Smoke dust removal system

A technology for soot and filtrate, which is applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems such as the lack of corresponding attention to the purification of the treatment liquid, the poor cohesion and absorption effect, and the greatly reduced design effect. , to achieve the effect of low maintenance cost, extended residence time and filtration quality up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

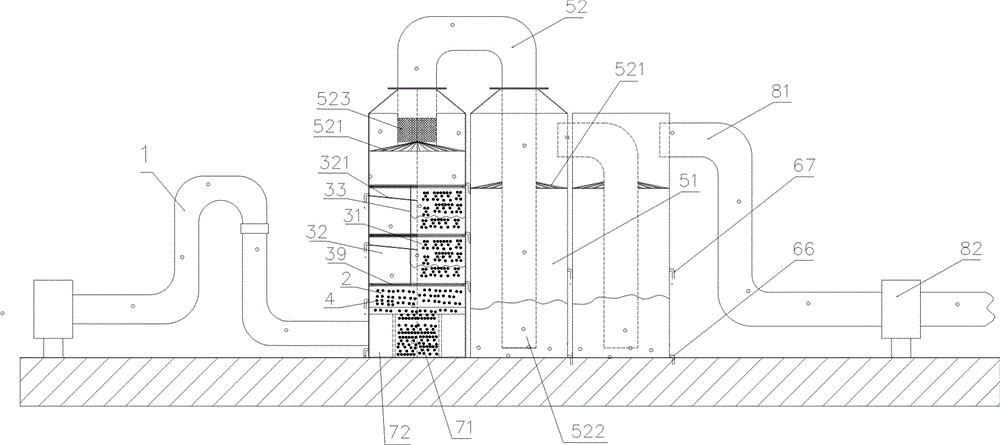

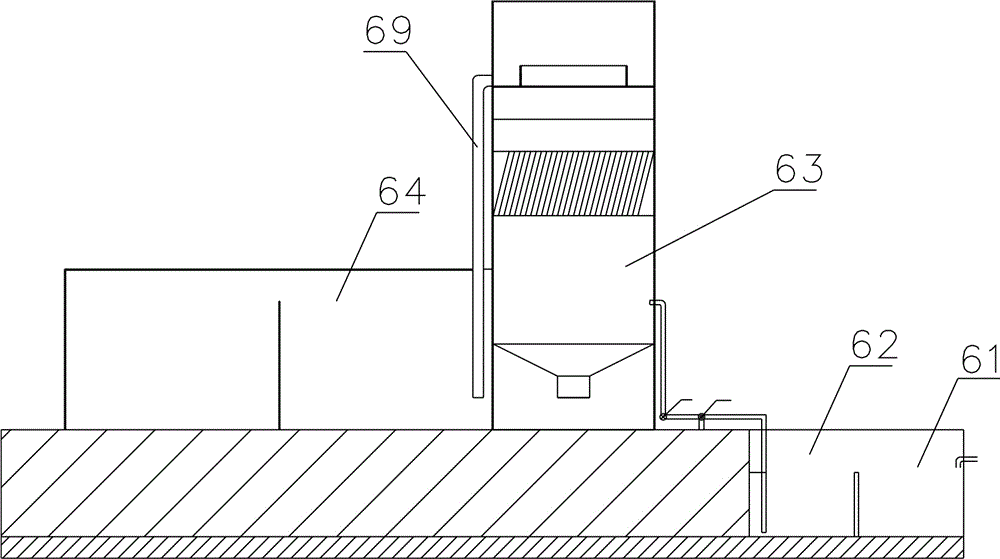

[0028] Such as figure 1 , 2 As shown, a dust removal system, including

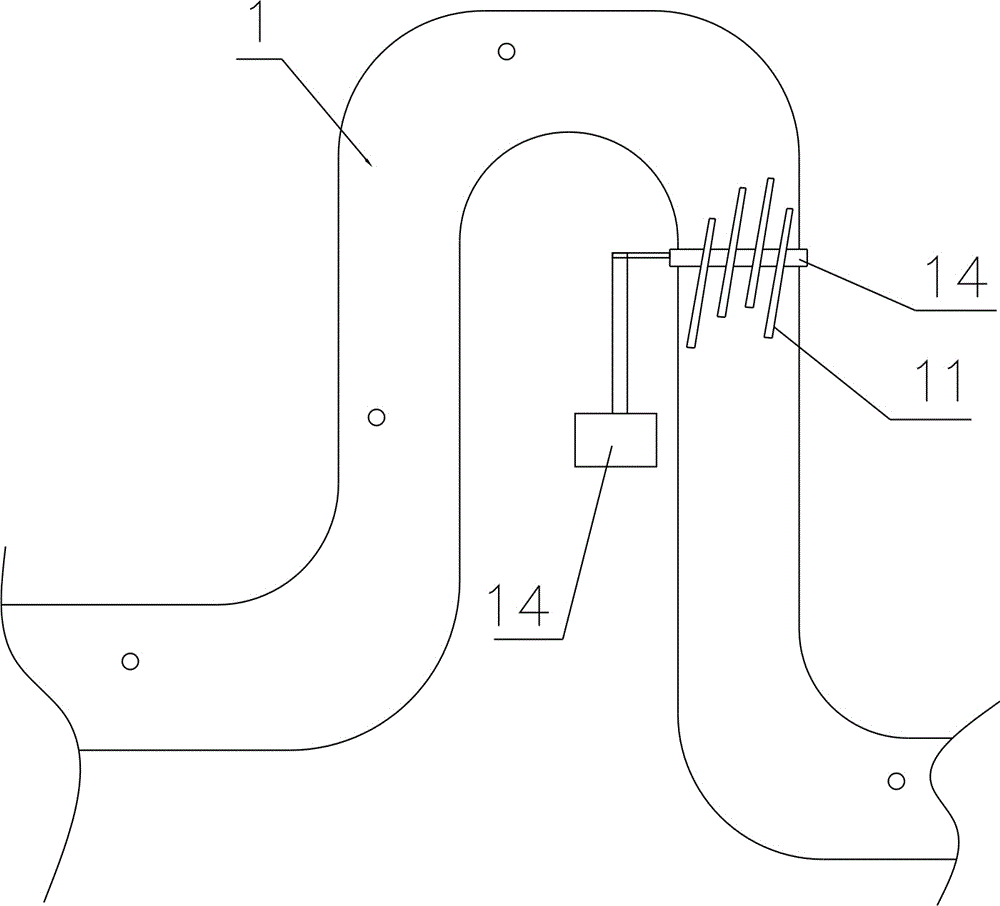

[0029] An air induction pipe 1 in an "n" shape, the front end of which is connected to a pollution source;

[0030] A cyclone device is used to guide the pollution source to rotate in the cyclone device, and its air inlet end is connected with the air outlet end of the air induction pipe 1; specifically, in this embodiment, the cyclone device includes an inner tube 71 And the outer tube 72 coated on the outside of the inner tube, the side wall of the inner tube 72 is evenly distributed along the circumferential direction with air guide holes connected to the side wall of the outer tube 72, and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com