Housing-and-tube heat exchanging device

A shell-and-tube heat exchange and equipment technology, which is applied in the field of shell-and-tube heat-exchange equipment, can solve the problems of the shell-and-tube heat exchanger being unable to be thoroughly cleaned, hindering the use range and efficiency of the heat exchanger, and being unable to use the heat source of the heat exchanger. , to achieve the effect of improving heat exchange efficiency, efficient heat exchange without scaling, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

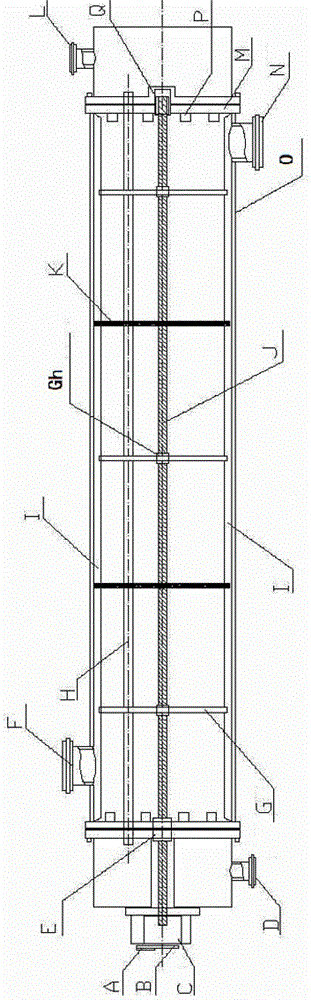

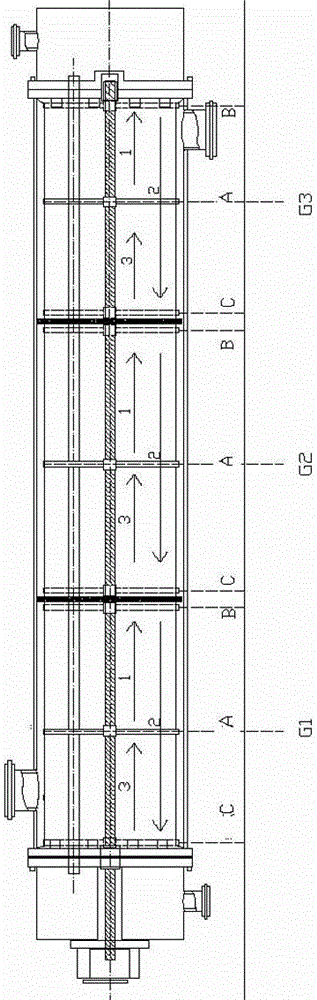

[0033] combined with figure 1 , to further describe the present invention:

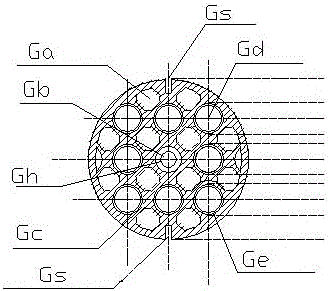

[0034]A shell-and-tube heat exchange device, including a shell (O), a heat exchange tube (H), a tube sheet (M), a sewage inlet (F), a softened water outlet (D), a softened water inlet (L) and a sewage outlet (N), the inner cavity of the shell (O) is provided with multiple sets of heat exchange tubes (H), the two ends of the heat exchange tubes (H) are fixedly connected by the tube plate (M), and one end of the shell (O) There is a sewage inlet (F) and a softened water outlet (D), and the other end is provided with a softened water inlet (L) and a sewage outlet (N). The softened water outlet (D), the heat exchange tube (H) and the softened The water inlet (L) is connected, the sewage inlet (F), the inner cavity of the housing (O) and the sewage outlet (N) are connected, and a cleaning plate assembly (G), Cleaning plate positioning guide rail (I), supporting plate (K), cleaning plate power screw (J) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com