Energy-saving high effective desulfurizing and dust control method and equipment using remaining heat

A desulfurization and dust removal, energy-saving technology, applied in the direction of separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of insufficient energy utilization, large flue gas resistance, and large energy consumption, and achieve desulfurization and dust removal efficiency High and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

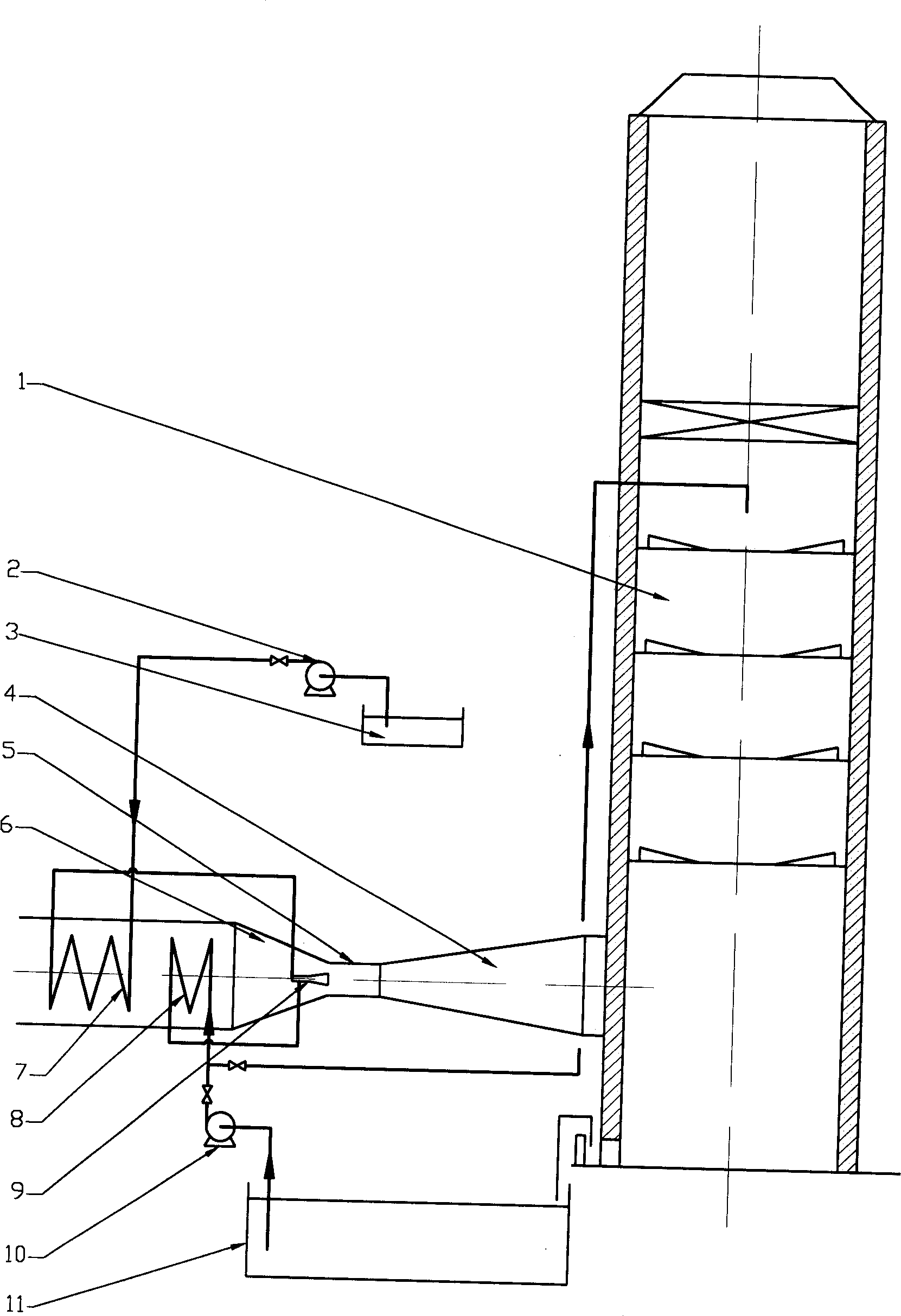

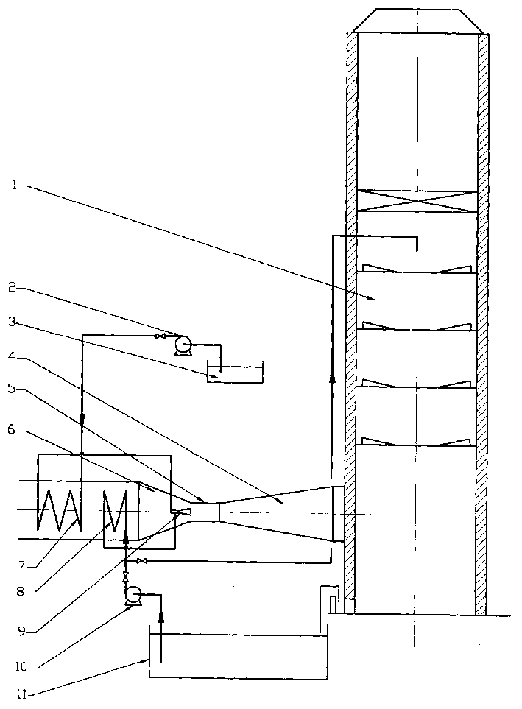

[0017] As shown in the figure, an energy-saving desulfurization and dust removal device for waste heat utilization includes a venturi tube and a desulfurization and dust removal tower 1. The venturi tube is composed of a contraction section 6, a mixing section 5, and a diffusion section 4. The contraction section 5 is equipped with The main heat exchanger 7, the auxiliary heat exchanger 8 and the nozzle 9, the inlet of the inner pipe of the main heat exchanger 7 communicates with the clear water tank 3 through the water pump 2, and the outlet communicates with the tail of the nozzle 9; the inlet of the inner pipe of the auxiliary heat exchanger 8 passes through The circulating water pump 10 is connected with the circulating water pool 11 of the desulfurization and dedusting tower 1 , and the outlet communicates with the middle part of the nozzle 9 .

[0018] The nozzle 9 is a water vapor two-phase nozzle, and the direction of the nozzle is consistent with the flow direction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com