Street lamp cooling device of waste heat drive Stirling engine

A Stirling engine and heat dissipation device technology, which is applied to hot air variable displacement engine devices, lighting device cooling/heating devices, machines/engines, etc., can solve the problem of insufficient heat dissipation and heat recovery of high-power LED street lamp radiators Use and other problems to achieve the effect of increasing the heat flux density and reducing the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

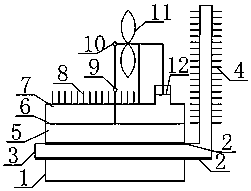

[0011] The present invention will be further described below in conjunction with specific embodiments. Such as figure 1 , figure 2 , a street lamp cooling device driven by waste heat Stirling engine, including LED street lamp beads 1, heat transfer medium 2, heat pipe radiator 3, heat dissipation fins 4 of heat pipe radiator, hot cylinder 5 of Stirling engine, heat-insulating and sealing piston 6. Cold cylinder 7 of Stirling engine, cooling fins 8 of Stirling engine, hinge mechanism 9 , eccentric hinge mechanism 10 , fan impeller 11 , piston 12 of cold cylinder.

[0012] When the LED street lamp bead 1 is working, a large amount of waste heat will be generated, and this part of waste heat will be transferred to the heating section of the heat pipe radiator 3 in the form of heat conduction, and then divided into two parts, which will be transferred to the heat of the Stirling engine through heat conduction. Cooling section of cylinder and heat pipe radiator 3. The Stirling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com