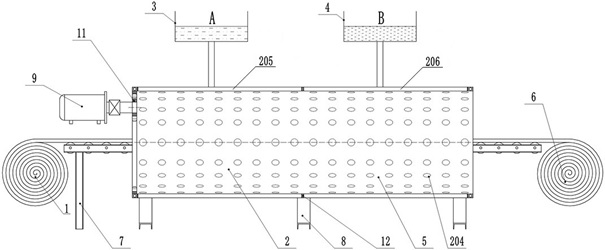

Equipment and method for rapidly preparing gel felt

A gel, fast technology, applied in the direction of textile and paper making, fiber processing, etc., can solve the problem of insufficient and uneven fiber mat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

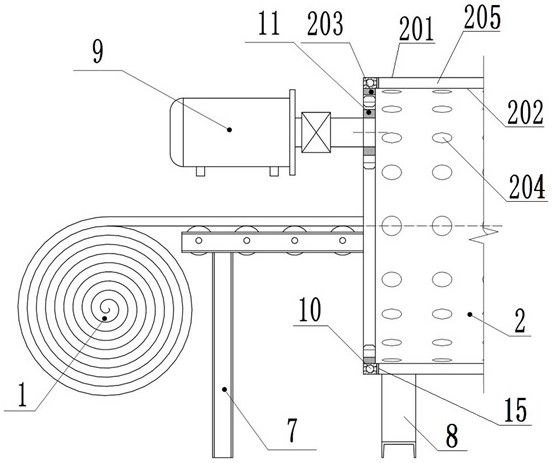

Method used

Image

Examples

Embodiment 5

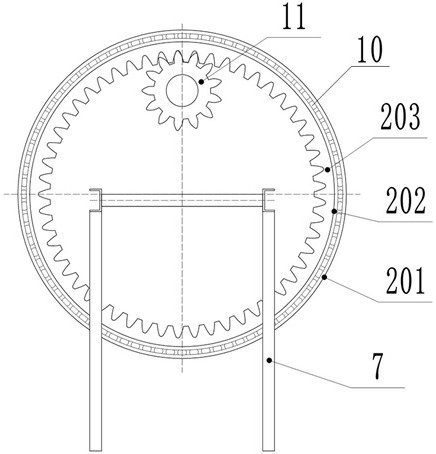

[0060] Embodiment 5 of the equipment for rapidly preparing gel felt in the present invention, the difference between this embodiment and Example 3 is that: the equipment for rapidly preparing gel in Embodiment 5 includes both the first storage tank 3 and the second storage tank 4 The connected second storage tank for storing catalyst has only one inlet and annular chamber on the outer cylinder, the second storage tank is connected with the inlet through a feed pipe, and then feeds catalyst into the annular chamber, and sprays the catalyst into the On the fiber mat impregnated with silica sol, the fiber mat impregnated with silica sol adopts the prior art to combine the fiber mat with silica sol.

[0061] In other embodiments of the equipment for quickly preparing gel mat, the equipment for rapidly preparing gel mat does not include a conveying device, and the fiber mat is maintained horizontally by the tension of unwinding and winding.

[0062] In other embodiments of the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com