Filtering processing device for air purification and air purifier

A processing device and air purification technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, transportation and packaging, etc., can solve the problem that the purification module cannot be processed in time, the installation and disassembly of the purification module is inconvenient, and a large amount of dust and particles accumulate and other issues, to achieve the effect of improving the quality of air purification treatment, improving the quality of air treatment, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

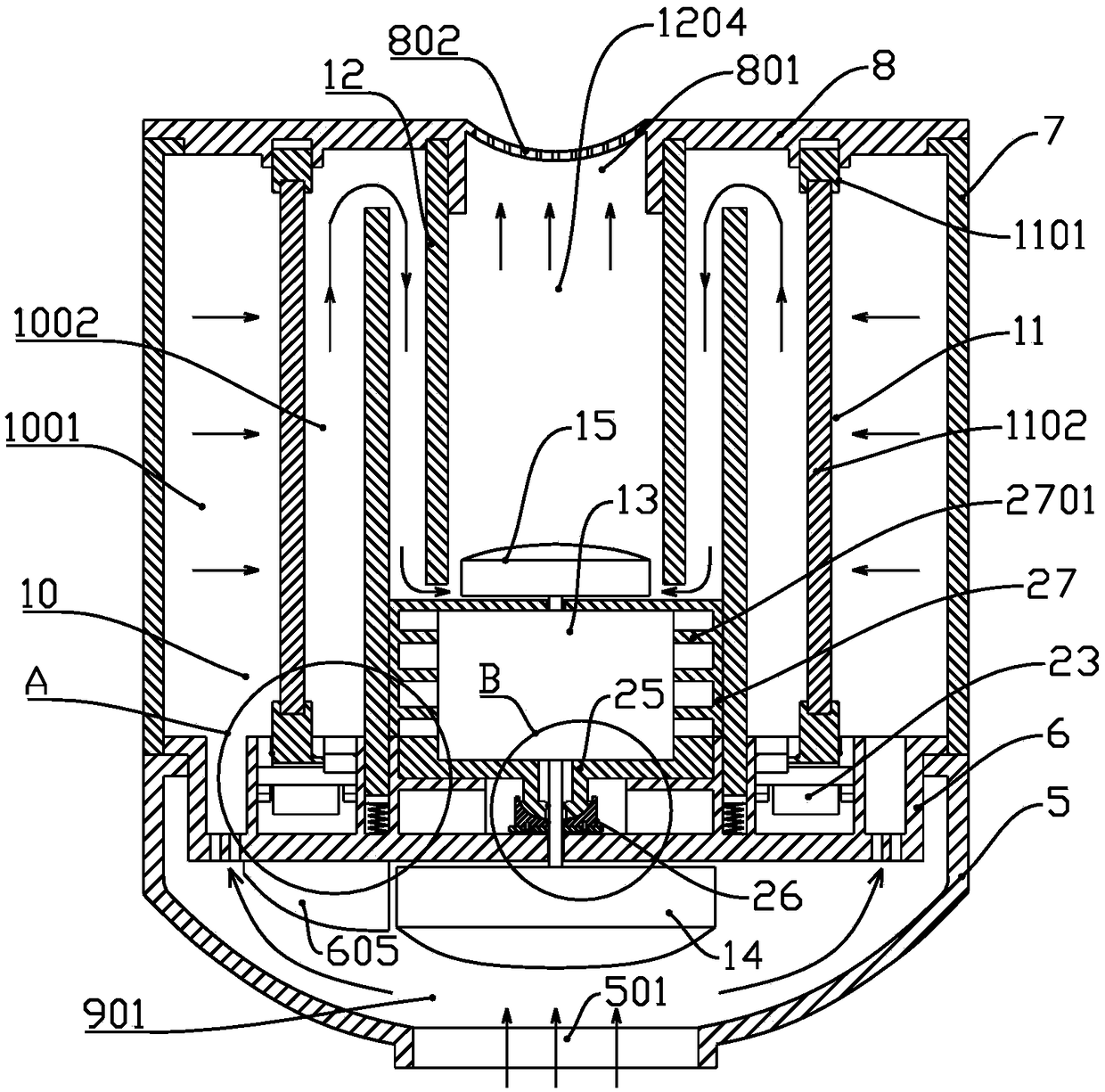

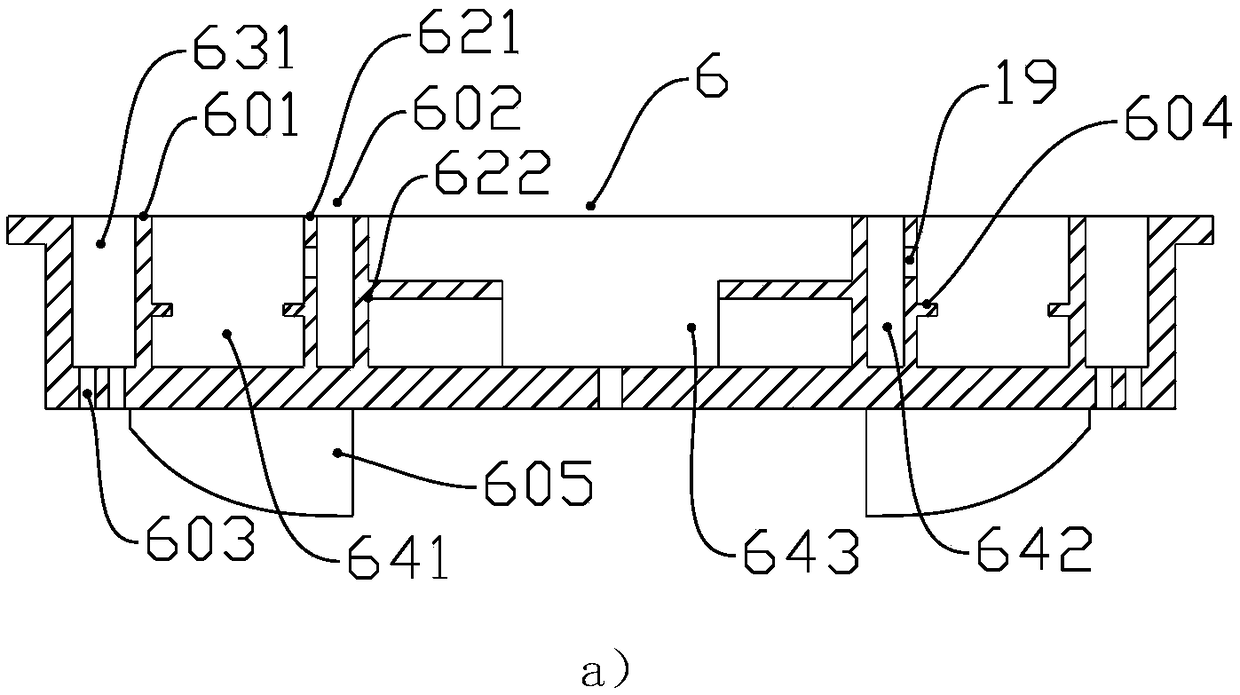

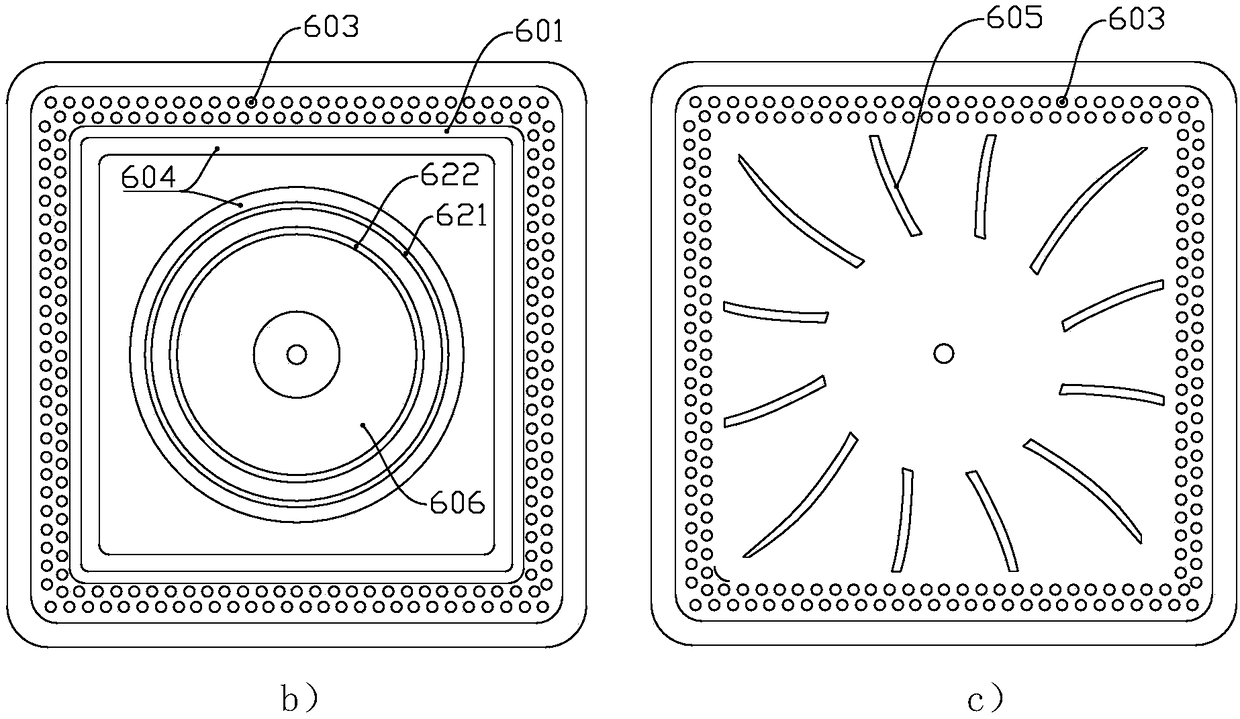

[0049] refer to figure 1 , the filter processing device that is used for air purification in the present embodiment, comprises air intake housing 5, mounting seat 6, host housing 7 and end cover 8, and the upper end of air intake housing 5 is an open structure, and air intake housing 5 The lower end is provided with an air intake channel 501 . The mounting seat 6 is arranged on one end of the open structure of the air intake housing 5, and the mounting seat 6 is connected with the open structure of the air intake housing 5 in a sealed fit, and a closed first air gap is formed between the mounting seat 6 and the air intake housing 5. The chamber 901 ; the host casing 7 is set on the intake casing 5 , the end cover 8 is set on the host casing 7 , and the host casing 7 is closed and connected to the intake casing 5 and the end cover 8 . The mounting seat 6 is arranged between the main engine casing 7 and the intake casing 5 , and a closed filter chamber 10 is formed between the ...

Embodiment 2

[0067] The filter treatment device that is used for air purification in the present embodiment, its structure and the difference among the embodiment one are:

[0068] Such as figure 1 and 6 A sealing mechanism is provided between the driving motor 13 and the intake fan 14, and the sealing mechanism includes an upper sealing assembly 25 and a lower sealing assembly 26 arranged on the driving shaft of the driving motor. The upper sealing assembly 25 includes a sealing sleeve 2501 provided with a central hole, a sealing tube 2502 connected to the central hole of the sealing sleeve and an upper sealing member 2503 connected to the end of the sealing tube; The upper driving flange 2601 and the lower sealing seat 2602 arranged on the driving flange. Here, the driving flange is fixedly connected to the driving shaft of the driving motor, and when the driving shaft rotates, the driving flange is driven to rotate together. The lower surface of the upper seal 2503 is set as an outer...

Embodiment 3

[0074] In this embodiment, it is an air purifier adopting the above-mentioned filter treatment device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com