Method To Improve The Efficiency Of Removal Of Liquid Water From Solid Bulk Fuel Materials

a fuel material and liquid water technology, applied in the direction of drying machines with progressive movements, furnaces, granular material drying, etc., can solve the problems of inability to meet the needs of industrial production, etc., to achieve the effect of improving the efficiency of thermal drying methods, reducing time and energy, and increasing efficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

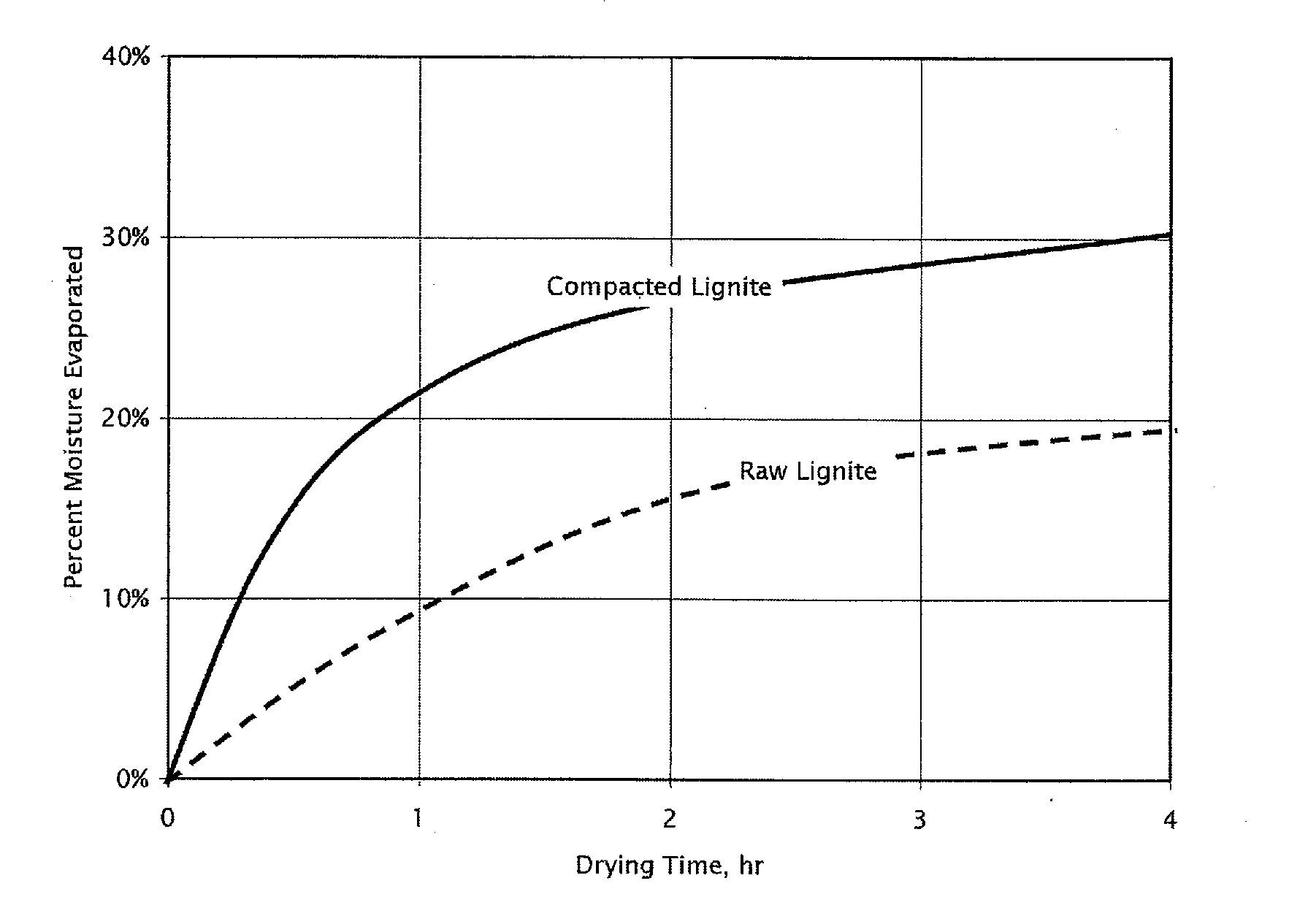

[0066]A detailed study of lignite (high-moisture lignite from North Dakota) was undertaken to assess the relative drying rates of raw material and compacted product. Experiments were conducted on materials spread out on a flat tarpaulin at ambient conditions. Samples of raw lignite and compacted lignite were taken periodically from the spread out material and assayed for total moisture. The measured moisture values were normalized as percent of the total water evaporated to compare the results on an equal basis. Drying conditions were 31° C., and 23% relative humidity. Results are plotted in FIG. 5.

[0067]These results demonstrate the increased drying rates possible by compacting the raw lignite. Table 1 summarizes the ratio of drying rates between raw and compacted lignite processed at ambient conditions of 31° C., 23% relative humidity.

TABLE 1Ratio of Relative Drying Rates for North Dakota Lignite% MoistureDryingRemovedTime, hrRawCompactedRatio0.54164.01.09222.41.513262.02.016281.8...

example 2

[0068]A detailed study of one LRC (high-moisture lignite from South East Asia) was undertaken to assess the relative drying rates of raw material and compacted product processed by an indirect rotary dryer (180 mm diameter×3000 mm long). The heated portion of the drying tube was 2000 mm long, the cooling zone was 600 mm long, and the feed zone was 400 mm long. Test conditions were identical for the compacted and raw materials. The results are summarized in Table 2.

TABLE 2Rotary Indirect Dryer Test ResultsCompactedRawTest ParameterMaterialMaterialFeed moisture, wt %4546Product moisture, wt %1638Residence time, min2020Sweep gas temperature, at130130feed point, ° C.Shell temperature, ° C.Less than 110Less than 110Maximum materialLess than 100Less than 100temperature, ° C.Sweep gas flow rate, L / min700700Material feed rate, kg / min1010

[0069]These data show the compacted material dries to a lower moisture content that is about half that of the raw material under identical drying conditions...

example 3

[0070]An experiment was conducted to measure the relative drying rates of South East Asia lignite held under warm, moist conditions that would be expected in a covered stockpile located in non-condensing, warm, humid tropical climates. Table 3 lists results.

TABLE 3Moisture Content of Lignite Stored in Warm, Humid Atmosphere30° C., >60% Relative HumidityRaw LigniteCompactedMoisture,Lignite Moisture,Time, hrswt %wt %04043483637

[0071]These test data show that the compacted material lost 50% more moisture than the raw material in 48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com