Process method for converting metal magnesium slag into desulphurizer of boiler

A technology of metal magnesium and desulfurization agent, which is applied in the direction of chemical instruments and methods, separation methods, solid waste removal, etc., can solve the problems of difficult transportation, affecting desulfurization effect, and inability to directly use boilers for desulfurization, so as to reduce dust pollution and improve Effect of waste heat recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

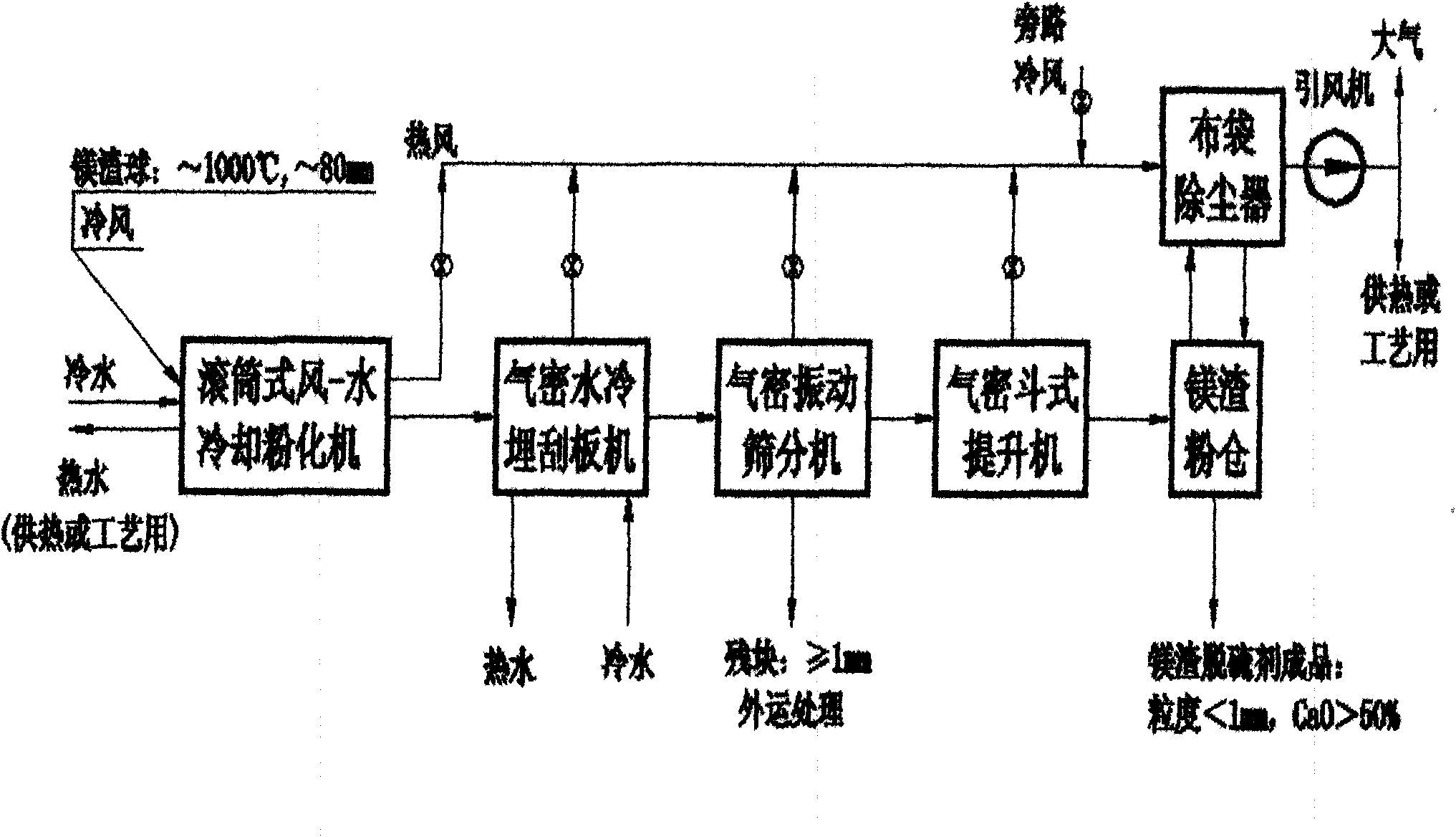

Image

Examples

Embodiment Construction

[0038] The specific embodiment of the present invention is described as follows step by step:

[0039] 1) Pour ~1000℃ high-temperature magnesium slag balls (equivalent diameter about 80mm) from the metal magnesium smelting reduction furnace into the drum-type air-water cooling pulverizer by a forklift, and pass through the water-cooled surface heat exchange and air-cooled contact Heat exchange to reduce the outlet temperature below 200°C. Since the main composition of magnesium slag is β-type calcium silicate (β-CaOSiO2), when the temperature drops below 675°C, it begins to transform into γ-type calcium silicate (γ-CaOSiO2), and the volume expands, making the slag ball gradually natural chalking. When the material leaves the cooling pulverizer, most of the slag balls that have been thermally reduced and reacted in the magnesium smelting furnace have been pulverized into fine powders less than 1 mm, but the incompletely reacted slag balls are pulverized on the outside and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com