Multi-stage spray venturi desulfurization and dust removal apparatus and method thereof

A desulfurization and dust removal and Venturi technology is applied in the field of desulfurization and dust removal integrated devices, which can solve the problems of insufficient mass transfer, high power consumption, and high flue gas resistance, and achieve high desulfurization and dust removal efficiency, small footprint, and flue gas passage. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

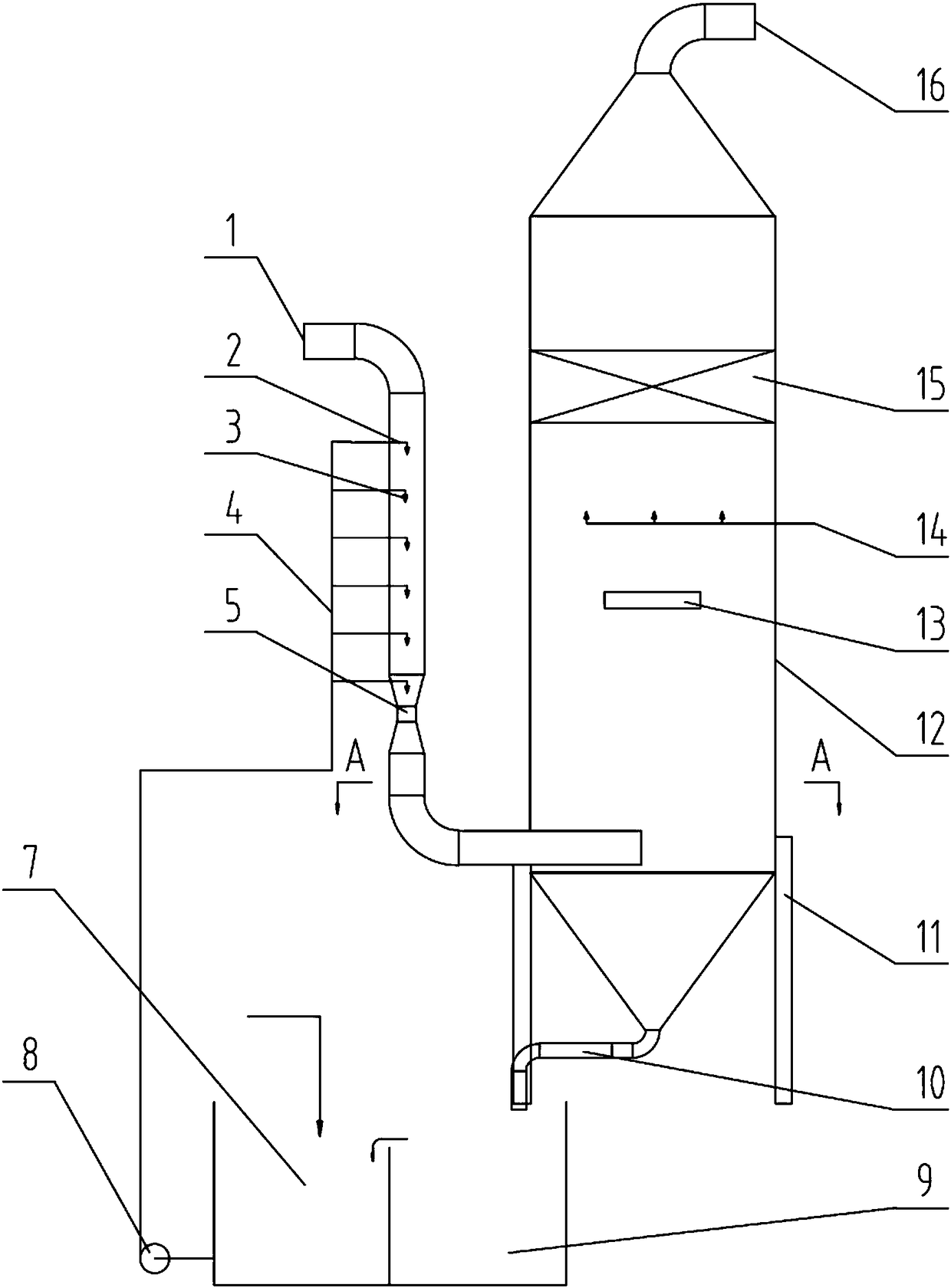

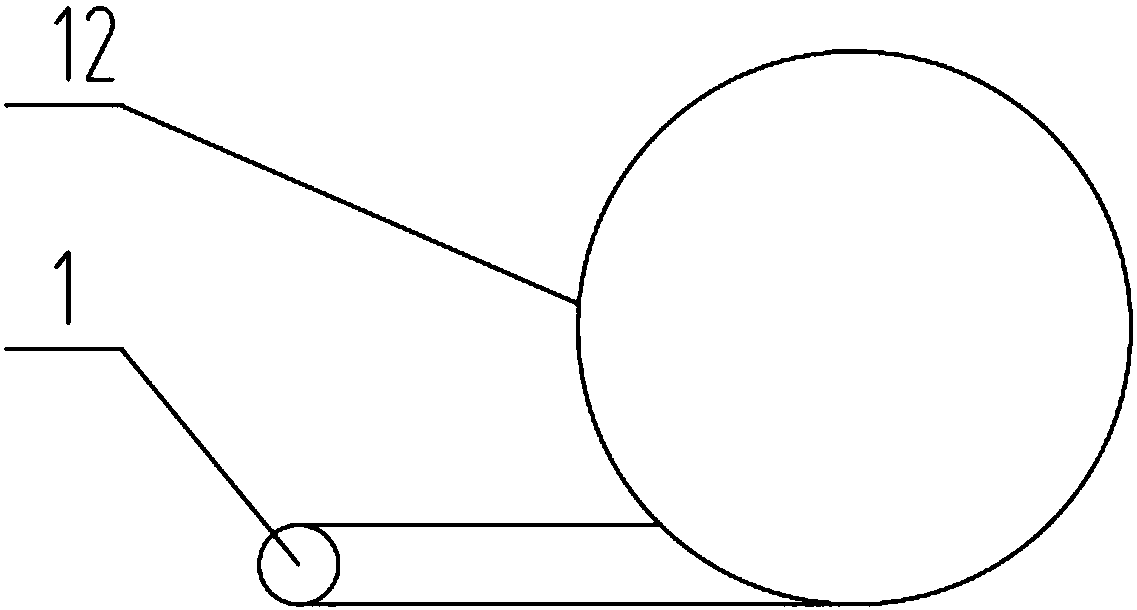

[0030] like figure 1 Shown is an off-line spray Venturi desulfurization and dust removal device according to an embodiment of the present invention, comprising a flue gas pipe 1 connected to both ends of the Venturi pipe 5, a desulfurization agent delivery pipe 4, a desulfurization and dust removal tower 12 and a sedimentation tank 9, The top of the desulfurization and dust removal tower 12 is provided with a clean flue gas outlet 14, and the bottom of the desulfurization and dust removal tower 12 is provided with a liquid outlet pipe 10 and a support 11; image 3 As shown, the flue gas pipe 1 is tangentially connected to the bottom of the desulfurization and dust removal tower 12, and the flue gas pipe 1 connected to the inlet section of the Venturi pipe 5 is provided with multi-layered spray baffles 2. The bottom end of the spray baffle 2 is provided with an atomizing nozzle 3, and the inlet end of the spray baffle 2 is connected to the desulfurizing agent delivery pipe 4; t...

Embodiment 2

[0033] According to the size, treatment effect and investment cost requirements of different desulfurization and dust removal equipment, the ultrasonic device 13 can be omitted on the basis of Embodiment 1.

Embodiment 3

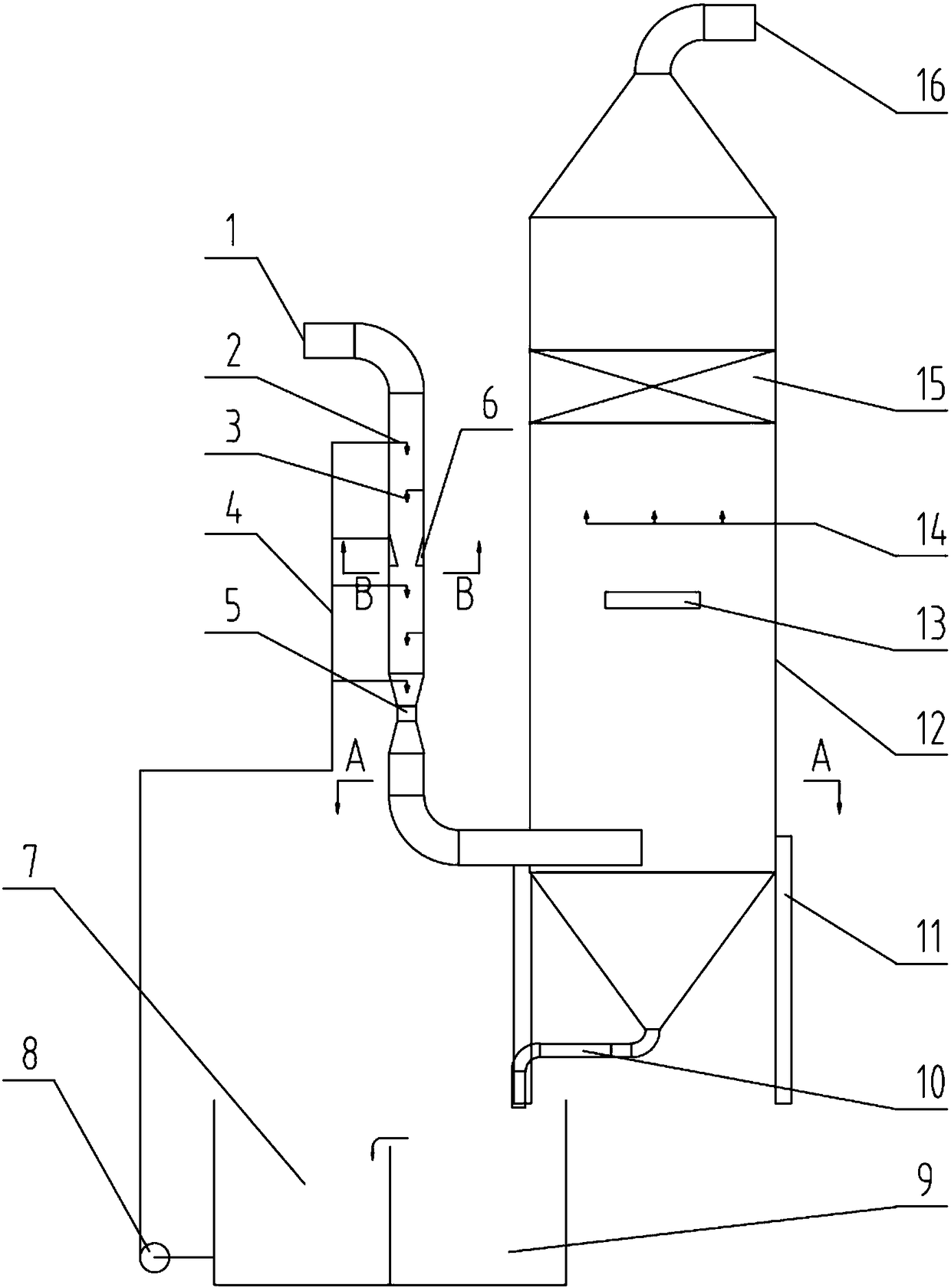

[0035] like figure 2 As shown, the difference from Embodiment 1 is that the spray baffles 2 and their adjacent spray baffles 2 are alternately arranged in the flue gas pipe 1 . like Figure 4As shown, the middle section of the flue gas pipe 1 connected to the inlet section of the Venturi tube 5 is also provided with an annular injection part 6 , and a plurality of atomizing nozzles 3 are evenly distributed in a circular shape at the bottom of the annular injection part 6 . The diameter of the outlet of the annular injection part 6 is smaller than the diameter of the inlet, and the diameter of the outlet is 0.6-0.8 times the inner diameter of the flue gas pipe 1 . The design of the large inlet and small outlet makes the middle section of the flue gas pipe 1 form a constriction port similar to a Venturi tube, forming the first-stage airflow change section, and the subsequent Venturi tube 5 forms the second-stage airflow change section, and the multi-stage airflow changes. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com