Desulfurization and dedusting absorption tower with porous current equalizer

A technology of desulfurization and dust removal, flow equalizer, applied in chemical instruments and methods, use of liquid separation agent, gas treatment, etc., can solve the problems of increasing investment cost, increasing equipment footprint, reducing feasibility, etc., to improve utilization Rate, lower liquid-gas ratio, lower flow and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

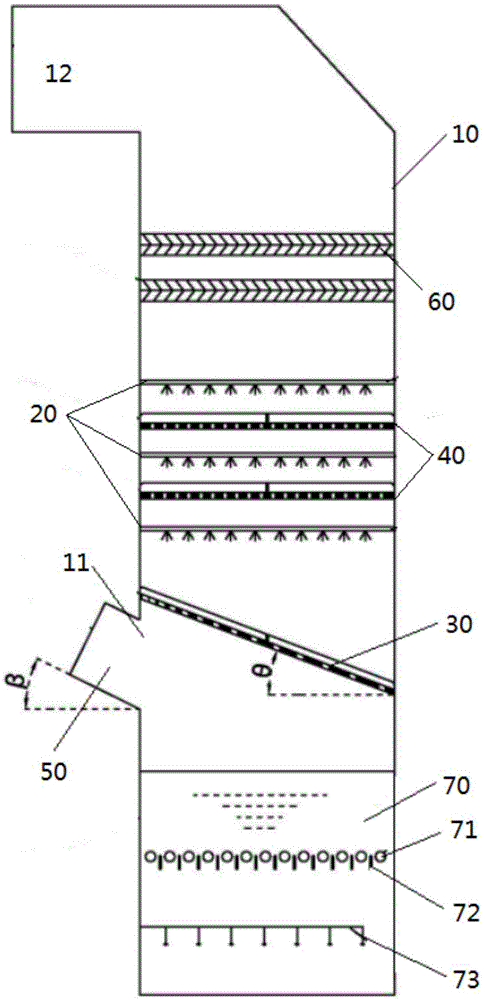

Embodiment 1

[0035] The first embodiment discloses a desulfurization and dust removal absorption tower provided with a porous homogenizer, comprising: a tower body, the tower body has a flue gas inlet and a flue gas outlet, the flue gas inlet is located at the lower part of the tower body, and the flue gas outlet is located on the tower body At least one sprayer, arranged in the tower body, between the flue gas inlet and the flue gas outlet of the tower body, for spraying the slurry; and at least one porous homogenizer, which is arranged in the tower body , Located above the flue gas inlet and below the sprinkler, the porous equalizer includes a porous equalizer plate. The porous equalizer plate is provided with a plurality of airflow holes for the flue gas and slurry to pass through. The upper surface of the flow plate receives the slurry sprayed by the sprayer and forms a liquid holding layer. When the flue gas passes through the liquid holding layer, "bubbling" occurs, thereby effectively...

Embodiment 2

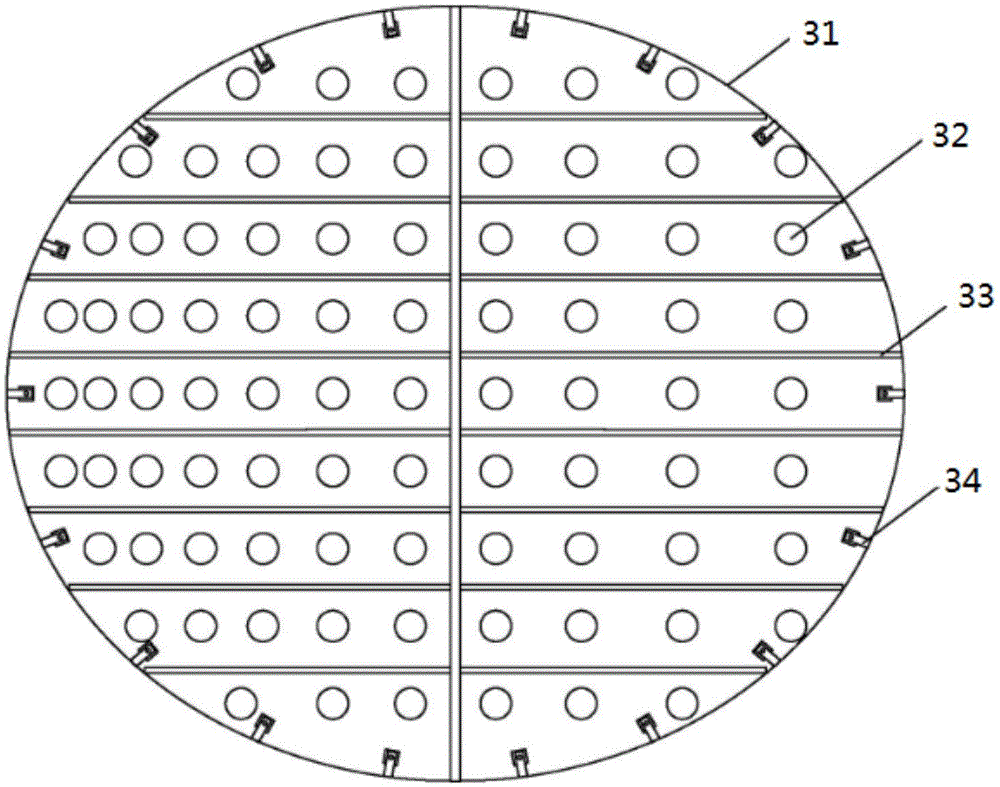

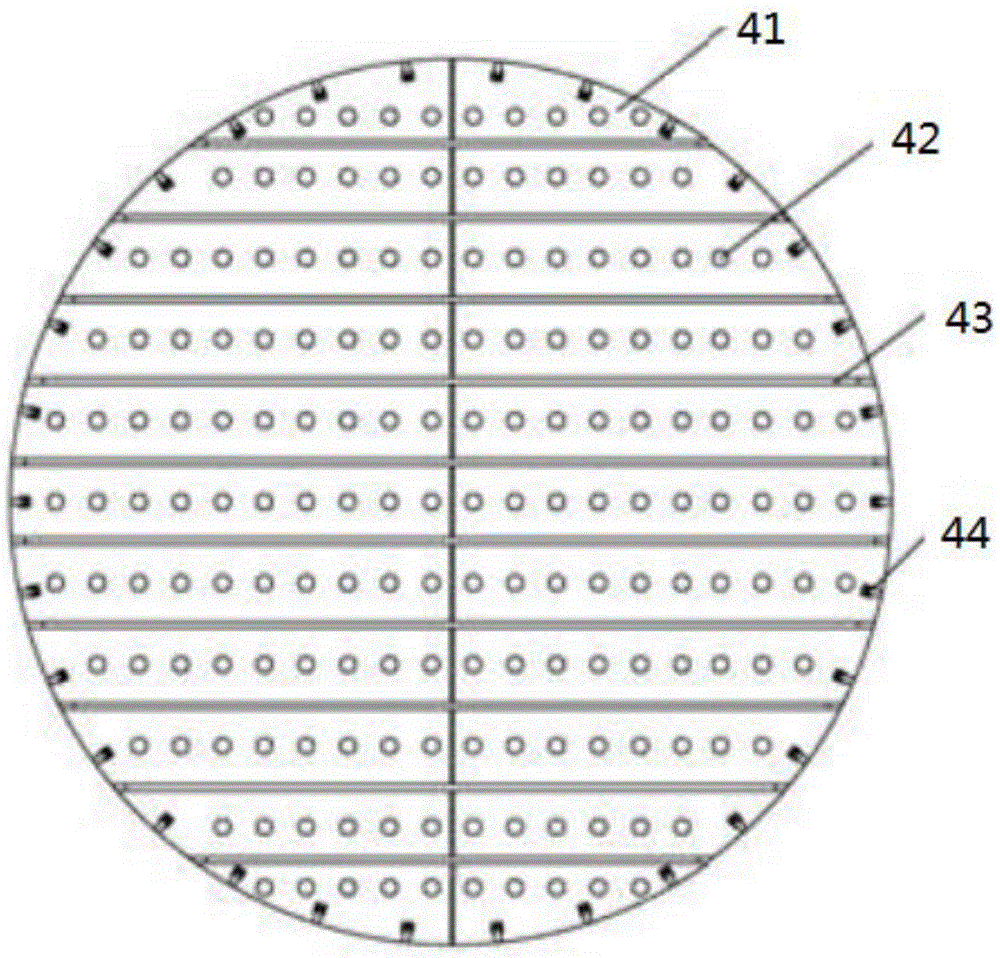

[0037] Compared with the first embodiment, the improvement of the second embodiment is that in the desulfurization and dust removal absorption tower with porous homogenizer in the second embodiment, the number of sprayers and porous homogenizers are both multiple, and the number of spray The shower and the porous homogenizer are arranged at intervals, and a porous homogenizer is correspondingly arranged under each shower. In this embodiment, the shower includes a plurality of nozzles, and the plurality of nozzles are evenly distributed above the porous homogenizer.

[0038] In this embodiment, each sprayer only sprays the slurry on the porous homogenizer located below it, so that a liquid holding layer is formed on the porous homogenizer of each layer of the porous homogenizer, and the flue gas is in the tower. The body passes through a multi-layer porous homogenizer to make the flue gas evenly distributed in the body, and then passes through the multi-layer liquid holding layer,...

Embodiment 3

[0040] Compared with the first embodiment, the improvement of the third embodiment is that, in the desulfurization and dust removal absorption tower provided with a porous homogenizer in the third embodiment, the porous equalizer closest to the flue gas inlet of the tower body The device is a first multi-hole current equalizer, the first multi-hole current equalizer includes a first multi-hole current equalizer, the first multi-hole current equalizer is obliquely arranged in the tower body, which is close to the side of the flue gas inlet It is higher than the side away from the flue gas inlet of the tower.

[0041] In this embodiment, the inclination angle of the first porous flow sharing plate in the tower body is 15°-25°; the first porous flow sharing plate is an elliptical plate, and the side wall of the elliptical plate is connected to the inner wall of the tower body. Laminated; the first porous flow-sharing plate is provided with a plurality of first airflow holes, the por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com