Preparation method of polyethylene microporous membrane and system thereof

A polyethylene microporous film, polyethylene technology, which is used in electrical components, circuits, battery pack parts and other directions, can solve the problems of high incidence of defective products, poor high temperature resistance and chemical corrosion resistance, and high cost, and can reach the soaking time. The effect of long, high temperature resistance and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

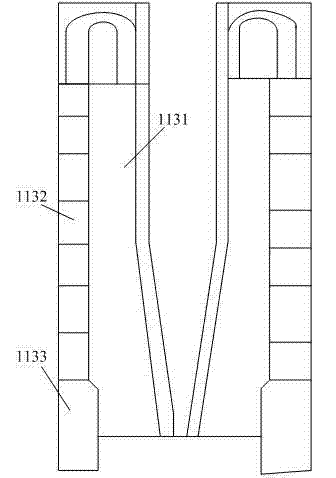

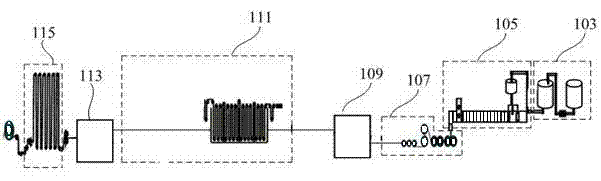

[0036] Embodiment 1, the steps of the preparation method of a kind of polyethylene microporous membrane in the present embodiment are as follows:

[0037] 1. Add polyethylene, polypropylene, cross-linking agent, antioxidant and mineral oil into the mixer in a certain proportion to fully stir the raw materials. The mass ratio of mineral oil to antioxidant is 500~1800:1 , the mass ratio of crosslinking agent to mineral oil is 1:30~35, the mass ratio of mineral oil to polypropylene is 1000:20~900, and the mass ratio of mineral oil to polyethylene is 2~10:1.

[0038] The antioxidants in this embodiment can be phenolic antioxidants Irganox and 2,6-di-tert-butyl-4-methylphenol, and the crosslinking agent is polynorbornene.

[0039] 2. Put the mixture stirred in step 1 into a twin-screw extruder and heat it at 80-300°C for continuous extrusion to form a substrate.

[0040] The screw diameter of the twin-screw extruder here is 10-200 mm, and its extrusion capacity is greater than 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com