Patents

Literature

144results about How to "Reduce plant power consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature electric precipitation system in fuel electric plant

InactiveCN103363536AImprove the dust collection rateMeet the requirements of emission standardsLighting and heating apparatusAir preheaterEnvironmental resistance

A low temperature electric precipitation system in a fuel electric plant comprises at least one air preheater, at least one electric precipitator and connecting pipes for connecting the air preheater and the electric precipitator together, a flue-gas heat exchanger for lowering the flue-gas temperature entering the electric precipitator to enable the flue-gas temperature to reach or be lower than flue-gas dew point at the temperature of 90 DEG C is arranged between the air preheater outlet and the electric precipitator inlet; the electric precipitator is communicated with a desulfuration absorption tower through an induced-draft fan; a chimney is connected with the rear part of the desulfuration absorption tower. The flue-gas heat exchanger adopts a backward flow heat exchange type; a vertical pipe heat exchange flow passage or a horizontal pipe heat exchange flow passage is arranged at the inner part of the flue-gas heat exchanger; the system has the characteristics that the project equipment investment is reduced; the auxiliary power ratio is lowered; the energy is saved; the consumption is reduced; the heat economy of the unit can be improved; the latest environment-friendly emission standard can be satisfied.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

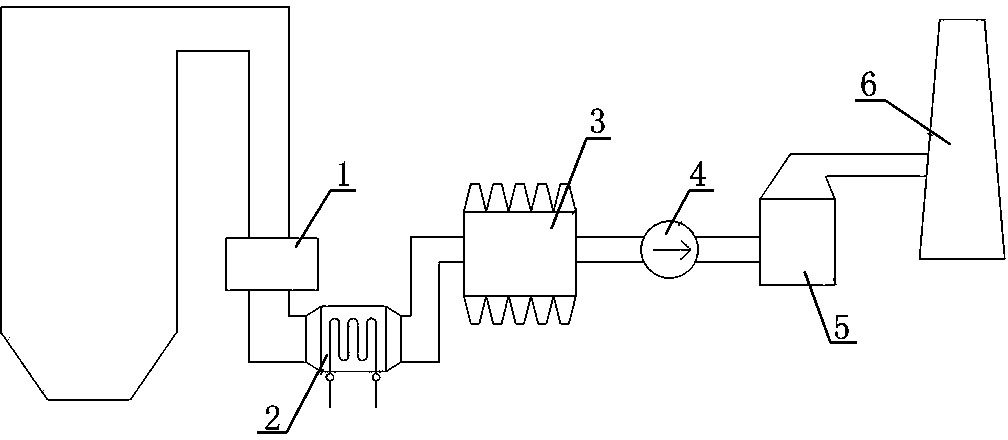

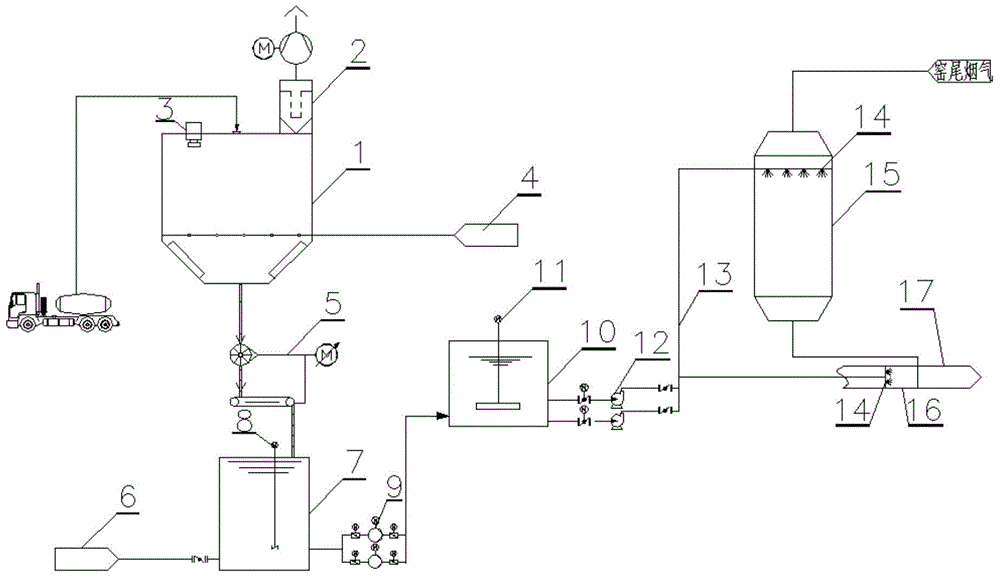

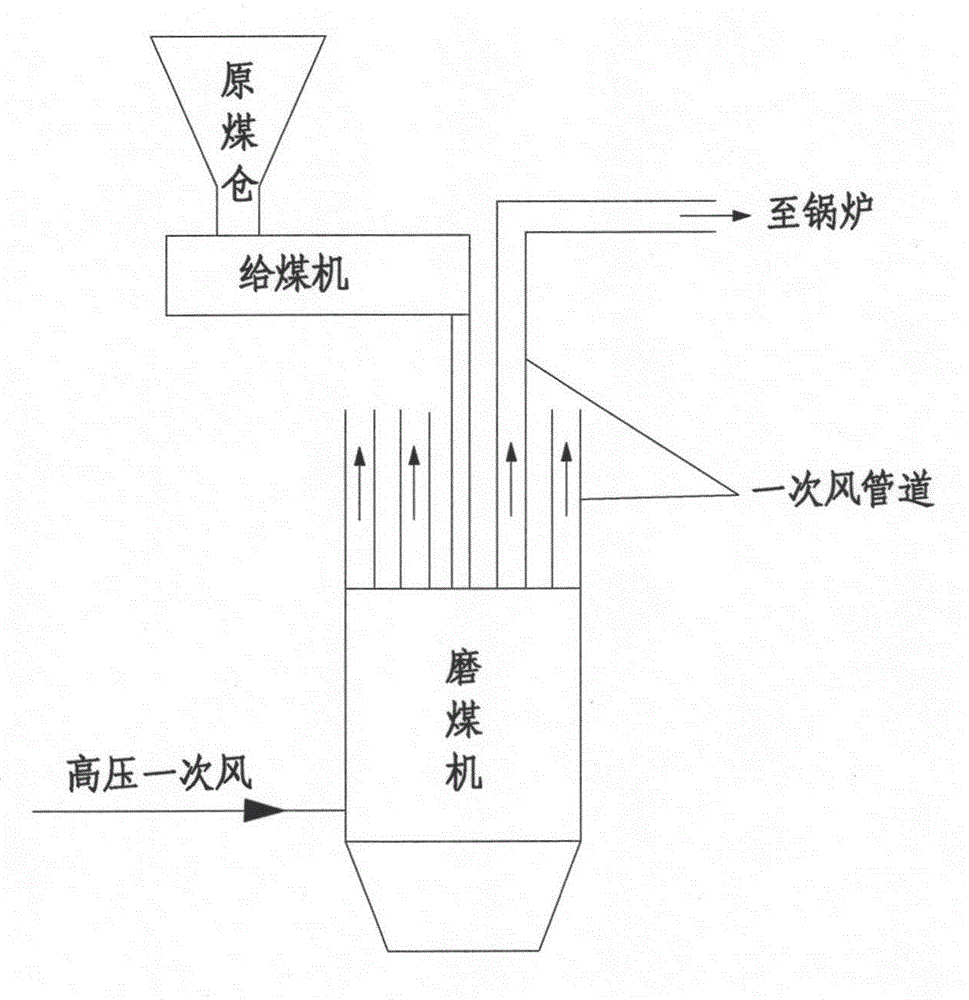

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

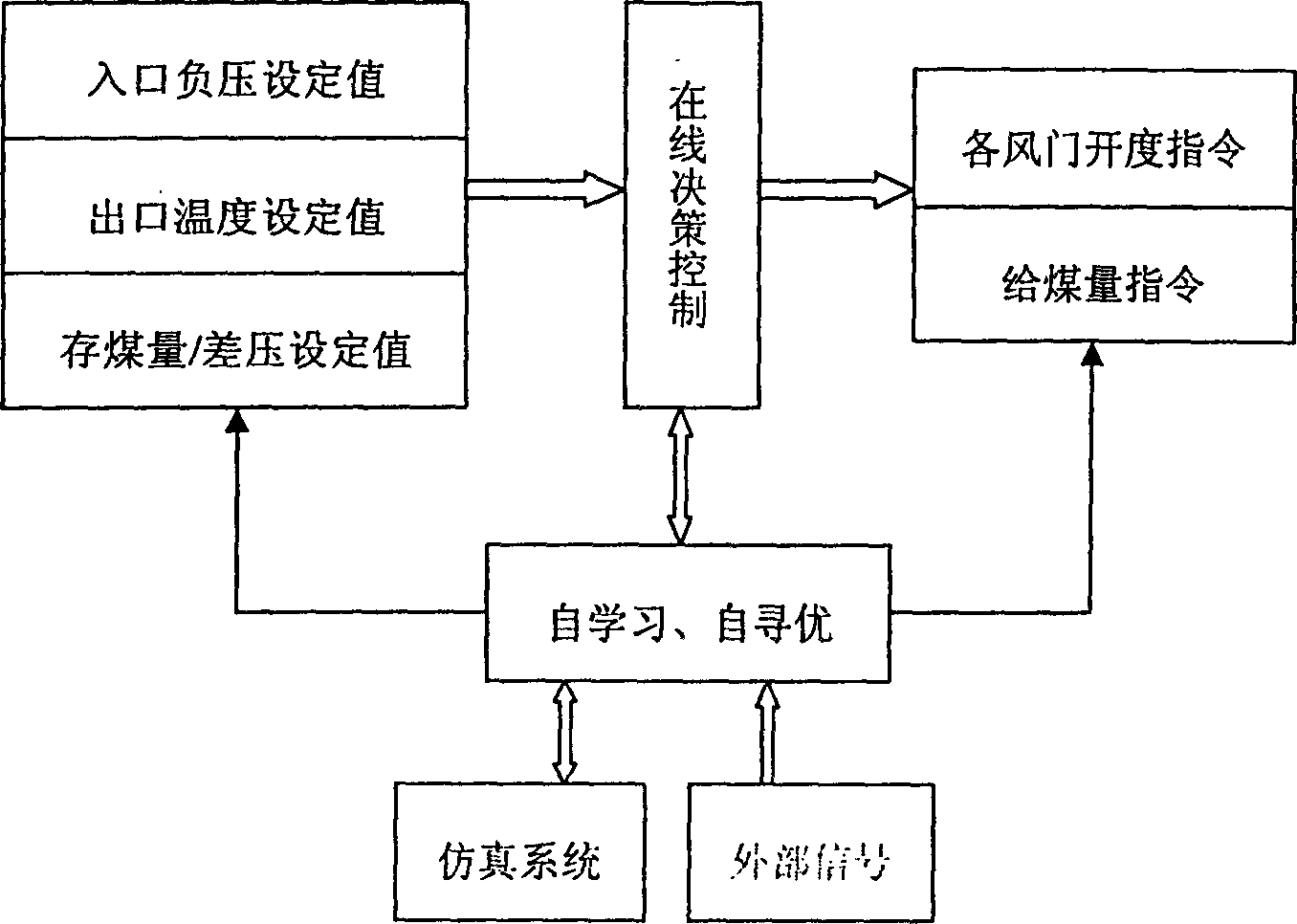

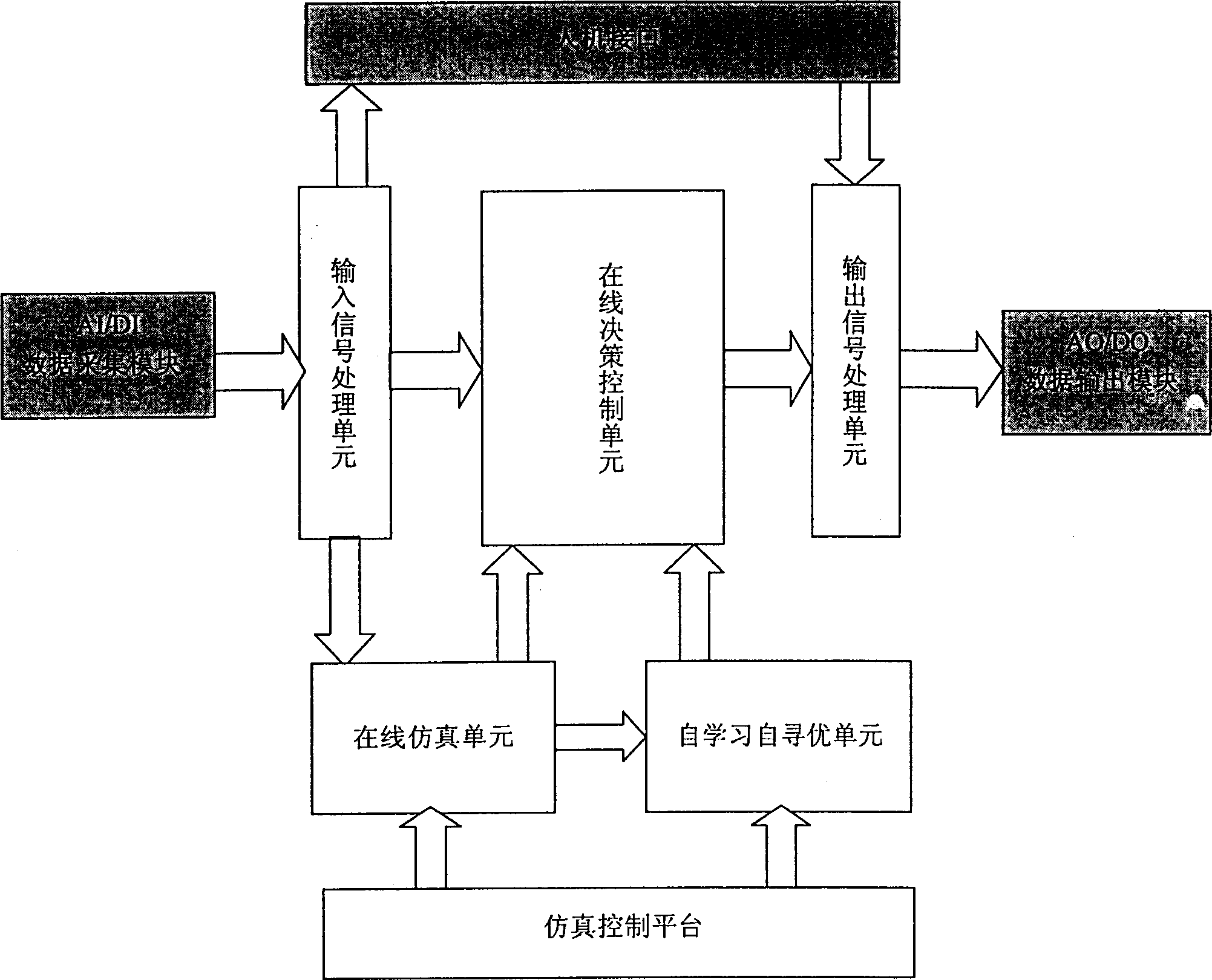

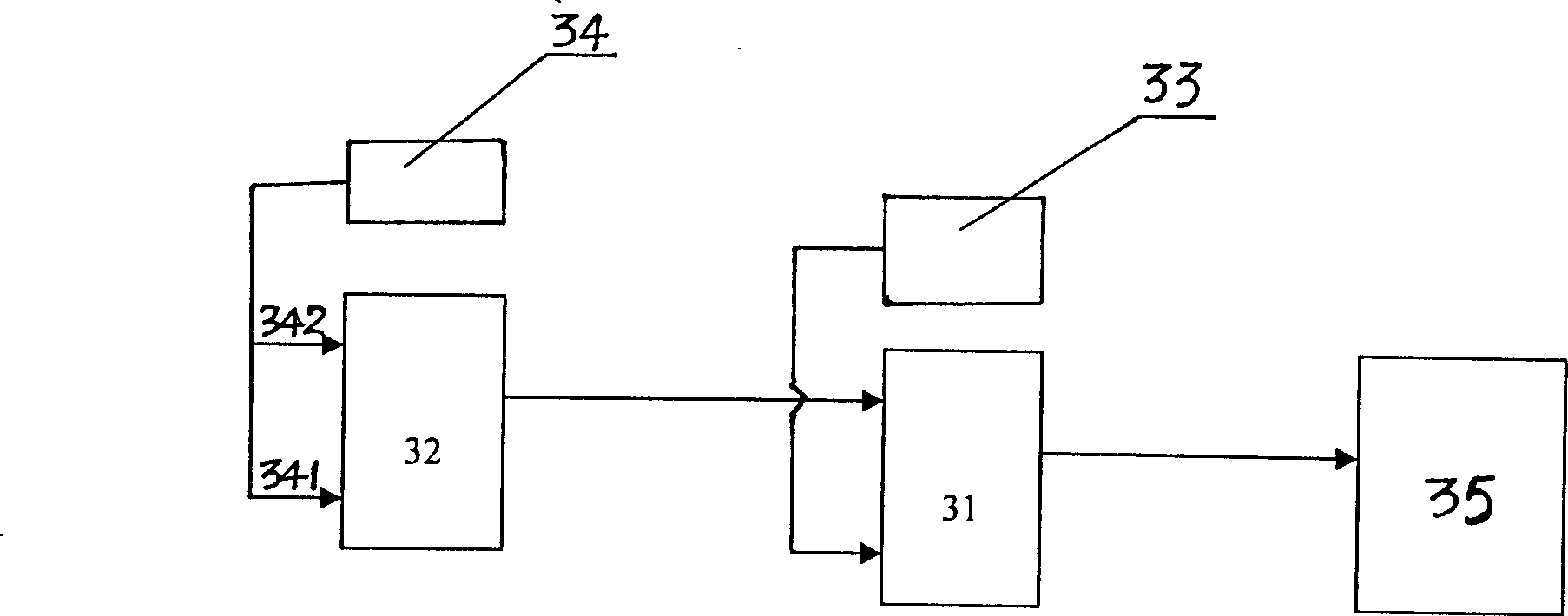

Controlling method and system for digital steel-ball coal grinder

A method for controlling coal grinder includes selecting measurement points on grinder and obtaining measured data, using artificial control platform to realize on line self optimizing for submitting out a set of optimum control policy on real time, applying said control information to control action of executing mechanism for coal grinder. A control system for realizing the method is also disclosed.

Owner:广东亚仿科技股份有限公司

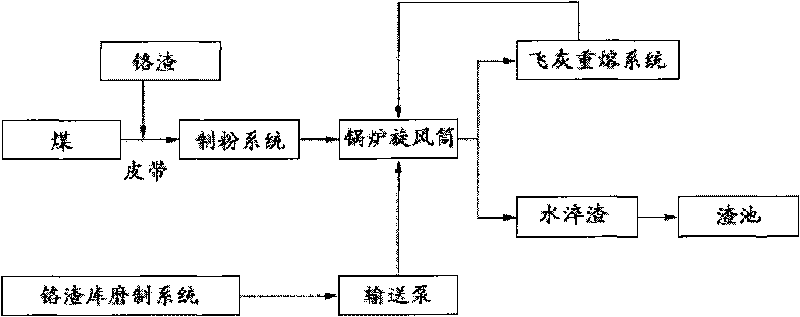

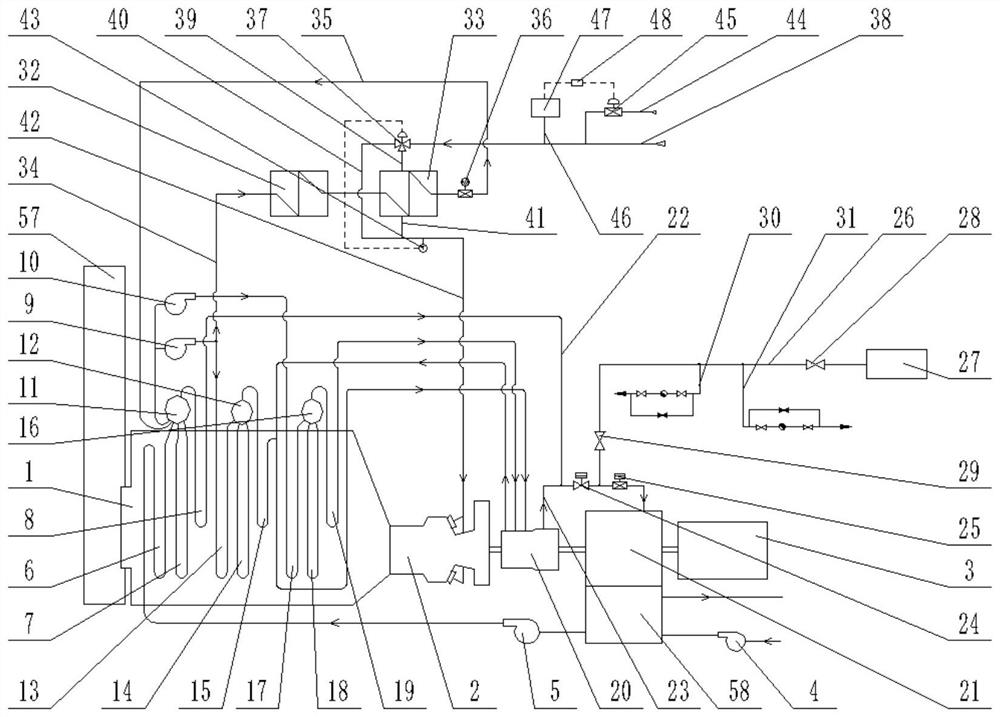

Boiler fly ash remelting chromium slag detoxification system for improving blend ratio of chromium slag and method thereof

InactiveCN101722171AImprove stabilityEnhance detoxification abilitySolid waste disposalCycloneWear resistant

The invention provides a boiler fly ash remelting chromium slag detoxification system and an implementation method thereof. The boiler fly ash remelting chromium slag detoxification system comprises boilers, a chromium slag blend ratio system, fly ash remelting systems, a pulverization system, a chromium slag warehouse grinding system, and cyclones on the boilers, wherein each boiler is provided with two cyclones, and each cyclone corresponds to one independent fly ash remelting system; upper and lower connection pipelines on each cyclone are provided with a wear-resistant tee respectively, two wear-resistant fly ash remelting nozzles are separated in opposite directions, and the total four fly ash remelting nozzles convey fly ash to the cyclones; and a chromium slag warehouse is provided with a fan mill, and the fan mill is connected with the fly ash remelting nozzles of the boilers through an ash conveying pump and pipelines. The boiler fly ash remelting chromium slag detoxification system can increase the blend ratio of treated chromium slag to be between 15 and 20 percent. The system not only increases the blend ratio of the chromium slag, accelerates the treatment speed of the chromium slag, but also improves the stability of chromium slag treatment equipment, has the practicability, and can be widely applied to the industry.

Owner:武汉光谷环保科技股份有限公司

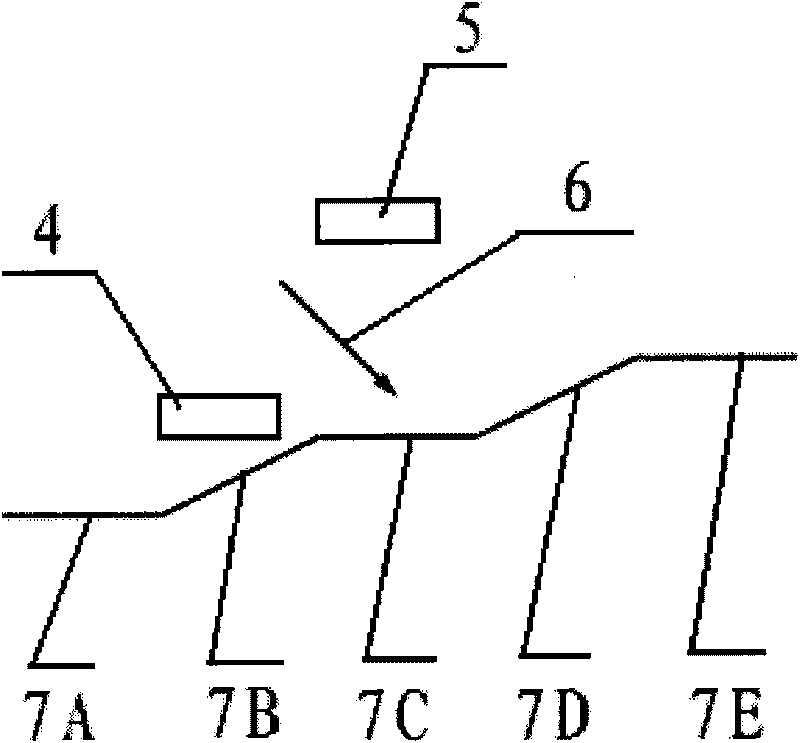

Super or super supercritical coal fired power generation heat system improvement method

InactiveCN101261002AIncrease feed water temperatureRaise the average endothermic temperatureSteam generation heating methodsIndirect carbon-dioxide mitigationAir preheaterSteam pressure

The invention discloses a measure for improving a supercritical or ultra supercritical coal-burning power generation thermal system belonging to the thermal power generation technical field, relating to the supercritical or ultra supercritical coal-burning power generation thermal system without an economizer and a parameter configuration. The invention concretely comprises following steps of removing the economizer which is requisite for a conventional boiler to simplify the flow of a boiler and reduce the flow resistance of a system and the station service power consumption rate; increasing a primary high-voltage bleeder heater to increase the feed temperature; possibly reducing the exhaust steam pressure and the temperature of a high pressure cylinder to enable the exhaust steam temperature of the high pressure cylinder to be equal or similar to the feed temperature; possibly increasing the temperature of reheat steam on the premise of guarantee of safety; and increasing or providing an air preheater and increasing the temperature of secondary wind to improve the average temperature of heat release of flue gas of the boiler to the cycle fluid of power generation and improve the second-law efficiency of the boiler and the combustion stability of unit coal species changing.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

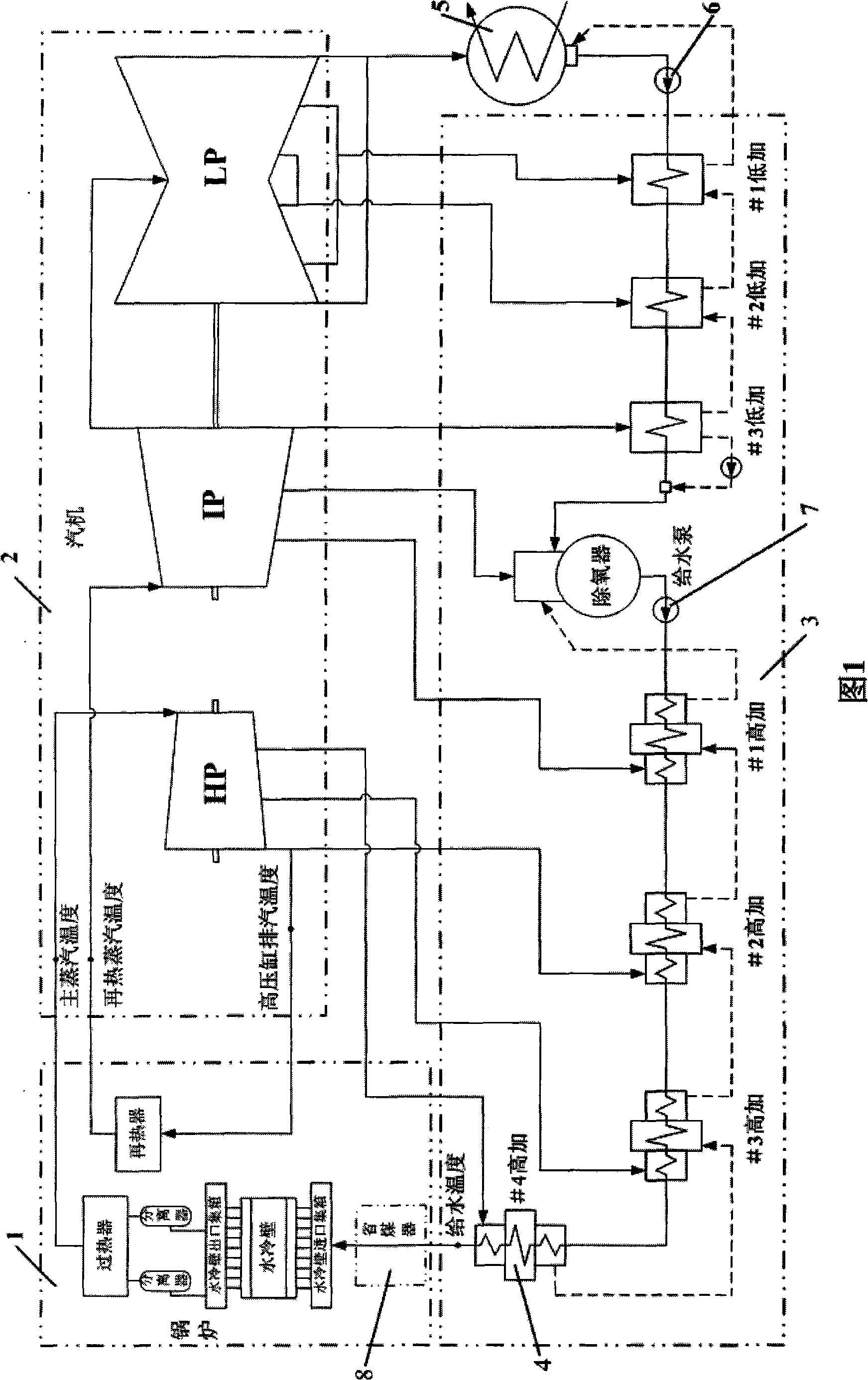

Spray drying desulfurizer used for cement plant and process method

ActiveCN104888599AReduce consumptionImprove availabilityDispersed particle separationInjection pointSlurry

The invention discloses a spray drying desulfurizer used for a cement plant, which comprises a quick lime storage bunker connected with a quick lime digestive system, wherein the quick lime digestive system comprises a slurry preparation tank and matched stirrer and a slaked lime slurry preparation pump and is used for preparing quick lime into slaked lime to be delivered to a desulfurizer storage and delivery system; the desulfurizer storage and delivery comprises a slaked lime slurry tank and matched stirrer and a slaked lime slurry supply pump and is used for delivering slaked lime slurry in the slaked lime slurry tank to an injection system; the injection system is composed of two sets of distribution pipe networks and a spray gun, the injection point of one set of distribution pipe network is located at a conditioning tower, and the injection point of the other set of distribution pipe network is located at the air inlet flue port of raw mill; and ash produced by desulfurization enters the raw mill. In addition, the invention further discloses a process method utilizing the device to desulfurize. According to the invention, SO2 and SO3 removal rates can reach more than 90%. The system is relatively simple, and can not only meet the environmental protection requirement, but also reduce the desulfurization cost of cement enterprises.

Owner:上海三融环保工程有限公司

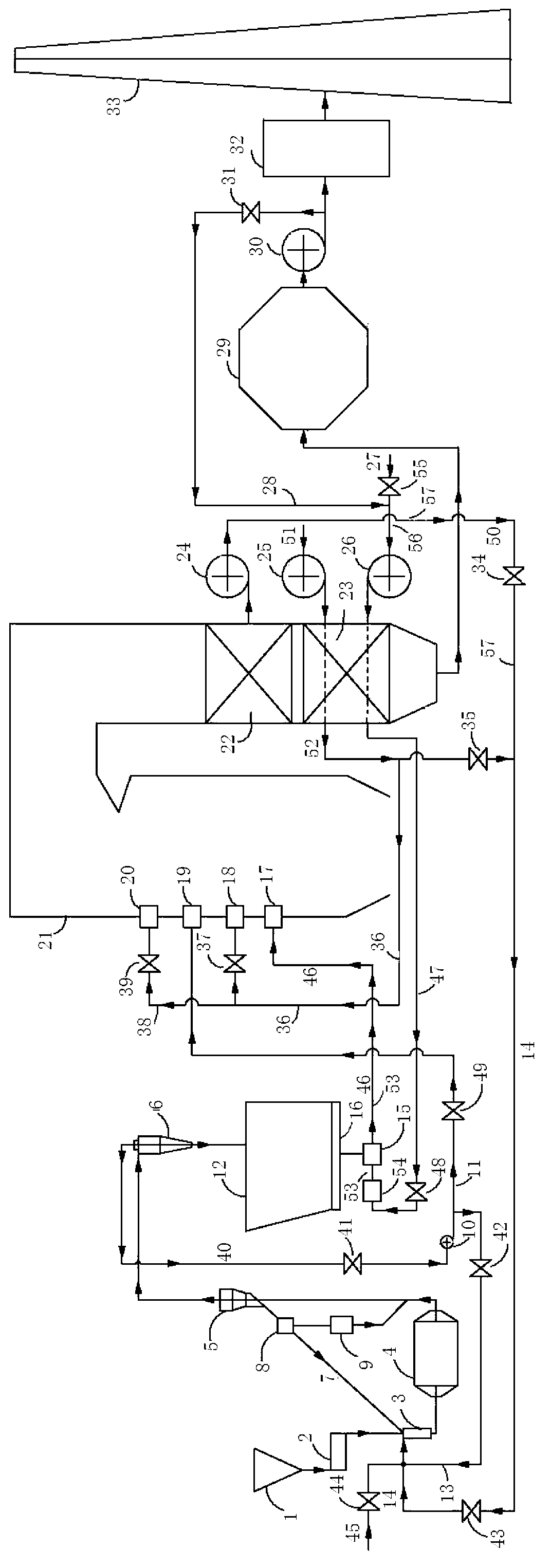

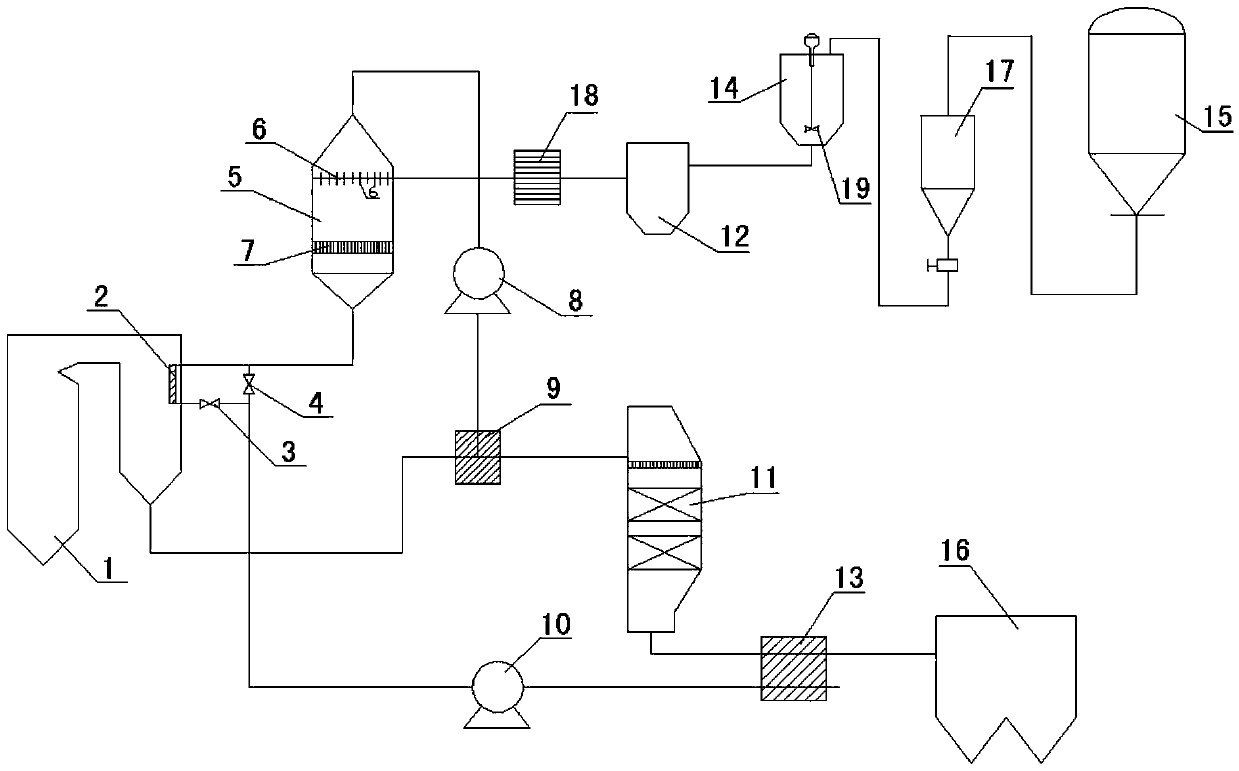

Automatic control SCR flue gas denitrification urea pyrolysis system

InactiveCN105498532AReduce plant power consumptionSolve the blockageGas treatmentCombustion processAutomatic controlUrea

The invention discloses an automatic control SCR flue gas denitrification urea pyrolysis system. The system is characterized in that a gas-gas heat exchanger is arranged in an inlet flue of an electric precipitator so as to form an air heating unit; a set of flue gas heating tube bundles are arranged in a boiler, so as to form an air reheating unit; after heated by the gas-gas heat exchanger and reheated by the flue gas heating tube bundles, air becomes high-temperature air at the temperature of heat resource required by urea pyrolysis; the high-temperature air is fed into a urea pyrolysis furnace and is mixed with a sprayed atomized urea solution, and then the pyrolysis is performed and an ammonia / air mixture is generated; the ammonia / air mixture is sprayed into an inlet flue of an SCR denitrification reactor through an AIG ammonia injection grating. The automatic control SCR flue gas denitrification urea pyrolysis system has the advantages that the technical structure is simple; the system can be widely applied to an SCR denitrification device of a coal-fired power plant; the urea atomizing pyrolysis efficiency can be effectively increased and the crystal plugging problem can be thoroughly solved; the waste-heat utilization of flue gas can be realized and the electrostatic precipitation efficiency can be increased; water used by a desulfurization system can be reduced.

Owner:ANHUI XINLT POWER TECH CONSULTING +1

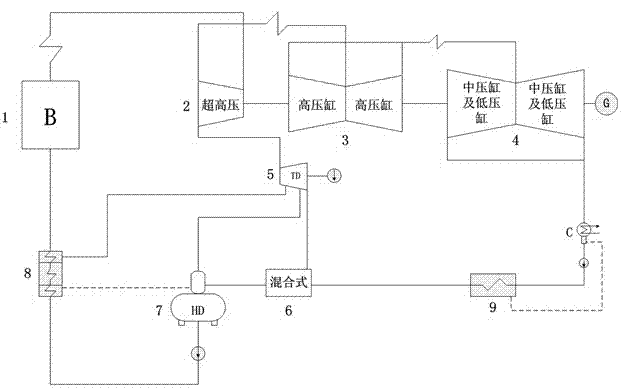

Matching method of supercritical secondary reheating unit reheater and thermal system

The invention belongs to the field of large supercritical secondary reheating thermal power generating units, and relates to a method capable making a heat exchange area needed by secondary reheating and a thermal system matched, in particular to a matching method of a supercritical secondary reheating unit reheater and the thermal system. According to the scheme, the heated face needed by the reheater is reduced, reasonable match between the reheater and the thermal system is achieved, exhausted steam of a water pump turbine is absorbed through a hybrid heater, the heat exchange area is reduced, and initial investment of a power plant is reduced. Heat for pumping steam of the water pump turbine can be finally recycled to the thermal system, and economical performance of the power plant is improved. Therefore, according to the scheme, the method is favorable for reducing the initial investment of the power plant and improving operating benefits of the power plant.

Owner:GUODIAN SCI & TECH RES INST +1

Circulating cooling water solar energy saving and controlling device for coal-based power plant

InactiveCN101886884AReduce plant power consumptionImprove energy saving control precisionSteam/vapor condensersHeat exchange apparatusEngineeringCoal

The invention discloses a circulating cooling water solar energy saving and controlling device for a coal-based power plant. In the invention, a solar-powered water distribution pump set and an energy-saving control device of the solar-powered water distribution pump set are arranged on the conventional circulating cooling water system for regulating the temperature of the circulating cooling water and reducing the plant power consumption rate of the circulating water pump of a machine by fully utilizing the day and night and seasonal characteristics of solar, and thus, an obvious energy-saving effect is achieved.

Owner:上海迪吉特控制系统有限公司

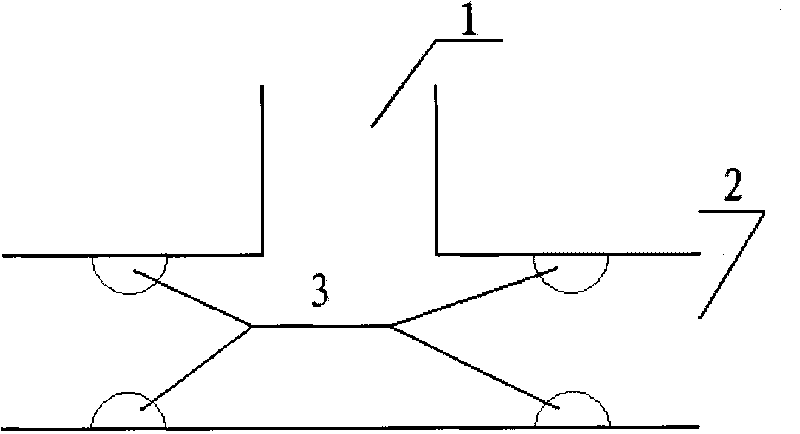

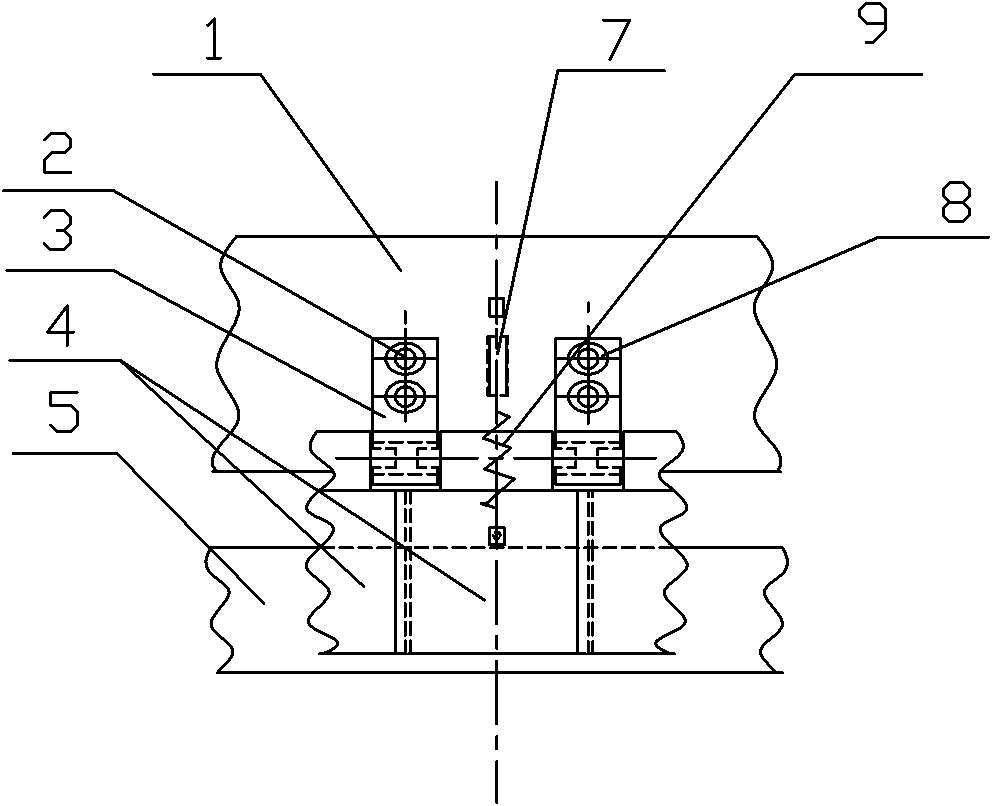

Seal structure between wind chamber and the lower part of sintering ring cold machine trolley of steel and iron plant

ActiveCN101655316AImprove the quality of useLow maintenanceFurnace typesHandling discharged materialIron plantEngineering

The invention discloses a seal structure between a wind chamber and the lower part of a sintering ring cold machine trolley of a steel and iron plant, which mainly comprises an outer seal piece, a seal contact plate and inner-side seal rubber, wherein the outer seal piece consists of a seal piece strut member, an outer limit plate, an inner limit plate, an elastic rubber cylinder, rubber in the shape of a seal groove, a support plate and an adjustable connection screw rod, the support plate is arranged in the rubber in the shape of a seal groove and is connected with the seal piece strut member through the adjustable connection screw rod in an adjustable way, outer seal is realized through the rubber in the shape of a seal groove and the seal contact plate, and inner seal is realized through the inner-side seal rubber. The invention improves the efficiency of smoke recycle and the quality of smoke utilization, fully recycles smoke, effeciently uses cold residual heat of sintering rings, decreases maintenance cost of the seal piece and shortens service life.

Owner:ZHEJIANG XIZI UNITED ENG

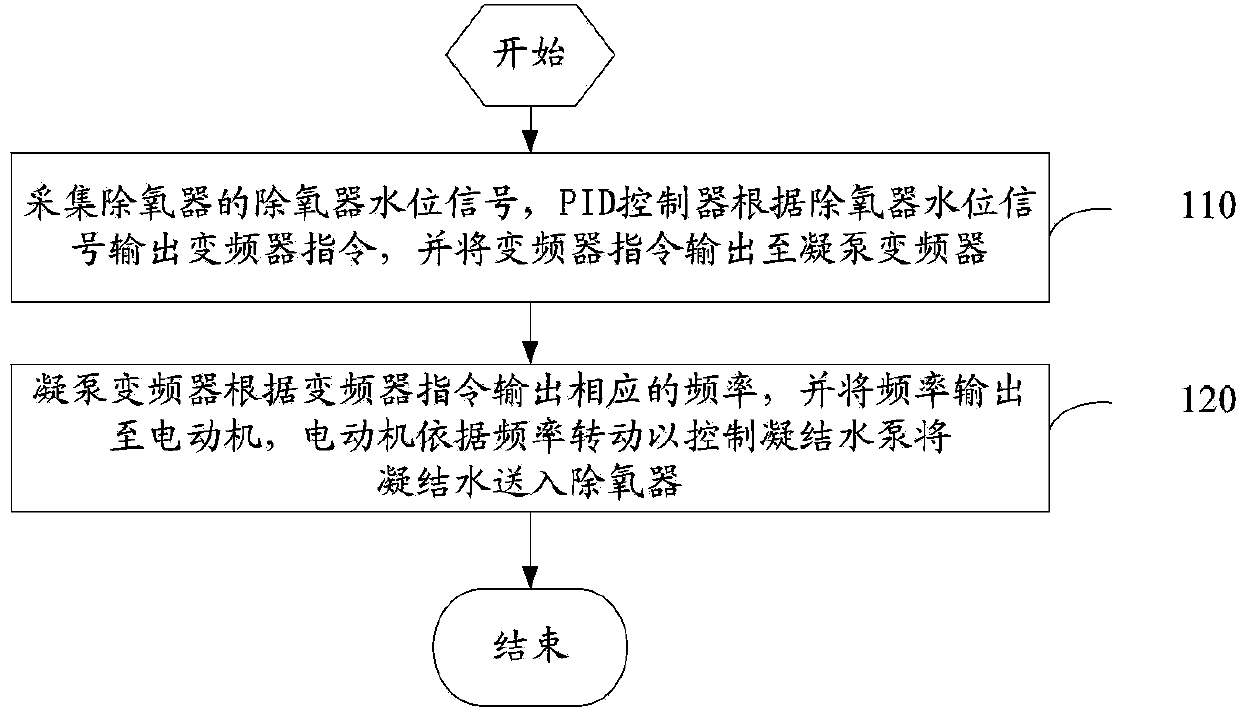

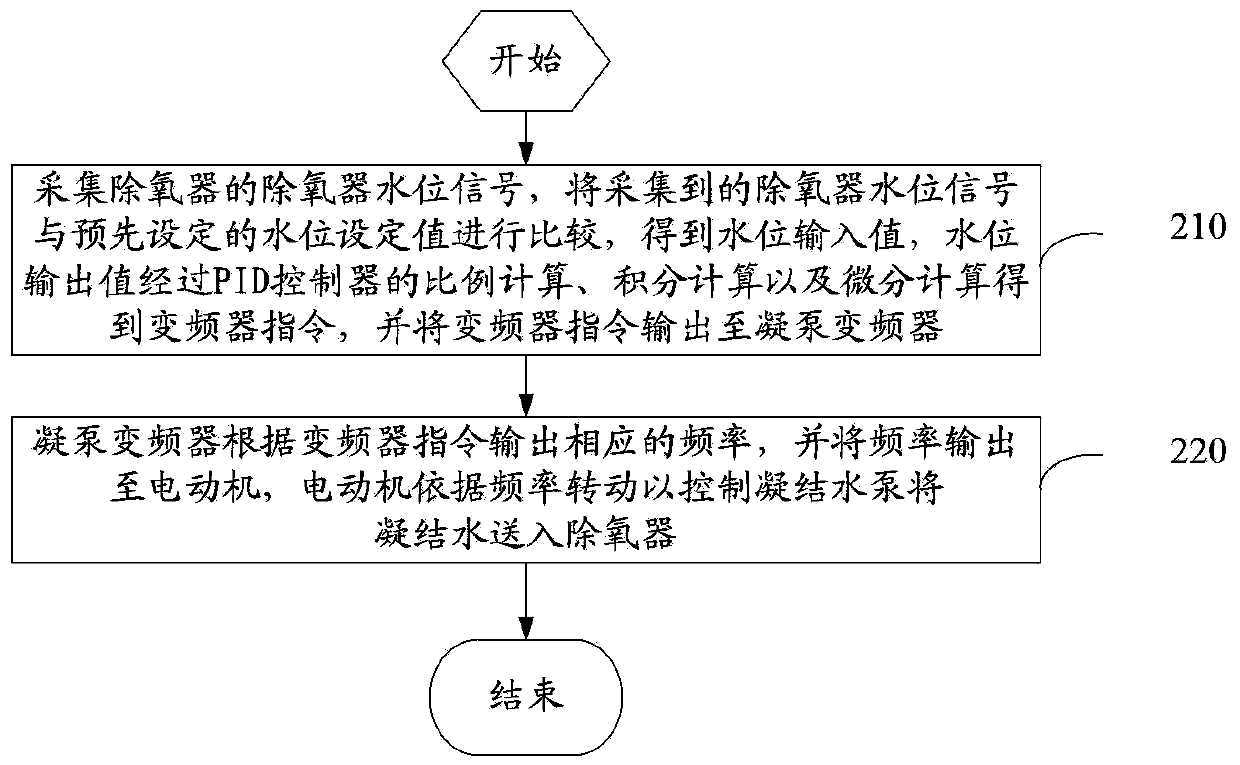

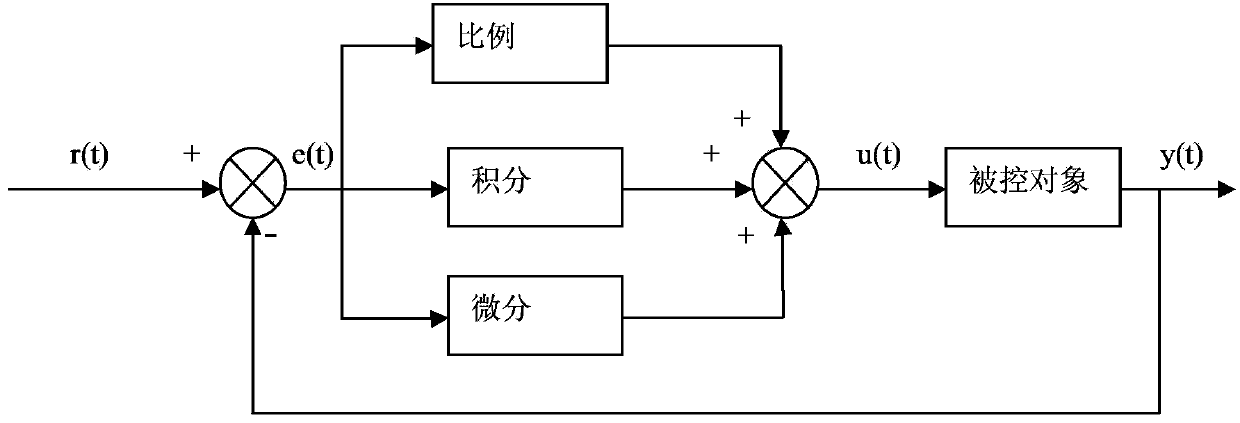

Condensate pump frequency conversion control method and device

ActiveCN103362792AHigh energy consumptionReduce energy consumptionPump controlPositive-displacement liquid enginesFrequency changerEngineering

The invention discloses a condensate pump frequency conversion control method and device, which are applied to a condensate pump frequency conversion control system. The system comprises a condensate pump frequency converter, a motor, a condensate pump and a deaerator. The method comprises the following steps: acquiring a deaerator water level signal of the deaerator, outputting a frequency converter instruction by a PID (Proportion Integration Differentiation) controller according to the deaerator water level signal and outputting the frequency converter instruction to the condensate pump frequency converter; outputting corresponding frequency by the condensate pump frequency converter according to the frequency converter instruction and outputting the frequency to a motor; and rotating the motor according to the frequency to control the condensate pump to convey condensate water into the deaerator. The conventional condensate pump frequency conversion adjustment is realized according to three impulses of the water level of the deaerator. According to the method provided by the invention, the three-impulse adjustment is changed into single-impulse adjustment, i.e., only the deaerator water level signal is acquired, and the frequency converter instruction is output by the PID controller according to the deaerator water level signal, so that the adjustment disturbance increased by a feed water flow and a condensate water flow can be reduced, the energy consumption of the condensate pump is reduced, and the station service power consumption rate is reduced.

Owner:HENAN CHINA RESOURCES POWER GUCHENG

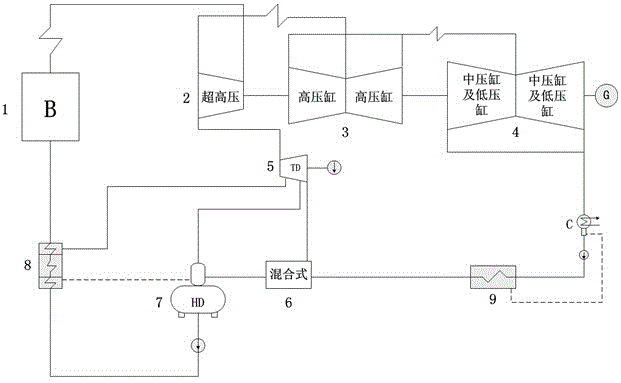

Secondary reheating system and method achieving efficient regeneration and steam exhaust optimization

The invention discloses a secondary reheating system and method achieving efficient regeneration and steam exhaust optimization, and relates to the field of thermal power generation. The system mainlycomprises a boiler, a regeneration steam turbine and a waste heat recovery system, wherein the waste heat recovery system replacing a traditional low-pressure heater is arranged between a condensatewater pump and feedwater of a seventh-stage low-pressure heater, condensate water is preliminarily heated by the waste heat recovery system through flue gas of the boiler and pipeline leaking steam ofthe regeneration steam turbine, and the waste heat recovery system is composed of a flue gas cooler, a low-temperature coal economizer and a sealing heater. The flue gas cooler, the low-temperature coal economizer and the sealing heater replace the traditional low-pressure heater to heat the feedwater, and steam exhaust energy losses of the steam turbine are reduced while heat of the boiler is recovered. The arrangement of a unit is optimized as a whole, efficient regeneration is further enhanced, and the complexity of the system is lowered. The coal consumption can be reduced by 2 g / kW.h to3 g / kW.h while the power supply efficiency of a traditional 1,000 MW secondary reheating unit is improved by 0.2% to 0.3%.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

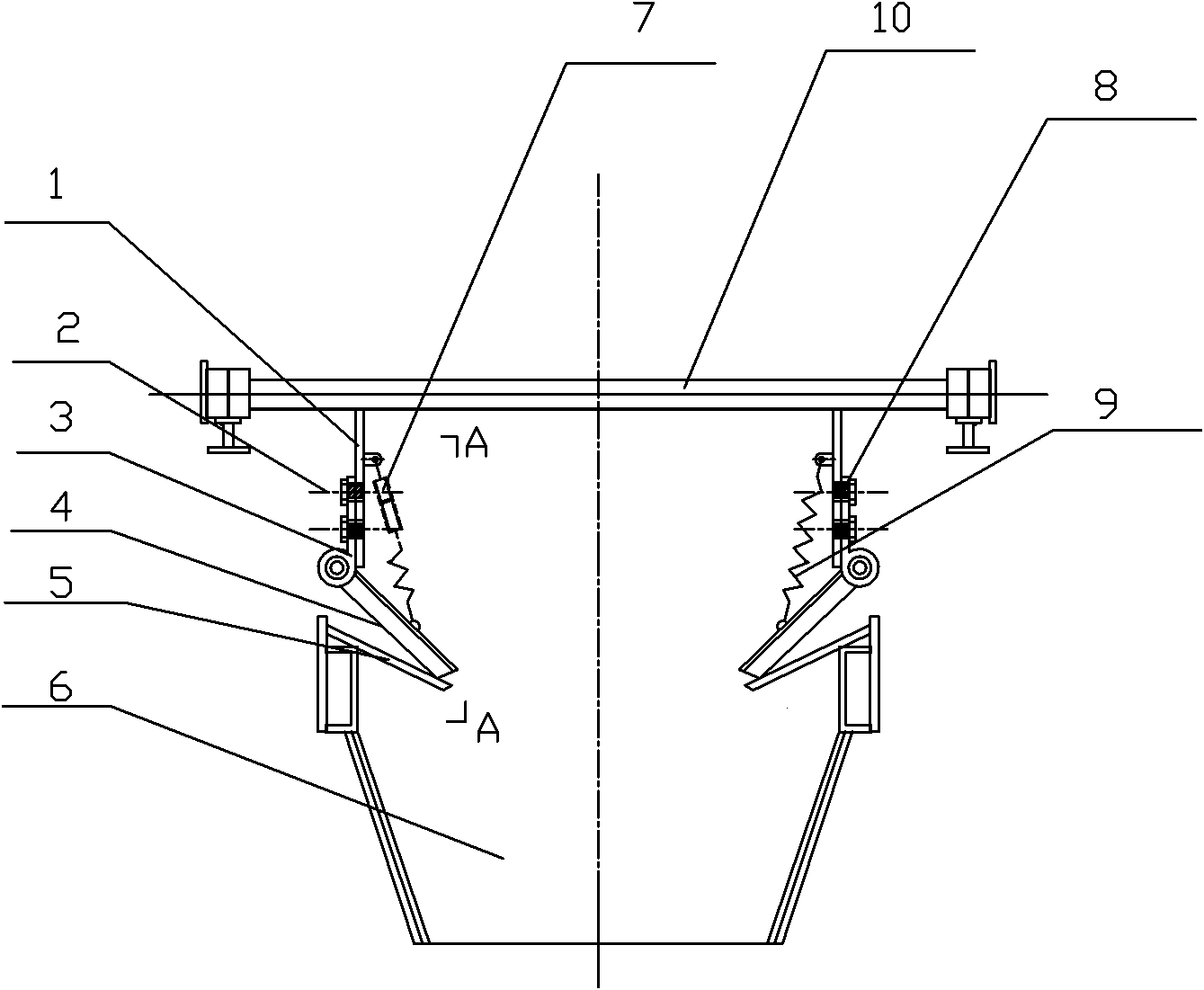

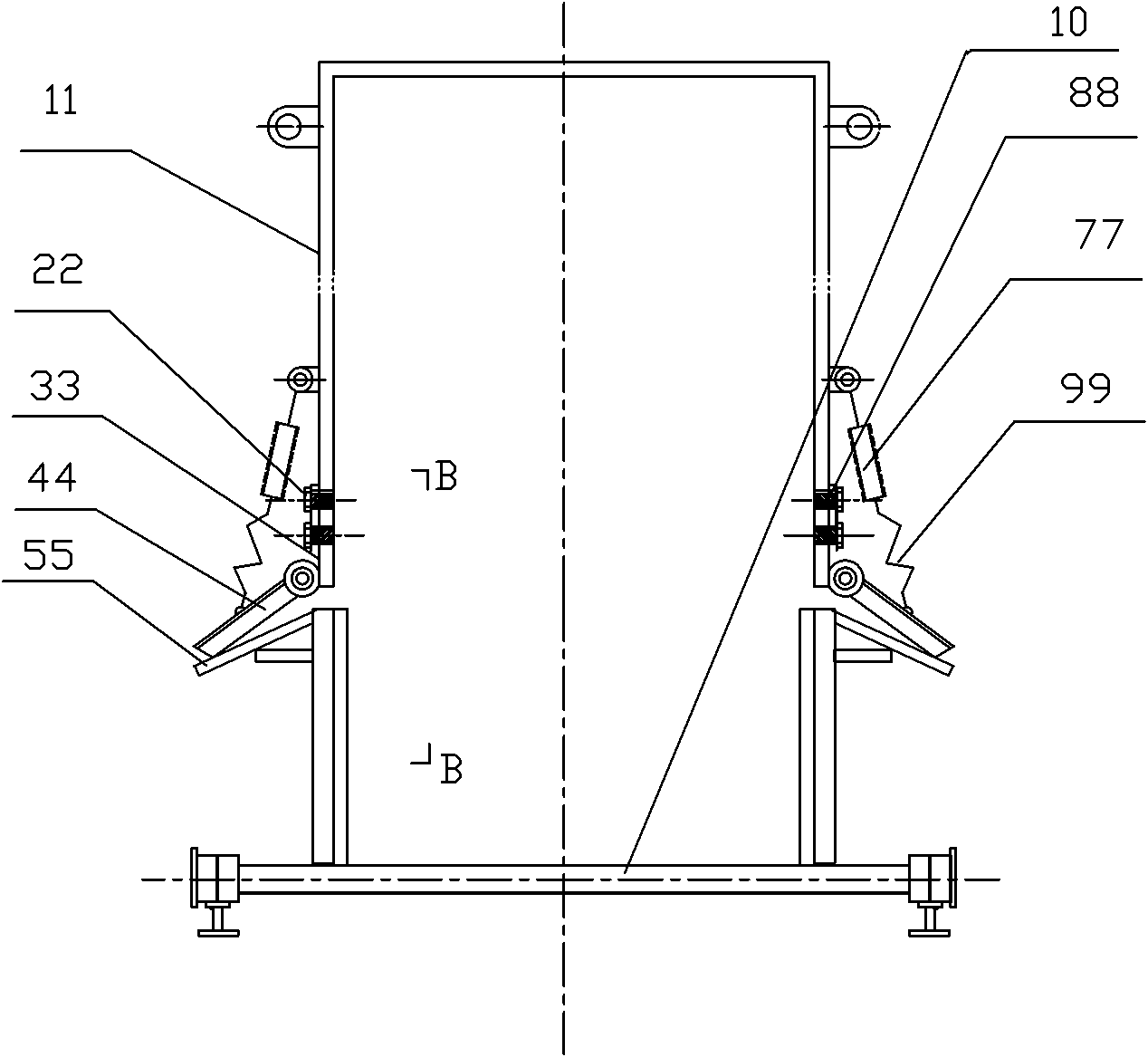

Sealing device for trolley of sintering circular cooler

InactiveCN102032785AReduce maintenance difficultyImprove wear resistanceEngine sealsFurnace typesEngineeringSmoke hood

The invention discloses a sealing device for a sintering circular cooler trolley, which comprises a movable sealing plate and a static sealing plate, wherein one end of the movable sealing plate is fixed by a pin shaft; the other end of the movable sealing plate is hung in the air and can rotate by using the pin shaft as an axis; the movable sealing plate and the static sealing plate are in contact matching; and the back surface of the movable sealing plate is provided with a heat resistant spring. The sealing device has skillful structure; the movable sealing plate can swing freely; under the action of wind pressure and self weight, the movable sealing plate is attached to the static sealing plate; the irregular movement of a trolley is absorbed by the free swing of the movable sealing plate to realize continuous contact slide type sealing; and the heat resistant spring can control the pressure of the movable sealing plate and the static sealing plate. The sealing device can solve the problem of serious wind leakage among the trolley, a lower wind chamber and an upper smoke hood, and solve the problems of short service life and difficult maintenance of sealing pieces among the trolley, the lower wind chamber and the upper smoke hood, thereby enhancing recycling ratio of smoke gas, enhancing the temperature of the smoke gas, largely enhancing generated electrical energy, efficiently utilizing circular cooling residual heat and benefiting popularization and utilization.

Owner:孙慕文

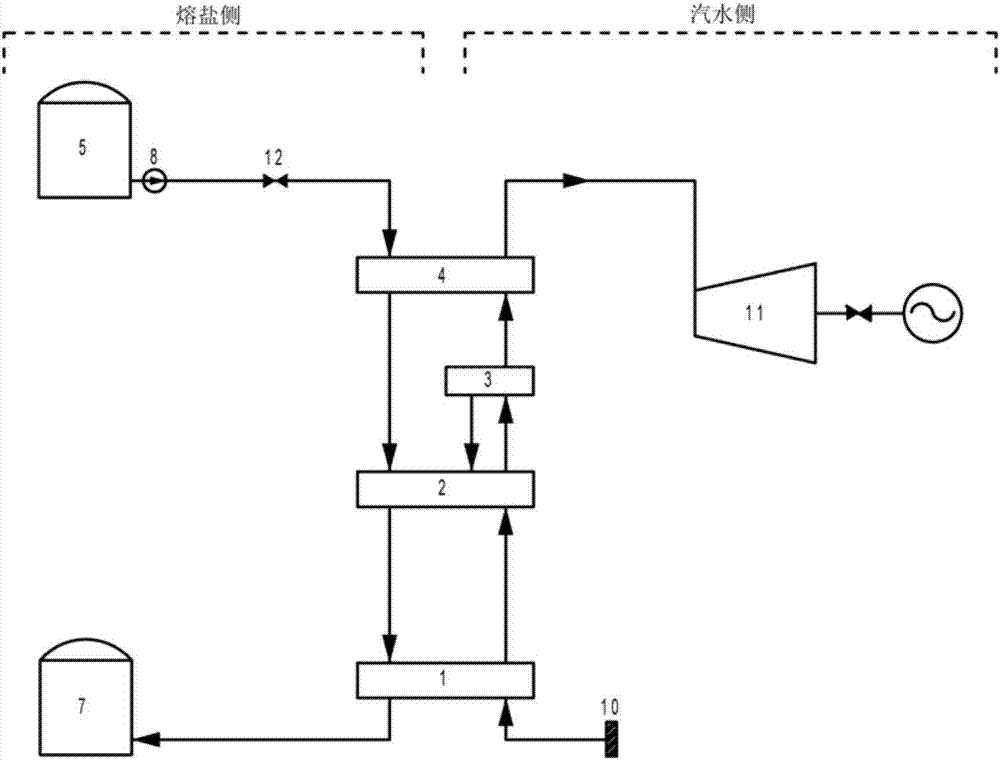

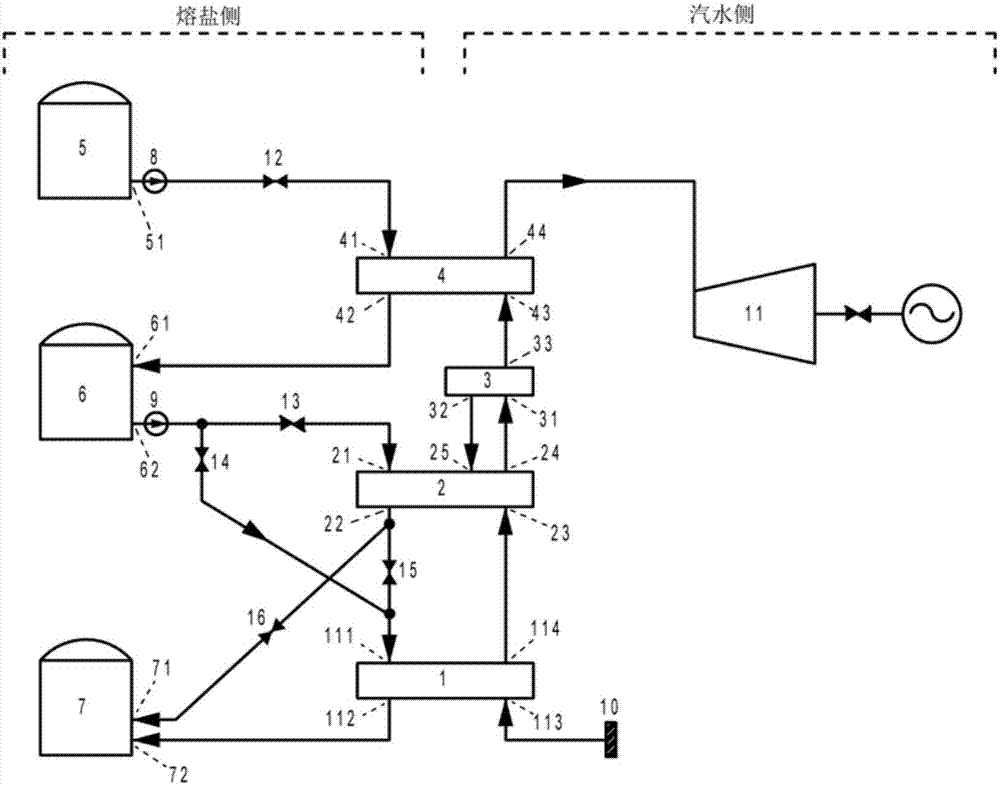

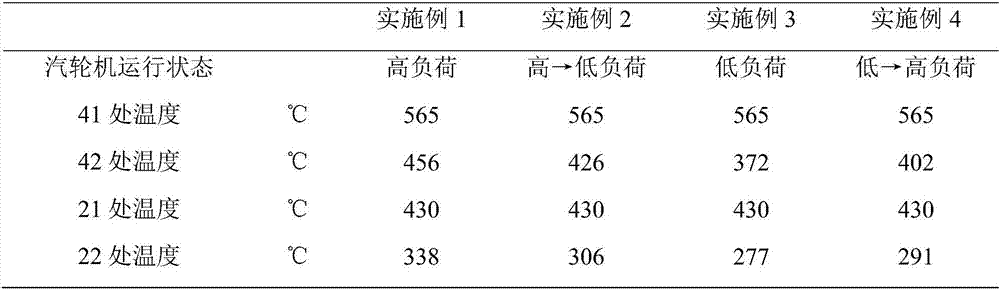

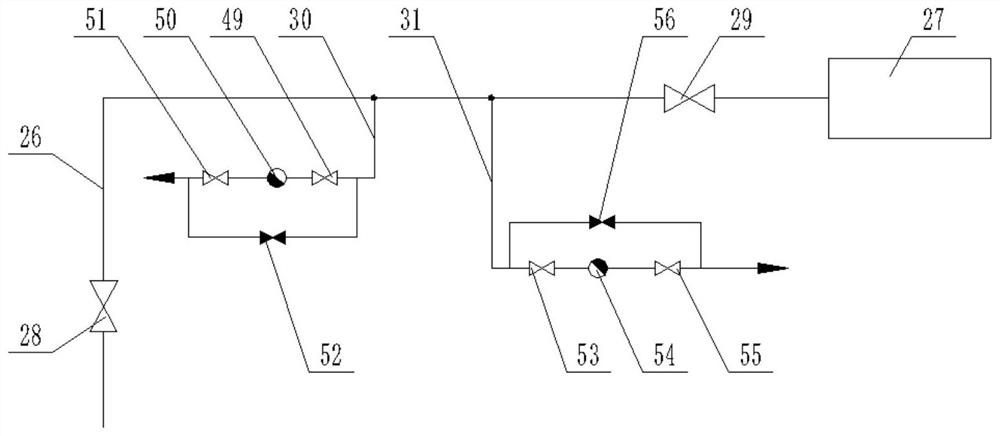

Full-load molten salt steam generating system and control method thereof

ActiveCN107191343AEasy to controlTake advantage ofFrom solar energySolar heat devicesMolten saltSuperheater

The invention discloses a full-load molten salt steam generating system and a control method thereof. The system is composed of a preheater, an evaporator, a steam drum, a superheater, a high-temperature molten salt tank, an intermediate-temperature molten salt tank, a low-temperature molten salt tank, a molten salt pump, a valve, a temperature measuring device and a flow measuring device. A water working medium passes through the preheater, the evaporator, the steam drum and the superheater in sequence to become overheated steam. High-temperature molten salt is subjected to heat exchange through the superheater and returns to the intermediate-temperature molten salt tank. Intermediate-temperature molten salt is divided into two paths and enters the evaporator or the preheater. Evaporator outlet molten salt is also divided into two paths and enters the low-temperature molten salt tank or the preheater. According to the system, the heat exchange process in the superheater, the evaporator and the preheater is decoupled, the molten salt flow passing through the superheater, the evaporator and the preheater can be controlled correspondingly by adjusting the opening degree of the valve when the load changes, and the solidification risk of the molten salt in the preheater is greatly reduced while stable steam parameter output is achieved.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

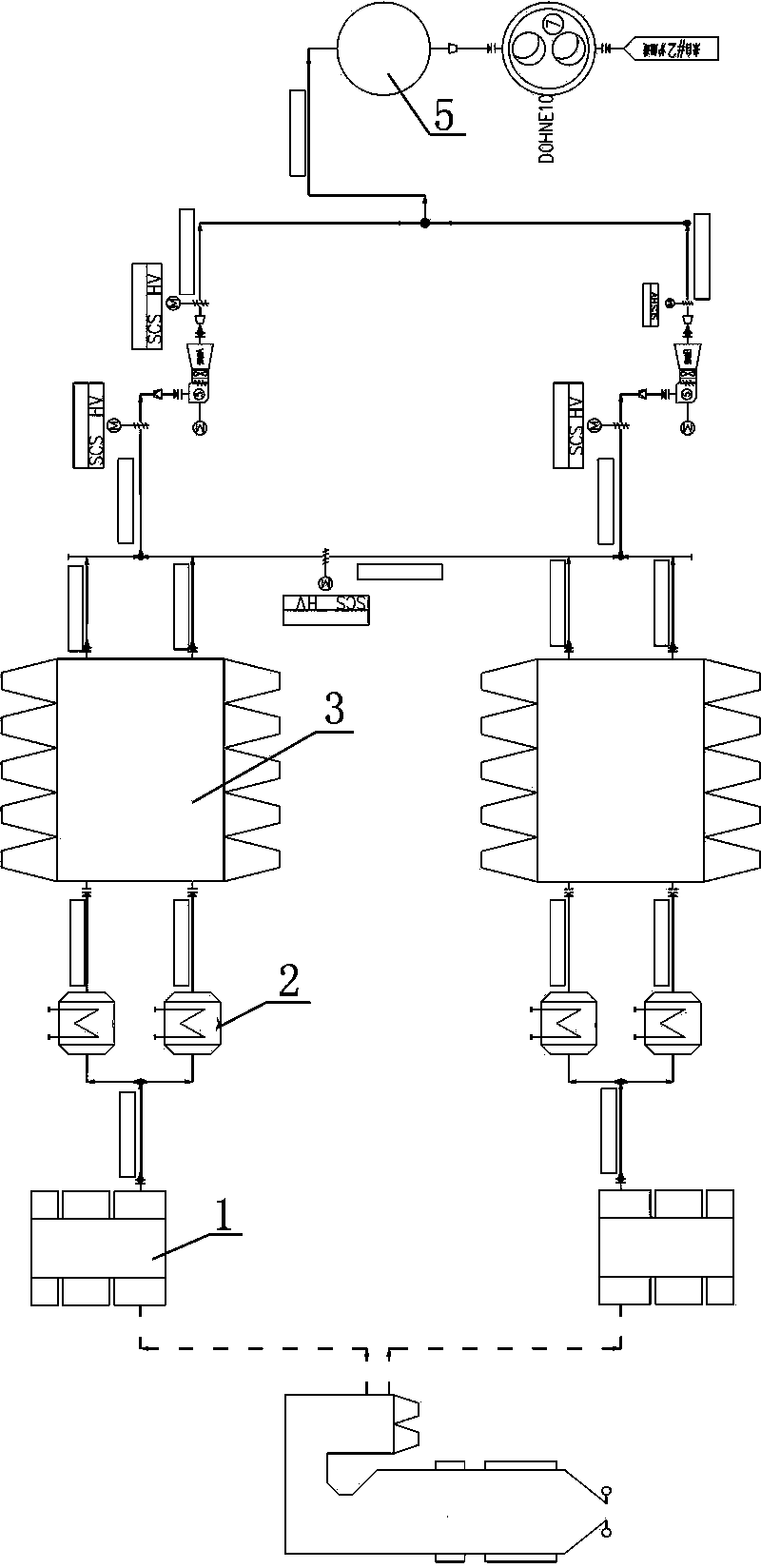

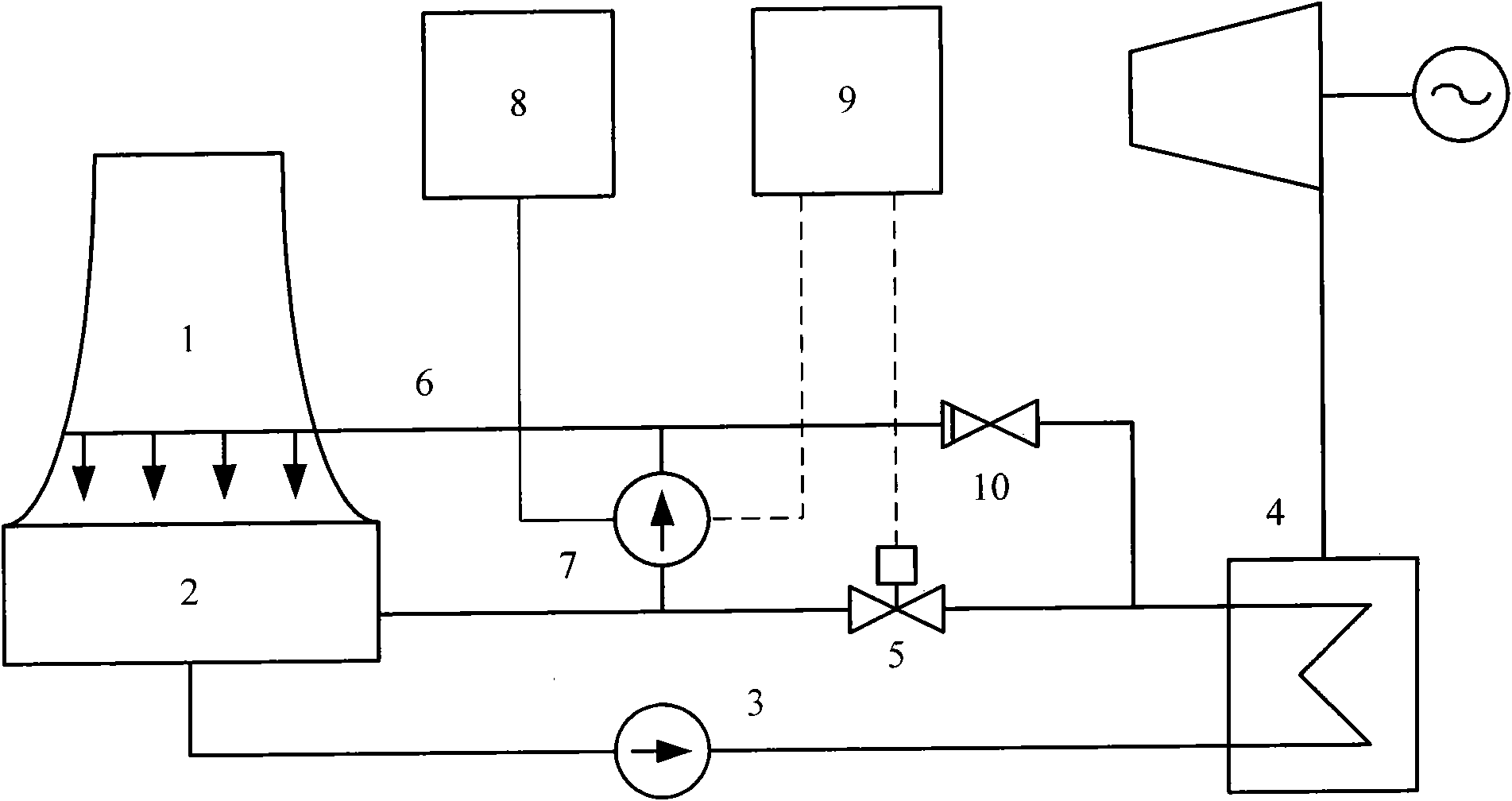

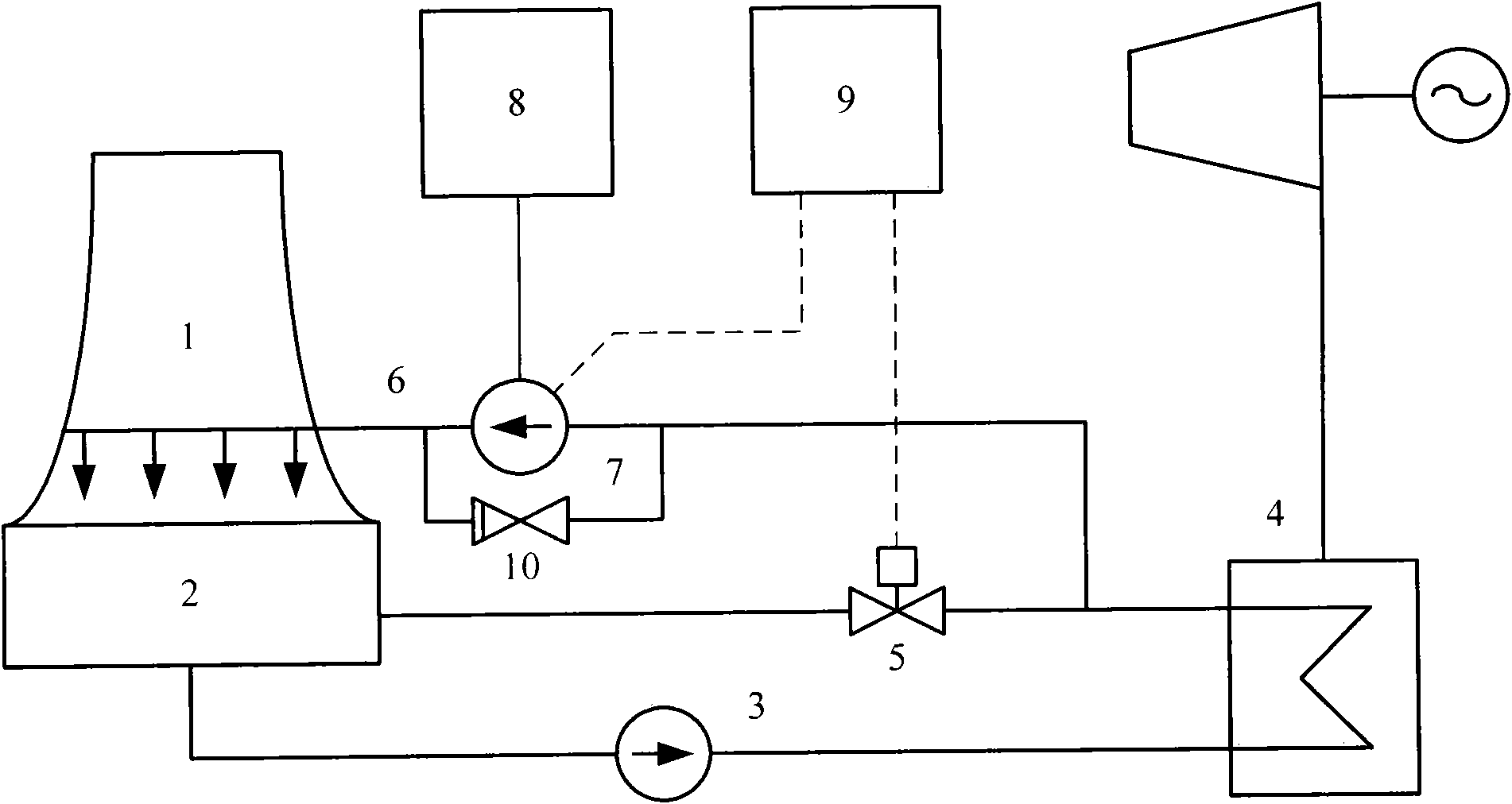

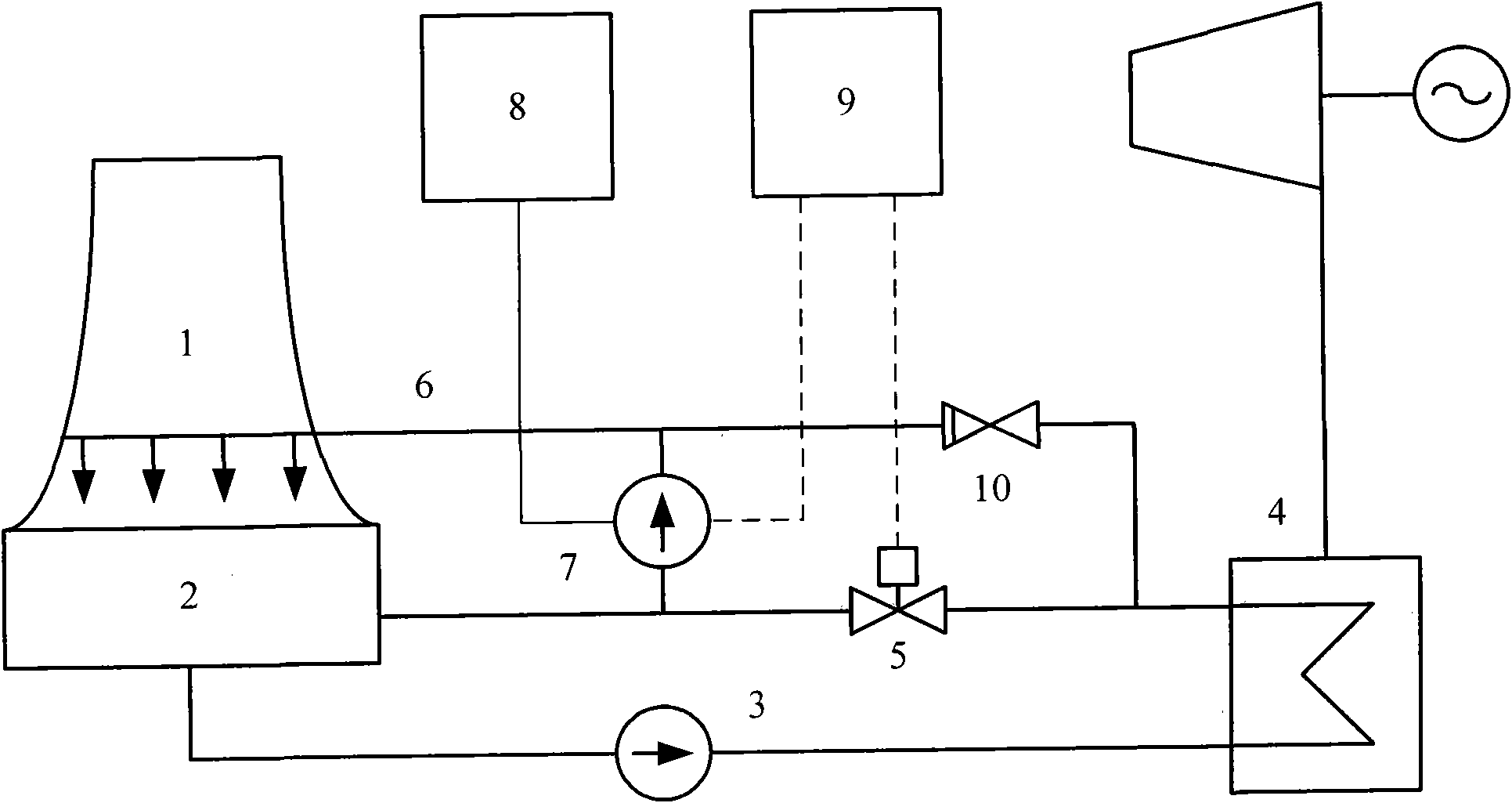

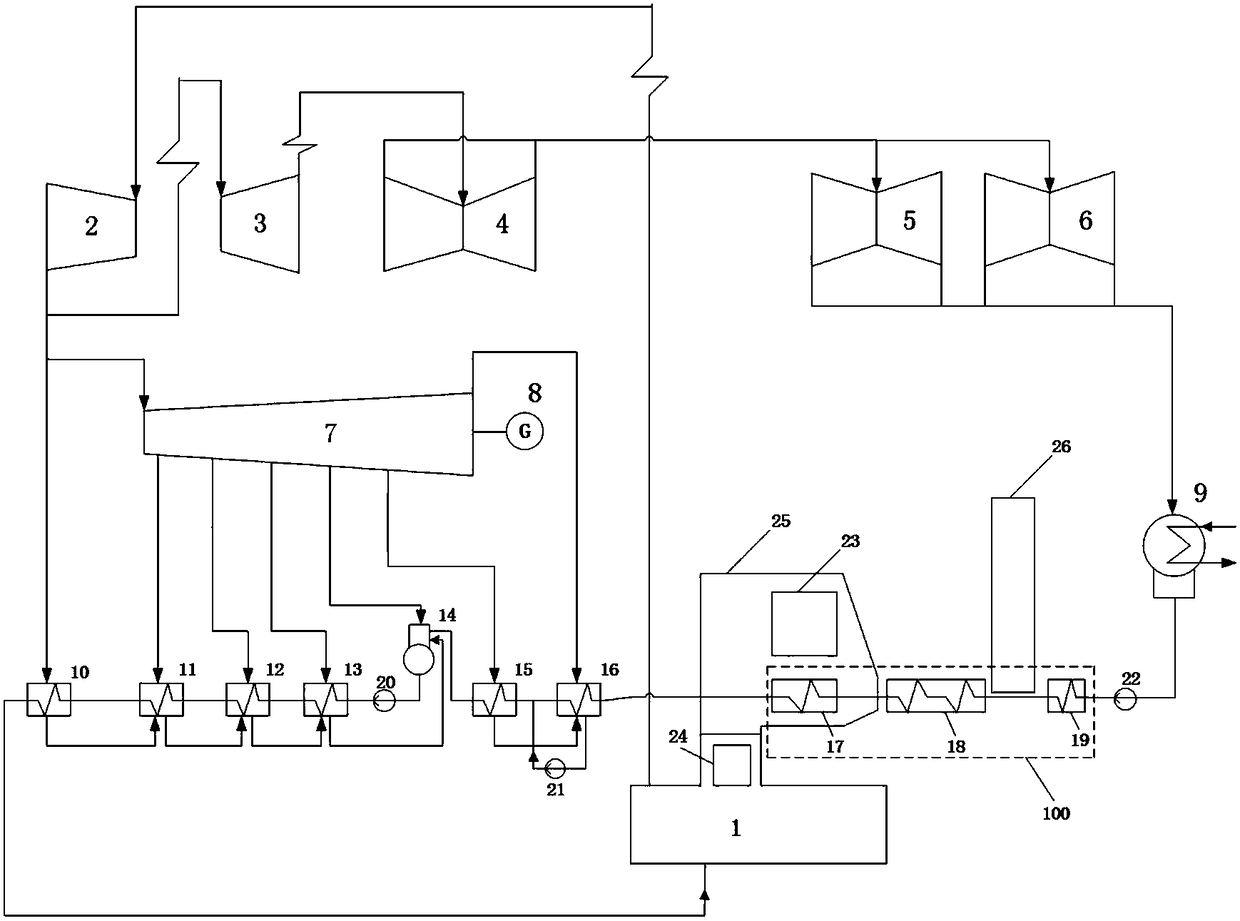

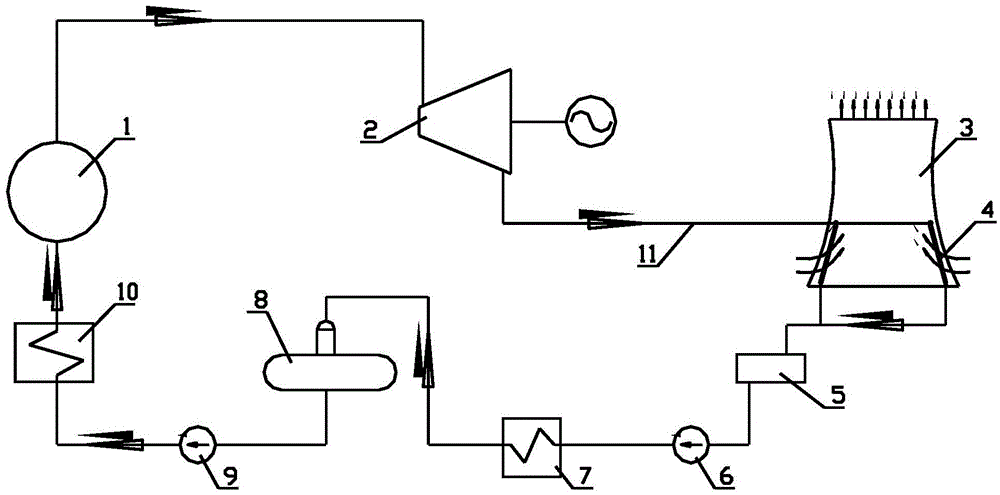

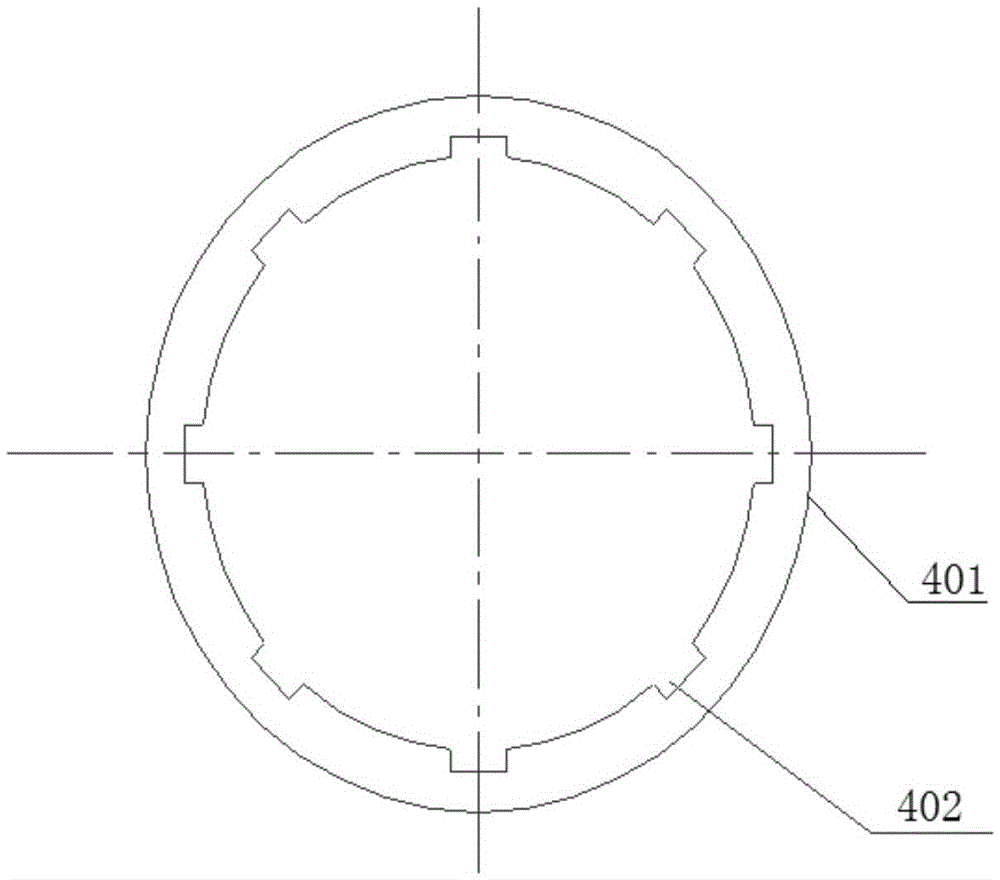

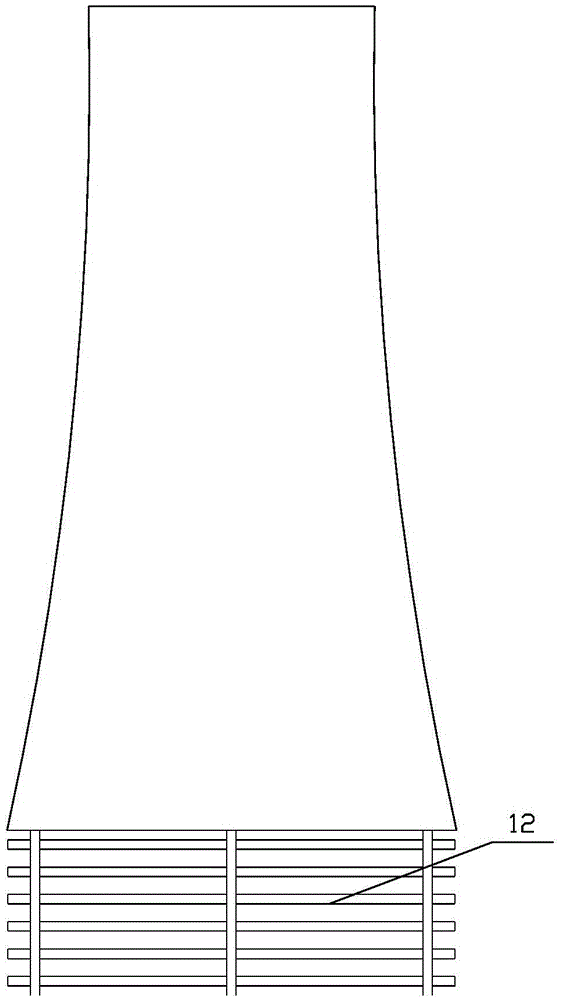

Direct-air-cooling power generation system with natural ventilation cooling tower

InactiveCN105464725ASmall footprintReduce power consumptionSteam/vapor condensersEngine componentsNatural ventilationCooling tower

The invention discloses a direct-air-cooling power generation system with a natural ventilation cooling tower. The direct-air-cooling power generation system comprises a boiler, an air-cooling condenser and the natural ventilation cooling tower. A plurality of air inlets are evenly formed in the bottom of the natural ventilation cooling tower in the circumferential direction. An air outlet is formed in the top of the natural ventilation cooling tower. The air-cooling condenser comprises a heat exchange pipe bundle which is composed of multiple heat exchange pipes. The heat exchange pipe bundle is arranged on the inner sides or the outer sides of the air inlets. Threads or grooves are formed in the inner surfaces of the heat exchange pipes. Fins are arranged on the outer sides of the heat exchange pipes. Multiple sets of shutters are arranged on the portion, on the peripheries of the air inlets, of the natural ventilation cooling tower. Each set of shutters include a plurality of blades which are horizontally arranged. By means of the direct-air-cooling power generation system, the power consumption of the direct-air-cooling power generation system can be lowered, the influences of natural air on running of the air-cooling system and a power generation set are reduced as much as possible, and the direct-air-cooling power generation system has important significance in improving operating economy, stability and reliability of a power plant.

Owner:WUHAN KAIDI ELECTRIC POWER ENG

Water-heat-power cogeneration system and method based on seawater desalination and cascade energy consumption

ActiveCN112761747AImprove energy level utilizationOcean eco-environmentally friendlySteam useCombined combustion mitigationCogenerationSeawater

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

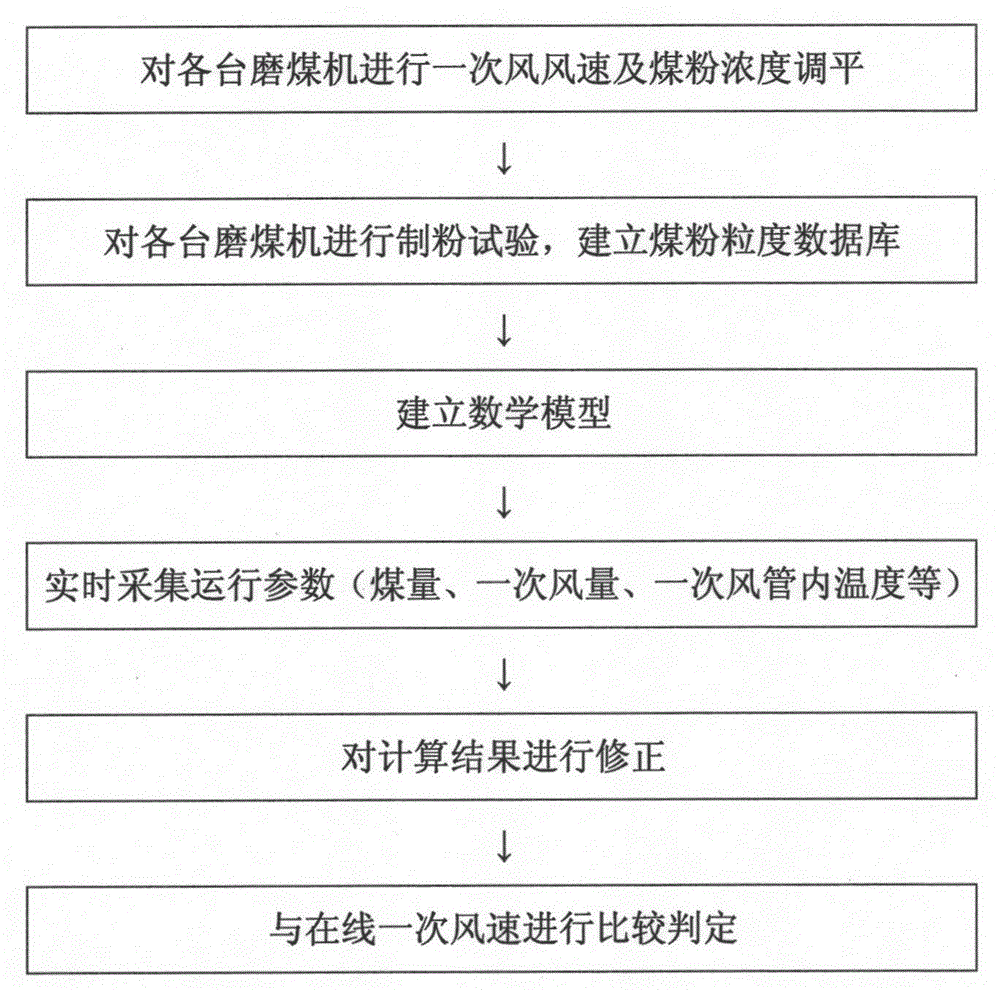

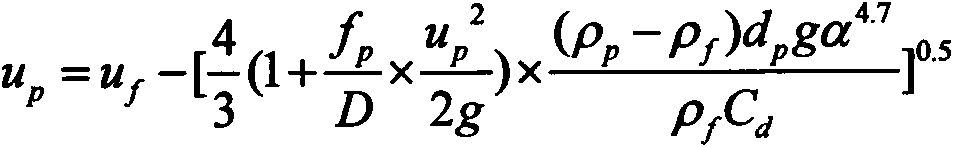

Online pipe anti-blocking method for utility boiler primary air pipe

The invention discloses an online pipe anti-blocking method for a utility boiler primary air pipe. The method comprises the steps that firstly, leveling is carried out on the air speed of primary air and pulverized coal concentration of each coal mill; secondly, a coal pulverizing system test is carried out on the coal mill, and a pulverized coal grain size database is established; thirdly, a mathematic model is established, according to parameters in operation collected in real time and the pulverized coal grain size database, the minimum fluidizing velocity of pulverized coal conveying under the theory state is calculated, a theoretical value is corrected according to the actual operation condition, the corrected minimum fluidizing air velocity is compared with the primary air speed measured online, and guiding opinions of the primary air speed are given. The online pipe anti-blocking method for the utility boiler primary air pipe can avoid the defects brought by too high primary air speed that pulverized coal ignition is delayed, the electric current of a primary air fan is too large, and air leakage of an air preheater is increased, and achieve energy saving and consumption reducing under the condition that the primary air pipe is not blocked.

Owner:SHANGHAI POWER EQUIP RES INST

Method for preventing blockage of heat storage element of rotary air preheater of coal-fired power plant boiler

InactiveCN109084322AReduce speedSolve the blockageCleaning heat-transfer devicesCombustion processAir preheaterLow speed

The invention discloses a method for preventing blockage of a heat storage element of a rotary air preheater of a coal-fired power plant boiler. When the resistance of the air preheater is increased by 15%-20% than a design value, the rotational speed of the air preheater is adjusted according to the unit load and the exhaust gas temperature of an outlet of the air preheater to increase the temperature of the cold end of the air preheater; the air preheater runs continuously at a low speed, and when the resistance decreases to the required level, the normal operation of the air preheater is resumed; by reducing the rotational speed of the air preheater, the exhaust gas temperature is increased; and when the rotational speed of the air preheater is reduced, the heat storage capacity of theheat storage element is increased, the exhaust gas temperature can be greatly increased, the cold end integrated temperature of the air preheater is increased, and the flue gas temperature in the middle portion of the heat storage element reaches 250 DEG C, so that ammonium hydrogen sulfate is sublimated. The method has the advantages that the purposes of removing ammonium hydrogen sulfate originally attached to the surface of the heat storage element and reducing the resistance of the air preheater are achieved, the boiler efficiency is improved, the power consumption rate of a plant is lowered, and hidden dangers of lowering output or even halt of a power station are eliminated.

Owner:HUADIAN WEIFANG POWER GENERATION CO LTD

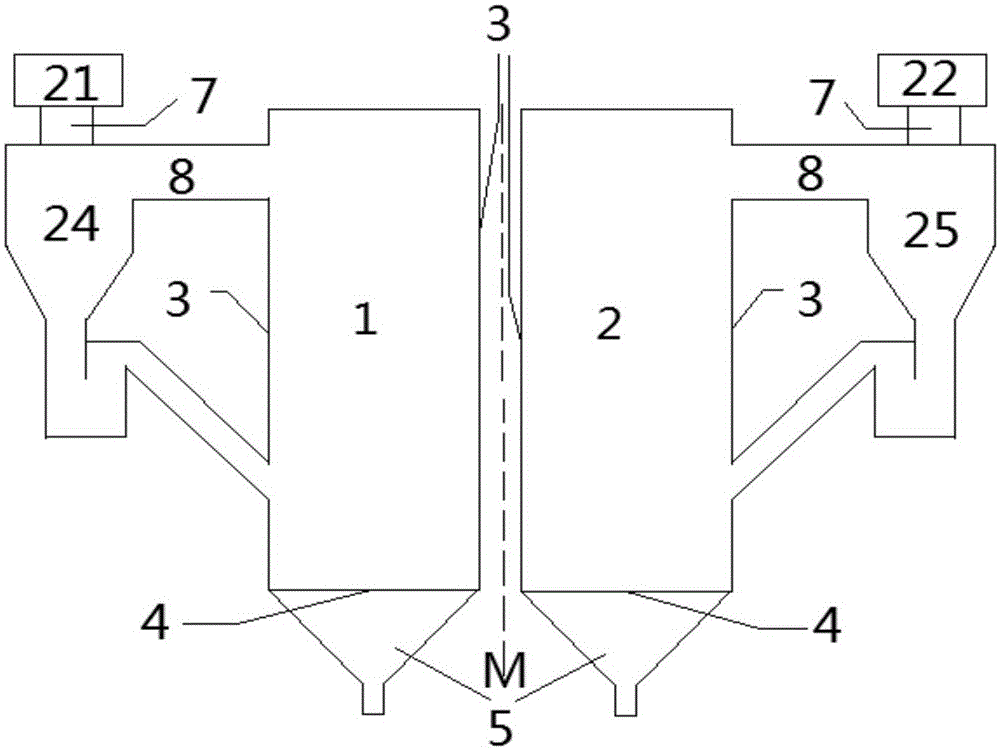

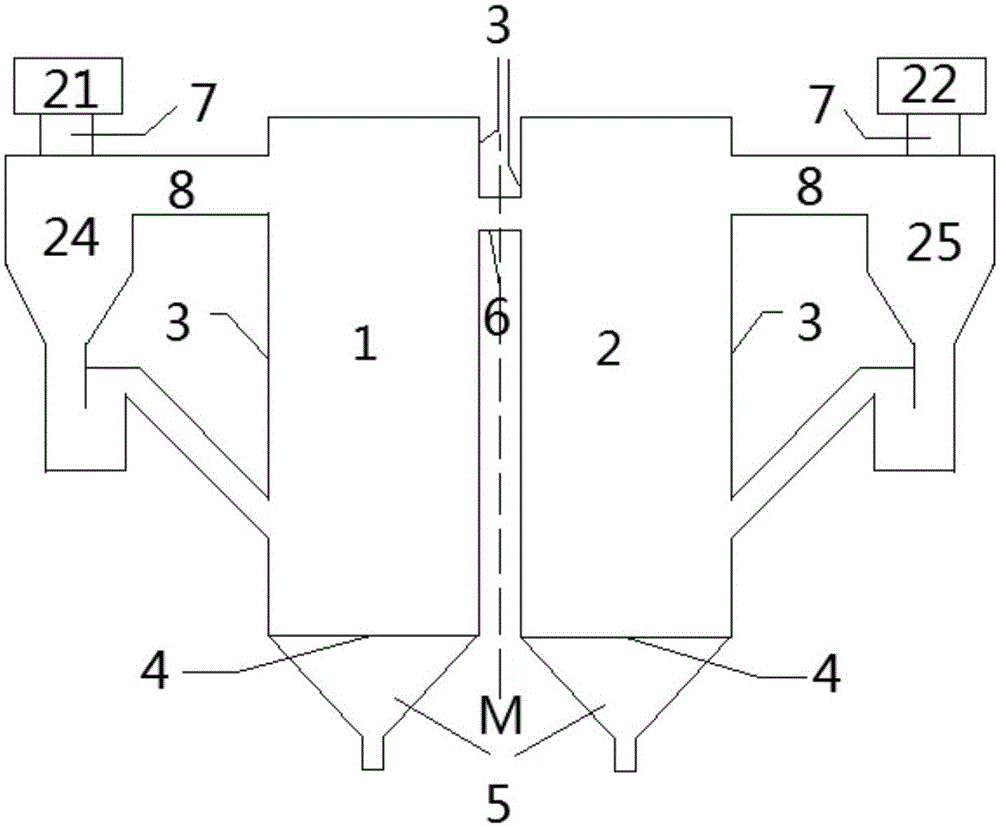

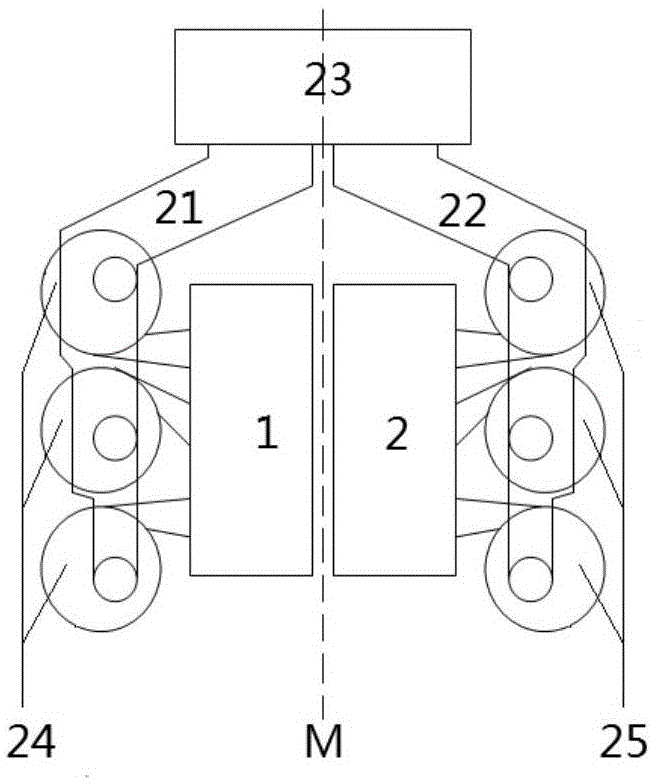

Double-hearth circulating fluidized bed boiler

ActiveCN105157021ASimple designAvoid heat load differencesFluidized bed combustionSteam boilersCycloneHearth

The invention discloses a double-hearth circulating fluidized bed boiler. The double-hearth circulating fluidized bed boiler comprises two completely separate hearths which are arranged side by side; a gap is reserved between the two hearths; a separate air distribution device and an air chamber are arranged at the lower part of each hearth; one group of cyclone separators with the same structures are arranged on the outer side of the surface opposite to each of adjacent surfaces of the two hearths; the two hearths, the two groups of separators and a common connection smoke channel are symmetrically arranged about the vertical center surface of the double-hearth circulating fluidized bed boiler; the two groups of cyclone separators are connected to the same tail convection smoke channel through the common connection smoke channel respectively. According to the double-hearth circulating fluidized bed boiler, single side of each water-cooled walls of each hearth is heated; the heat load difference between parallel tube screens and the table-tilting phenomenon caused by bed pressure fluctuation can be avoided; the reliability and the adjustment flexibility of the control system in the running process are further improved; the power consumption rate of the boiler factory is reduced; the favorable condition is provided for the arrangement of the high-temperature heated surface of the secondarily-heated supercritical circulating fluidized bed boiler; meanwhile, the hearths are simple in design and convenient to enlarge.

Owner:TSINGHUA UNIV

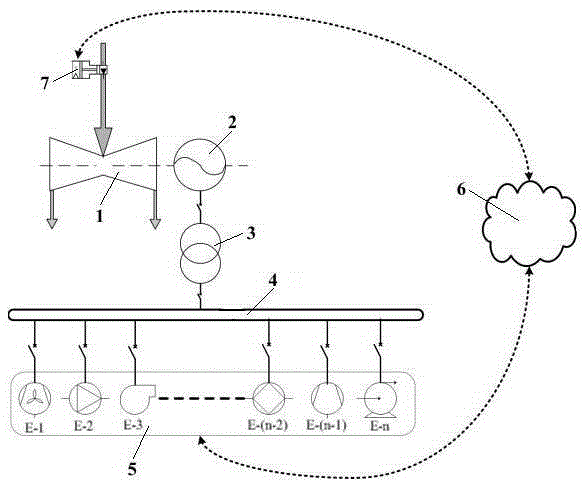

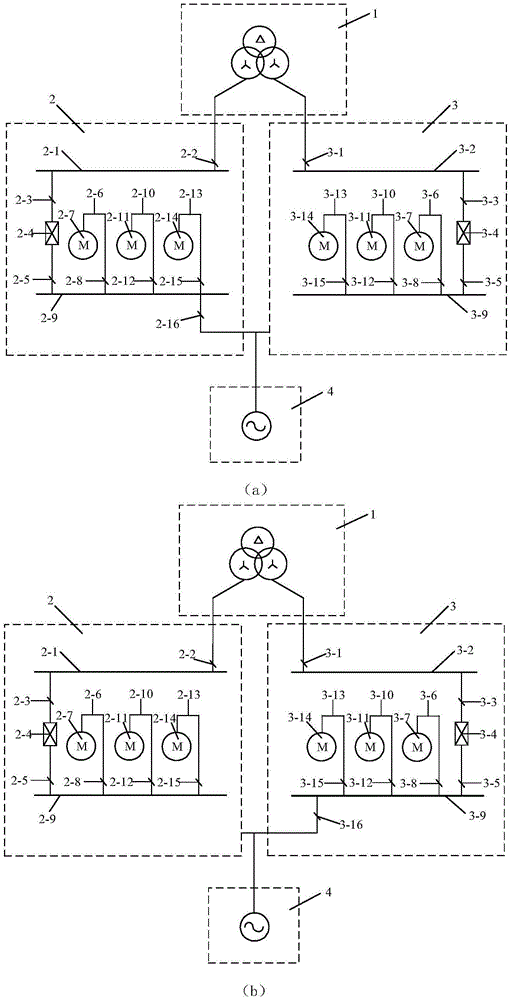

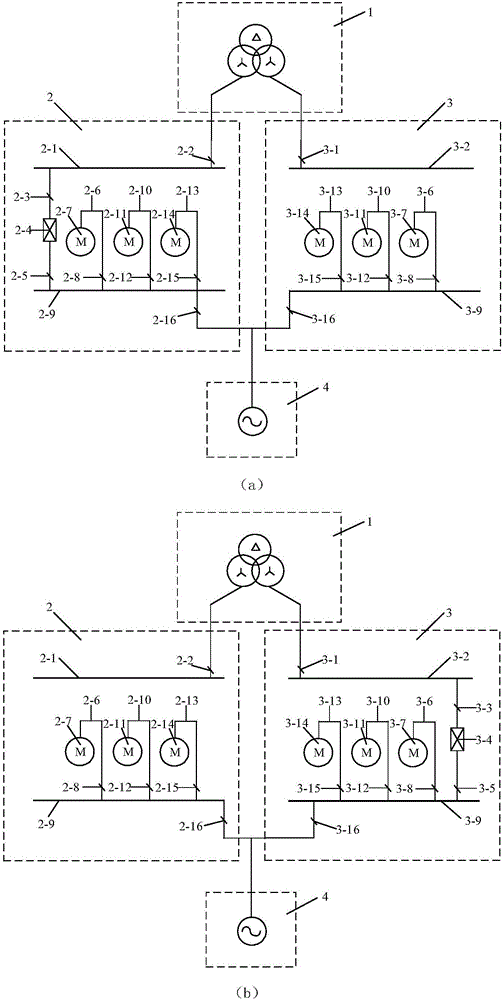

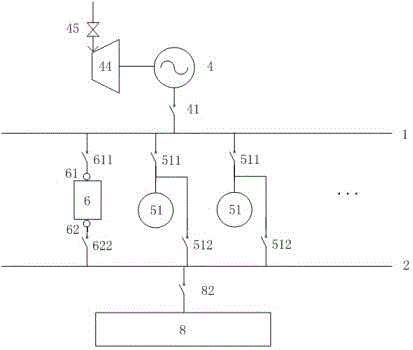

Power plant system with additional steam turbine and variable frequency auxiliary machines and control method

ActiveCN105317474ATake advantage ofRealize cascade utilizationMachines/enginesEngine componentsCurrent loadBusbar

The invention relates to a power plant system with an additional steam turbine and variable frequency auxiliary machines and a control method. Systems and control methods similar to the power plant system and the control method which greatly improve power generating efficiency are absent at present. The system comprises an auxiliary machine equipment cluster, and is characterized in that the system further comprises the additional steam turbine, a power generator, a transformer, an auxiliary machine busbar, a steam turbine speed adjusting device and a distributed control system (DCS); the steam turbine speed adjusting device is connected with the additional steam turbine; the transformer is connected with the auxiliary machine busbar; the auxiliary machine busbar is connected with the auxiliary machine equipment cluster. The control method includes the steps that the DCS generates a proper control instruction according to current load information of a thermal power generating unit and variable frequency voltage value required by the auxiliary machine equipment cluster; the control instruction acts on the inside of the steam turbine speed adjusting device; and 20-50HZ voltage is generated through the power generator and the transformer and directly transmitted to all auxiliary machine equipment in the auxiliary machine equipment cluster through the auxiliary machine busbar. According to the power plant system with the additional steam turbine and the variable frequency auxiliary machines and the control method, the structural design is reasonable, and power generating efficiency is greatly improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

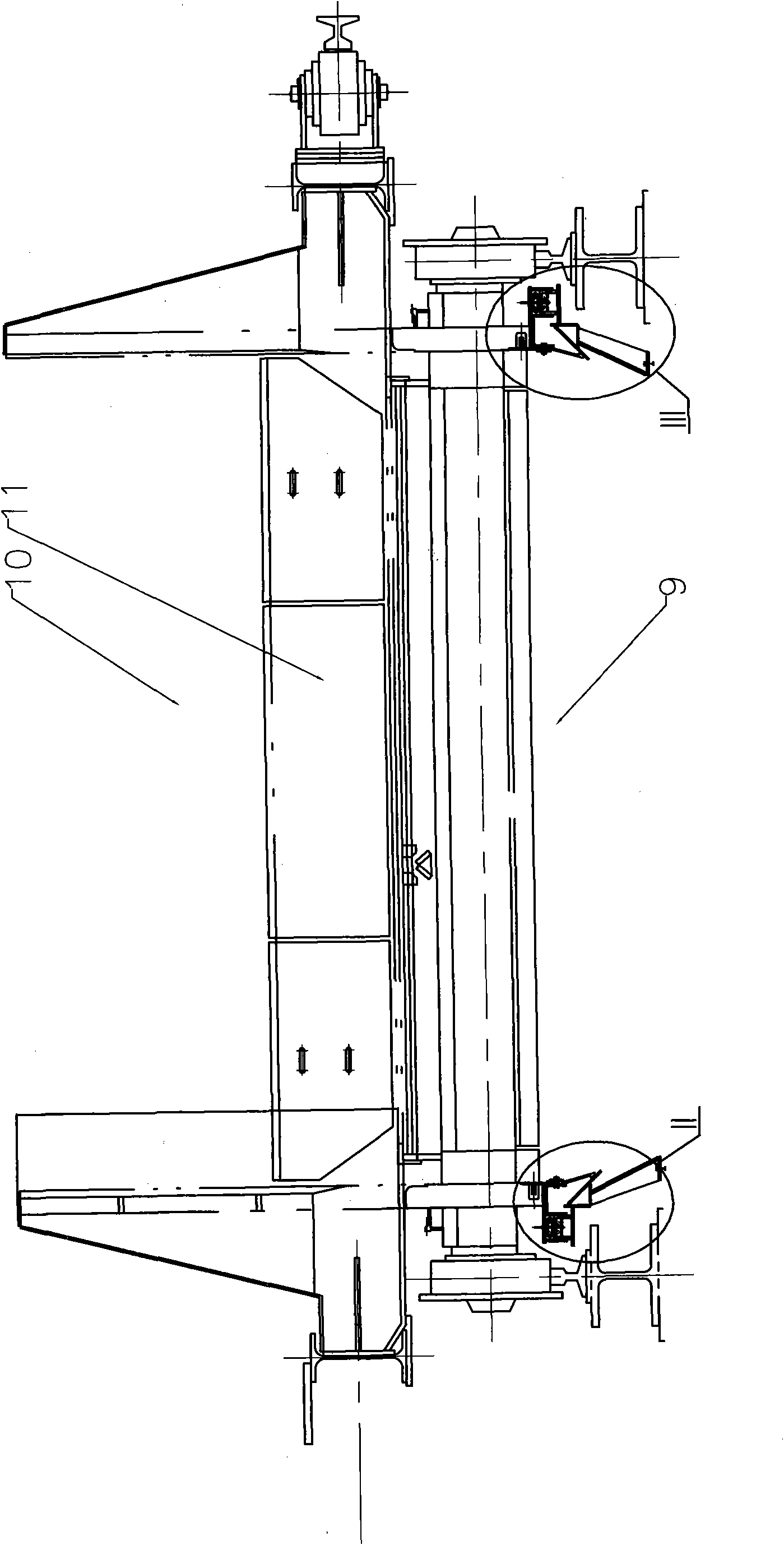

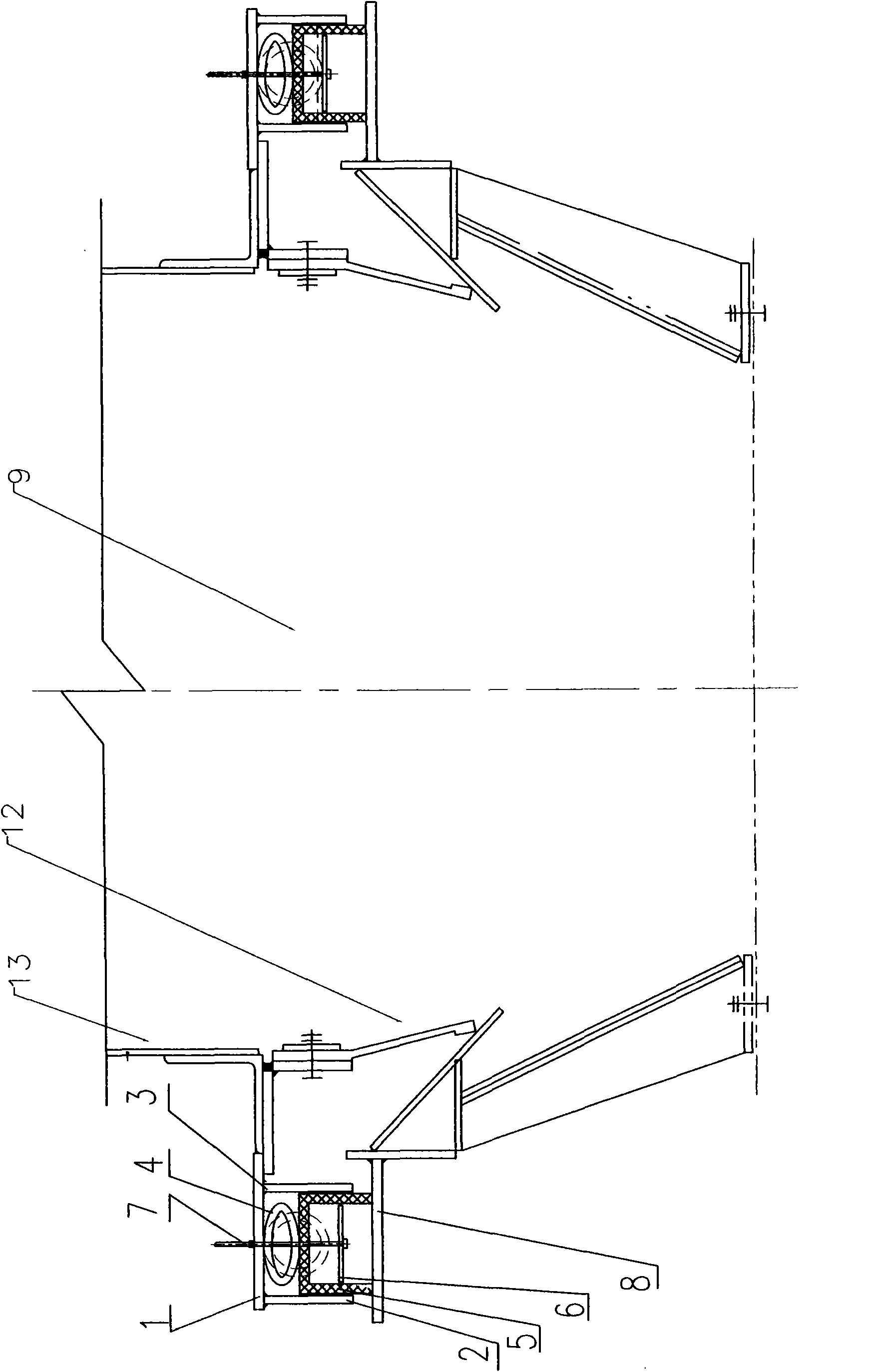

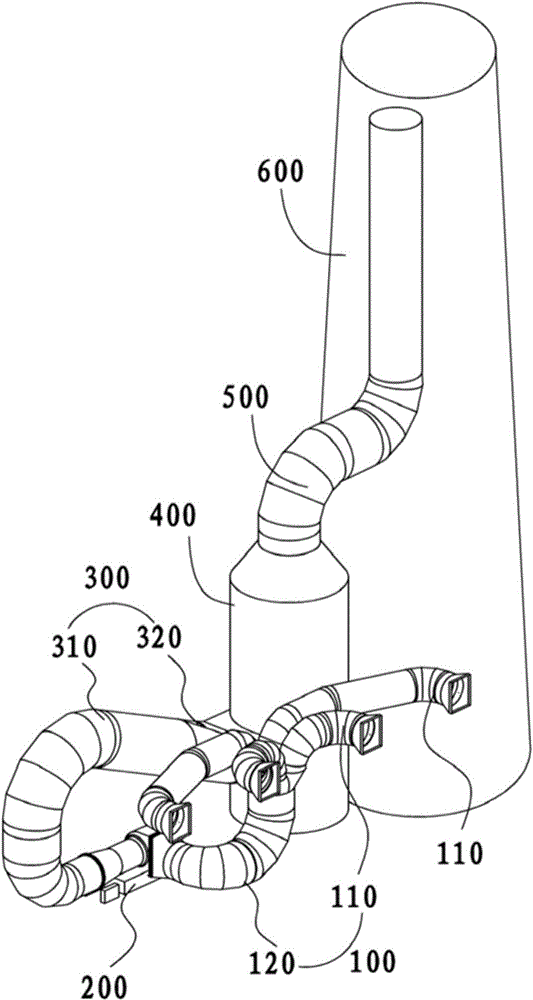

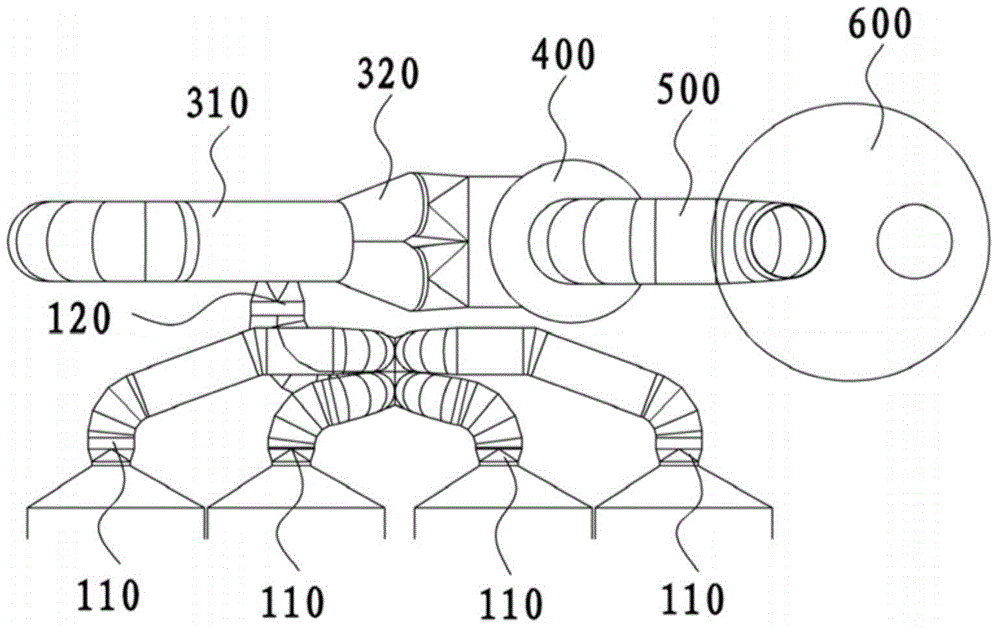

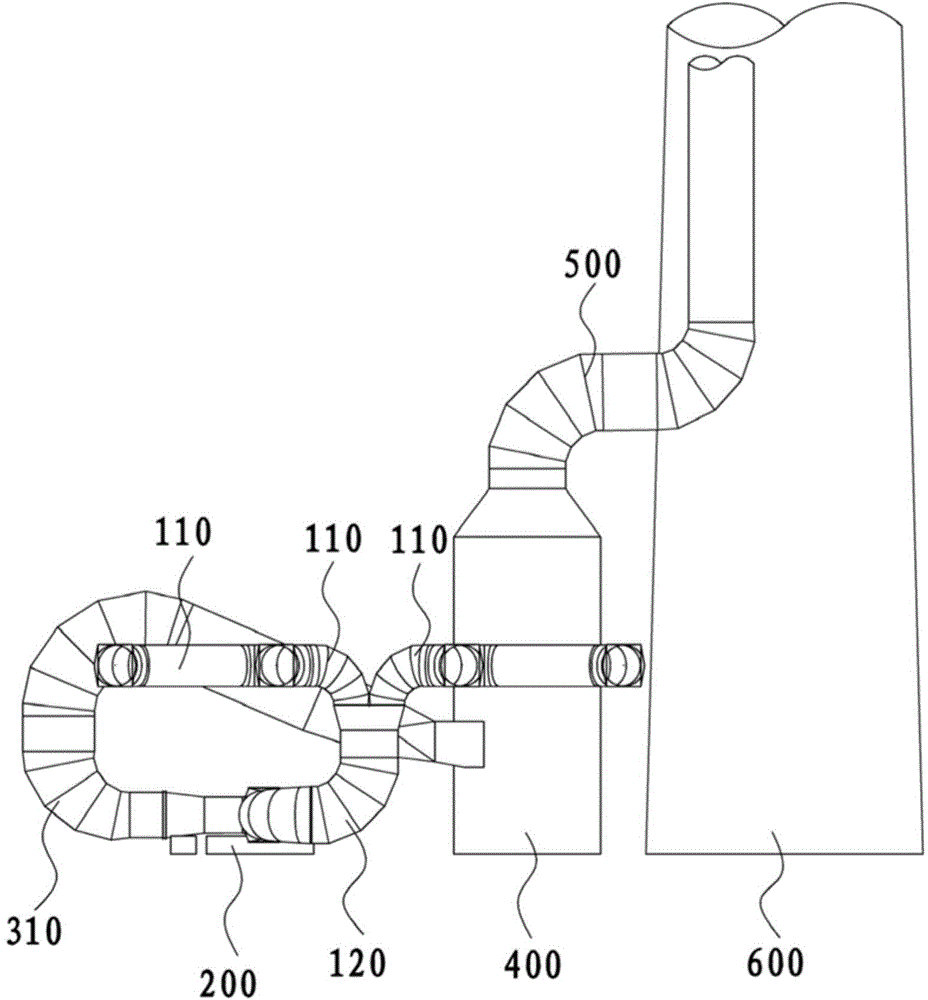

Equipment arrangement structure provided with single-row induced draft fan behind dust catcher and flue gas system

The invention discloses an equipment arrangement structure provided with a single-row induced draft fan behind a dust catcher and a flue gas system. The equipment arrangement structure provided with a single-row induced draft fan behind the dust catcher comprises the single-row induced draft fan, a desulfurization absorption tower and a chimney, wherein the single-row induced draft fan, the desulfurization absorption tower and the chimney are successively connected by flues; the center lines of the single-row induced draft fan, the desulfurization absorption tower and the chimney are positioned on the same plane; the desulfurization absorption tower and the chimney are both vertically arranged; the single-row induced draft fan is laterally arranged on the outer side of the desulfurization absorption tower; the outlet of the single-row induced draft fan is back onto the desulfurization absorption tower; an outlet flue is connected by directly facing the inlet of the desulfurization absorption tower after slowly rotating. All pieces of equipment behind the dust catcher are subjected to spatial combined arrangement of a horizontal straight line shape, so that the arrangement among all pieces of equipment is more compact, occupied lands are reduced, the length of connection flues is reduced so as to save the materials of the flues, all pieces of equipment behind the dust catcher are reasonably arranged, and a stereo space behind the dust catcher is effectively utilized.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

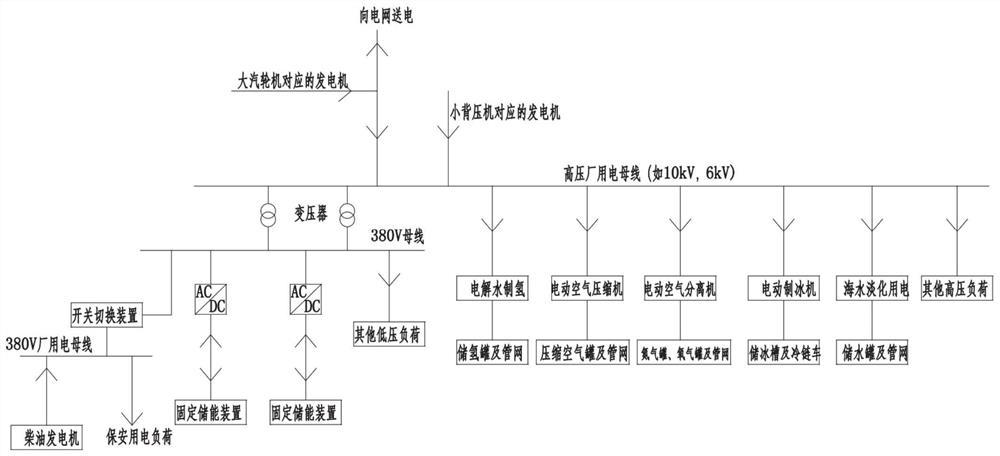

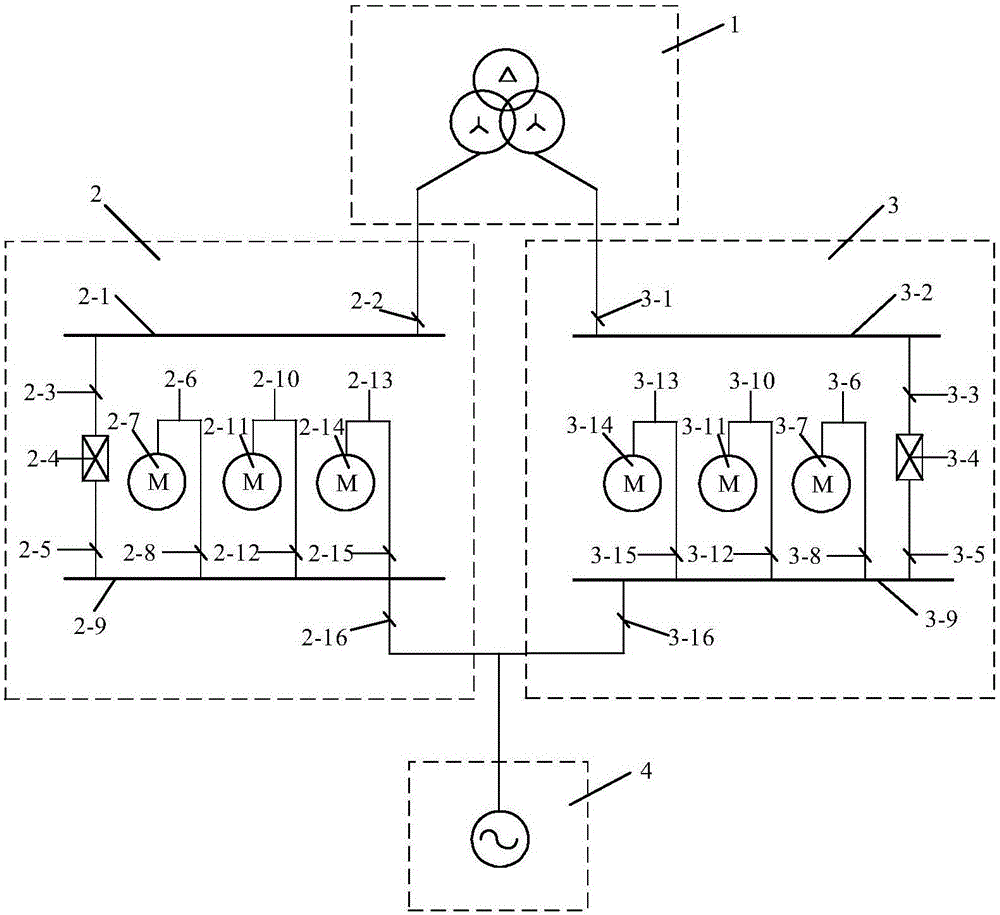

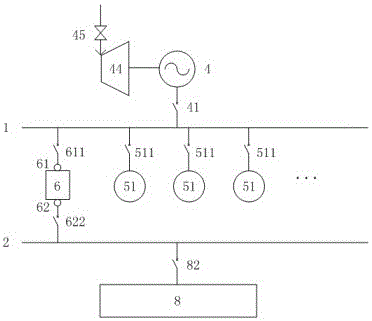

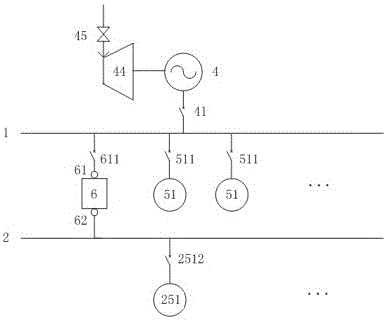

Auxiliary engine tracking power source system for power plant

ActiveCN106208153ASimple structureShorten the lengthEnergy industrySingle network parallel feeding arrangementsAir volumeTransformer

The invention discloses an auxiliary engine tracking power source system for a power plant. The auxiliary engine tracking power source system comprises a high-voltage station transformer, station auxiliary engines and a tracking power source generator, wherein a turbine-drive tracking power source generator is adopted to supply power to the station auxiliary engines; the rotary speeds of the auxiliary engines, such as a draught fan and a water pump are adjusted to the optimal working condition according to requirements of different loads for air volume and water volume, so that energy loss caused by air door baffle cut-off can be avoided. The auxiliary engine tracking power source system adopts a novel energy-saving and consumption-reducing technology for the power plant, so that the station service power consumption rate of the power plant can be substantially lowered.

Owner:XIAN XIRE ENERGY SAVING TECH +1

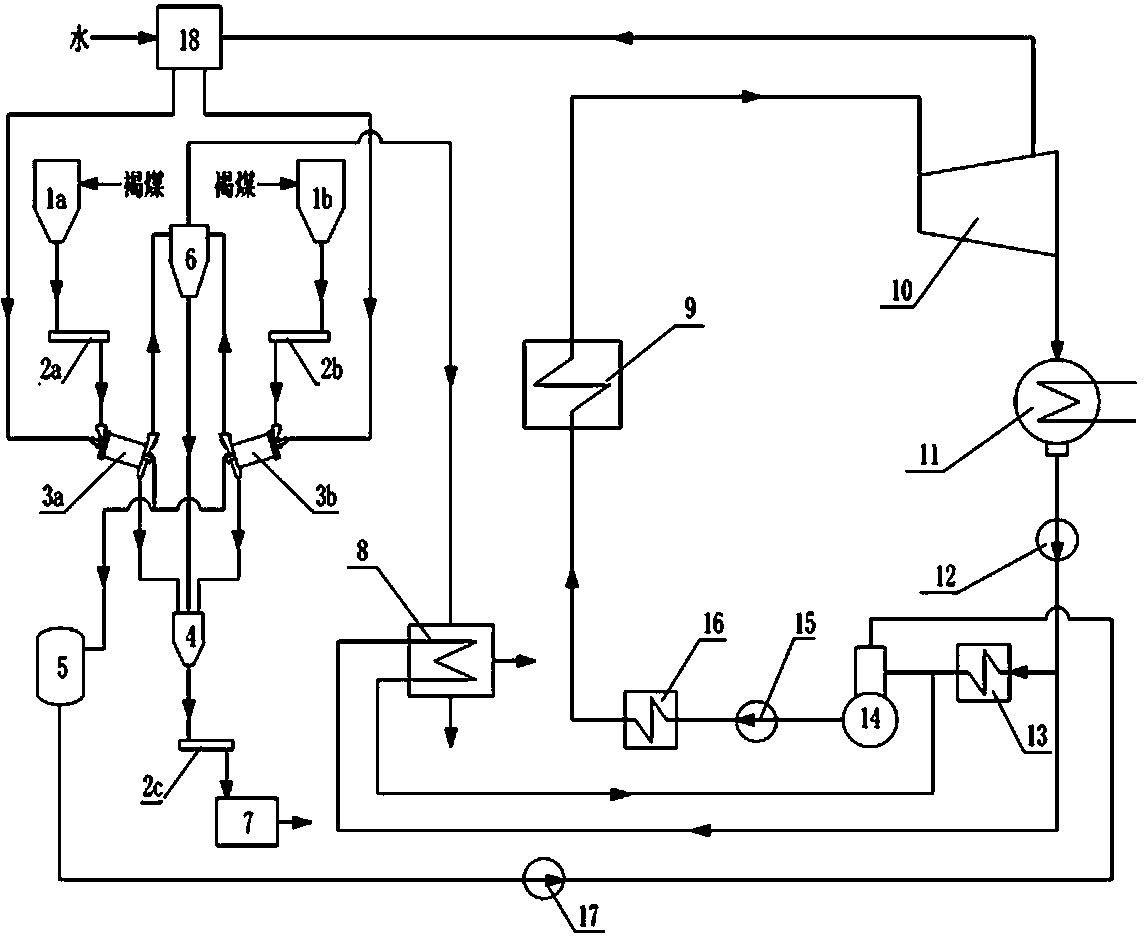

Brown coal drying power generating system capable of recycling water in coal and implementation method of brown coal drying power generating system

ActiveCN104179537AHigh thermal efficiencyReduce cold end heat lossSteam useHeating arrangementBrown coalBunker

The invention discloses a brown coal drying power generating system capable of recycling water in coal and an implementation method of the brown coal drying power generating system. The brown coal drying power generating system comprises a boiler, a steam turbine, a water feed pump, a condenser, a coal mil, a brown coal drying device, a device for recycling the water in the coal, a raw coal bunker, a low-pressure heater, a deaerator, a high-pressure heater, a condensate pump and a steam-water mixer. The brown coal drying device is connected with the device for recycling the water in the coal, the raw coal bunker, the low-pressure heater, the deaerator, the high-pressure heater, the condensate pump, the steam-water mixer, the boiler, the steam turbine, the water feed pump, the condenser and the coal mill. Operation of a large-capacity brown coal power generating set is achieved by integral design of the brown coal drying device and the boiler and combination of the device for recycling the water in the coal and the steam turbine.

Owner:BEIJING POWER EQUIP GRP

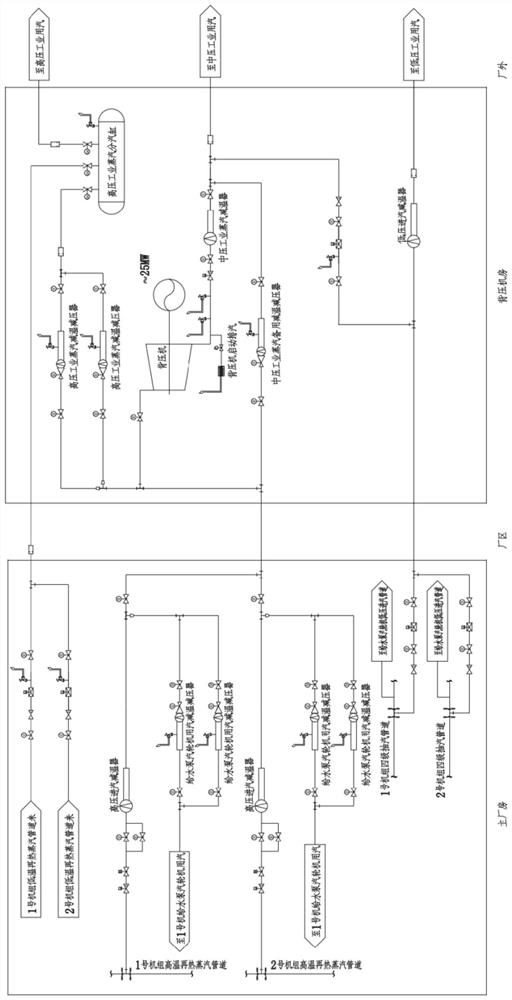

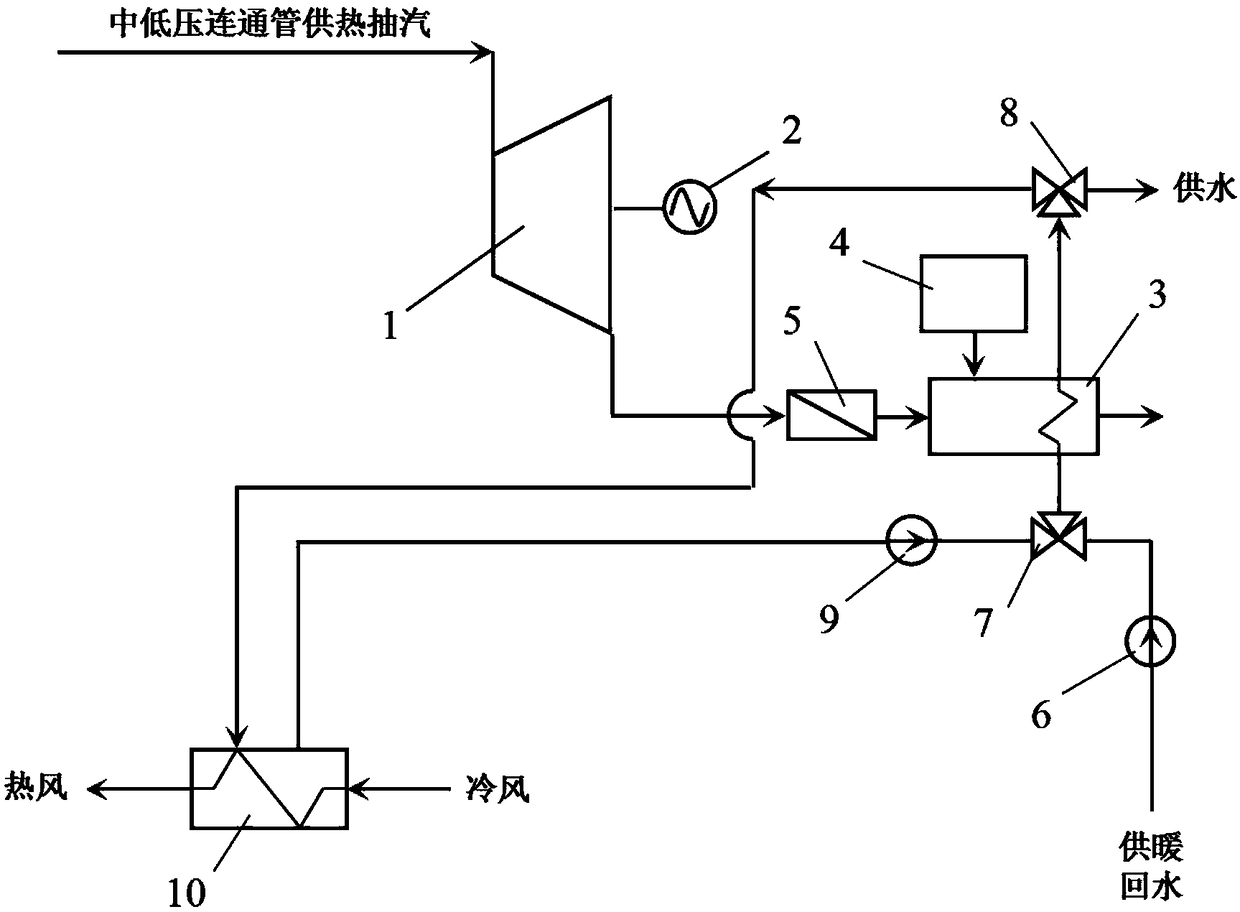

Steam energy cascade heat recovery utilization system for operation under full working conditions and working method

PendingCN108561201AIncrease operating hoursRealize full working condition operationCombustion processClimate change adaptationAbsorption heat pumpEngineering

The invention relates to a steam energy cascade heat recovery utilization system for operation under full working conditions and a working method. The system and the working method are mainly appliedto a heat supply unit. The system comprises a back pressure steam turbine, an absorption type heat pump and an air heater; a main steam turbine pumps air and supplies heat through a medium and low pressure communication pipe, and an air inlet of the back pressure turbine is connected to a heat-supplying and air-pumping pipe of the main steam turbine; heat supplying steam is used for driving the steam turbines to rotate, so that a power generator is driven to generate electricity, high-grade energy of the steam is recovered, and the generated electricity is incorporated into a plant power system; an exhausting drive absorption type heat pump of the back pressure turbine recovers low-grade waste heat. During a heating season, the absorption heat pump heats net water to supply heat to the outside; during a non-heating season, through switching of a three-way valve, the absorption type heat pump is used for heating air entering a boiler to achieve heat recovery. By adopting the system, operation of the back pressure steam turbine under the full working conditions and cascade use of the steam are achieved, coal consumption and a plant power consumption rate are decreased, and the economic performance of the unit is improved.

Owner:HUANENG CLEAN ENERGY RES INST

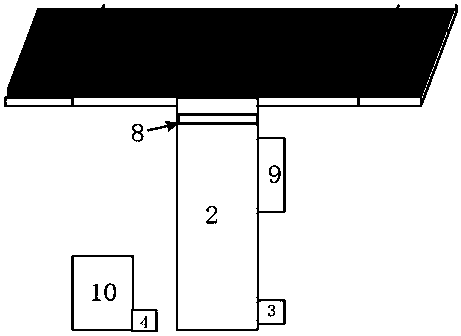

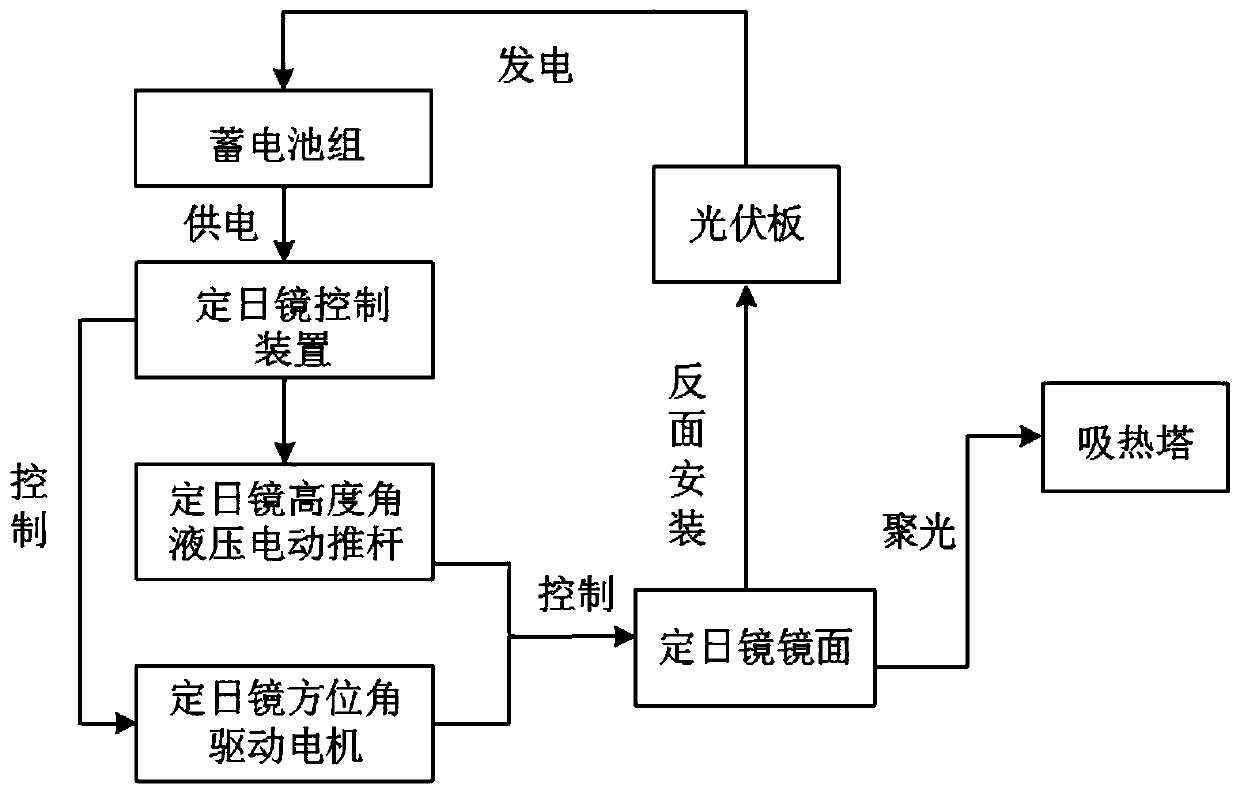

Heliostat and photovoltaic panel combined heliostat system for tower-type photothermal power generation

ActiveCN110609575AReduce plant power consumptionReduce power generation costsControl without using feedbackCharge and dischargeSunlight

The invention provides a heliostat and photovoltaic panel combined heliostat system for tower-type photothermal power generation. The system comprises a heliostat field provided with several rows of heliostats, a heliostat control subsystem for controlling an azimuth and a horizontal angle of the heliostat, and a photovoltaic power generation subsystem for providing power for the heliostat controlsubsystem; the heliostat comprises a heliostat mirror surface main body and a heliostat support column; the photovoltaic power generation subsystem comprises a photovoltaic panel, a storage battery pack and a charging and discharging controller; the photovoltaic panel is arranged at the back of the heliostat mirror surface main body; and the photovoltaic panel at the back of the heliostat mirrorsurface main body at a front row is used for receiving sunlight reflected by the front of the heliostat mirror surface main body at a rear row sheltered by the back of the heliostat mirror surface main body at the front row. The system provided by the invention can effectively reduce sheltering efficiency loss of the heliostat field, improve power generation efficiency of a photothermal power generation station and effectively reduce power generation cost.

Owner:浙江中光新能源科技有限公司

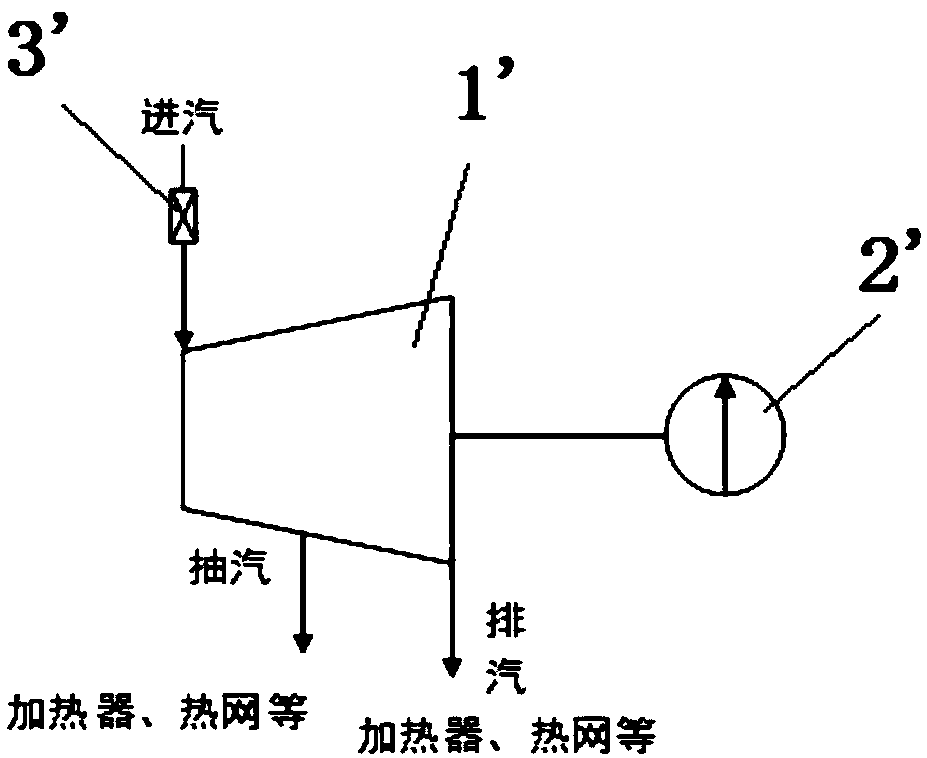

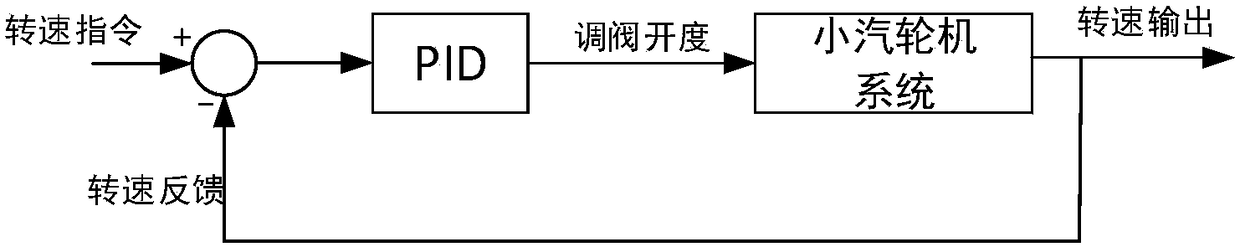

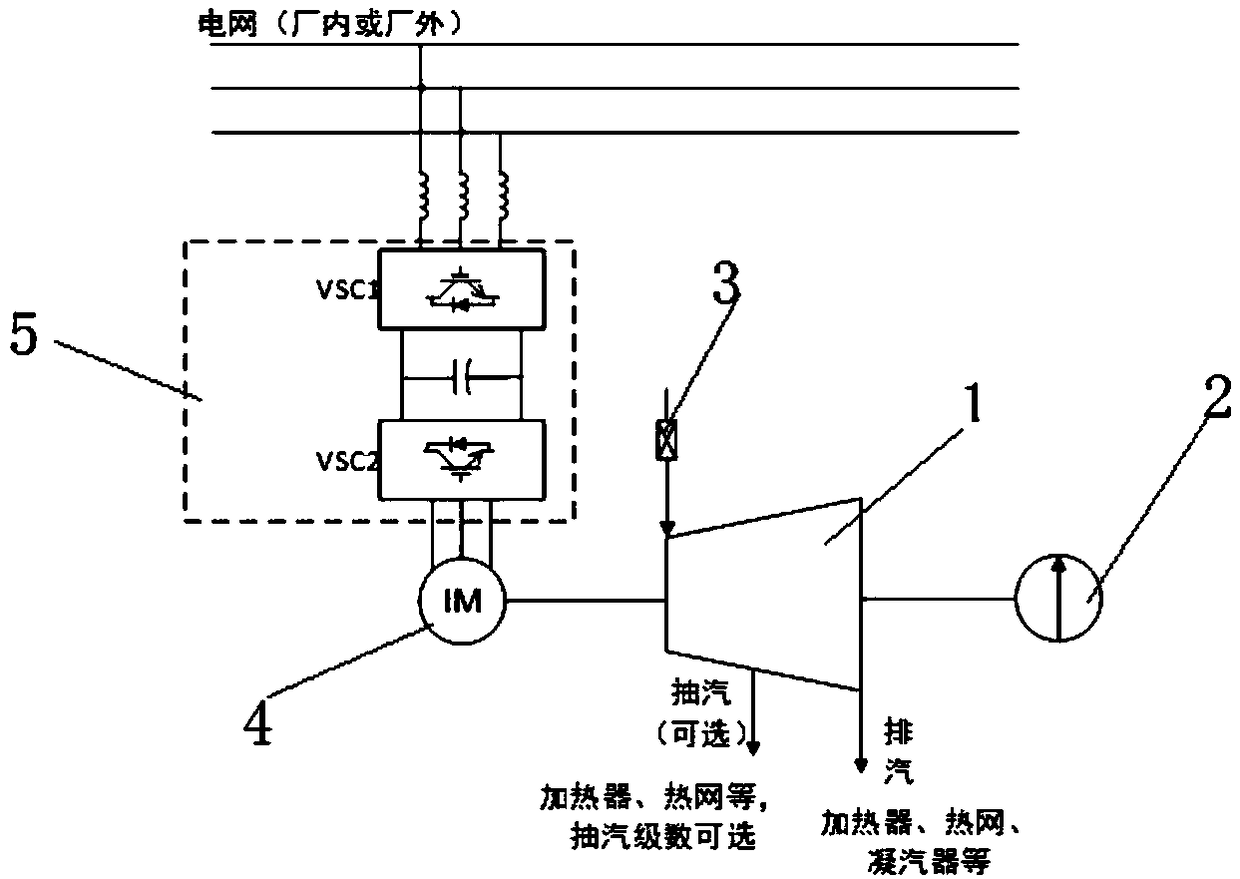

Small turbine control system and method based on asynchronous motor full power converter speed regulation

PendingCN108397242AReduce throttling lossGuaranteed work efficiencyMachines/enginesSafety/regulatory devicesHeat regenerationPower grid

The invention relates to a small turbine control system based on asynchronous motor full power converter speed regulation and a control method of the small turbine control system. The small turbine control system comprises a full power converter, an asynchronous generator, a small turbine and a controller. The asynchronous generator and the small turbine are connected so as to match rotation speedparameters; the asynchronous generator and the full power converter are connected to conduct voltage and current level matching; and the full power converter and a power grid are connected to conductvoltage level matching, the asynchronous generator conducts rotation speed control through the full power converter and generates power on a grid through the surplus small turbine power, and the controller controls rotation speed control of the asynchronous generator through control over the full power converter. The small turbine control system based on asynchronous motor full power converter speed regulation and the control method of the small turbine control system have the beneficial effects that according to the technical scheme that the heat regeneration small turbine is provided with the generator, the heat efficiency of a heat regeneration system can be greatly improved, and unit losses are reduced. The electric quantity generated by the generator can be used for reducing the auxiliary power ratio, and the electricity selling incomings are increased.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

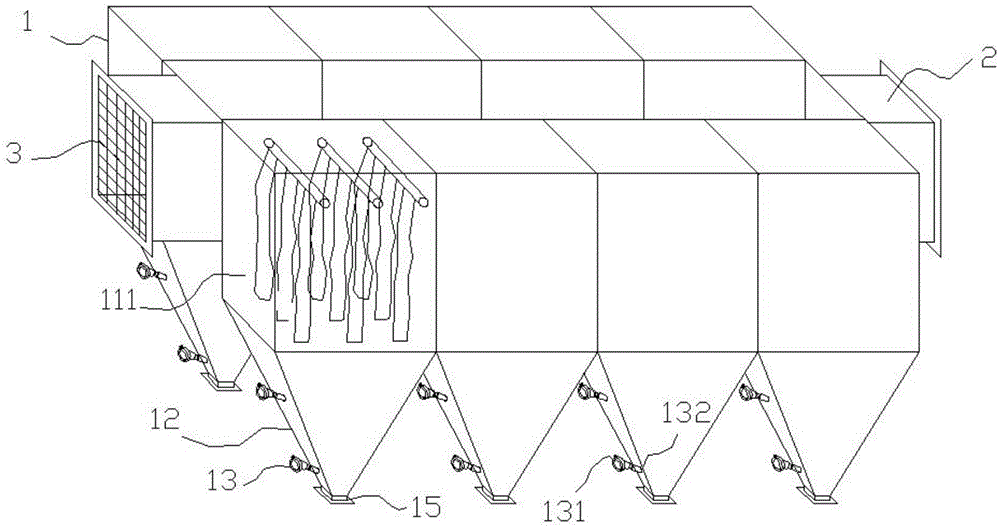

Dust removal environment-friendly purification device

InactiveCN105032056ASimple structureReal-time monitoring of backlog levelsDispersed particle filtrationDisplay deviceEngineering

The invention discloses a dust removal environment-friendly purification device which comprises a plurality of dust removal cavities. The dust removal cavities are communicated in sequence. Each dust removal cavity is provided with an air inlet and an air outlet. The air inlet and the air outlet are each provided with a filter net. Each dust removal cavity comprises a hollow dust removal device body and a hollow dust removal hopper, wherein the dust removal device body is fixedly connected to the dust removal hopper, and a sensing device is installed on the dust removal hopper. Each sensing device comprises a temperature sensor and a display device, wherein the temperature sensor is inserted into the corresponding dust removal hopper, one end of the temperature sensor is arranged in the dust removal hopper, and the other end of the temperature sensor is connected with the display device. A plurality of dust removal cloth bags are arranged inside each dust removal device body and suspended inside the corresponding dust removal device body. The dust removal environment-friendly purification device is simple in structure.

Owner:启东寅昶精密铸造有限公司

Electric energy converting-switching system and method and application thereof

PendingCN106849089AIncrease output powerReduce plant power consumptionSingle network parallel feeding arrangementsSingle ac network with different frequenciesAutomotive engineeringElectric energy

The invention discloses an electric energy converting-switching system and method applied to a thermal power plant. The frequency and / or voltage of at least one connection end can be adjusted through an electric energy transducer, and electric energy is controlled to flow among plant buses of different frequencies, or the electric energy can be controlled at different frequencies and can be controlled to flow among the plant buses of different frequencies, so that the throttling loss is reduced and even eliminated, the performance of a variable-frequency generating set is brought into full play, and the overall system efficiency is increased, thereby lowering the energy consumption and creating a greater economic benefit; meanwhile, a method of starting and switching through a motor of an auxiliary machine for a plant is improved, so that the flexibility of the overall running manner of the system is improved.

Owner:上海申能电力科技有限公司

Matching method of supercritical secondary reheating unit reheater and thermal system

The invention belongs to the field of large supercritical secondary reheating thermal power generating units, and relates to a method capable making a heat exchange area needed by secondary reheating and a thermal system matched, in particular to a matching method of a supercritical secondary reheating unit reheater and the thermal system. According to the scheme, the heated face needed by the reheater is reduced, reasonable match between the reheater and the thermal system is achieved, exhausted steam of a water pump turbine is absorbed through a hybrid heater, the heat exchange area is reduced, and initial investment of a power plant is reduced. Heat for pumping steam of the water pump turbine can be finally recycled to the thermal system, and economical performance of the power plant is improved. Therefore, according to the scheme, the method is favorable for reducing the initial investment of the power plant and improving operating benefits of the power plant.

Owner:GUODIAN SCI & TECH RES INST +1

Turbine cooling and natural gas heating integrated gas turbine system

ActiveCN114687805AAvoid wastingLow costBlade accessoriesSafety/regulatory devicesTemperature controlSteam drum

The embodiment of the invention provides a turbine cooling and natural gas heating integrated gas turbine system which comprises a gas turbine system, a turbine cooling and natural gas heating integrated system and a natural gas heat value adjusting system. The other end is communicated with the water inlet end of the TCA system; the TCA system is used for cooling air exhaust of a gas compressor of the gas turbine 2; the water outlet end of the TCA system is communicated with the water inlet end of the FGH system; one end of the low-pressure return water conveying pipeline is connected to the water outlet end of the FGH system, and the other end is communicated with the low-pressure steam pocket; the gas inlet end of the automatic three-way temperature control valve is communicated with a natural gas supply pipeline, and two gas outlet ends are respectively connected with a first conveying pipeline and a second conveying pipeline; the first conveying pipeline is communicated with the air inlet end of the FGH system; the gas outlet end of the FGH system is connected with a third conveying pipeline; and the second conveying pipeline and the third conveying pipeline are converged and then are communicated with a natural gas inlet pipeline.

Owner:HUANENG BEIJING CO GENERATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com