Alkali-water desulphurization dust removal technology

A desulfurization and dust removal, process technology technology, applied in separation methods, chemical instruments and methods, use of liquid separation agents, etc., can solve the problems of reduced desulfurization effect, increased operating costs, and equipment can not operate normally, and achieves long gas-liquid contact time. , Not easy to scale and block, to ensure the effect of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

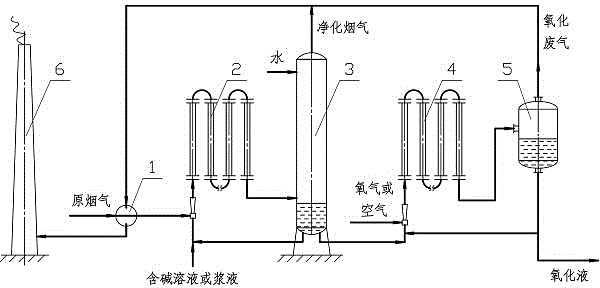

[0025] The desulfurization and dust removal device used in Example 1 includes: gas-gas heat exchanger (1), tubular desulfurization reactor (2), gas-liquid separation and desulfurization tower (3), tubular oxidation reactor (4), oxidation gas-liquid Separator (5), chimney (6), connecting pipelines and intermediate tanks between equipment, gas delivery device, liquid delivery device, control and display instruments and accessories. Among them, the tubular desulfurization reactor (2) and the tubular oxidation reactor (4) are composed of straight pipes and curved pipes, the straight pipe part is a commercially available static mixer, and the curved pipe is an empty pipe; the gas-liquid separation and desulfurization tower (3 ), the upper and middle parts are equipped with demisters and multi-layer nozzles for atomizing the second desulfurizing agent, and the lower part is a gas-liquid separation space; a tubular desulfurization reactor (2) and a gas-liquid separation and desulfuriz...

Embodiment 2

[0028] Example 2 is basically the same as Example 1, except that the first desulfurizing agent used in this example is magnesium hydroxide slurry.

Embodiment 3

[0030] Example 3 is basically the same as Example 1, except that the tubular desulfurization reactor is equipped with chemical fillers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com