Microemulsion fuel oil prepared from waste and abandoned animal grease and processing method thereof

A technology of animal fat and micro-emulsion, applied in fuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of complex equipment, waste of resources, high cost, etc., and achieve the effect of high safety, effective utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

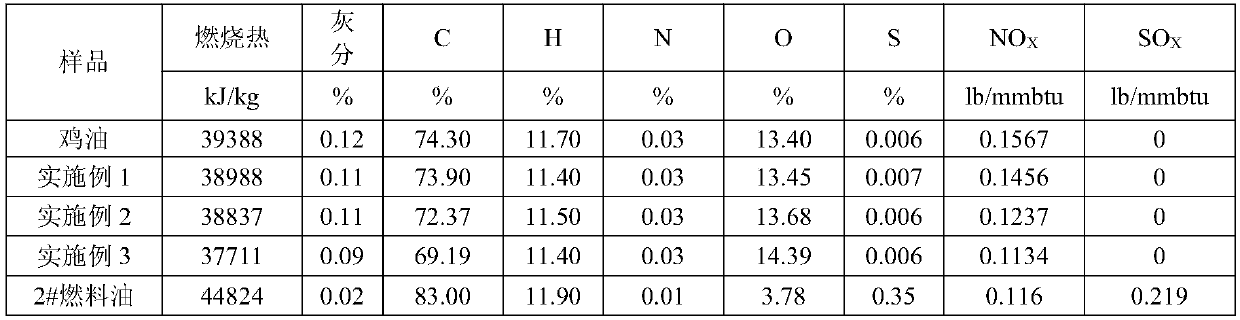

Examples

Embodiment 1

[0017] A method for preparing microemulsified fuel oil by using waste animal fat, comprising the steps of:

[0018] (1) Pretreatment of chicken fat: Boil waste chicken fat at 120°C for 30 minutes, increase the temperature and control it at 135°C as the water content decreases, until deep red color appears, and keep it for 90 minutes to get the pretreatment processed chicken fat;

[0019] (2) Modification of chicken fat: take by weighing 65g of pretreated chicken fat and 60g of methyl acetate, the purity of methyl acetate is 98%; slowly stir the chicken fat at 60°C, and take 1 drop of chicken fat through a separatory funnel Add methyl acetate dropwise at a speed of / second, after the dropwise addition is completed, continue to stir for 20min to make a modified solution;

[0020] (3) Preparation of mixed solution: Weigh 10g of methanol, 2g of isobutanol and 1g of fatty alcohol polyoxyethylene ether (AEO-3); stir methanol continuously at 40°C, and mix isobutanol and fatty alcoh...

Embodiment 2

[0023] A method for preparing microemulsified fuel oil by using waste animal fat, comprising the steps of:

[0024] (1) pretreatment of chicken fat: same as step (1) operation among the embodiment 1;

[0025] (2) Modification of chicken fat: take by weighing 65g of pretreated chicken fat and 30g of methyl acetate, the purity of methyl acetate is 97%; slowly stir the chicken fat at 70°C, and add 1 drop of chicken fat through a separatory funnel Add methyl acetate dropwise at a speed of 1 / sec, after the dropwise addition is completed, continue to stir for 10min to make a modified solution;

[0026] (3) Preparation of mixed solution: Weigh 5g of methanol, 2g of n-butanol and 2g of fatty alcohol polyoxyethylene ether (AEO-3); keep stirring methanol at 50°C, and mix n-butanol and fatty alcohol polyoxyethylene ether ( AEO-3) was added into the heated methanol, and continued to stir for 5 minutes to make a mixed solution;

[0027] (4) Microemulsification: Pour the modified solution...

Embodiment 3

[0029] A method for preparing microemulsified fuel oil by using waste animal fat, comprising the steps of:

[0030] (1) pretreatment of chicken fat: same as step (1) operation among the embodiment 1;

[0031] (2) Modification of chicken fat: take by weighing 41g of pretreated chicken fat and 27g of methyl acetate, the purity of methyl acetate is 96%; slowly stir chicken fat at 55°C, and use 1 drop of chicken fat through a separatory funnel Add methyl acetate dropwise at a speed of 1 / sec, after the dropwise addition is completed, continue to stir for 15min to make a modified solution;

[0032] (3) Preparation of mixed solution: Weigh 2g of methanol, 2g of isobutanol and 0.4g of fatty alcohol polyoxyethylene ether (AEO-3); stir methanol continuously at 30°C, and mix isobutanol and fatty alcohol polyoxyethylene ether (AEO-3) was added into the heated methanol and continued to stir for 10 minutes to make a mixed solution;

[0033] (4) Microemulsification: slowly pour the modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com