Methanol reforming gas generator

A generator and methanol technology, applied in the direction of electrochemical generators, hydrogen/synthesis gas production, electrical components, etc., can solve the problems of affecting test and activation results, uneven mixing, high gas temperature, etc., to avoid overheating of power generation High, high stability, simple process effect

Pending Publication Date: 2022-06-17

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing technology includes that the reformer is directly assembled on the test bench to prepare hydrogen-rich mixed gas. The main problem of this technical solution is that the temperature of the gas directly entering the battery reaction is too high, which makes the battery unable to operate stably for a long time. The test data Unreliable; Another solutio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

[0032]实施例1

[0033]采用上述结构,加热棒控制甲醇汽化腔温度为200℃,重整腔温度200℃,通过热电偶反馈控制相应加热棒局部的温度区间至±1℃。60%体积分数甲醇水溶液经过甲醇汽化腔汽化后,经过隔板,流入重整腔,液态甲醇流量10mL / min,出口处气体成分(体积浓度)为75%氢气,1%一氧化碳,24%二氧化碳等,气体流量10L / min。混合气体直接注入高温质子交换膜电堆作为燃料发电。

Example Embodiment

[0034]实施例2

[0035]采用上述结构,与其不同之处内部不设电加热元件;甲醇重整气体发生器置入烘箱中,维持恒定烘箱温度为200℃,烘箱为真空烘箱通过热辐射维持气体发生器温度,或者烘箱为鼓风烘箱通过空气对流维持重整器温度。60%体积分数甲醇水溶液经过甲醇气化腔汽化后,经过隔板,进入重整腔,流量10mL / min,出口处气体成分(体积浓度)为75%氢气,1%一氧化碳,24%二氧化碳等,流量10L / min。混合气体直接注入高温质子交换膜电堆作为燃料发电。

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

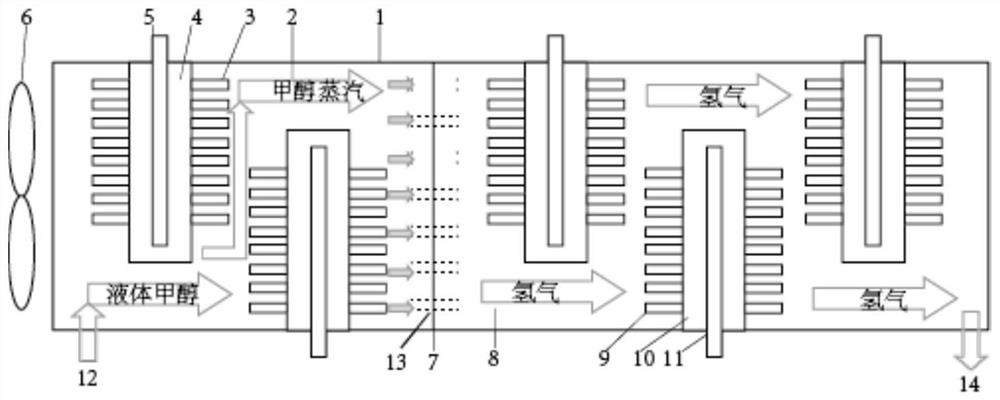

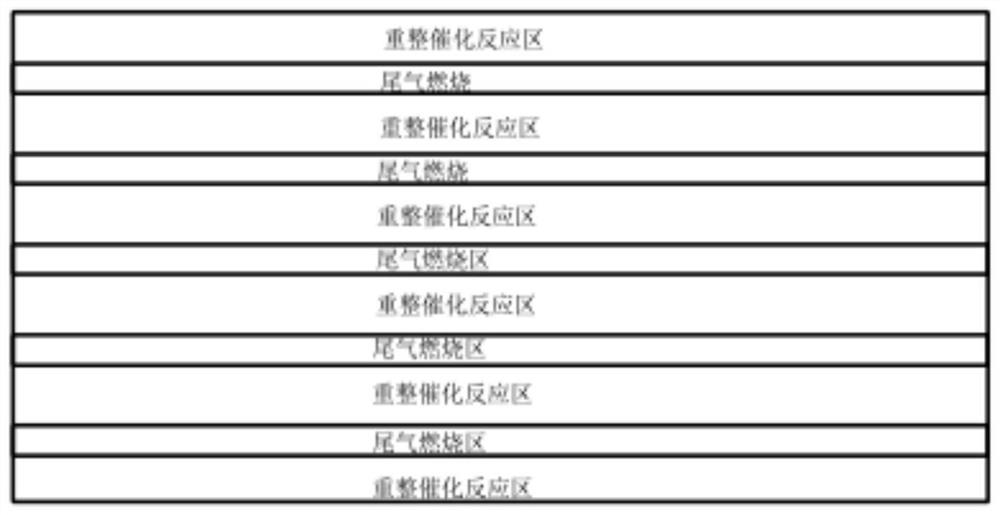

The invention relates to a high-temperature fuel cell, in particular to a methanol reformed gas generator for testing an electric pile of the high-temperature fuel cell. Comprising a hollow closed container, a partition plate is arranged in the container and divides the interior of the container into a left cavity and a right cavity which are not communicated with each other, the left cavity serves as a methanol gasification cavity, the right cavity serves as a methanol reforming cavity, and electric heating elements are arranged in the methanol gasification cavity and the methanol reforming cavity respectively. An electric heating element arranged on the methanol gasification cavity is used for heating the methanol gasification cavity, and an electric heating element arranged on the methanol reforming cavity is used for heating the methanol reforming cavity; a methanol inlet and an oxidant inlet are formed in the wall surface of the methanol gasification cavity, and a methanol reformed gas outlet is formed in the wall surface, far away from the methanol gasification cavity, of the methanol reforming cavity; a through hole is formed in the partition plate between the methanol gasification cavity and the methanol reforming cavity, and a mixed material of methanol and an oxidizing agent in the methanol gasification cavity enters the methanol reforming cavity through the through hole; and the methanol reforming cavity is filled with a methanol reforming catalyst.

Description

technical field [0001] The invention relates to a high-temperature fuel cell, in particular to a methanol reforming gas generator used for high-temperature fuel cell stack testing. Background technique [0002] Due to climate change and the fossil energy crisis, research and development of clean energy will be crucial in the coming decades. As one of the important clean energy sources, fuel cell has received more and more attention. Among them, high-temperature proton exchange membrane fuel cell is an electrochemical reaction device that directly converts the chemical energy of fuel into electrical energy, and has the ability to tolerate CO. Strong, fast electrode reaction rate and simple hydrothermal management advantages. [0003] However, in the research and testing process of high-temperature fuel cells, it is usually necessary to use an anode fuel containing CO or other inert gases for testing. The existing technology includes that the reformer is directly assembled o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B3/40H01M8/0612

CPCC01B3/40H01M8/0618C01B2203/0227C01B2203/066C01B2203/1076C01B2203/1064C01B2203/1223

Inventor 孙海赵世雄孙公权

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com