New energy battery cover plate assembly

A battery cover, new energy technology, applied in battery pack components, electrical components, secondary batteries, etc., can solve the problems of poor internal heat dissipation, troublesome disassembly and assembly, and no shock absorption effect on the cover, and achieve heat dissipation effect. Good, not easy to heat agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

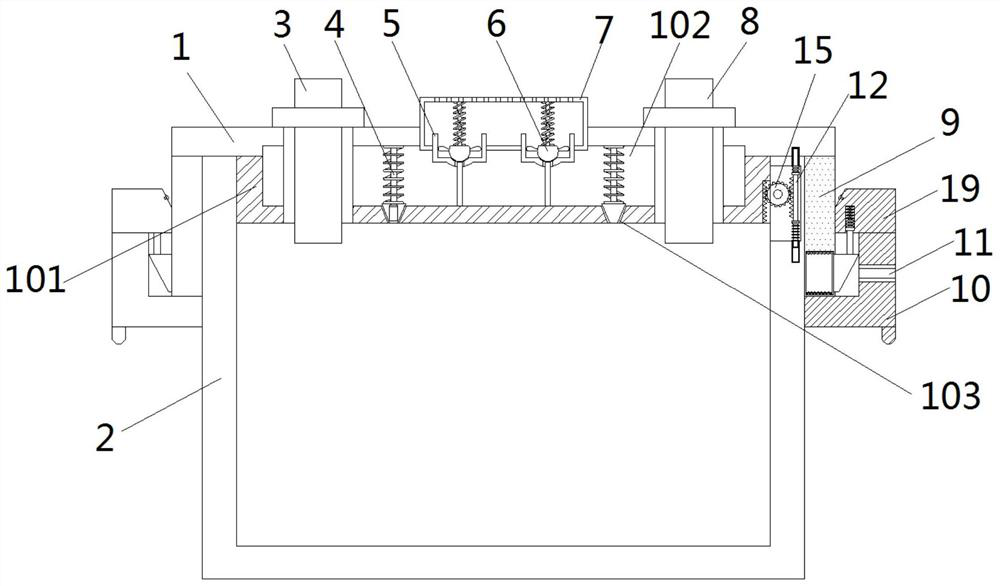

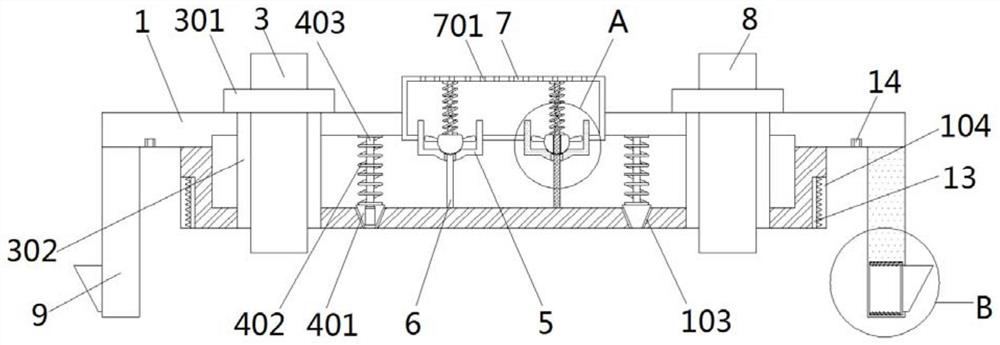

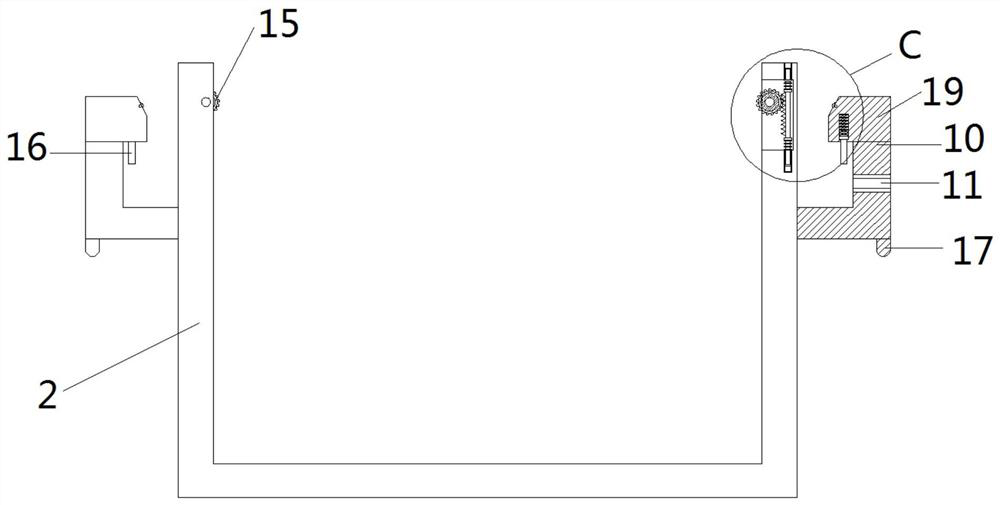

[0032] As attached figure 1 Attached Picture 9 Shown: a new energy battery cover plate assembly, including a cover plate 1, a battery box 2, a positive pole 3, a pole base 301, an insulating sleeve 302, and a negative pole 8. The upper ends of the left and right sides of the battery box 2 are fixedly connected with L-shaped support plate 10, the top of L-shaped support plate 10 is fixedly connected with stopper assembly 19, the upper and lower ends of the left and right sides of the battery box 2 are equipped with No. 2 grooves 201, and the inside of the No. 2 groove 201 is close to the center of the battery box 2. A shaft is transferred between the front and rear of the upper end of one side, and the center of the shaft is fixedly connected with a gear 15, and the center of the upper and lower ends of the second groove 201 away from the center of the battery box 2 is provided with the second slot 203 and the first socket respectively. The rack assembly 12 is movably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com