Multi-material gradient mixed liquid drop formation device based on micro-fluidic chip

A microfluidic chip and mixed liquid technology, applied in the field of chemical analysis, can solve the problems of high complexity and instrument cost, complex channel design of the chip, fluid-driven turbulent flow and reverse flow, etc., to achieve system simplification, avoid premixing, The effect of tackling waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

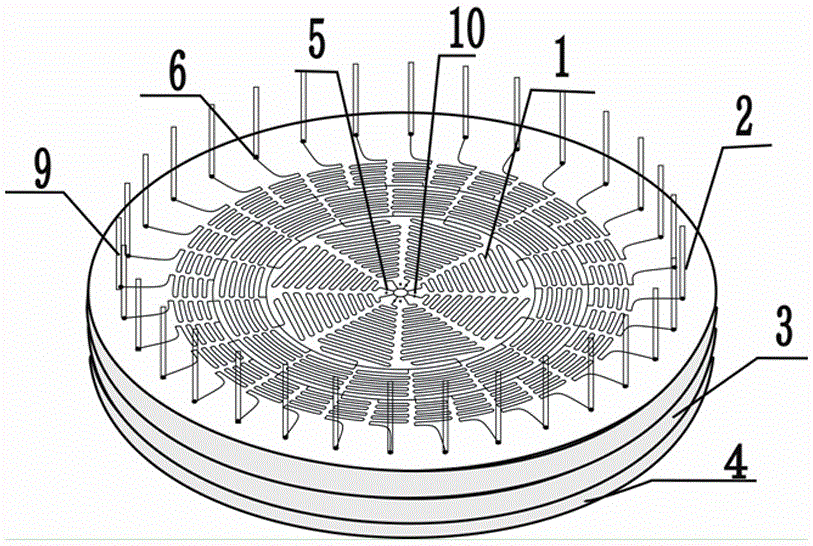

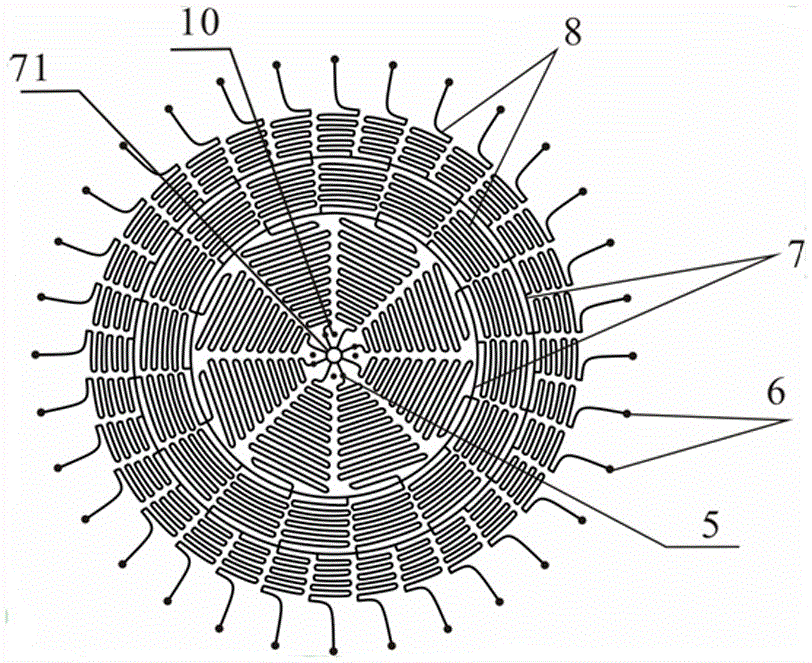

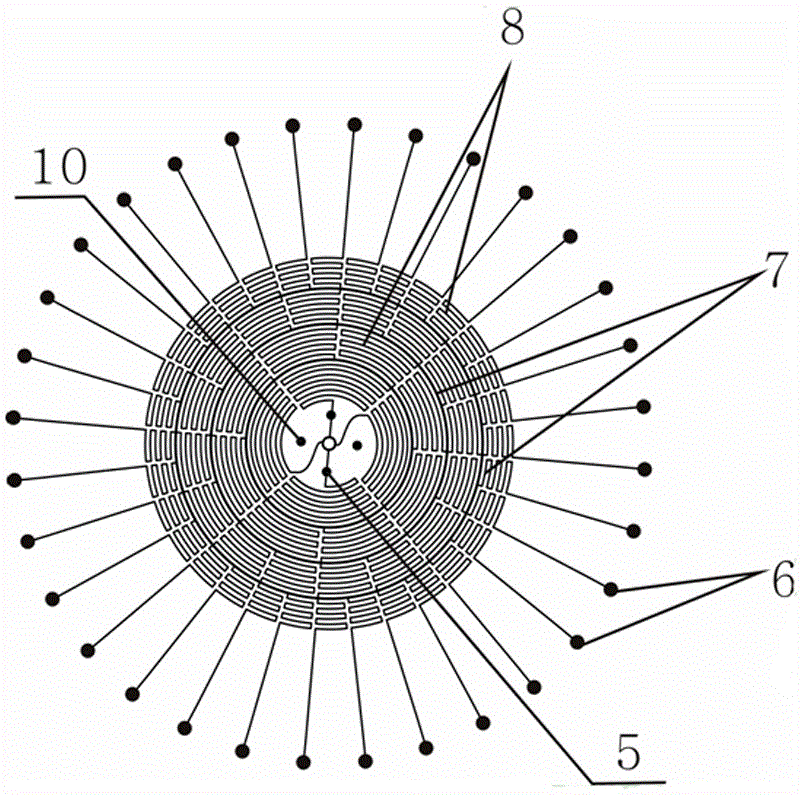

[0040] A microfluidic chip-based multi-substance gradient mixed droplet forming device, its structure is as follows figure 1 As shown, it includes the upper microfluidic chip 2, the middle microfluidic chip 3 and the lower flat plate chip 4, and the material of each chip is polydimethylsiloxane, wherein the upper microfluidic chip 2 and the middle microfluidic chip 3 are respectively provided with 4 solution inlets, 3 concentric circular channels and 3 groups of radial branch channels, and solution outlets; the upper microfluidic chip 2 is also provided with the middle microfluidic chip The solution inlets are connected and correspond to the four through holes 10 one by one, and the four solution inlets 5 and the four through holes 10 of the upper microfluidic chip are all located in the first concentric circular channel 71 at the center of the chip and the first group of radial branch passages, and each along the first concentric circular passage 71 is center-symmetrically di...

Embodiment 2

[0053] The multi-substance gradient mixed droplet forming device based on the microfluidic chip of this embodiment is the same as that of Embodiment 1, the difference is that the number of solution inlets on the upper microfluidic chip and the middle microfluidic chip are 2 respectively, and the upper microfluidic chip The number of through holes in the control chip is 2, the number of concentric circular channels and radial branch channels on the two-layer microfluidic chip is 4; the number of independent branch channels in the first group of radial branch channels is 4, and the number of There are 8 in the second group, 16 in the third group, and 32 in the fourth group; the radii of the 4 concentric circular channels arranged in sequence from the direction of the center to the outside are: 0.4 mm, 4.0mm, 6 mm, 8.0 mm; the lengths of independent branch channels in the first group to the fourth group of radial branch channels were 40 mm, 25 mm, 14 mm, and 8 mm, respectively. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com