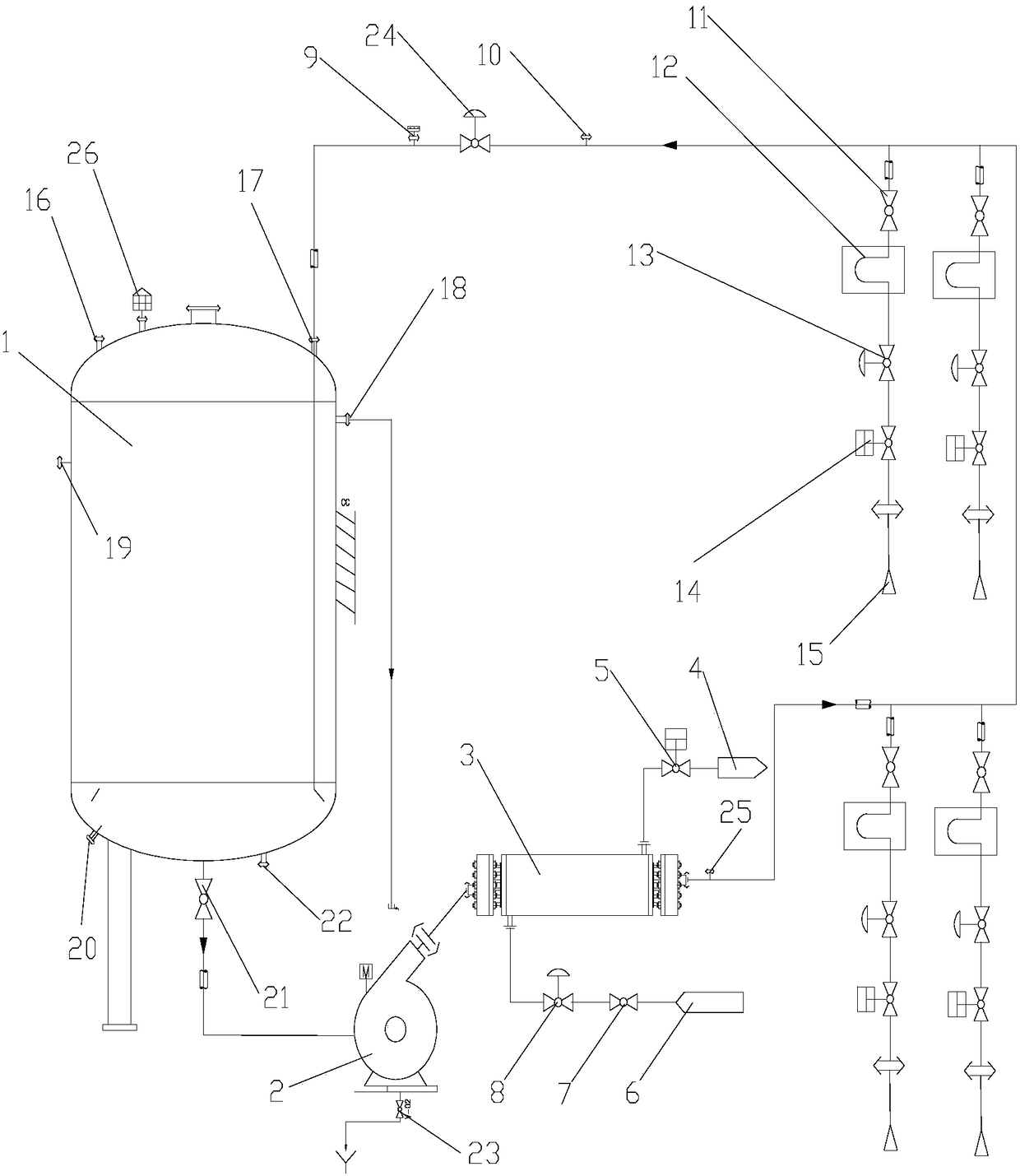

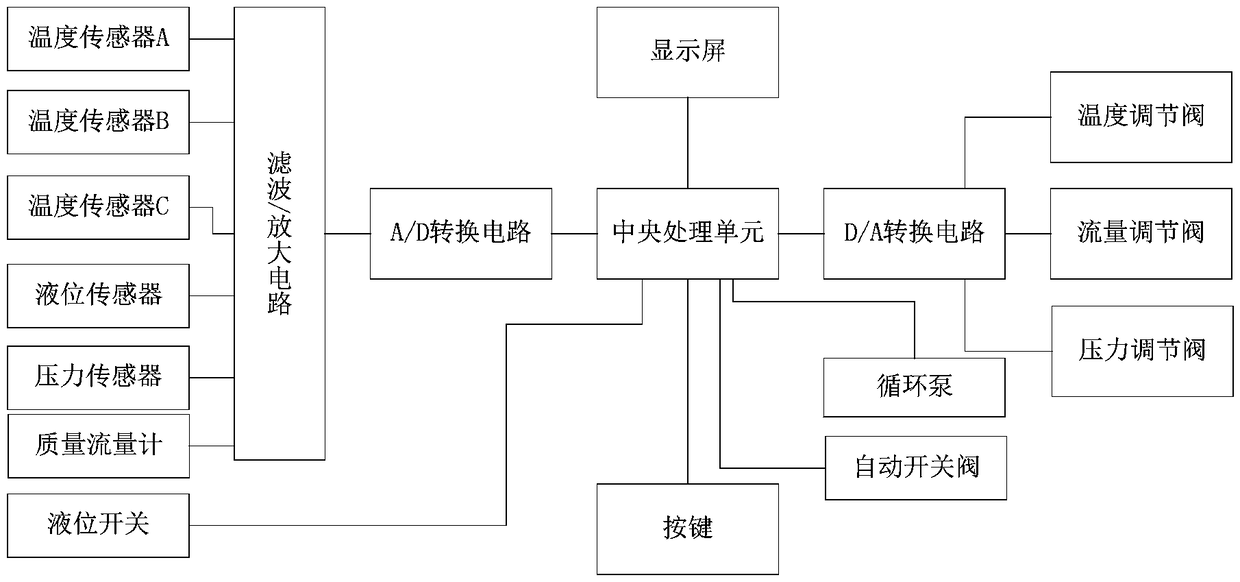

Automatic cycling liquid adding system

ActiveCN106000148ASimplified dosing processEasy to operateFlow mixersTransportation and packagingLiquid storage tankEngineering

The invention discloses an automatic cycling liquid adding system. The automatic cycling liquid adding system comprises a liquid storage tank, a heat exchanger, a circulating pump, a liquid consuming branch and a controller. The liquid inlet of the circulating pump communicates with the liquid outlet of the liquid storage tank, the liquid outlet of the circulating pump communicates with the inlet of the heat exchanger, and the outlet of the heat exchanger is connected with the circulating liquid inlet of the liquid storage tank through a pipeline. The liquid storage tank is provided with a temperature sensor A, a liquid level sensor and a liquid level switch. The liquid consuming branch is connected to the connection pipeline between the outlet of the heat exchanger and the circulating liquid inlet of the liquid storage tank. A temperature sensor B is arranged on a connection pipeline between the outlet of the heat exchanger and the liquid consuming branch. A temperature sensor C, a pressure sensor and a pressure adjusting valve are arranged on a connection pipeline between the liquid consuming branch and the circulating liquid inlet of the liquid storage tank. The automatic cycling liquid adding system is high in automation degree, and the product quality and the efficiency can be improved.

Owner:CHENGDU RONGSHENG PHARMA

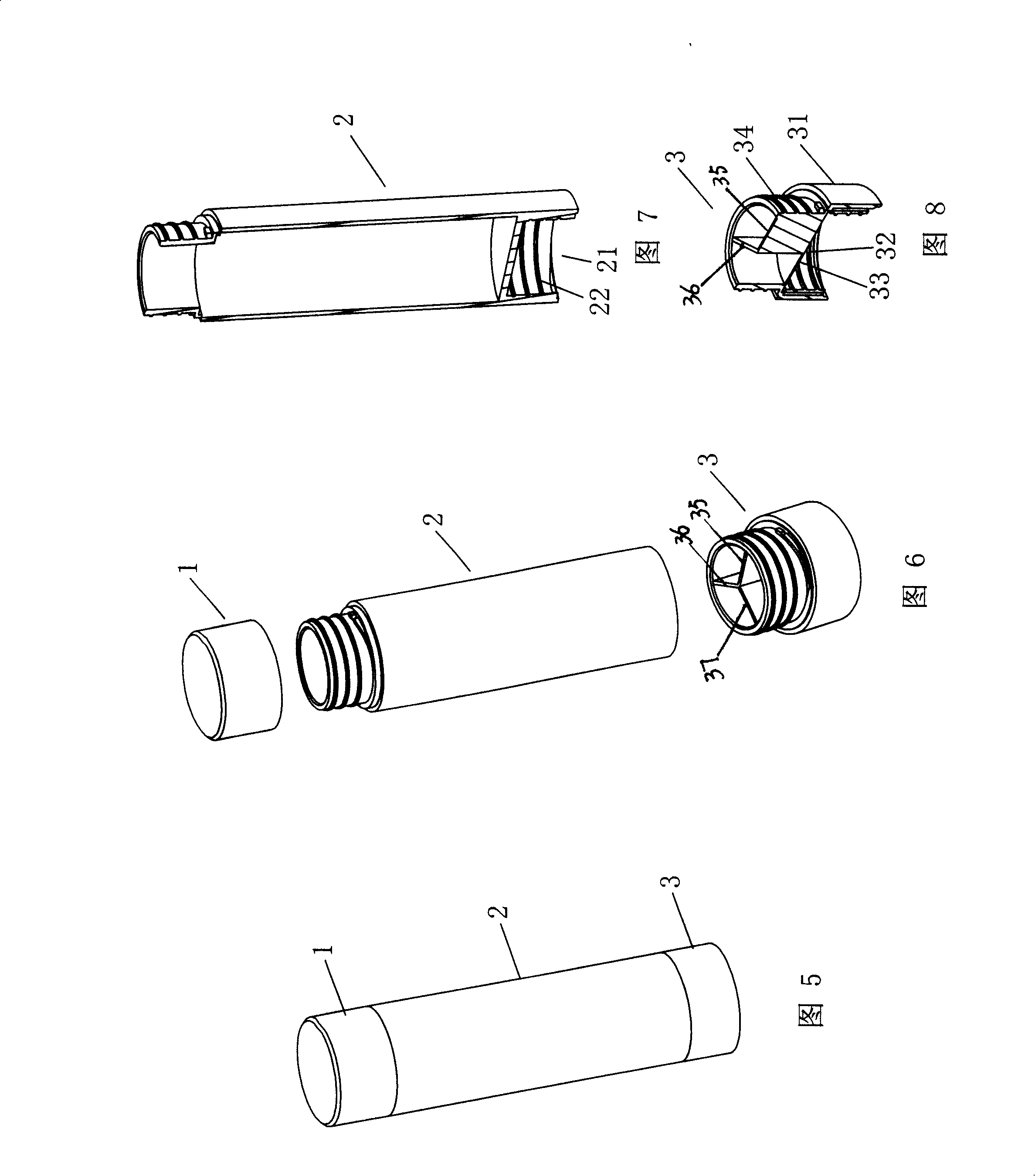

Combined type multi cavity container and solute storing device thereof

The invention provides a combined type multi-cavity container and a solute storage device, and the combined type multi-cavity container includes a bottle body, a bottle cap and at least one solute storage device arranged between the bottle cap and the bottle body. The bottle cap and the uppermost solute storage device, the two neighboring solute storage devices, the downmost solute storage device and the bottleneck of the bottle body are all connected by thread. The solute storage device contains a tubular main body and a transversal partition board arranged in the tubular main body, the transversal partition board divides the tubular main body into a lower concave cavity and an upper concave cavity used for storing the solute, the inner wall of the lower half of the tubular main body and the outer wall of the upper half all are provided with threads. The combined type multi-cavity container is used for preparing the solute and the solvent that need to be blended and used on the spot, which can not only avoid the phenomenon that the chemical materials are mixed in advance and get useless due to the chemical reaction, but also needs no calculation and weighing operation in the blending, so the preparing procedures are considerably simplified. The solute storage device is combined with the bottle body and the bottle cap by thread and the use is simple and convenient.

Owner:陈红锋

A device for forming multi-substance gradient mixed droplet based on microfluidic chip

The invention provides a multi-substance gradient mixed droplet forming device based on a microfluidic chip, which includes an upper microfluidic chip, a middle microfluidic chip and a lower flat chip. The upper microfluidic chip and the middle microfluidic chip The control chip is respectively provided with a solution inlet, a microchannel network and a solution outlet; the microchannel networks of the upper microfluidic chip and the middle microfluidic chip are respectively composed of the same number of concentric annular channels and radial branch channels. It is composed of alternately arranged connections; the solution inlets of the upper microfluidic chip and the middle microfluidic chip are respectively connected to the first concentric annular channel and the first group of radial branch channels in the microchannel network of the same layer chip. ; The solution outlets of the upper microfluidic chip and the middle microfluidic chip are respectively connected to the last group of radial branch channels in the microchannel network of the same layer chip, and the upper microfluidic chip and the middle microfluidic chip The solution outlets of the fluidic chip are connected to each other and correspond one to one.

Owner:NORTHEASTERN UNIV LIAONING

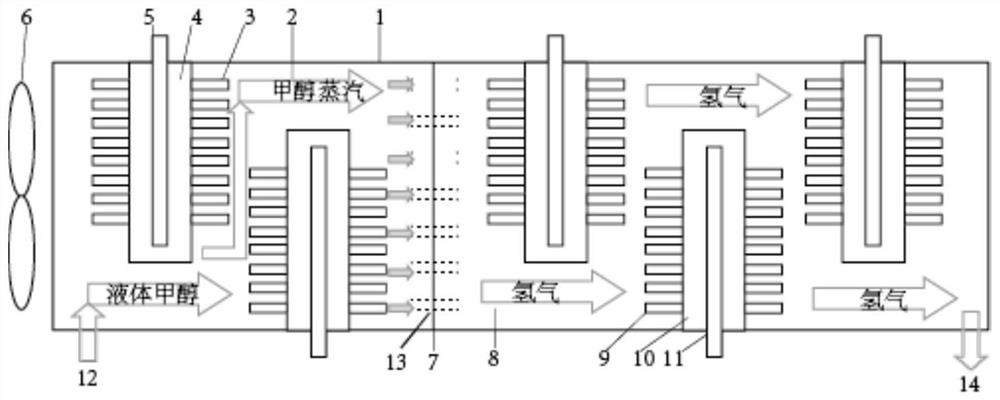

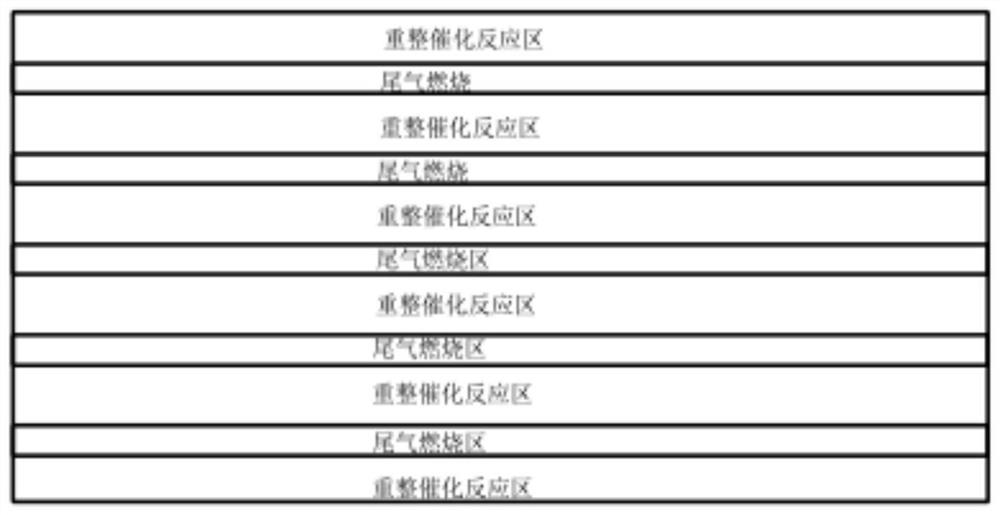

Methanol reforming gas generator

PendingCN114634161AAvoid overheating of power generationSimple processHydrogenHydrogen/synthetic gas productionChemistryElectric heating

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

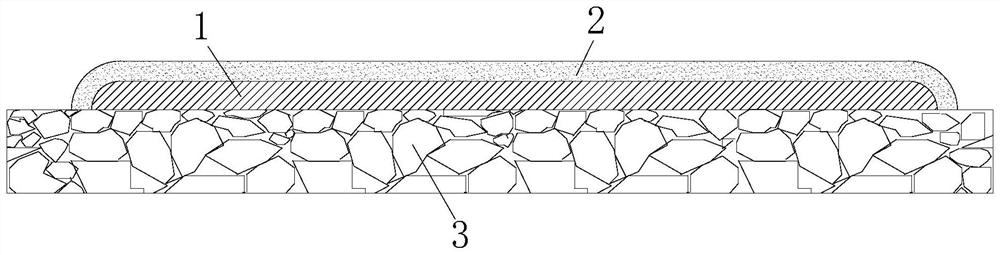

Construction method of novel composite marking structure

PendingCN111851339AAvoid premixingAvoid clumpingTraffic signalsRoad signsRoad surfaceMechanical engineering

The invention discloses a construction method of a novel composite marking line structure, which is used for making marking lines on the ground. The construction method comprises the following steps of: performing a cleaning step: sweeping and cleaning the ground on which marking lines are to be made; manufacturing a hot-melt pavement marking coating layer: coating the pavement with the hot-melt pavement marking coating to form the hot-melt pavement marking coating layer; performing a two-component marking coating mixing step: according to actual material requirements, putting two coatings ofthe two-component marking coating into a mixing container, and fully performing mixing to prepare the two-component marking coating; and performing a two-component marking coating layer manufacturingstep: coating the prepared two-component marking coating on the surface of the hot-melt pavement marking coating layer. The hot-melt pavement marking coating layer is used as the first layer, so thatthe marking flatness and the binding power with the asphalt concrete pavement can be effectively ensured. And the second layer is plated with the two-component marking coating layer, so that the excellent reflective property, friction resistance and corrosion resistance of the material can be effectively exerted.

Owner:GUANGZHOU JISHI CONSTR GRP

Oral delivery system comprising two compartments

InactiveUS20170172938A1Efficient use ofLow production priceOrganic active ingredientsPharmaceutical containersCross-linkDentistry

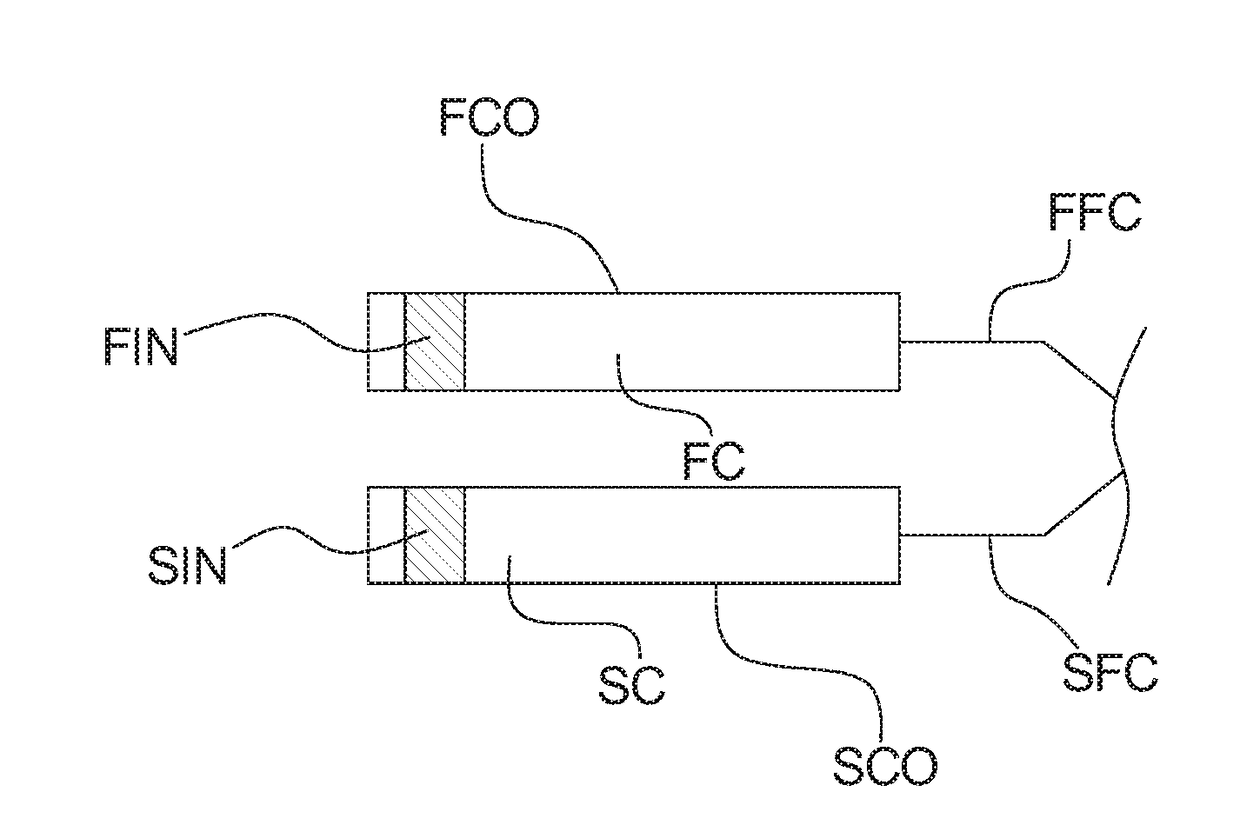

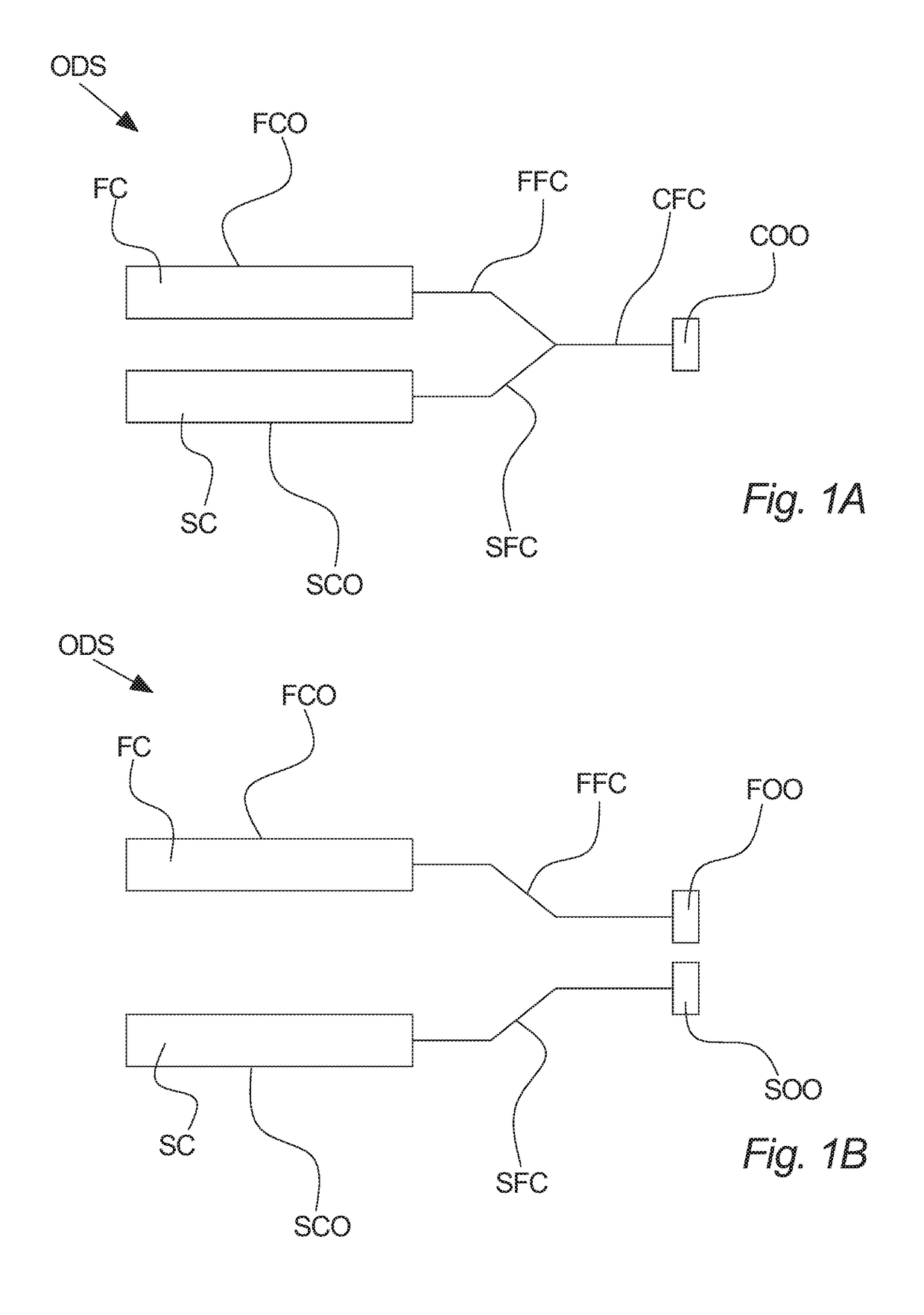

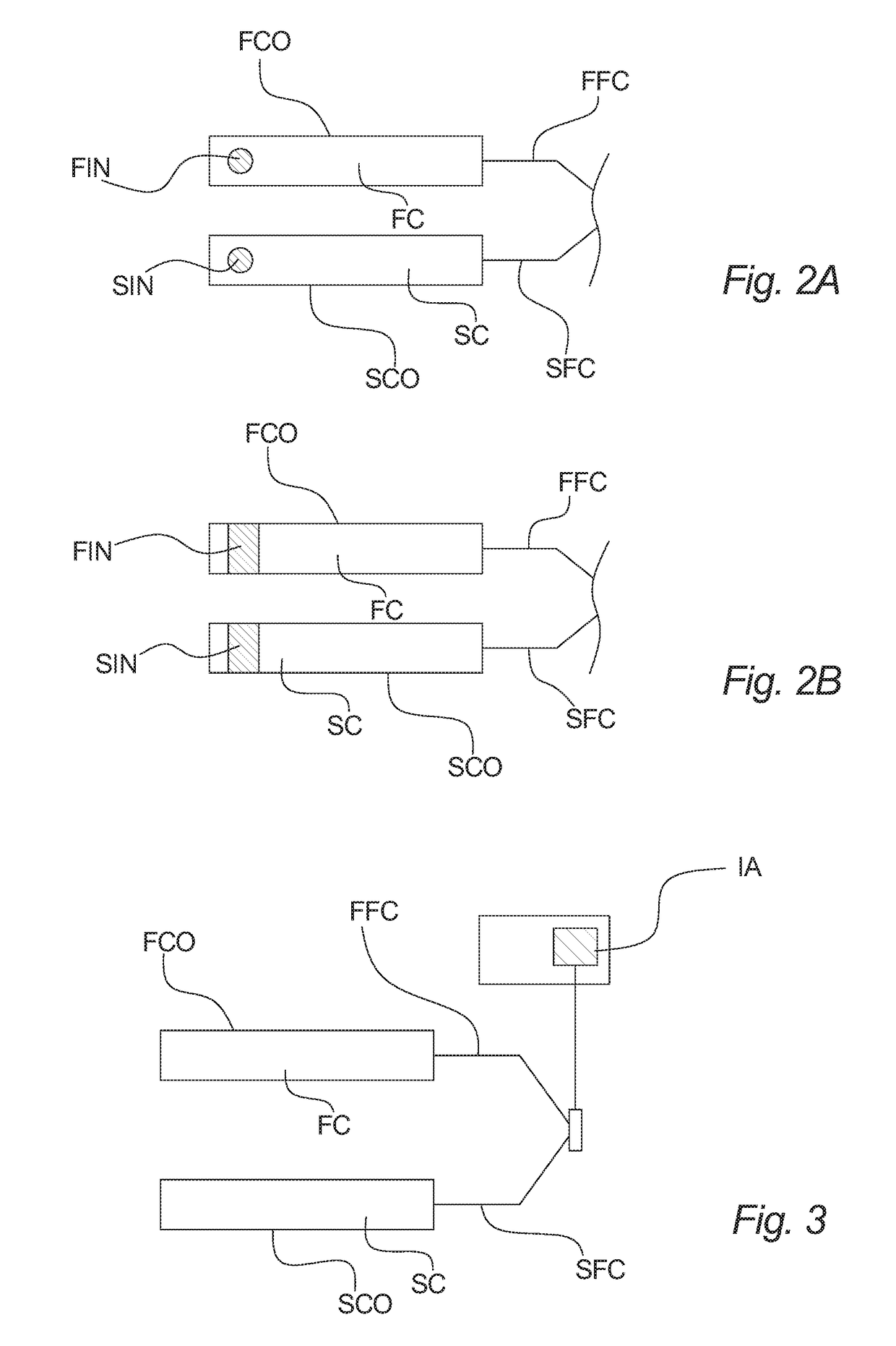

An oral delivery system (ODS) is disclosed, the oral delivery system (ODS) comprising a first compartment (FCO) and a second compartment (SCO), said first compartment (FCO) comprising a first component (FC) comprising natural unbranched polysaccharide, said second compartment (SCO) comprising a second component (SC) comprising multivalent cations, wherein the oral delivery system (ODS) is adapted for administering the first and second components (FC, SC) in a synchronized manner to the oral cavity, whereby a bioadhesive gel is formed from said natural unbranched polysaccharide and said multivalent cationsin a cross-linking reaction.

Owner:FERTIN PHARMA AS

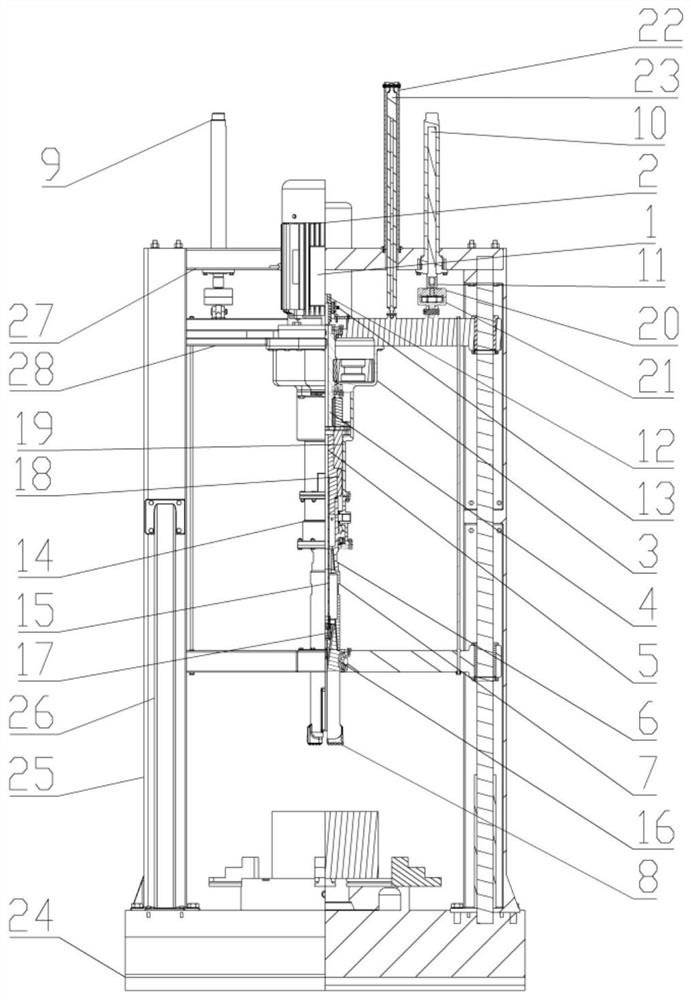

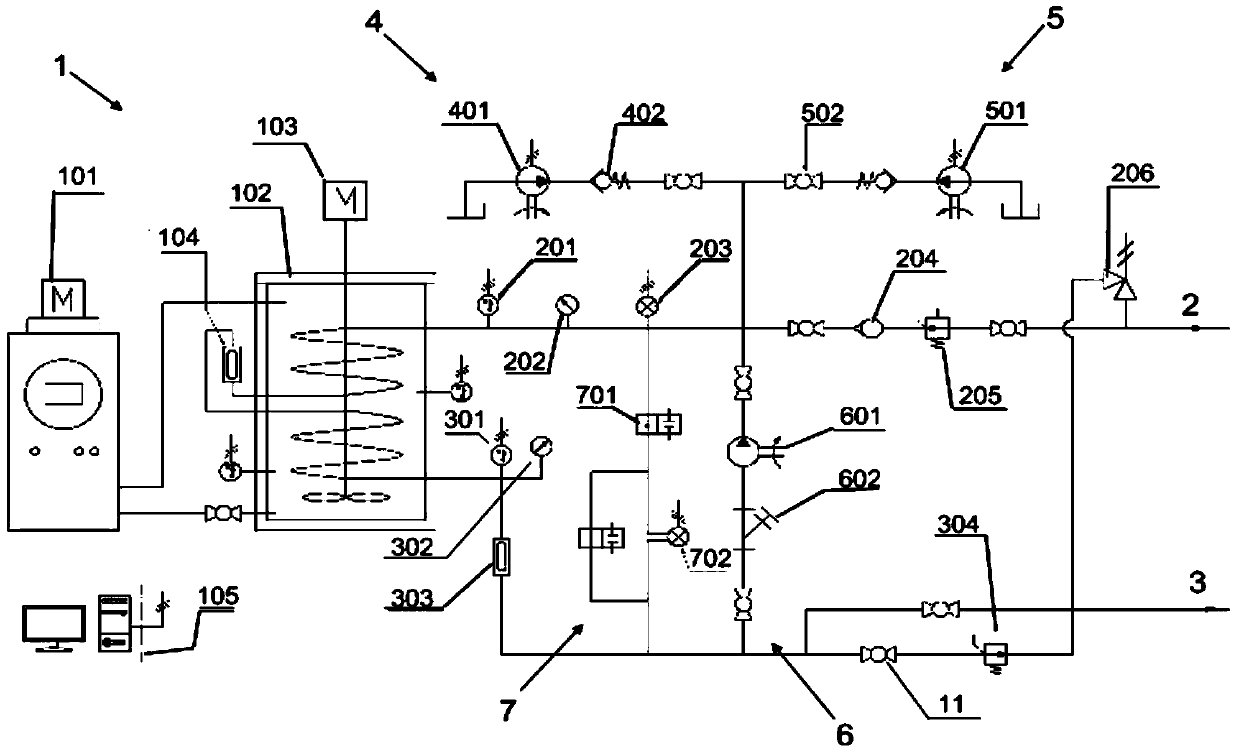

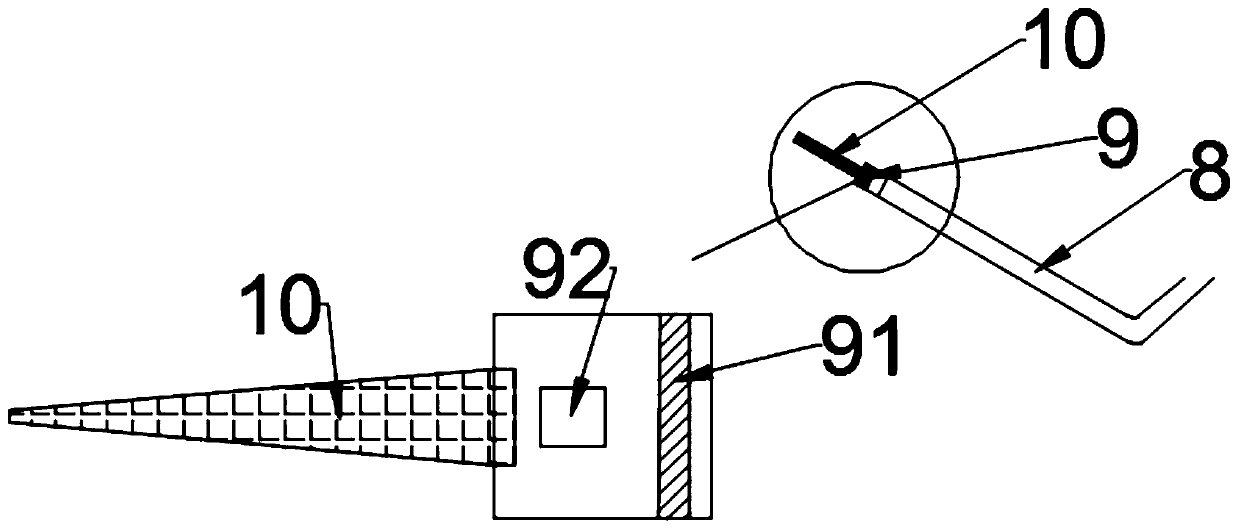

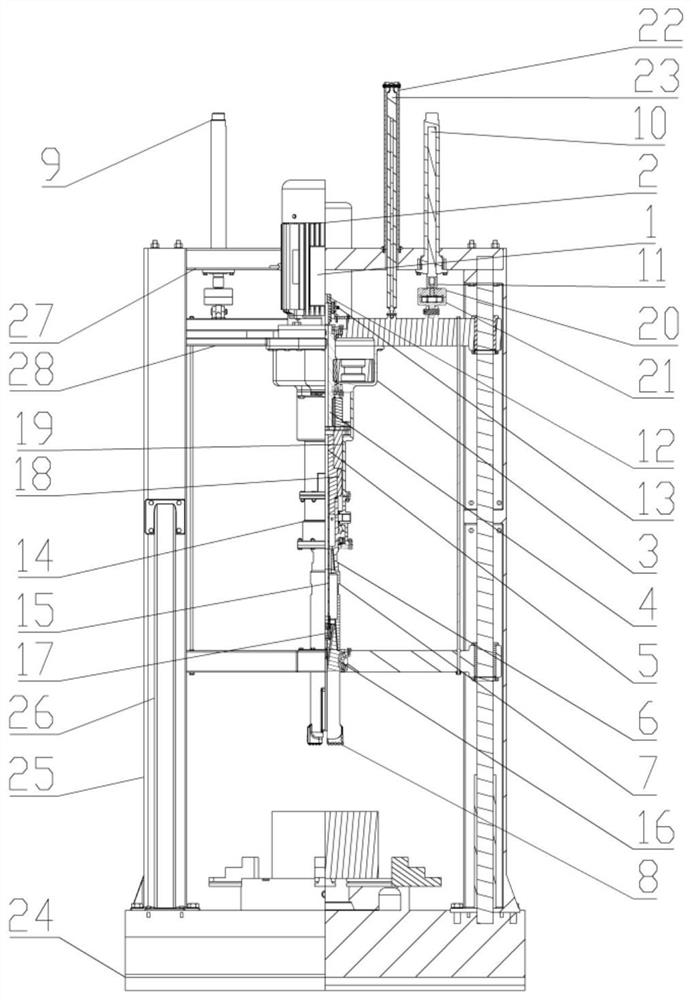

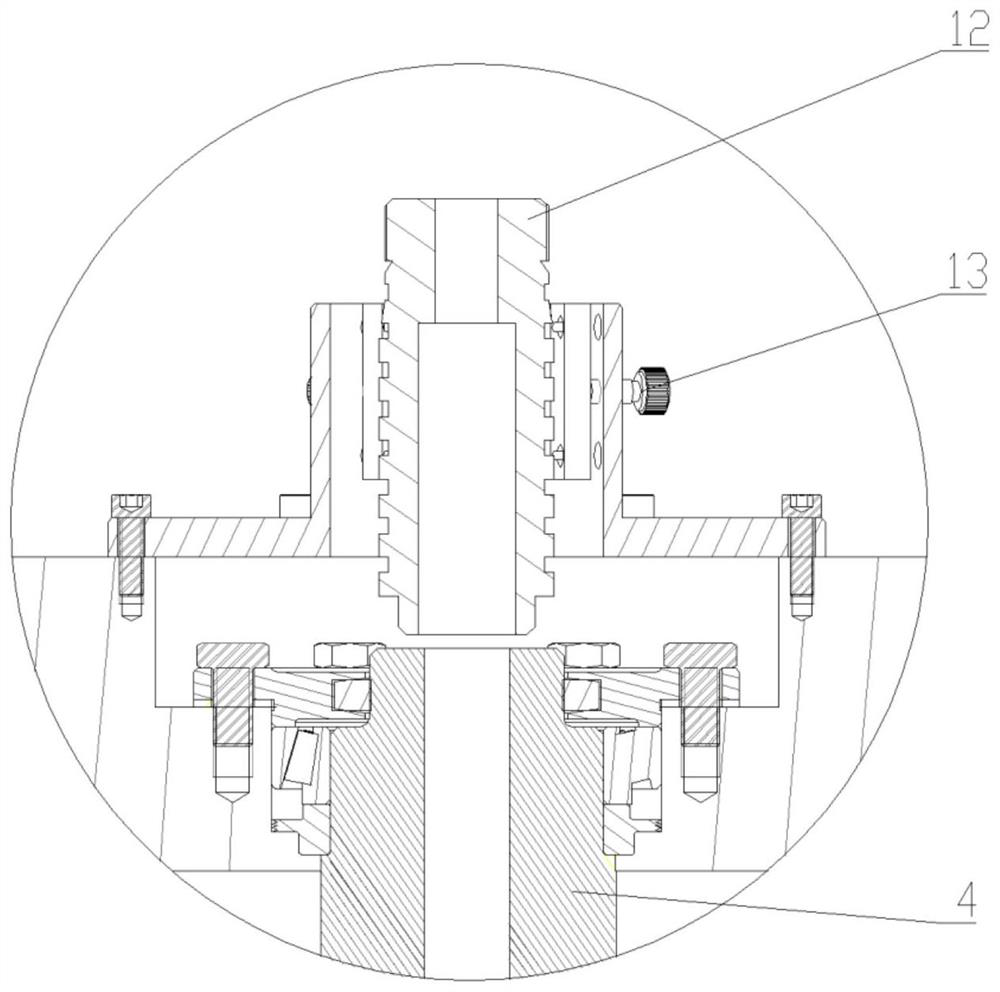

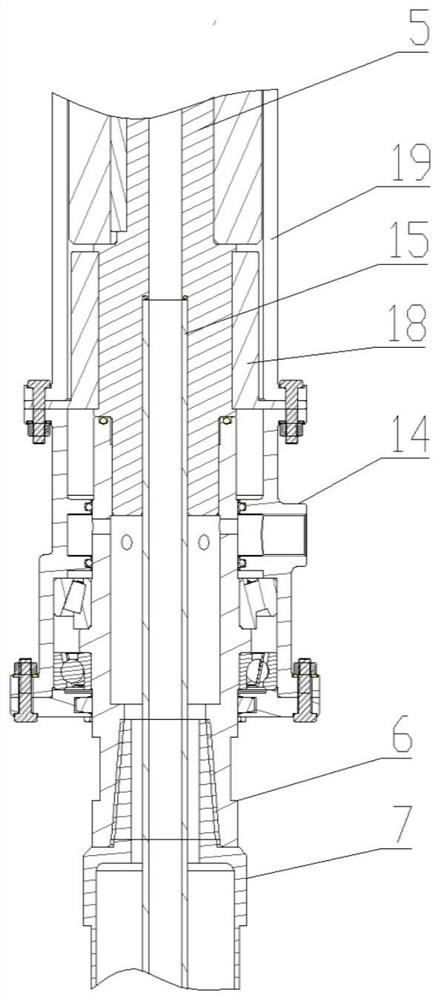

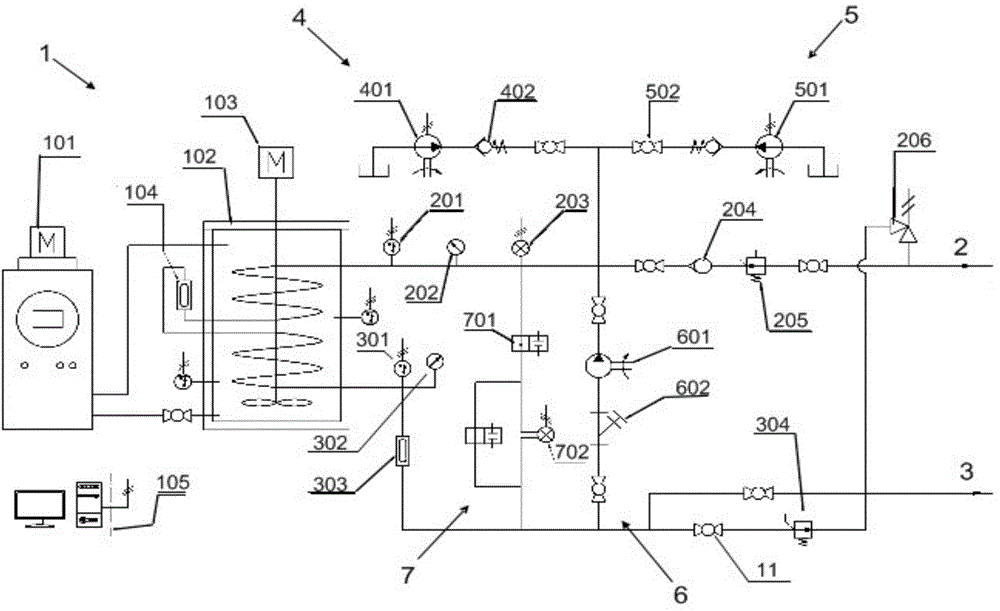

Laser-mechanical rock breaking test device

A laser mechanical rock breaking test device is mainly composed of a rotating system, a hydraulic control system, a light path and gas path system, a test and data processing system and a supporting system. The rotating system is mainly composed of a motor, a speed reducer, a drill rod and a drill bit; the hydraulic control system is mainly composed of a hydraulic cylinder and a telescopic rod, the light path and gas path system is mainly composed of a laser head, a laser head angle adjuster, a gas inlet disc and a phosgene mixing cylinder, and the laser head angle adjuster can adjust the emission angle of laser. Laser and gas are mixed in the phosgene mixing cylinder and finally act on the bottom of the drill bit; the testing and data processing system is mainly composed of a torque sensor, a spoke type pressure sensor and a displacement sensor, and the supporting system is mainly composed of a base and a main stand column. According to the laser-mechanical rock breaking test device,research on tests such as a laser mechanical rock breaking mechanism and efficient collaborative parameter matching can be developed, and the laser mechanical rock breaking test device has important significance in promoting development of a laser mechanical rock breaking technology.

Owner:SOUTHWEST PETROLEUM UNIV

A method and device for producing ethylene by hydrogenation of high-concentration acetylene

ActiveCN105061131BAvoid overwritingAvoid premixingHydrocarbon by hydrogenationLiquid-gas reaction processesHigh concentrationHydrogen

The invention relates to a method for acetylene hydrogenated ethylene production. The method is of gas phase-liquid phase two-phase reaction, a gas phase comprises hydrogen gas and acetylene, and a liquid phase comprises a liquid-phase solvent and a liquid-phase catalyst. The method comprises the following steps: respectively introducing hydrogen gas and acetylene into the liquid phase from different positions of a reaction device, and enabling the interior of the liquid phase to form density difference and then carry out self circulation; and enabling hydrogen gas and acetylene to be subjected to full reaction under the condition of self circulation, and collecting the product. The invention also relates to a device for acetylene hydrogenated ethylene production. According to the device, acetylene and hydrogen gas can be separately fed, and the liquid phase is subjected to self circulation under the action of density difference, so that the efficiency of acetylene hydrogenated ethylene production is increased.

Owner:北京锦泰诚瑞科技发展有限公司

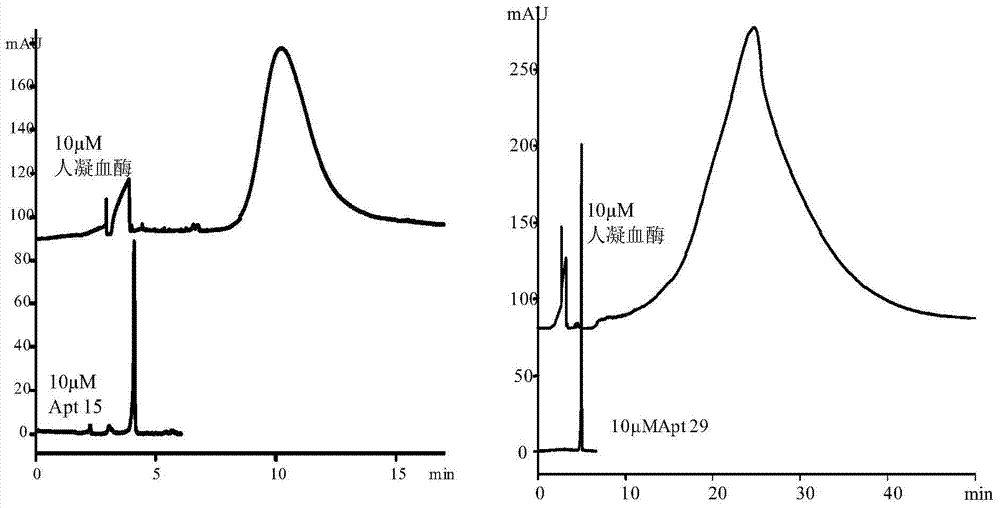

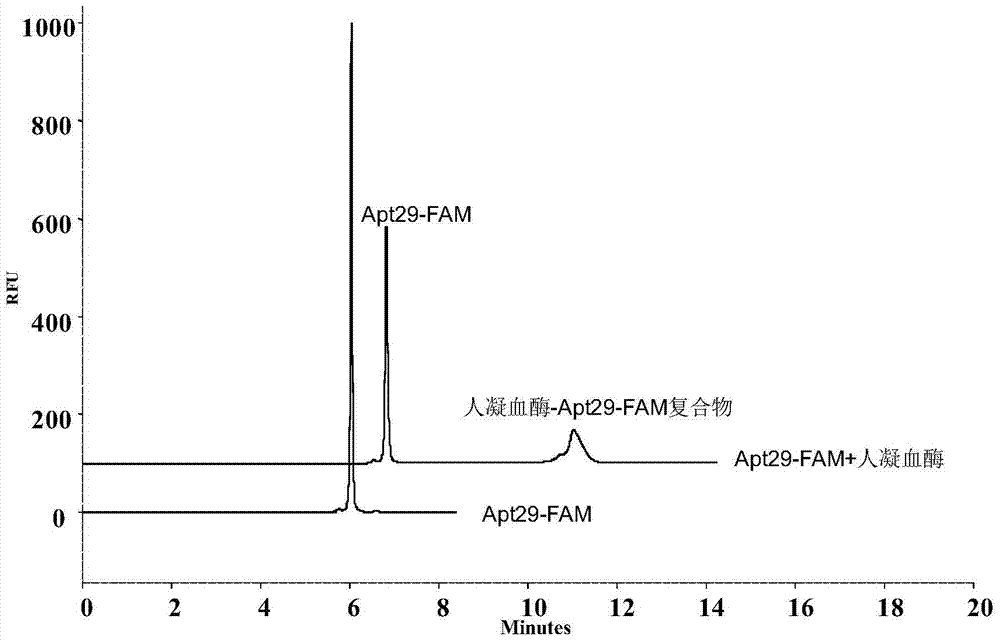

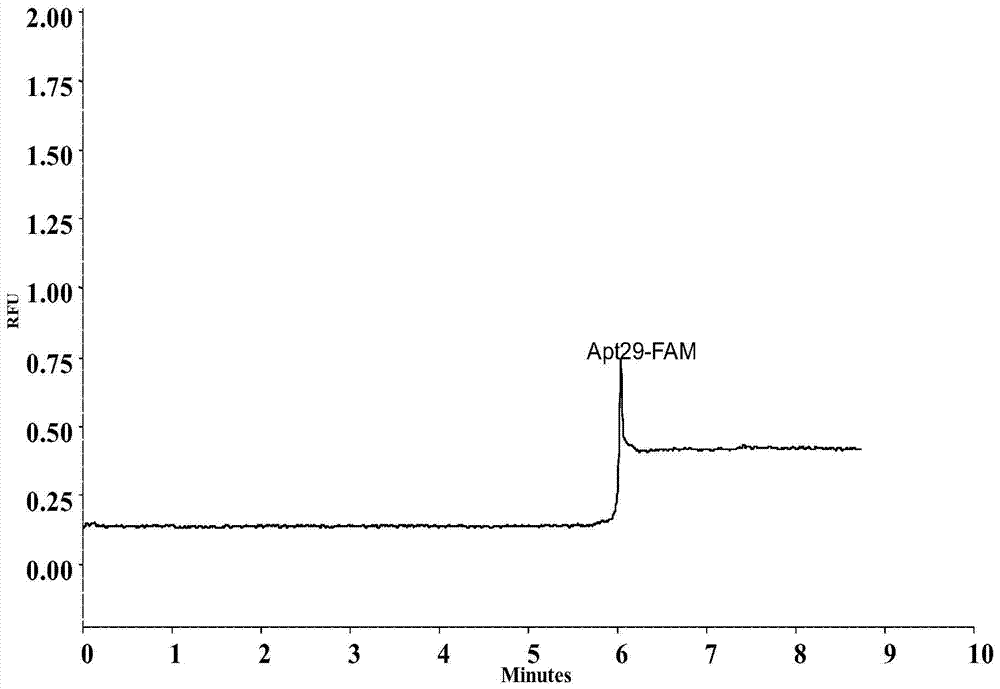

Capillary Electrophoresis Method for On-line Reaction Separation of Protein-oligonucleic Acid Complex

ActiveCN104297325BAvoid premixingReduce demandMaterial analysis by electric/magnetic meansFluorescence/phosphorescenceCapillary electrophoresisElectrophoresis

The invention relates to a method applied to on-line reaction and separation of a protein-oligonucleotide compound by capillary electrophoresis, belonging to the technical field of biological separation and analysis. The method comprises the following steps: carrying out capillary zone electrophoresis on reactants; sequentially feeding samples, namely reactants with low migration rate in the capillary, an electrophoresis buffer solution and reactants with high migration rate in the capillary; reacting and mixing the reactants with different migration rates in the capillary during the electrophoresis process online and then carrying out electrophoresis, separating and collecting electrophoresis products, and carrying out capillary electrophoresis-laser-induced fluorescence detection on the products. The products comprise protein and ssDNA. According to the method, the two reactants are mixed and reacted online in the capillary electrophoresis process in the absence of incubation; the compound is quickly, simply and conveniently separated online; the method is high in efficiency and high in speed, few in samples and high in utilization rate of samples, and is especially suitable for protein which is inadequate in source and high in cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

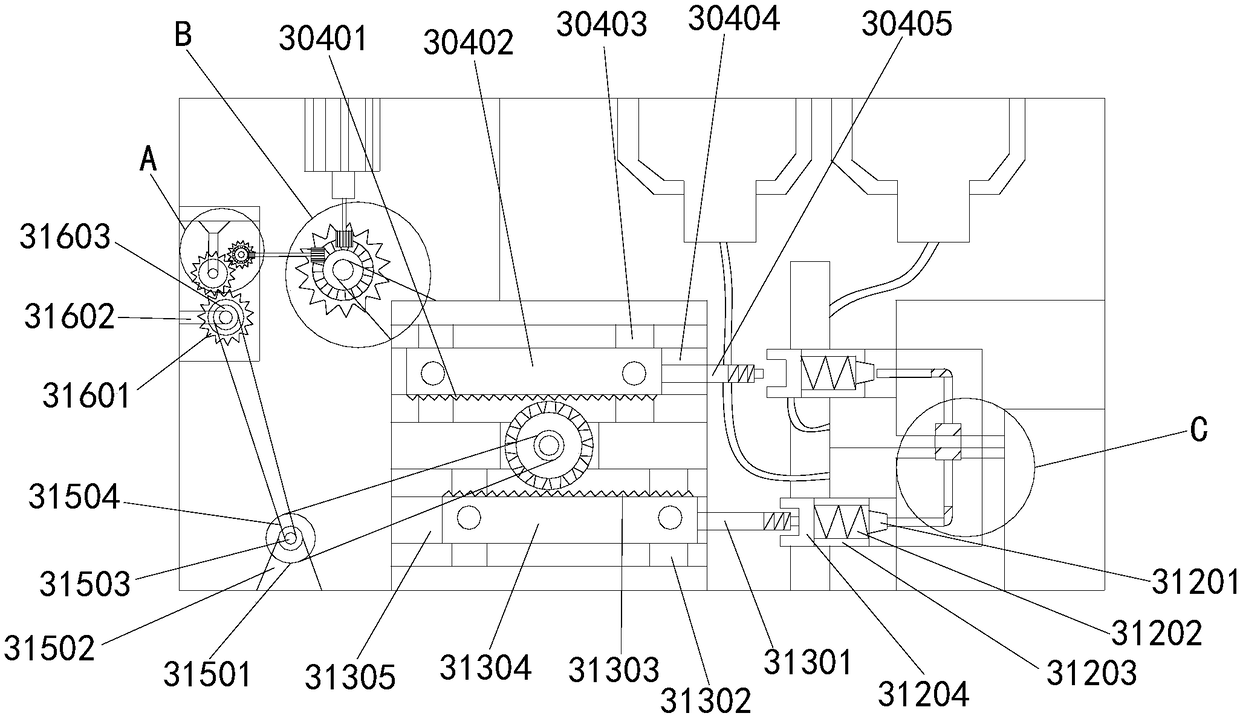

Storage type precision quantitative oil and gas well downhole working agent injection system and injection method

ActiveCN104948134BGuaranteed accuracyImprove efficiencyCleaning apparatusFluid removalStorage typePetroleum engineering

A storage-type precise quantitative injection system for injection of an underground oil or gas well operating agent and an injection method thereof. The injection system comprises an injection tube (3-2) and overground pressurizing equipment. The injection tube is provided with one or more sets of injection units therein. Each set of the injection units comprises an operating agent container (3-7) having a variable volume. The overground pressurizing equipment is configured to generate a pressure acting on the operating agent container (3-7) having the variable volume so as to expel an operating agent (3-8). The injection method adopts the storage-type precise quantitative injection system using the underground oil or gas well operating agent (3-8), and injects a fixed amount of the operating agent (3-8) into a target location in the underground well. By injecting in advance the fixed amount of the operating agent into the operating agent container, the injection system can inject an accurate and fixed amount of the operating agent and ensure accuracy of an injection amount of the operating agent. The injection method can inject an accurate amount of the operating agent into the target location, providing accuracy of the injection amount and accuracy of the injection location and ensuring a favorable injection effect.

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

Combined type multi cavity container and solute storing device thereof

A combined multi-chamber container and its solute storage container, the combined multi-chamber container includes a bottle body, a bottle cap and at least one solute storage device arranged between the bottle cap and the bottle body, the bottle cap and the uppermost solute storage container , the two adjacent solute storages, and the lowermost solute storage are all screwed to the bottle mouth of the bottle body. The solute reservoir includes a tubular body and a diaphragm arranged in the tubular body, the diaphragm divides the interior of the tubular body into a lower cavity and an upper cavity for storing solute, the inner wall of the lower half of the tubular body and the upper cavity The outer walls of the half parts are all provided with threads. The combined multi-chamber container is used to store solutes and solvents that need to be used and prepared immediately. It can not only avoid mixing chemical materials in advance and causing chemical reactions to fail, but also does not need to be calculated and weighed during preparation, which greatly simplifies preparation. step. The solute reservoir is combined with the bottle body and the bottle cap through screw connection, which is simple and convenient to use.

Owner:陈红锋

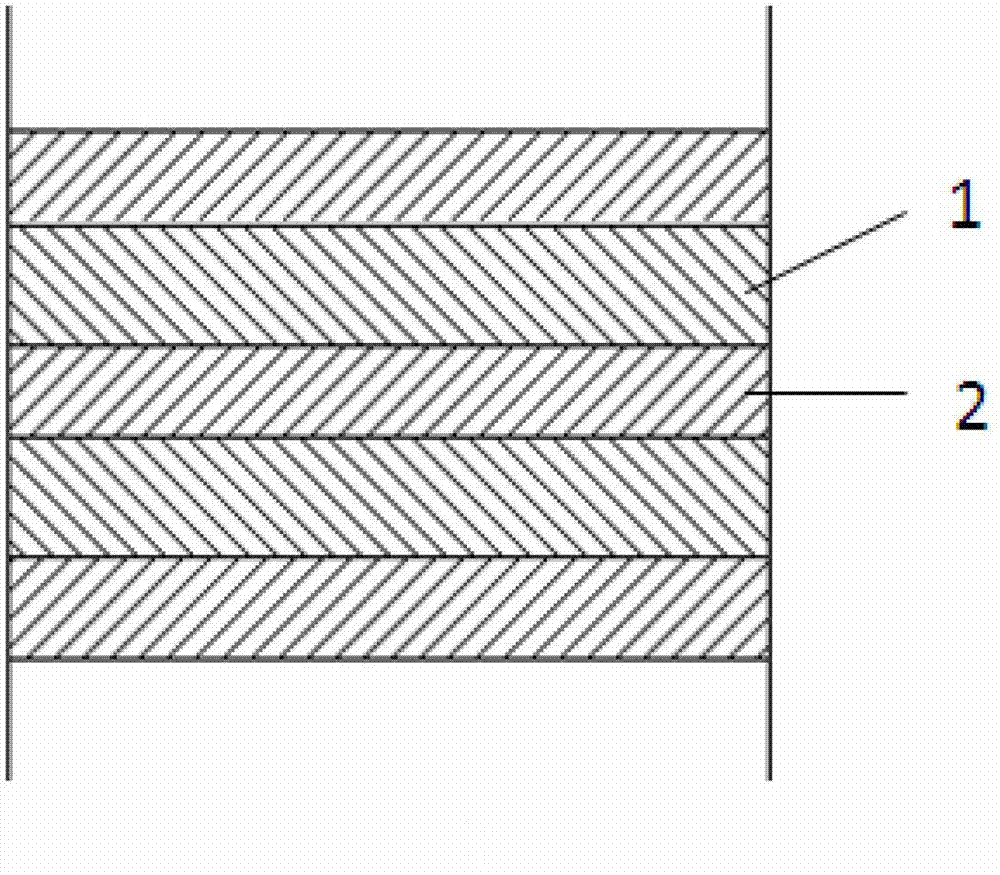

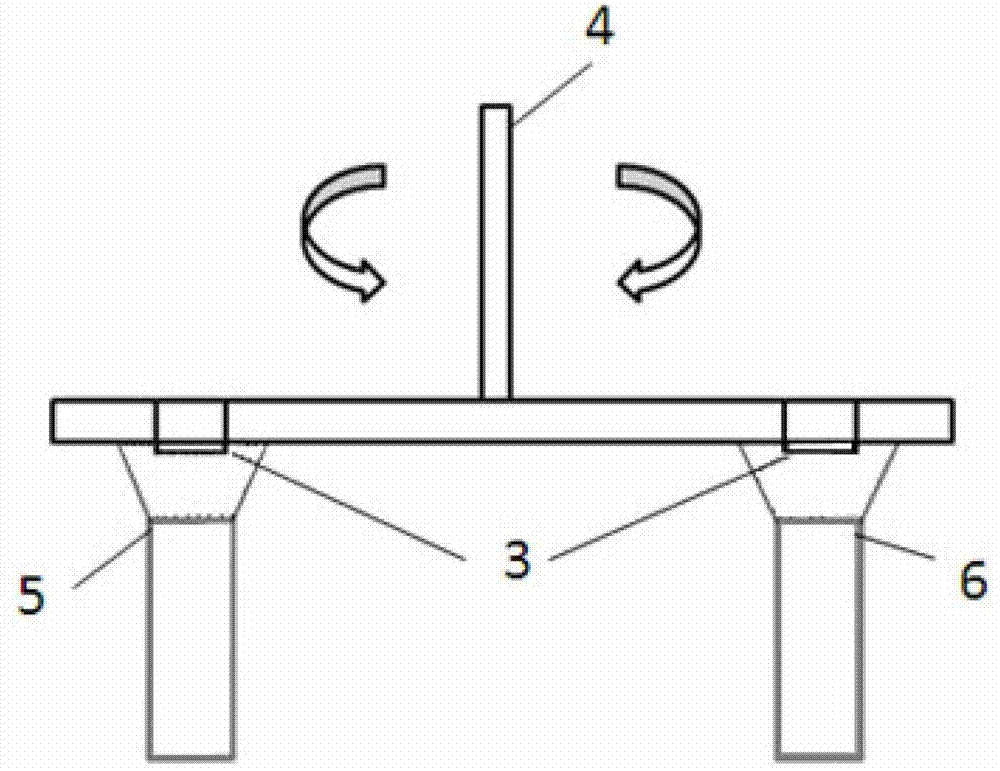

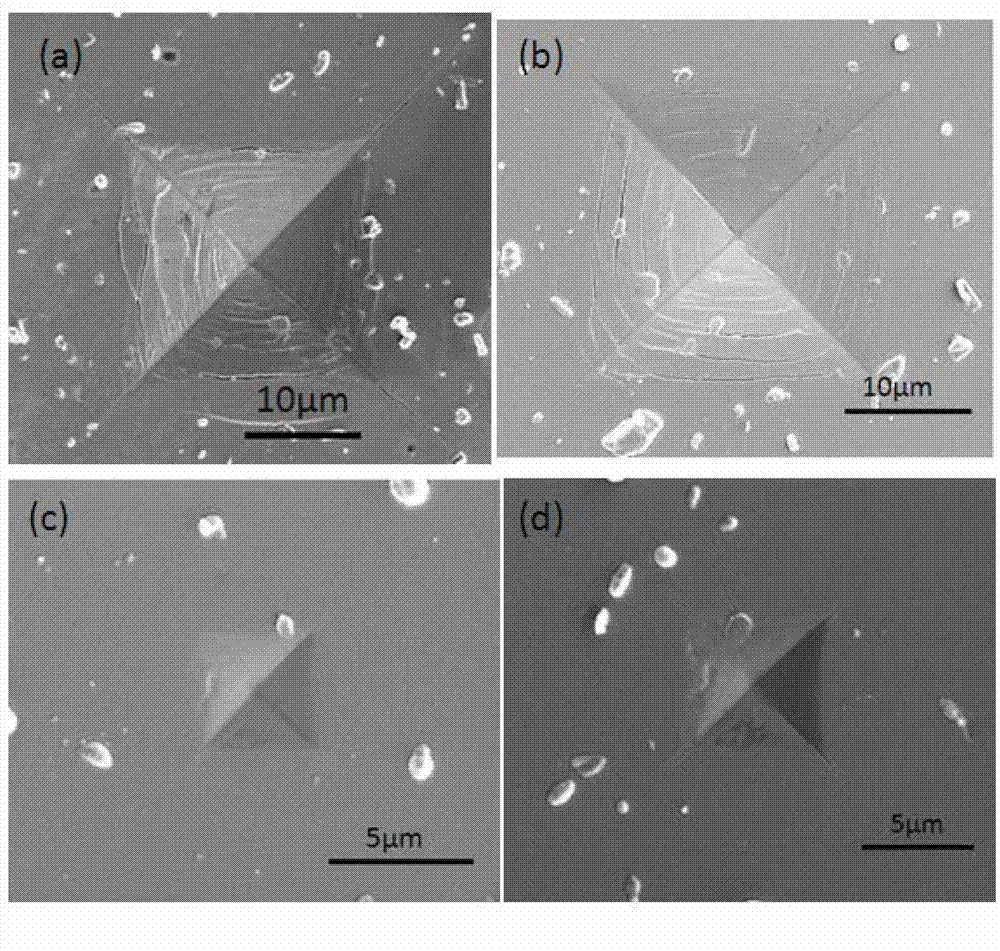

VC/Co toughening coating layer with nanometer multilayer structure and preparation method thereof

ActiveCN103042753AEasy to operateImprove controllabilityMaterial nanotechnologyVacuum evaporation coatingTarget surfaceWear resistant

The invention discloses a VC / Co toughening coating layer with a nanometer multilayer structure. The coating layer is formed by alternatively depositing VC layers and Co layers; adjacent one VC layer and one Co layer form one double-layer periodic layer; each double-layer periodical layer is 1-88 nm in thickness; the thickness ratio of the VC layer to the Co layer in each double-layer periodic layer is (1.0-3.0):1; and the total thickness of the double-layer periodic layer is 1-5 microns. The invention further discloses a preparation method for the VC / Co toughening coating layer with the nanometer multilayer structure; the method comprises the steps of respectively mounting VC targets and Co targets on medium-frequency cathodes, placing target surfaces perpendicular to a rotary working table, and adopting the magnetron sputtering method to deposit matrixes. At the same time of keeping higher hardness, the VC / Co toughening coating layer with the nanometer multilayer structure improves the toughness, so that the hardness and toughness requirements of protection coating layers and wear-resistant coating layers can be satisfied; and the preparation method has the advantages of strong operability, good controllability and easiness in industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

An Angled Rotary Joint with Multiple Channels Entering and Exiting the Same Channel

The invention discloses an angle rotary connector capable of entering and exiting the same channel by a plurality of channels. The channels are arranged at the outer end of a lower shell body; 4-32 channels are arranged; each channel is internally provided with an annular sealing part, a first O-shaped ring, a spring cushion and a spring in sequence; a rotary shaft is arranged in an upper shell body; a star-shaped sealing ring is arranged under a first bearing between the rotary shaft and the lower shell body; a common channel is arranged on one side of the upper shell body; an annular groove is formed in the horizontal plane of the lower part of the rotary shaft; the annular groove corresponds to the common channel in the vertical direction; a second O-shaped ring is arranged on one side of the annular groove and a third O-shaped ring is arranged on the other side of the annular groove; the annular groove of the rotary shaft is internally provided with a rotary shaft channel and the rotary shaft channel corresponds to the channel; a star-shaped ring is arranged between the rotary shaft above a second bearing and the shell body; a key slot is formed in the outer end of the rotary shaft; and the upper shell body and the lower shell body are fixedly connected through a bolt. The angle rotary connector is simple in structure, is supported by the double bearings and is flexible to rotate and the torque is alleviated. The sealing effect is ensured and the service life is prolonged.

Owner:TENGZHOU TIANXUAN ROTARY UNION

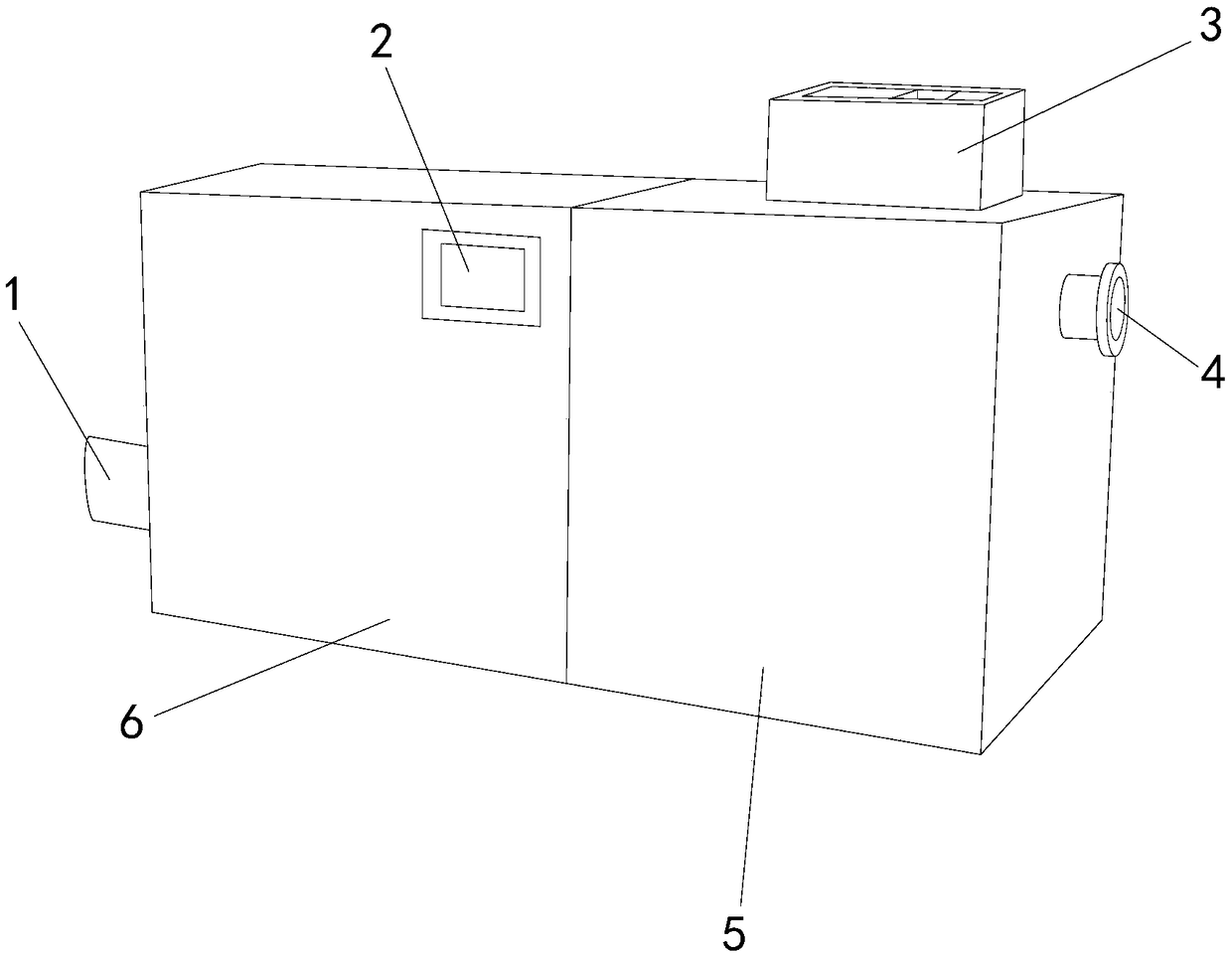

Mobile natural gas hydrate evaluation device

The invention discloses a movable natural gas hydrate evaluation apparatus. The apparatus comprises a temperature field device, a natural gas injection pipeline, a natural gas outflow pipeline and a component water injection pipeline; the temperature field device comprises a temperature field tank and a refrigerating unit; an internal coil pipe is arranged in the temperature field tank; the temperature field tank is respectively connected with the refrigerating unit and an acquisition processor; the sidewall of the temperature field tank is provided with a visual window; the natural gas injection pipeline is connected with the internal coil pipe; the natural gas outflow pipeline is connected with the internal coil pipe; and the water injection pipeline is connected with the natural gas injection pipeline. The movable natural gas hydrate evaluation apparatus can be used to evaluate and research hydrate formation conditions and additives in the exploitation field of natural gas, and has the advantages of convenient transportation, convenient operation and strong applicability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Industrial wastewater biological membrane multi-stage treatment device

InactiveCN108298678AComplete controlReasonable controlWater/sewage treatmentMultistage water/sewage treatmentIndustrial waste waterBiological membrane

The invention discloses an industrial wastewater biological membrane multi-stage treatment device which structurally comprises a water outlet tube, a control panel, a purification medicine holding cabin, a water inlet tube, a biological membrane treatment water cabin and a multi-stage purification water cabin, wherein the water outlet tube is mounted on the left side of the multi-stage purification water cabin and is welded with the multi-stage purification water cabin; the multi-stage purification water cabin is a rectangle; the control panel is arranged above the right part of the front sideof the multi-stage purification water cabin; the multi-stage purification water cabin is buckled with the control panel; the biological membrane treatment water cabin is arranged on the right side ofthe multi-stage purification water cabin; the multi-stage purification water cabin is locked with the biological membrane treatment water cabin; the biological membrane treatment water cabin is mounted below the purification medicine holding cabin and is in clearance fit with the purification medicine holding cabin; the biological membrane treatment water cabin is a rectangle. When the equipmentis used, through a medicine control mechanism, the problems that purification medicines can be mixed in advance when being not stored independently, and medicines are not completely purified since theholding ratios are not precise, can be avoided, and the equipment can be relatively reasonable in medicine control and relatively complete in purification.

Owner:谢彬彬

Automatic circulation liquid addition system

ActiveCN106000148BSimplified dosing processEasy to operateFlow mixersTransportation and packagingPlate heat exchangerLiquid storage tank

The automatic circulating liquid adding system disclosed by the present invention comprises a liquid storage tank, a heat exchanger, a circulation pump, a liquid consumption branch and a controller, the liquid inlet of the circulation pump is connected to the liquid outlet of the liquid storage tank, and the liquid outlet of the circulation pump The port is connected to the inlet of the heat exchanger, and the outlet of the heat exchanger is connected to the circulating liquid inlet of the liquid storage tank through a pipeline. The liquid storage tank is equipped with a temperature sensor A, a liquid level sensor and a liquid level switch, and the liquid consumption branch is connected to the heat exchanger On the connecting pipe between the outlet of the heat exchanger and the circulating liquid inlet of the liquid storage tank, the temperature sensor B is installed on the connecting pipe between the outlet of the heat exchanger and the liquid consumption branch, and the liquid consumption branch and the circulating liquid inlet of the liquid storage tank A temperature sensor C, a pressure sensor and a pressure regulating valve are arranged on the connecting pipeline between them. The invention has a high degree of automation, and can improve product quality and efficiency.

Owner:CHENGDU RONGSHENG PHARMA

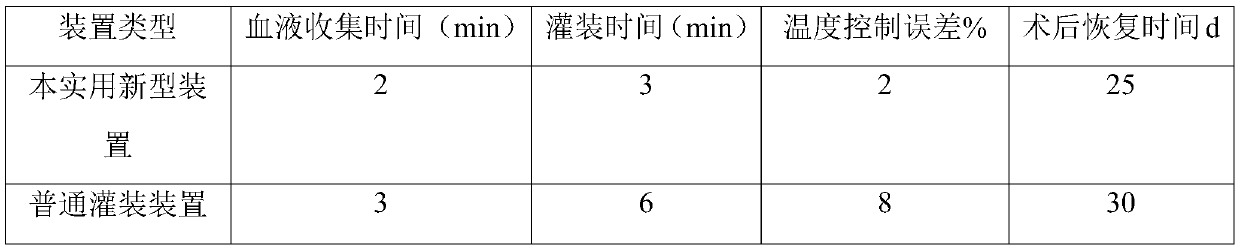

Myocardial protection liquid perfusion device

PendingCN111097078AGuaranteed accuracyPrevent cardiac stressOther blood circulation devicesMedical devicesBlood drawsHeart damage

The invention discloses a myocardial protection liquid perfusion method. A myocardial protection liquid perfusion device comprises a liquid storage chamber and an infusion chamber, wherein the liquidstorage chamber comprises a bag shell, an air bag, a bent pipeline and a filtering sieve plate; the air bag is arranged below the bag shell; the bent pipeline is arranged below the air bag; the filtering sieve plate is arranged below a liquid leakage hole of the bent pipeline; a first three-way switch is arranged at the lower end of the infusion chamber; the first three-way switch is connected with a blood drawing tube and a conveying tube; a second three-way switch is arranged at one side, far away from the liquid storage chamber and the infusion chamber, of the conveying tube; the other sideof the second three-way switch is connected with a blood outlet tube and an infusion tube; and the infusion tube can be connected with an upper needle head through a slot. The myocardial protection liquid perfusion device has the beneficial effects that a blood drawing and transfusion integrated function is realized by utilizing the first three-way switch and the second three-way switch; and a constant pressure system is formed by utilizing the air bag and an air chamber, so that heart damage is prevented, and myocardial protection liquid is delivered for assist.

Owner:成都市中西医结合医院

A kind of processing method of waste lithium iron phosphate

ActiveCN110690429BIncrease compaction densityIncrease capacityCell electrodesWaste accumulators reclaimingO-Phosphoric AcidPhosphate

The invention discloses a treatment method for waste lithium iron phosphate. The waste lithium iron phosphate material is pretreated, and the pretreated material is added to a phosphoric acid solution to react and then filtered to obtain a first filtrate and a first filter residue; the first filtrate is added to a sulfide reaction, and then filtered to obtain a second filtrate and a second filter residue; Add iron powder to the second filtrate, remove iron after stirring and reacting, add battery-grade lithium carbonate to the obtained iron-removing material, stir and react until no bubbles are generated, and obtain the reaction material; add the reaction material to a water-soluble organic carbon source, stir to disperse and dissolve , the obtained material is spray-dried in a spray dryer to obtain a dry material; the dried material is put into a roller furnace for calcination, and after crushing, mixing, screening and iron removal, vacuum packaging is obtained. The invention can realize the resource utilization of waste lithium iron phosphate, realize high-end circulation, and at the same time, have a high recovery rate of each element, produce less waste water, and obtain excellent performance of the obtained lithium iron phosphate.

Owner:四川朗晟新能源科技有限公司

A laser-mechanical rock breaking test device

Owner:SOUTHWEST PETROLEUM UNIV

Method and device for high-concentration acetylene hydrogenated ethylene production

ActiveCN105061131AAvoid overwritingAvoid premixingHydrocarbon by hydrogenationLiquid-gas reaction processesHigh concentrationHydrogen

The invention relates to a method for acetylene hydrogenated ethylene production. The method is of gas phase-liquid phase two-phase reaction, a gas phase comprises hydrogen gas and acetylene, and a liquid phase comprises a liquid-phase solvent and a liquid-phase catalyst. The method comprises the following steps: respectively introducing hydrogen gas and acetylene into the liquid phase from different positions of a reaction device, and enabling the interior of the liquid phase to form density difference and then carry out self circulation; and enabling hydrogen gas and acetylene to be subjected to full reaction under the condition of self circulation, and collecting the product. The invention also relates to a device for acetylene hydrogenated ethylene production. According to the device, acetylene and hydrogen gas can be separately fed, and the liquid phase is subjected to self circulation under the action of density difference, so that the efficiency of acetylene hydrogenated ethylene production is increased.

Owner:北京锦泰诚瑞科技发展有限公司

Movable natural gas hydrate evaluation apparatus

ActiveCN105445142AImprove accuracy and precisionIncrease profitMaterial analysisProcess engineeringNatural gas

The invention discloses a movable natural gas hydrate evaluation apparatus. The apparatus comprises a temperature field device, a natural gas injection pipeline, a natural gas outflow pipeline and a component water injection pipeline; the temperature field device comprises a temperature field tank and a refrigerating unit; an internal coil pipe is arranged in the temperature field tank; the temperature field tank is respectively connected with the refrigerating unit and an acquisition processor; the sidewall of the temperature field tank is provided with a visual window; the natural gas injection pipeline is connected with the internal coil pipe; the natural gas outflow pipeline is connected with the internal coil pipe; and the water injection pipeline is connected with the natural gas injection pipeline. The movable natural gas hydrate evaluation apparatus can be used to evaluate and research hydrate formation conditions and additives in the exploitation field of natural gas, and has the advantages of convenient transportation, convenient operation and strong applicability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com