A method and device for producing ethylene by hydrogenation of high-concentration acetylene

A technology for acetylene hydrogenation and ethylene production, which is applied in the fields of hydrogenation to hydrocarbon production, chemical methods, chemical instruments and methods for reacting liquid and gas medium, etc. Liveness and other issues, to achieve the effect of sufficient response, sufficient contact, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

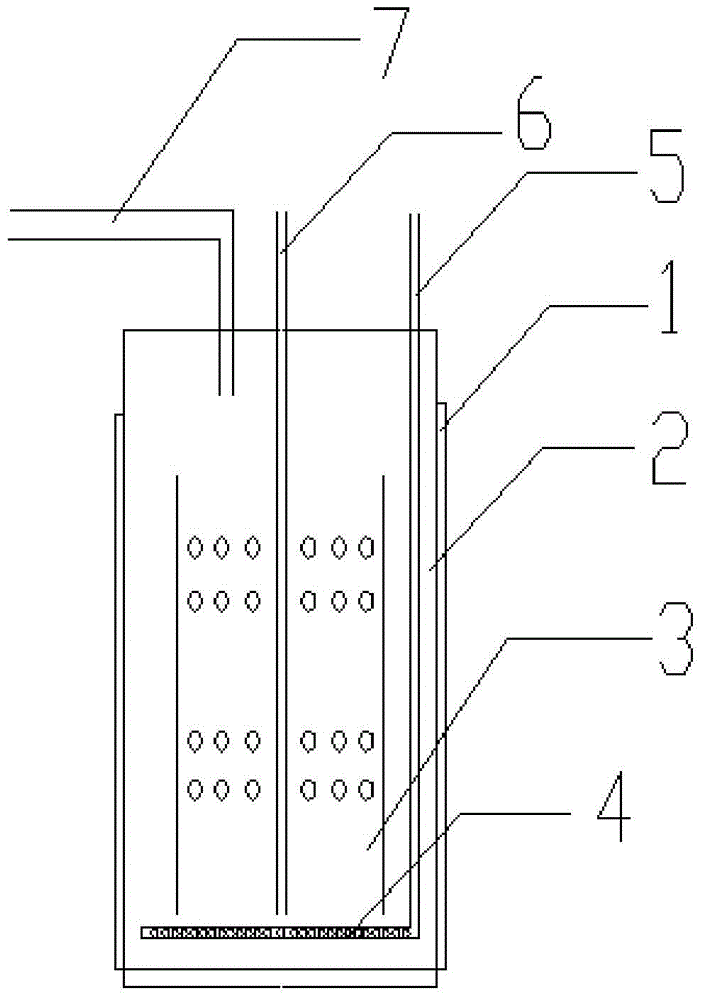

[0037] Acetylene hydrogenation to ethylene plant (such as figure 1 shown), the device includes a reactor outer cylinder 2 and a reactor inner cylinder 3 and an annular distributor 4 located inside the reactor outer cylinder 2; it also includes a heating jacket 1 covering the outer wall of the reactor outer cylinder 2 ;

[0038] The reactor outer cylinder 2 and the reactor inner cylinder 3 are cylindrical; the top and the bottom of the reactor inner cylinder 3 are open structures; the reactor outer cylinder 2, the reactor inner cylinder 3 and the annular Distributor 4 coaxial setting;

[0039] The horizontal cross-sectional diameter of the reactor inner cylinder 3 is 138 mm, the horizontal cross-sectional diameter of the reactor outer cylinder 2 is 200 mm, and the outer ring diameter of the annular distributor 4 is 150 mm;

[0040] The distance between the annular distributor 4 and the reactor inner cylinder 3 is 15mm;

[0041] The distance between the annular distributor 4 an...

Embodiment 2

[0046] The device provided in Example 1 was used to carry out the "gas-liquid" two-phase contact reaction of selective hydrogenation of high-concentration acetylene;

[0047] The method adopts high-purity acetylene and hydrogen as reaction raw materials, acetylene and hydrogen are fed separately, acetylene enters the reactor through the acetylene inlet 6, hydrogen enters the reactor through the hydrogen inlet 5, and the hydrogen and acetylene entering the reactor The ratio of the ratio is 4:1, so that there is a certain density difference between the inner cylinder and the outer cylinder area of the reactor at the bottom of the reactor. The density of the solution in the inner cylinder area is greater than the density of the solution in the outer cylinder area, so the solution of acetylene is dissolved in the inner cylinder. Enter the outer cylinder area from the hole on the inner cylinder wall and the lower part of the reactor to contact with the hydrogen, and react under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com