Electrode with coating and lithium ion battery with electrode

A technology of electrodes and coatings, applied in the direction of secondary batteries, battery electrodes, battery components, etc., can solve problems such as combustion or explosion, rapid heating, etc., achieve the effects of not being easy to explode, and improving thermal stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

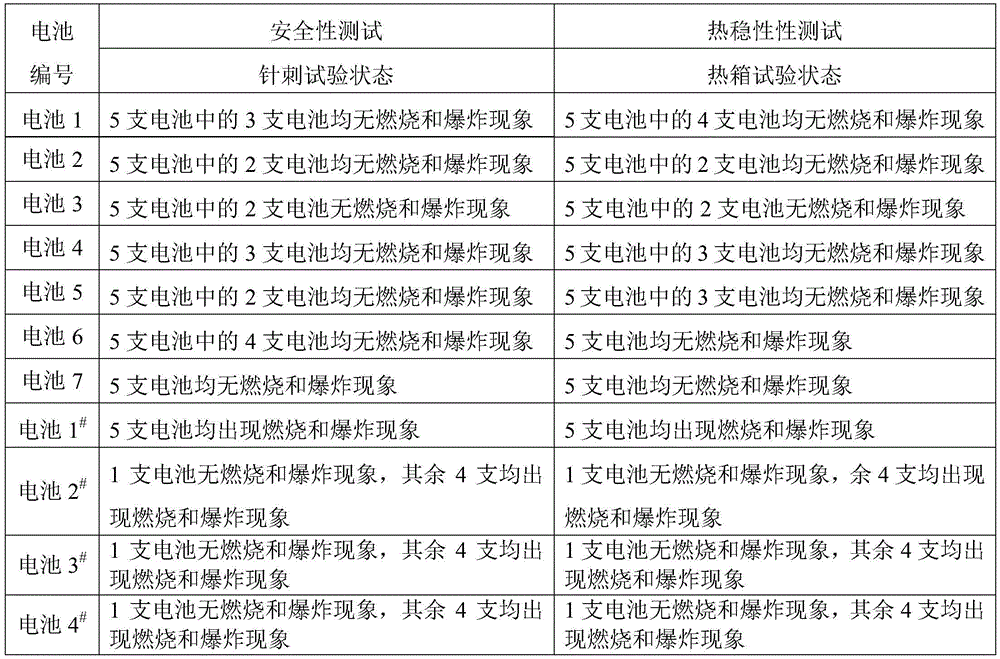

Examples

Embodiment 1~7

[0033] Preparation of Examples 1-7 Lithium-ion Batteries (referred to as batteries) 1-7

[0034] 1. The positive electrode sheet, negative electrode sheet and electrolyte in batteries 1 to 7 are prepared according to the following method:

[0035] (1) Preparation of positive electrode sheet

[0036] The positive electrode active material lithium cobalt oxide LiCoO 2 , conductive agent conductive carbon black Super-P, binder polyvinylidene fluoride (PVDF) is LiCoO by weight 2 :Super-P:PVDF=96:2:2 for mixing, then add the mixed material to N-methylpyrrolidone (NMP) and mix evenly to obtain positive electrode slurry; apply the positive electrode slurry on the aluminum foil of the positive electrode current collector , after drying at 85°C, cold pressing; then edge trimming, cutting, and stripping, and then drying at 85°C for 4 hours under vacuum conditions, and welding the tabs to obtain the positive electrode sheet.

[0037] (2) Preparation of negative electrode sheet

[003...

Embodiment 1

[0041] Preparation of Example 1 Battery 1

[0042] (1) the first inorganic particles Al(OH) 3 , the first binder polymethyl methacrylate, thickener sodium carboxymethyl cellulose (CMC) is Al(OH) by weight 3 : the first binder: CMC=98:1:1 mixed, then the mixed material is added to deionized water, mixed evenly, to obtain the first material layer slurry, the obtained first material layer slurry is coated on After the surface of the negative electrode sheet prepared above was dried to form a first material layer, the thickness of the first material layer was detected to be 3 μm;

[0043] (2) Mix the second binder polyvinylidene fluoride and polyacrylonitrile in a weight ratio of polyvinylidene fluoride:polyacrylonitrile 90:10, add the mixed material to deionized water, mix evenly, and obtain the first Two-substance layer slurry, after coating the obtained second substance layer slurry on the surface of polyethylene isolation film, drying to form a second substance layer, the th...

Embodiment 2

[0045] Example 2 Preparation of Battery 2

[0046] Repeat the preparation of battery 1 in Example 1, wherein the first inorganic particles Al(OH) 3 Boehmite (γ-AlOOH) was replaced, and the rest of the conditions remained unchanged, and a battery 2 with a thickness of 4.2 mm, a width of 34 mm, and a length of 82 mm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com