S-shaped strip-shaped bubble cap desulfurization tower tray device with gradually changed height

A technology for desulfurization towers and trays, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve problems such as solid deposition, desulfurization and dust removal efficiency, and slurry overflow in the middle tray, and achieve good phase change condensation. The removal effect, uniform gas-liquid mixing, and the effect of reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

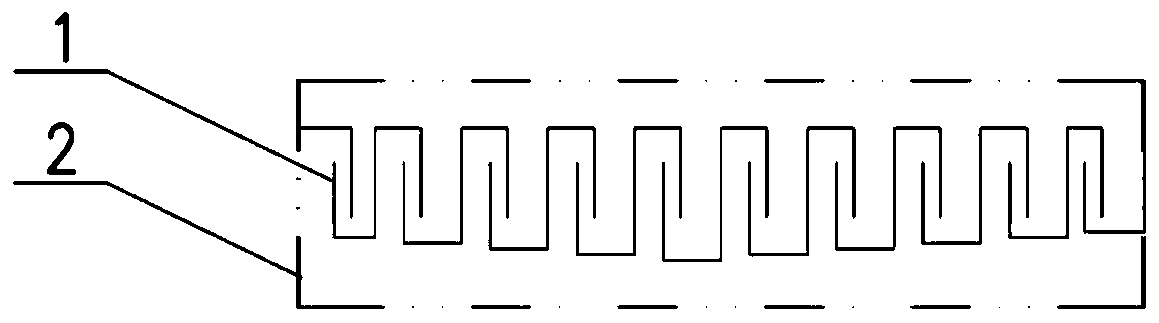

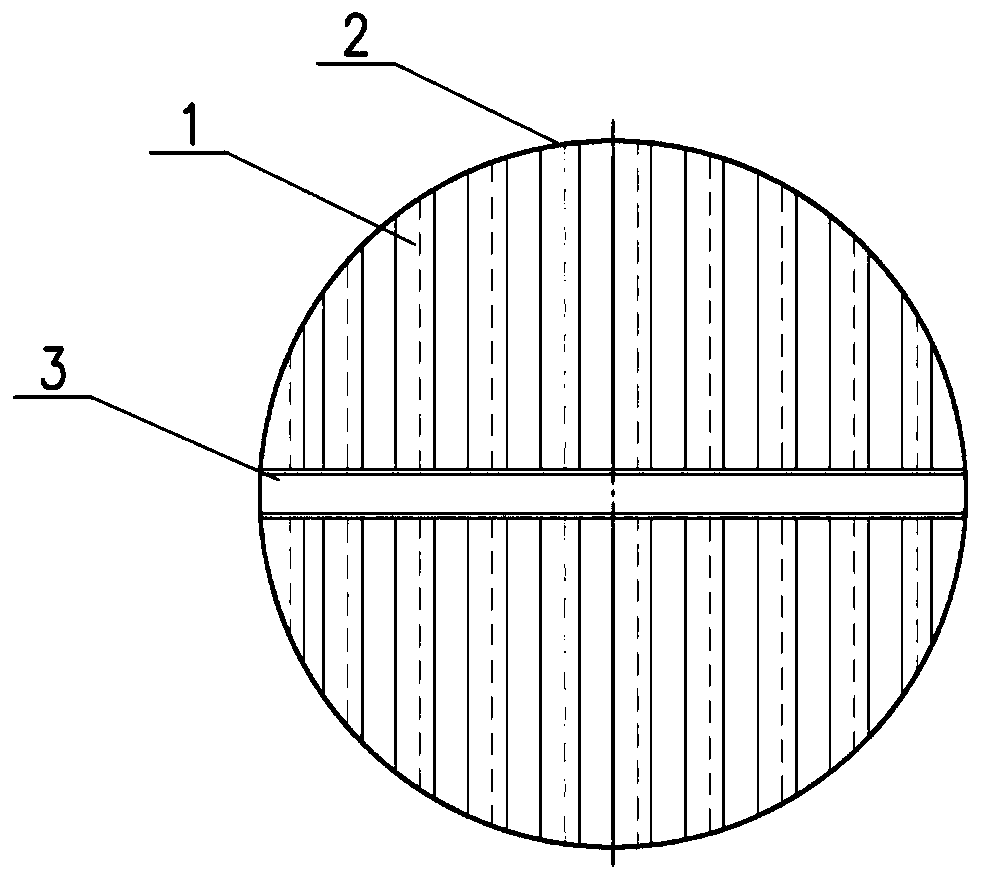

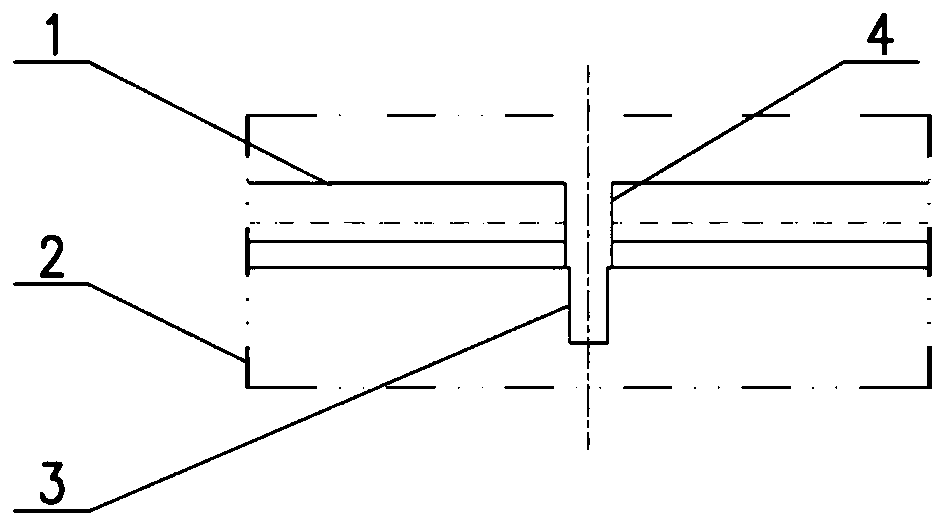

[0021] Such as Figure 1~3 The shown one kind of S-shaped strip bubble cap desulfurization tray device with gradual change in height includes at least one U-shaped support and a tray 1, the U-shaped support is fixedly installed in the absorption tower 2, and the U-shaped support Part 3 is provided with a U-shaped groove, and the U-shaped groove is provided with an outlet for communicating with the slurry outflow pipeline; the tray 1 is vertically installed above the U-shaped support member 3, and the tray 1 is formed by a plurality of sections in a transverse direction. S-shaped strip plates 8 are arranged side by side, and the S-shaped ends between adjacent plates are interlaced and arranged at intervals. Air inlet, the upward opening of the strip-shaped plate body 8 constitutes the smoke o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com