Comprehensive treatment method of sulfur-containing flue gas

A comprehensive treatment and flue gas technology, applied in the chemical industry, can solve the problems of difficult to achieve zero emission of sulfur dioxide, difficulty in desulfurization efficiency close to 100%, high operating cost, achieve high desulfurization and dust removal efficiency, ensure long-term stable operation, and reduce investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

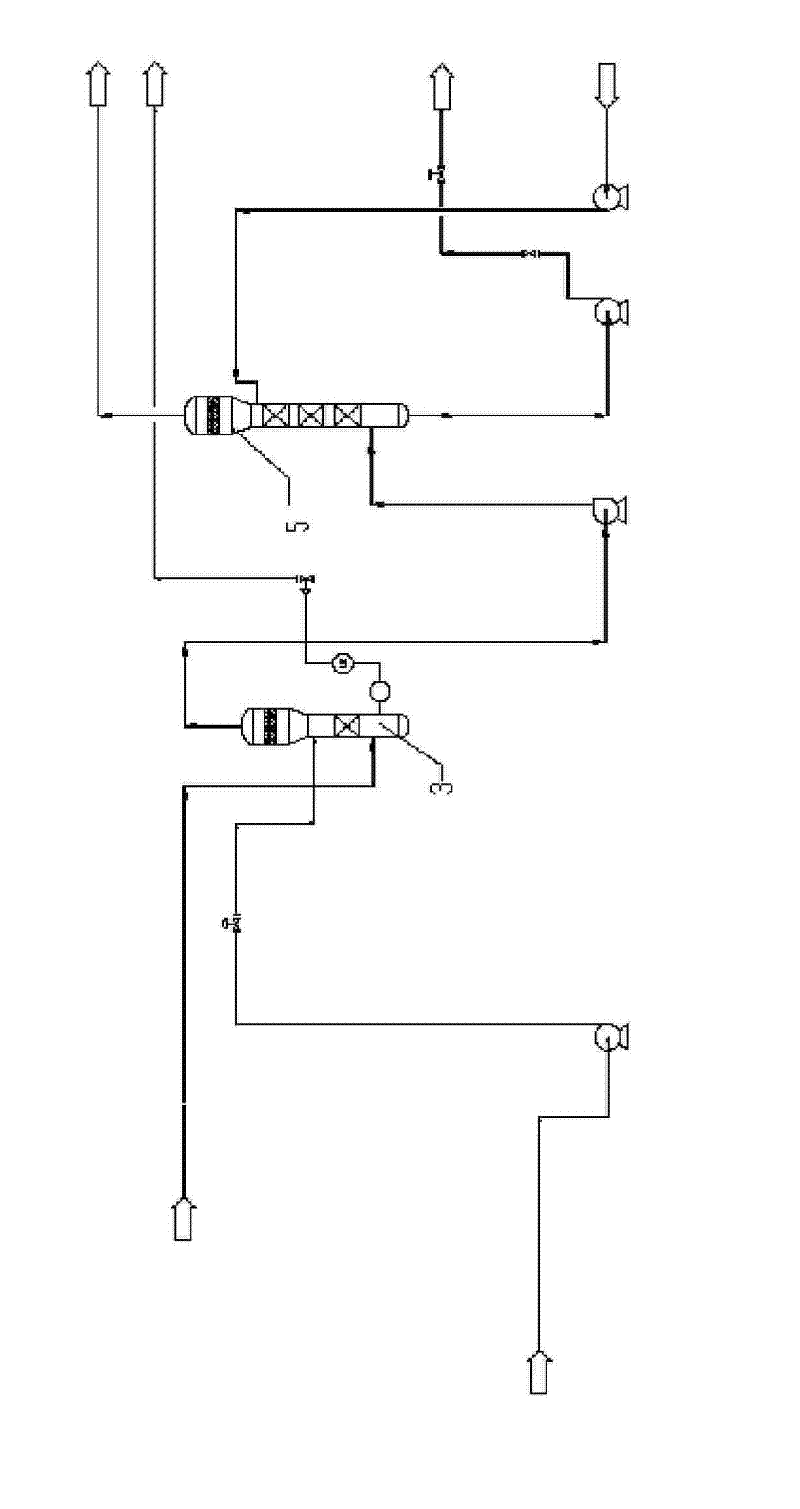

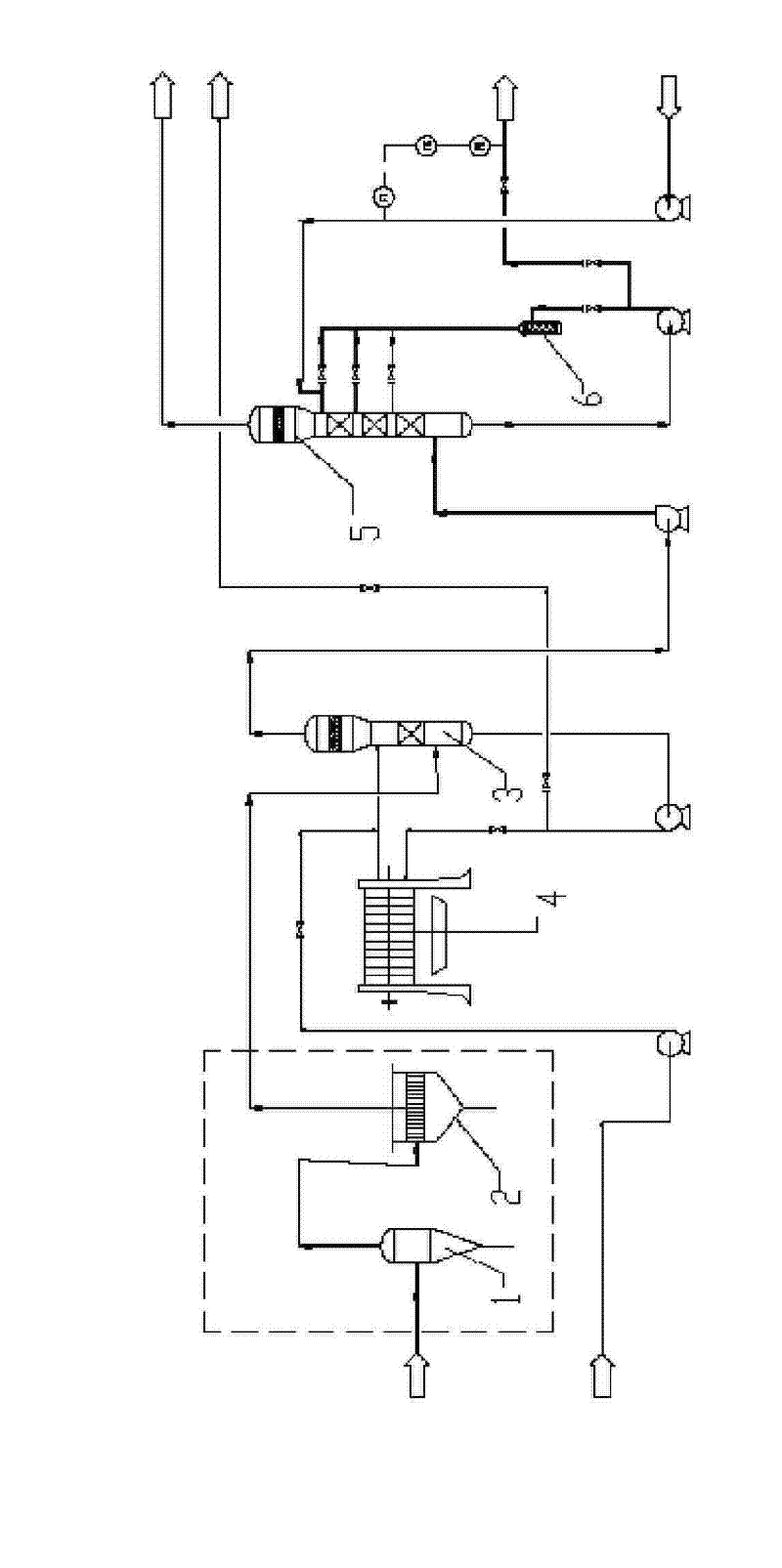

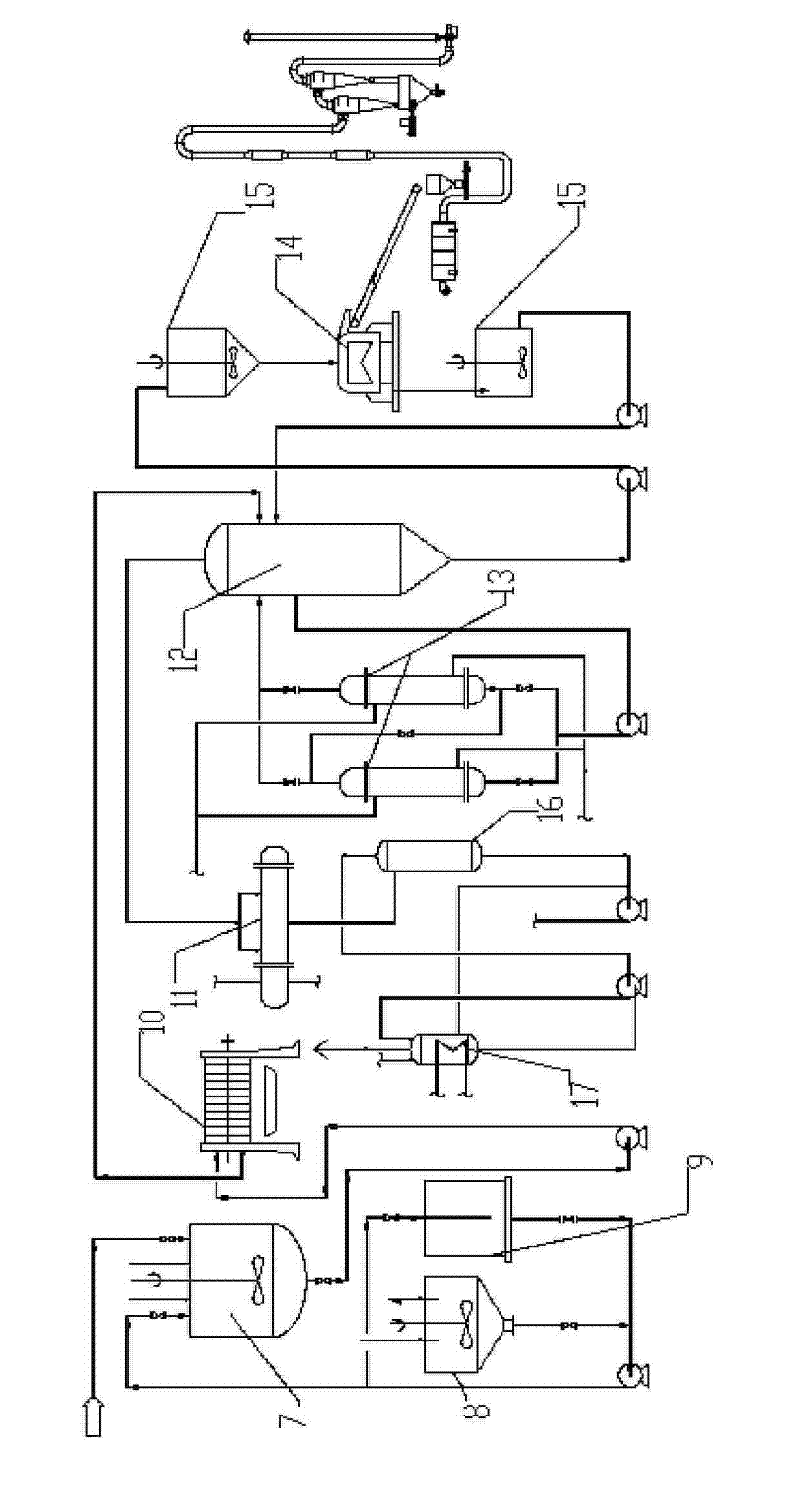

[0056] The device settings of this embodiment are as follows figure 2 , 3 shown.

[0057] 1. Flue gas pre-dust removal

[0058] The temperature of the mixed flue gas of lapis lazuli high-temperature coal reduction flue gas, Claus sulfuric acid tail gas incineration flue gas, and carbonization tower pressure relief incineration flue gas is 200 °C, and the composition (mol) is:

[0059] CO 2 12~18%;O 2 6~7%;N 2 +Ar 75~82%;

[0060] SO 2 4000mg / Nm 3 Above; Dust 22~25g / Nm 3 .

[0061] Use the cyclone dust collector to reduce the dust content in the flue gas to 5000mg / Nm 3 , and then use the electric precipitator to reduce the dust content in the flue gas to 600mg / Nm 3 , Flue gas temperature 150 ~ 220 ℃. Then send it to the water washing tower for washing, cooling and dust removal, the standard flow rate is 24000Nm 3 / h, working condition flow rate 41582.42m 3 / h. The process conditions of the washing tower are as follows:

[0062] 1) Flue gas entering the tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com