An energy storage constant temperature water system suitable for high temperature and high load thermal printers

A technology of thermal printers and constant temperature water, applied in printing, heat exchangers, indirect heat exchangers, etc., can solve the problem of waste heat not being fully utilized, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

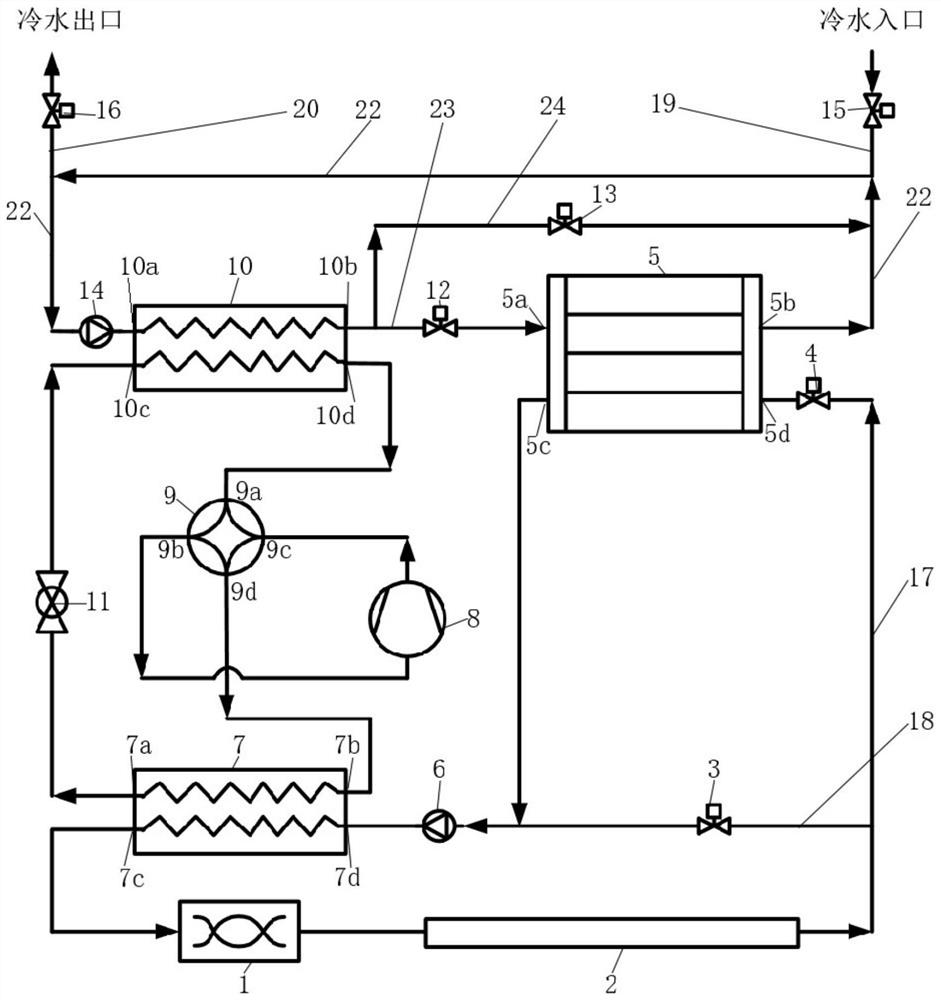

[0036] Such as figure 1 As shown, the energy-storage constant-temperature water system suitable for high-temperature and high-load thermal printers in this embodiment includes a constant-temperature water circuit, a refrigerant circuit and an evaporator-side chilled water circuit. The three circuits cooperate with each other to form three working modes, respectively Applicable to thermal printer 1 standby, normal work and continuous long-term working state;

[0037] The constant-temperature water circuit: preheats the thermal print head at a constant temperature during standby, cools the thermal print head during normal operation and recycles the waste heat during work; the refrigerant circuit: controls the temperature of the constant-temperature water, and supplies constant temperature Water heating, heating the constant temperature water during normal work, and cooling the constant temperature water during continuous long-term work; the evaporator side chilled water circuit:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com