A laser-mechanical rock breaking test device

A test device and laser technology, which is applied in the new field of high-efficiency rock breaking and laser-mechanical rock breaking in oil and gas drilling, can solve the problems of not being widely used, low drilling efficiency, narrow application range, etc., and achieve the safety of optical path and gas path system Reliable, functional, high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

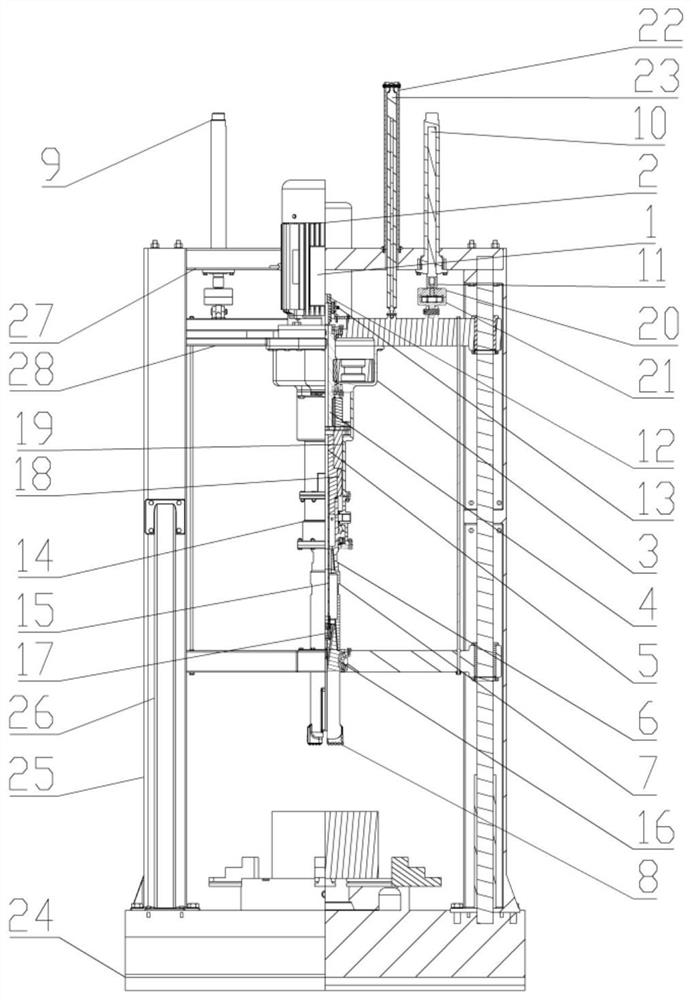

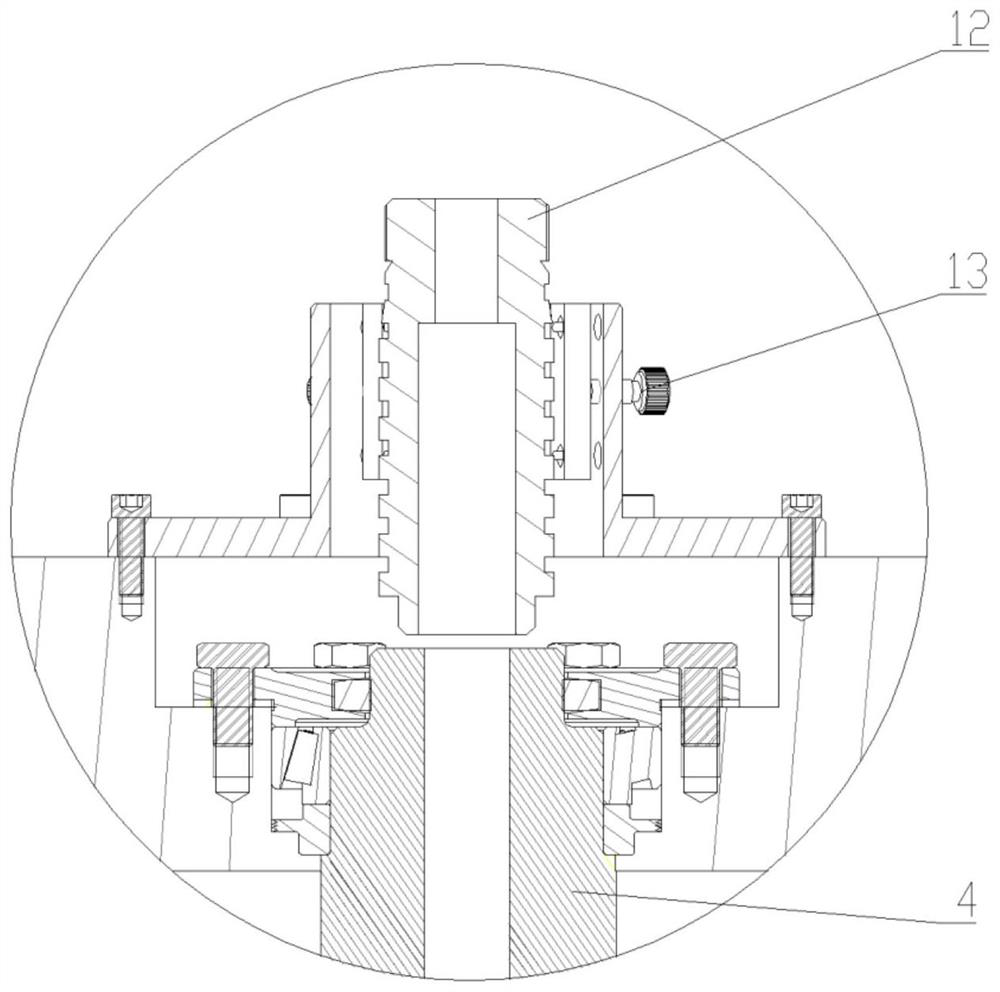

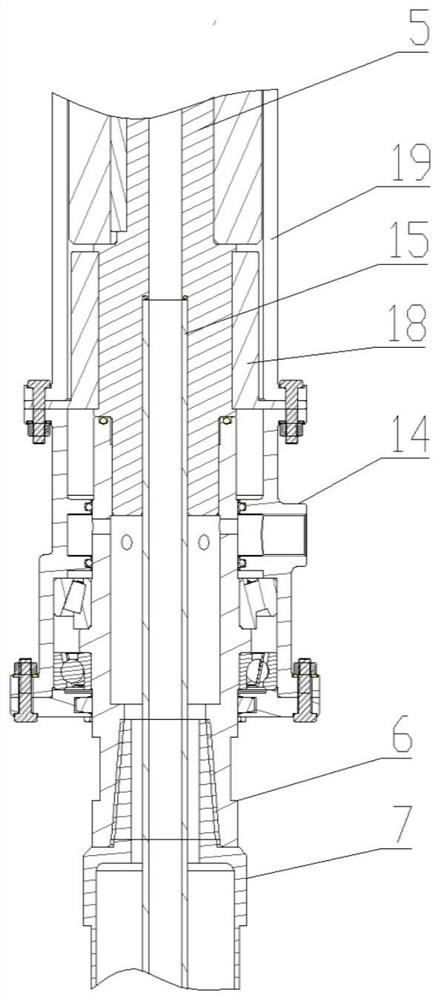

[0021] The structure of the present invention will be further described below with reference to the accompanying drawings and this embodiment.

[0022] like figure 1 As shown in the figure, a laser-mechanical rock breaking test device is mainly composed of a rotating system, a hydraulic control system, an optical circuit and a gas circuit system, a testing and data processing system, and a supporting system: the rotating system is mainly composed of a frequency converter 1, a motor 2, a reducer 3. The output shaft of the reducer 4, the dynamic torque sensor shaft 5, the drill pipe joint 6, the drill pipe 7, and the drill bit 8 are composed of, among which, the motor 2 can realize stepless speed regulation through the frequency converter 1, and the motor 2 is connected vertically by bolts. At the upper end of the main beam 28 , the output shaft of the motor 2 is connected to the reducer 3 , the box of the reducer 3 is fixed to the lower end of the main beam 28 by bolting, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com