Horizontal annular wet flue gas desulfurization device and method

A technology of wet flue gas desulfurization and desulfurization equipment, which is applied in the direction of separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of fan output upgrading and transformation, increase of flue gas flow resistance, and increase of tower internal components, etc., to achieve Reduce the height of spraying operation, reduce the demand for output, and improve the effect of desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

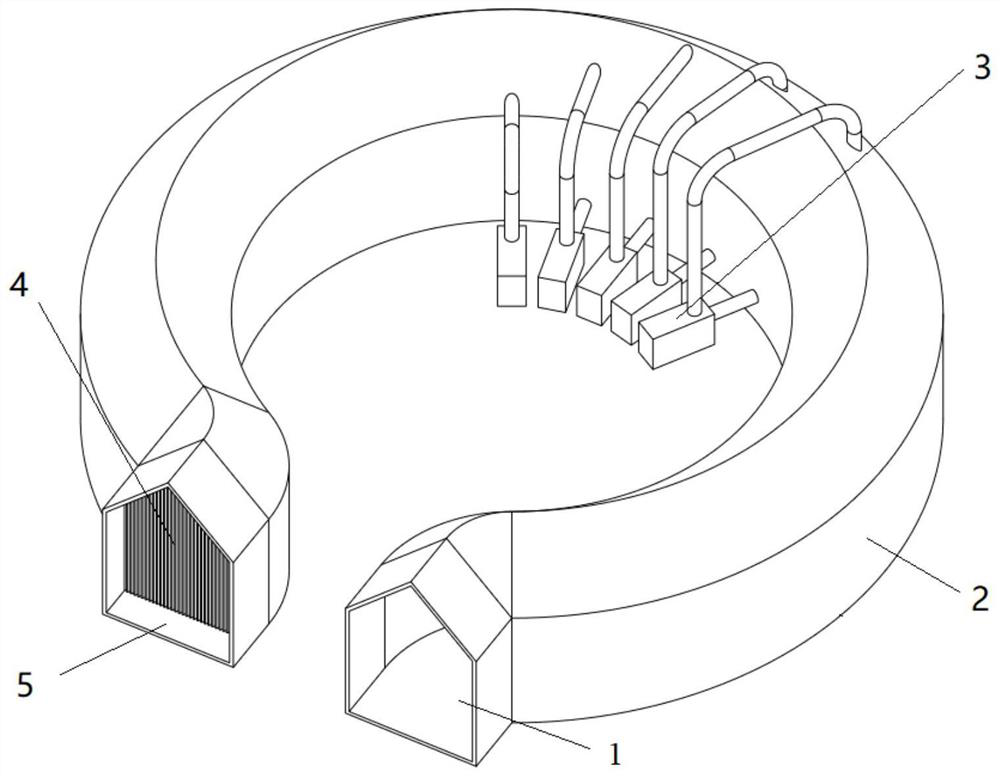

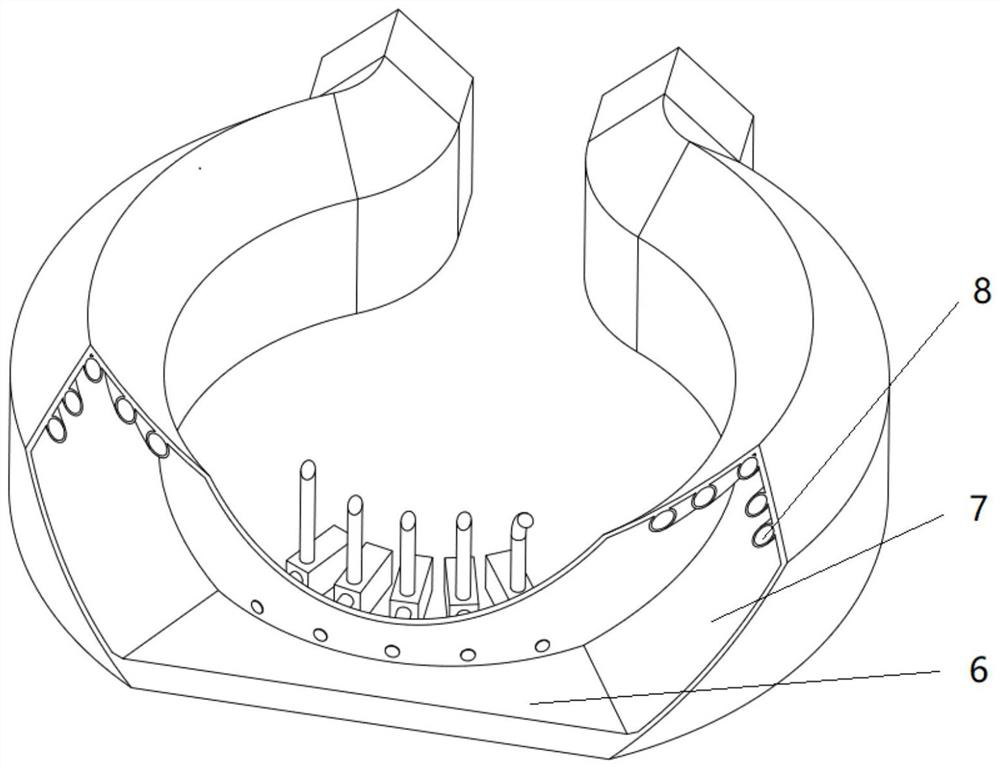

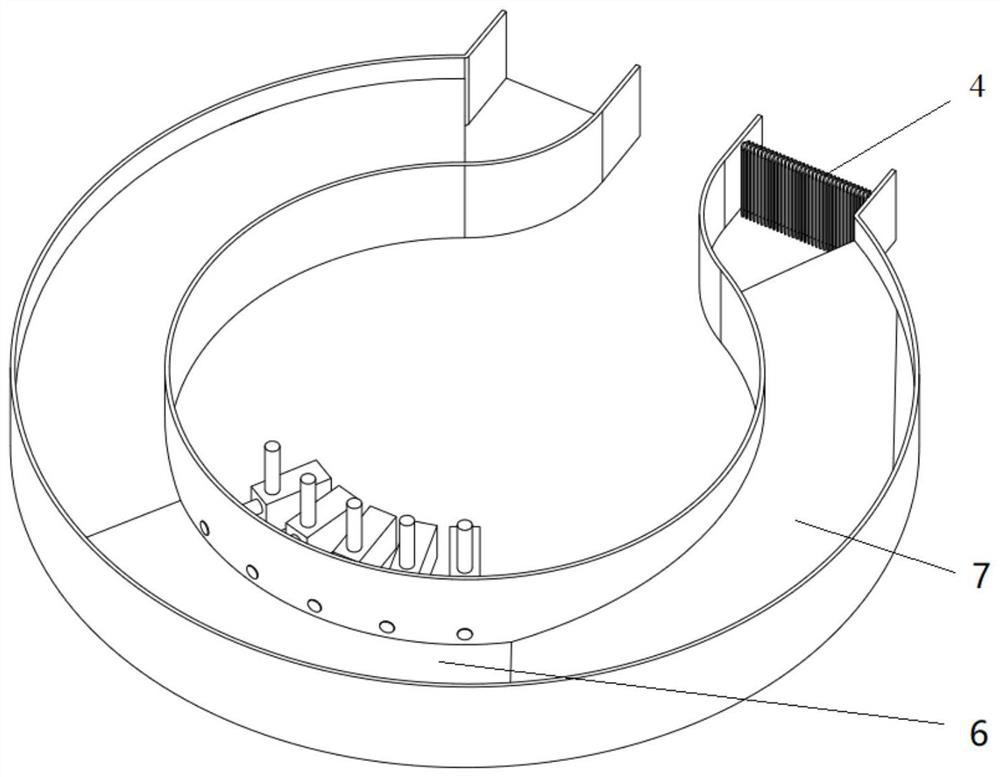

[0051] In the horizontal annular wet flue gas desulfurization device of this embodiment, the main body 2 of the desulfurization device is horizontal and has a "C" shape structure of a large semi-circle as a whole. One of the two ends of the desulfurization device body 2 is the flue gas inlet 1, The other side is the net flue gas outlet 5. There are no unnecessary parts such as trays and gas collecting rings in the desulfurization device body 2, and the flue gas flow resistance is small.

[0052] The top of the desulfurization device body 2 is a ridge structure (that is, a triangular top), and the slurry distribution main pipe 8 is fixed on the inner wall of the ridge. The circulation main pipe 8 corresponds to a slurry circulation pump 3 . The main body of the desulfurization device adopts a roof structure. On the one hand, the installation space of the spray distribution main pipe is expanded. Multiple turns of the slurry distribution main pipe can be arranged within the lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com