Storage type precision quantitative oil and gas well downhole working agent injection system and injection method

A technology of injection system and working agent, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of large amount of glue used, affecting the working efficiency of working fluid, and the decline of adhesive performance, etc., to achieve Excellent injection accuracy and position accuracy, simple and efficient operation method, easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

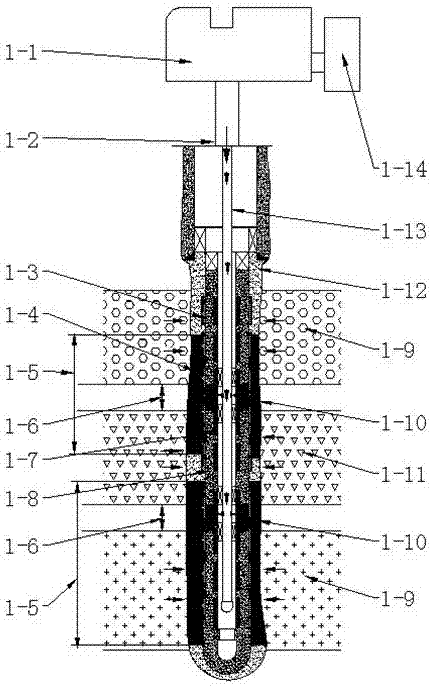

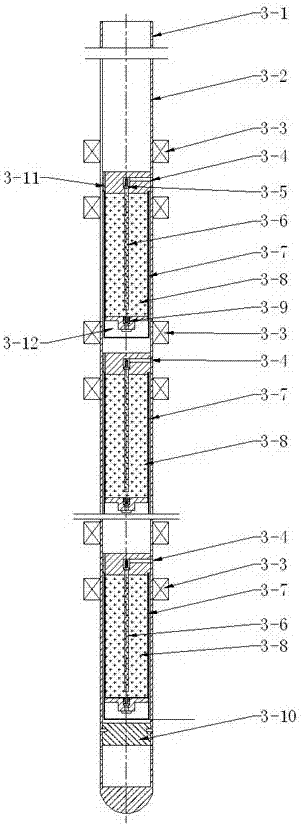

[0079] This embodiment is a storage type precision quantitative oil and gas well downhole working agent injection system, such as image 3 Shown is the working agent injection system of the capsule storage of three groups of injection units, 3-1 is the feeding pipe; 3-2 is the injection pipe; 3-3 is the packer; 3-4 is the discharge port; 3- 5 is a constant pressure valve; 3-6 is a catheter; 3-7 is a working agent storage; 3-8 is a working agent; 3-9 is an injection port; 3-10 is an oil drain; 3-11 is a pressure transmission hole ; 3-12 protective sleeves. The injection system includes an injection pipe and a ground pressurization device, and three groups of injection units are arranged in the injection pipe; each group of injection units includes a variable-volume working agent storage, and the working agent outlet connected to the outside of the injection pipe is arranged on the injection pipe. The discharge port is connected with the working agent storage; the ground pressu...

Embodiment 2

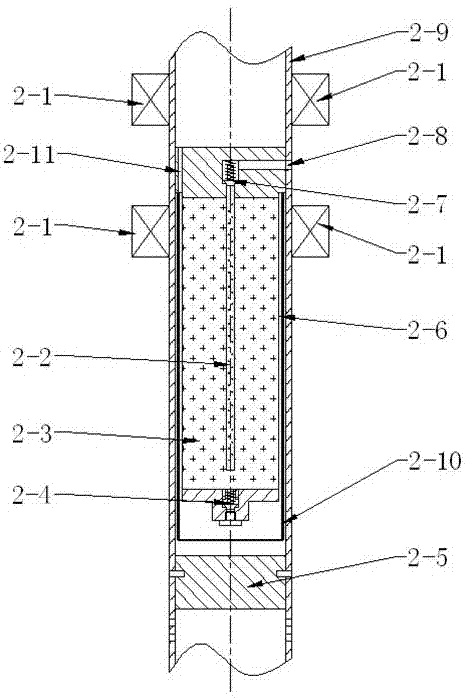

[0083] This embodiment is a storage type precision quantitative oil and gas well downhole working agent injection system, such as Figure 5 The working agent injection system of cylinder liner and piston reservoir of a group of injection units is shown, 5-1 is the drainer; 5-2 is the positioning device; 5-3 is the feeding pipe; 5-4 is the packer ; 5-5 is the discharge port; 5-6 is the constant pressure valve; 5-7 is the cylinder liner; 5-8 is the working agent; 5-9 is the piston; 5-10 is the one-way valve; Screw; 5-12 is an injection pipe; 5-13 is a pressure transmission hole. The injection system includes an injection pipe and a ground pressurization device, and a group of injection units is arranged in the injection pipe; each group of injection units includes a variable-volume working agent storage, and the working agent discharged from the injection pipe communicates with the outside of the injection pipe. The discharge port is connected with the working agent storage; th...

Embodiment 3

[0086] An injection method using a storage-type precision quantitative downhole working agent injection system for oil and gas wells. The injection method is to inject the working agent into a variable-volume working agent storage on the surface in advance, and lower the injection pipe to the target position in the downhole; The pressurizing device generates a pressure in the injection pipe that acts on the variable-volume working agent reservoir and is higher than the pressure outside the injection pipe. The volume of the variable-volume working agent reservoir decreases, and the working agent flows out to the outside of the injection pipe through the outlet. annulus.

[0087] This embodiment 3 uses the working agent injection system of the capsule storage of the three groups of injection units described in embodiment 1 to carry out the injection operation. This embodiment is carried out in the oil recovery horizontal well of the bottom water reservoir, in order to prevent the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com