Patents

Literature

109results about How to "Not easy to explode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

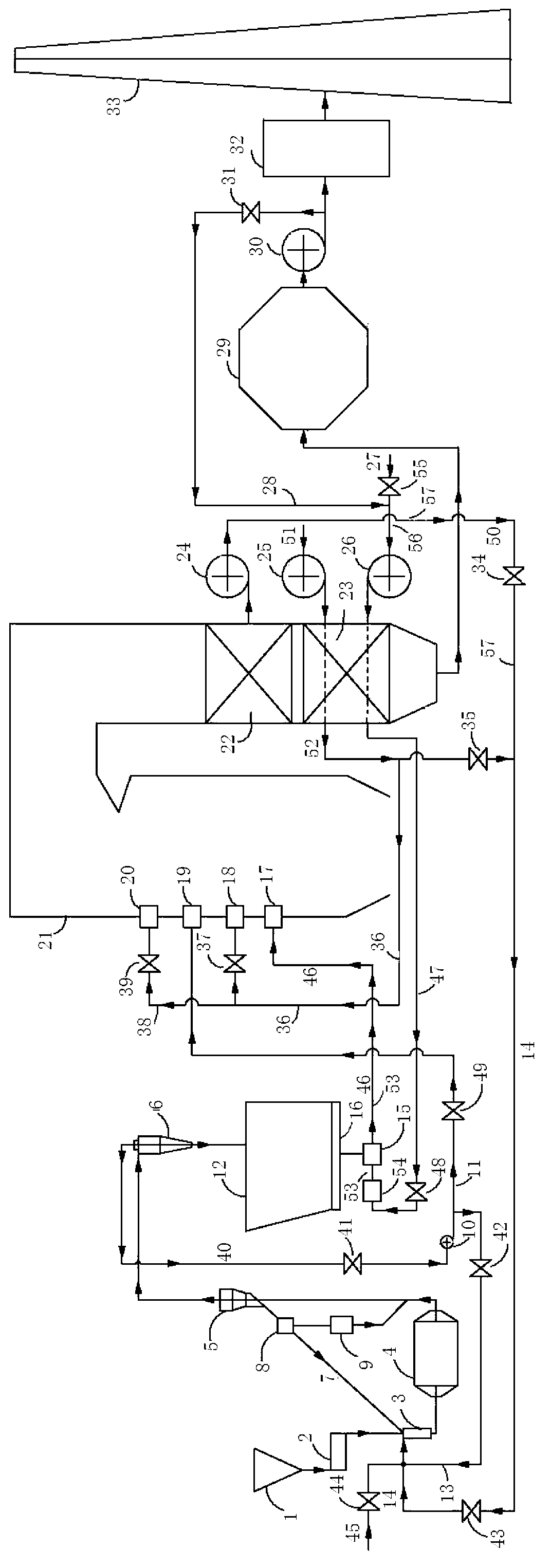

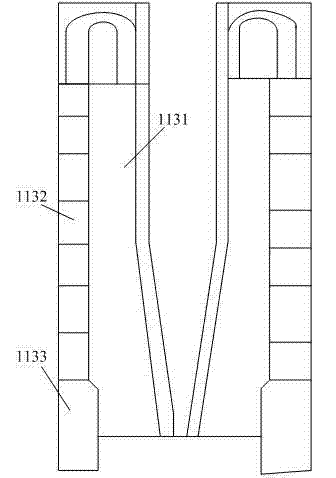

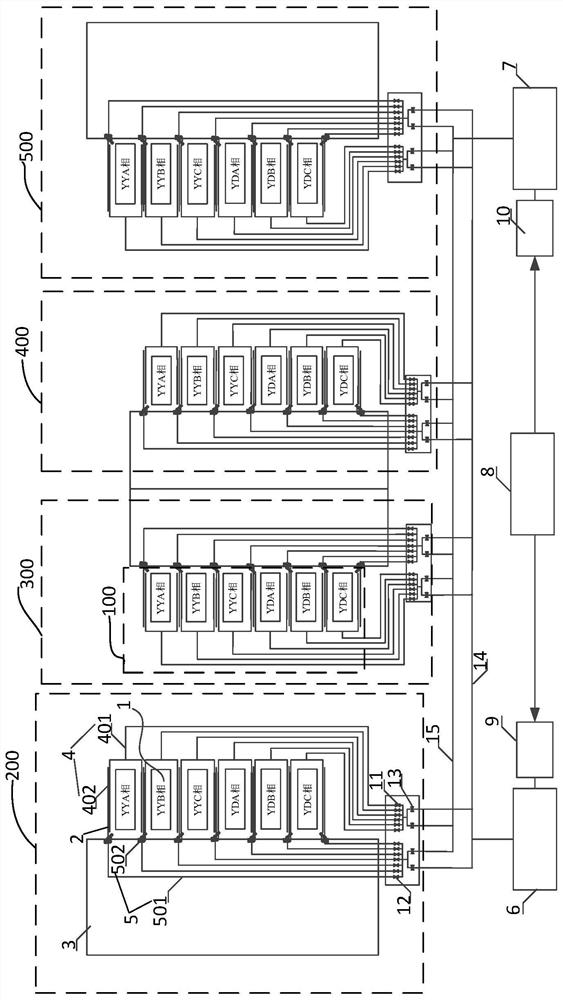

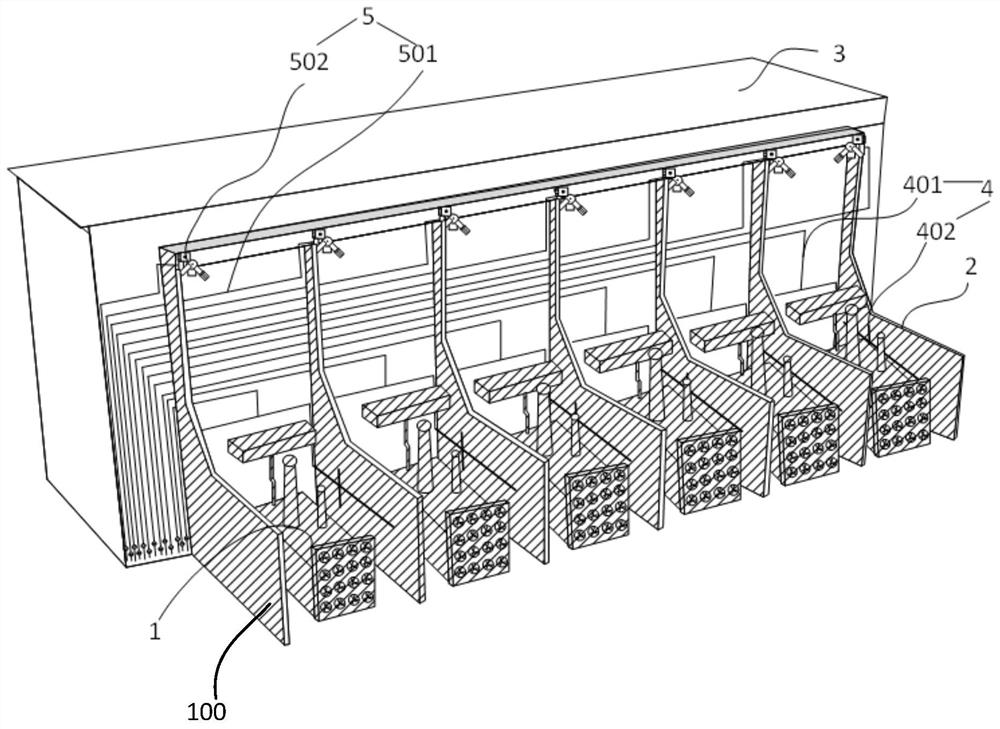

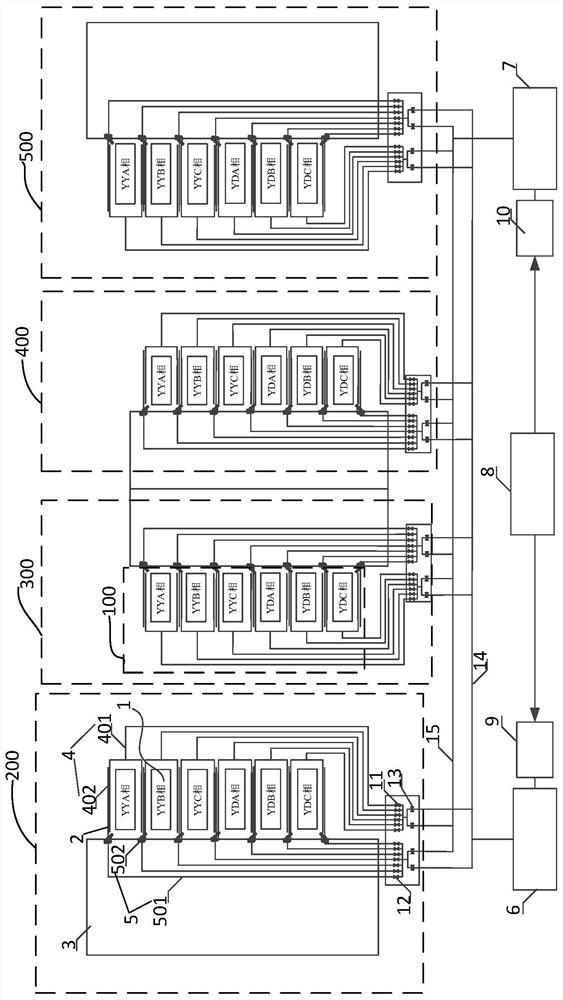

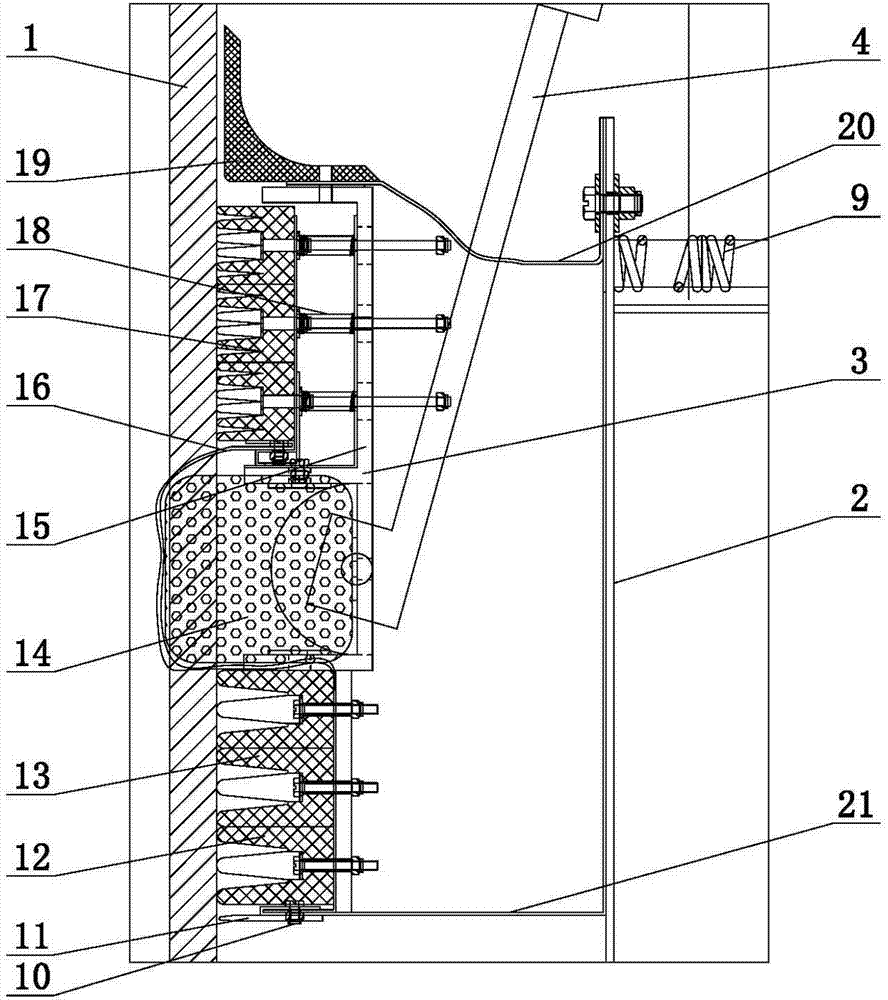

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

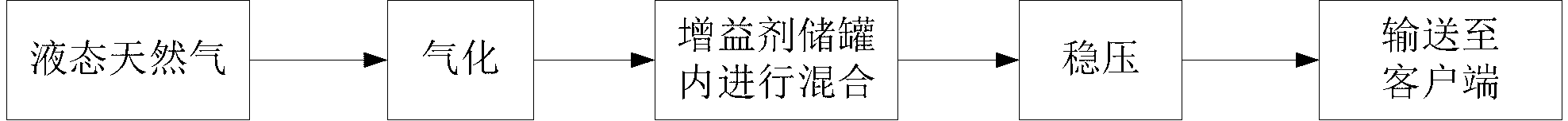

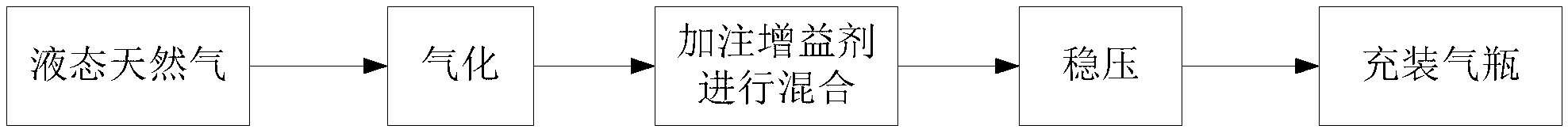

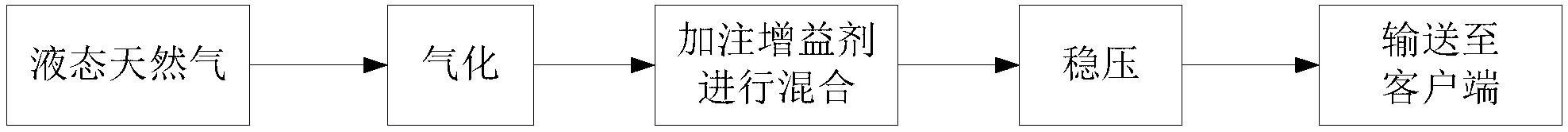

Welding and cutting gas and preparation method thereof

InactiveCN103320190AEasy to prepareNo pollution in the processGaseous fuelsNonaneRare earth metal compounds

The invention discloses a welding and cutting gas which consists of a natural gas and a gain agent, wherein the gain agent consists of a rare earth metal compound, a transition metallocene compound, methanol, toluene, methyl tertiary butyl ether, cyclohexane, nonane, decane and water. Compared with acetylene and propane, the welding and cutting gas is more economical, more energy-saving, more environment-friendly, safer and cleaner. The invention also provides a preparation method of the welding and cutting gas.

Owner:CANGXI COUNTY CHASE GAS INVESTMENT

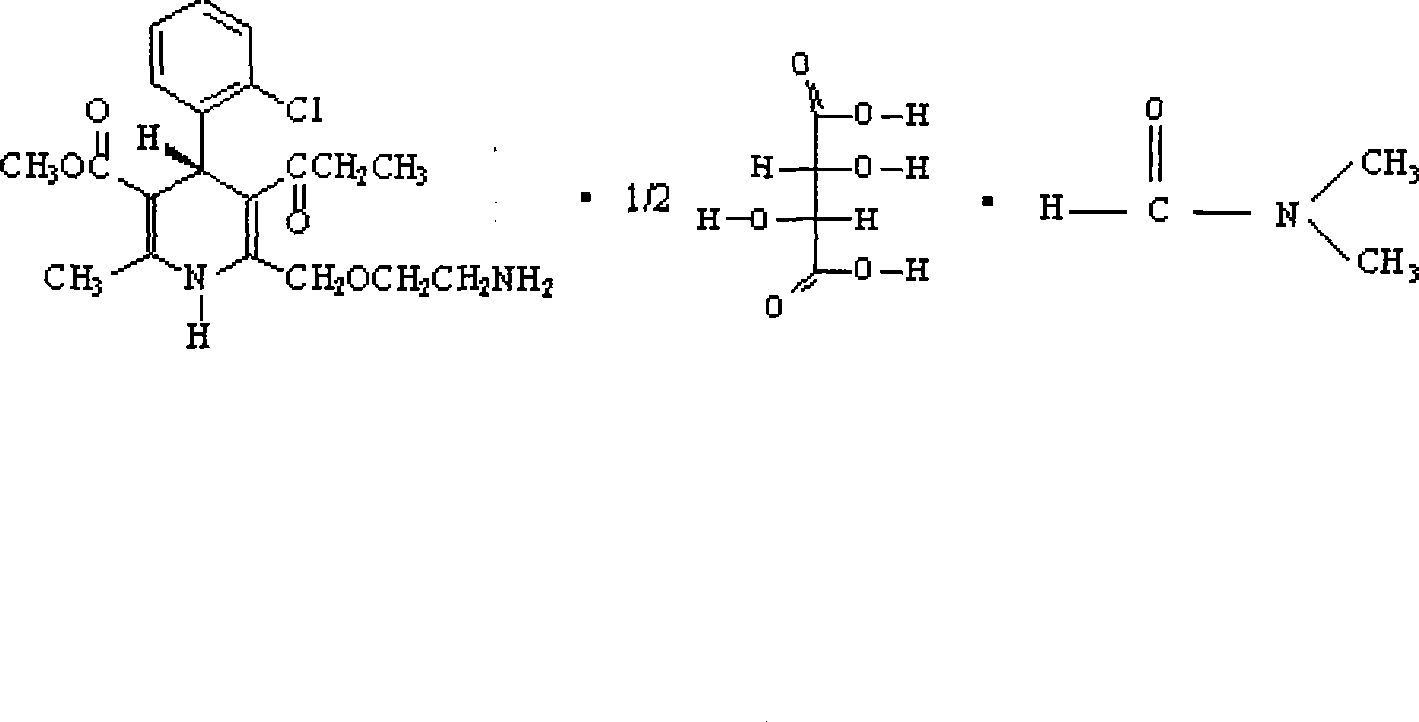

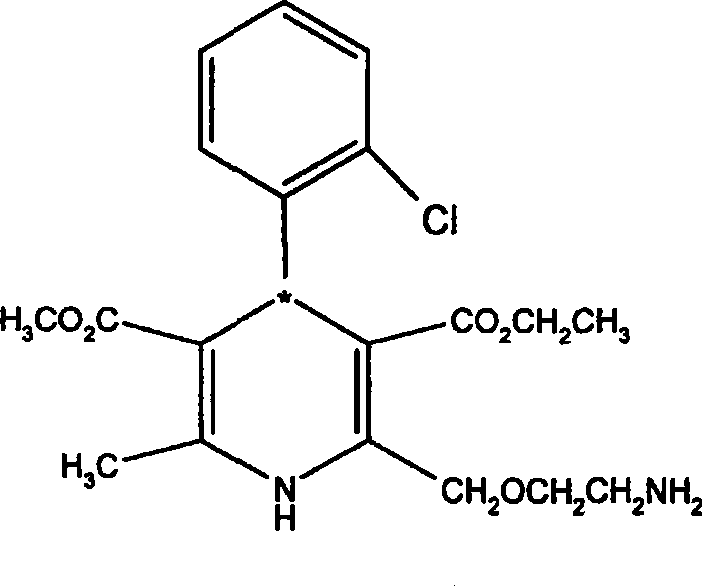

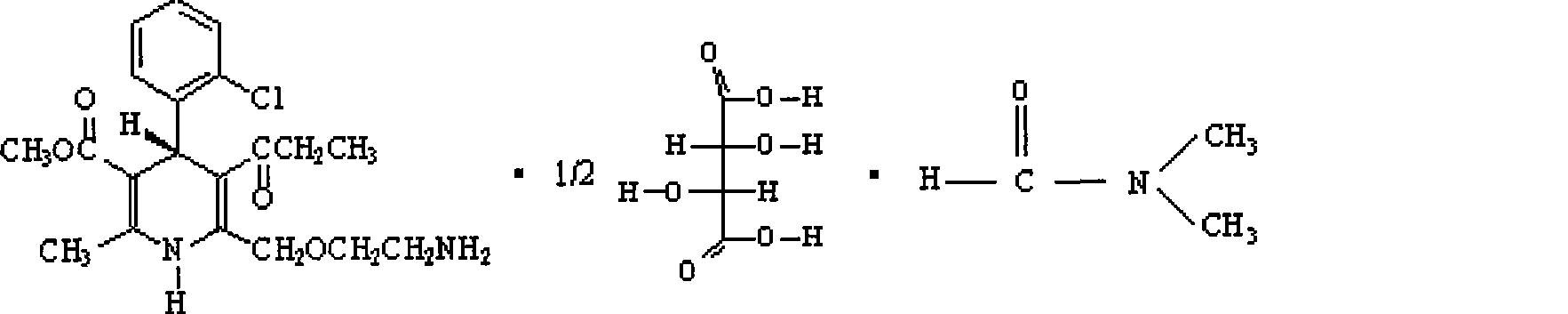

Method for preparing amlodipine

ActiveCN101544597AEasy to recycleEasy to polluteOrganic active ingredientsOptically-active compound separationN dimethylformamideSolvent

The present invention relates to a method for preparing a novel S-(-)-amlodipine, and especially to a novel method for preparing S-(-)-amlodipine through the resolution of racemic amlodipine. The N,N-dimethylformamide (DMF) is used as a dissolvent. The L-(+)-tartaric acid is used as a resolving agent. Not only can the excellent resolving effect be obtained, but also the cost is low and safety is excellent.

Owner:北京天衡药物研究院有限公司

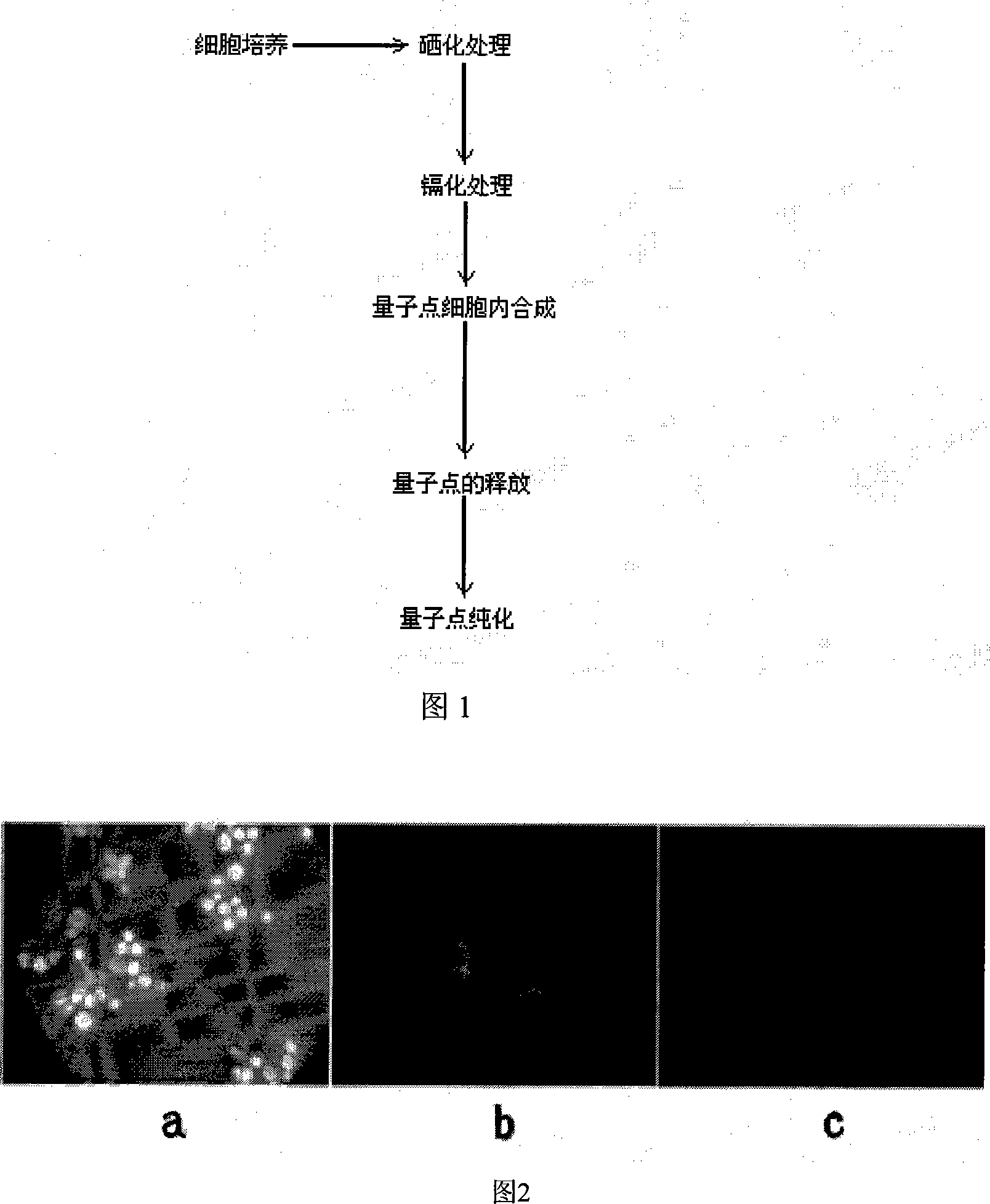

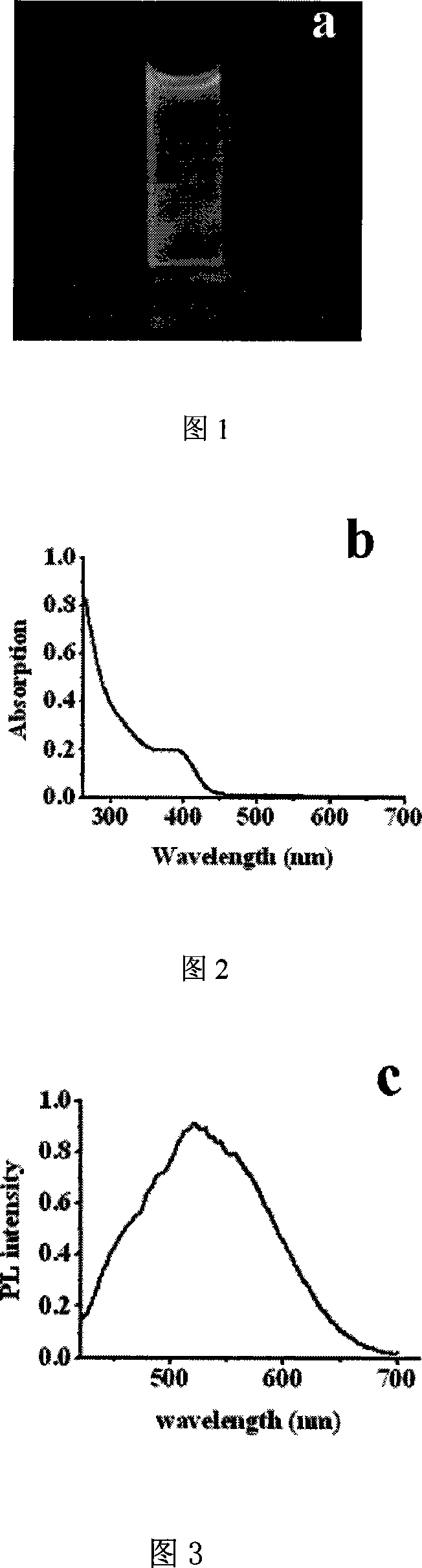

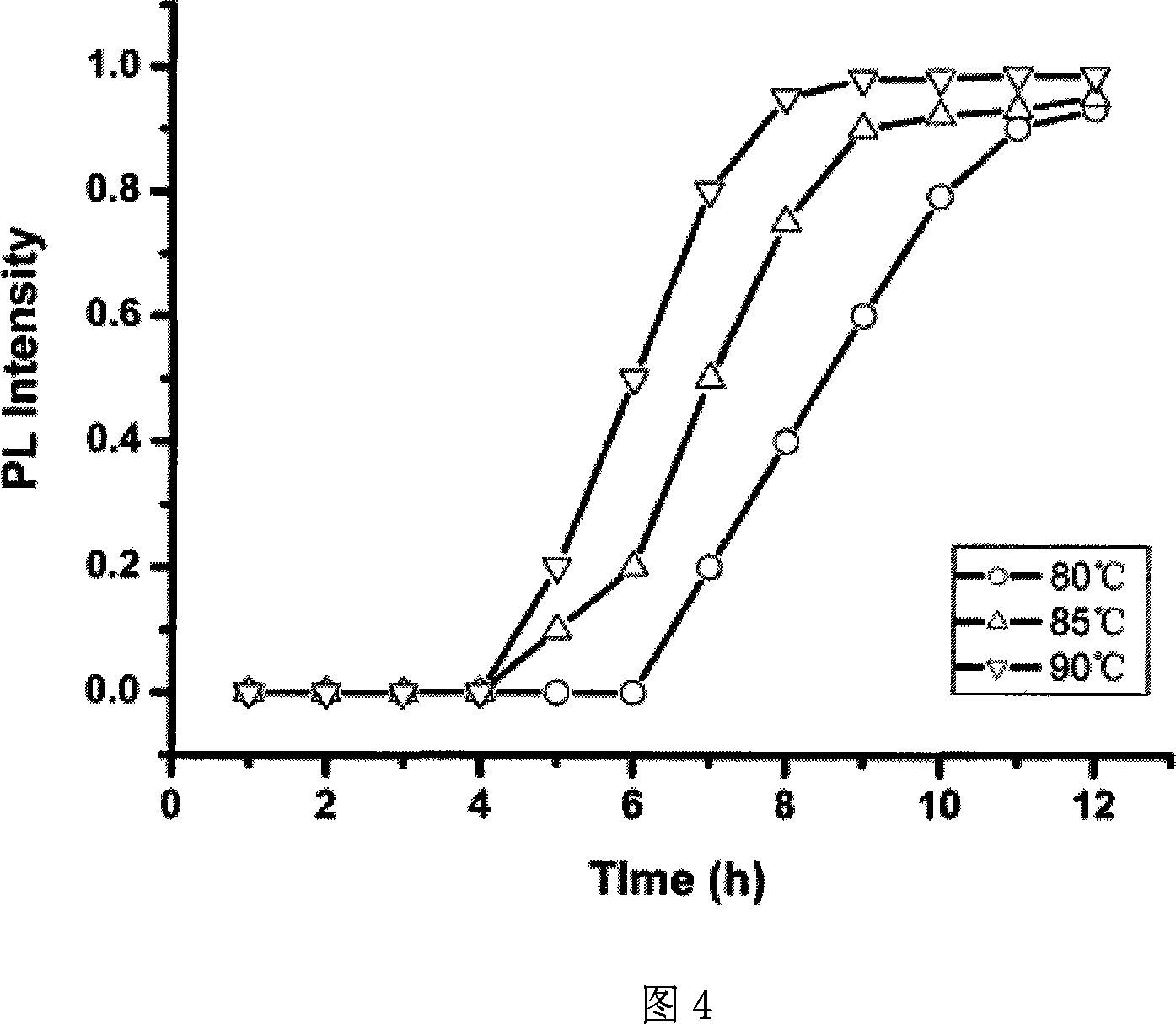

Method for preparing cadmium selenide quantum dots by using microbial cells

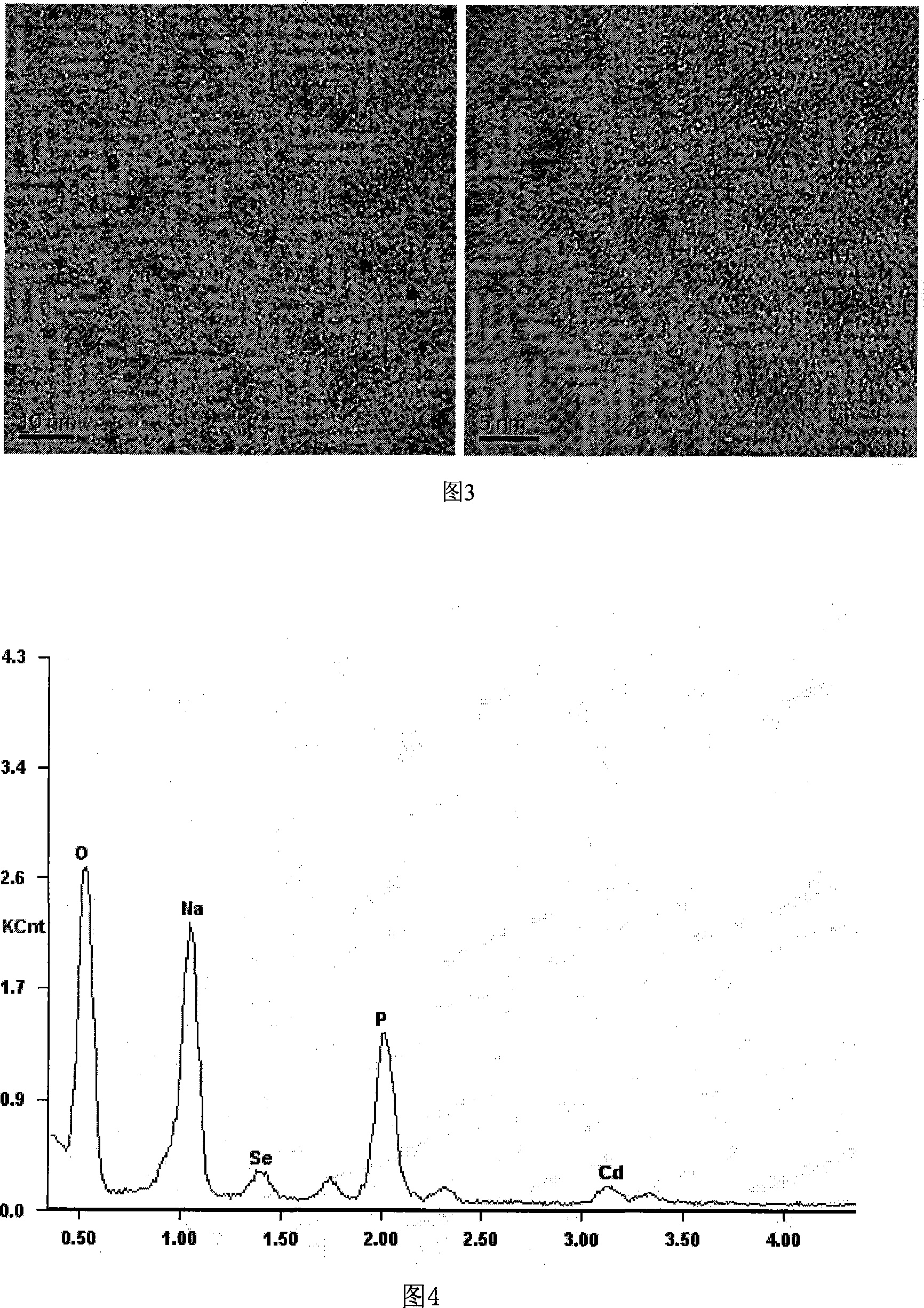

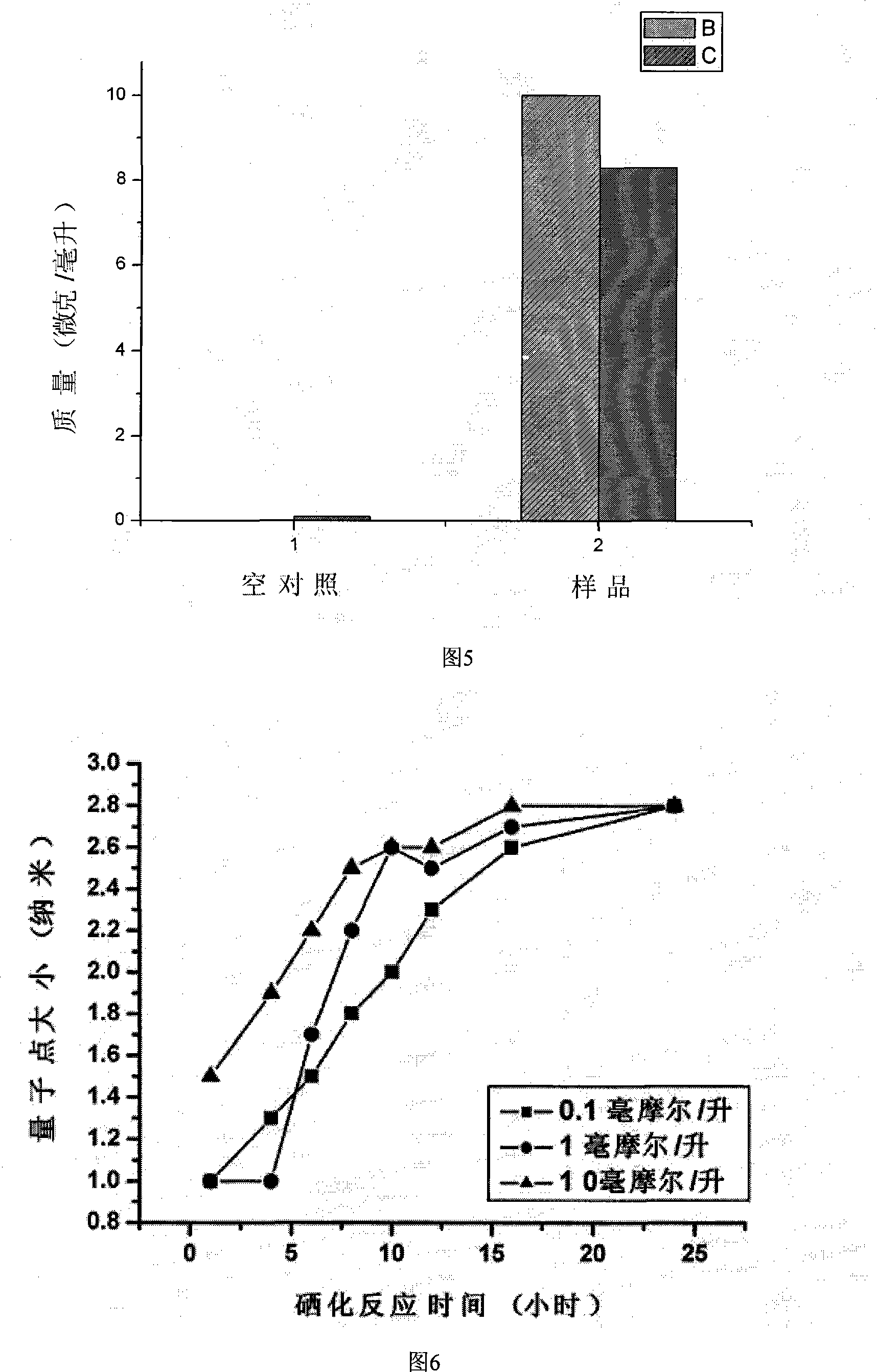

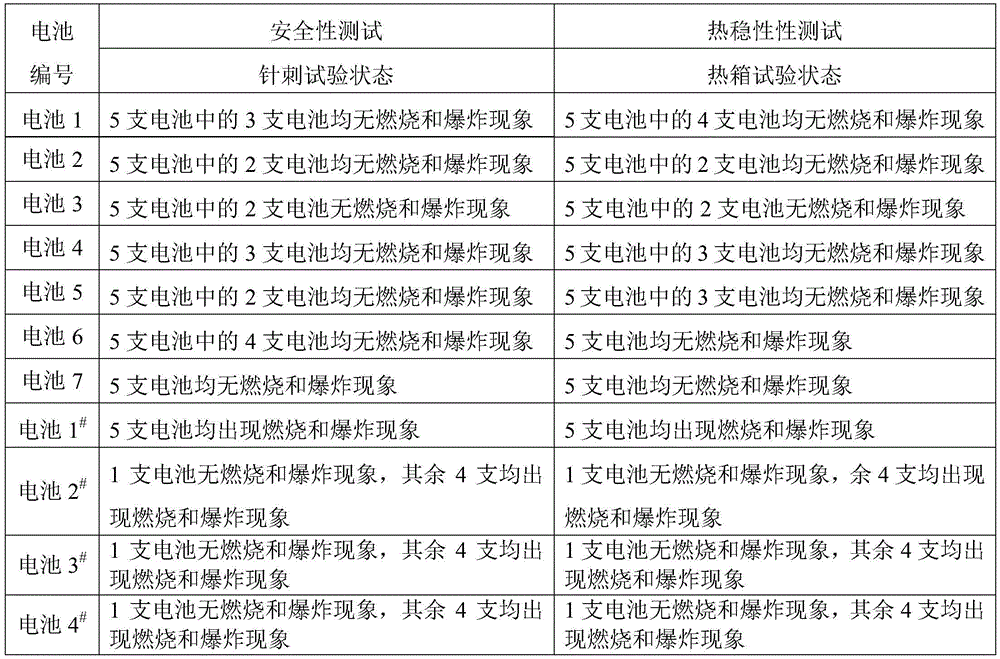

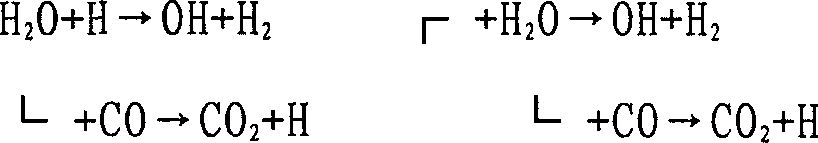

InactiveCN101096687AEasy to separateImprove uniformityBacteriaFermentationMicrobial fuel cellCadmium selenide

The invention discloses a synthesizing method of cadmium selenide quantum point through microbe cell, which comprises the following steps: A. A. preparing microbe cell; B. selenidizing the microbe cell; C. cadmating the cell to culture continuously; D. extracting CdSe quantum point from cell; E. purifying the CdSe quantum point. The invention simplifies the operation without organic metal compound and inert gas to protect, which is beneficial to do industrialization synthesis of nanometer particle (quantum point).

Owner:WUHAN UNIV

Method for preparing Bi2S3 quantum dot sensitized TiO2 membrane electrodes

InactiveCN101515506ANon-toxicNot easy to explodeLight-sensitive devicesSolid-state devicesState of artPorous membrane

A method for preparing Bi2S3 quantum dot sensitized TiO2 membrane electrodes relates to a method for preparing quantum dot sensitized TiO2 membrane electrodes The invention solves the problem that the H2S gas which is adopted during the process for preparing the Bi2S3 quantum dot sensitized TiO2 membrane electrodes is explosive and harmful to human bodies in the prior art. The method comprises the following steps: preparing a porous TiO2 membrane electrode; soaking the porous membrane electrode into the ethanol solution of ethyl thioglycollic acid; and alternately soaking the porous membrane electrode in Bi(NO3)3 solution and Na2S solution to obtain the TiO2 membrane electrodes. The TiO2 membrane electrodes prepared by the method of the invention has the advantages that the Bi2S3 quantum dots compounded on the surface thereof are numerous and evenly distributed, and the photoelectric conversion efficiency is as high as 1.10% to 1.22%; the preparation process of the method dispenses with the H2S gas, the method is not harmful to human bodies or not easy to explode, thereby ensuring the environment friendliness; furthermore, the method of the invention is easy to operate.

Owner:HARBIN INST OF TECH

Electrode with coating and lithium ion battery with electrode

ActiveCN105529433AImprove thermal stabilityImprove securityElectrolytesNon-aqueous electrolyte accumulator electrodesInorganic particleBoron containing

The invention relates to an electrode with a coating and a lithium ion battery with the electrode. The electrode comprises a first material layer close to the electrode, and a second material layer close to the first material layer and away from one side of the electrode, the first material layer comprises first inorganic particles and a first binder, the second material layer comprises a second binder, and the first inorganic particles are chosen from at least one of metal hydroxide and a boron-containing compound. The electrode comprises the first material layer and the second material layer, thermostability and safety of the battery can be improved through synergistic action of the first material layer and the second material layer, for example, when the inside and the outside of the battery are at high temperature, the battery is less prone to burning and exploding.

Owner:CONTEMPORARY AMPEREX TECH CO

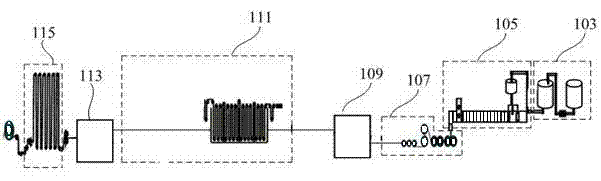

Environmental protective diesel oil, and preparation method

This invention relates to environmentally friendly diesel oil, which is composed of: diesel oil 13-20 parts, water 15-30 parts, plant oil 20-25 parts, methanol 8-11 parts, kerosene 10-30 parts, and composite additive 5-8 parts. The composite additive is composed of: triton X-100 2.0-2.65 parts, ethanolamine 1.5-3 parts, NaOH 14-16 parts, 99.5% ammonia solution 50-55 parts, n-butylamine 5.0-6..0 parts, isopropane 18-21 parts, water 2.0-2.3 parts, and cetane 0.2-1.0 parts. The environmentally friendly diesel oil is prepared in a raw material tank, an aid tank, a product tank, a sealing device, a high-energy static magnetic device and pipelines. This invention solves the problems of low stability, easy separation of oil and water, large amount of emulsifier, high price and difficult transportation faced by present W / O emulsified diesel oil, and has such advantages as abundant raw materials and wide applications.

Owner:陈志红

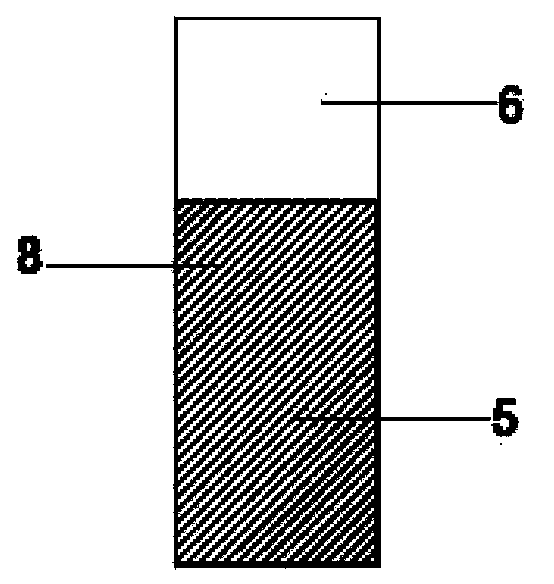

Preparation method of polyethylene microporous membrane and system thereof

InactiveCN102731883AImprove high temperature resistanceLow shrinkageCell component detailsMicrometerTemperature resistance

The invention brings forward a preparation method of a polyethylene microporous membrane and a system thereof. The preparation system of the polyethylene microporous membrane comprises a stirring device, an extrusion device, a cooling molding device, a bidirectional stretching device, an extraction device, a breadthwise stretching and a heat treatment device, wherein the stirring device, the extrusion device, the cooling molding device, the bidirectional stretching device, the extraction device, the breadthwise stretching device and the heat treatment device are connected in order. The preparation method provided by the invention can be adopted to produce an ultrathin polyethylene microporous membrane of 6 micrometers thickness and has advantages of high temperature resistance, corrosion resistance, good stability and long service life.

Owner:SHANGHAI QIANCHENG TOY TECH

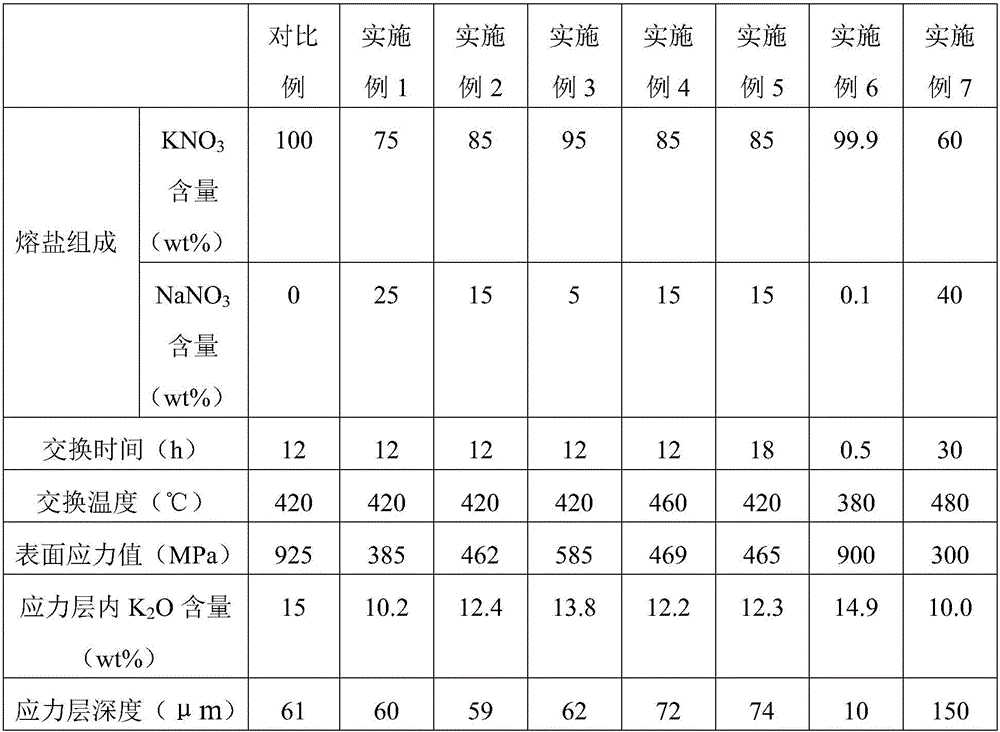

Chemical enhancement method of high-alkalinity aluminum silicate glass with controllable surface stress

The invention relates to a chemical enhancement method of high-alkalinity aluminum silicate glass with controllable surface stress. The method comprises steps of 1) mixing potassium nitrate and sodium nitrate, melting, and clarifying to obtain molten salt; 2) preheating a high-alkalinity aluminum silicate glass sample, immersing in the molten salt, carrying out high-temperature molten salt ion exchange, removing and cooling, and washing and drying to obtain chemically enhanced high-alkalinity aluminum silicate glass. The chemical enhancement method of controllable surface stress high-alkalinity aluminum silicate glass according to the invention is simple to perform, is free of noise and environmental pollution and is suitable for industrial batch production; surface stress can be controlled by adjusting the composition of molten salt, surface stress depth can be controlled by adjusting ion exchange temperature and time, and the high-alkalinity aluminum silicate glass is imparted a deep stress layer under relatively low surface stress, has decreased inner tensile stress, is rarely self-destructed, and has improved scratch resistance and toughness.

Owner:BEIJING HANGBO NEW MATERIAL TECH

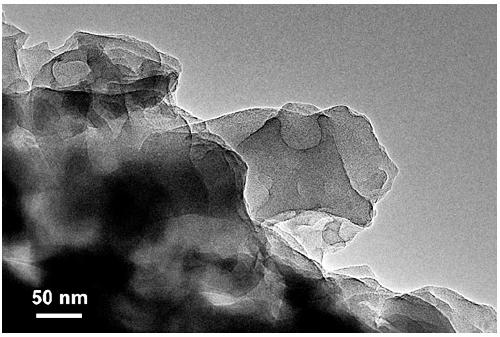

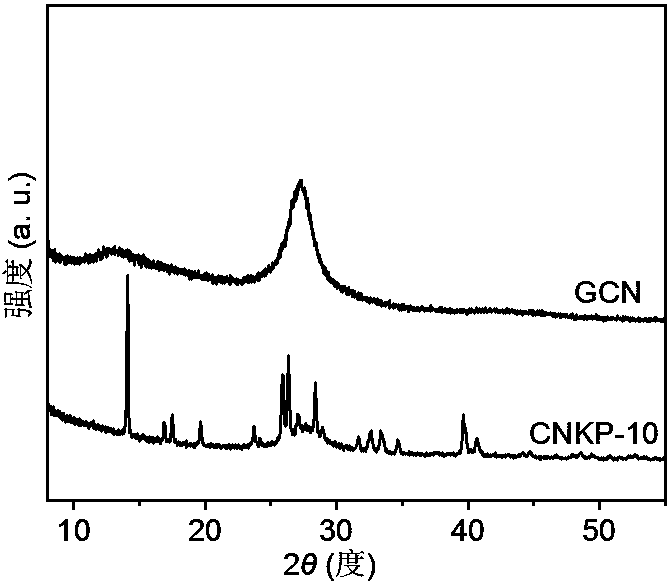

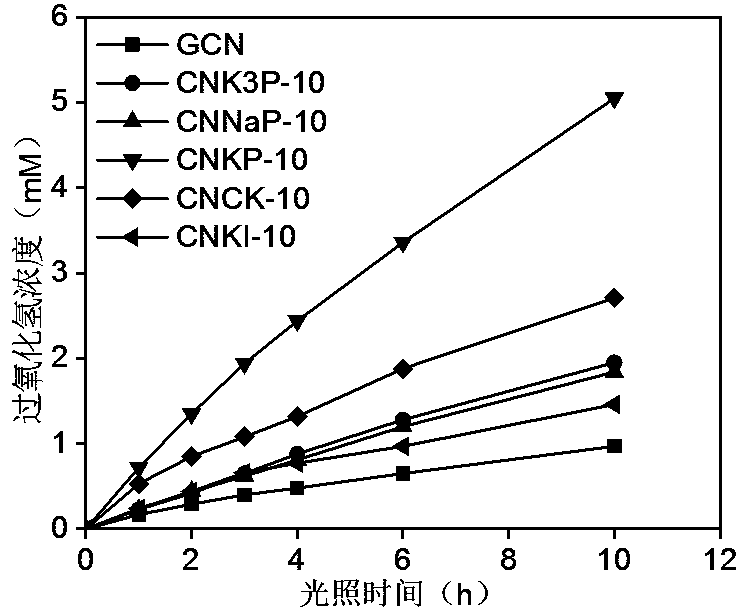

Catalyst for synthesis of hydrogen peroxide by catalyzing oxygen reduction under visible light and preparation method thereof

InactiveCN109012728ANot easy to explodeReduce transportation safety risksHydrogen peroxidePhysical/chemical process catalystsPotassiumOxygen

The invention belongs to the technical field of catalysts, and in particular relates to a catalyst for synthesis of hydrogen peroxide by catalyzing oxygen reduction under visible light and a preparation method thereof. The catalyst of the invention is a phosphorus- and potassium-doped graphite-phase carbon nitride catalyst. A graphite-phase carbon nitride material is derived from thermal polymerization of urea, and phosphorus and potassium elements are introduced in situ during the thermal polymerization of urea to be doped in the skeleton structure of graphite-phase carbon nitride. By using the doped components to promote graphite-phase carbon nitride, synthesis of hydrogen peroxide by catalyzing oxygen reduction in the liquid system under visible light, at normal temperature and at ordinary pressure is realized. In comparison with the existing graphite-phase carbon nitride catalyst prepared by phosphorus and potassium co-modified melamine thermopolymerization, the graphite-phase carbon nitride catalyst prepared by phosphorus and potassium co-modified urea thermopolymerization shows a higher catalytic activity in the photocatalytic oxygen reduction reaction under visible light forsynthesis of hydrogen peroxide.

Owner:FUDAN UNIV

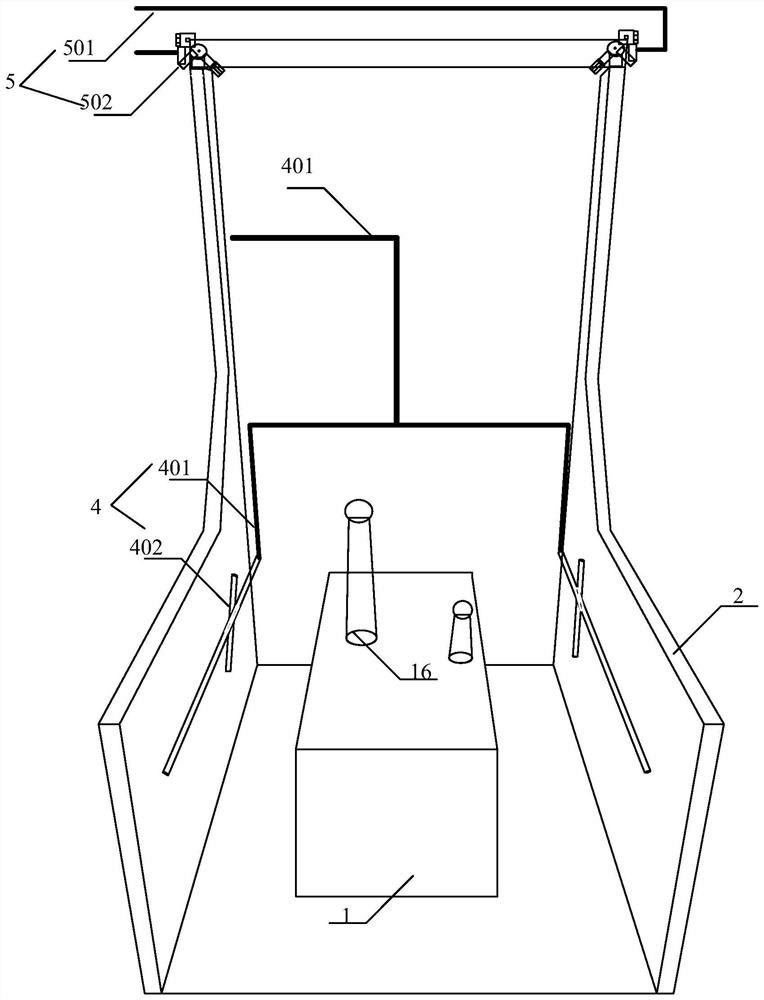

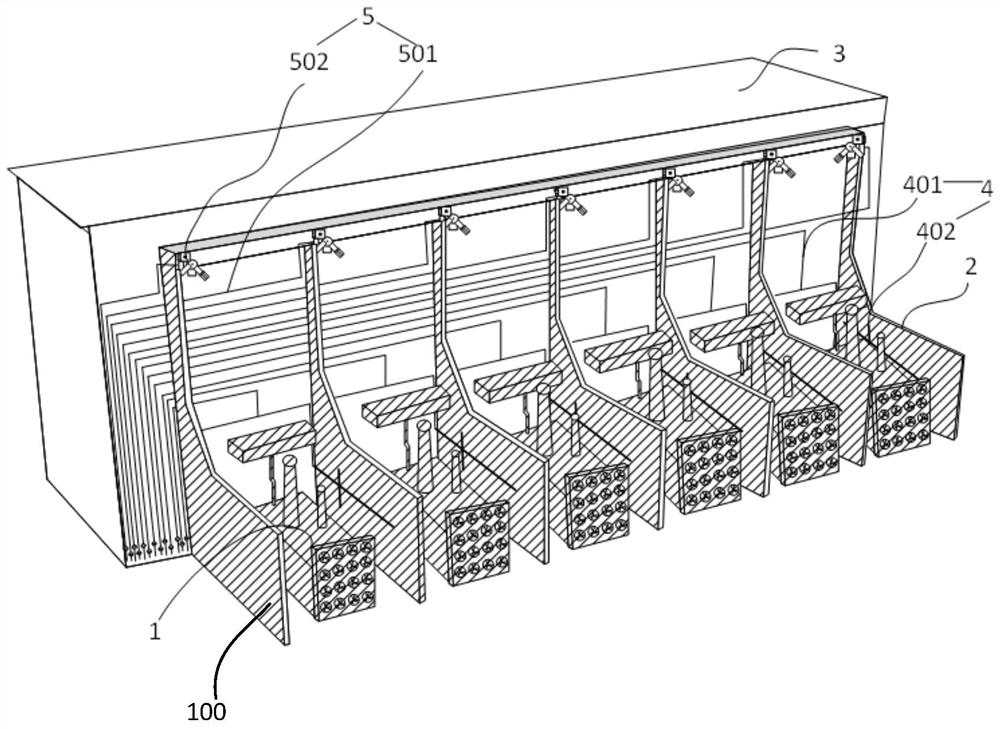

Fire extinguishing system and method suitable for ultrahigh voltage converter station and ultrahigh voltage converter station

The invention discloses a fire extinguishing system and method suitable for an ultrahigh voltage converter station and the ultrahigh voltage converter station. The fire extinguishing system comprisesa spray fire extinguishing system and a fire monitor fire extinguishing system, the spray fire extinguishing system comprises first fire pipelines and spray pipes, and the fire monitor fire extinguishing system comprises second fire pipelines and fire monitors. One fire monitor is arranged over each of fire walls on two sides of each converter transformer in the ultrahigh voltage converter station, each fire monitor communicates with one second fire pipeline, one spray pipe is arranged on each of the fire walls on two sides of each converter transformer, each spray pipe communicates with one first fire pipeline, and the fire monitors and outlets of the first fire pipeline spray pipes at the position of each converter transformer right face the converter transformer. The fire extinguishingsystem and method have the advantages of overcoming the shortcomings and defects of an existing fire extinguishing system design and realizing efficient and reliable fire fighting.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

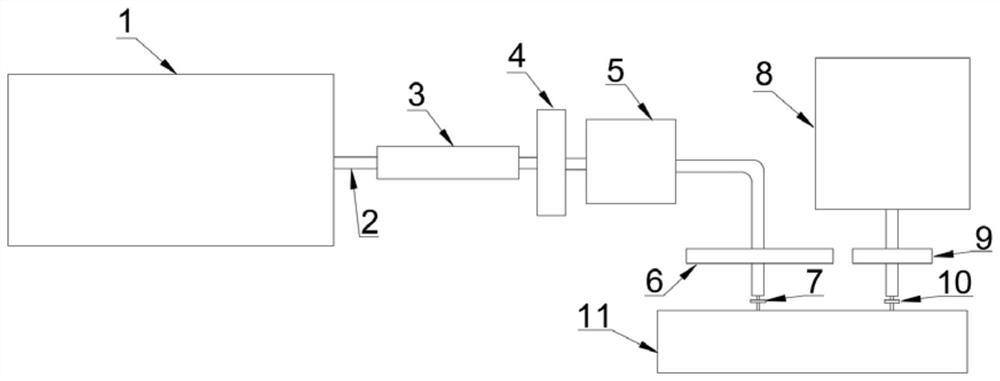

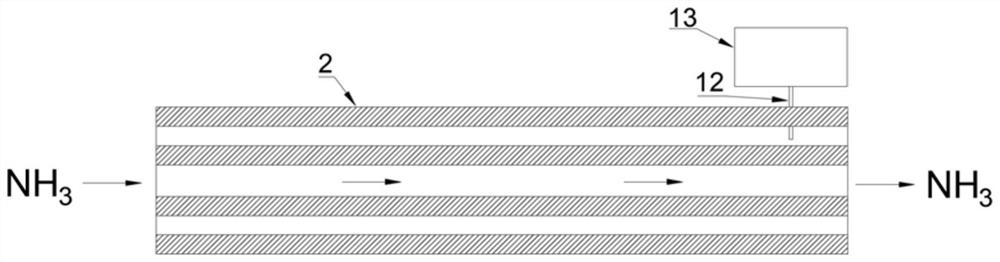

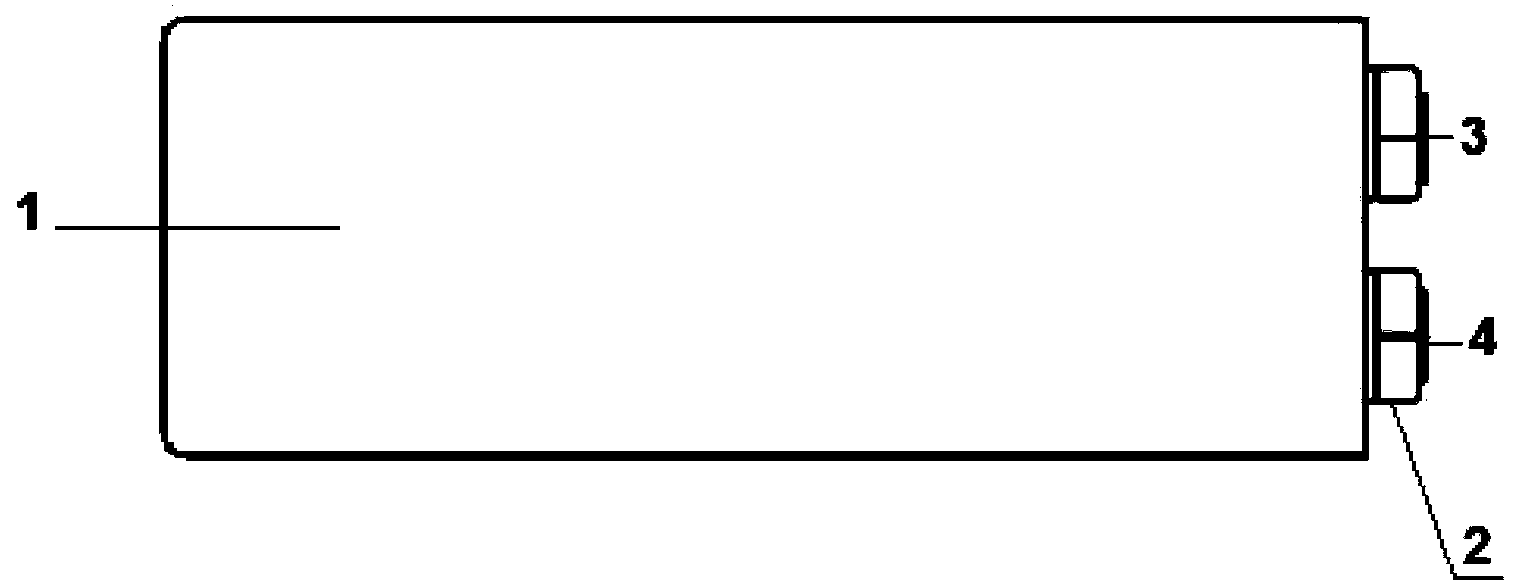

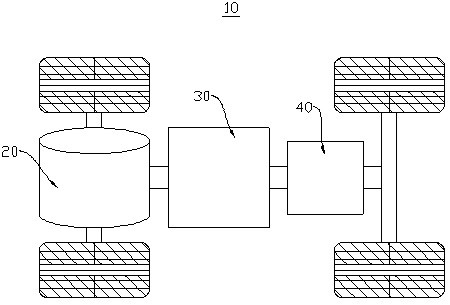

Marine diesel engine ammonia fuel supply system

InactiveCN112628030AEnsure safetyIncrease energy densityInternal combustion piston enginesFuel supply apparatusAmmonia storageCommon rail

The invention aims to provide a marine diesel engine ammonia fuel supply system. The marine diesel engine ammonia fuel supply system comprises a diesel engine, an ammonia storage tank and an oil tank, wherein the ammonia storage tank is sequentially connected to a vaporization tank, a filter cavity, a pressurizing tank and an ammonia high-pressure common rail pipeline through an ammonia transmission pipeline, the ammonia high-pressure common rail pipeline is connected to the diesel engine through an ammonia injection valve, the oil tank is connected to a diesel oil high-pressure common rail pipe, and the diesel high-pressure common-rail pipe is connected to a diesel engine through a diesel atomizer. According to the marine diesel engine ammonia fuel supply system, ammonia can be used as fuel for the engine to burn, environmental problems such as emission pollution and the like are reduced, the ammonia is coupled with high-activity fuel for blending combustion, so that the combustion characteristic of the ammonia can be effectively improved, the external output power is increased, in addition, vaporization heat absorption of the ammonia can be applied to a refrigerating system of a steamship, and the utilization efficiency of energy on the steamship is improved.

Owner:HARBIN ENG UNIV

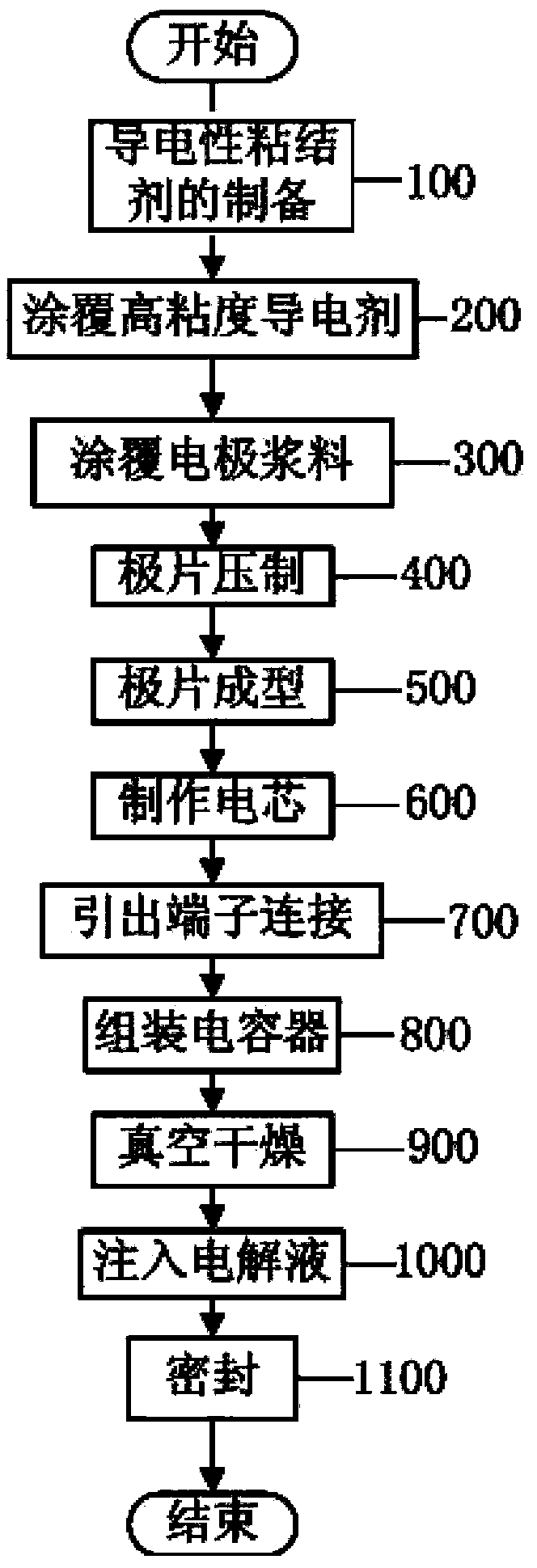

Method of manufacturing a supercapacitor

The invention discloses a method of manufacturing a supercapacitor. According to the invention, corrosion aluminum foil is first coated with a conductive adhesive, and the conductive adhesive is then coated with electrode paste. The presence of the conductive adhesive allows the electrode paste to be stably pasted on the corrosion aluminum foil. The electrode provided by the invention can withstand pressing under the pressure from 150t to 200t without the electrode paste layer falling off and being deformed, and the density of the electrode paste layer can reach between 0.65 to 0.70. The supercapacitor manufactured by the method has the characteristics of high reliability, power density, energy density and safety without the proneness of explosion.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

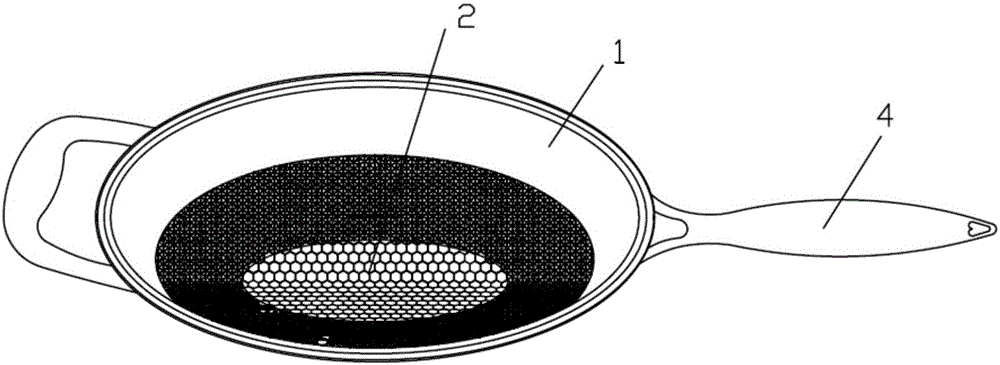

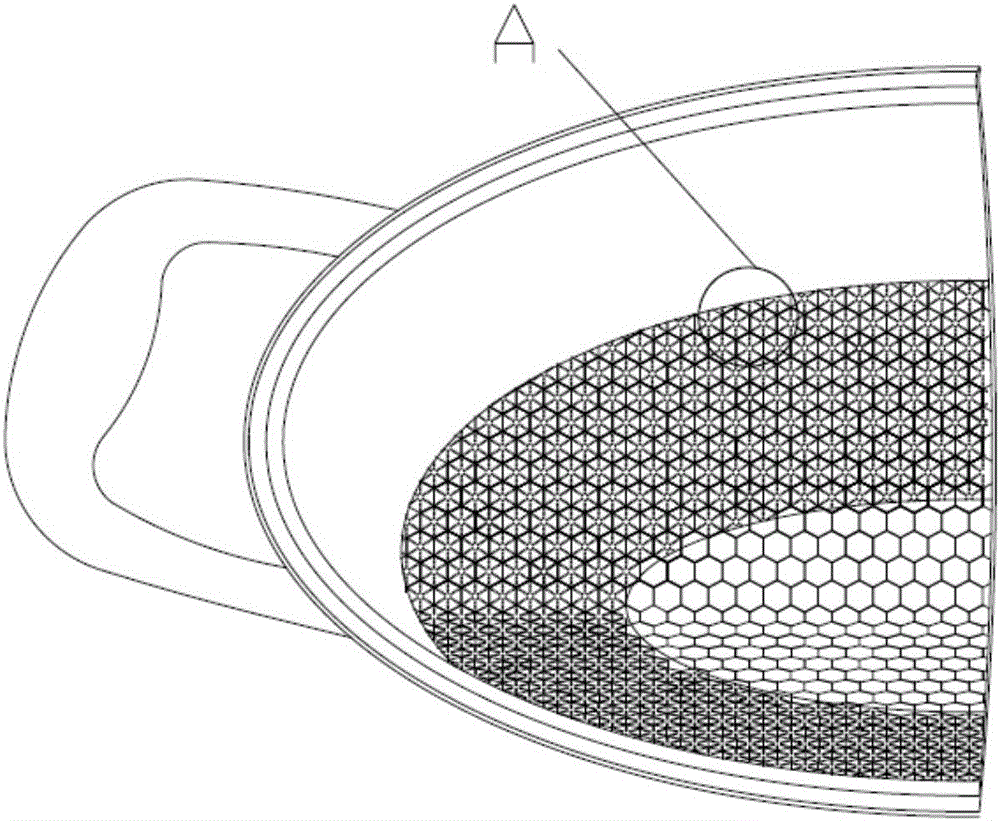

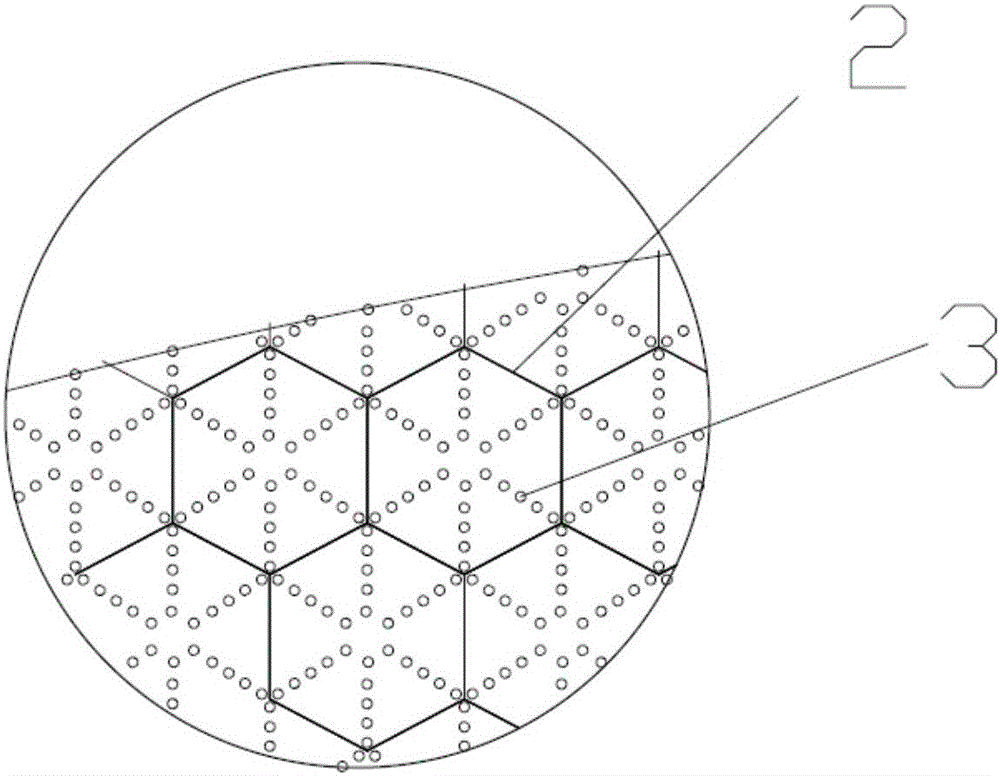

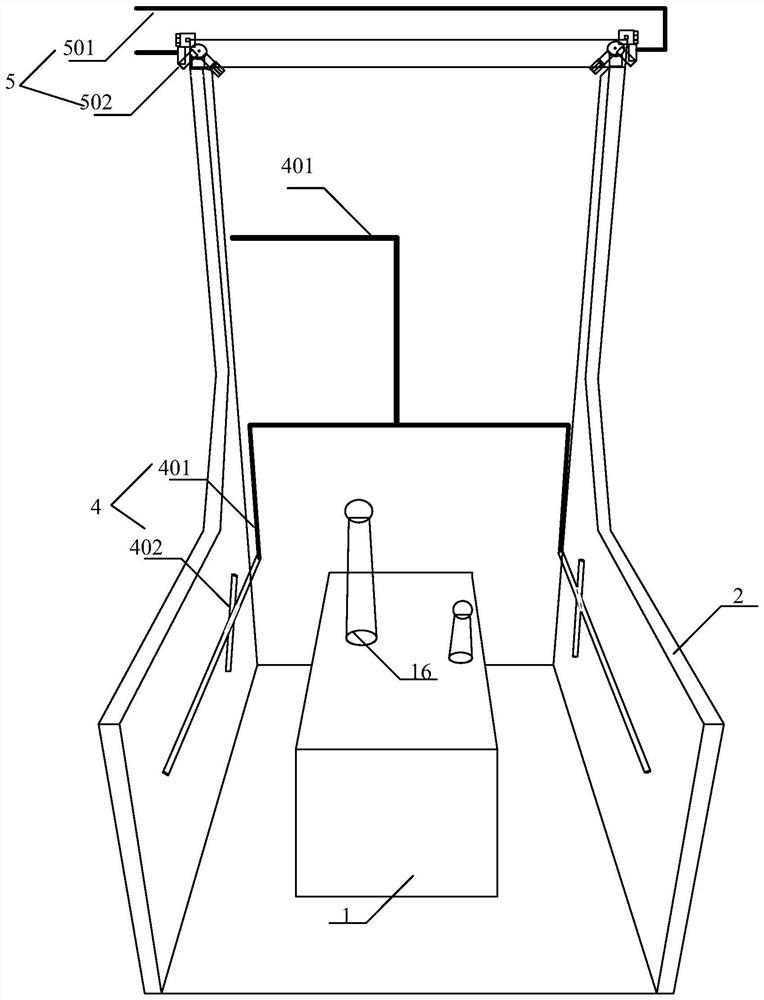

Honeycomb coating non-stick marmite

InactiveCN105768852AEvenly heatedImprove energy efficiencyCooking-vessel materialsCooking vessel constructionsHoneycombHoneycomb Pattern

The invention discloses a honeycomb coating non-stick marmite which comprises a marmite body, and a pattern formed on the inner side of the marmite body through an etching process.The pattern at least comprises a honeycomb pattern body at the bottom of the inner side of the marmite body.The inner layer and the outer layer of the marmite body are coated with non-stick coating layers.By arranging the honeycomb pattern body at the bottom in the marmite body and the non-stick coating layers on the inner side and the outer side of the marmite body, the marmite body is evenly heated, energy efficiency is high, energy is saved, it is avoided that when a user uses the marmite, food sticks to the marmite, and the marmite is convenient to clean, not prone to oil splash during cooking and safer.

Owner:SUZHOU JIAYI STAINLESS STEEL PROD

Hot-melt adhesive for pipe adhesion of plate-type evaporator

InactiveCN104017517AFast curingImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesParaffin waxParaffin oils

The invention discloses a hot-melt adhesive for the pipe adhesion of a plate-type evaporator. The hot-melt adhesive comprises the following components in parts by weight: 60-100 parts of basic resin, 4-6 parts of paraffins, 4-6 parts of hydrogenated rosin glycerin ester, less than 0.5 part of organic silicon and less than 0.5 part of nitrate The hot-melt adhesive disclosed by the invention overcomes the defects of the prior art and has the advantages of reasonable formula design, high solidifying speed and stable adhesive force.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

Fire extinguishing system suitable for extra-high voltage converter station, fire extinguishing method and extra-high voltage converter station

The invention discloses a fire extinguishing system suitable for an extra-high voltage converter station, a fire extinguishing method and the extra-high voltage converter station. The fire extinguishing system comprises a spraying fire extinguishing system and a fire monitor fire extinguishing system; the spraying fire extinguishing system comprises first fire fighting pipelines and spraying pipes, and the fire monitor fire extinguishing system comprises second fire fighting pipelines and fire monitors; and one fire monitor is arranged right above firewalls on the two sides of each converter transformer in the extra-high voltage converter station, each fire monitor communicates with one corresponding second fire fighting pipeline, the spraying pipes are arranged on the firewalls on the twosides of each converter transformer, each spraying pipe communicates with one corresponding first fire fighting pipeline, the fire monitor at the position of each converter transformer and outlets ofthe corresponding first fire fighting pipeline and the spraying pipe right face the converter transformer; The fire extinguishing system has the advantages that the defects of an existing design of afire extinguishing system are overcome, and efficient fire extinguishing and reliable fire extinguishing are achieved.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

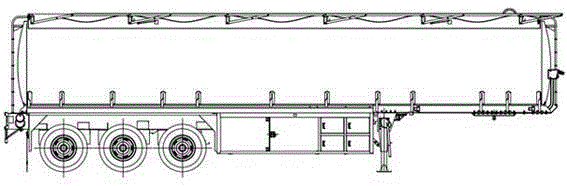

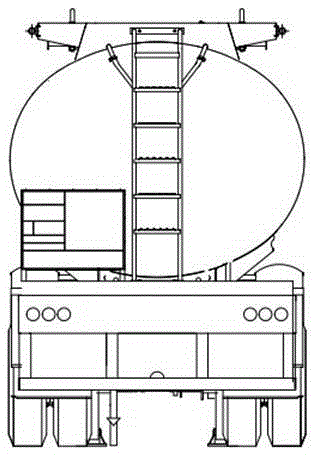

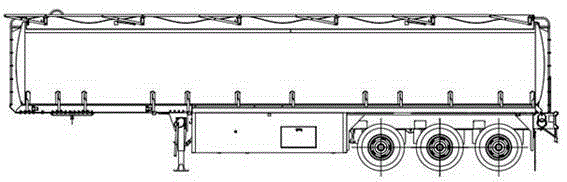

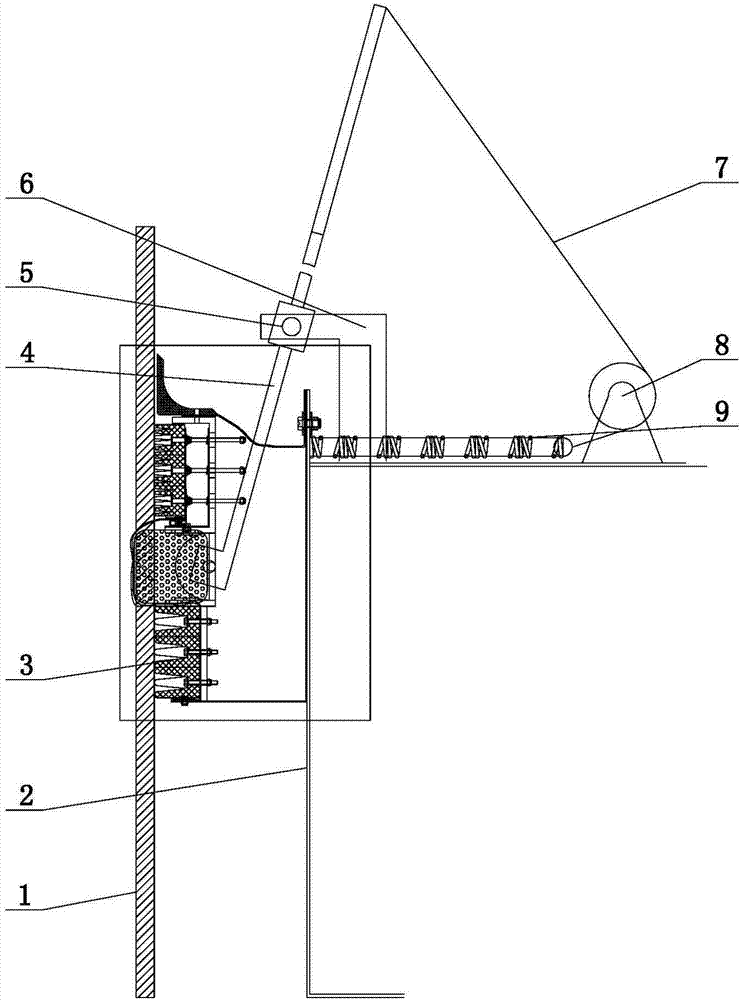

Semi-trailer oil tank truck with aluminum alloy structure

InactiveCN105383361AReduce fuel consumptionLight curb weightTank vehiclesItem transportation vehiclesSemi-trailerTruck

The invention discloses a semi-trailer oil tank truck with an aluminum alloy structure. The semi-trailer oil tank truck comprises an aluminum alloy tank body, an aluminum alloy supporting seat and an aluminum alloy frame, wherein the aluminum alloy tank body and the aluminum alloy supporting seat are welded; the aluminum alloy frame is fixedly connected to the aluminum alloy tank body; axles and tires are mounted on the aluminum alloy frame; an oil feeding and discharging pipeline is mounted at the right side of the aluminum alloy tank body. The semi-trailer oil tank truck is light in mass, high in loading mass, small in oil consumption, safe, clean, and environmentally friendly.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

Combined type sealing mechanism for external floating roof oil tank

ActiveCN104724409AImprove sealingWide range of deformation compensationLarge containersWear resistanceOil tank

The invention discloses a combined type sealing mechanism for an external floating roof oil tank, belongs to the technical field of external floating roof tank sealing devices for crude oil storage, and particularly relates to a combined type sealing mechanism. The combined type sealing mechanism for the external floating roof oil tank is large in deformation compensation amount, good in oil resistivity, high in abrasive resistance and good in sealing performance. The combined type sealing mechanism comprises a floating roof and sealing assemblies and is characterized in that an annular sealing body formed by the sealing assemblies is arranged around the floating roof, a spring compensation mechanism connected with each sealing assembly is arranged on the floating roof, and mackintosh is arranged between the floating roof and the sealing assemblies.

Owner:沈阳新飞宇橡胶制品有限公司

Method for synthesizing cadmium selenide quantum dots based on amino acid and polypeptide

InactiveCN101104807AEasy to separateImprove uniformityLuminescent compositionsCadmium selenideNanoparticle

The invention discloses a method of synthesizing CdSe quantum dots with Amino acid and polypeptide, comprising the following steps: A, preparing cell-free system of selenium-containing amino acid; B, preparing Cd-glutathione; C, synthesizing CdSe quantum dots. The invention is provided with a simple technology and mild reaction conditions. As no organometallic compounds are included in the preparation, the protection from the inert gas is not needed. The production is safe and low in cost, helpful to the industrial synthesis of the nano-particles (including quantum dots).

Owner:WUHAN UNIV

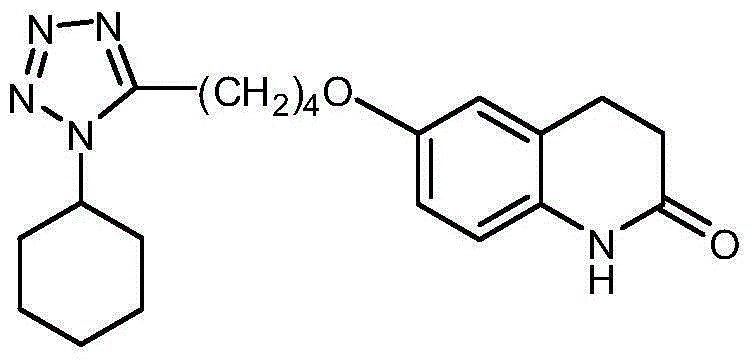

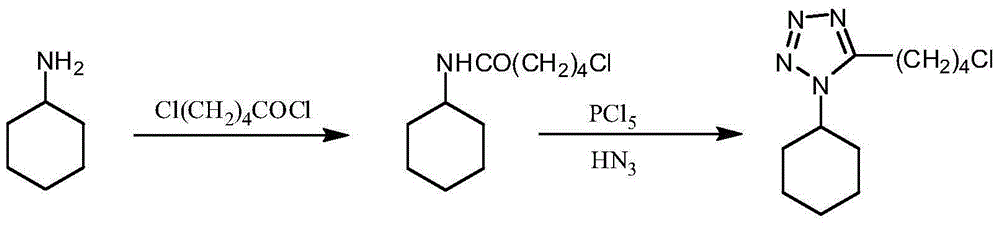

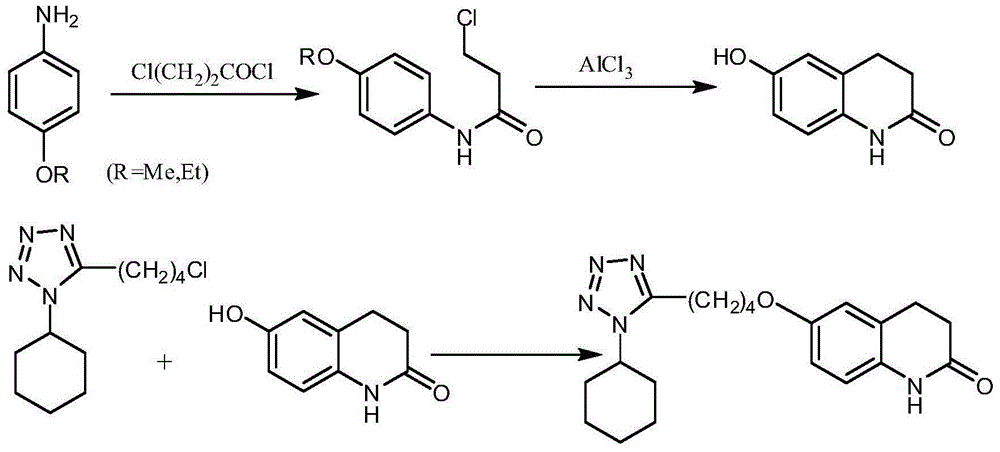

Method for synthesizing cilostazol

The invention discloses a method for synthesizing cilostazol. The method comprises the following steps: cyclohexylamine and 5-chlorovaleryl chloride undergo an acylation reaction to generate 5-chloro-N-cyclohexylpentanamide, and then 5-chloro-N-cyclohexylpentanamide reacts with phosphorus pentachloride and azidotrimethylsilane to generate a tetrazole compound 5-(4-chloro n-butyl)-1-ch cyclohexyl tetrazole; para amino phenol and 3-chloropropionylchloride undergo an acylation reaction to generate 3-chloro-4'-phenol propionamide, and under the effect of aluminum trichloride, 6-hydroxyl-3,4-dihydro-2(1H) quinolinone is generated through cyclization; with methanol serving as a solvent, under the high alkaline conditions of potassium hydroxide, two intermediates undergo a backflow reaction, and cilostazol is generated through butt joint. Raw material costs of the process route are low, the safety risk is low, the environmental pollution is small, and the method is suitable for industrial production.

Owner:ZHEJIANG KINGLYUAN PHARMA

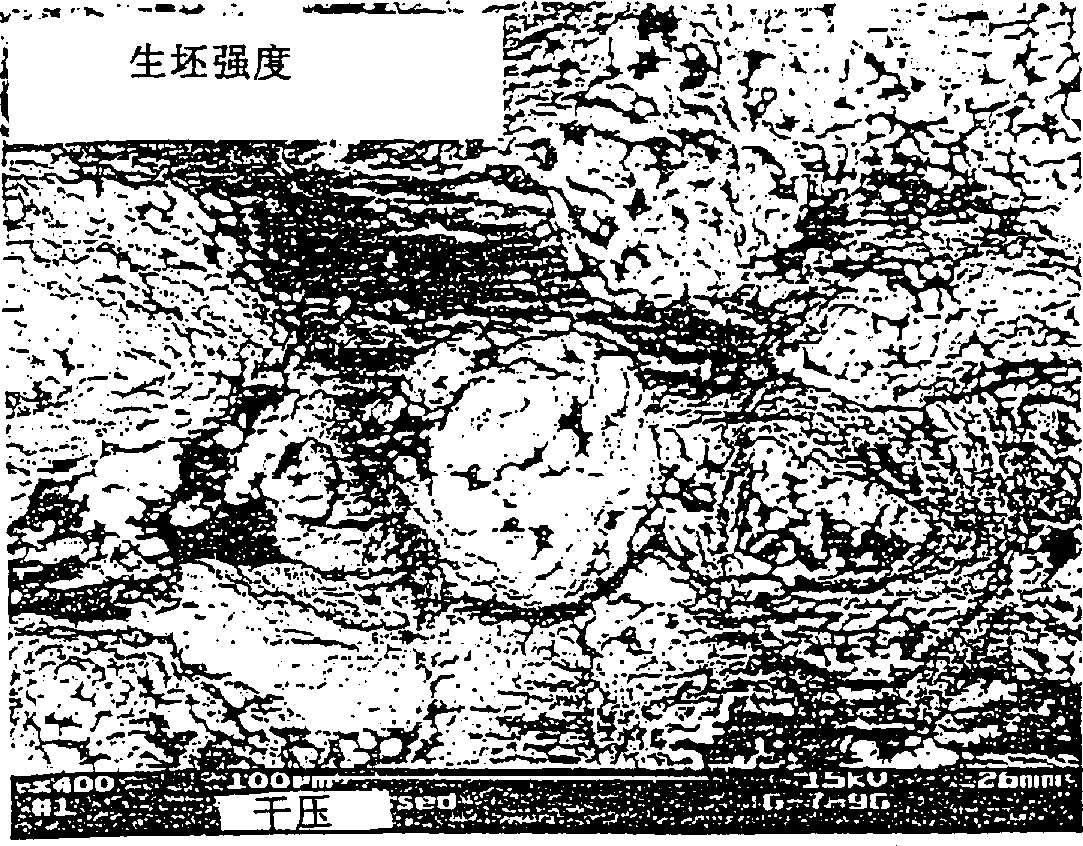

Ambient temperature method for increasing the green strength of parts and articles made by consolidating powder, particulate, sheet or foil materials

InactiveCN1244149AImprove securityNot easy to explodeImpression capsTransportation and packagingParticulatesMolten salt

The present invention relates to a process for consolidating powder, particulates, foils or sheets of metal coated composites, elemental metallic or metallic alloy or intermetallic compounds into net shapes having increased green strength at or near ambient temperature comprises treating the material with an aqueous activation solution. The aqueous activation solution is selected from dilute acids, reducing agents, molten salt electrolytes and mixtures thereof. Pressure is used to consolidate the treated powders, particulates, foils or sheets into a net shape at or near ambient temperature.

Owner:MATERIALS INNOVATION INC

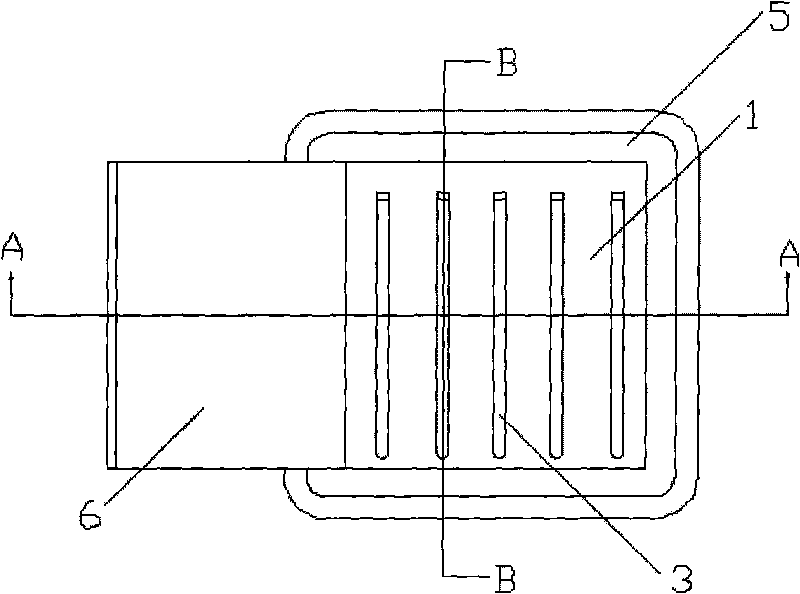

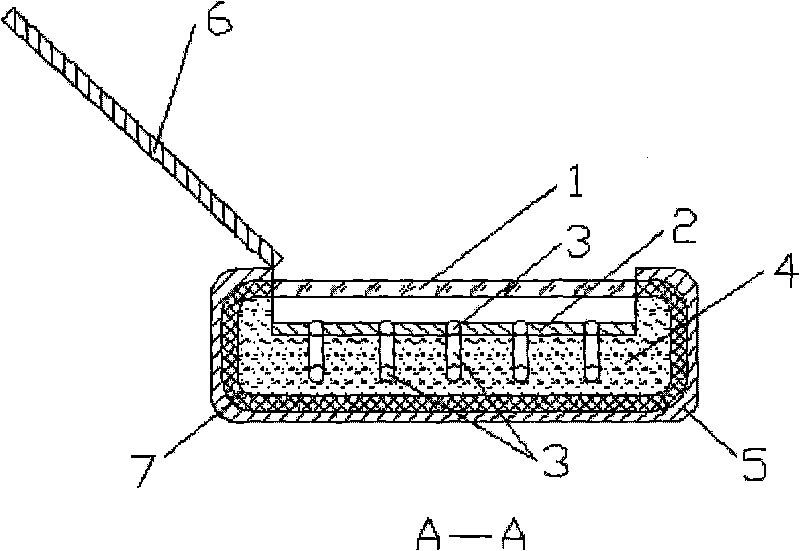

Solar heat collecting cake

InactiveCN101762086AEvenly heatedHigh thermal efficiencySolar heating energySolar heat devicesElectric energyEngineering

The invention discloses a solar heat collecting cake, which comprises a cake body and heat storage materials in the cake body. A transparent cover plate is arranged on the upper surface of the cake body. A heat absorbing plate is arranged in the cake body and is in contact with the heat storage materials. The invention takes solar energy as source energy, rays are transmitted to the heat absorbing plate through a transparent plate, the heat absorbing plate converts optical energy into heat energy and the heat energy is transferred to the heat storage materials through heat transfer medium. The cake body can be made of hard material, the heat storage materials can be solid heat storage materials, and the heat storage materials are enclosed by hard cake materials. The structure and the materials are not apt to cause explosion. Even though explosion occurs, the external hard materials enclosing the heat storage materials are just cracked, the internal heat storage materials are not spilt disorderly and the safety of other people is not endangered. The invention has the advantages that the natural resource is fully utilized, the electric energy and the hydraulic energy are saved, the occurrence probability of serious accidents is reduced, and the safety factor and the thermal efficiency are improved.

Owner:HANGZHOU LIUYI TECH

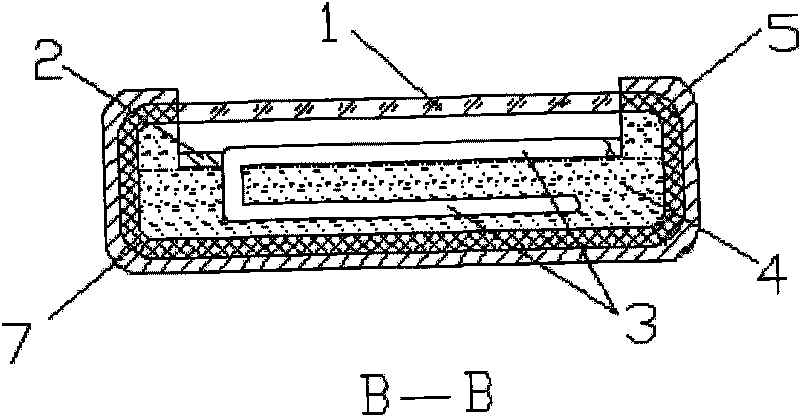

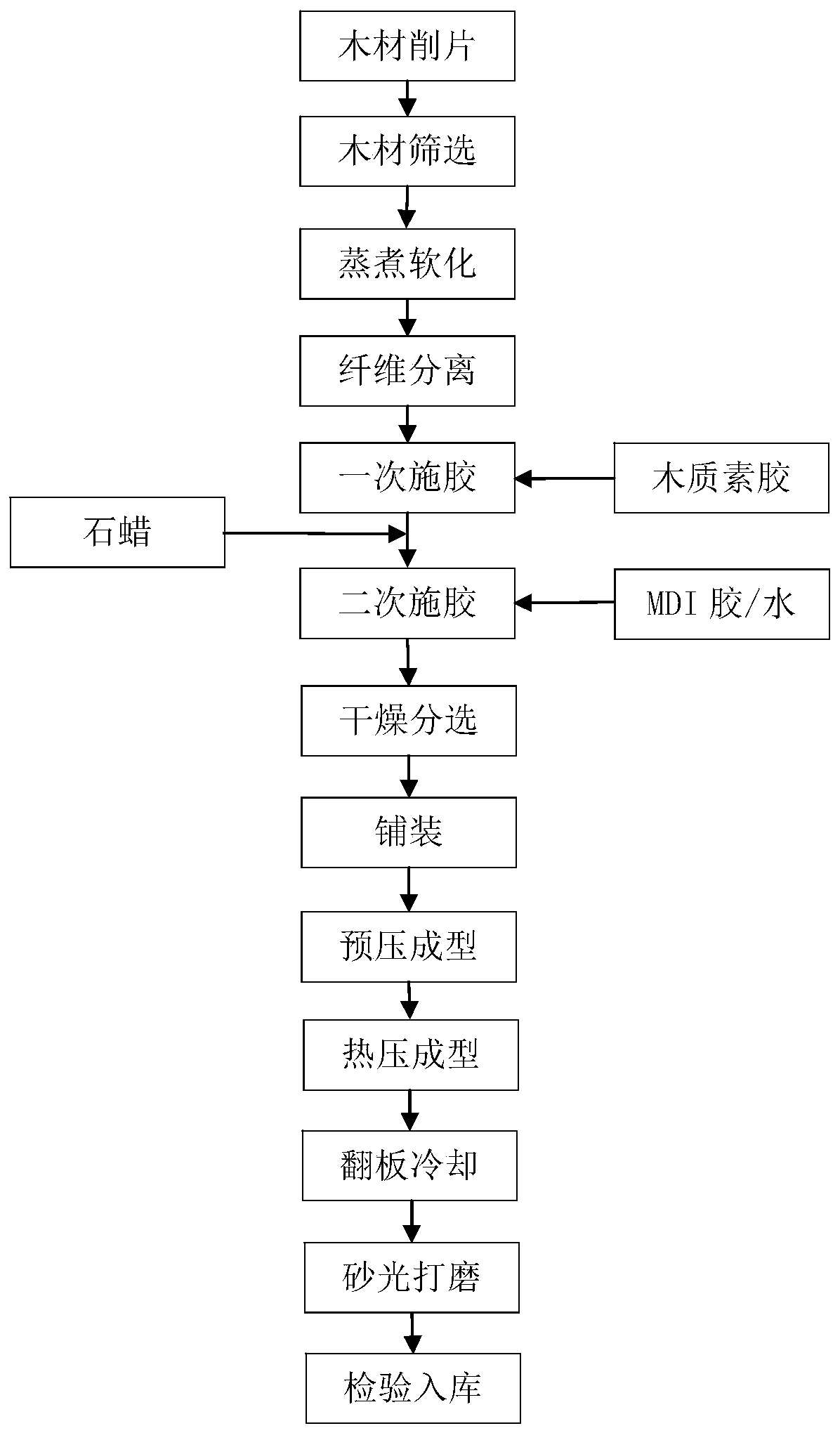

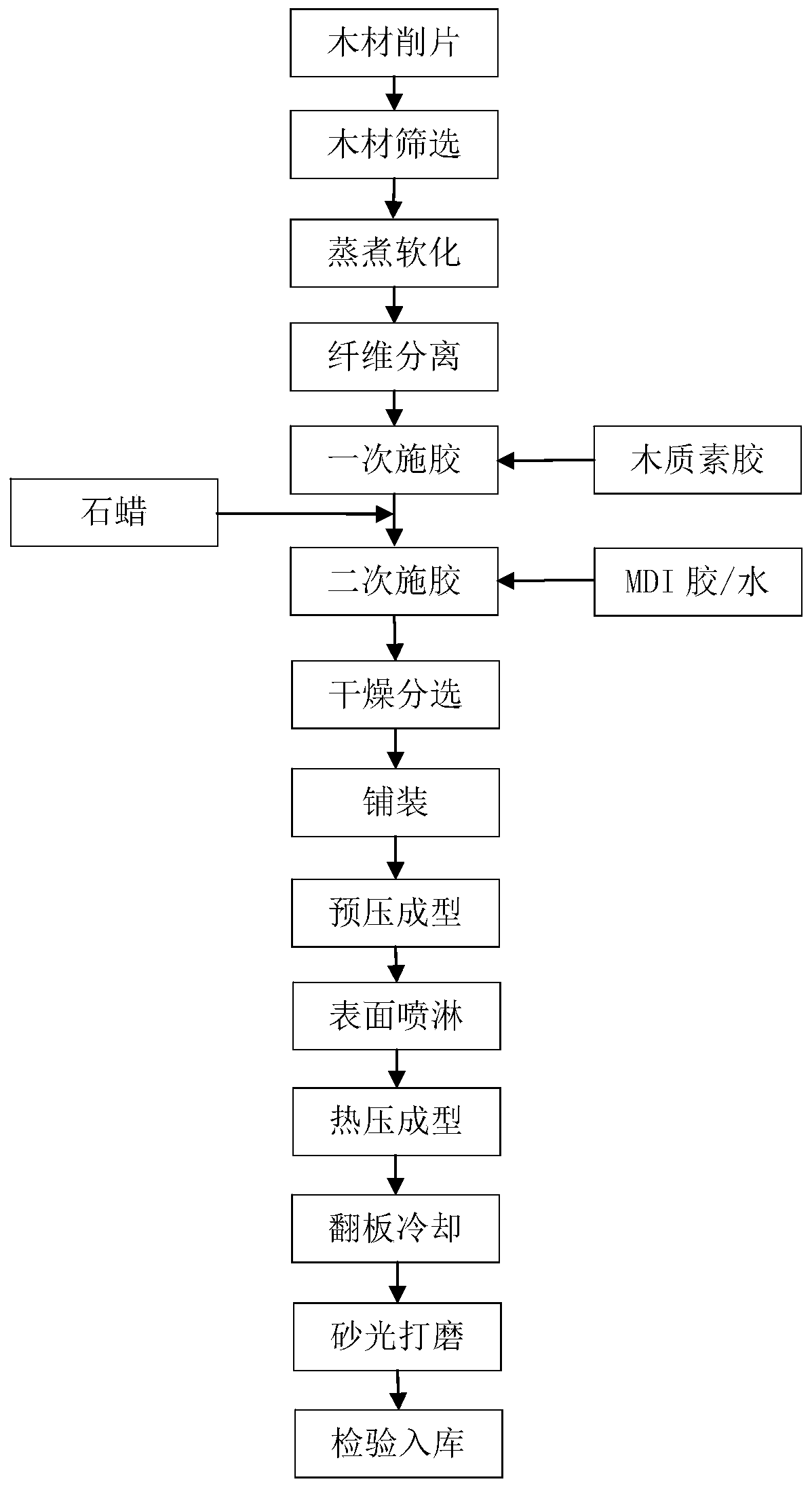

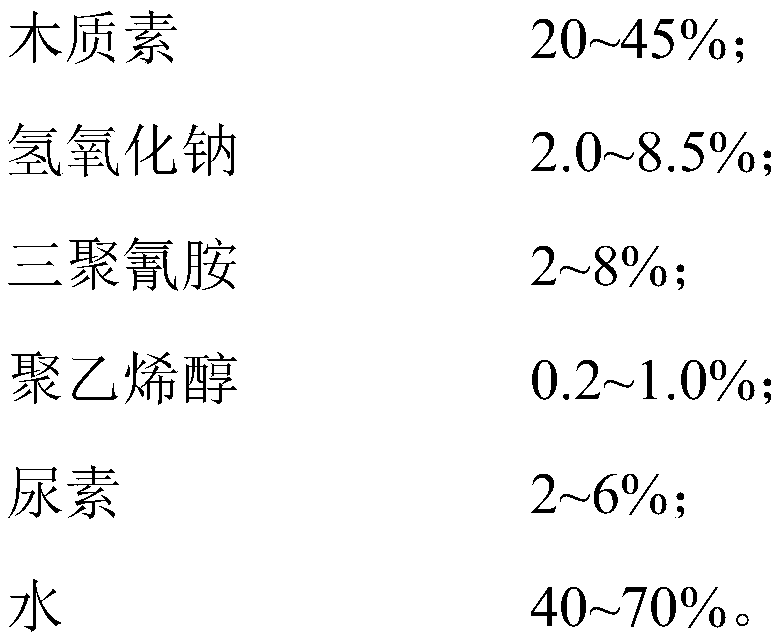

Formaldehyde-free medium-high-density board capable of meeting deep facing requirements and manufacturing method of medium-high-density board

ActiveCN110281341AImprove permeabilityMildew proofPolyureas/polyurethane adhesivesFlat articlesFiberHigh density

The invention relates to a formaldehyde-free medium-high-density board capable of meeting deep facing requirements and a manufacturing method of the medium-high-density board. The medium-high-density board comprises the following steps of wood chipping, screening, cooking and softening, fiber separating, gluing, drying and sorting, paving, pre-pressing, hot pressing, cooling, sanding, and inspection and warehousing. The gluing comprises two steps of gluing, and specifically comprises the steps of carrying out primary gluing by using lignin glue, carrying out waterproof treatment, and then carrying out secondary gluing by using MDI glue. According to the manufacturing method, a biomass adhesive and a formaldehyde-free adhesive are adopted, a curing agent, an anti-mildew agent and the like are not added, by virtue of a two-time gluing method, formaldehyde pollution is completely eradicated from a source, and formaldehyde-free production and formaldehyde-free products are realized; and the gluing process is controlled in sequence and glue types and proportion are controlled, so that the surface hardness of the products can be improved, and the final products can be subjected to deep facing so as to achieve 2-8 millimeters.

Owner:BEIJING FORESTRY UNIVERSITY +2

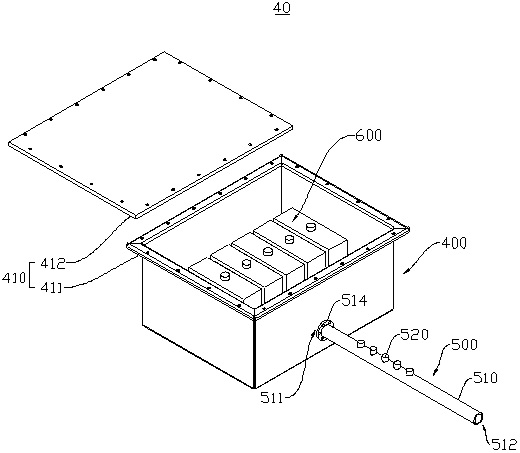

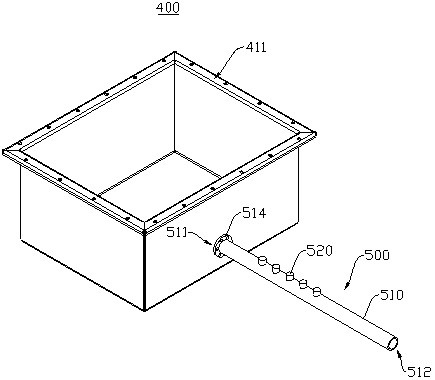

Fire-fighting device, box body assembly, battery, electric device and method for preparing battery

ActiveCN112103445AReduce the temperatureReduce concentrationFinal product manufactureNon-aqueous electrolyte cellsElectrical batteryCombustible gas

The invention provides a fire-fighting device, a box body assembly, a battery, an electric device and a method for preparing the battery, and relates to the technical field of battery safety. The fireprotection device comprises a pipeline, a gas release mechanism and a blocking structure, wherein the pipeline is provided with a gas inlet end and a gas exhaust end, and the gas inlet end is used for being connected with a box body of the battery, so the combustible gas generated during thermal runaway of the battery can enter the pipeline from the box body through the gas inlet end and is exhausted out of the pipeline through the gas exhaust end; the gas release mechanism is used for being connected with a pipeline, and the gas release mechanism is configured to release fire-fighting gas into the pipeline when the battery is in thermal runaway; the pipeline is internally provided with a blocking structure, and the blocking structure is used for blocking combustible gas and fire-fightinggas and changing the flowing direction, so the combustible gas and the fire-fighting gas can be mixed before being discharged out of the pipeline. The fire protection device provided by the inventioncan reduce the risk of generating open fire during thermal runaway of the battery, and can inhibit spreading of the thermal runaway of the battery.

Owner:JIANGSU CONTEMPORARY AMPEREX TECHNOLOGY LIMITED

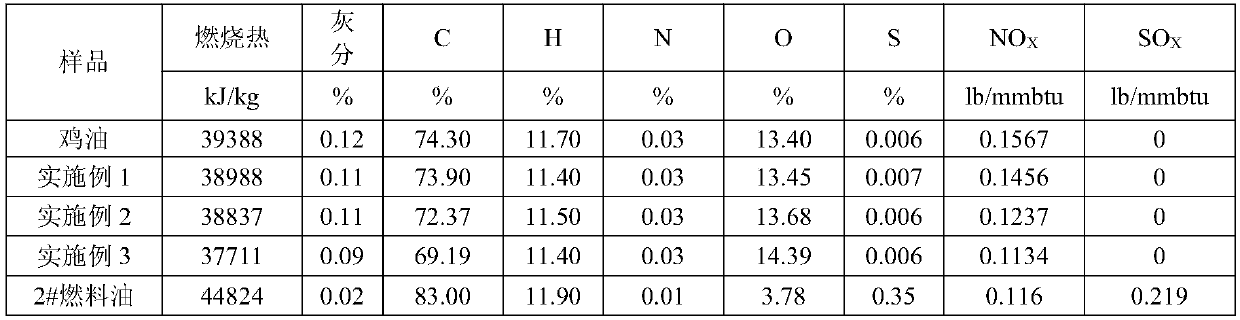

Microemulsion fuel oil prepared from waste and abandoned animal grease and processing method thereof

The invention belongs to the technical field of fuel oil processing, and relates to microemulsion fuel oil prepared from waste and abandoned animal grease and a processing method thereof. The microemulsion fuel oil is prepared from 40 to 70 parts of animal grease, 25 to 60 parts of methyl acetate, 1 to 10 parts of methyl alcohol, 0.2 to 10 parts of co-emulsifiers and 0.2 to 2 parts of emulsifiers,wherein the animal grease is waste and abandoned animal grease and is prepared from one or several kinds of materials in chicken oil, cow oil, sheep oil or duck oil. By using the microemulsion fuel oil, the raw materials are waste and abandoned animal grease and industrial production byproducts of methyl acetate; the sources are wide; the cost is low; the prepared fuel oil has low sulfur content,low moisture content and high calorific value, can not easily explode, can be conveniently stored and transported, can be matched with diesel oil and gasoline, and has high combustion efficiency; thepreparation method is simple, low-carbon and the environmentally-friendly; the effective utilization of resources can be realized; the added value of the animal grease can be improved.

Owner:宁夏莱德环保能源有限公司

New energy battery cover plate assembly

InactiveCN111613742AGood cooling effectNot easy to heat accumulationSecondary cellsCell component detailsElectrical batteryStructural engineering

The invention provides a new energy battery cover plate assembly. The new energy battery cover plate assembly comprises a cover plate and a battery box, and L-shaped supporting plates are fixedly connected to the upper ends of the left and right sides of the battery box; and the top of each L-shaped supporting plate is fixedly connected with a stop block assembly. Second grooves are formed in thefront and back of the upper ends of the left and right sides in the battery box; a rotating shaft is rotationally connected between the front and rear sides of the upper end of one side close to the centers of the battery boxes in the second grooves; a gear is fixedly connected to the center of the rotating shaft; the positive pole and the negative pole are sleeved and fixed with a pole base at the upper end of the cover plate; the upper ends, located in the first hollow groove, of the positive pole and the negative pole are sleeved and fixed with insulating sleeves; and first grooves are formed in the front and back of the lower ends of the left and right sides of the sealing block. The bottoms of the first groovesarein a notch shape, second racksarefixedly connected into the first grooves, and limiting holes are formed in the positions, located between the sealing blocks and the side plates, of the front end and the rear end of the bottom of the cover plate. The new energy battery cover plate assembly provided by the invention can solve the problems that an existing new energy battery cover plate assembly is trouble in dismounting and mounting and cannot meet the requirements ofnew energy batteries.

Owner:耿凤玲

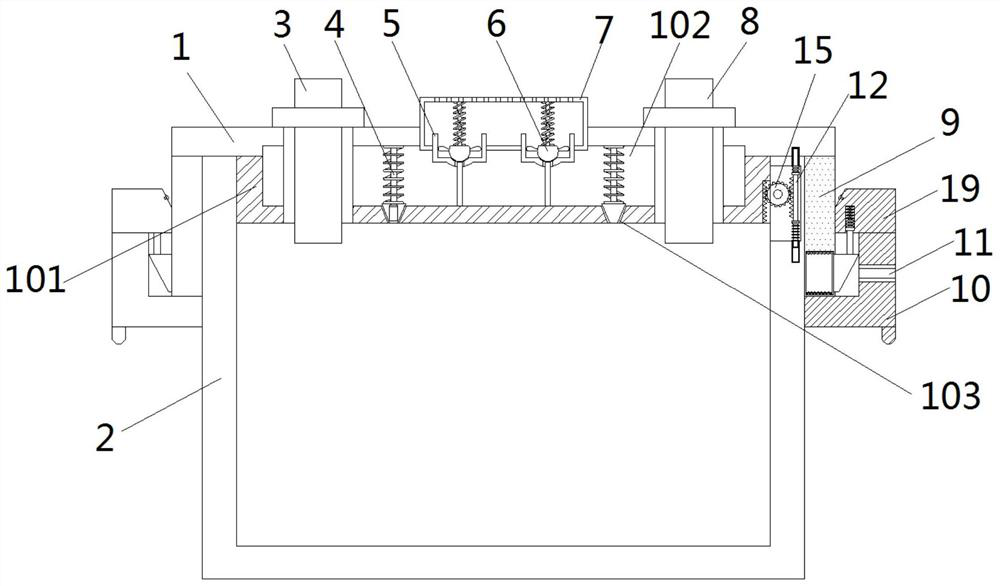

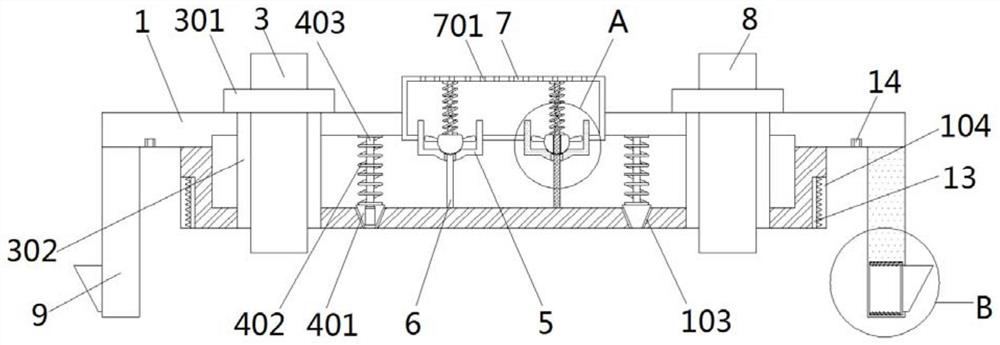

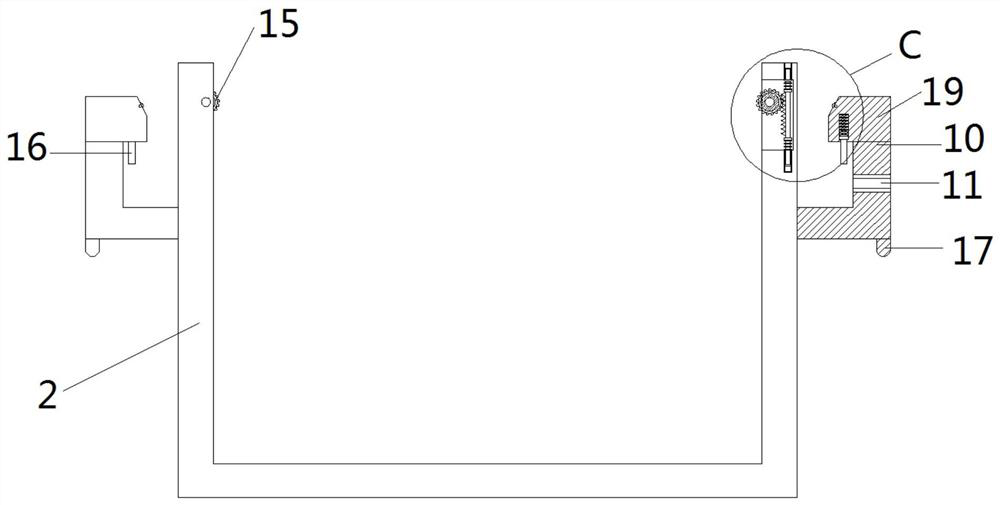

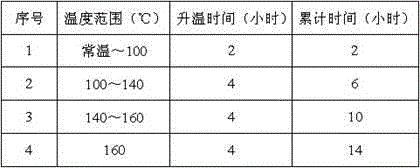

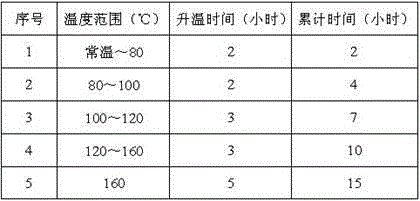

Production method of grinding wheel for steel tube

InactiveCN102941539ALow costImprove cutting performanceAbrasion apparatusGrinding devicesPorosityZirconia alumina

The invention discloses a production method of a grinding wheel for a steel tube. The grinding wheel comprises, by weight, 100 parts of abrasives, wherein 30-50 parts of fused zirconia alumina, 50-70 parts of brown fused alumina, 17-25 parts of phenolic resin, 4-8 parts of pyrite, 1-3 parts of feldspar, 1-3 parts of cryolite, 1-3 parts of carbon black and 3-5 parts of gypsum. In a molding process, feeding is performed for three times and two wheel rims are placed in a non-grinding area; and in a hardening process, segmented heating or heat preservation is performed, the temperature is heated from a normal temperature to 160 DEG C gradually, and the hardening time is 14-16 hours. According to the method, mixed abrasives containing the fused zirconia alumina and the brown fused alumina with multi-granularity are used, the cost of the raw materials is effectively reduced, and the cutting capacity and strength of the grinding wheel are improved; on-load grinding is achieved and the grinding efficiency is improved due to placement of the two wheel rims; the hardening temperature and time are optimized and improved, and the effect is ideal; and the porosity of the grinding wheel is enlarged, the cooling performance is good, the grinding wheel is not easy to explode, and the safety factor is high.

Owner:JIANGSU SUBEI GRINDING WHEEL FACTORY

Process for preparing polymer microporous membrane and usage of same

InactiveCN101199918AChemically stableNo toxicitySemi-permeable membranesCell component detailsPolymer sciencePolymer

The invention provides a preparation method of polymer microporous membrane, including: a) polymer membrane material containing one or a plurality of small molecular additives is provided; b) supercritical fluid is used to elute the small molecular additives in the polymer membrane material so as to form a micropore structure inside the membrane; c) the micropore membrane which is extracted and cleaned by supercritical fluid is dried so as to get the poly microporous membrane.

Owner:上海世龙科技有限公司

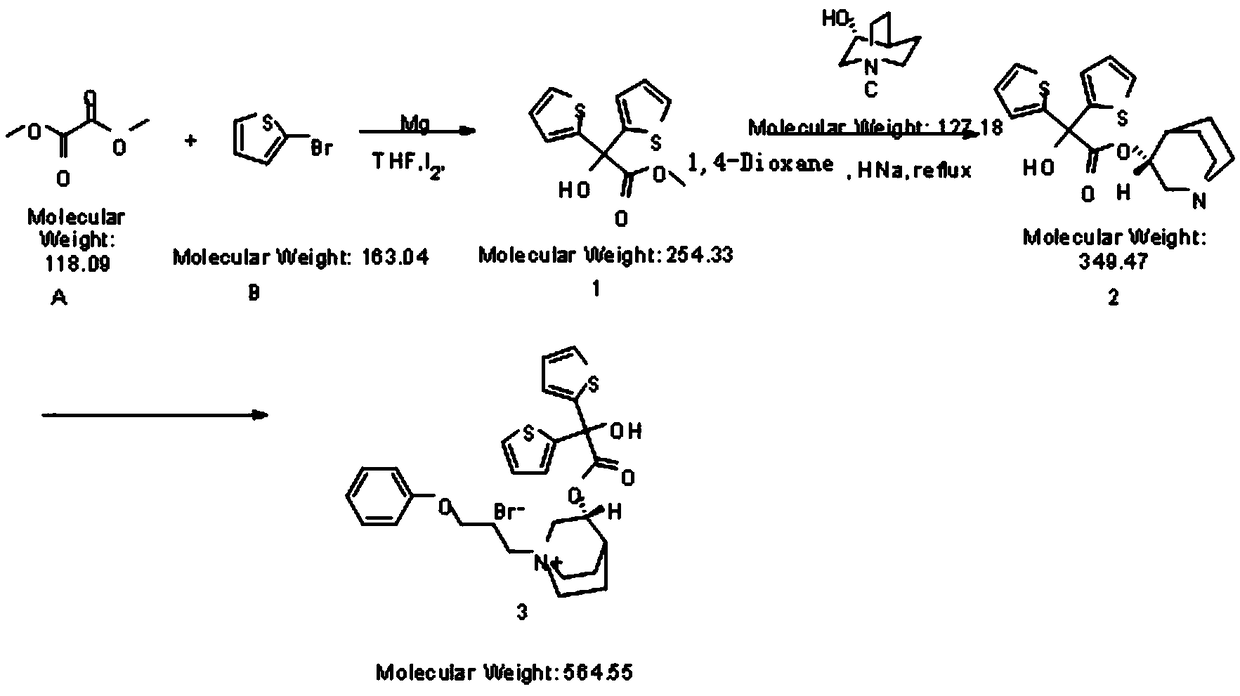

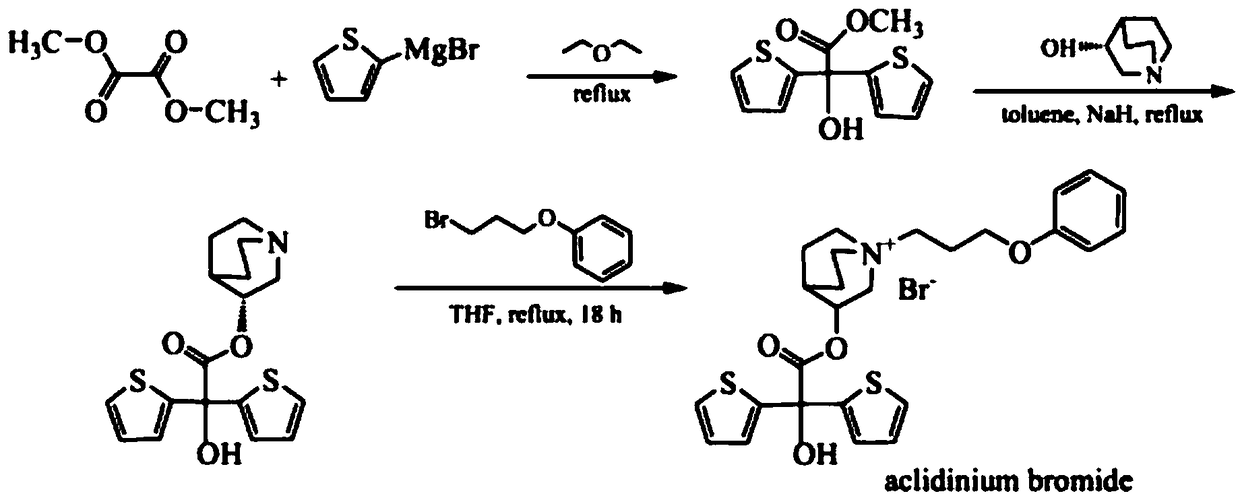

Novel method for synthesis and purification of aclidinium bromide

The invention discloses a novel method for synthesis and purification of aclidinium bromide. According to the method, tetrahydrofuran is used, haloalkane is used as an initiator, and a finished product is obtained through solvent extraction and recrystallization after acidification. The preparation process is mild in reaction conditions, simple and convenient to operate, high in yield and high infinished product purity, and breakthrough progress is made for the process in China.

Owner:FARMASINO PHARMA ANHUI

Method for preparing magnesium-based nanocomposite hydrogen storage material

InactiveCN111515405ATo achieve the purpose of hydrogen storageNot easy to explodeMaterial nanotechnologyReversible hydrogen uptakeCarbon nanotubeChemical adsorption

The invention relates to a method for preparing a magnesium-based nanocomposite hydrogen storage material, and belongs to the technical field of hydrogen storage materials. In the method, carbon nanotubes are grown in situ on the surface of a molecular sieve to serve as a substrate, rare earth lanthanum is used as a target, a layer of lanthanum hydride film is formed on the surface of the substrate by sputtering to serve as a filler of the hydrogen storage material, and with magnesium hydride as a raw material, the magnesium-based nanocomposite hydrogen storage material is prepared by mechanical ball milling. When hydrogen molecules make contact with the material, the hydrogen molecules are adsorbed on the alloy surface, H-H bonds of the hydrogen molecules dissociate into atomic hydrogen,hydrogen atoms diffuse inwards from the material surface to be immersed into metal atoms with the radius much larger than that of the hydrogen atoms and among crystal lattices in the gaps of metal toform a solid solution, hydrogen solidly dissolved in the metal continues to diffuse inwards, the diffusion must have activation energy of conversion from chemical adsorption to dissolution, after thesolid solution is saturated by hydrogen, excess hydrogen atoms react with the solid solution to produce metal hydride, and thus the purpose of hydrogen storage is achieved.

Owner:深圳市亚环环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com