Combined type multi cavity container and solute storing device thereof

A storage and combined technology, applied in the field of multi-chamber containers, can solve the problems of restricting the scope of use, unfavorable to the promotion, application and popularization of new products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

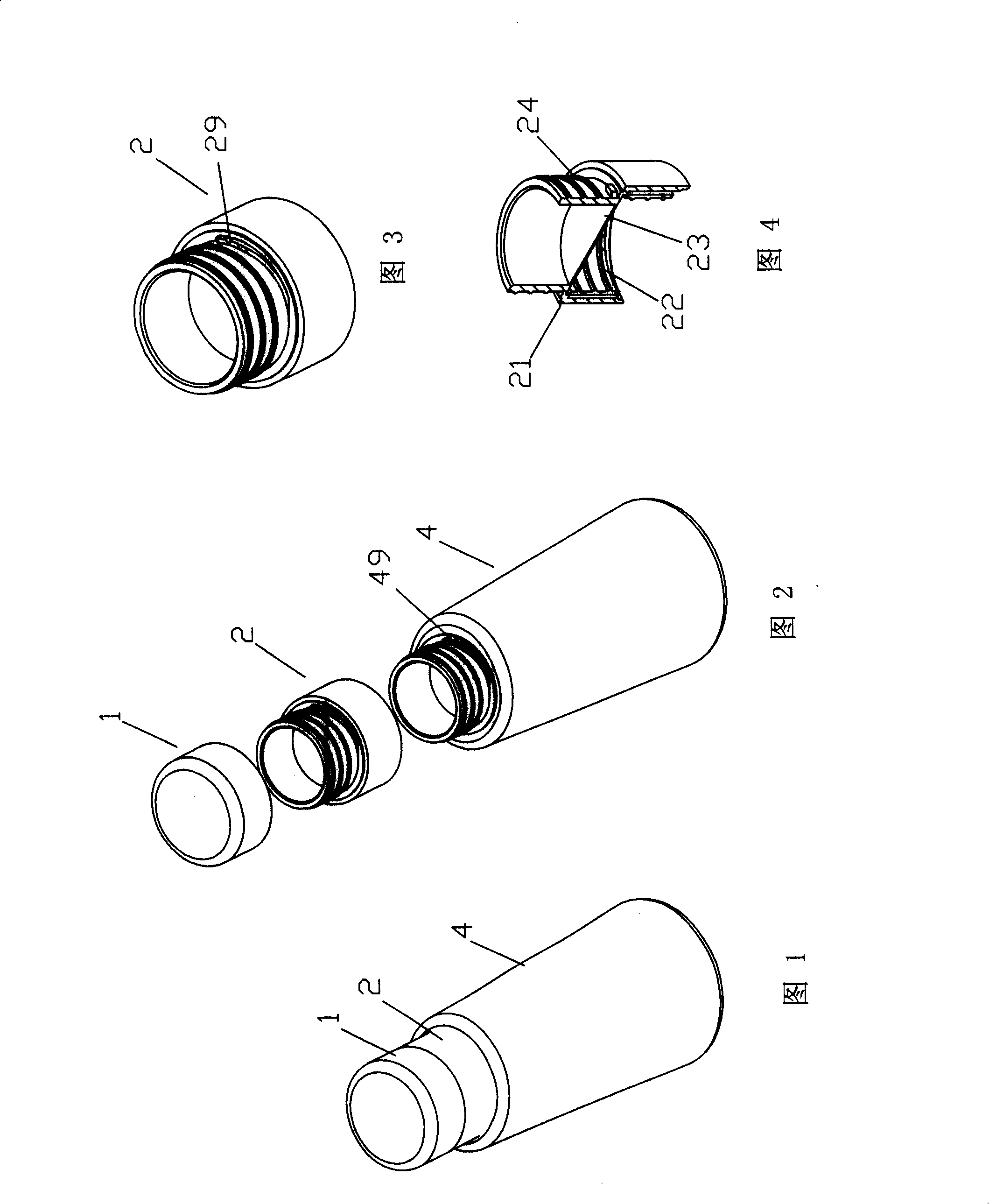

Embodiment 1

[0024] As shown in Figures 1-4, the combined multi-chamber container of Embodiment 1 includes a bottle body 4 and a bottle cap 1, and also includes a solute reservoir 2, which contains a tubular body 21 and is arranged in the tubular body 21. A diaphragm 23, the diaphragm 23 divides the interior of the tubular body 21 into a lower cavity and an upper cavity for storing solute, the inner wall 22 of the lower half of the tubular body 21 and the outer wall 24 of the upper half are all provided with threads , the lower half of the solute reservoir 2 is threadedly connected to the bottle mouth of the bottle body 4 , and the bottle cap 1 is threadedly connected to the upper half of the solute reservoir 2 .

[0025] A buckle in place is arranged between the solute storage 2 and the bottle cap 1, and the buckle in place includes a concave buckle 29 arranged on the solute storage 2 and a convex buckle arranged at a corresponding position on the bottle cap 1; 2 is provided with a convex...

Embodiment 2

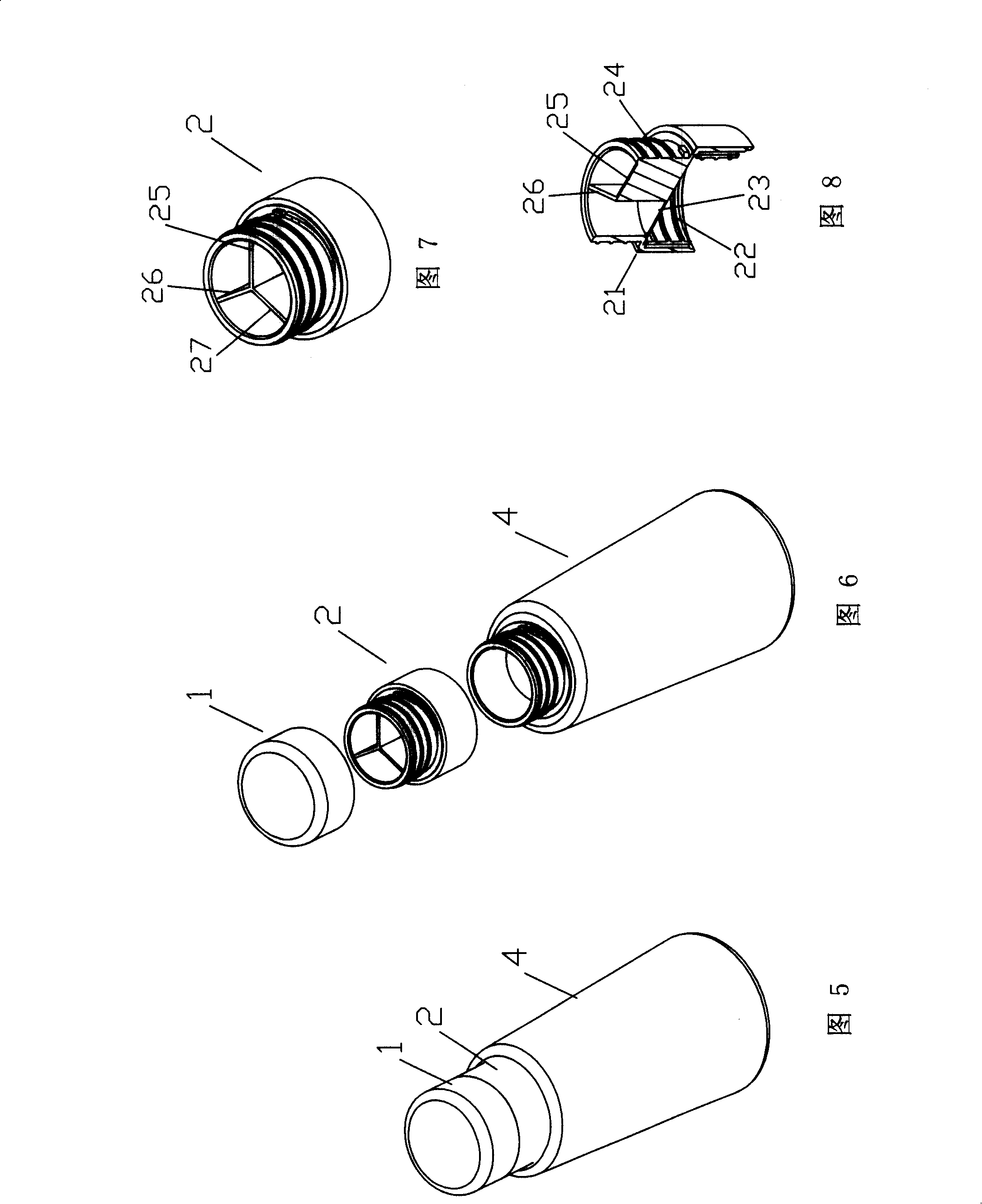

[0028] As shown in Figures 5-8, the combined multi-chamber container of Embodiment 2 includes a bottle body 4 and a bottle cap 1, and also includes a solute reservoir 2, which contains a tubular main body 21 and is arranged in the tubular main body 21. A diaphragm 23, the diaphragm 23 divides the interior of the tubular body 21 into a lower cavity and an upper cavity for storing solute, the inner wall 22 of the lower half of the tubular body 21 and the outer wall 24 of the upper half are all provided with threads , the lower half of the solute reservoir 2 is threadedly connected to the bottle mouth of the bottle body 4 , and the bottle cap 1 is threadedly connected to the upper half of the solute reservoir 2 .

[0029] Three vertical partitions 25, 26, 27 are also arranged in the upper concave cavity of the solute storage 2, and the upper concave cavity of the solute storage 2 is divided into three storage units by the three vertical partitions 25, 26, 27. The storage unit can...

Embodiment 3

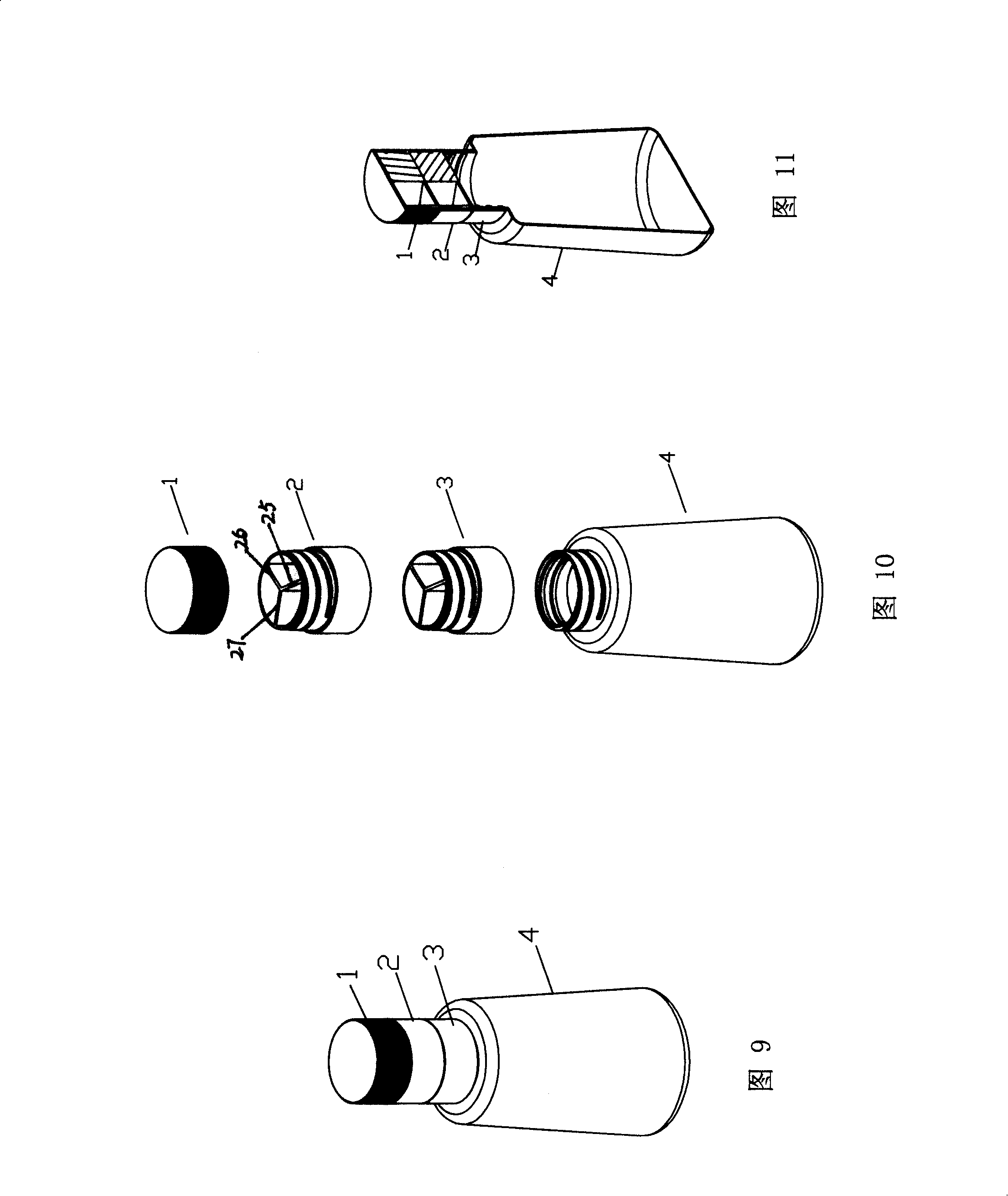

[0034] As shown in Figures 9-12, the combined multi-chamber container of Embodiment 3 includes a bottle body 4 and a bottle cap 1, and two solute storage containers 2, 3. Each solute reservoir contains a tubular body 21, and a diaphragm 23 is arranged in the tubular body 21 to separate the interior of the tubular body 21 into a lower cavity and an upper cavity for storing solute. The tubular body 21 Both the inner wall 22 of the lower half and the outer wall 24 of the upper half are threaded, the bottle cap 1 is threaded to the top solute reservoir 2, the two adjacent solute reservoirs 2 and 3 are threaded, and the bottom solute storage The bottle mouth of device 3 and bottle body 4 is threadedly connected.

[0035] Three vertical baffles 25, 26, 27 are arranged in the upper cavity of the solute storage 2, 3, and the upper cavity of the solute storage 2, 3 is divided into three storage spaces by the three vertical baffles 25, 26, 27. unit.

[0036] Example 3 The combined mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com