Evaporation device applied to wastewater desulfurization and control method

A technology of desulfurization waste water and evaporation device, which is applied in the direction of auxiliary controller with auxiliary heating device, water treatment parameter control, temperature control by electric mode, etc. It can solve the problems of corrosive and easy scaling, complex composition and high salt content , to achieve the effect of low operation and maintenance costs, small equipment volume, and improved purification quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

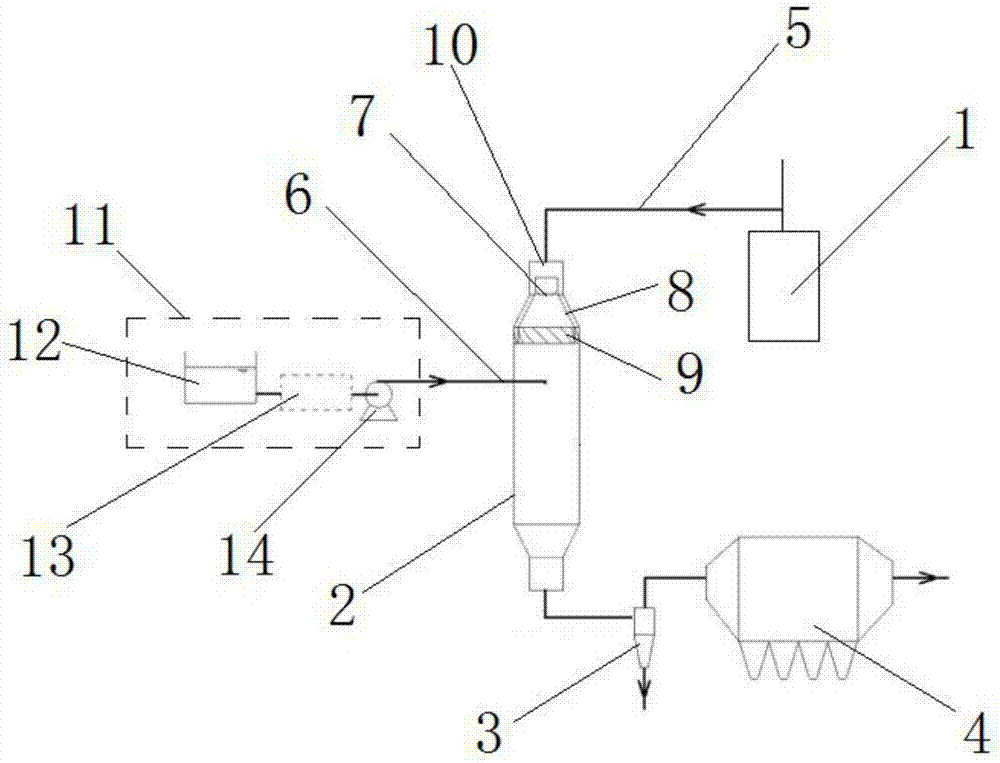

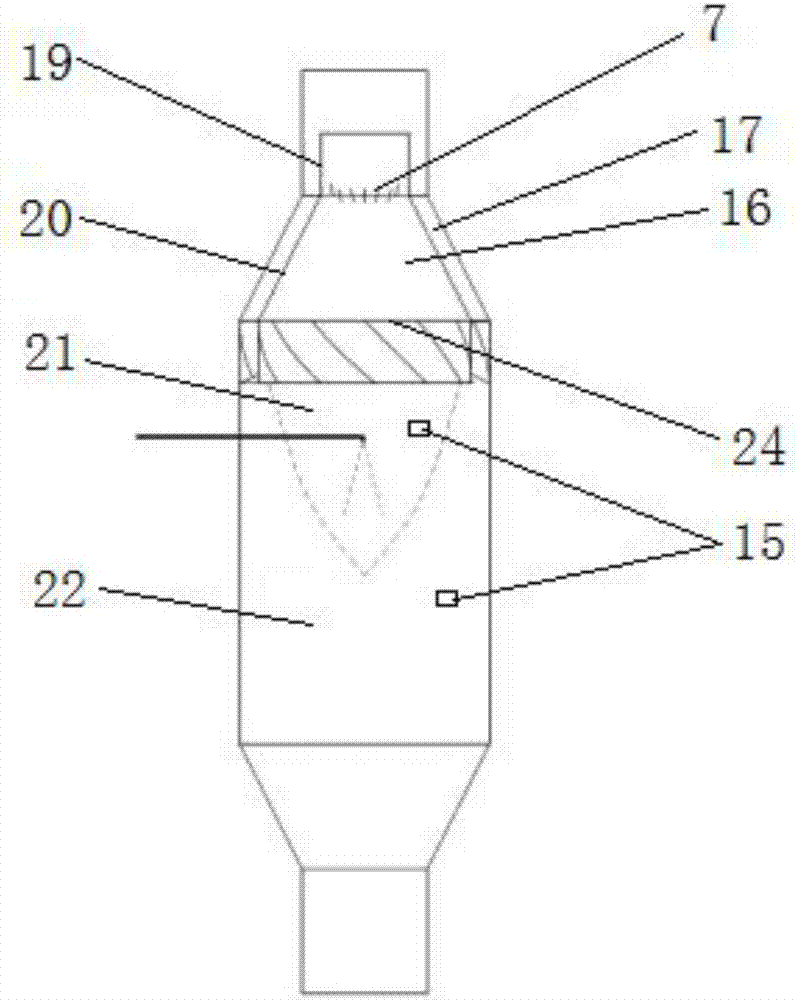

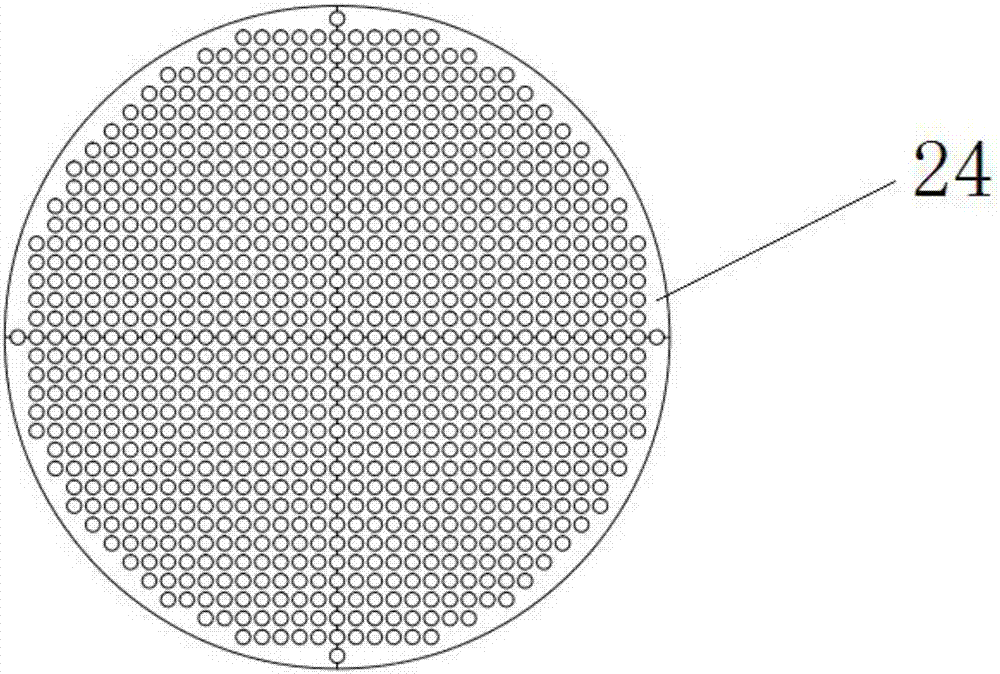

[0026]Embodiment 1 of the present invention: an evaporation device applied to desulfurization wastewater, comprising an air preheater 1, an evaporation tower 2, a crystallization salt recovery device 3 and an electric dust collector 4, and the air preheater 1 communicates with the flue gas pipe 5 The evaporation tower 2 is connected, the evaporation tower 2 is connected with the crystallized salt recovery device 3, the crystallized salt recovery device 3 is connected with the electrostatic precipitator 4, and the evaporation tower 2 is provided with an adjusting baffle 7, a partition partition 8, a swirling blade 9 and a smoke The gas uniform distribution plate 24 is provided with small holes on the smoke gas uniform distribution plate 24, and the small opening rate on the smoke gas uniform distribution plate 24 is 40%. The adjusting baffle 7 is set at the flue entrance 10 of the evaporation tower 2, the partition partition 8 is set between the flue entrance 10 and the swirl bl...

Embodiment 2

[0027] Embodiment 2 of the present invention: an evaporation device applied to desulfurization wastewater, comprising an air preheater 1, an evaporation tower 2, a crystallization salt recovery device 3 and an electric dust collector 4, and the air preheater 1 passes through a flue gas pipe 5 and The evaporation tower 2 is connected, the evaporation tower 2 is connected with the crystallization salt recovery device 3, the crystallization salt recovery device 3 is connected with the electrostatic precipitator 4, and the evaporation tower 2 is provided with an adjusting baffle 7, a partition partition, a swirl blade 9 and a flue gas The uniform distribution plate 24 is provided with small holes on the smoke uniform distribution plate 24, and the small opening rate on the smoke gas uniform distribution plate 24 is 30%. The adjusting baffle 7 is set at the flue entrance 10 of the evaporation tower 2, the partition partition 8 is set between the flue entrance 10 and the swirl blade ...

Embodiment 3

[0034] Embodiment 3 of the present invention: a control method applied to an evaporation device for desulfurization wastewater, including detecting the temperature of the flue gas swirl area and / or the flue gas parallel flow area, and comparing the detected temperature value with the preset value of each area value, and control and adjust the opening of the baffle 7 according to the comparison result, and adjust the temperature of the dry desulfurization wastewater in the evaporation tower 2; compare the detected temperature value of the flue gas swirling area with the preset value, when When the temperature value in the flue gas swirling area is lower than the preset value in the flue gas swirling area, the opening of the flue gas regulating baffle 7 is reduced; the detected temperature value in the flue gas parallel flow area Compared with the preset value, when it is detected that the temperature in the flue gas parallel flow area is lower than the preset value in the flue g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com