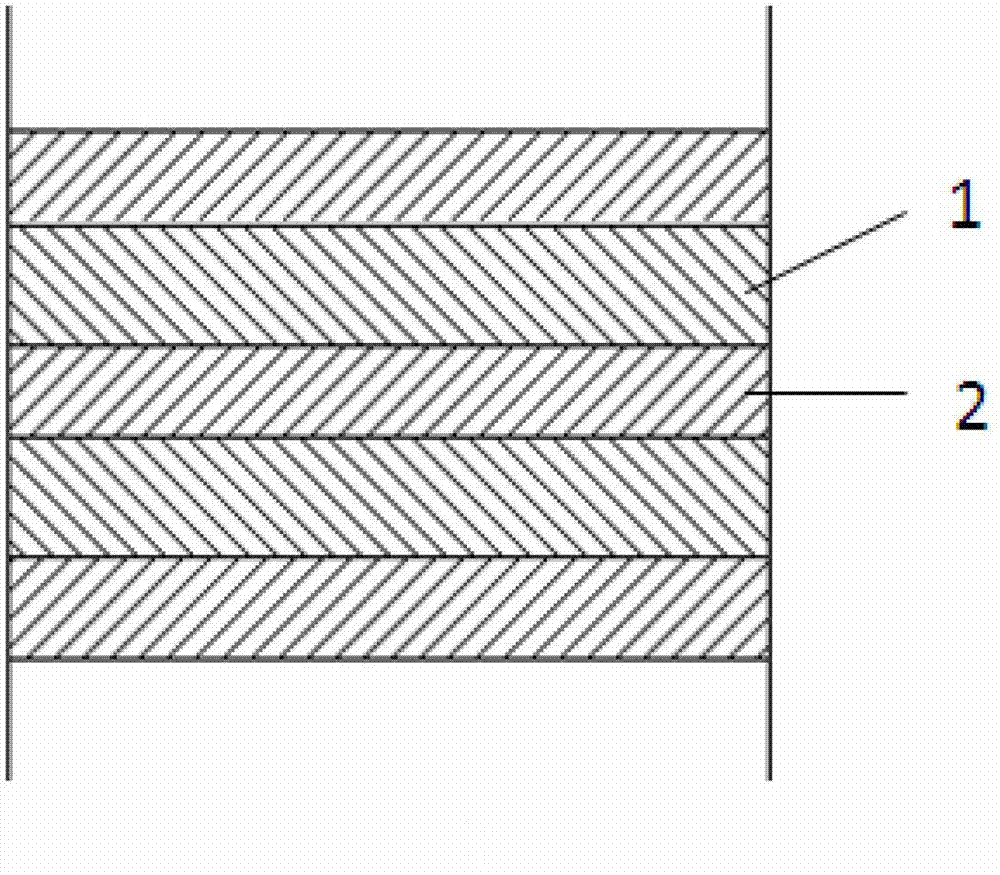

VC/Co toughening coating layer with nanometer multilayer structure and preparation method thereof

A nano-multi-layer and toughening technology, applied in coatings, nanotechnology, nanotechnology, etc., can solve the problems of VC/Co coatings with no nano-multilayer structure and toughened coatings with no toughening effect , to achieve the effect of great application value, easy implementation and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

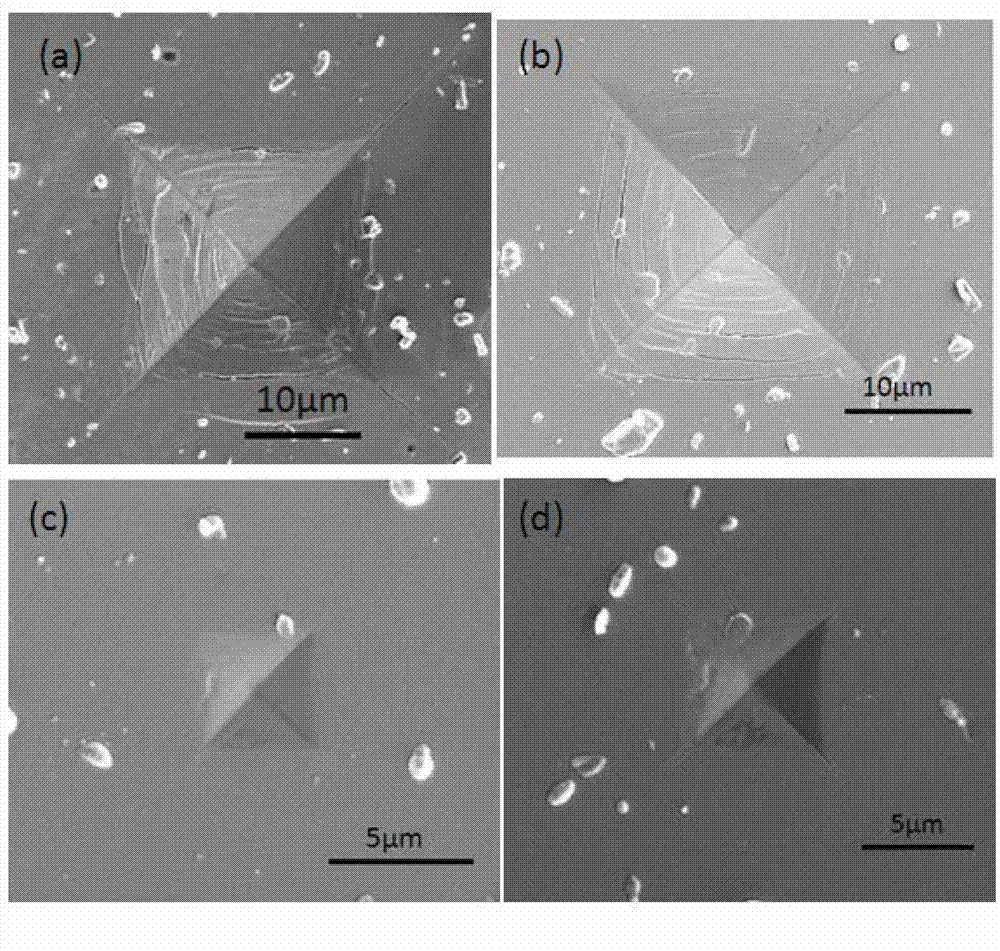

Examples

preparation example Construction

[0030] The preparation method of coating in comparative example and embodiment 1~11:

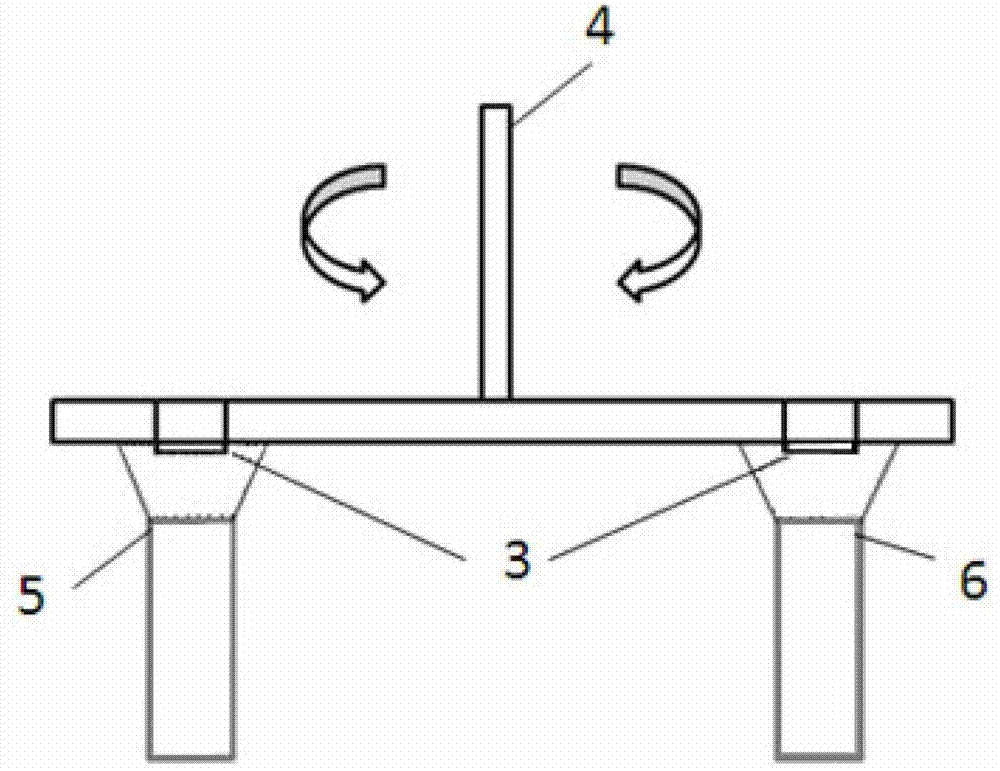

[0031] Firstly, clean the substrate 3 (i.e., the silicon wafer). Put the substrate 3 into the detergent of model HT1401 produced by Borer Company and ultrasonically clean it for 3 minutes at a temperature of 60°C, and then put it into the detergent of model HT1233 produced by Borer Company. Ultrasonic cleaning in detergent at 50°C for 3 minutes, then ultrasonic cleaning in 45°C deionized water for 0.5 minutes, and finally put the cleaned substrate 3 into a vacuum oven at 95°C and bake for 3 minutes. After drying, place on a rotating table in a vacuum chamber.

[0032] Install the VC target 5 and the Co target 6 on the intermediate frequency cathode respectively, evacuate the vacuum chamber, and heat the substrate to the required deposition temperature, when the background pressure of the vacuum chamber (background vacuum) reaches the required pressure When the Ar gas is introduced, the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com