Single-inlet double-oil-way composite atomizing nozzle

An atomizing nozzle and dual oil circuit technology, applied in combustion methods, lighting and heating equipment, continuous combustion chambers, etc., can solve problems such as increased oil leakage risk, increased assembly difficulty, and deteriorating combustion performance, and increased complexity. , The assembly difficulty is low, the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

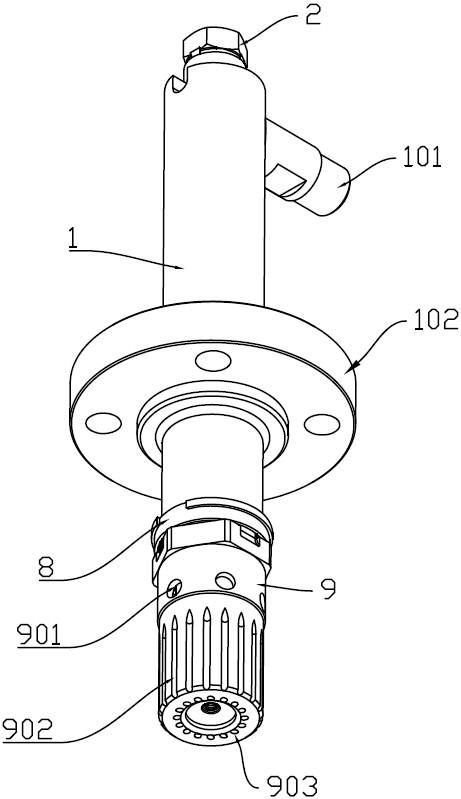

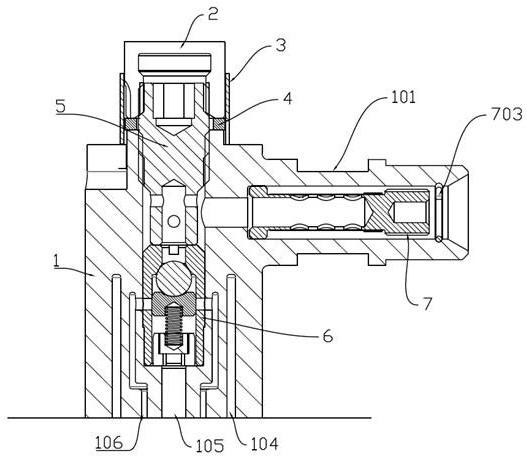

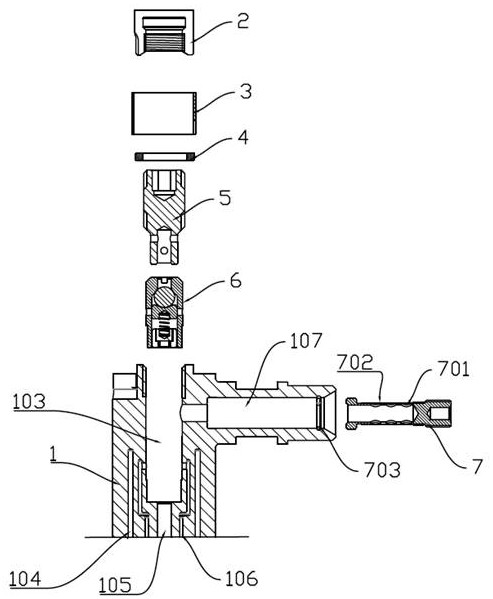

[0033] like Figure 1 to Figure 4 As shown, this embodiment designs a single-inlet dual-oil path compound atomizing nozzle, which is used to simplify the combustion chamber structure and avoid the dual fuel supply required by conventional dual-oil path nozzles under the condition of satisfying more fuel supply. pipeline. At present, with the increase in the power demand of gas turbines, the combustion chamber of the gas turbine often requires a wider flow of fuel injection combustion. In order to meet this requirement, the common idea in the prior art is to use a dual-oil path centrifugal nozzle. This nozzle It not only ensures the atomization quality of small flow, but also meets the requirements of large flow under the limitation of oil supply pressure; however, conventional dual oil circuit nozzles often use dual oil supply pipelines to supply oil to the two oil circuits in the nozzle respectively. , the dual oil supply channels will occupy more space, limit the installati...

Embodiment 2

[0041] like Figure 1 to Figure 4 As shown, on the basis of the structure of the first embodiment, in order to reduce the solid particle impurities in the fuel oil in the oil supply channel from entering the atomizing nozzle, the oil filter 7 is provided in the oil inlet nozzle 101 in this embodiment.

[0042] like figure 2 , image 3 As shown in the figure, the oil inlet nozzle 101 is vertically connected to the side wall of the oil inlet end of the nozzle rod body 1. The oil inlet nozzle 101 has a filter cavity 107, and an oil filter 7 is installed in the filter cavity 107. The oil filter 7 includes a pipe sleeve shape and one end of which is blocked. The pipe wall of the oil filter 7 is provided with an oil inlet hole 701 and a filter screen 702. The fuel can enter from the outside of the oil filter 7 through the oil inlet hole 701. inside, and in the process achieves fuel filtration.

[0043] A collar 703 for preventing the oil filter 7 from sliding out is provided at ...

Embodiment 3

[0045] like figure 1 and Figure 5-Figure 8 As shown, this embodiment designs a single-inlet dual-oil path composite atomizing nozzle, which is used to improve the atomization quality and particle size distribution of the nozzle and achieve the thermal protection requirements of the nozzle. At present, in order to improve the performance of the gas turbine, the boosting ratio of the compressor is often increased, which indirectly increases the inlet temperature of the combustion chamber. When the nozzle is in a high-temperature working environment for a long time, coking and carbon deposition are prone to occur, which deteriorates the combustion performance. Increased risk of component damage. In addition, in order to further improve the performance of the combustion chamber, it is necessary to ensure a reasonable air flow structure and good atomization in the combustion chamber, as well as proper oil and gas matching, especially when the fuel with higher viscosity is used. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com