Patents

Literature

64results about How to "Obvious benefits of energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-carbon high-performance concrete supplementary cementitious material

The invention discloses a low-carbon high-performance concrete supplementary cementitious material which is prepared from 20-70 parts of slag, 20-70 parts of coal ash, 5-10 parts of silica fume, 3-10 parts of desulfurized gypsum and 1-3 parts of water reducing agent by weight to form an admixture, wherein the slag, the coal ash, the silica fume and the desulfurized gypsum are micro aggregates of 100 nanometers to 100 microns; and the materials are sequentially placed in a mixer and stirred for 60-120 minutes at a speed of 60-120 rpm at normal temperature under normal pressure to obtain the supplementary cementitious material. The low-carbon high-performance concrete supplementary cementitious material disclosed by the invention can replace 70% of cement in concrete when applied to concrete; and even if the 70% of cement is replaced, the strength of the prepared concrete also can reach C15-C60. The low-carbon high-performance concrete supplementary cementitious material is suitable to be used as a building material and also has special purposes of back-fill grouting, toxic waste solidification and the like.

Owner:宁夏新丰益节能科技有限公司

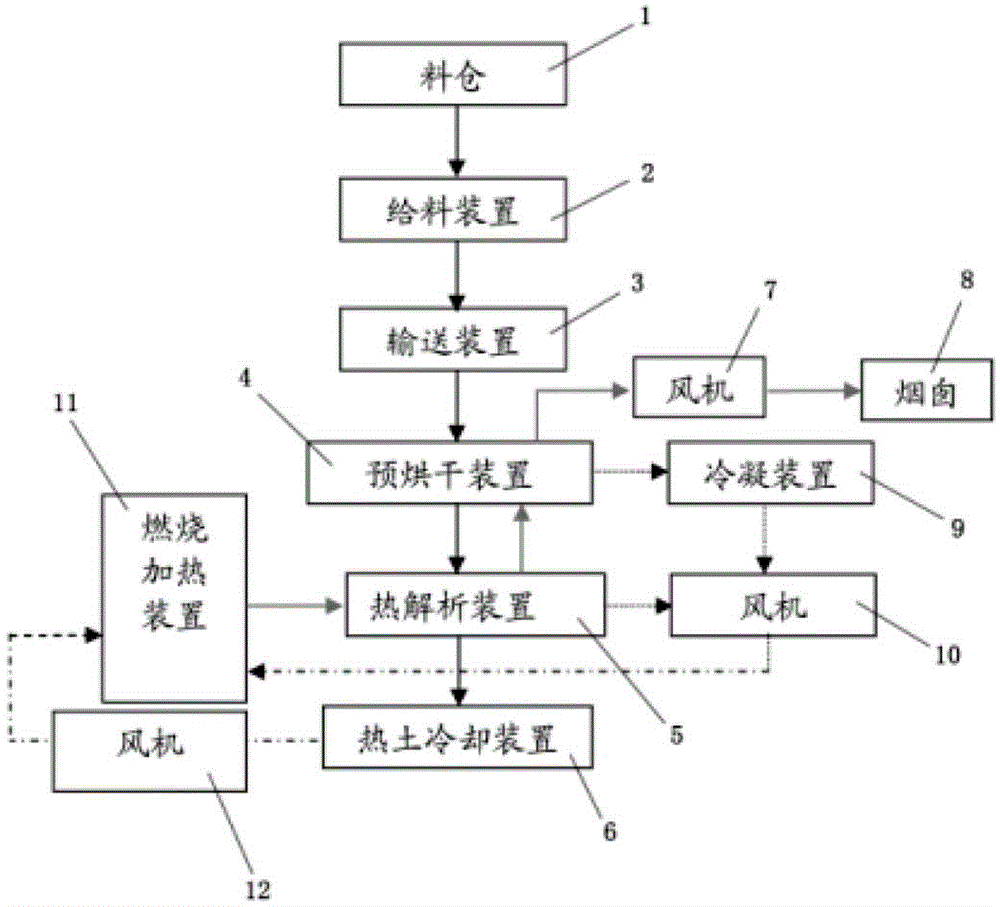

Method and device for treating organic polluted soil by two-section-type indirect thermal desorption technology

ActiveCN104874593AReduce consumptionEasy temperature controlContaminated soil reclamationThermal desorptionPollution

The invention discloses a method and a device for treating organic polluted soil by a two-section-type indirect thermal desorption technology. The method comprises the following steps: carrying out predrying and dehydrating moisture in organic polluted soil at low temperature so as to enable the moisture content to be reduced to be less than 5%; heating the predried organic polluted soil in a thermal desorption device indirectly so as to obtain altithermal soil and organic pollutant gas; directly introducing the organic pollutant gas into a combustion heating device to be combusted together with fuels at high temperature so as to achieve the complete innocent treatment of organic pollutants; cooling the high-temperature soil indirectly by a hot soil cooling device, recycling the altithermal soil to sense heat so as to preheat air for the fuel combustion for the combustion heating device, thereby obtaining raw materials for building materials for further deep processing. The technology is simple; the investment is low; the running management expense is low; the energy source efficiency is high; tail gas pollution and any other environment problem are not generated; the technical economy is feasible, and the energy conservation and environment-friendly benefit is obvious; the concept of clean production and circulation economy is shown fully.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

Multi-steam turbine combined power generation type ultra-supercritical unit

ActiveCN104358596AImprove cycle thermal efficiencyIncrease steam intake parametersSteam engine plantsEvaporationEngineering

The invention relates to a multi-steam turbine combined power generation type ultra-supercritical unit which comprises an ultra-supercritical pressure secondary heating boiler (comprising a heating evaporation overheater, a primary reheater and a secondary reheater), a front steam turbine generator unit (comprising an ultrahigh-pressure cylinder and a back pressure extraction turbine) and a plurality of low-parameter steam turbine generator units, wherein the steam outlet of the heating evaporation overheater is connected with the steam inlet of the ultrahigh-pressure cylinder through a steam conveying pipeline; the steam outlet of the ultrahigh-pressure cylinder is connected with the steam inlet of the primary reheater and the steam inlet of the back pressure extraction turbine through pipelines respectively; the steam outlet of the back pressure extraction turbine is connected with the inlet of an oxygen remover through a pipeline; the steam outlet of the primary reheater is connected with the steam inlet of a high-pressure cylinder of the low-parameter unit through a pipeline; the steam outlet of the high-pressure cylinder is connected with the inlet of the secondary reheater through a pipeline. According to the ultra-supercritical unit provided by the invention, the circulating heat efficiency of the two or more low-parameter generator units is greatly improved, the power consumption is greatly reduced, and huge energy-saving and emission-reducing benefits are realized.

Owner:大唐(北京)能源科技有限公司

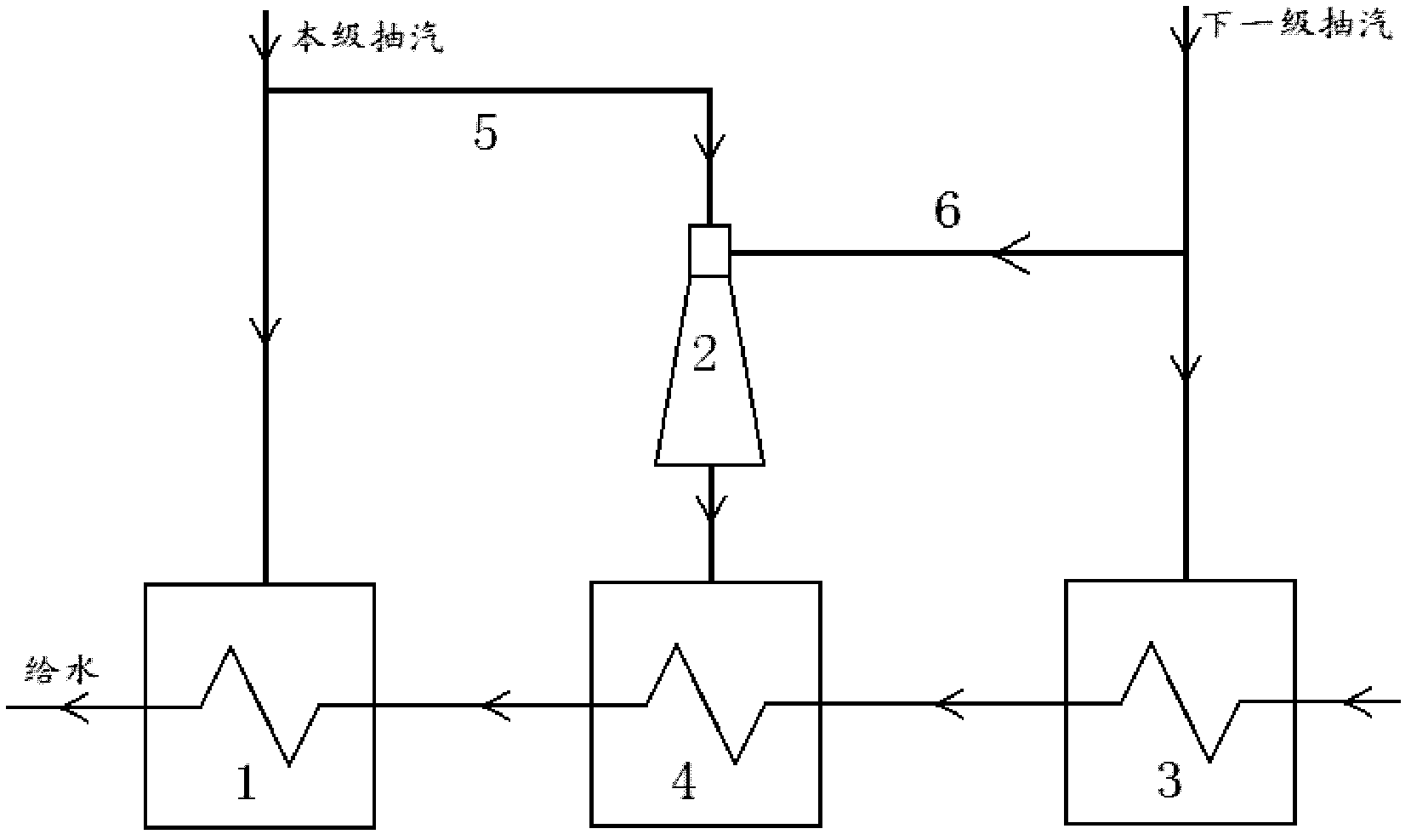

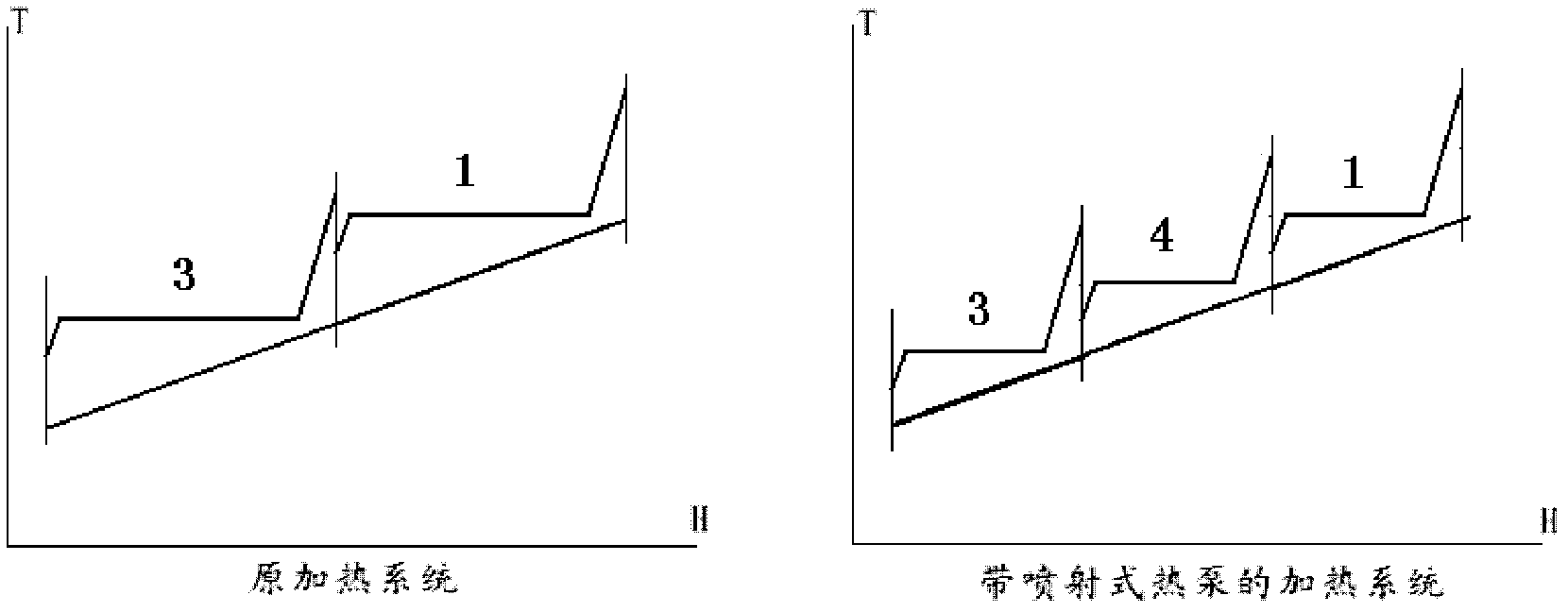

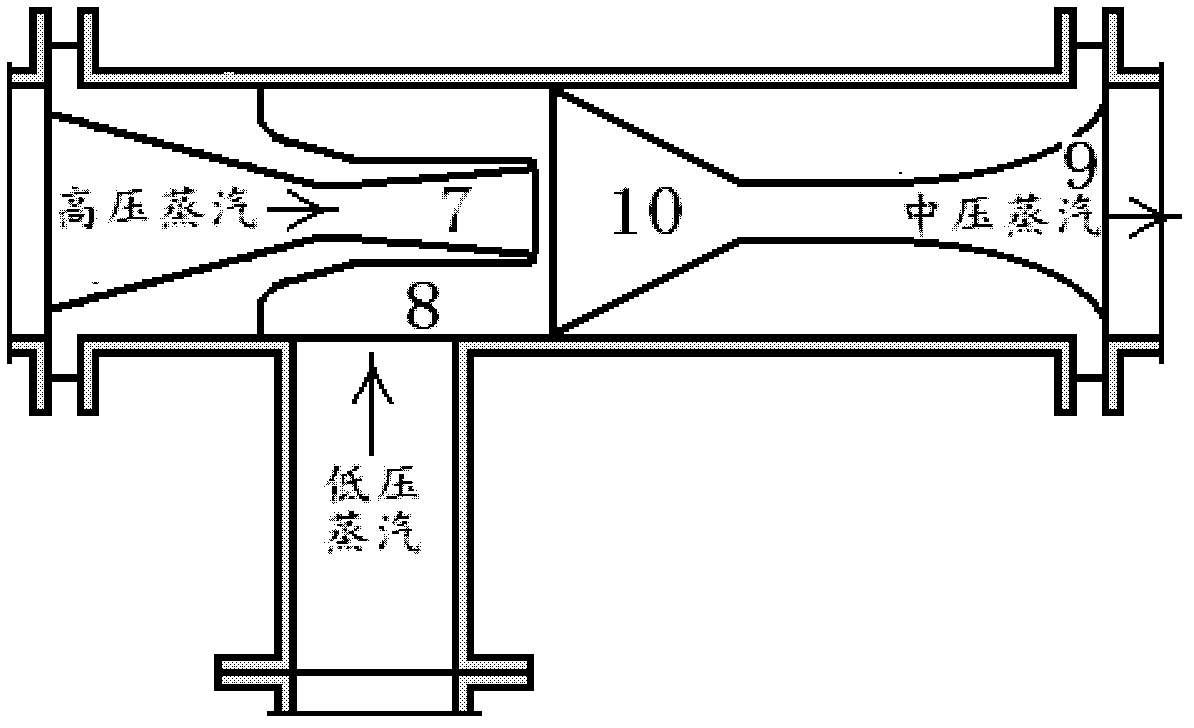

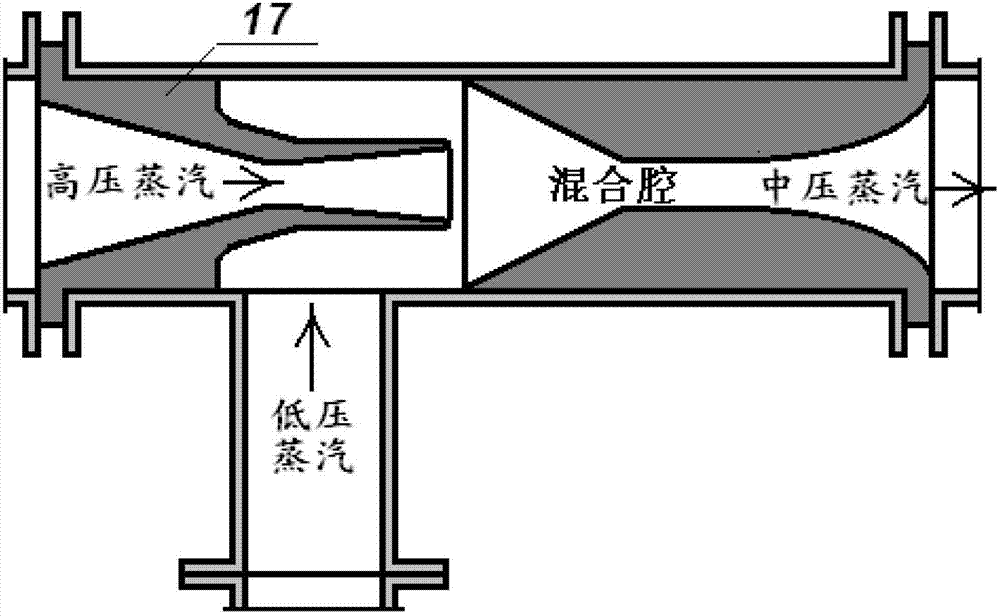

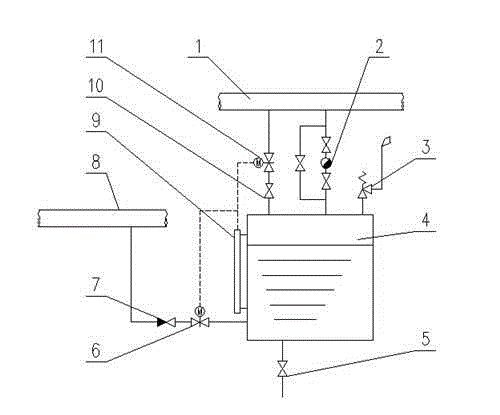

Heat regenerative system adopting jet-type heat pumps

ActiveCN102537935AHigh thermal efficiencyReduce irreversible lossFeed-water heatersRegenerative processEngineering

The invention relates to a heat regenerative system adopting jet-type heat pumps. The heat regenerative system comprises a plurality of levels of heaters which are successively connected, wherein the heater of each level is respectively connected with an extraction steam pipeline of the level, and an indirect heater is arranged between the heaters of every two adjacent levels and is communicated with the heaters of the two adjacent levels; and a jet-type heat pump is arranged between the extraction steam pipelines of the heaters of every two adjacent levels, is communicated with the extraction steam pipelines of the heaters of the two adjacent levels and are corresponding to the indirect heater of the level, and the outlet of each jet-type heat pump is connected with the inlet of each indirect heater. The jet-type heat pumps are arranged in the heat regenerative system provided by the invention, extraction steam with higher pressure is utilized to inject lower-level extraction steam with lower pressure, so that mixed steam the pressure of which is between the pressures of two levels of extraction pressure is generated; and an indirect regenerative heater utilizing the mixed streamas a heating stream source is additionally arranged, thereby reducing the irreversible loss of a regenerative process, and improving the heat efficiency of a machine set.

Owner:XI AN JIAOTONG UNIV

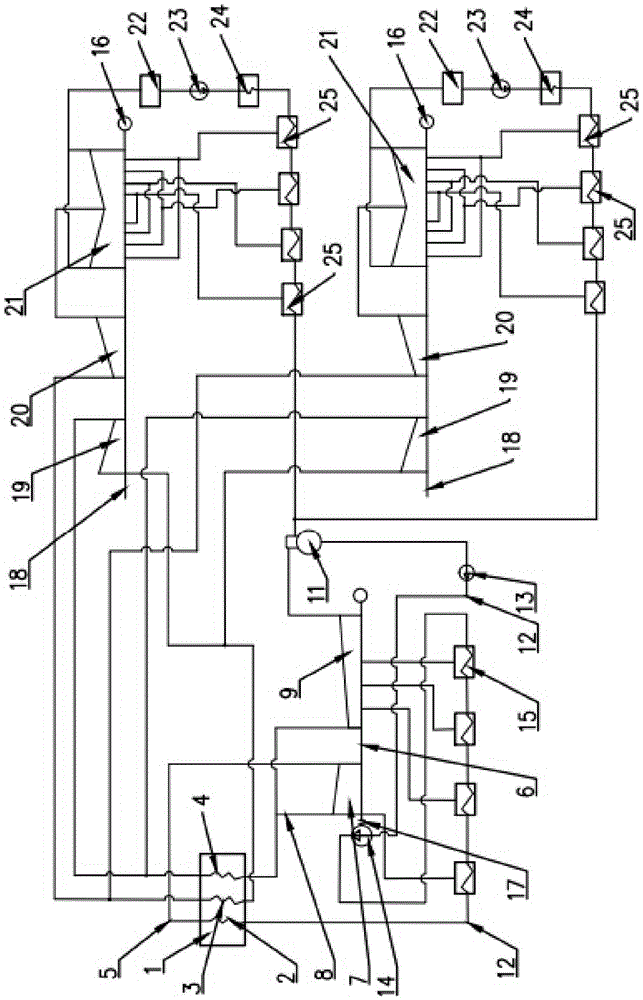

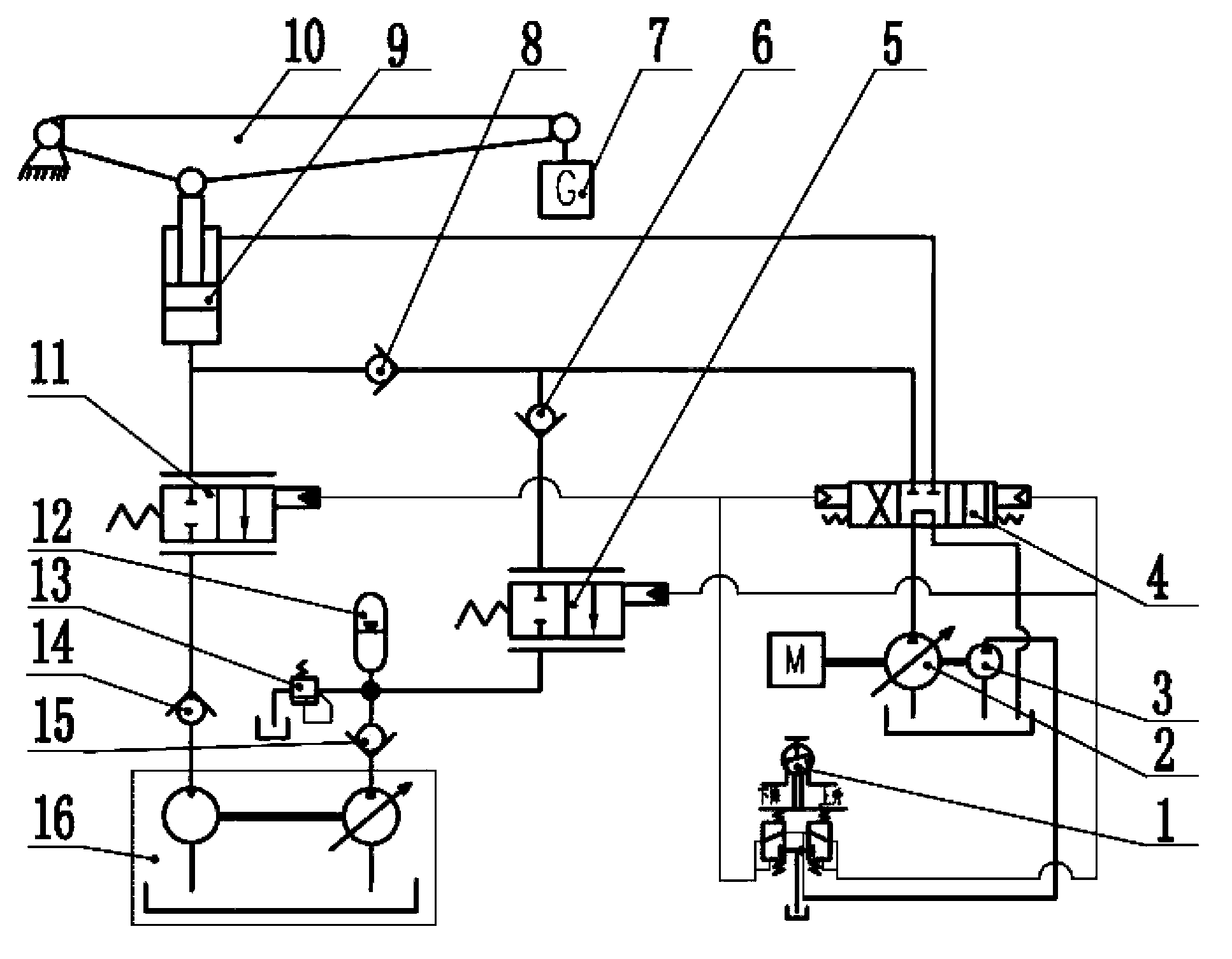

Energy recovery and reusing device

ActiveCN103671365AReduce loadReduce the required powerFluid-pressure actuator componentsHydraulic pumpEnergy recovery

The invention relates to an energy recovery and reusing device. The energy recovery and reusing device comprises a cargo boom component and a hydraulic system. According to the device, lower pressure oil is converted to high pressure oil which is then stored in an energy accumulator when a cargo boom descends, and when the cargo boom ascends, the high pressure oil is supplied so that the cargo boom can ascend. The full hydraulic system is utilized, potential energy generated during descending of the cargo boom is converted to pressure energy of fluids, the pressure energy is stored in a hydraulic accumulator and used for lifting heavy cargos next time, and the potential energy obtained by power consumption can be regenerated so that loads and power for driving a main hydraulic pump can be reduced. The energy recovery and reusing device has the advantages that the recovery and regeneration efficiency is high, effects on energy conservation and emission reduction are remarkable, the device is simple, and convenient and easy to operate, investments are small, the service life is long, and the device can be configured on a newly produced machine or added to an old transformed machine, and can be widely applied to large engineering machinery such as excavating machinery, loading equipment and hoisting equipment.

Owner:山重建机有限公司

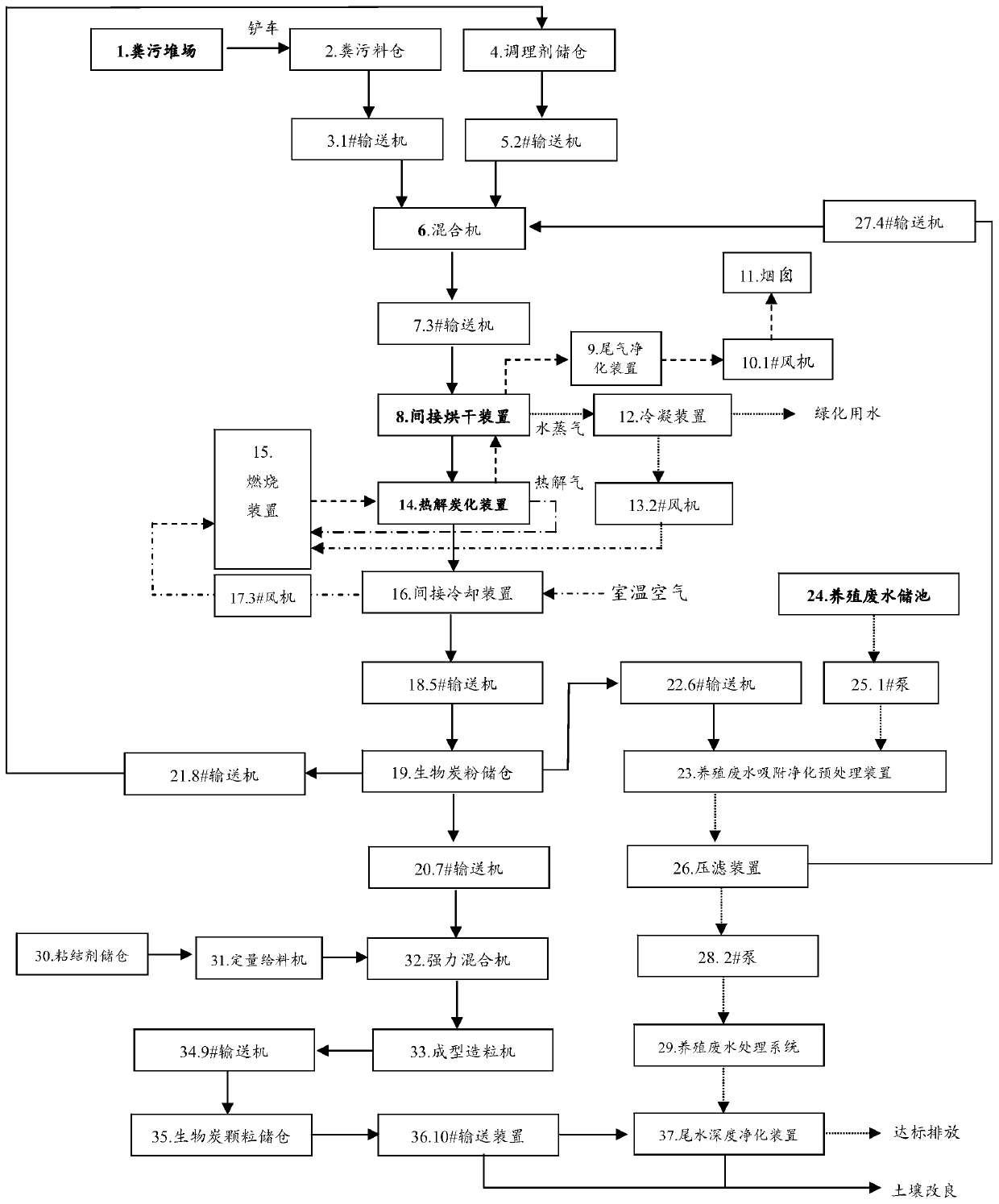

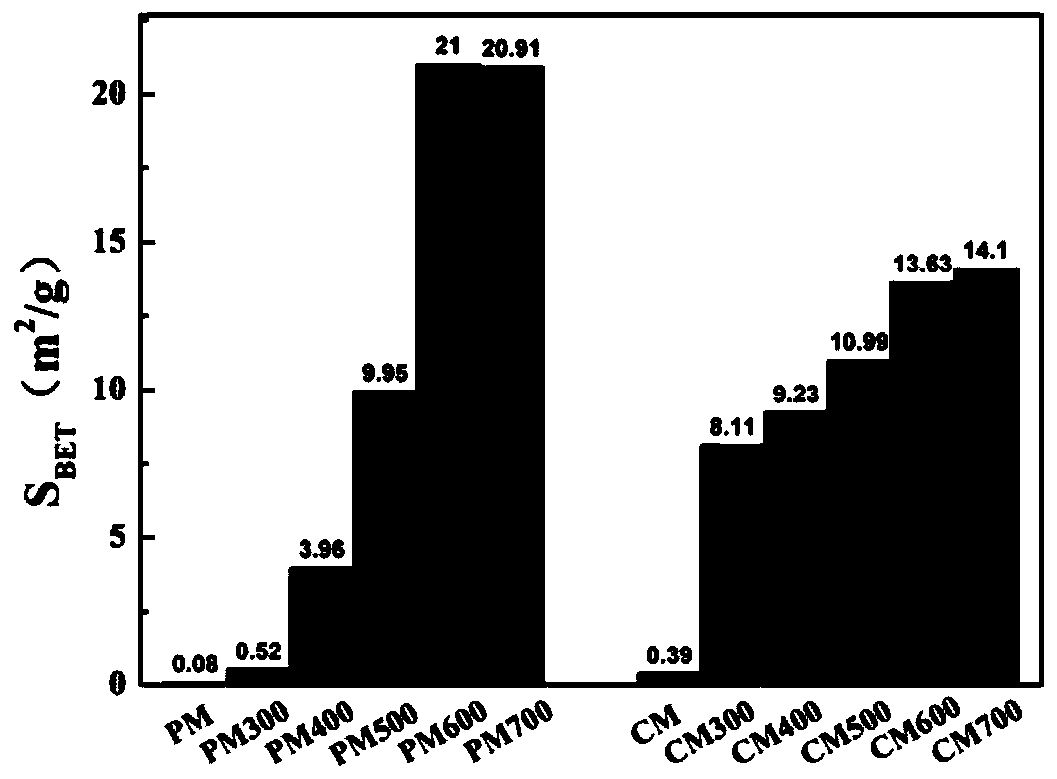

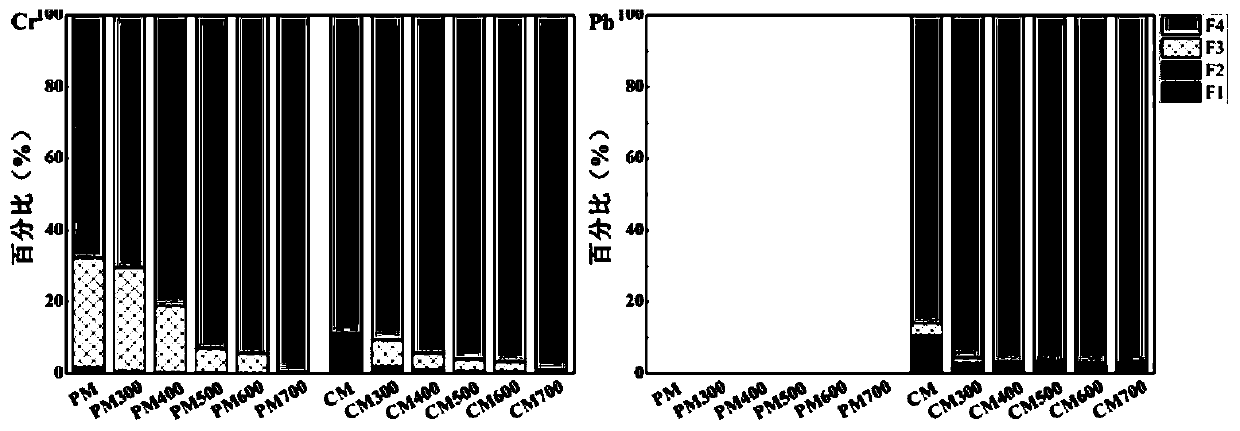

Method and device for cyclically treating breeding wastewater and/or improving soil by utilizing livestock and poultry manure

PendingCN111423096ASolving Dehydration ProblemsLow viscositySludge treatment by de-watering/drying/thickeningOther chemical processesAmmoniacal nitrogenCarbonization

The invention discloses a method and a device for cyclically treating breeding wastewater and / or improving soil by utilizing livestock and poultry manure. The method comprises the following steps: adding a conditioner into livestock and poultry manure for mixing and conditioning; then pre-drying and dehydrating at low temperature to reduce the moisture content to be less than 10% to obtain dried livestock and poultry manure, indirectly heating the livestock and poultry manure in a pyrolysis and carbonization device, indirectly cooling the obtained charcoal powder, and adding the obtained cooled charcoal into breeding wastewater; and forming charcoal particles; the invention can be directly used for soil improvement; part of COD, ammonia nitrogen, phosphorus and other effective elements andantibiotics and other micropollutants can be pre-removed, and the biochemical treatment load of the aquaculture wastewater is reduced; or the invention is used for deep adsorption and purification ofaquaculture wastewater before tail water is discharged. According to the method and device, pollution caused by simple composting of livestock and poultry manure is avoided, comprehensive treatment of breeding waste is fully achieved, and good social benefits, economic benefits and environmental benefits are achieved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

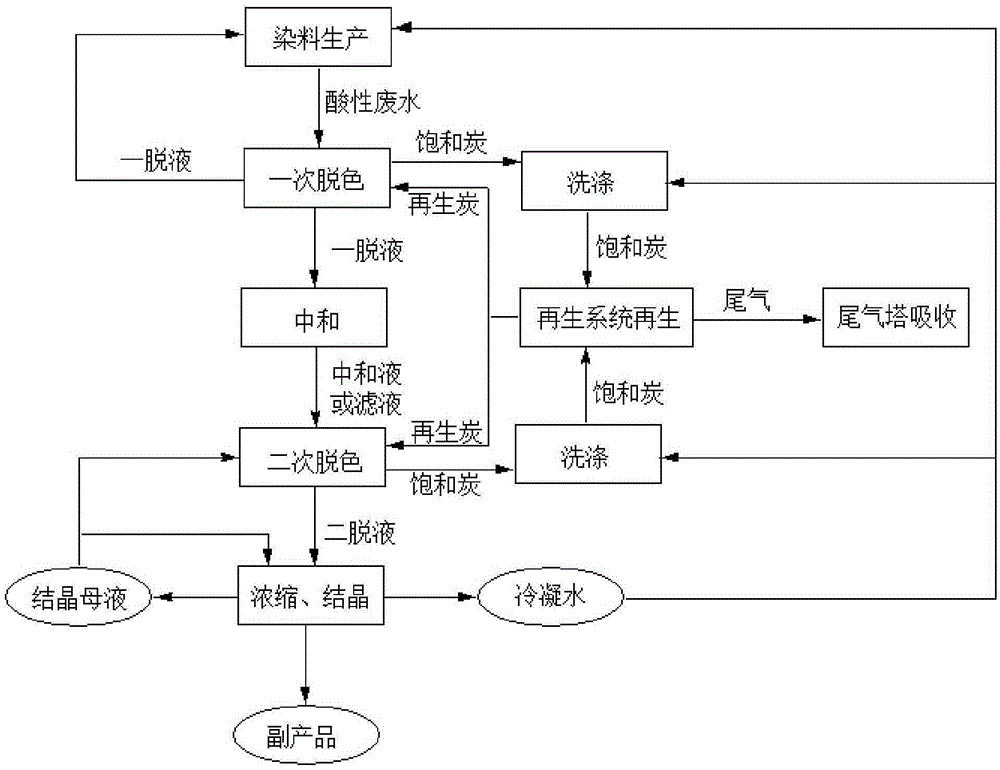

Continuous treatment method for dye industry acid wastewater

ActiveCN105417816AReduce manufacturing costAvoid wasteSpecific water treatment objectivesWater contaminantsExhaust gasChemistry

The invention provides a continuous treatment method for dye industry acid wastewater. The method includes the steps of A, primary decoloring, wherein the sulfuric acid or hydrochloric acid containing acid wastewater generated in the production process of the dye industry continuously enters the bottom of a granular activated carbon adsorption column, adsorption decoloring is conducted from bottom to top, and primarily-decolored liquid is obtained; B, neutralizing, wherein the primarily-decolored liquid is neutralized to the state that the pH value ranges from 2.5 to 7, and neutralized liquid is obtained; C, secondary decoloring, wherein the neutralized liquid continuously enters the bottom of the granular activated carbon adsorption column, secondary adsorption decoloring is conducted from bottom to top, and secondarily-decolored liquid is obtained; D, concentration and crystallization; E, activated carbon regeneration, wherein saturated granular activated carbon discharged in the step A and the step C is washed with water to the state that the pH value ranges from 2 to 7, then the washed saturated granular activated carbon is fed into a regeneration system to be regenerated, the regenerated granular activated carbon enters the granular activated carbon adsorption column to be recycled, but tail gas generated by the regeneration system is absorbed by a tail gas tower.

Owner:ZHEJIANG LONGSHENG GROUP +1

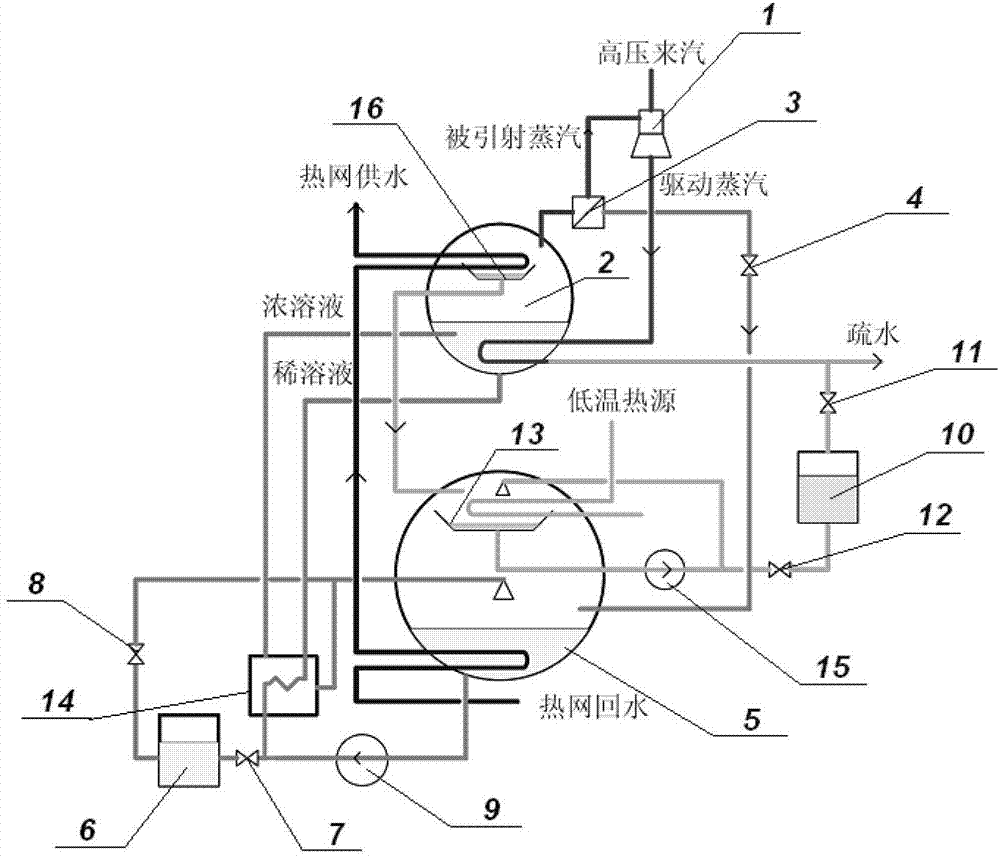

Compound heat pump with steam type injection/lithium bromide absorption

ActiveCN102954617AObvious benefits of energy saving and emission reductionSimple structureRefrigeration machinesLithium bromideInjector

The invention provides a compound heat pump with steam type injection / lithium bromide absorption. The compound heat pump with the steam type injection / lithium bromide absorption comprises an evaporator, wherein the evaporator is externally connected with a low temperature heat source pipeline; the evaporator is arranged in the interior of an absorber; a liquid outlet of the absorber is connected with a generator in which a condenser is arranged through a dilute solution pipeline, and then communicated with a first liquid inlet of the absorber through a concentrated solution pipeline; the absorber is connected with a heat net pipeline; the heat net pipeline passes through the absorber and the condenser in order, and then is output to a user supplied with heat by a heat net; a coolant outlet of the condenser is connected to a first coolant inlet of the evaporator through a pipeline; a steam outlet of the generator is communicated with a steam injector externally connected with a high pressure steam incoming pipeline through an injected steam pipeline; and an outlet of the steam injector is output through by a motive steam pipeline, a drain pipeline on the bottom part of the generator and a motive steam drain pipeline. With the adoption of the compound heat pump provided by the invention, the safe stable operation of a system can be realized; the steam energy is utilized efficiently; and the effect of energy conservation and emission reduction is obvious.

Owner:XI AN JIAOTONG UNIV

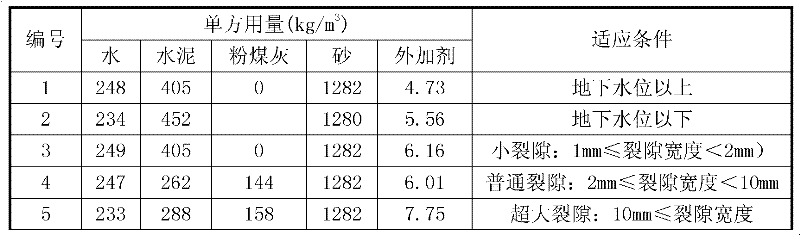

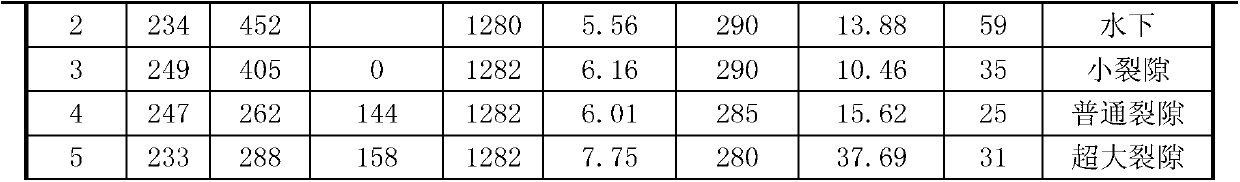

Self-compaction mortar and deep hole curtain pouring construction method

ActiveCN102505701ALow costSimple and effective construction management measuresFoundation engineeringMarine site engineeringWashoutOperability

The invention discloses a self-compaction mortar and a deep hole curtain pouring construction method. The deep hole curtain pouring construction method comprises the following steps of: preparing for construction, drilling a hole, detecting the drilled hole, pouring, finishing pouring, checking the pouring effect and sealing the drilled hole. The self-compaction mortar utilized in the construction comprises the following components in parts by weight: 0.52-0.94 parts of water, 1 part of cement, 0-0.55 parts of fly ash, 2.83-4.89 parts of sand, and 0.01-0.03 parts of admixture, wherein the admixture consists of 1 part of melamine, 0.2-0.6 parts of polyacrylamide anti-washout admixture, 0.1-0.5 parts of UWB-II type anti-washout admixture and 0.05-0.15 parts of flocculating agent. The self-compaction mortar and the deep hole curtain pouring construction method disclosed by the invention are suitable for different geological conditions; the self-compaction mortar is low in cement content and small in hydration temperature rise; a temperature control measure can be simplified and even omitted; gaps of crushed zones can be fully filled without vibrating the mortar; diffusivity of 600mm does not cause segregation and exudation; and in addition, the deep hole curtain pouring construction method has the advantages of simple and effective construction management, constant standard, strong operability, reduced human intervention, and more easily ensured construction quality and stability.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

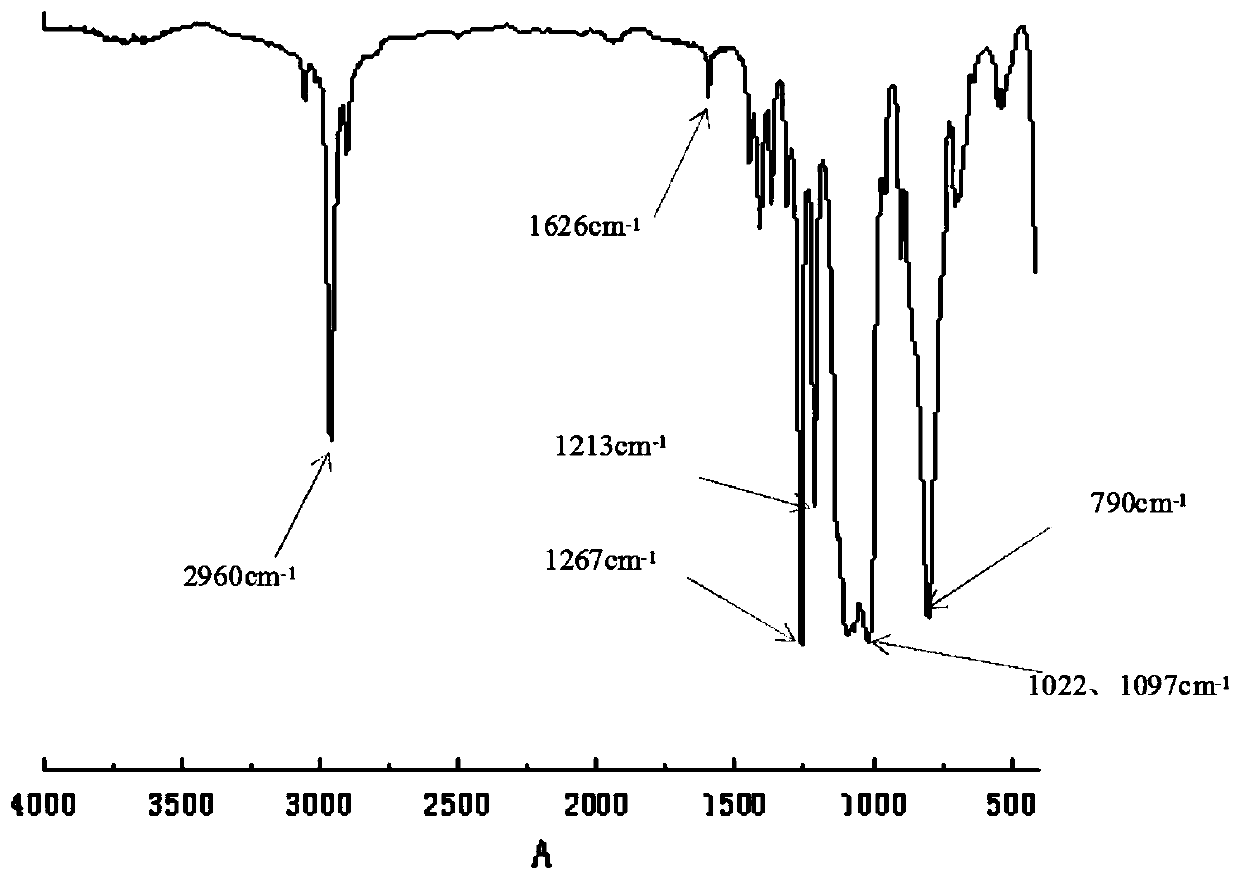

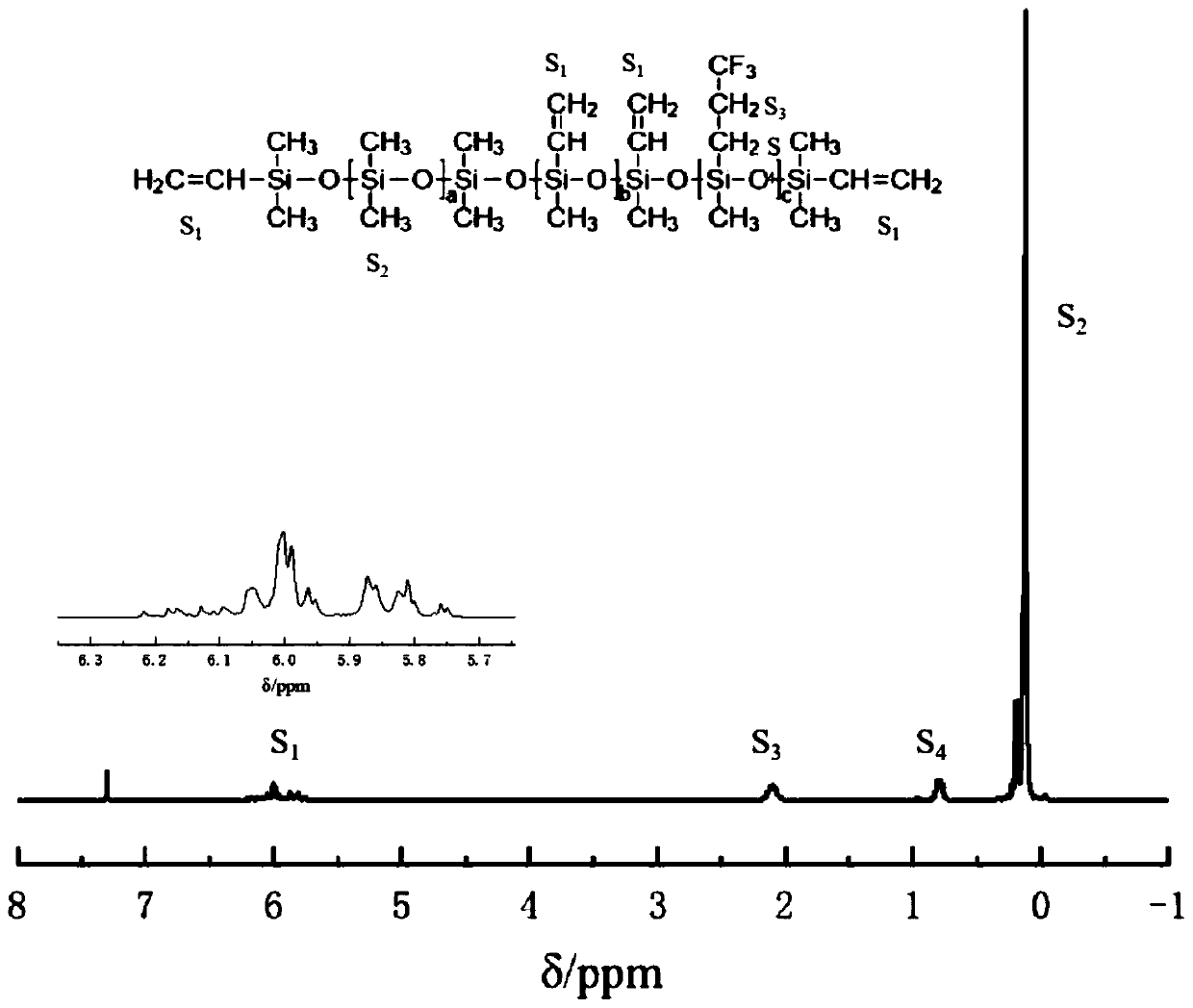

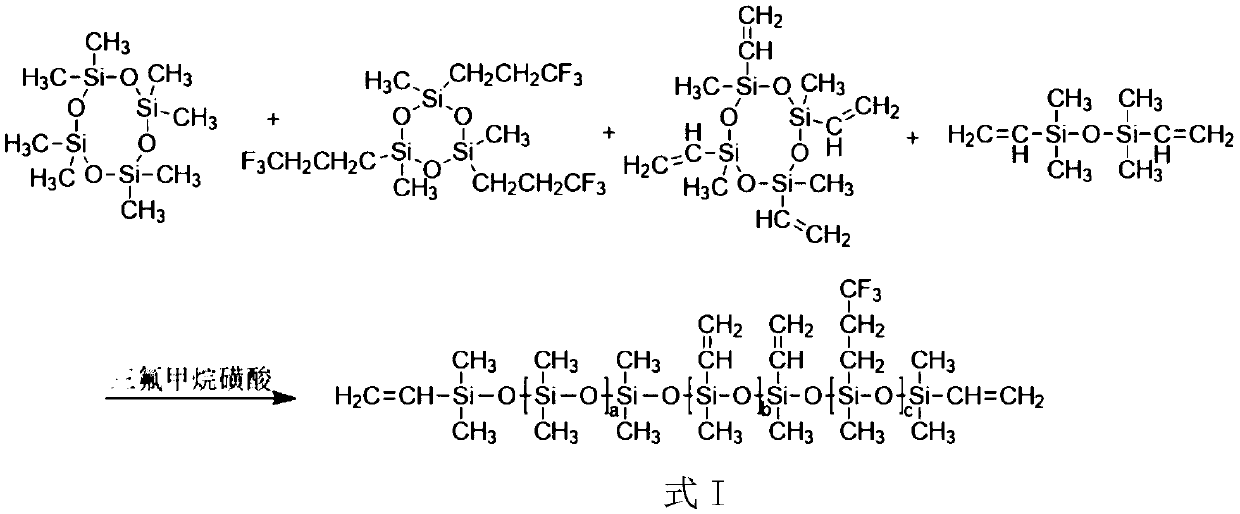

Preparation method and application of fluorine-silicon modified acrylate emulsion

ActiveCN110642999ALow level of professionalism requiredRaw materials are easy to getDyeing processIsooctyl acrylateHexadecane

The invention discloses a preparation method of a fluorine-silicon modified acrylate emulsion and application of the fluorine-silicon modified acrylate emulsion in liquid disperse dye printing. The preparation method comprises the following steps: (1) synthesis of fluorosiloxane; (2) taking isooctyl acrylate, methyl methacrylate, acrylic acid, n-hexadecane and the fluorosiloxane obtained in the step (1), uniformly stirring, and adding into an emulsifier aqueous solution to obtain a pre-emulsified liquid; and adding the pre-emulsified liquid into a reactor to serve as a seed emulsion, adding anammonium persulfate aqueous solution into the seed emulsion to react, and cooling to obtain the fluorine-silicon modified acrylate emulsion. According to the method, a fluorine-silicon chain segmentis introduced on the basis of acrylate. The handfeel of a printed fabric can be effectively improved by utilizing the softness of an organic silicon chain segment; by utilizing short C-F covalent bonds and large bond energy of organic fluorine segments, the hydrophobicity of the adhesive film is improved, the solubility parameter and the refractive index of the adhesive film are reduced, and the color fastness and the color yield of the fabric are improved.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation process of bovine blue wet leather

ActiveCN109628663AGood emulsifying and moisturizing effectImprove uniformityLeather manufacturingLeather clicking/perforating/clickingHair removalSalt free

The invention relates to the technical field of leather processing and provides a preparation process of bovine blue wet leather with a large leather area, broad growth patterns, great comprehensive performance and small environmental pollution. The bovine blue wet leather prepared by the preparation process of the bovine blue wet leather is large in width, broad in pattern, compact and fine in grain surfaces, consistent in color, uniform in thickness, soft, plump and elastic in leather body and high in physical strength. Moreover, the production process flow is simple and easy to implement, and the production cost is proper; in an implementation process, recycling of wastewater, preservation and removal of hair with less ash and sulfur, ammonia-free deashing and softening, salt-free pickling chrome tanning and other clean production technologies are also adopted. The water for tanning can be saved, the pollution of tanning is obviously reduced, the pollution disposal cost is lowered,considerable benefits of energy conservation and emission reduction are provided, and the preparation process is suitable for industrial production and use. The preparation process of the bovine bluewet leather specifically comprises the following steps of batching of bovine raw material leather, soaking in water, hair removal and expansion, beef removal, splitting, ash removal and softening, pretreatment, dewatering and peeling, soaking in acid and tanning with chrome and washing with water and discharging.

Owner:XUZHOU XINGNING LEATHER CO LTD

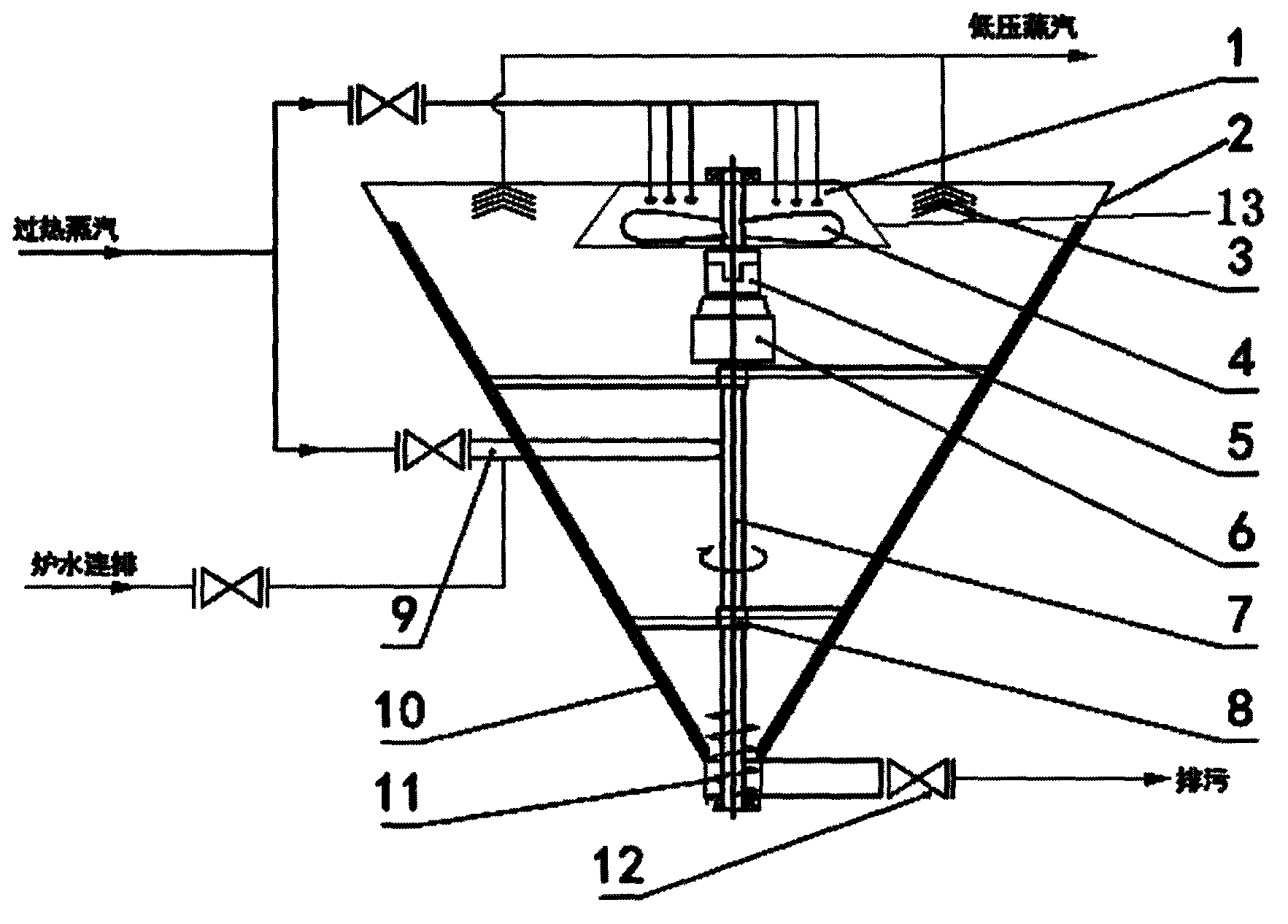

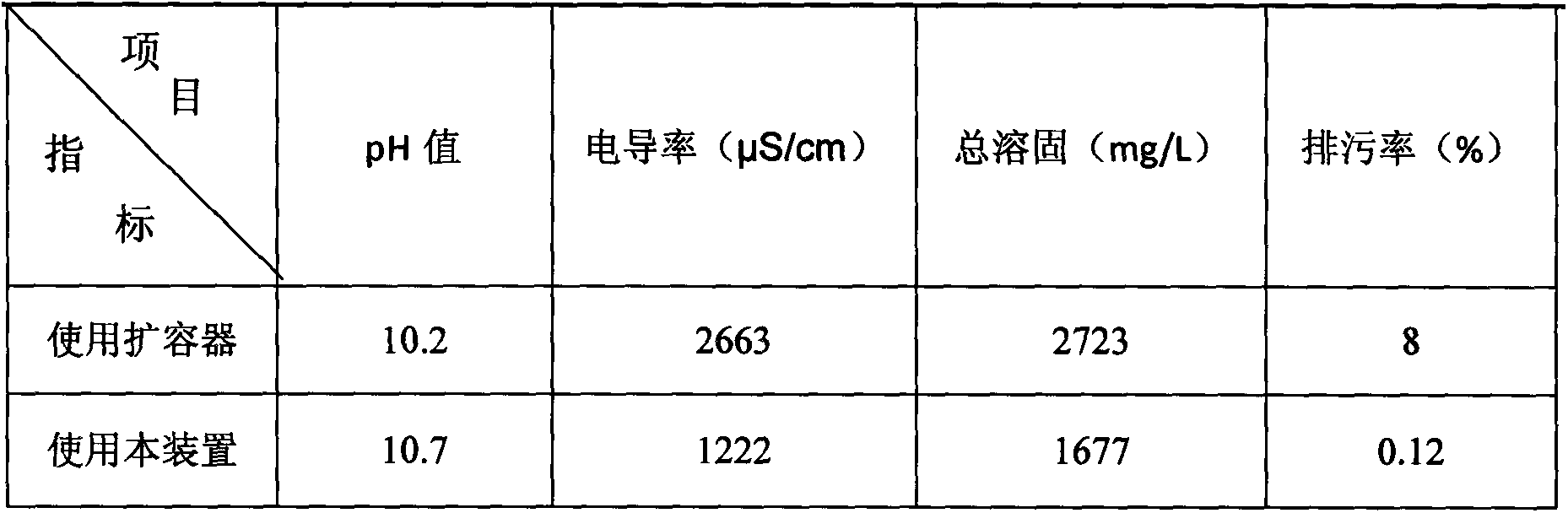

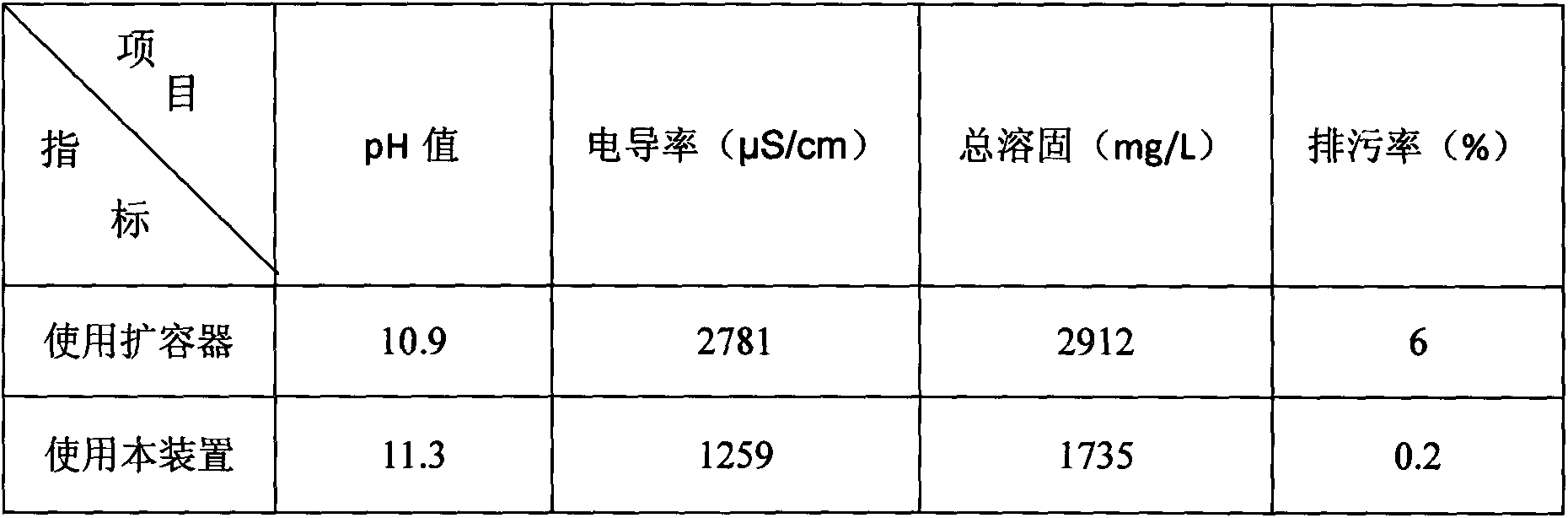

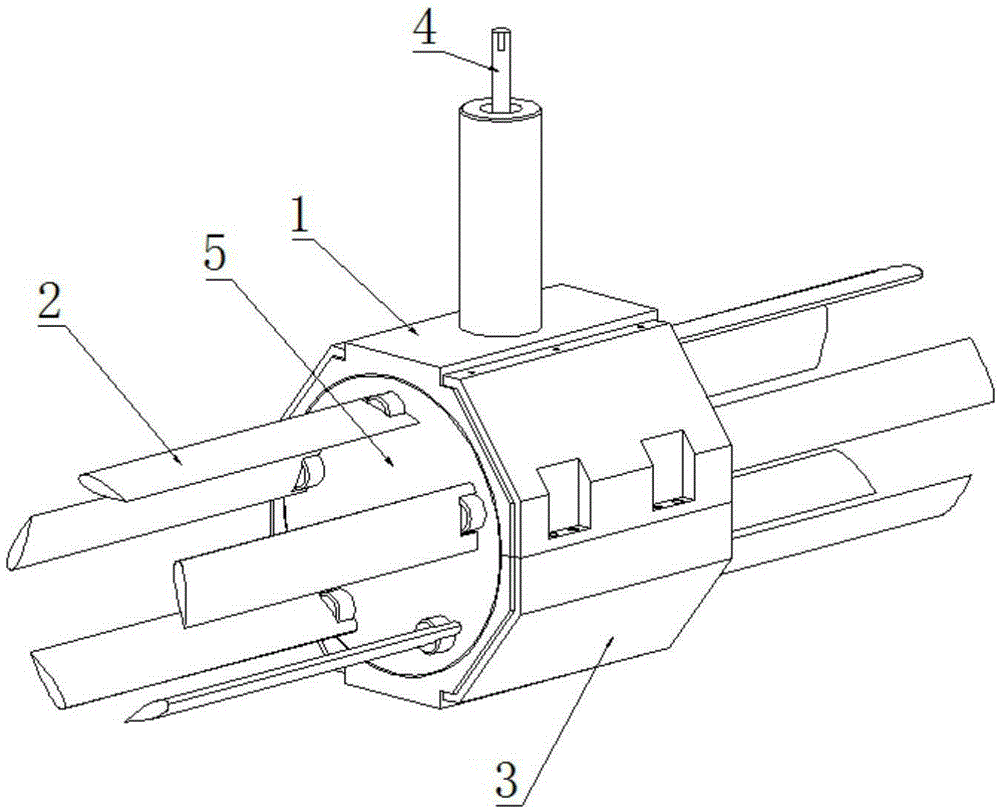

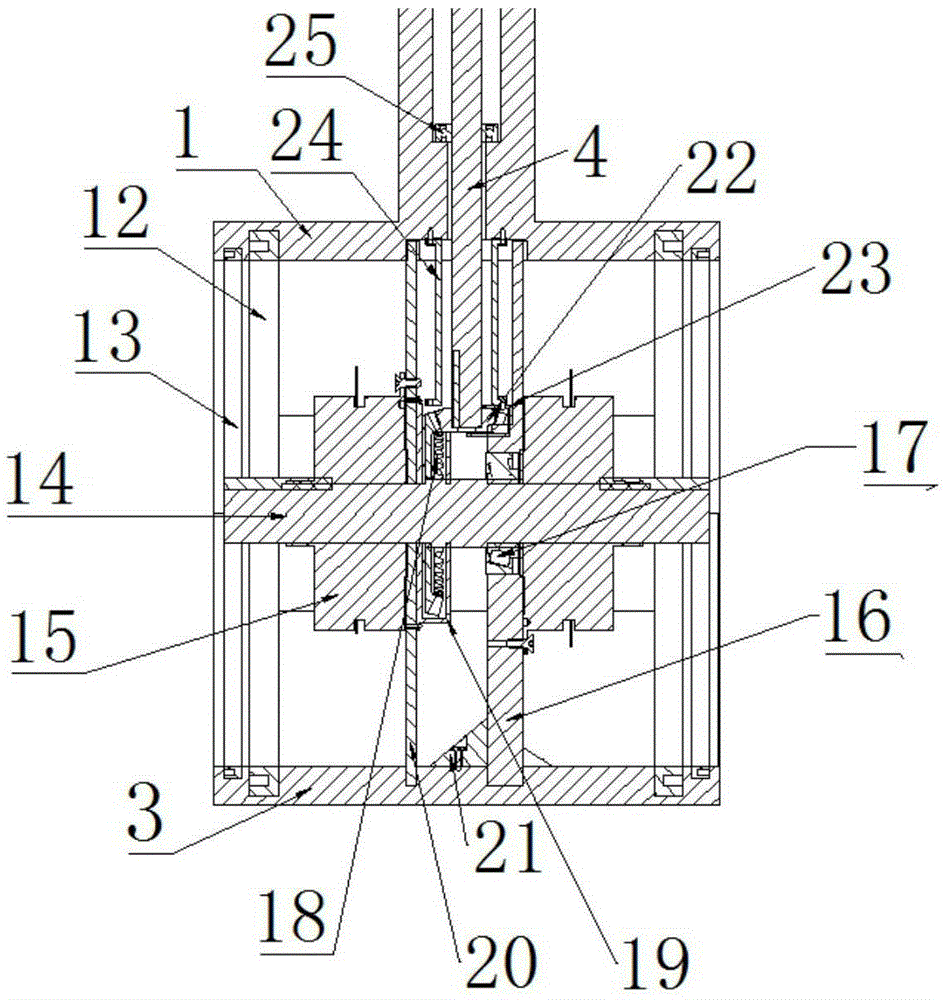

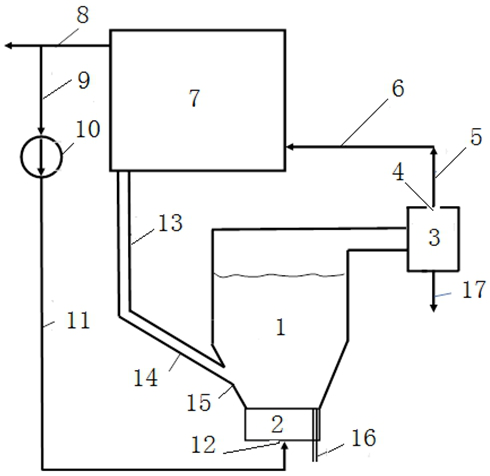

Energy-saving blowdown device for industrial boilers

The invention relates to an energy-saving blowdown device for industrial boilers. The energy-saving blowdown device comprises a shell, a turbine device, a steam-water mixer and a screw conveyor, the steam-water mixer is mounted outside the shell and connected with the side face thereof, the screw conveyor is mounted below the shell, the turbine device is arranged in the shell and comprises turbine blades and a speed reducer, steam spray heads are mounted above the turbine blades, a rotating shaft for the turbine blades is connected with the speed reducer through a magnetic coupler, the lower portion of the speed reducer is connected with a scraper transmission shaft, a scraper support is mounted on the scraper transmission shaft, the outer end of the scraper support is connected with scrapers, and a rotary shaft of the screw conveyor is connected with the scraper transmission shaft through a transmission chain. The energy-saving blowdown device for the industrial boilers does not need external power sources and effectively solves the problems of drainage waste and heat loss of traditional boiler flash tanks; and blowdown ratio and water supplement quantity of the boilers are decreased, water and heat waste of traditional flash tank equipment is avoided, and remarkable energy saving and emission reduction benefits are brought to enterprises.

Owner:QINGDAO JIENENG ENVIRONMENTAL PROTECTION CO LTD

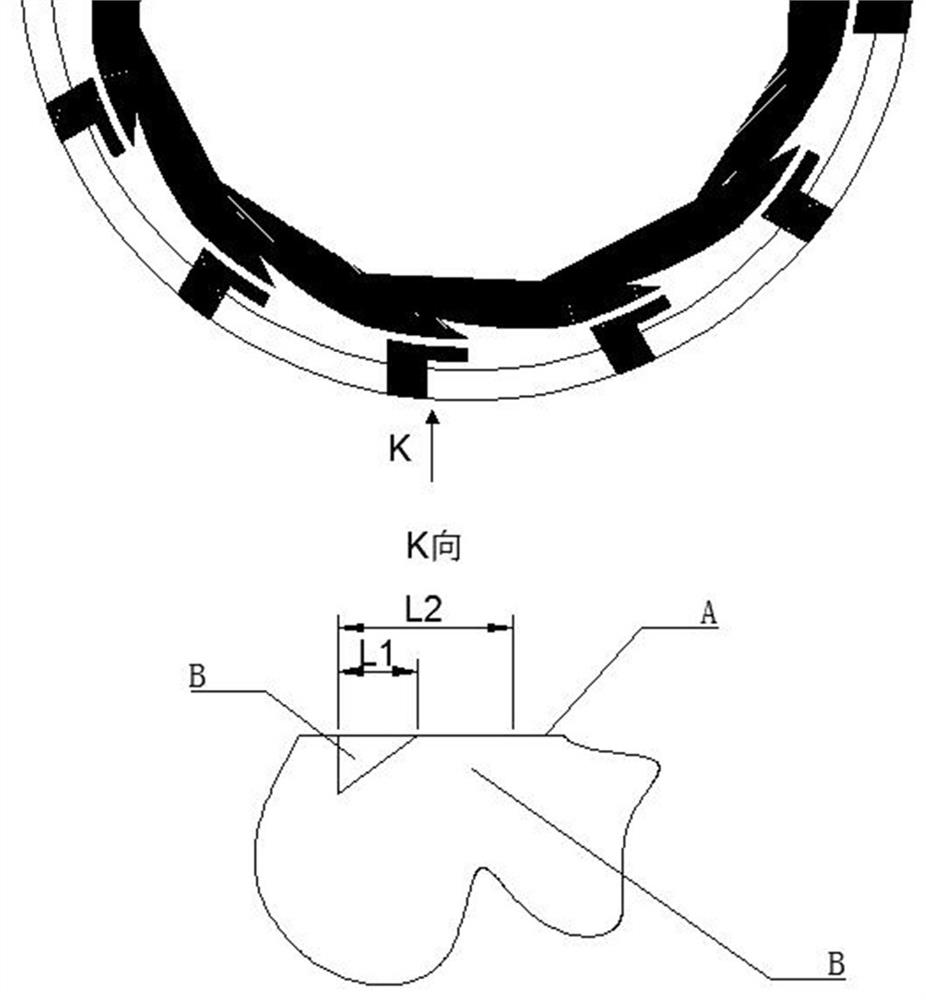

Structural device of ship whale tail wheel propeller based on stepping motor control

ActiveCN105346694AObvious benefits of energy saving and emission reductionChange the swing patternPropulsive elements of non-rotary typePropulsive elements of rotary typeMotor controlPropulsive efficiency

The invention relates to a structural device of a ship whale tail wheel propeller based on stepping motor control. The device is mainly composed of a pod shell, a runner (5) arranged in the pod shell, a plurality of blades (2) connected with the two sides of the runner (5), a drive mechanism driving the runner (5) to rotate, and a drive mechanism driving the blades (2) to swing. The pushing force can be changed by adjusting the blade swinging rule and the rotating speed of the runner according to different work conditions, a propelling device can run with the high propelling efficiency, the utilization rate of the output power of a main machine is increased, and beneficial effects are achieved in the aspect of ship energy saving.

Owner:WUHAN UNIV OF TECH

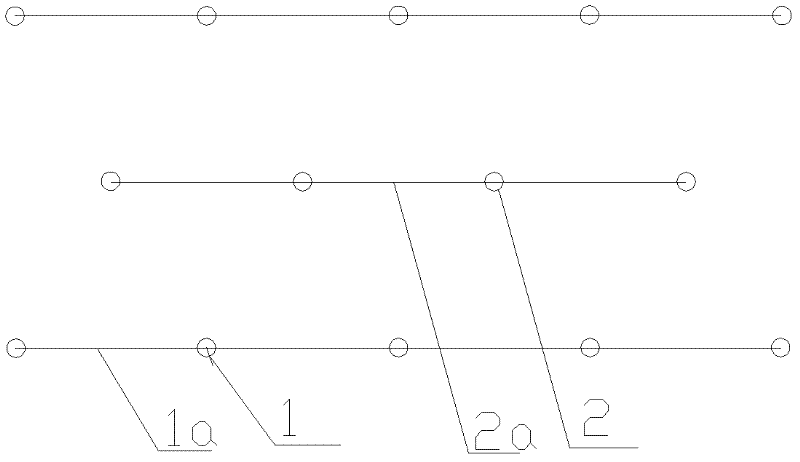

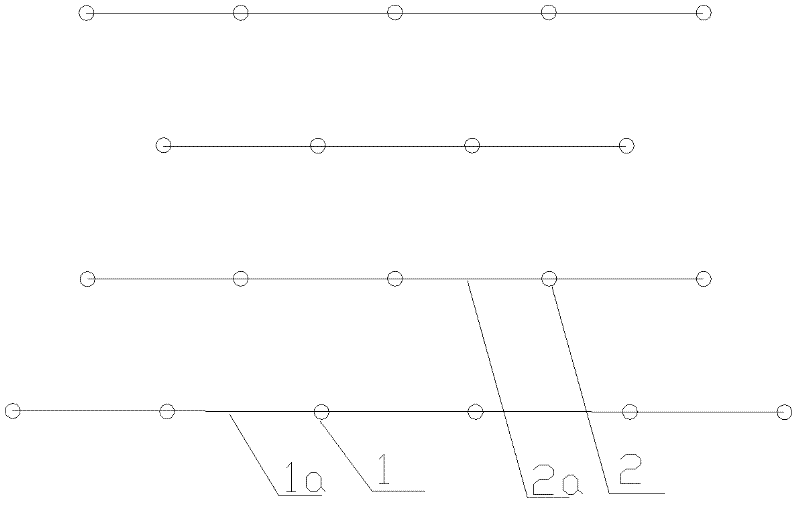

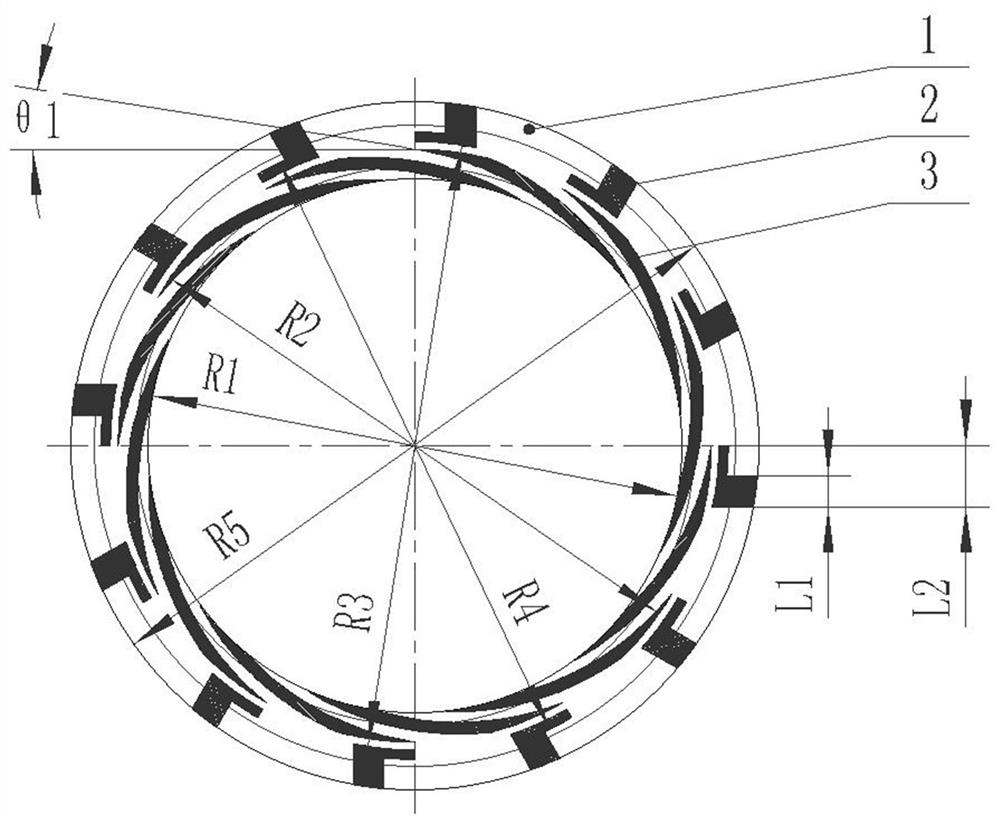

Liquid film lubrication zero-leakage mechanical seal with double rows of grooves

The invention provides a liquid film lubrication zero-leakage mechanical seal with double rows of grooves, relates to the technical field of friction and lubrication of mechanical seals, and solves the technical problems that general groove shapes cannot achieve complete sealing and zero leakage. The liquid film lubrication zero-leakage mechanical seal with the double rows of grooves comprises a sealing ring (1), L-shaped grooves (2) and spiral grooves (3). The liquid film lubrication zero-leakage mechanical seal with the double rows of grooves can be used in the situation that the mechanicalseal of a fluid machine is required to realize the zero escape of a sealed medium. The liquid film lubrication zero-leakage mechanical seal with the double rows of grooves realizes the zero escape ofthe sealed medium, and has strong durability and low maintenance cost.

Owner:CHENGDU YITONG SEAL

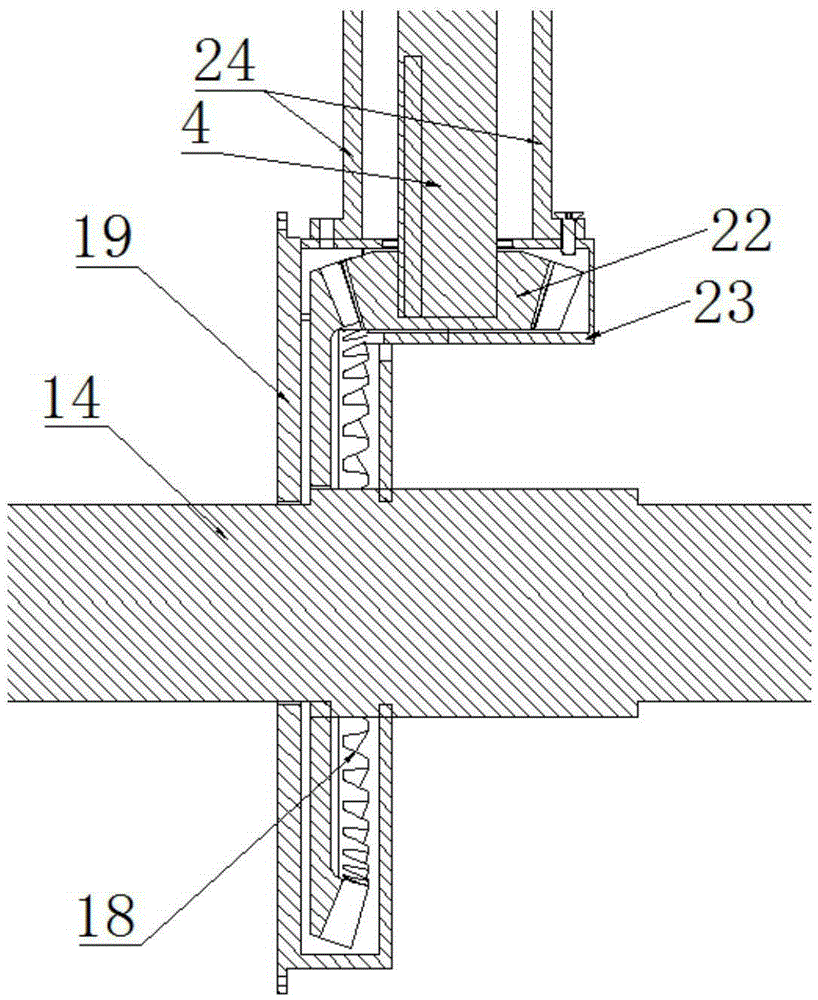

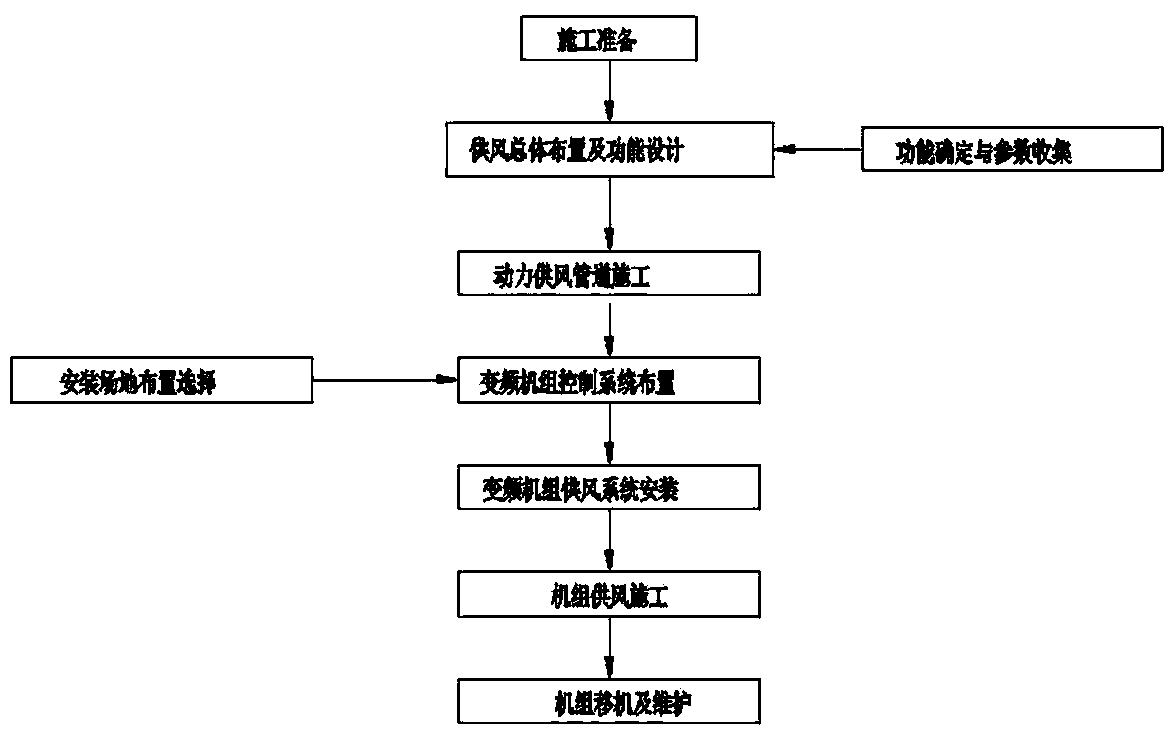

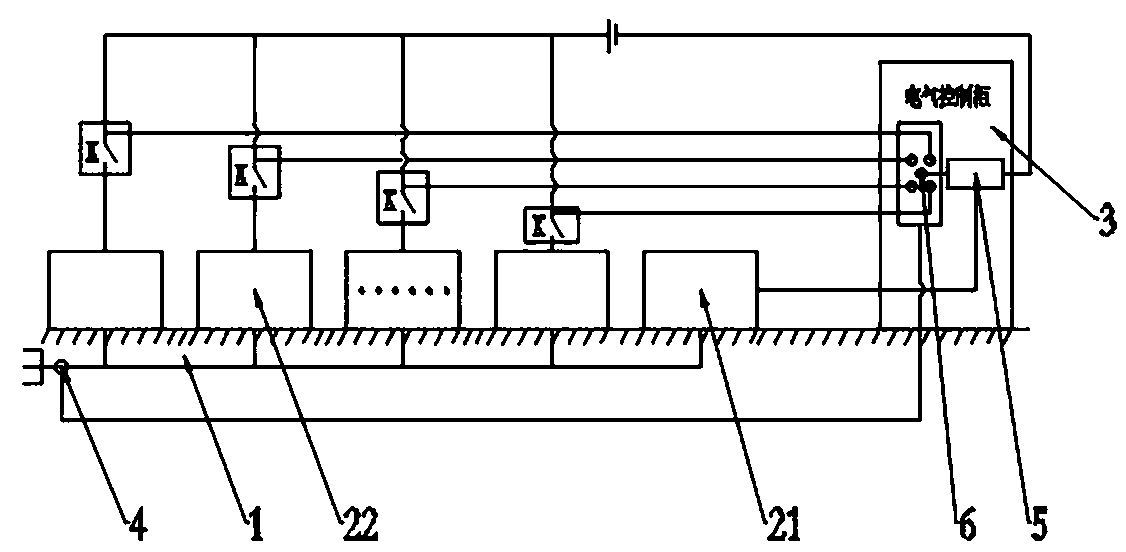

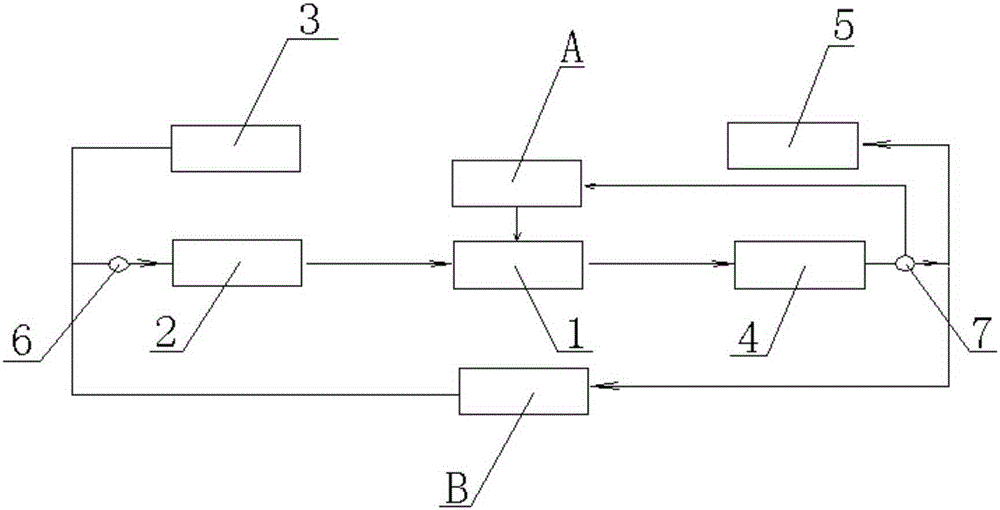

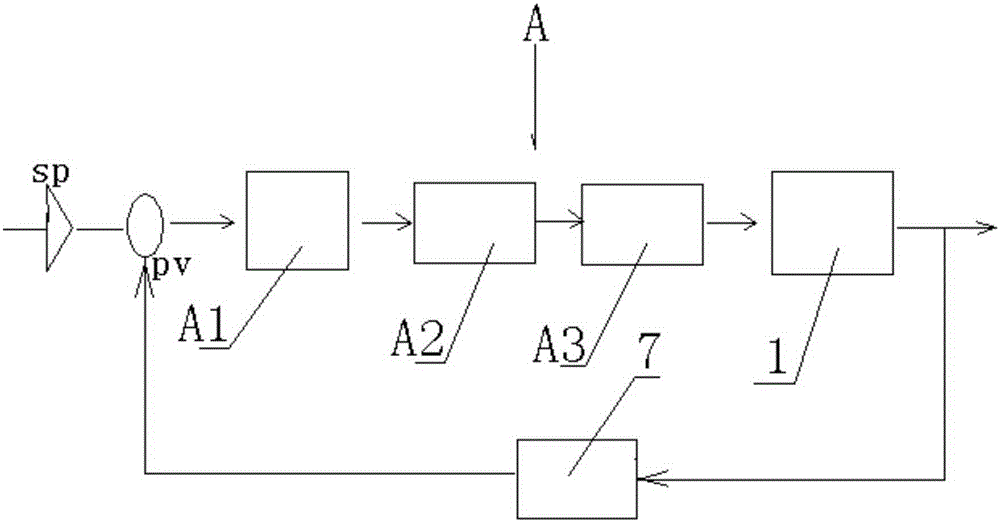

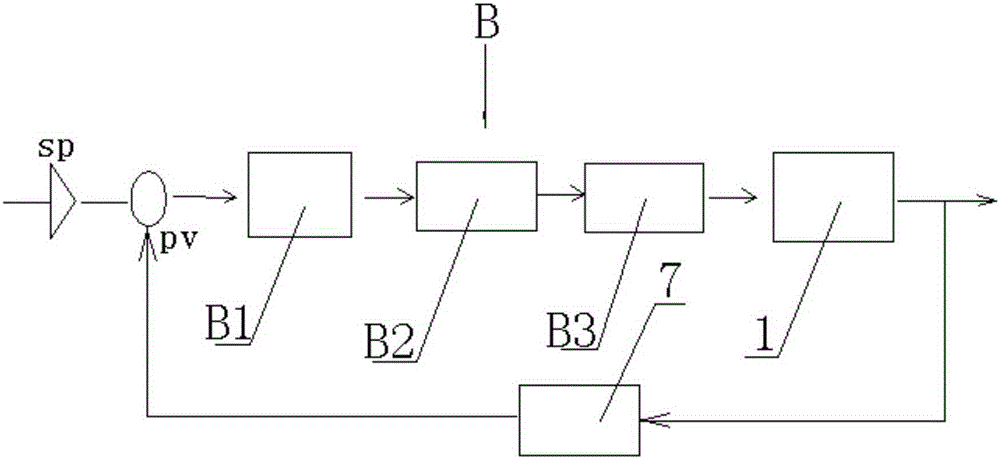

Tunnel frequency-changing air compressor unit intelligent power air supply system and construction method

PendingCN109958609AGood economic benefitsReduce energy wasteMining devicesPump controlContinuous/uninterruptedControl system

The invention relates to the technical field of control, in particular to a tunnel frequency-changing air compressor unit intelligent power air supply system and construction method. The constructionmethod specifically includes the following eight steps of construction preparation, air supply general distribution, air supply general distribution and function design, power air supply pipeline construction, frequency-changing unit control system distribution, mounting of frequency-changing unit air supply system, unit air supply construction and unit moving and maintenance. Compared with a traditional method, sensors are used for measuring and controlling amount of blast in real time, under the condition of insufficient blast capacity, a PLC control system is used for continuously startinga plurality of air compressors, continuous uninterrupted stepless speed regulation of motors is achieved through the air compressors of an air supply system, and thus amount of blast is continuously changed; and under the situation of sufficient amount of blast, the rotate speeds of the motors are decreased in real time until the multiple air compressors are closed, and energy waste is reduced.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG +1

Coal gas pressing device and coal gas pressing control method for furnace kiln coal gas

InactiveCN106556259AReasonable structureEasy to implementControl devices for furnacesFrequency changerReflux valve

The invention discloses a coal gas pressing device and a coal gas pressing control method for a furnace kiln coal gas. The coal gas pressing device comprises a coal gas pressing machine, wherein the coal gas pressing machine is provided with a frequency converter assembly; a stable pressure of the coal gas pressing machine is maintained through variable-frequency speed adjustment of the frequency converter assembly; one end of a backflow valve assembly is communicated to a gas channel between a coal gas inlet valve and a converter coal gas supply pocket; the other end of the backflow valve assembly communicates with a gas channel between a coal gas outlet valve and a furnace kiln system; a coal gas inlet pressure detection device is arranged on the gas channel communicating with the coal gas inlet valve, of the backflow valve assembly; and a coal gas outlet pressure detection device is arranged on the gas channel communicating with the coal gas outlet valve, of the backflow valve assembly. The device part disclosed by the invention is reasonable in structure and easy to implement; and a closed-loop adjustment control system is adopted in the method part, the pressure of a converter coal gas before entering a furnace kiln is subjected to pressing adjustment to meet the fuel requirements of the furnace kiln, heat in the kiln is stably controlled, the quality indexes of lime production can meet the need of steel making, and remarkable effects of energy conservation and emission reduction are achieved.

Owner:BAOSTEEL STAINLESS STEEL

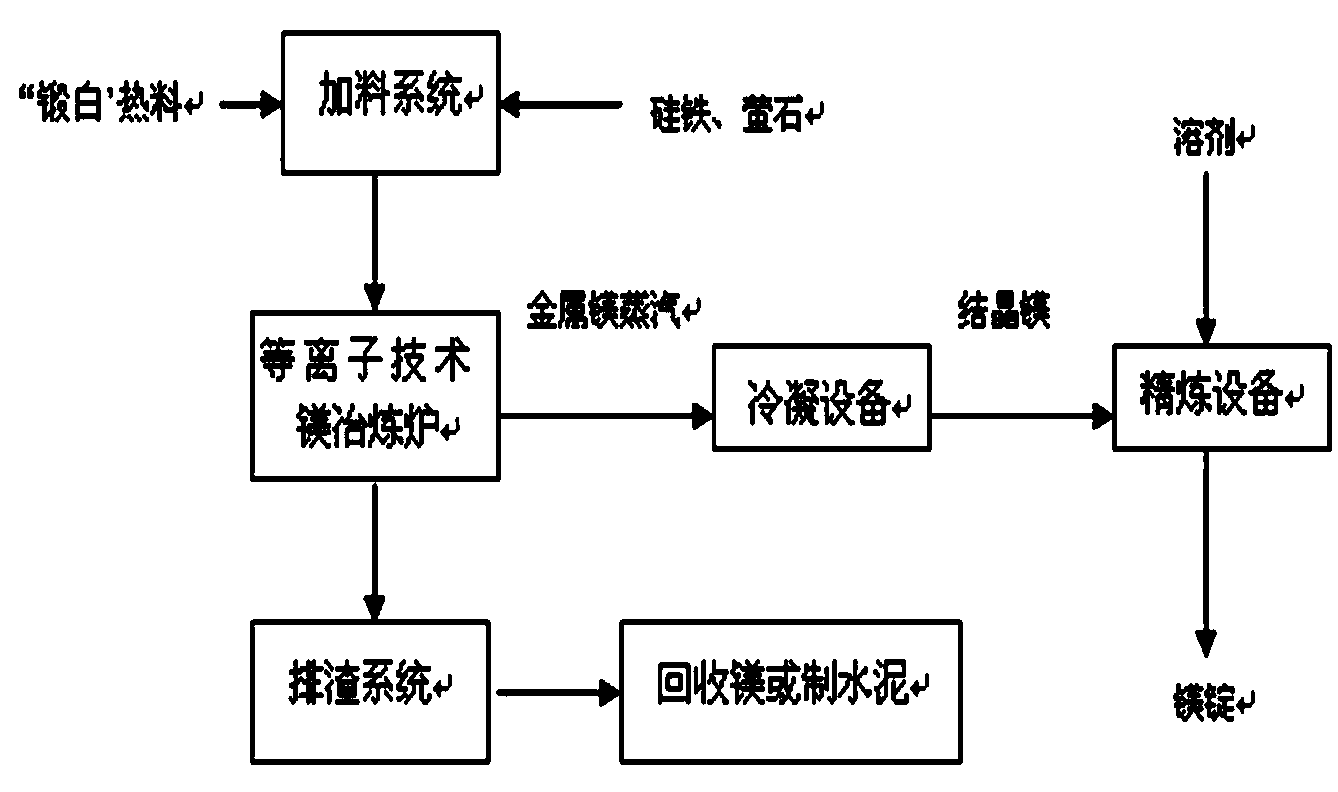

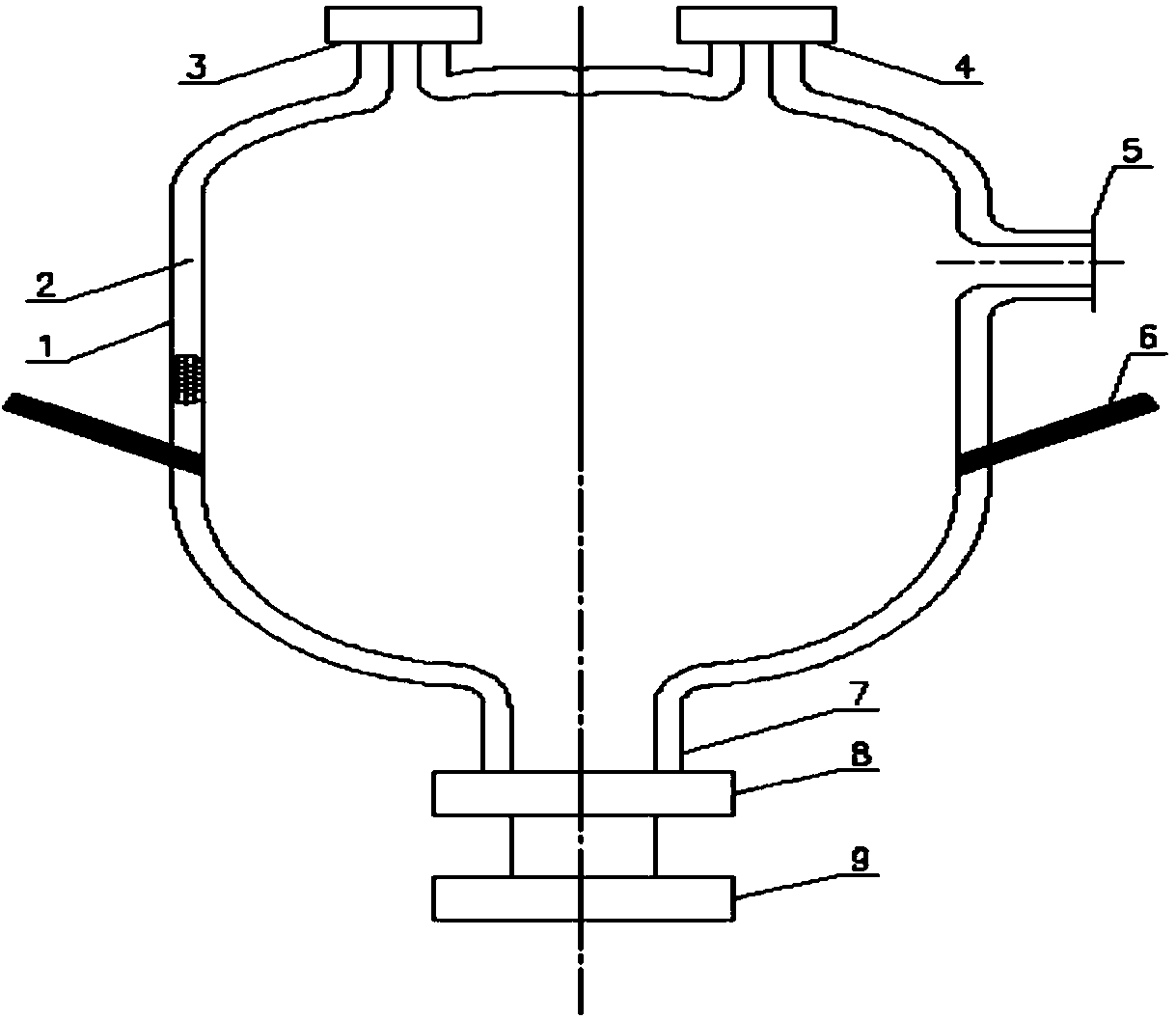

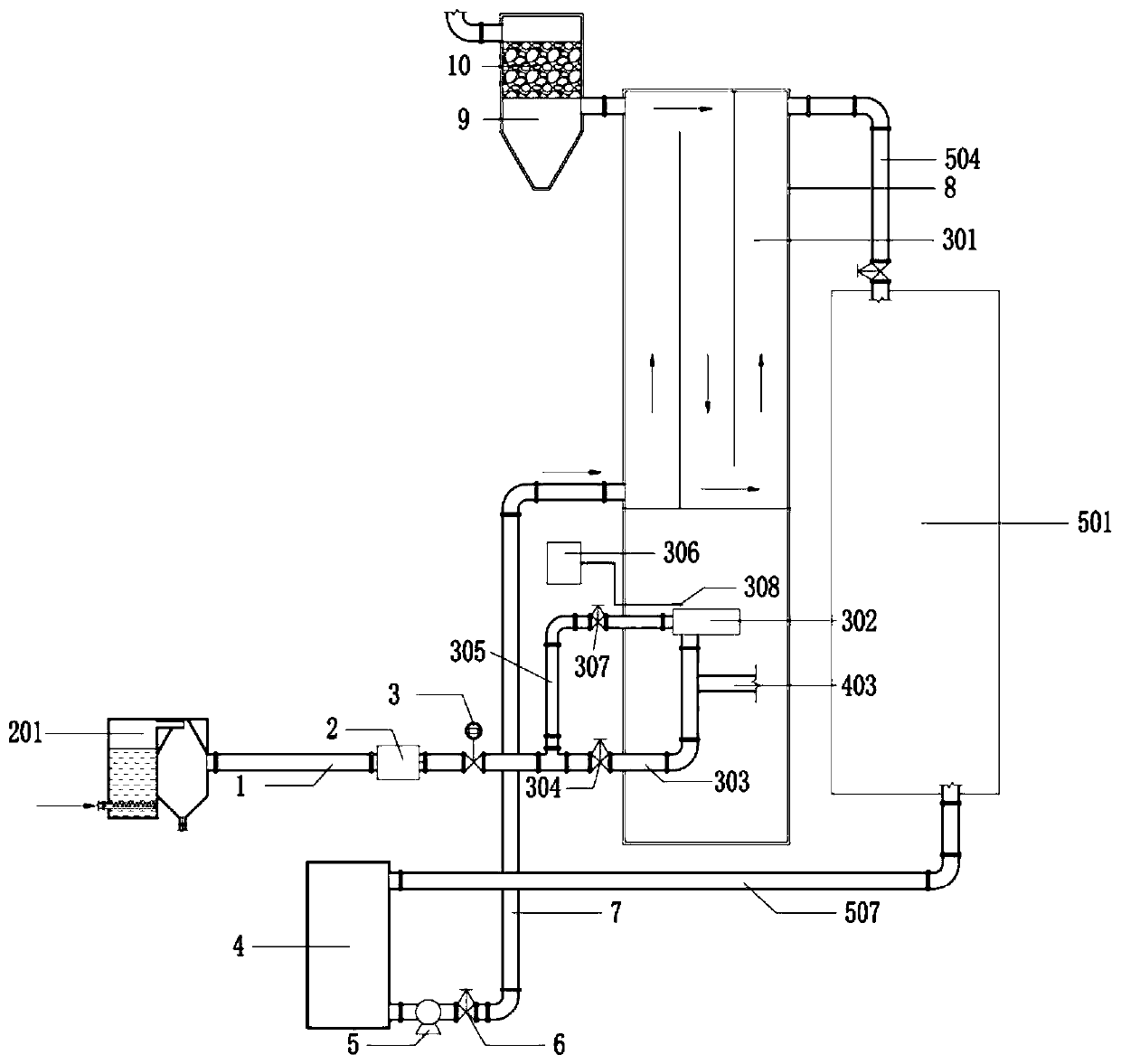

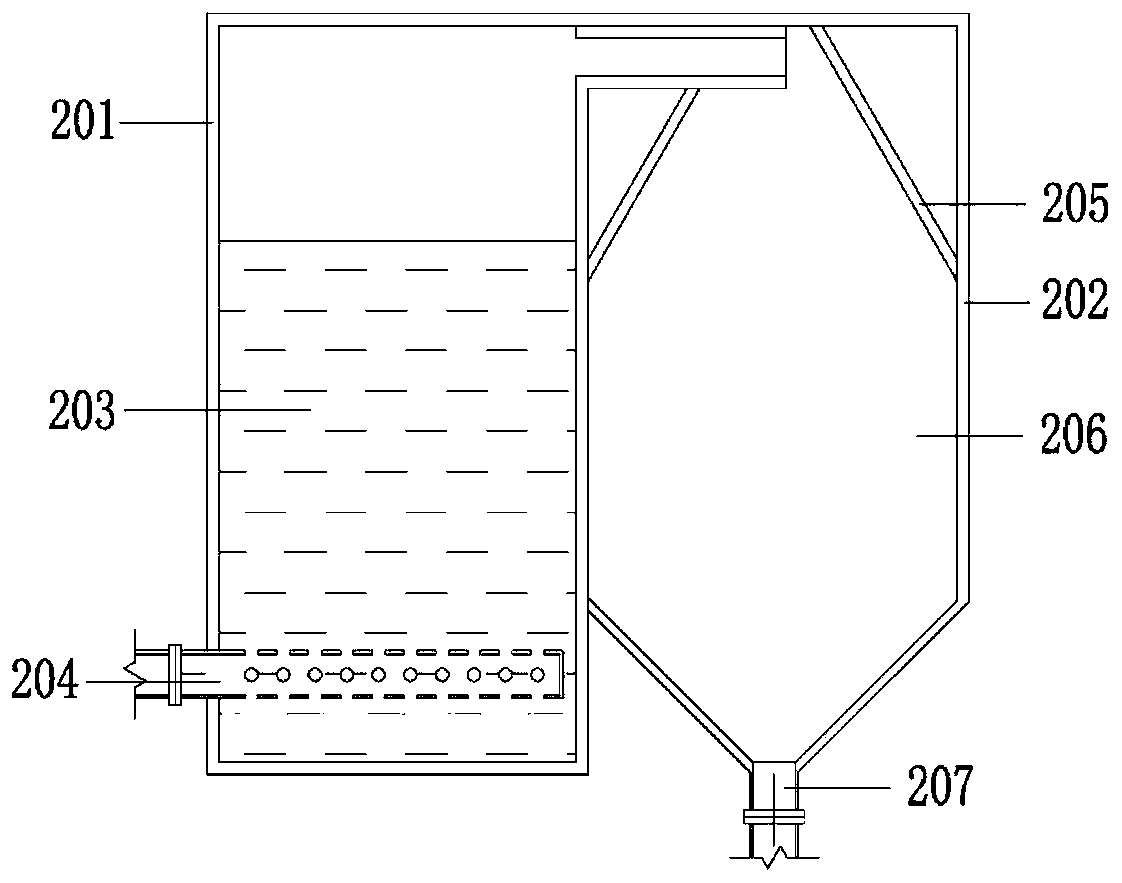

Magnesium metal smelting method and device employing plasma torch heating technology

InactiveCN103589879AHigh efficiency mass transfer and heat transfer processSolve moisture absorptionProcess efficiency improvementPlasma torchSlag

The invention relates to a magnesium metal smelting method and a device employing a plasma torch heating technology. The method comprises the steps that: 1, an inert gas shielded automatic charging system adds prepared raw materials for smelting magnesium metal into a plasma magnesium metal smelting furnace, 2, the raw materials perform continuous silicothermic reduction reaction in the smelting furnace to produce magnesium metal steam and reducing slag, a plasma torch provides a heat source for the reduction reaction, and 3, the magnesium metal steam from the smelting furnace enters a condenser to be condensed into crystal magnesium, the reducing slag is discharged by an inert gas shielded automatic deslagging system, the crystal magnesium can be refined continuously to form a magnesium ingot, and the reducing slag serves as a raw material of cement or is processed for recovery. The method and the device overcome the disadvantages of indirect heating and discontinuous production of a reduction pot, poor mass transfer and heat transmission during reduction, low heat efficiency and low production efficiency in the traditional magnesium smelting technology, a direct heating mode and continuous production are adopted, and the method and the device have a good energy-saving effect and a positive significance for environmental protection.

Owner:北京环宇冠川等离子技术有限公司

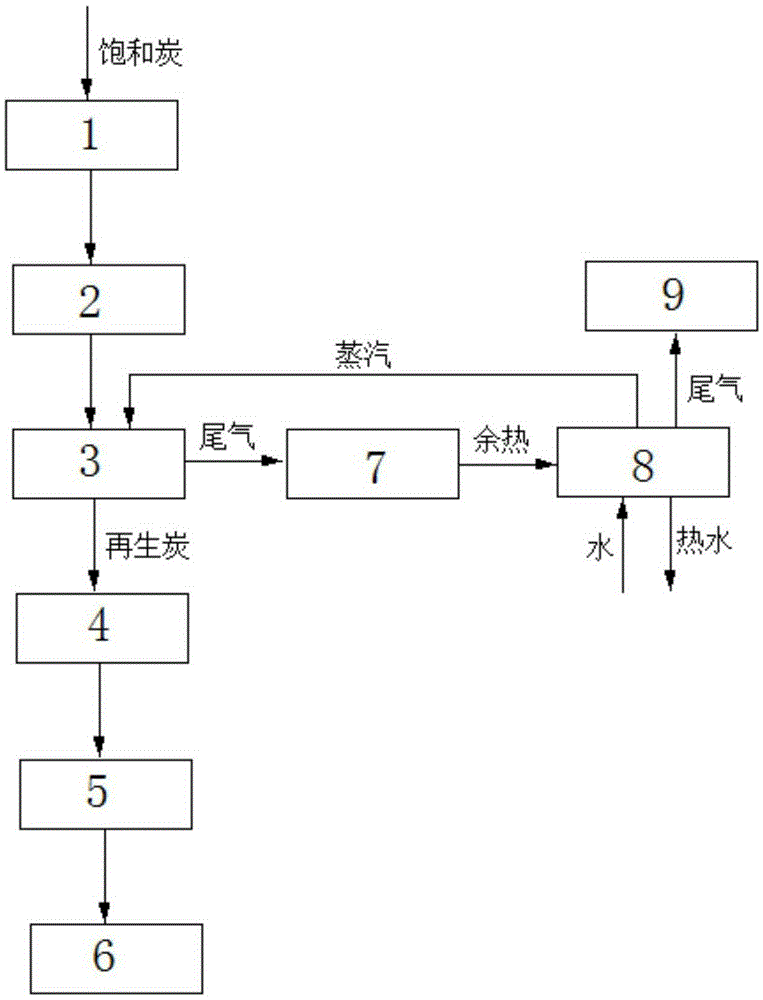

Device and method of recovering heat energy in waste water anaerobic treatment process

InactiveCN111536514AImprove toleranceStable combustionGaseous fuelsWaste based fuelHeat conductingPollutant emissions

The invention discloses a device and a method of recovering heat energy in a waste water anaerobic treatment process. Biogas is generated in waste water anaerobic treatment. Heat energy generated by combustion of biogas is transferred to a heat conducting fluid by means of a thin-walled tubular heat exchanger, and the heated heat conducting fluid heats a target according to a process demand, so that heat energy is recovered and utilized. According to the method, a combustion-supporting air / gas ratio and an air distributing pressure are set according to compositions of biogas, so that biogas iscombusted fully, and the emission amount of combusted tail gas is reduced. A thin-walled heat exchange tube system which is good in heat conducting property transfers heat to the heat conducting fluid efficiently, so that the comprehensive recycling ratio of heat energy of the waste water anaerobic fermentation product biogas reaches 80-90% which is far higher than 30% of biogas power generation.The method is suitable for recycling combustion heat energy of various organic waste water anaerobic fermentation products, has the advantages of being high in recycling ratio of heat energy, safe and easy to operate and small in tail gas pollutant emission, and has an application prospect in the field of recycling organic pollutant energy sources in waste water.

Owner:SOUTH CHINA UNIV OF TECH

Wet state dyeing and finishing one-bath technology for cattle instep leather

ActiveCN106834556AImprove permeabilityImprove bindingLeather manufacturingTanning treatmentSocial benefitsEconomic benefits

The invention relates to the technical field of tanning chemical and engineering, and provides a wet state dyeing and finishing one-bath technology for cattle instep leather. In the wet state dyeing and finishing process, the procedures of chromium retanning, neutralizing, filling retanning, dyeing, stuffing and the like are conducted in a one-bath manner, different materials act in a one-bath manner and can mutually promote seepage and diffusion, the technology process is simple, and operation is convenient and easy to achieve. Crust leather manufactured through the wet state dyeing and finishing one-bath technology for the cattle instep leather is soft and full in body and rich in elasticity, a grain surface is smooth, delicate, compact and free of a loose side, and various physical and chemical properties meet the industry requirement. Meanwhile, the wet state dyeing and finishing one-bath technology for the cattle instep leather has obvious energy saving and emission reducing benefits, waste water pollution can be greatly relieved, and the material usage amount and the water usage amount are reduced. The production time is shortened, the production cost is reduced, the production efficiency is improved, and good economic benefits and social benefits are achieved.

Owner:XINGYE LEATHER TECH CO LTD

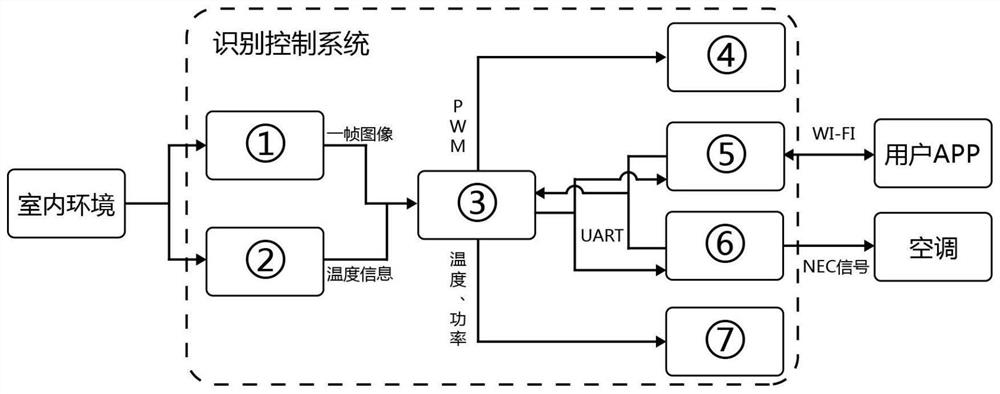

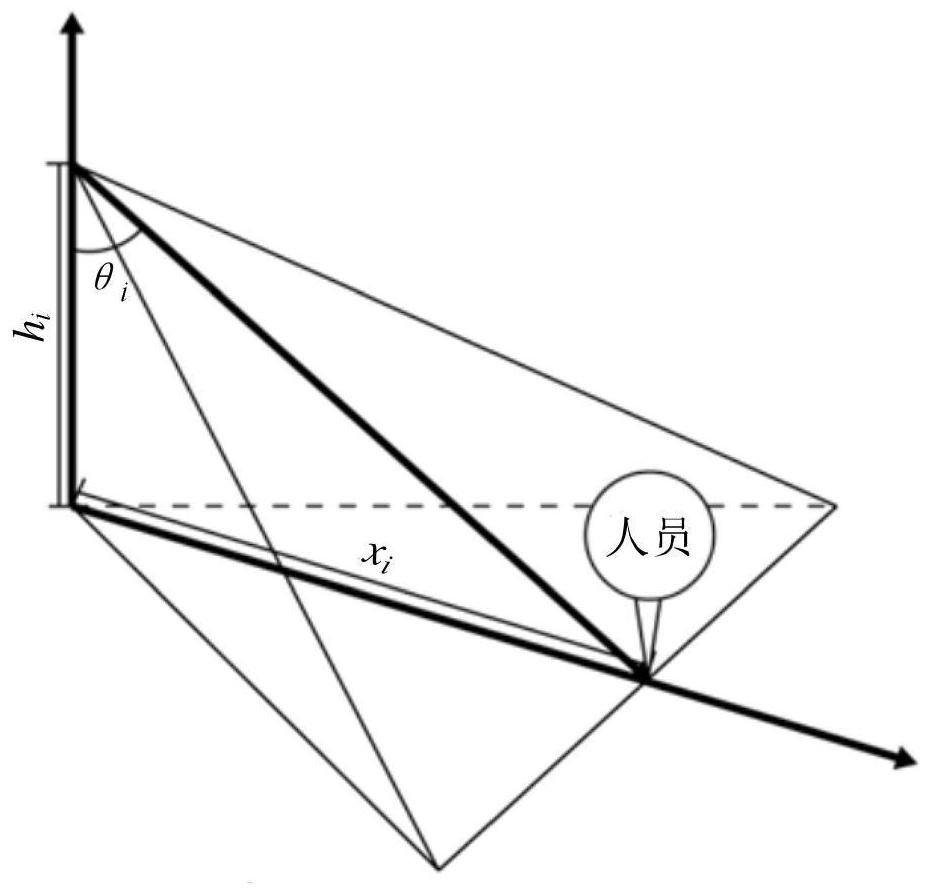

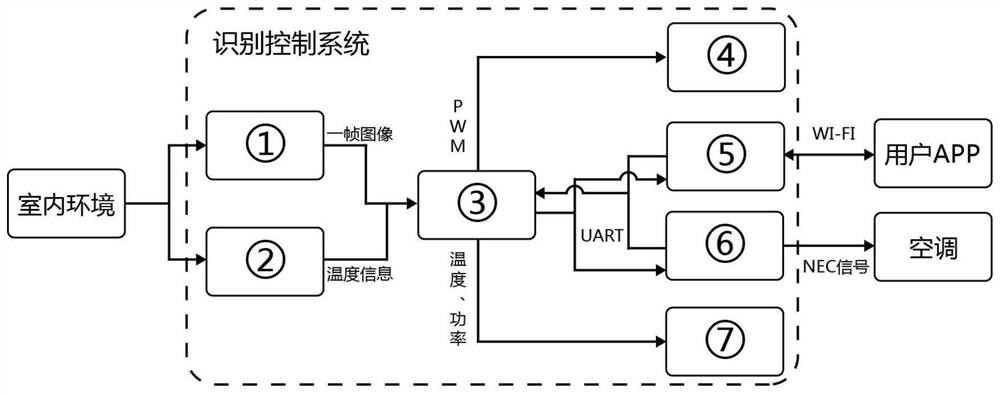

Intelligent wind guide system for air-conditioner based on deep learning and dynamic wind guide method thereof

InactiveCN112066530AEfficient use ofReduce lossMechanical apparatusLighting and heating apparatusWind runRemote control

The invention discloses an intelligent wind guide system for an air-conditioner based on deep learning and a dynamic wind guide method thereof. In the prior art, air-conditioner equipment capable of dynamically adjusting the wind output direction according to positions of personnel in space and the temperature distribution situation in the space is lacked. The system comprises an image sensor, a wind direction adjusting module and an infrared remote control module. The wind direction adjusting module is installed at a wind outlet of the air-conditioner. The image sensor is installed on the side portion of the air-conditioner and collects image data within the wind supply range of the air-conditioner. The infrared remote control module is connected with a controller and used for controllingthe wind speed and the wind output temperature of the air-conditioner under control of an instruction sent by the controller. According to the system, dynamic adjusting is carried out according to the distribution positions of the personnel in the space and the temperature distribution situation of the space, efficient utilization of cold wind of the air-conditioner can be achieved, thus power consumption is reduced on the premise of guaranteeing comfort of a human body, the loss of a compressor of the air-conditioner is reduced, and the system has huge energy conservation and emission reduction benefits.

Owner:ZHEJIANG UNIV OF TECH

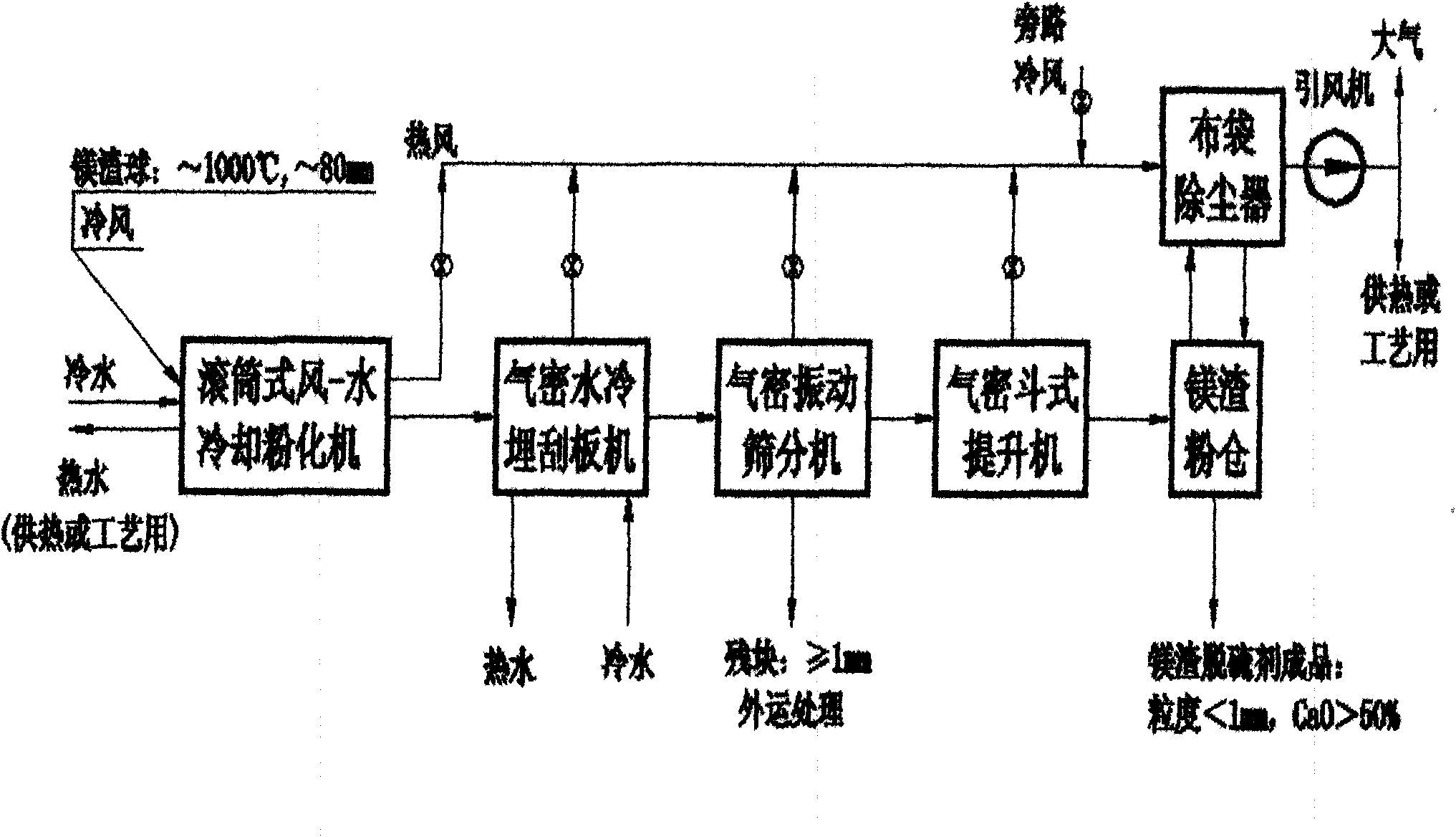

Process method for converting metal magnesium slag into desulphurizer of boiler

InactiveCN101791622BImprove cooling efficiencyEasy to handleSolid waste disposalDispersed particle separationSlagCrusher

Owner:山西猗顿生态环保股份有限公司

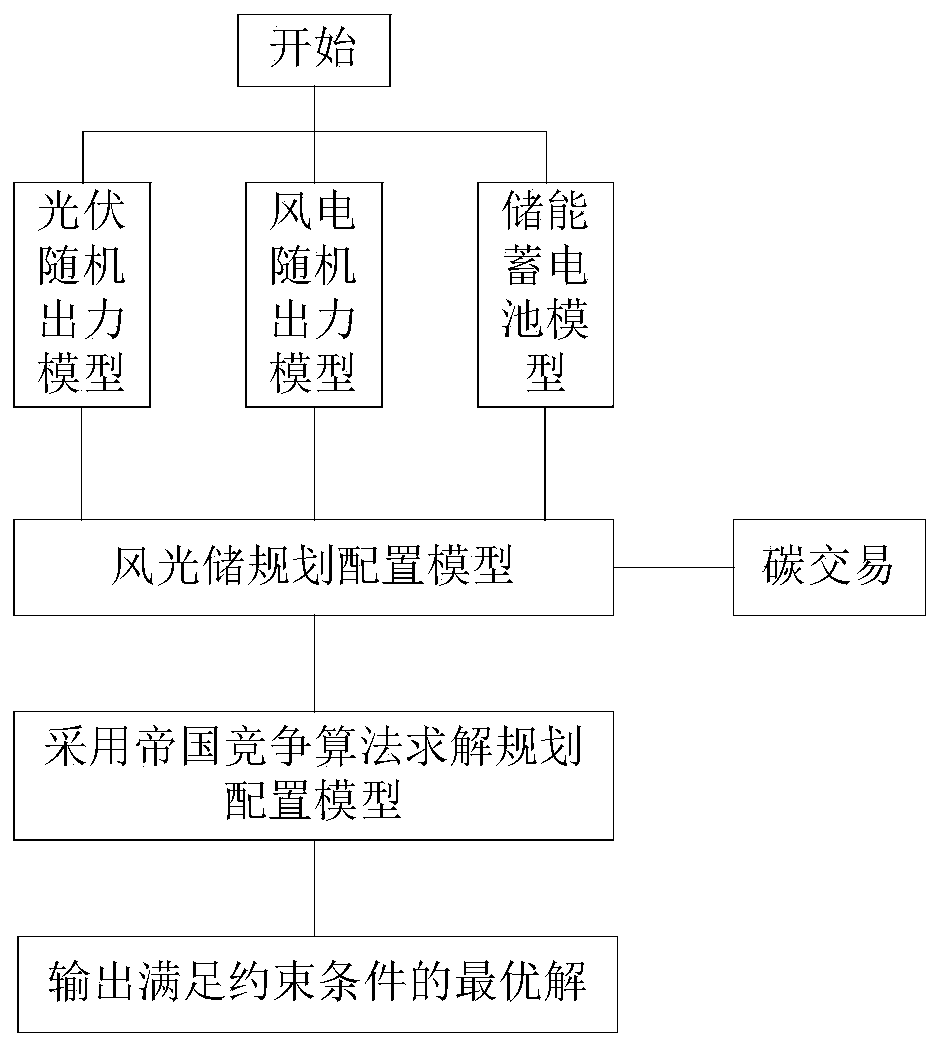

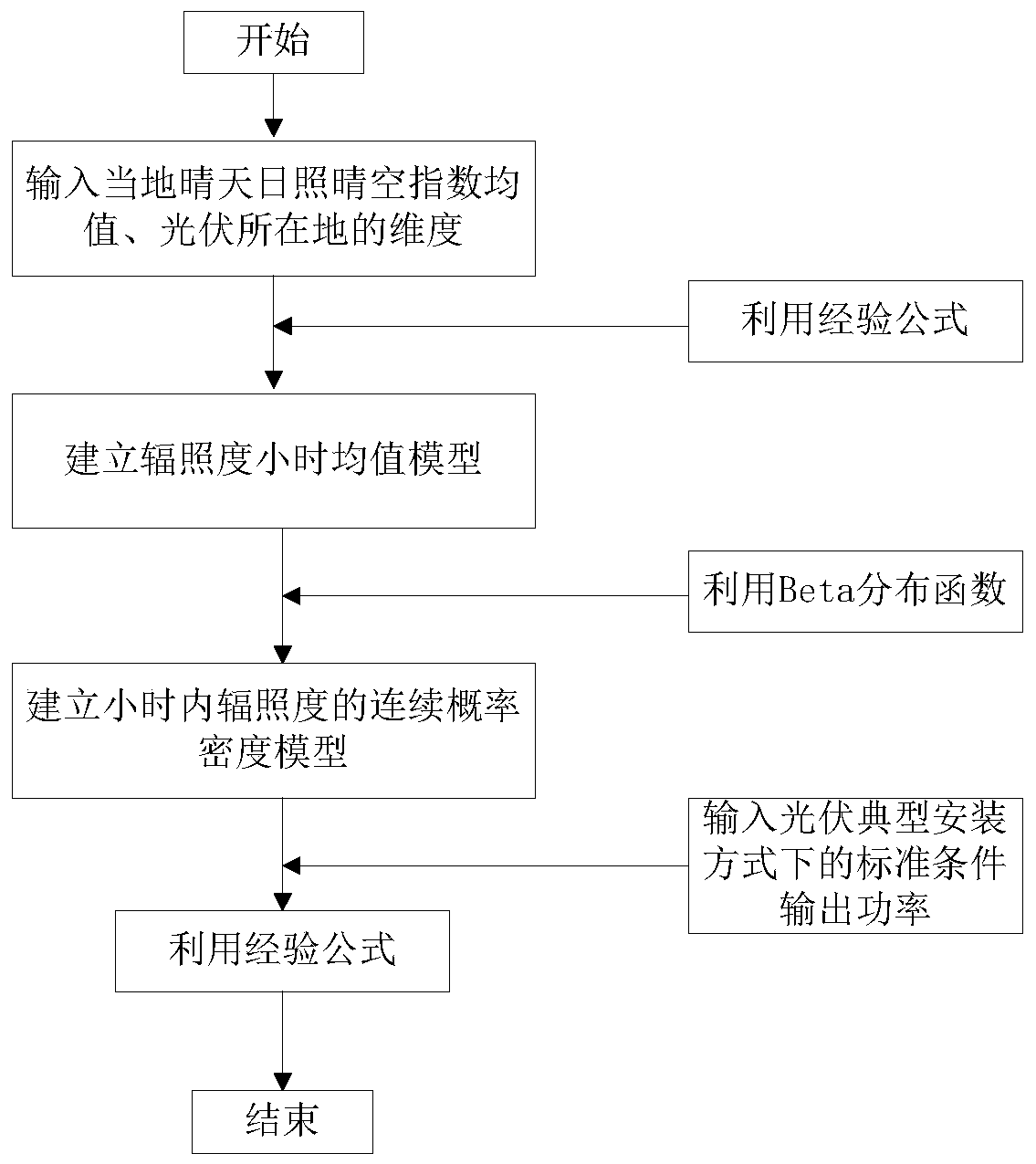

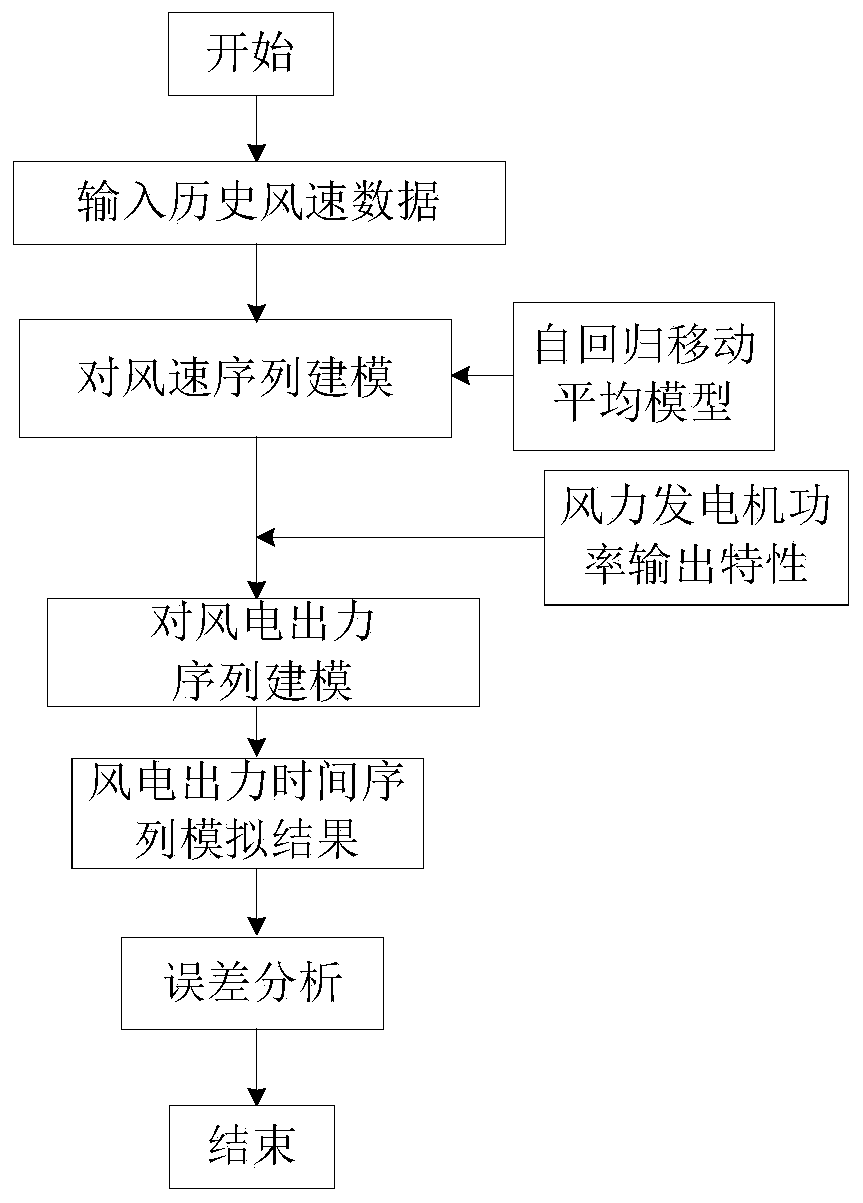

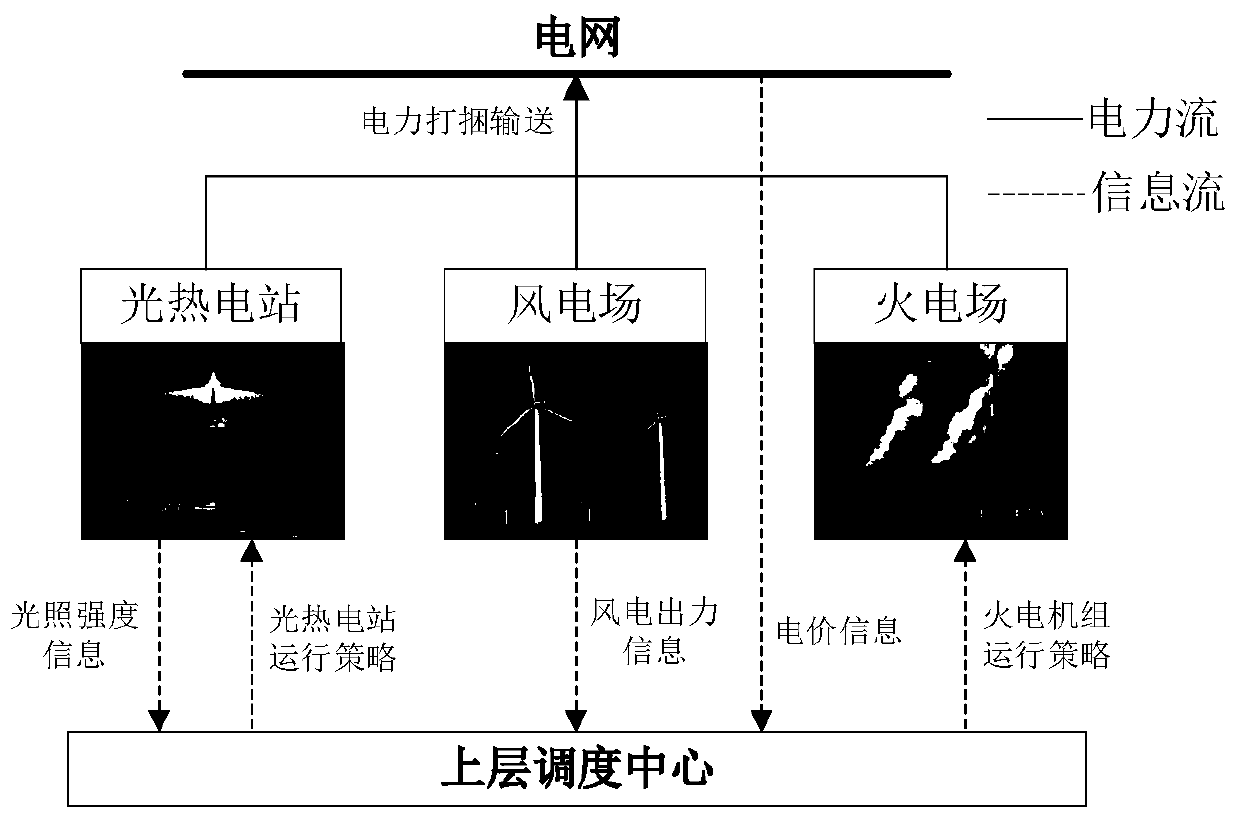

Wind-solar storage capacity planning method based on carbon transaction mechanism

InactiveCN110334856AReduce the amount of investment and constructionThe number of construction projects increasedForecastingArtificial lifeProbabilistic methodElectric power system

The invention provides a wind-solar storage capacity planning method based on a carbon transaction mechanism. In a regional power system containing wind-solar storage, the wind-solar storage capacityplanning method establishes a random output model of a photovoltaic power generation system and a wind power generation system according to change characteristics of solar radiation and wind speed onthe basis of mathematical statistics and probabilistic methods; and then considering the carbon transaction cost, taking the minimum total cost of the system as an economic optimization target, solving the optimal solution meeting the constraint condition according to the planning model, and outputting the optimal solution meeting the constraint condition, thereby realizing the optimal configuration of the wind-solar storage capacity of the regional power grid.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

Auxiliary cementitious material for low carbon high performance concrete

The invention discloses a low-carbon high-performance concrete supplementary cementitious material which is prepared from 20-70 parts of slag, 20-70 parts of coal ash, 5-10 parts of silica fume, 3-10 parts of desulfurized gypsum and 1-3 parts of water reducing agent by weight to form an admixture, wherein the slag, the coal ash, the silica fume and the desulfurized gypsum are micro aggregates of 100 nanometers to 100 microns; and the materials are sequentially placed in a mixer and stirred for 60-120 minutes at a speed of 60-120 rpm at normal temperature under normal pressure to obtain the supplementary cementitious material. The low-carbon high-performance concrete supplementary cementitious material disclosed by the invention can replace 70% of cement in concrete when applied to concrete; and even if the 70% of cement is replaced, the strength of the prepared concrete also can reach C15-C60. The low-carbon high-performance concrete supplementary cementitious material is suitable to be used as a building material and also has special purposes of back-fill grouting, toxic waste solidification and the like.

Owner:宁夏新丰益节能科技有限公司

Self-compacting mortar combination and preparation method thereof

The invention discloses a self-compacting mortar combination and a preparation method thereof. The self-compacting mortar combination comprises the following components by weight parts: 0.52-0.94 part of water, 1 part of cement, 0-0.55 parts of fly ash, 2.83-4.89 parts of sand, and 0.01-0.03 parts of additive, wherein the additive is composed of the following components by weight parts: 1 part ofmelamine, 0.2-0.6 parts of polyacrylamide high performance anti-washout agent, 0.1-0.5 parts of UWB-II type underwater anti-washout agent, and 0.05-0.15 parts of flocculating agent. The preparation method comprises the following steps: feeding the additive into a container based on the order and ratio of each component, stirring, and then adding each component of the self-compacting mortar into the container according to the ratio, and stirring. The self-compacting mortar of the invention is adaptable to different geological conditions, in this way, the comprehensive cost is greatly reduced, the usage of cement is greatly decreased, stirring time is shortened by about 20% than that for normal mortar, the clearance of broken zones is compactly filled without vibration, the mortar does not separate or bleed water even at the diffusance of 600 mm, the viscosity is good, the mortar can be used in deep hole curtain grouting in the presence of groundwater, and the grouting effect is good.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

Coal-fired flue gas CO2 curing adsorption system

ActiveCN113074366AReduce carbon contentReduce energy consumptionFluidized bed combustionEmission preventionSlagComponents of crude oil

The invention discloses a coal-fired flue gas CO2 curing adsorption system. The coal-fired flue gas CO2 curing adsorption system comprises a bubbling adsorption bed system, a flue gas recirculation system and a slag feeding and discharging system. The coal-fired flue gas CO2 curing adsorption system is characterized in that on the basis of the process advantages of medium-temperature combustion of a circulating fluidized bed boiler, calcination desulfurization of limestone in the boiler and medium-temperature slag discharging, slag discharging waste heat and CaO contained in the slag discharging waste heat are used for carrying out carbonation reaction to adsorb CO2, so that pollution is controlled by waste, the method is simple in process, low in cost and simple in process, cooperative treatment of the coal-fired solid waste and the flue gas CO2 is achieved, meanwhile, the carbon content of the fly ash of the CFB boiler is reduced, and the advantage that the circulating fluidized bed boiler controls coal-fired pollutants at low cost is further expanded.

Owner:TAIYUAN UNIV OF TECH +1

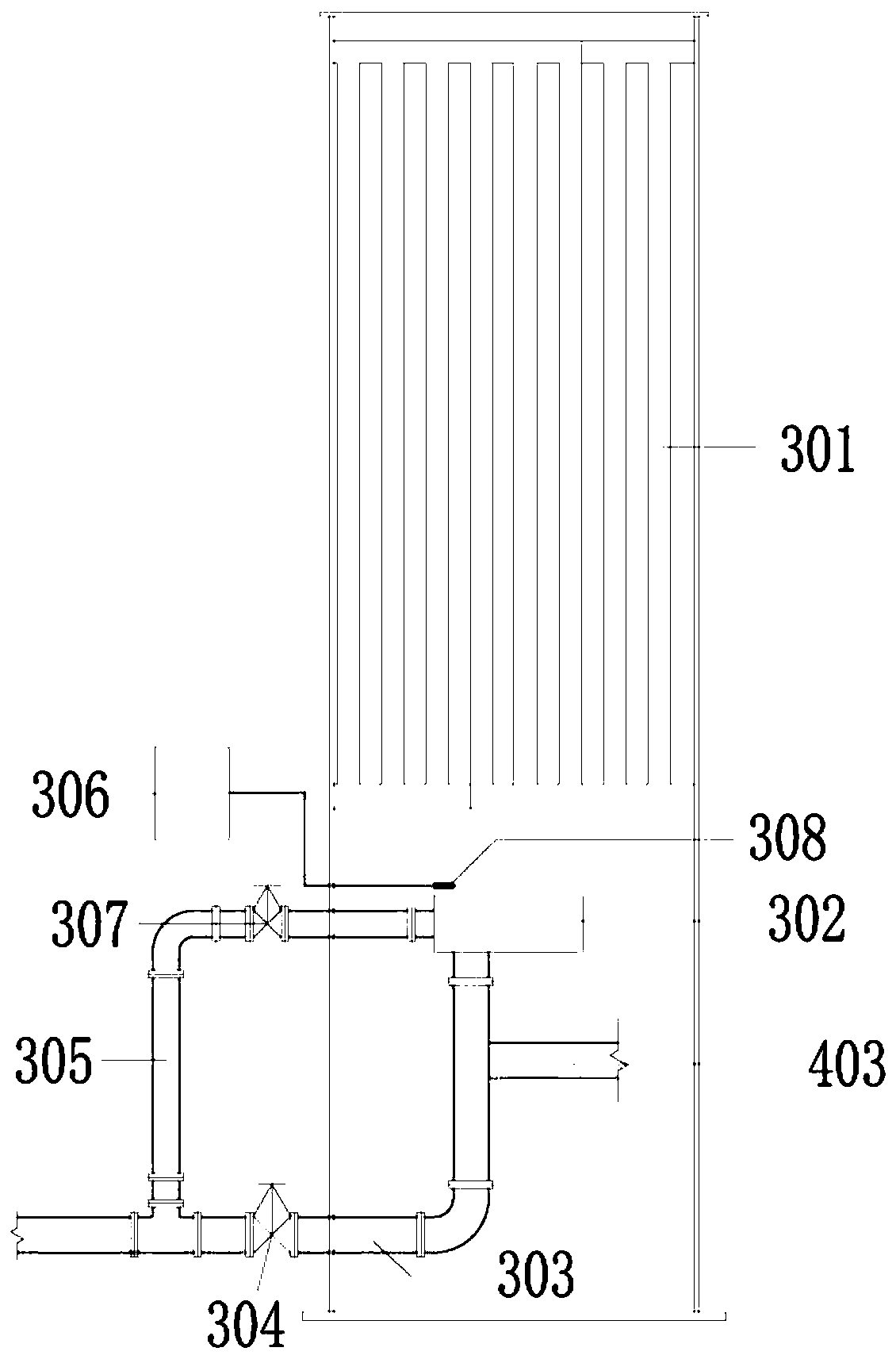

Steam pipeline drain recovery system

PendingCN104964166AEfficient recyclingAvoid direct dischargePipeline systemsEngineeringHigh pressure

The invention relates to a steam pipeline drain recovery system which is composed of high-pressure steam pipelines, a drain valve set, a steam inlet electric valve, a pressure reduction valve, a drain box, a water drainage electric valve, a check valve and a low-pressure water pipeline. One high-pressure steam pipeline is connected with the drain box through the drain valve set, and the other high-pressure steam pipeline is connected with the drain box through the steam inlet electric valve and the pressure reduction valve. The outlet of the drain box is connected with the low-pressure water pipeline through the water drainage electric valve and the check valve by means of a pipeline. A safety exhaust device, a liquid level meter and a water drainage device are arranged on the drain box. According to the steam pipeline drain recovery system, by means of the reasonable steam drain collection and recovery design, steam diffusion in the drain process of the high-pressure steam pipelines can be reduced, condensed water can be recovered, noise is reduced, and water is saved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

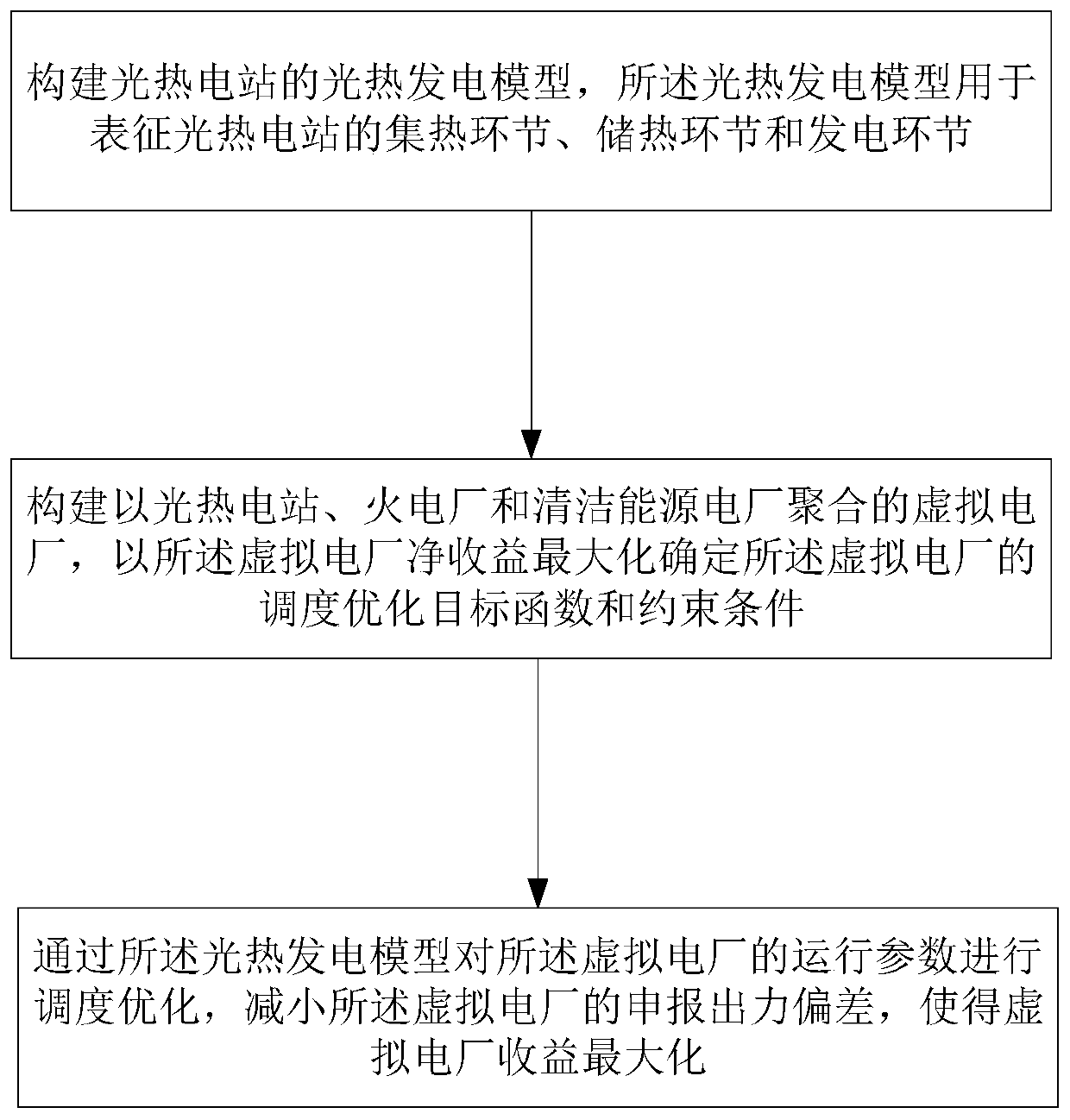

Optimal dispatching method for virtual power plant containing photothermal power station

InactiveCN110137954ALower emission levelsCoordinate and optimize output arrangementsSingle network parallel feeding arrangementsWind energy generationNuclear engineeringVirtual power plant

The invention discloses an optimal dispatching method for a virtual power plant containing a photothermal power station, which comprises the following steps: S1, constructing a photothermal power generation model of a photothermal power station, which is used to characterize the heat collection, heat storage and power generation links of the photothermal power station; S2, constructing a virtual power plant combining the photothermal power station, a thermal power plant and a clean energy power plant, and determining the objective function and constraints of dispatching optimization of the virtual power plant by maximizing the net income of the virtual power plant; and (3) optimizing the operation parameters of the virtual power plant through the photothermal power generation model so as to reduce the deviation of declared output of the virtual power plant and maximize the income of the virtual power plant. The method of the invention is simple, and can improve the adjustment flexibility of the virtual power plant, enable the virtual power plant to obtain better operation benefit, maximize the net income in the dispatching cycle, improve the energy utilization efficiency and reduceenvironmental pollution.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Titanium dioxide acid wastewater treatment and recovery process

PendingCN112939312AAchieving "Zero Emissions"Efficient separationSulfur-trioxide/sulfuric-acidMultistage water/sewage treatmentHollow fibreIon exchange

The invention belongs to the technical field of wastewater treatment, and particularly relates to a titanium dioxide acid wastewater treatment and recovery process. The titanium dioxide acid wastewater enters an ultrafiltration system and is filtered by a hollow fiber ultrafiltration membrane to obtain membrane filtrate; the obtained membrane filtrate enters an ion exchange system and is adsorbed by resin, ferric salt is recycled from wastewater containing ferric salt obtained through separation, the resin adsorbing free acid is cleaned, and relatively pure dilute sulfuric acid is obtained; and the obtained relatively pure dilute sulfuric acid is pumped into a nanofiltration system to be filtered, membrane permeate is pure sulfuric acid, then multi-effect evaporation and concentration are carried out, and clean sulfuric acid with the concentration larger than or equal to 50% is obtained and reused in a titanium dioxide production system. According to the titanium dioxide acid wastewater treatment and recovery process, sulfuric acid, water and ferrous iron in the acid wastewater are efficiently separated and can be completely reused in the production process for recycling or resource reutilization, and finally zero emission of the titanium dioxide acid wastewater is achieved.

Owner:SHANDONG YUXIN ENVIRONMENTAL SCI & TECH

Preparation method of p-aminobenzene sulfonic acid

ActiveCN110054575AAvoid scarcityAvoid the problems that are likely to cause three wastesOrganic compound preparationSulfonic acid preparationSulfanilic acidInorganic salts

The invention discloses a preparation method of p-aminobenzene sulfonic acid. The preparation method includes the steps of firstly, performing reduction sulfonation, to be more specific, sequentiallyadding water, a non-proton polar organic solvent, nitrobenzene and a reduction sulfonation agent into a reactor, and heating to 95-130 DEG C to perform reflux reaction; secondly, removing salt, to bemore specific, cooling the material obtained in the first step to 0-20 DEG C to separate out inorganic salt, performing suction filtration or filter pressing, and collecting filtrate 1; thirdly, performing acidification, to be more specific, heating the filtrate 1 obtained in the second step to 30-70 DEG C, adding sulfuric acid to regulate pH to 1-3, performing suction filtration or filter pressing, collecting filtrate 2 and filter cake, and drying the filter cake to obtain the p-aminobenzene sulfonic acid. The method has the advantages that one-step nitrobenzene reduction sulfonation is achieved, the obtained p-aminobenzene sulfonic acid is high in purity, three-waste problems are avoided, and clean production is achieved truly.

Owner:ZHEJIANG LONGSHENG CHEM RES

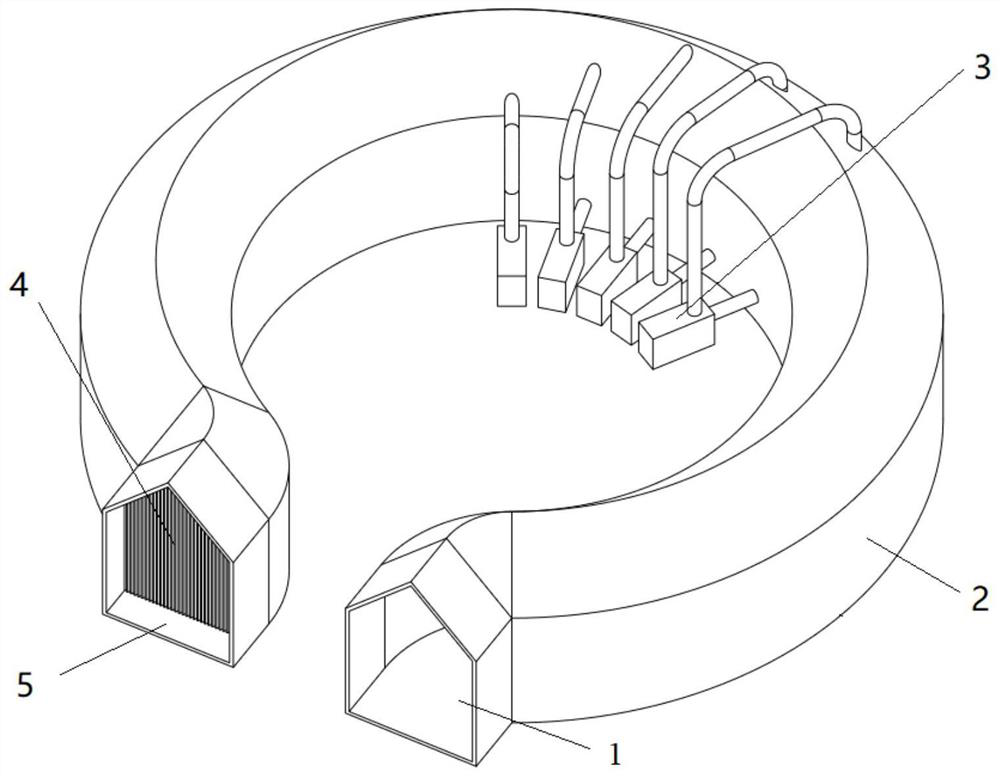

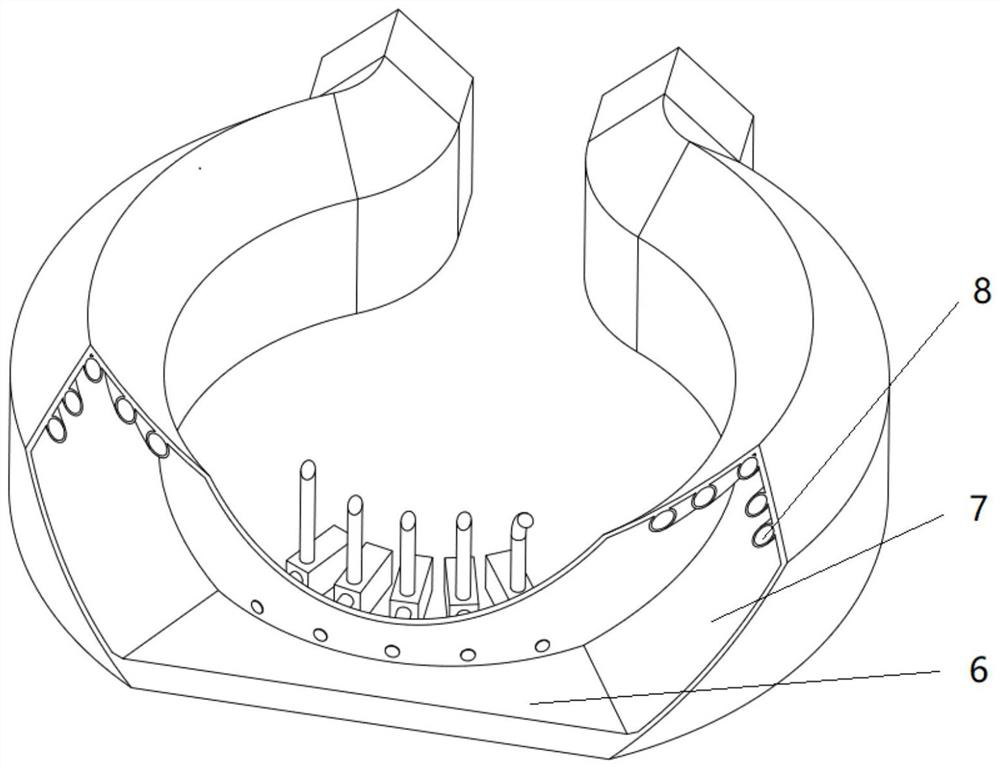

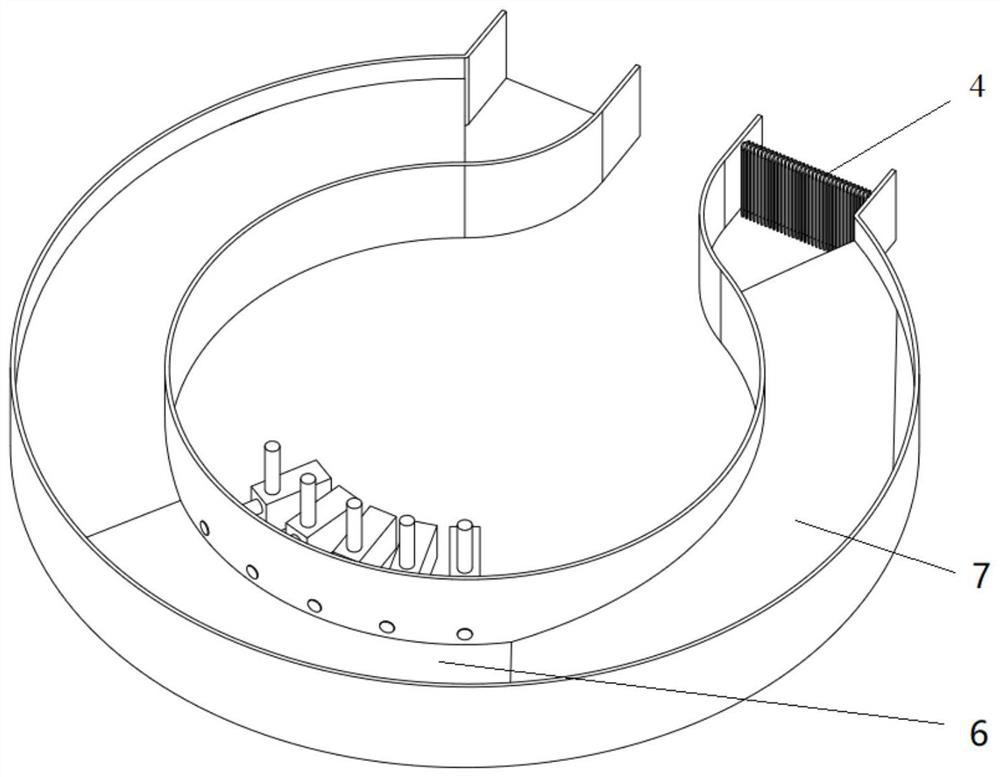

Horizontal annular wet flue gas desulfurization device and method

PendingCN112588084ALower the spray heightReduce output demandGas treatmentDispersed particle separationSlurryCirculating pump

The invention discloses a horizontal annular wet flue gas desulfurization device and method. In the horizontal annular wet flue gas desulfurization device, a desulfurization device body is of a hollowtubular structure, one end of the desulfurization device body is a flue gas inlet, the other end of the desulfurization device body is a purified flue gas outlet, an annular shape is defined by the desulfurization device body from the flue gas inlet to the purified flue gas outlet, a demister is arranged in the purified flue gas outlet, a slurry distribution main pipe is arranged in the desulfurization device body and distributed in the length direction of the desulfurization device body, an inlet of a slurry circulating pump is connected with a slurry pool, and an outlet of the slurry circulating pump is connected with the slurry distribution main pipe. According to the invention, the vertical flow direction of flue gas in a conventional wet flue gas desulfurization device is changed into the horizontal flow direction, the slurry supply height is reduced, and the power required by the slurry circulating pump is remarkably reduced. An annular structure is adopted, a flue gas through-flow path is prolonged, the desulfurization reaction time is prolonged, internal components of the device are simple, flue gas flowing is facilitated, and the output requirement of a desulfurization booster fan is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com