Sewage and wastewater source steam compression dry heat pump unit

A technology of heat pump units and compression drying, which is applied in heat pumps, refrigerators, refrigeration components, etc., can solve the problems of inability to use waste heat and heat sources of industrial sewage and waste water, and achieve the effects of recycling, efficient and clean utilization, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

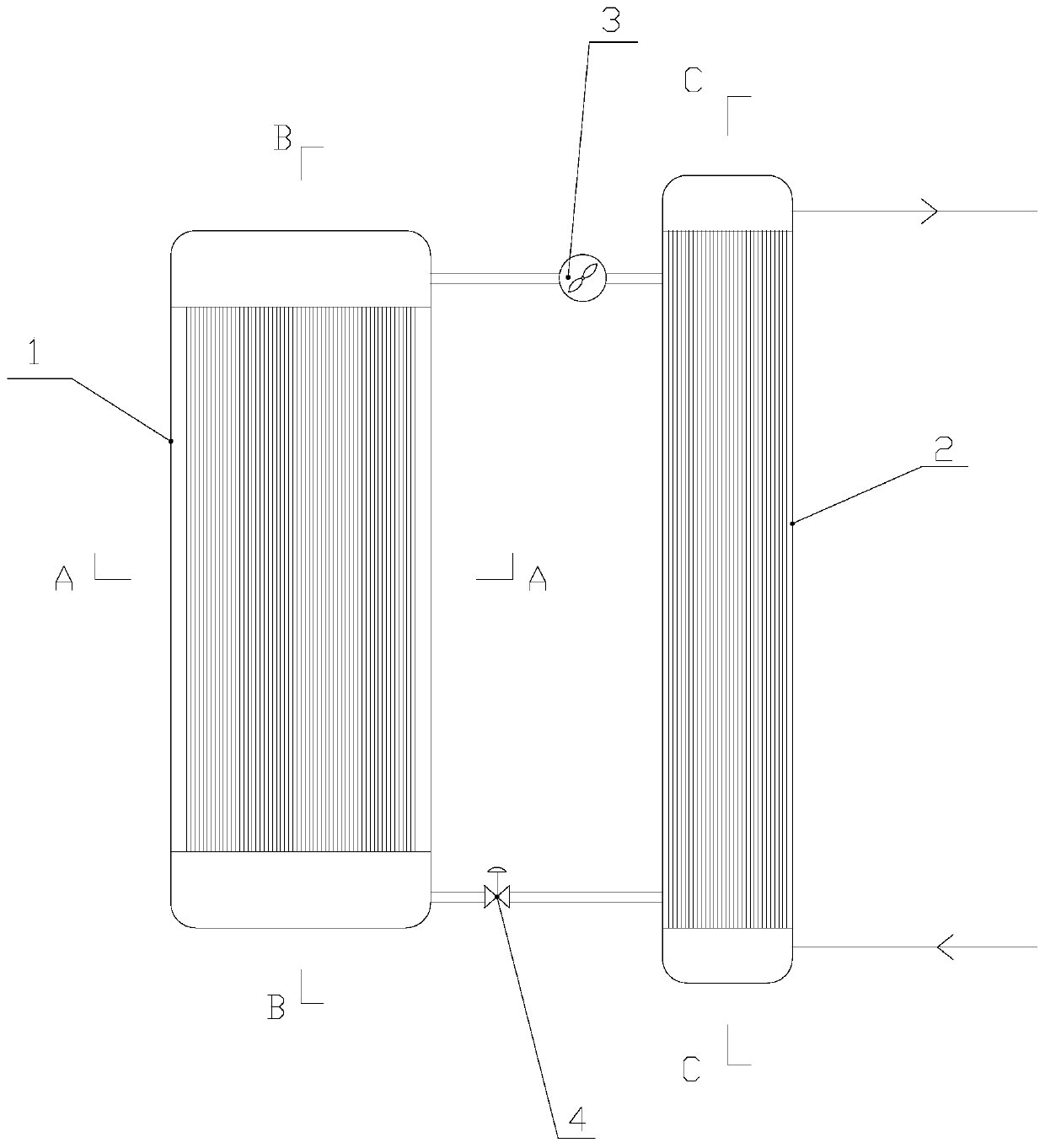

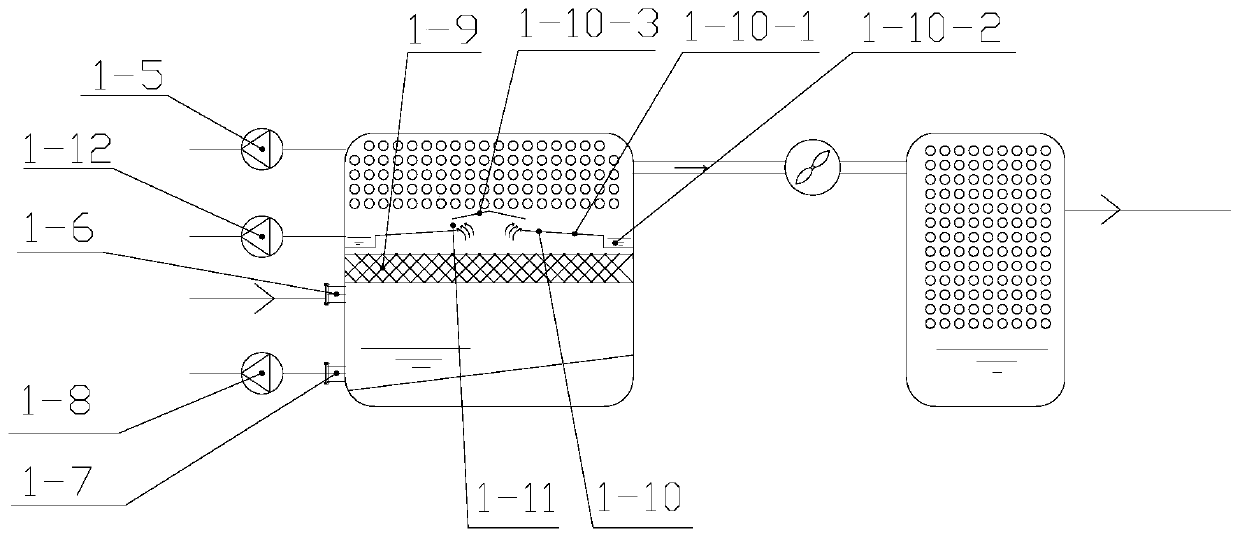

[0028] Specific implementation mode one: combine Figure 1~6 Description of this embodiment, the waste water source vapor compression dry heat pump unit includes an evaporator 1, a condenser 2, a compressor 3 and an expansion valve 4,

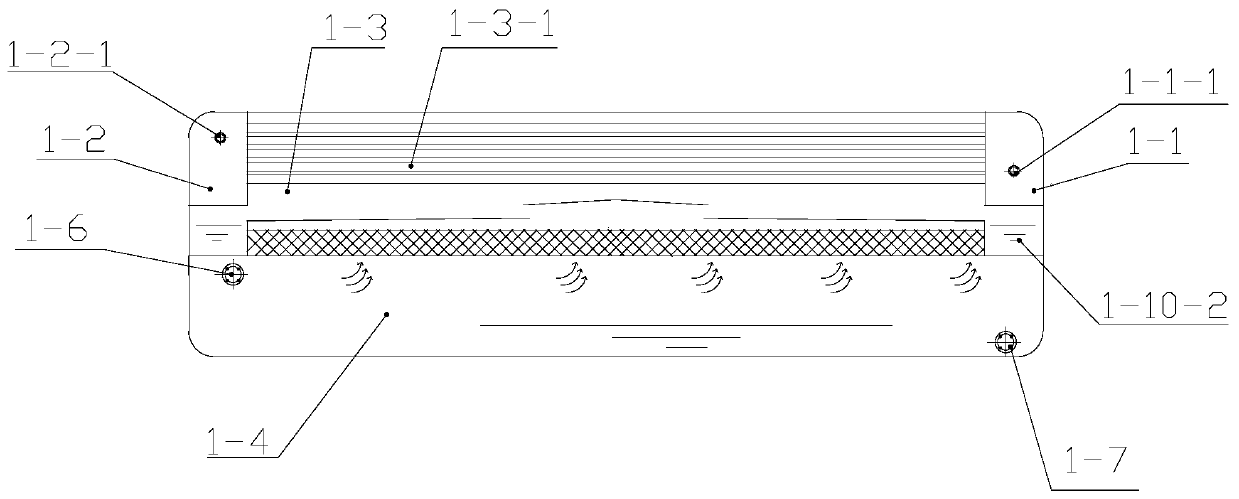

[0029] The evaporator 1 includes a working fluid inlet chamber 1-1 and a working fluid outlet chamber 1-2, and the condenser 2 is respectively communicated with the working fluid inlet chamber 1-1 and the working fluid outlet chamber 1-2 through pipelines. The expansion valve 4 is arranged on the pipeline between the working fluid inlet chamber 1-1 and the condenser 2, and the compressor 3 is arranged on the pipeline between the working fluid outlet chamber 1-2 and the condenser 2,

[0030] The evaporator 1 also includes a first heat exchange chamber 1-3 located on the upper part and a flash chamber 1-4 connected and arranged below the first heat exchange chamber 1-3, and the working fluid enters the chamber 1-1 and the working fluid The mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com