Patents

Literature

30results about How to "Reduce excess air ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

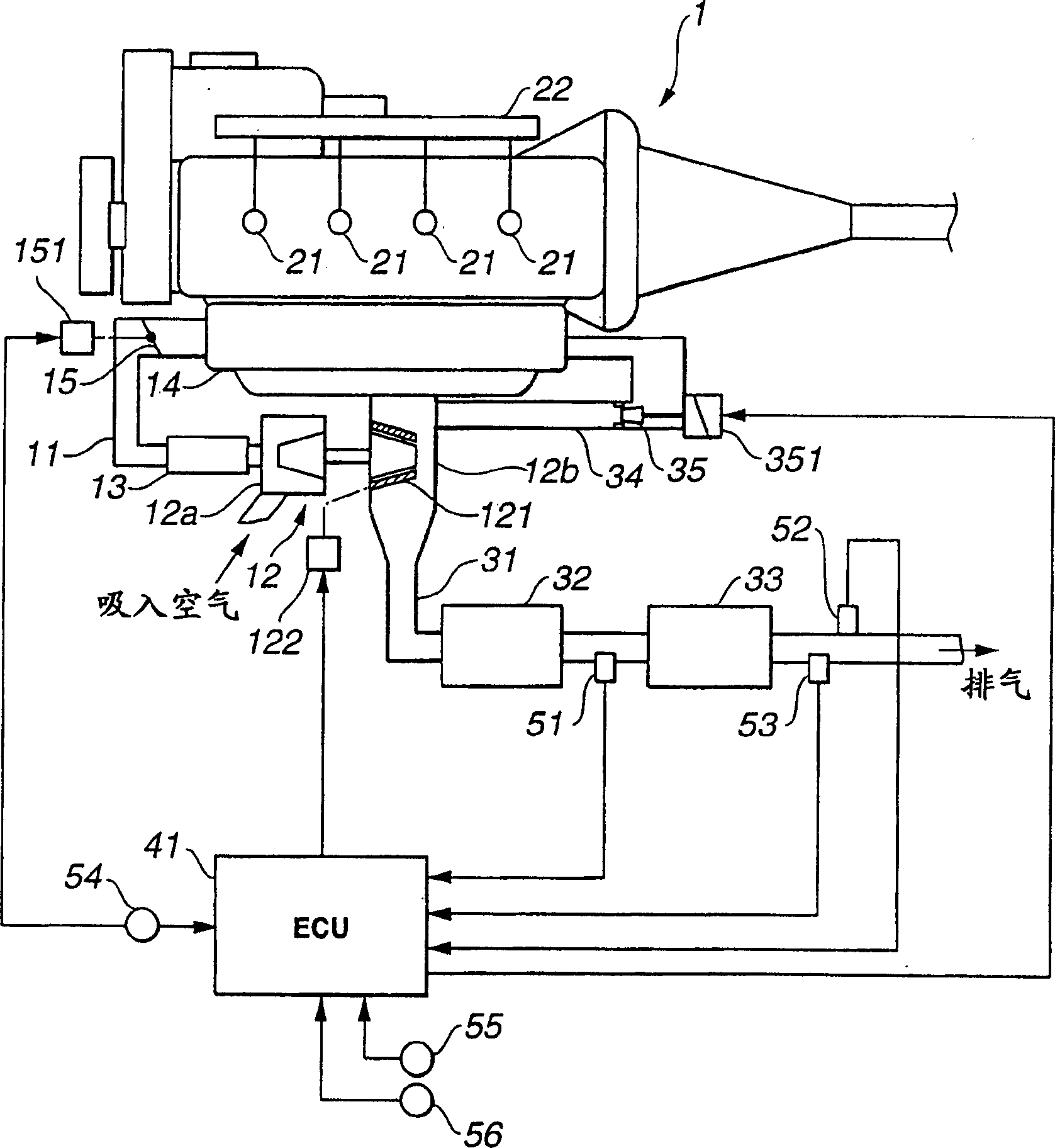

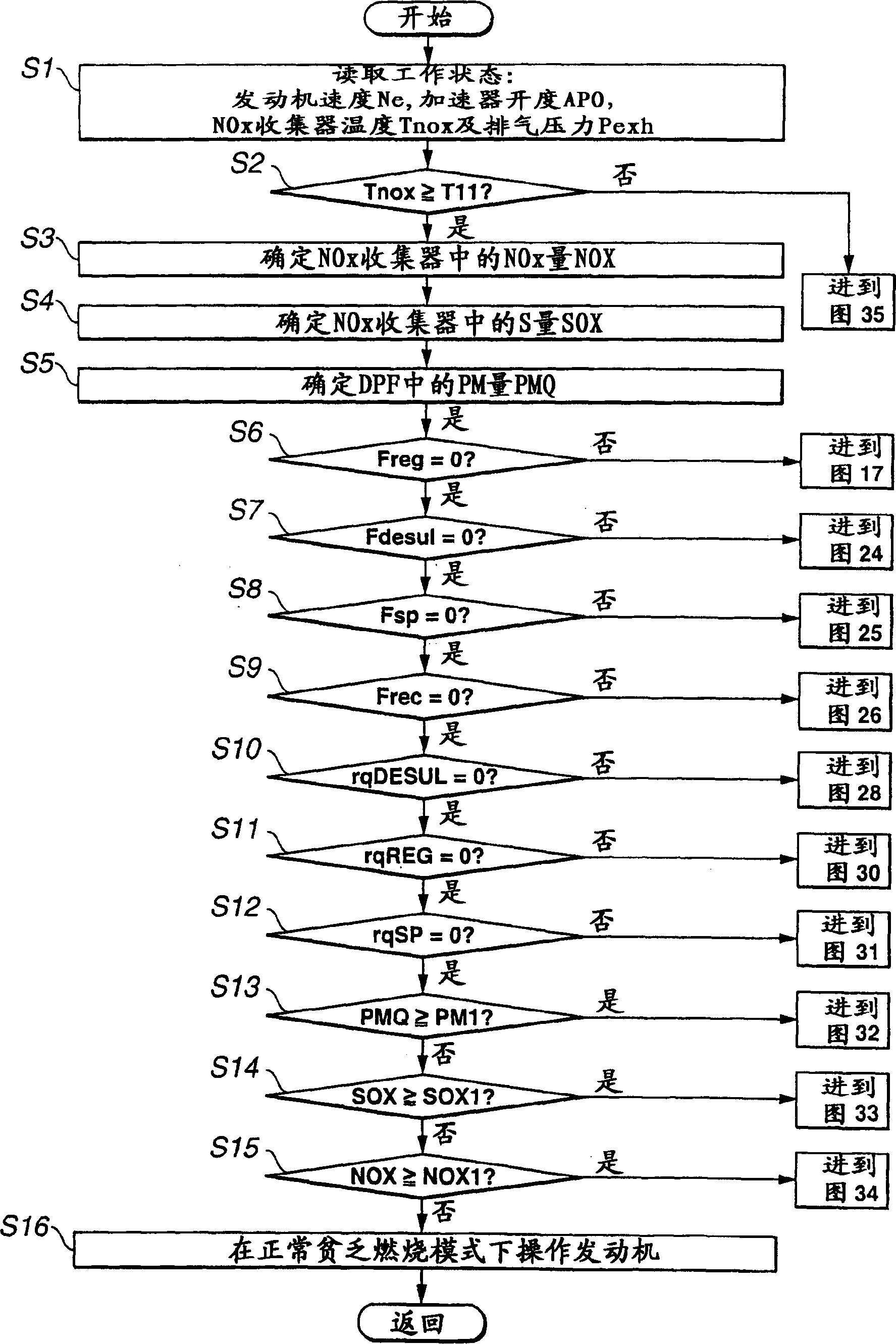

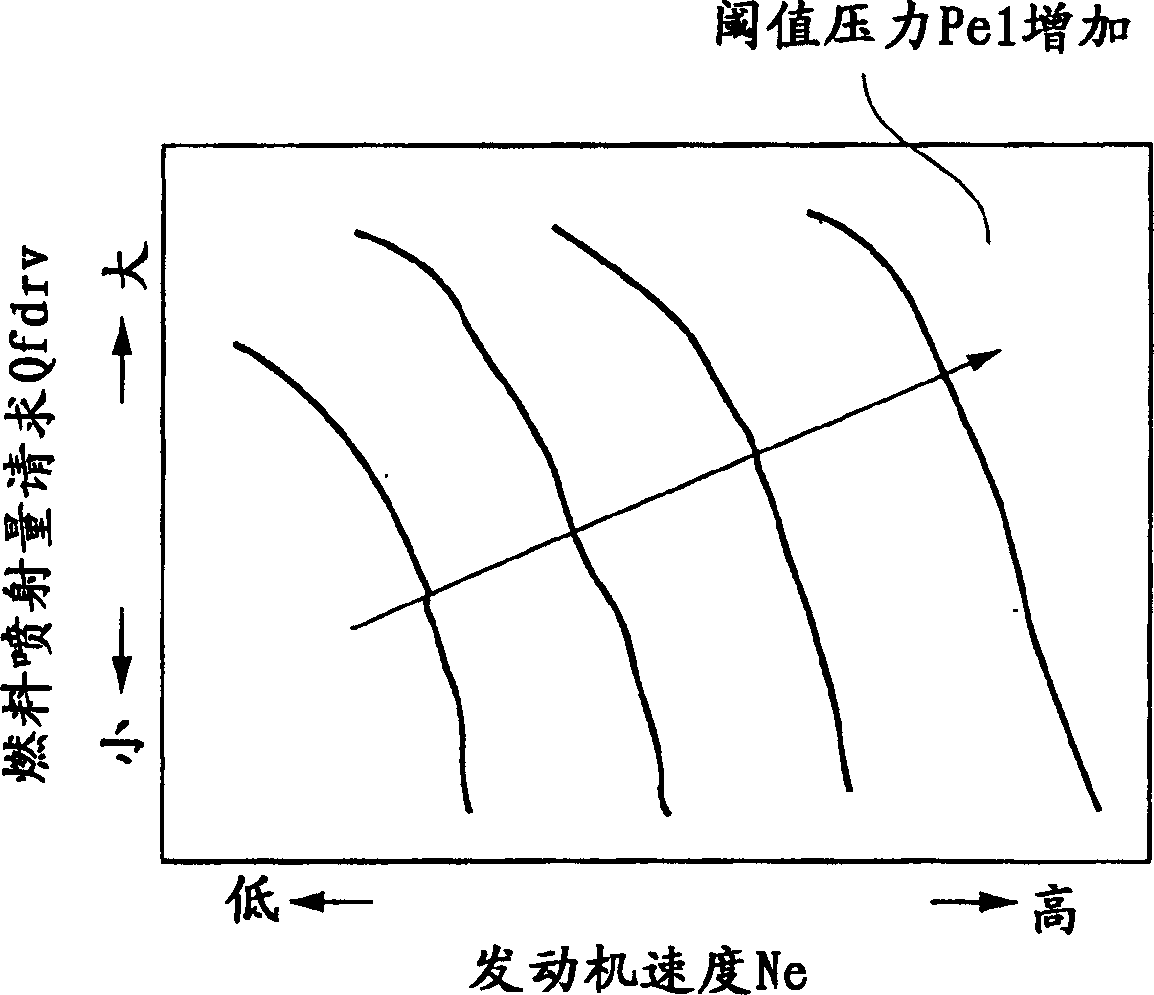

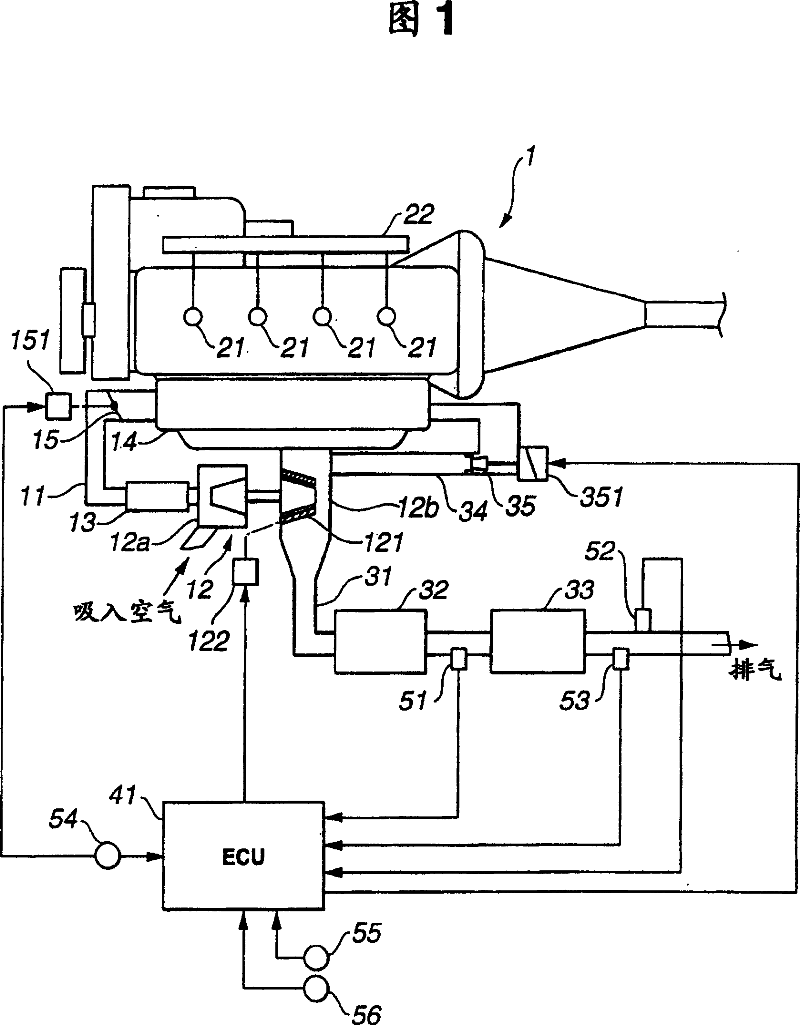

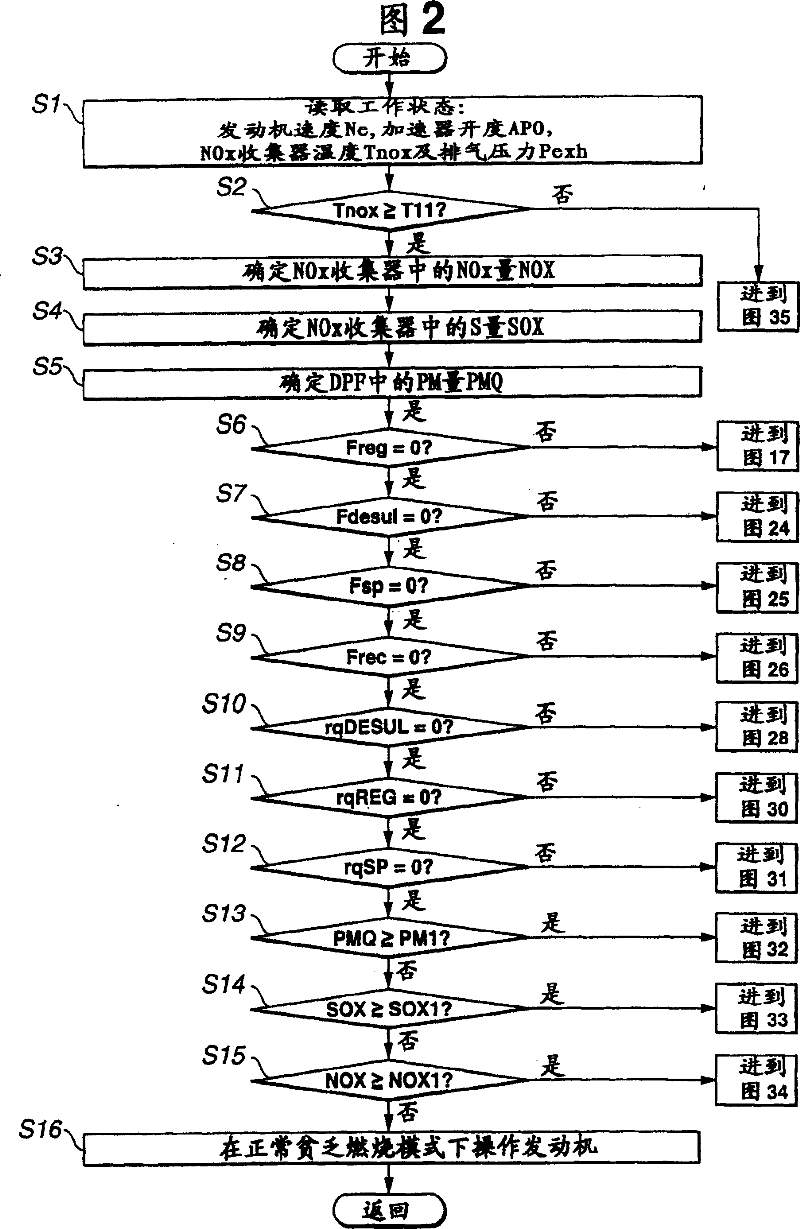

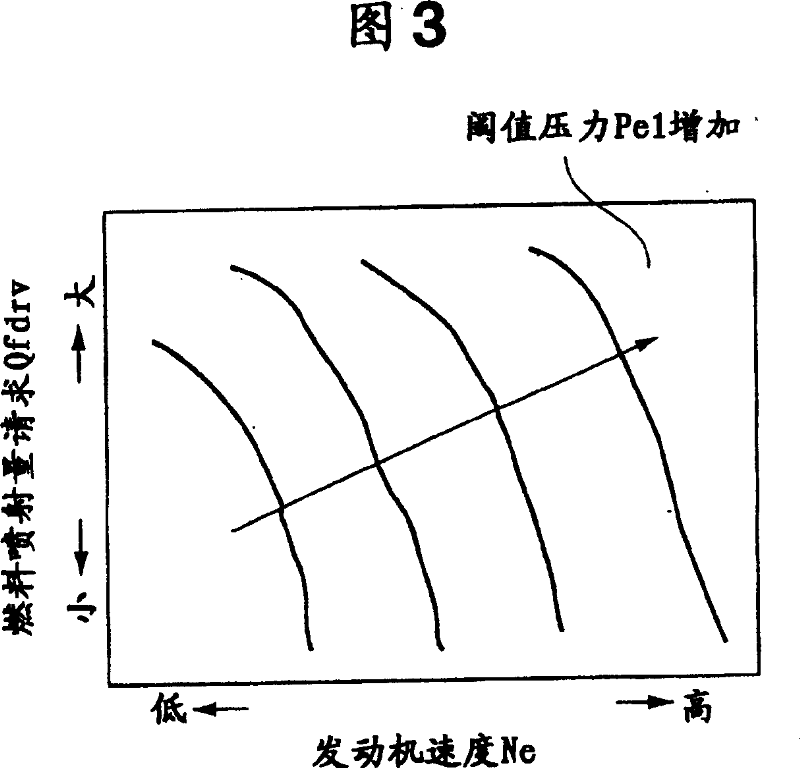

Combustion control apparatus for internal combustion engine

InactiveCN1576531AReduce excess air ratioIncrease exhaust temperatureElectrical controlInternal combustion piston enginesParticulatesOperating point

A combustion control apparatus operates an internal combustion engine in a split retard combustion mode during regenerating an exhaust purifier such as a particulate filter. In the split retard combustion mode, the combustion control apparatus controls a first fuel injection to cause preliminary combustion at or near top dead center, and controls a second fuel injection to cause main combustion after an end of the preliminary combustion. In this manner, the combustion control apparatus controls an exhaust gas temperature, or an exhaust air-fuel ratio, without increasing exhaust smoke. During the split retard combustion mode, the combustion control apparatus controls an EGR rate of the engine. The EGR rate in the split retard combustion mode is set lower than in the normal combustion mode, in each operating point of the engine.

Owner:NISSAN MOTOR CO LTD

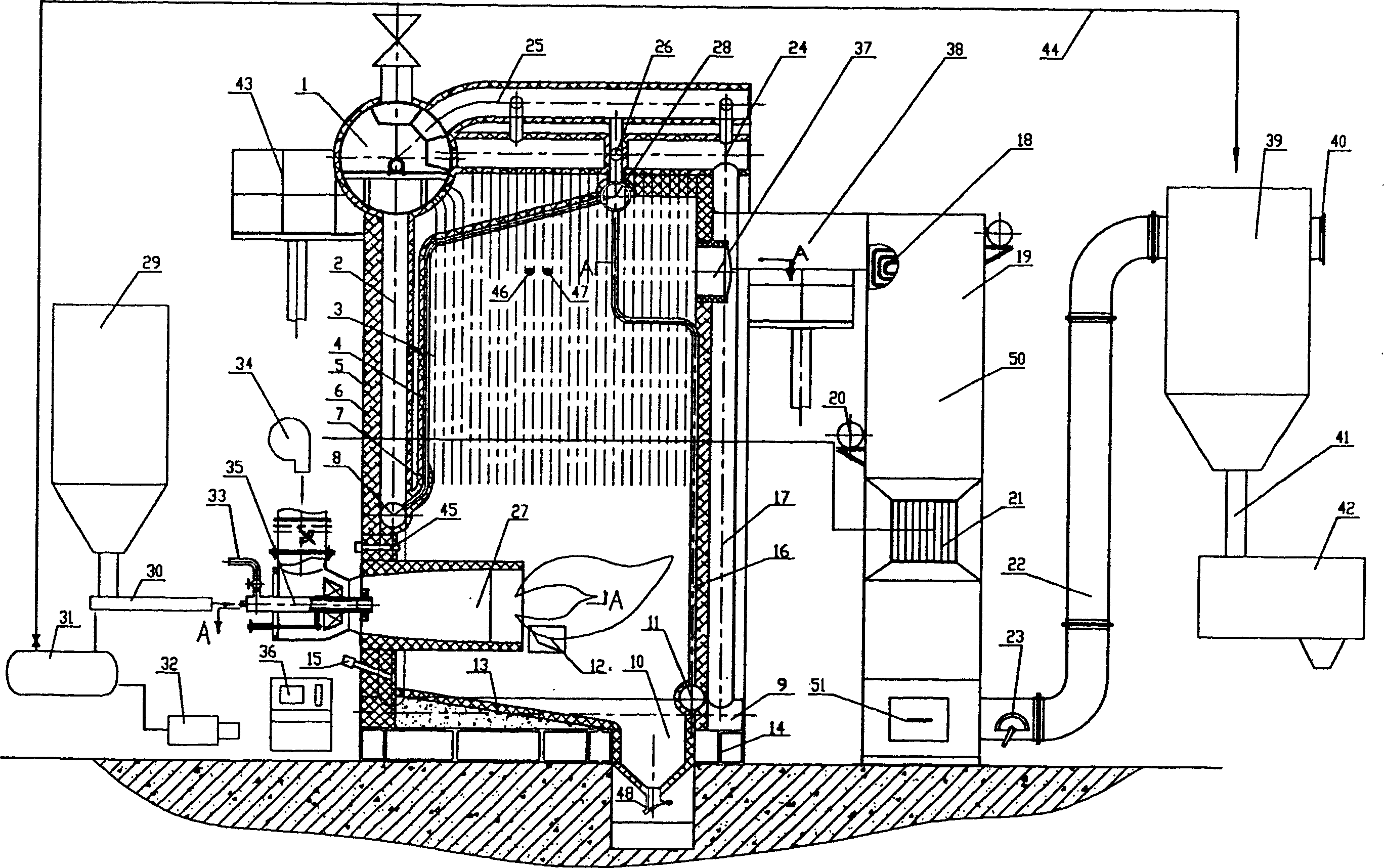

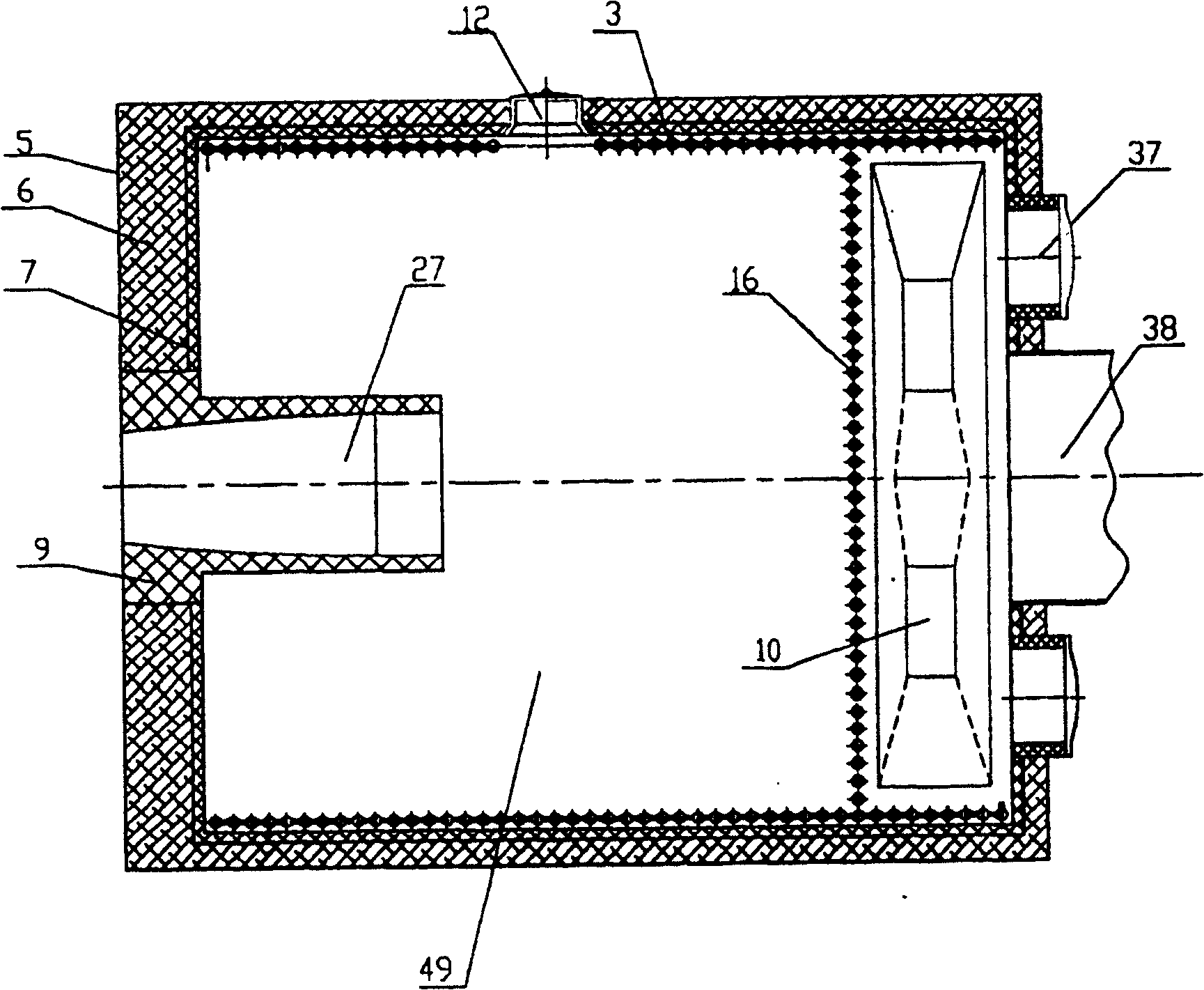

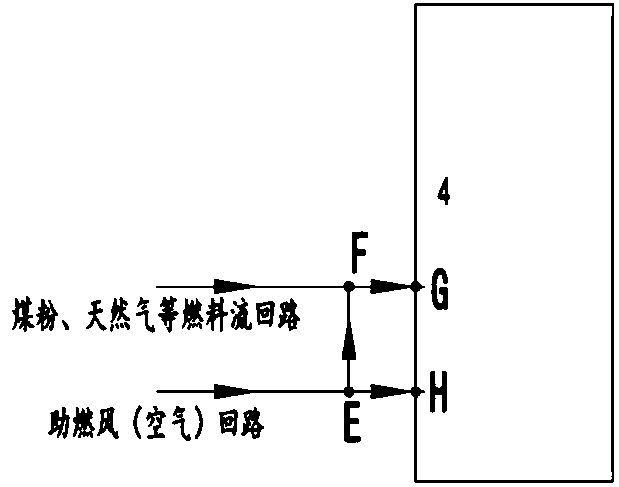

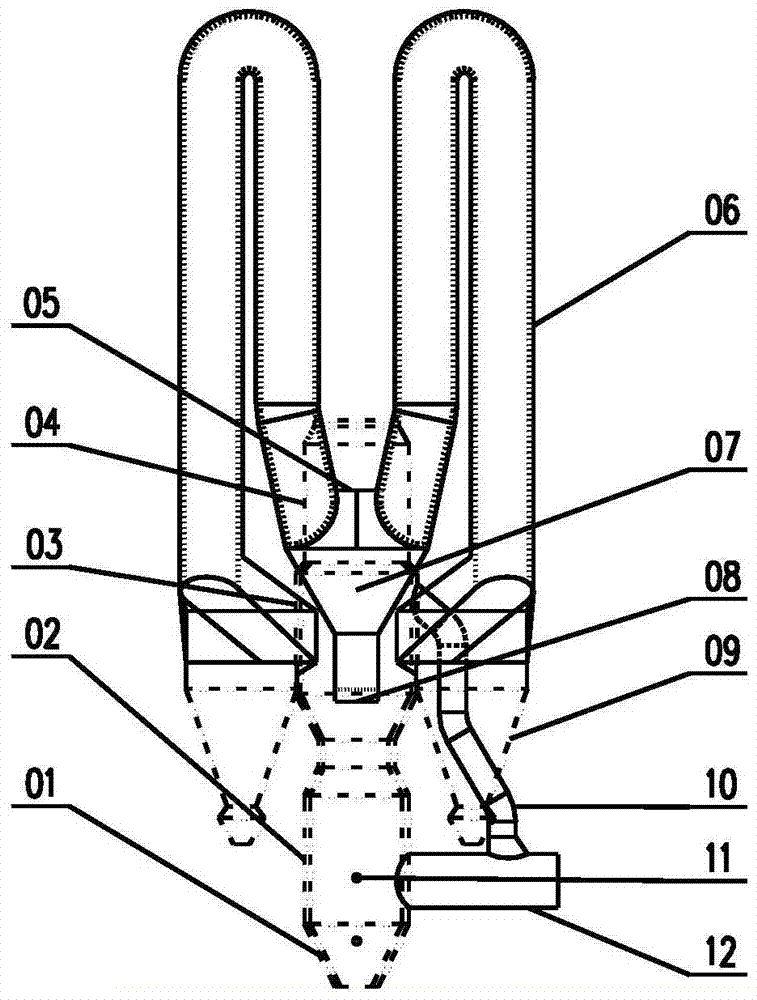

Industrial boiler of multi-fuel burning using ultrafine coal dust as main fuel

InactiveCN1724928AImprove burnout rateFully mixed combustionBurnersCombustion using multiple fuelsMultifuelCoal dust

The invention discloses an industrial boiler fired by multiple mixed fuels with superfine powder coal(water coal slurry) as the primary and natural gas or oil products as the auxiliary, and it is an industrial boiler with the advantages of high firing efficiency, low cost, auto control and reduction of environmental pollution, especially applied to middle-small scale industrial boilers.

Owner:姜政华

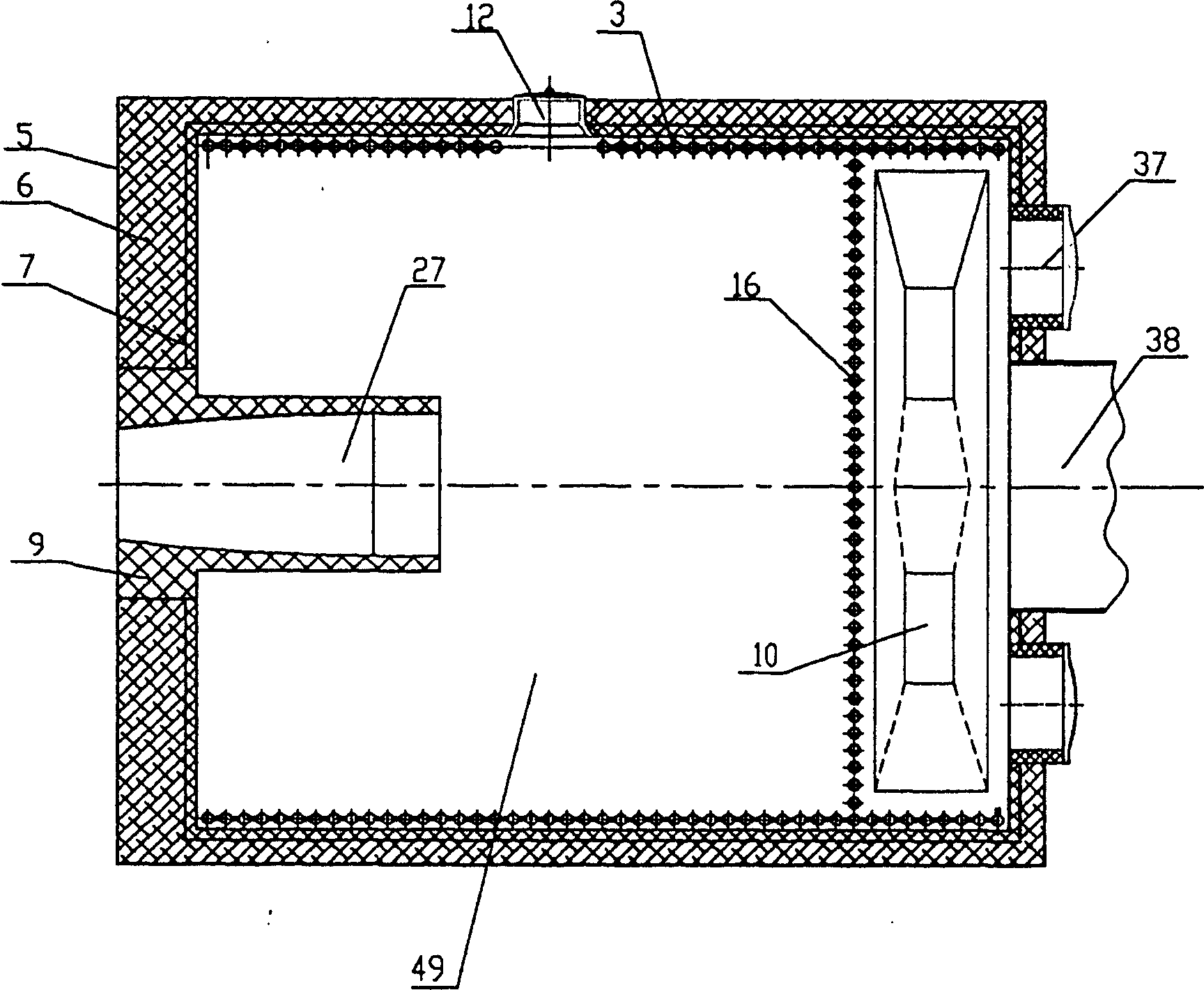

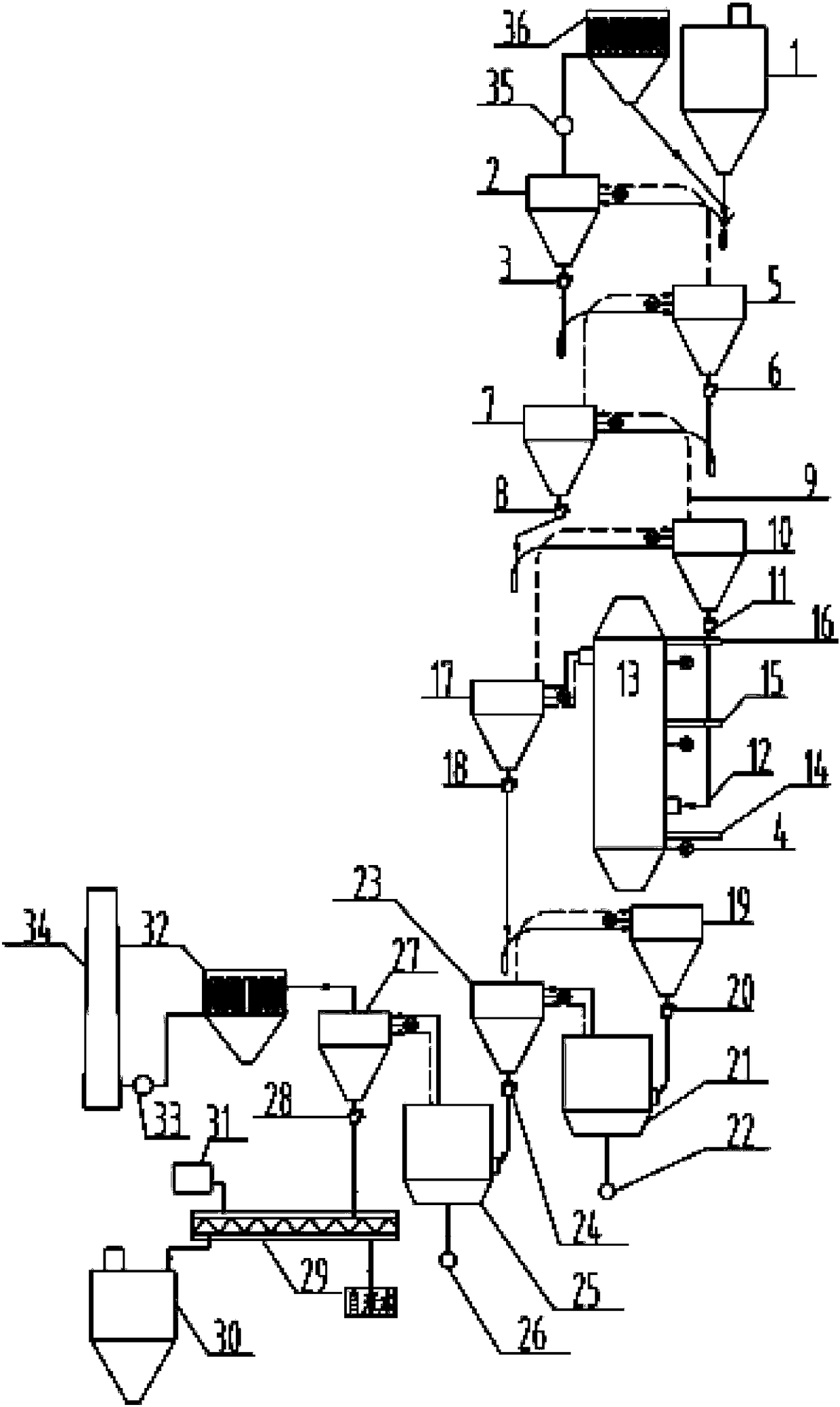

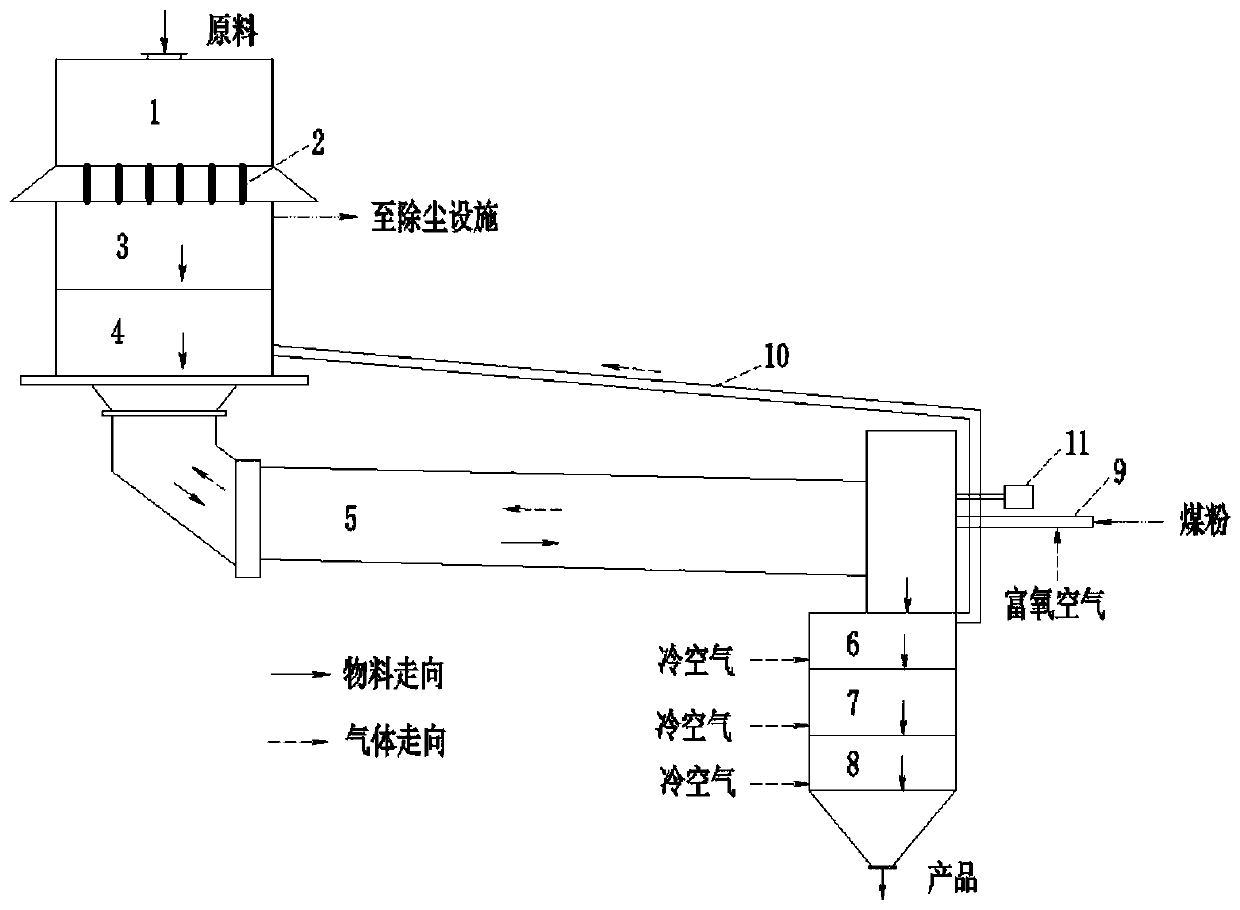

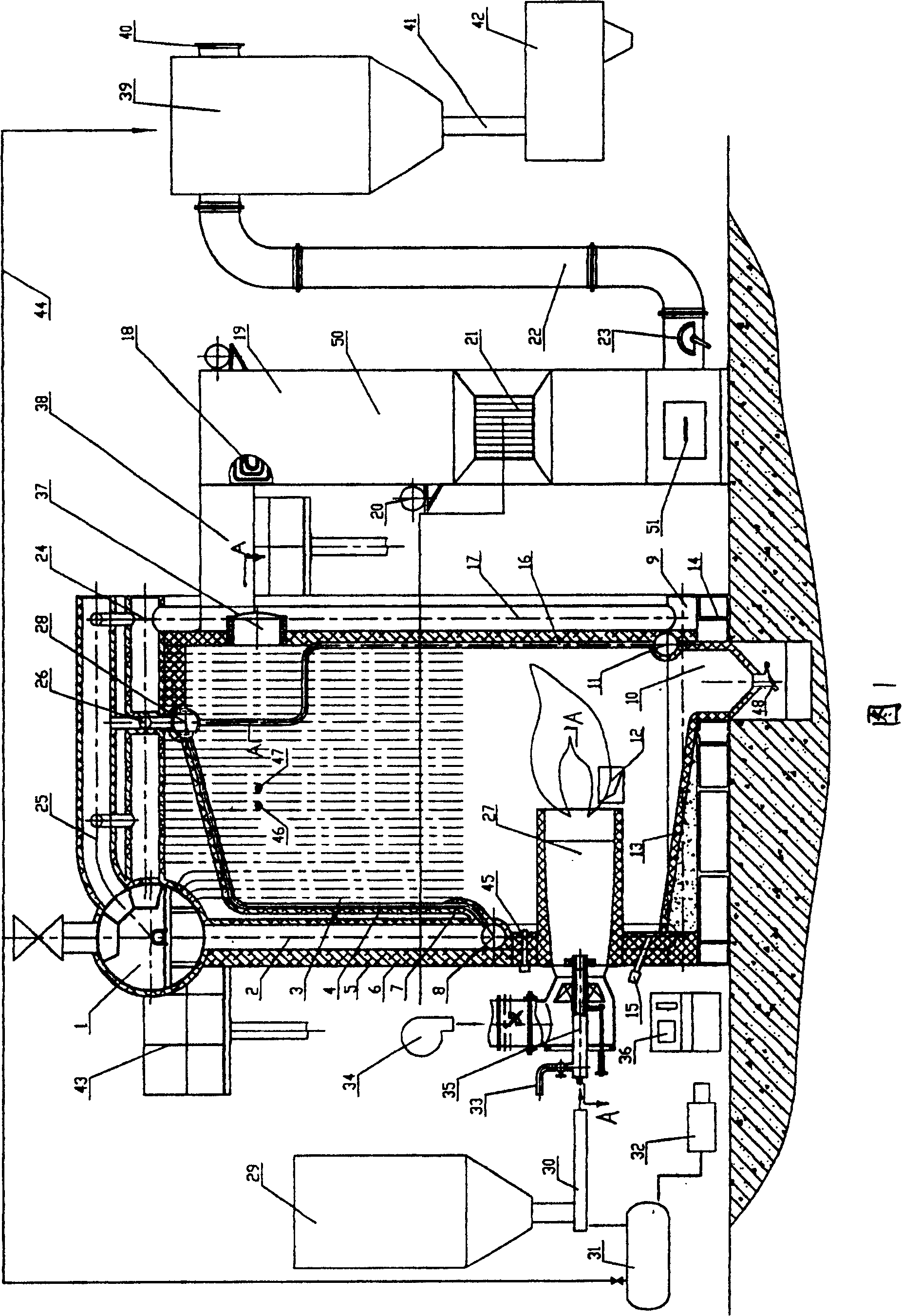

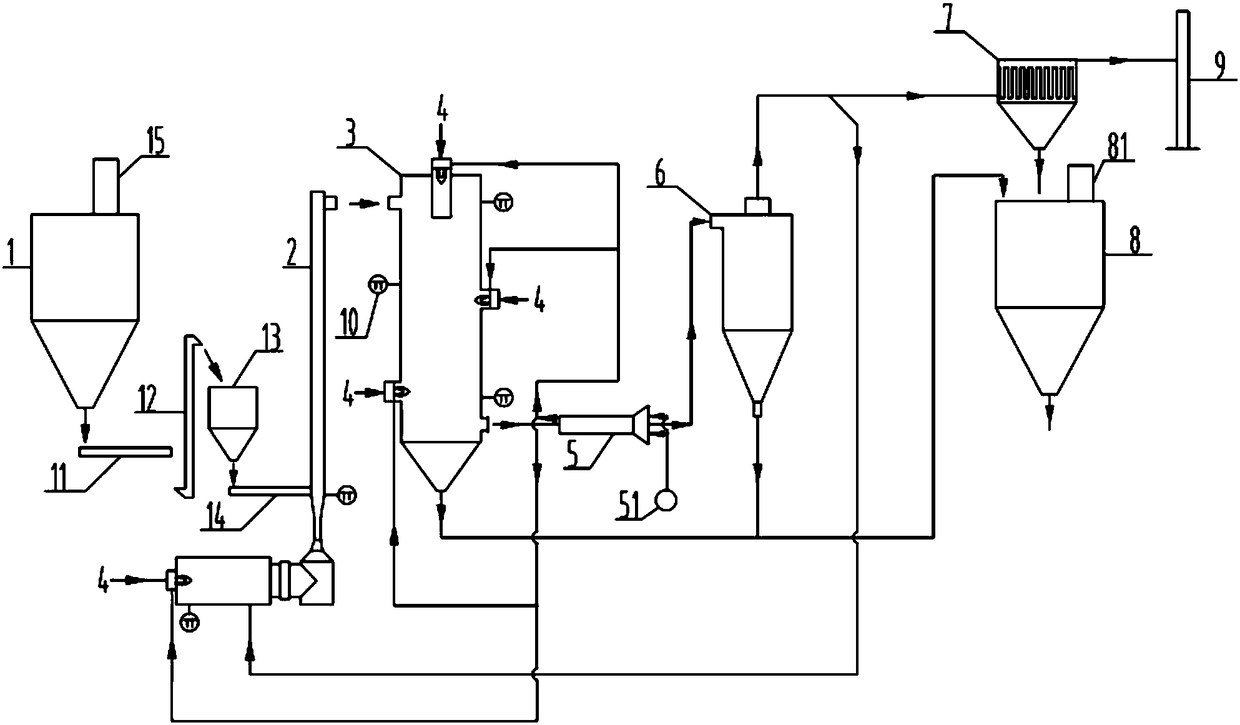

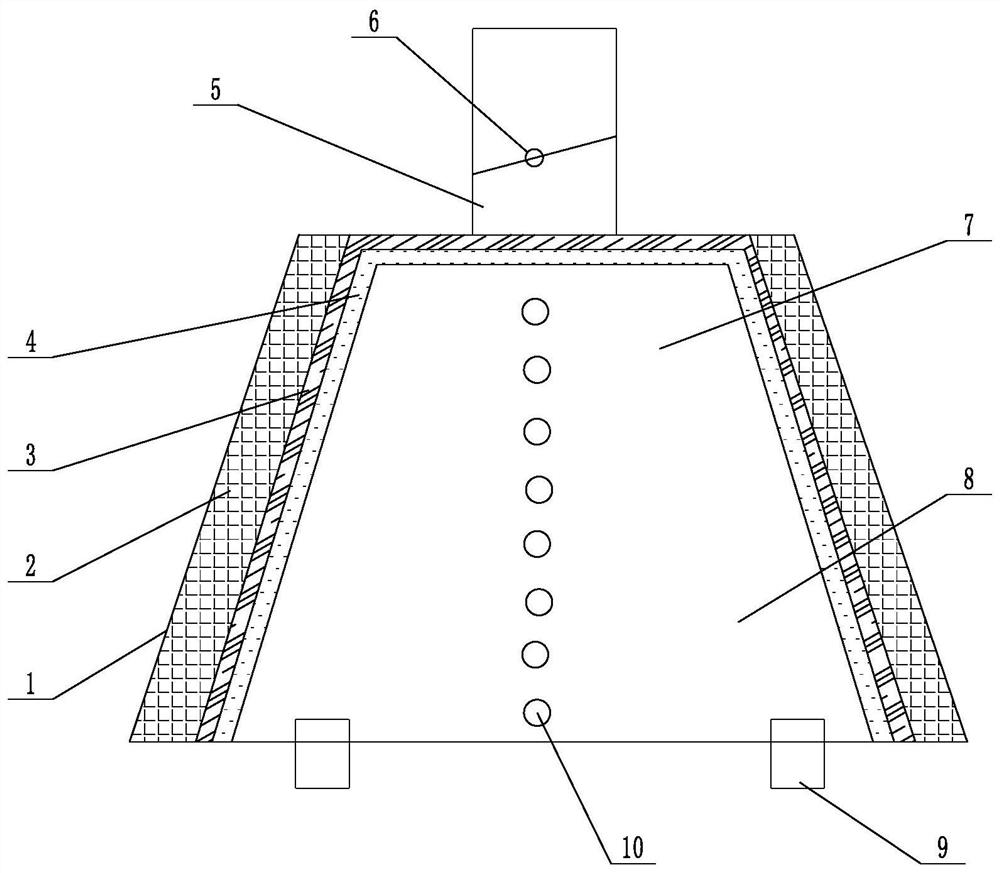

Light roasting MgO suspension calcination production process and device

The invention discloses a light roasting MgO suspension calcination production process and device. The device comprises a raw material cabin, a five-stage cyclone preheating tube, a suspension calcination furnace, three sets of combustion systems, a three-stage suspension cooling cylinder, a two-stage fluidized bed, a waste gas treatment device, a sleeve type water cooling spiral conveyor, a finished product cabin, a fan, a turning plate valve, a temperature detector and the like. The defects that the existing light calcination MgO calcination equipment has the narrow calcination temperature regulation range, the activity of the produced light calcination MgO product is single, collapse materials under the abnormal work conditions cannot be timely treated, the stable operation of the wholesystem is influenced, and the like are overcome. The combustion systems are arranged in the height direction and the radial direction of the suspension calcination furnace; the two-stage fluidized bed is arranged at the discharging opening of the suspension calcination furnace; the problem of the material collapse phenomenon occurring under the abnormal work conditions can be solved; meanwhile, the precise different-region calcination of the MgO with different activities can be realized; the popularization and application of the light calcination MgO in the building industry can be facilitated.

Owner:ZHENJIANG SOBUTE NEW MATERIAL CO LTD +1

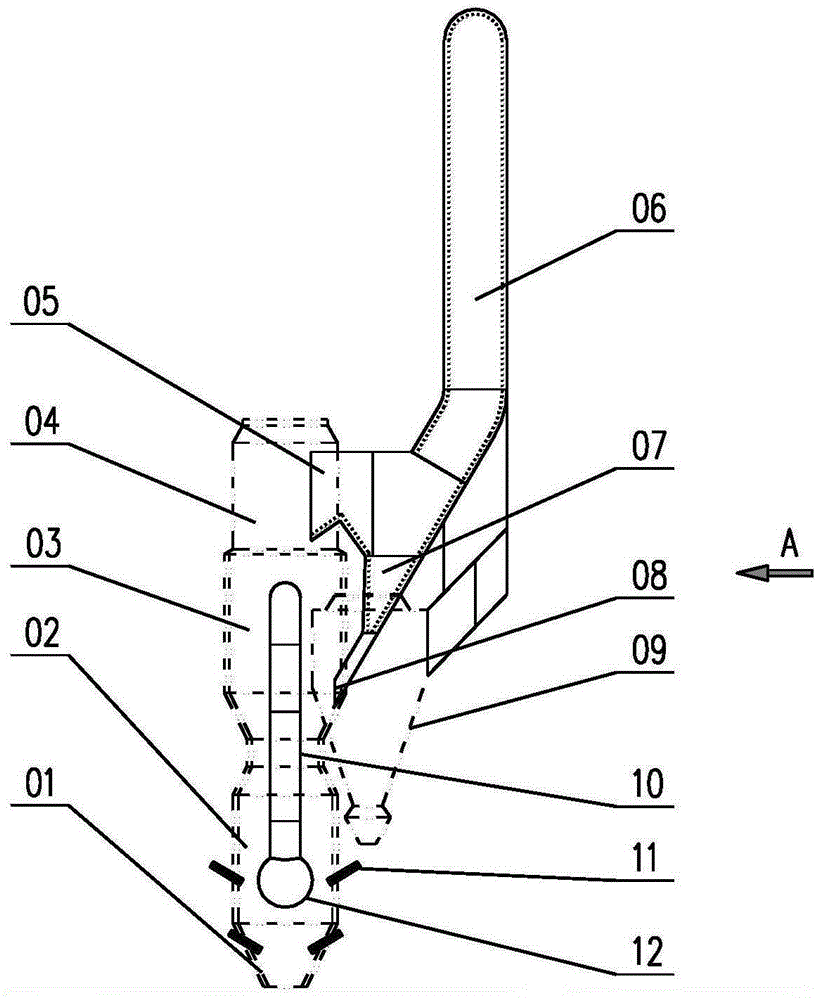

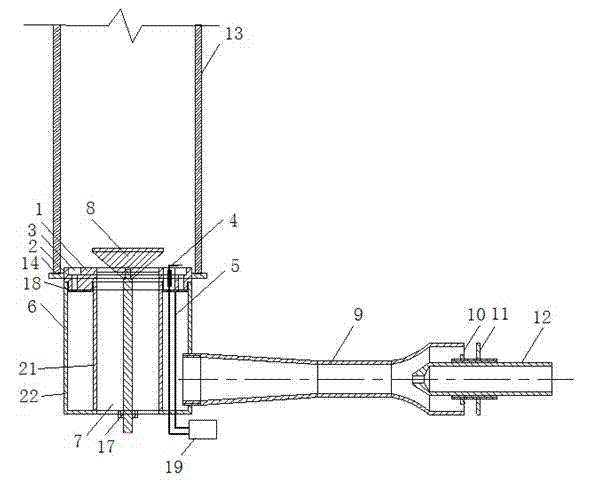

Atmospheric gas radiation heating device

ActiveCN101900324AHigh blacknessImprove Radiation AbilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelEngineeringPetrochemical

The invention discloses an atmospheric gas radiation heating device which comprises a burner, a quartz glass radiant tube and an igniter, wherein the burner comprises a nozzle, an injection tube and a burner head part; the burner head part consists of an inner tube and an outer tube which are concentric, and one end of an annular belt between the inner tube and the outer tube is sealed; the injection tube is communicated with the annular belt; the end of the sealed annular belt of the inner tube is a secondary air inlet, while the other end of the inner tube is provided with an inner flame cover; a corresponding end of the outer tube is provided with an outer flame cover, and a flame hole is formed between the inner flame cover and the outer flame cover; and the inner tube is internally provided with a secondary air conditioning device. The invention has simple structure, convenient mounting, low manufacture and maintenance cost, high burning strength, long service life and large burner load regulation ratio, can meet the requirement of different heating powers to a larger extent and can be widely applied to industrial kilns of the industries of steel, petrochemical industry, machinery, building materials, boilers, waste incineration, and the like.

Owner:ENN CHINA GAS ENVESTMENT

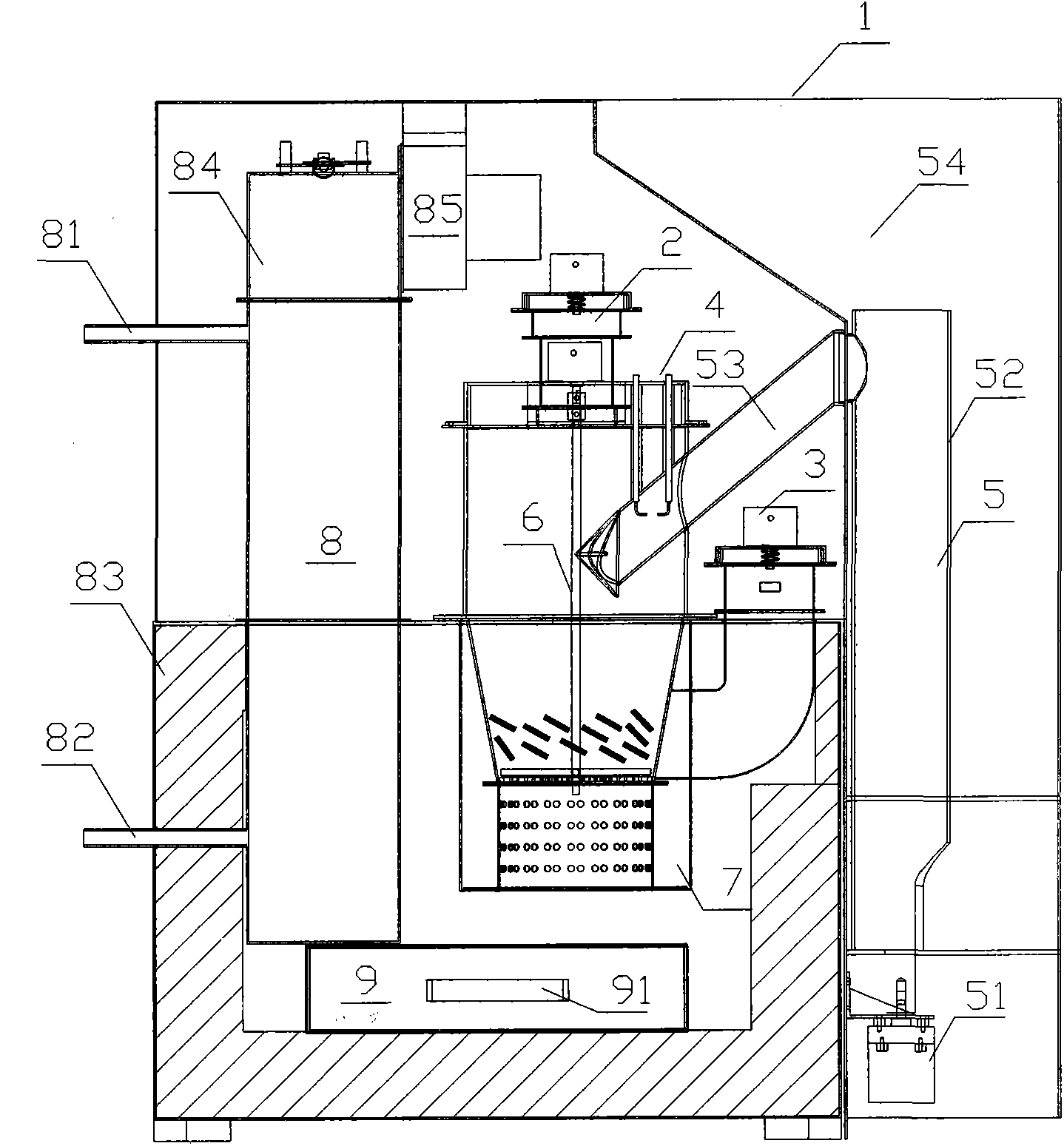

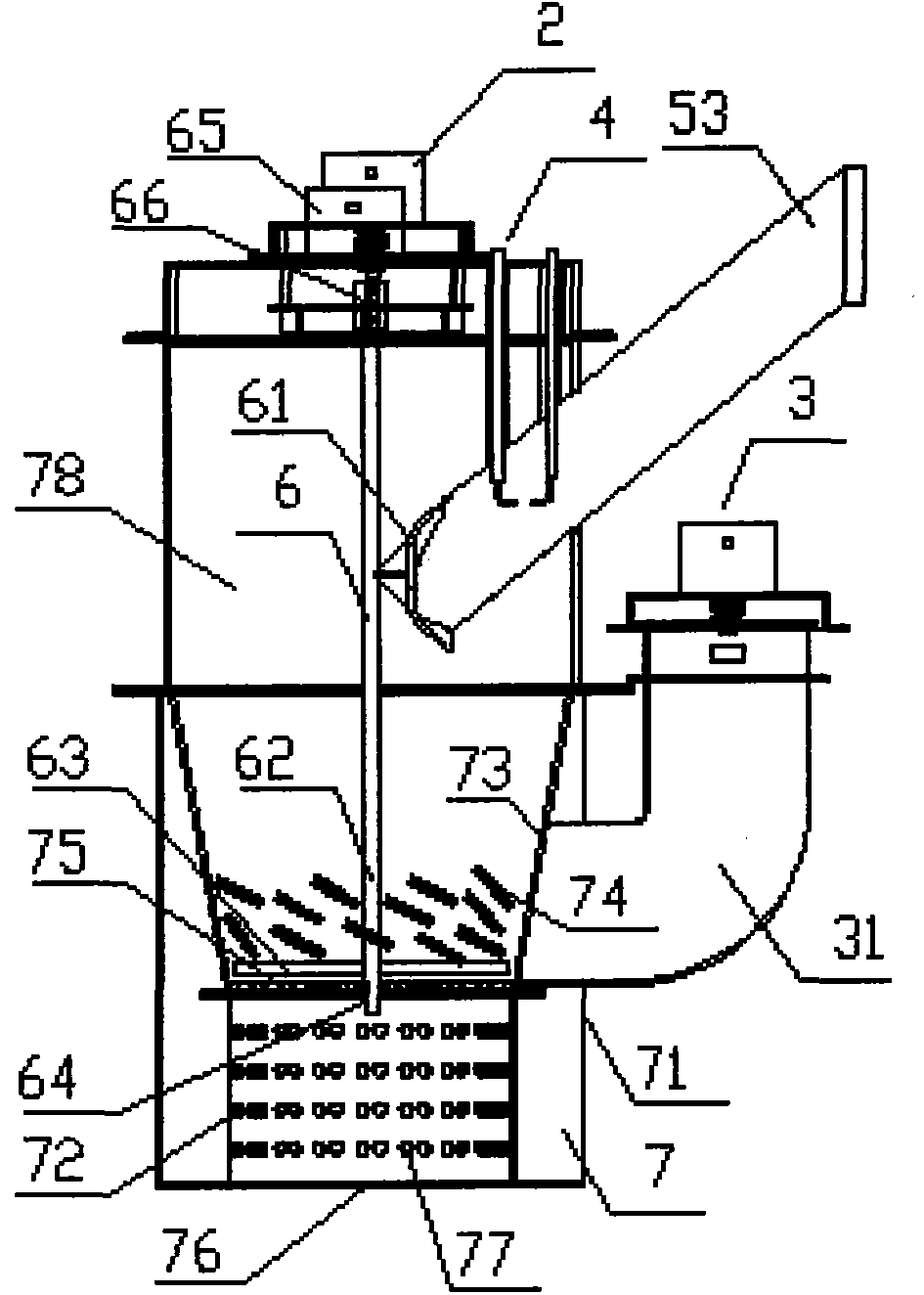

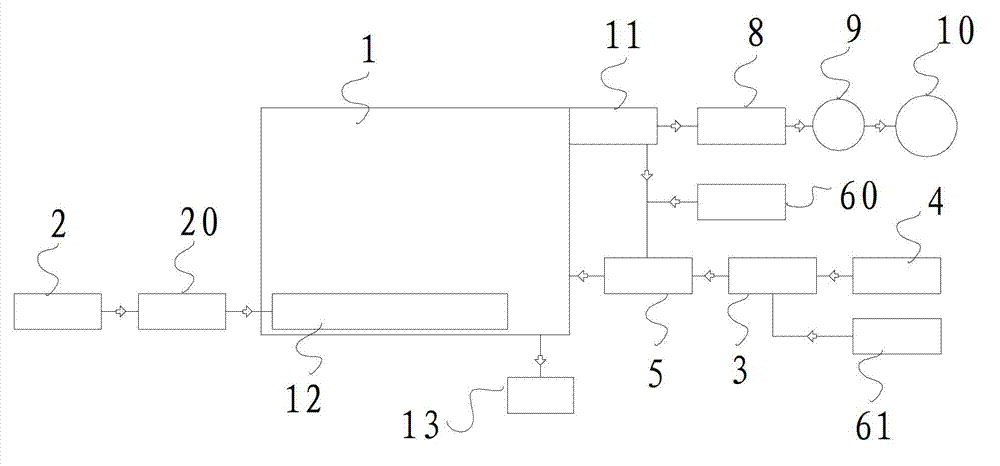

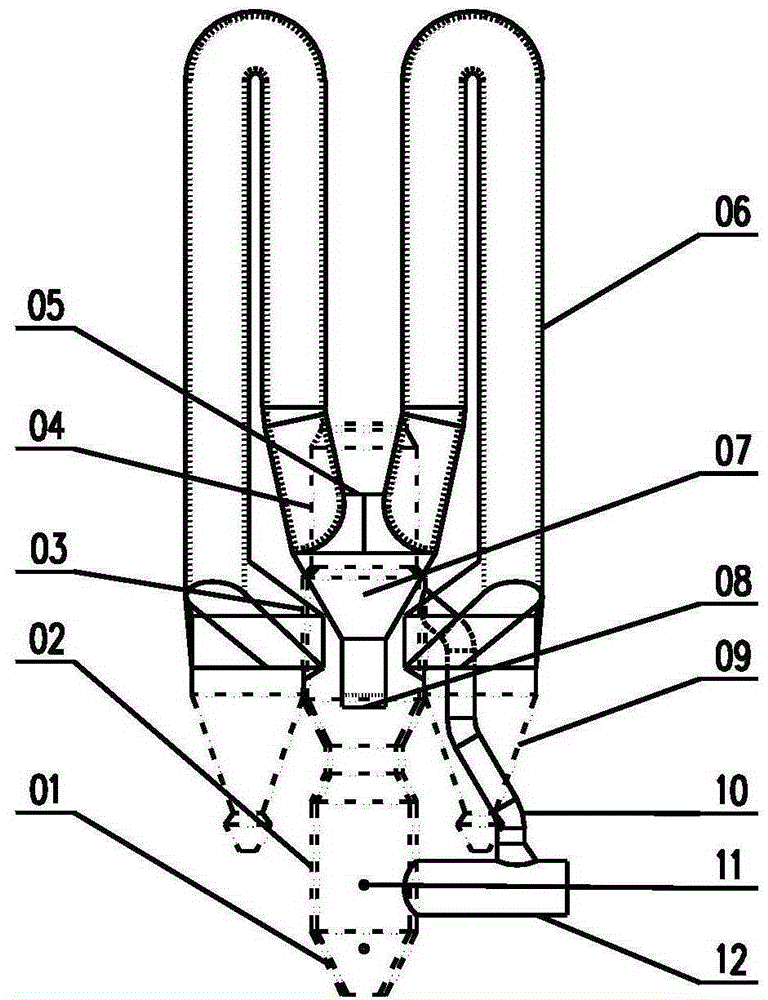

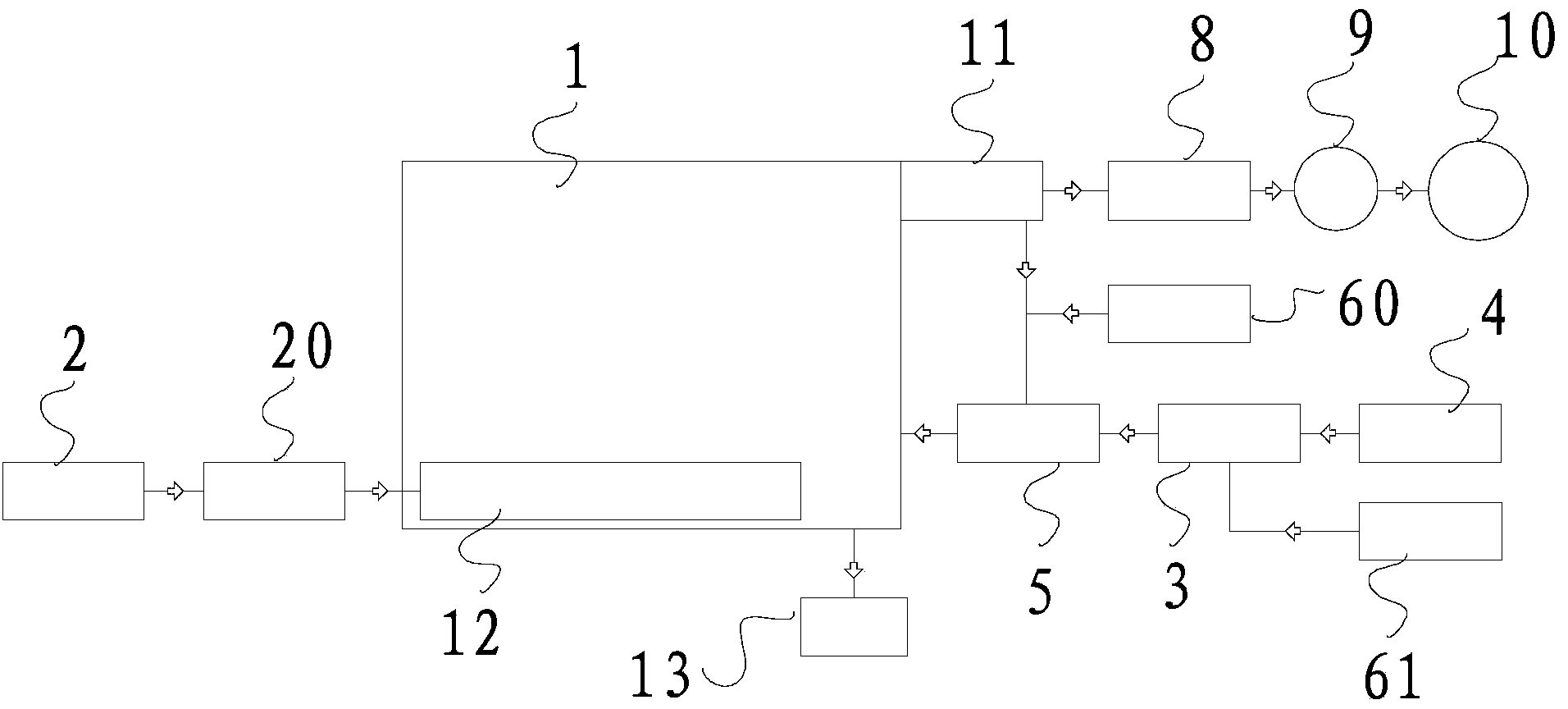

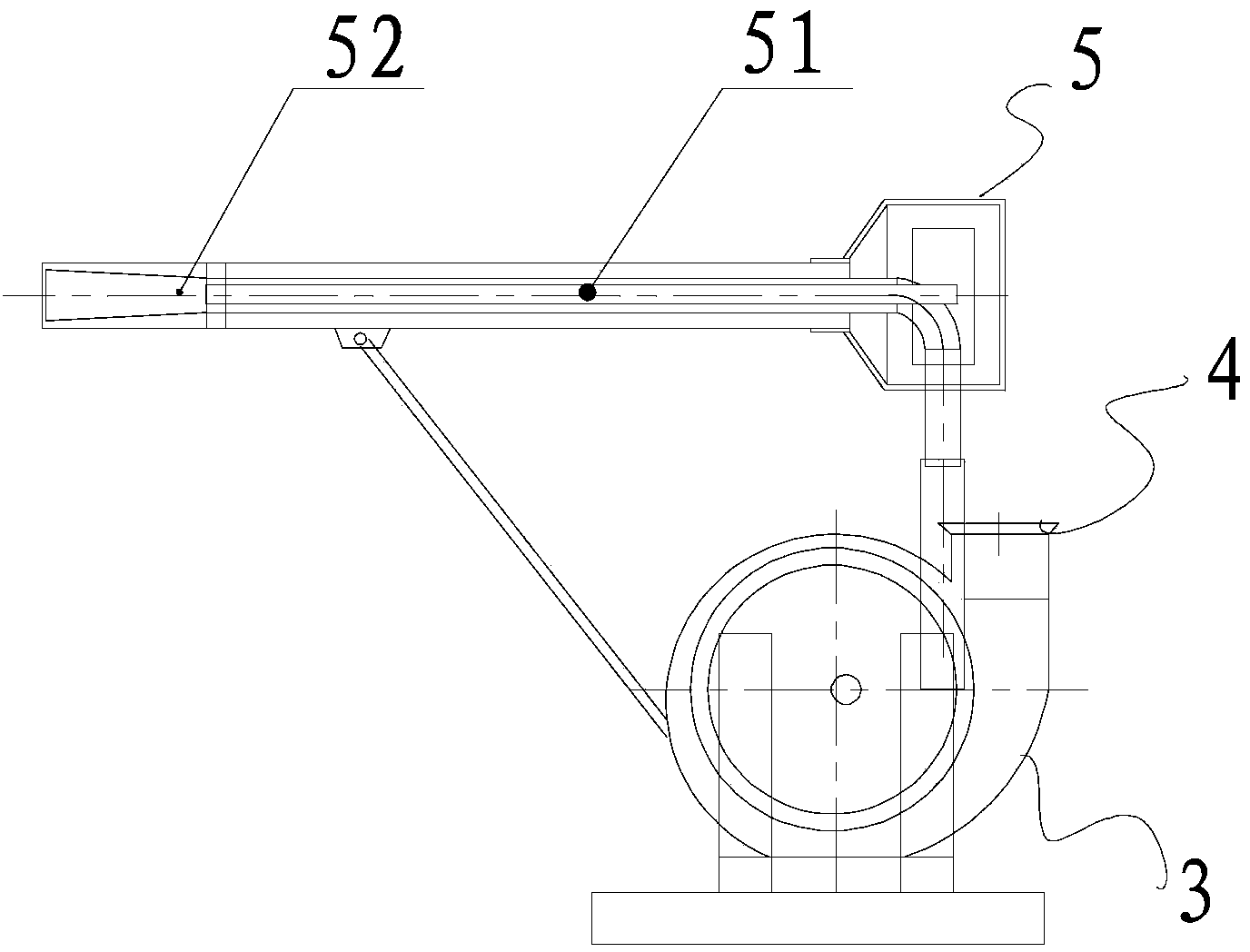

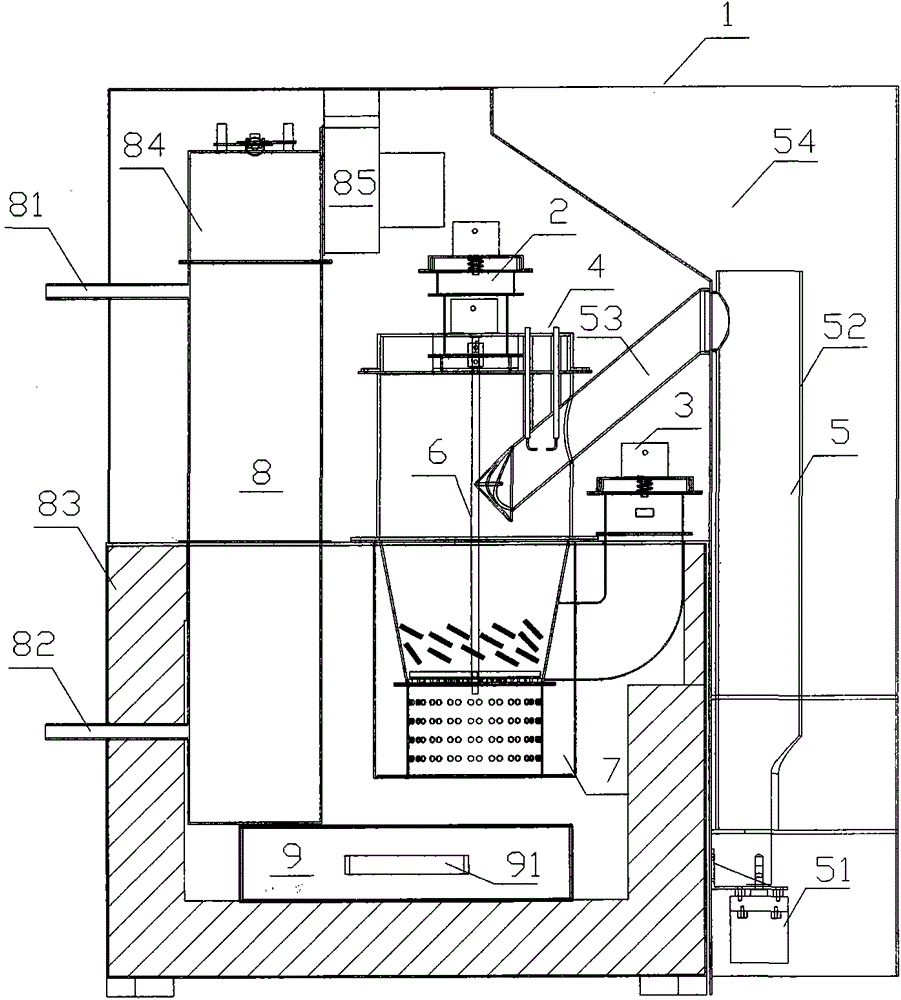

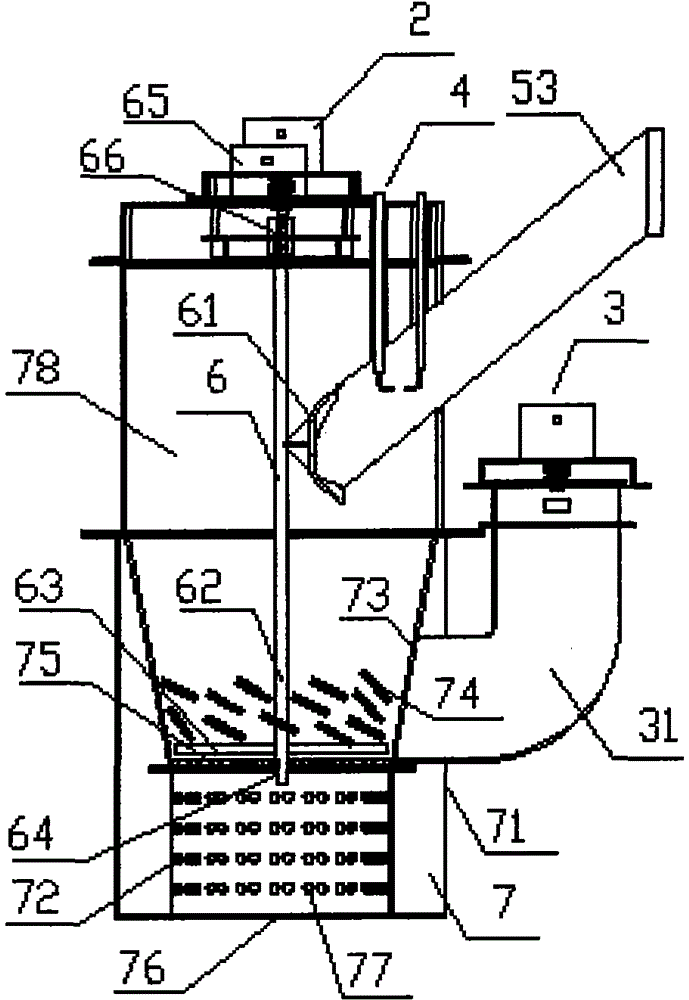

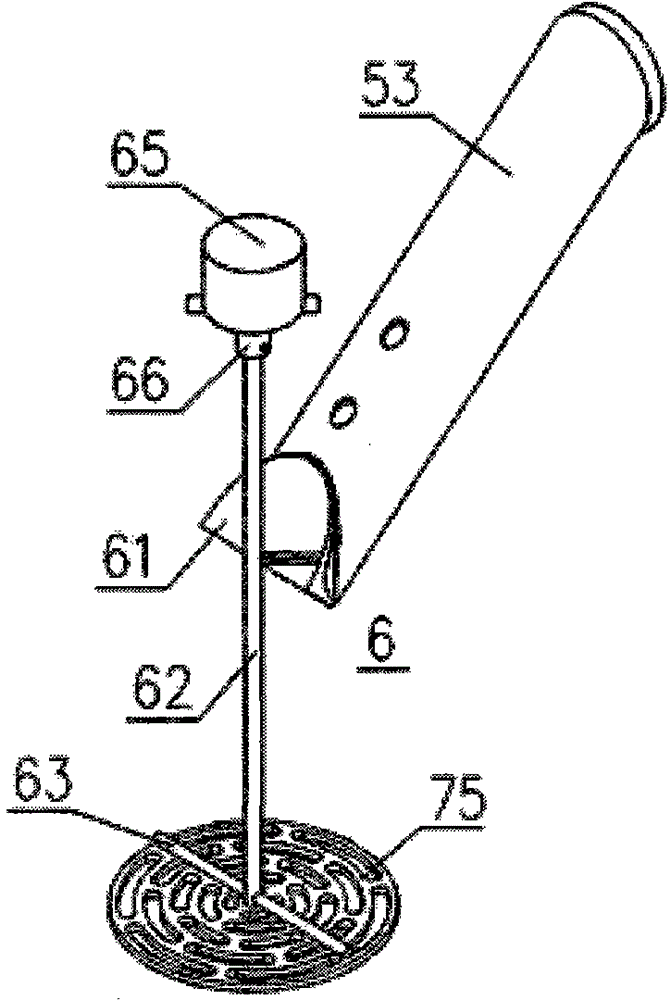

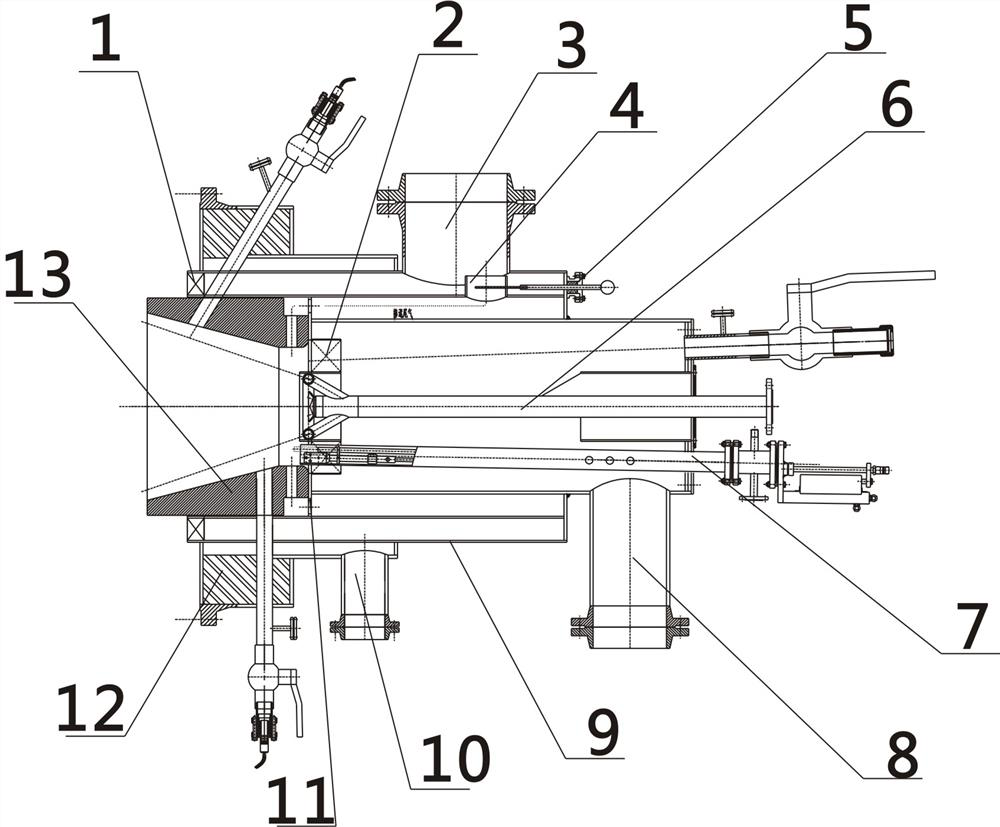

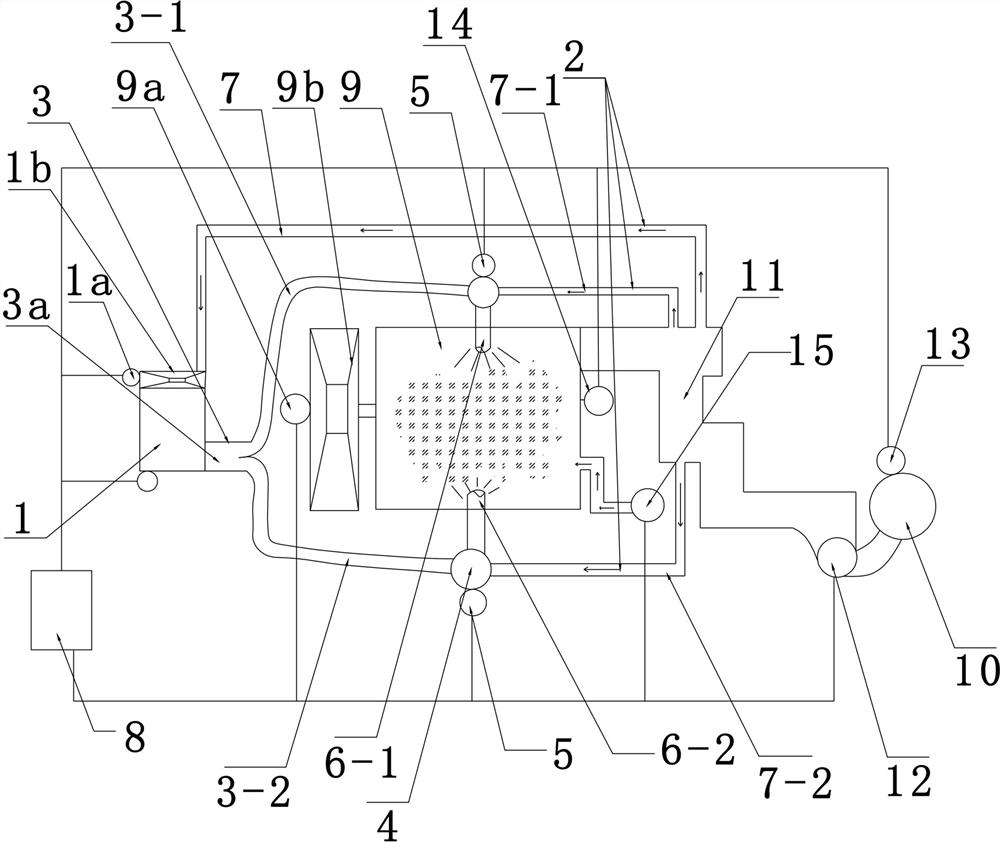

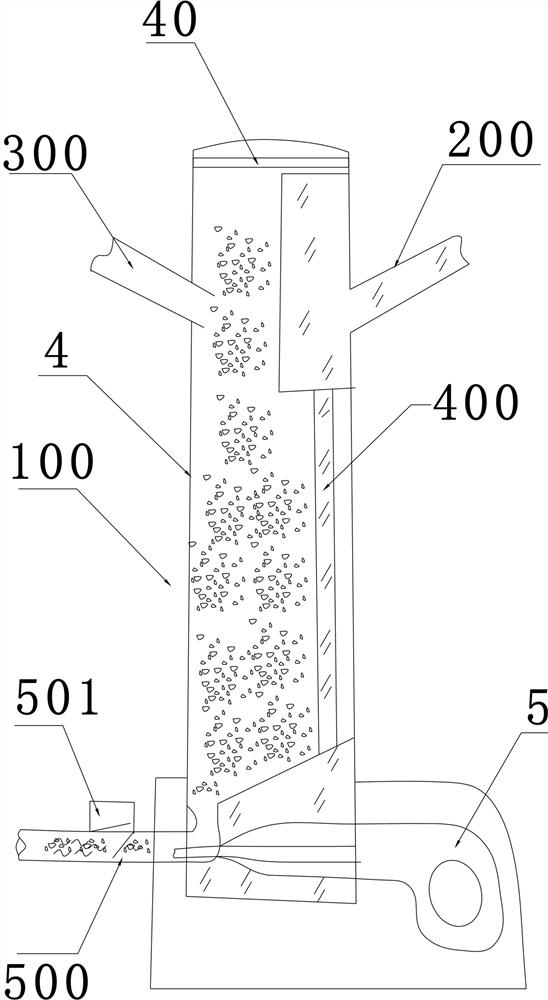

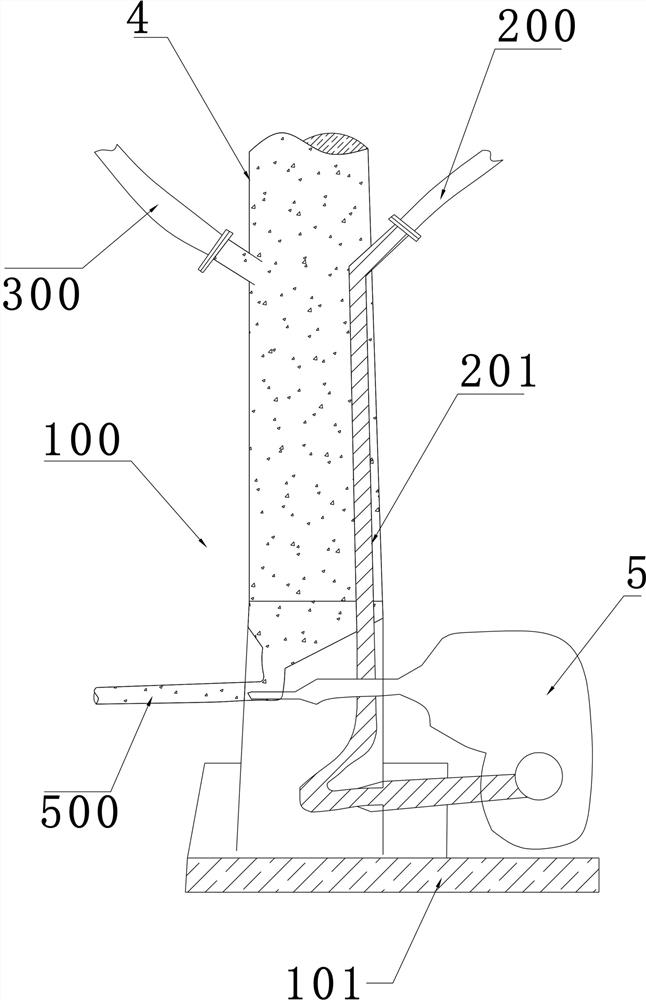

Stable and effective biomass pellet fuel combustion device and method

ActiveCN103912866APromotes efficient combustionImprove combustion efficiencySolid fuel combustionCombustion apparatusAutomotive engineeringHigh energy

The invention discloses a stable and effective biomass pellet fuel combustion device and method. The stable and effective biomass pellet fuel combustion device comprises a combustion furnace shell, a primary air device, a secondary air device, an ignition device, a feed device, a burner, a heat exchange device, a stirring device and an ash tray. The stable and effective biomass pellet fuel combustion device and method are capable of guaranteeing the stable and effective combustion of the fuel and preventing slagging and caking in combustion so as to realize continuous stable combustion. The volatile component and fixed carbon in the biomass are burnt in two stages, the air quality is controlled, and the pollutant emission is lowered in combustion. The ignition device achieves low ignition energy consumption and low ignition pollutant emission; the combustion is safely isolated from stored materials; the stable and effective biomass pellet fuel combustion device and method have high energy conservation and emission reduction benefit and application value.

Owner:济南长城空调公司

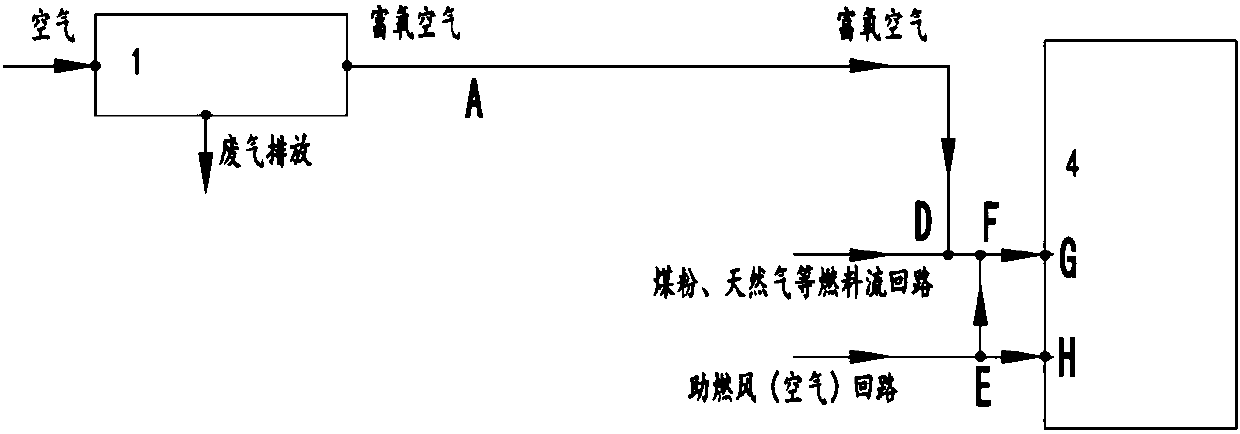

Oxygen-enriched air mixed blowing combustion adjuvant boiler energy-saving method and equipment used thereby

InactiveCN101413674AHigh flame temperatureLower the ignition temperatureSolid fuelsIndirect carbon-dioxide mitigationEngineeringKiln

The invention provides an energy-saving method of an oxygenized air mixed blowing supporter combustion boiler and equipment used by the method, belonging to an energy-saving and emission-reduction combustion technology of the boiler; the invention more particularly relates to an efficient energy-saving combustion technology combining oxygenized air technology and supporter combustion technology and equipment thereof; the effects of energy-saving and emission-reduction of the invention are different according to the different running situations and equipment of the boiler (kiln); the statistics obtained from the cases studies of dozens of boilers and kilns proves that the lowest coal-saving ratio is 5.7%, the highest coal-saving ratio is 25%, and the coal-saving ratio of a pulverized coal fired boiler of 670t / h in a thermal power plant is 8.34%, so that the statistical data shows that the effects of energy-saving and emission-reduction of the technical improvement measure are excellent, the technology can be widely popularized, and good social and economical benefits can be brought about.

Owner:张开军

Process method for preparing active calcium oxide through oxygen-enriched calcination

InactiveCN110627384AHigh activityLow ignition pointCalcium/strontium/barium oxides/hydroxidesDecompositionHeat transfer efficiency

The invention discloses a process method for preparing active calcium oxide by oxygen-enriched calcination. The process method the following steps of firstly crushing and sieving raw limestone to enable the particle size of the raw limestone to be 10-55 mm, conveying the raw limestone into a stock bin with a circular cross section, wherein the stock bin is arranged at an upper part of a vertical preheater; then, uniformly conveying the raw materials in the stock bin into the vertical preheater through a blanking pipe, and preheating the raw materials by using high-temperature kiln gas and cooling gas of a vertical cooler; then, feeding the materials into a rotary kiln, and importing oxygen-enriched air from a kiln head to perform oxygen-enriched calcination; and then, feeding the calcium oxide obtained after calcination and decomposition into the vertical cooler to be cooled by air, namely, obtaining the active calcium oxide. According to the process method disclosed by the invention,through the integration of the processes of graded preheating, oxygen-enriched calcination, graded cooling, dynamic temperature monitoring and the like, and the raw materials are preheated by combining the high-temperature kiln gas and the high-temperature gas discharged from the cooler, the heat transfer efficiency of the system is greatly improved, the activity of calcium oxide is obviously improved, the energy consumption is reduced, and the energy conservation and emission reduction are realized.

Owner:HUBEI UNIV

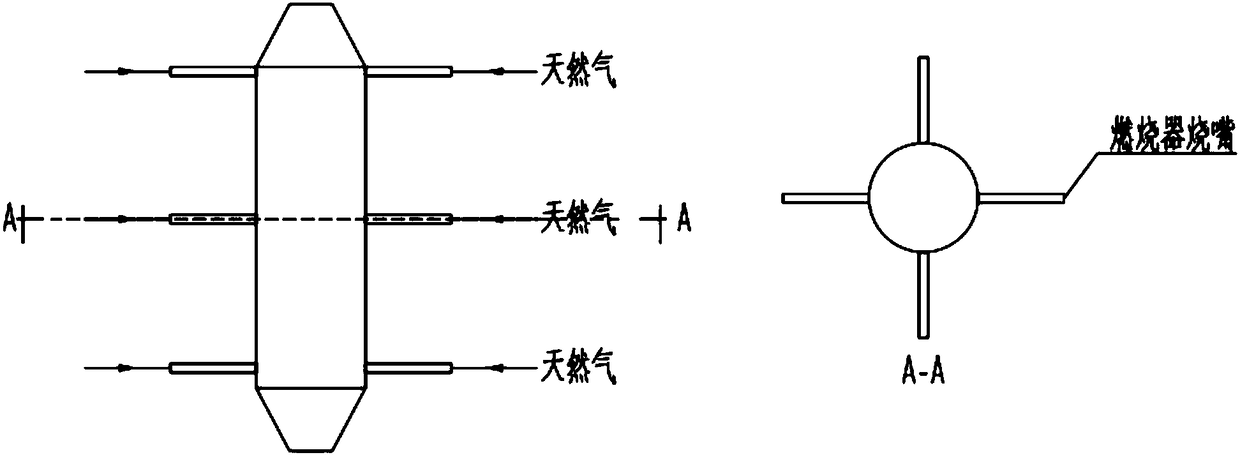

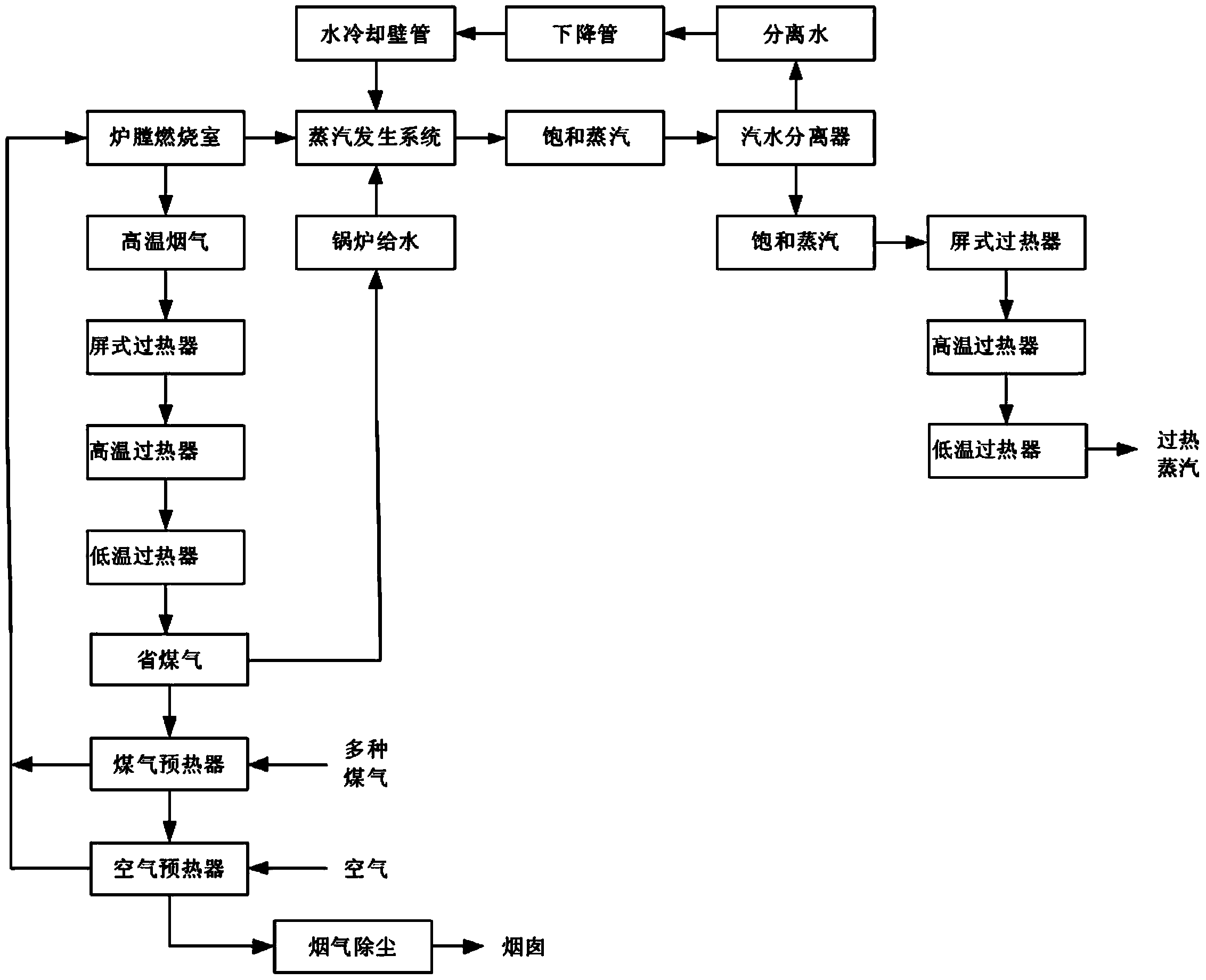

Multi-gas mixed combustion boiler and combustion method

InactiveCN104033877AShort stayEnergy savingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSuperheaterFlue gas

The invention discloses a multi-gas mixed combustion boiler and a combustion method, and belongs to boilers and combustion methods. The multi-gas mixed combustion boiler structurally comprises a hearth, a hearth water cooling wall, a steam generating system, a platen superheater, a high-temperature superheater, a low-temperature superheater, a coal economizer, an air preheater and a gas preheater. A gas combustion stabilizer is arranged on the lower portion of the hearth, three layers of gas combustors are arranged on the outer side of the gas combustion stabilizer, and the outer sides of the three layers of gas combustors are respectively connected with three gas pipelines. The combustion method includes enabling various gases and air to proportionally flow into the hearth to be combusted; transmitting heat to the steam generating system; enabling saturated steam to flow through the superheaters and then heating the saturated steam to obtain superheated steam; enabling flue gas to flow through the superheaters; then preheating water by the aid of the coal economizer, and heating the flue gas by the air preheater and the coal preheater; finally exhausting the flue gas into the atmosphere. The flue gas is generated after fuel is combusted. The water is about to be fed to the boiler. The multi-gas mixed combustion boiler and the combustion method have the advantages that coke-oven gas, blast-furnace gas and converter gas can be combusted by the aid of the multi-gas mixed combustion boiler and the combustion method; a large quantity of energy can be saved, severe environmental pollution due to gas emission can be prevented, the production cost can be reduced, and the like.

Owner:JIGANG GRP

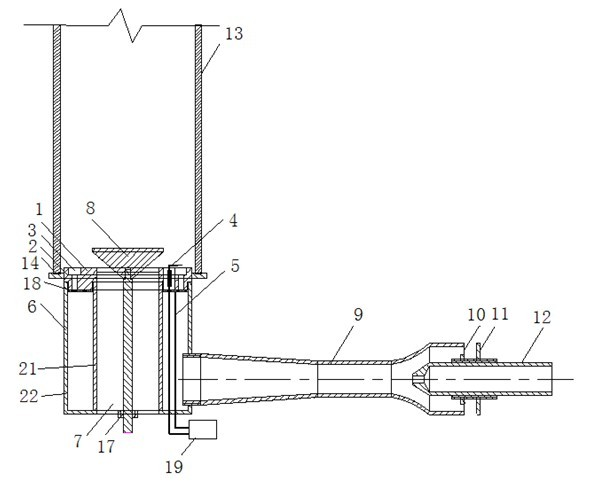

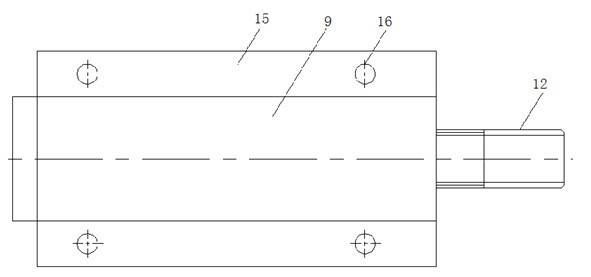

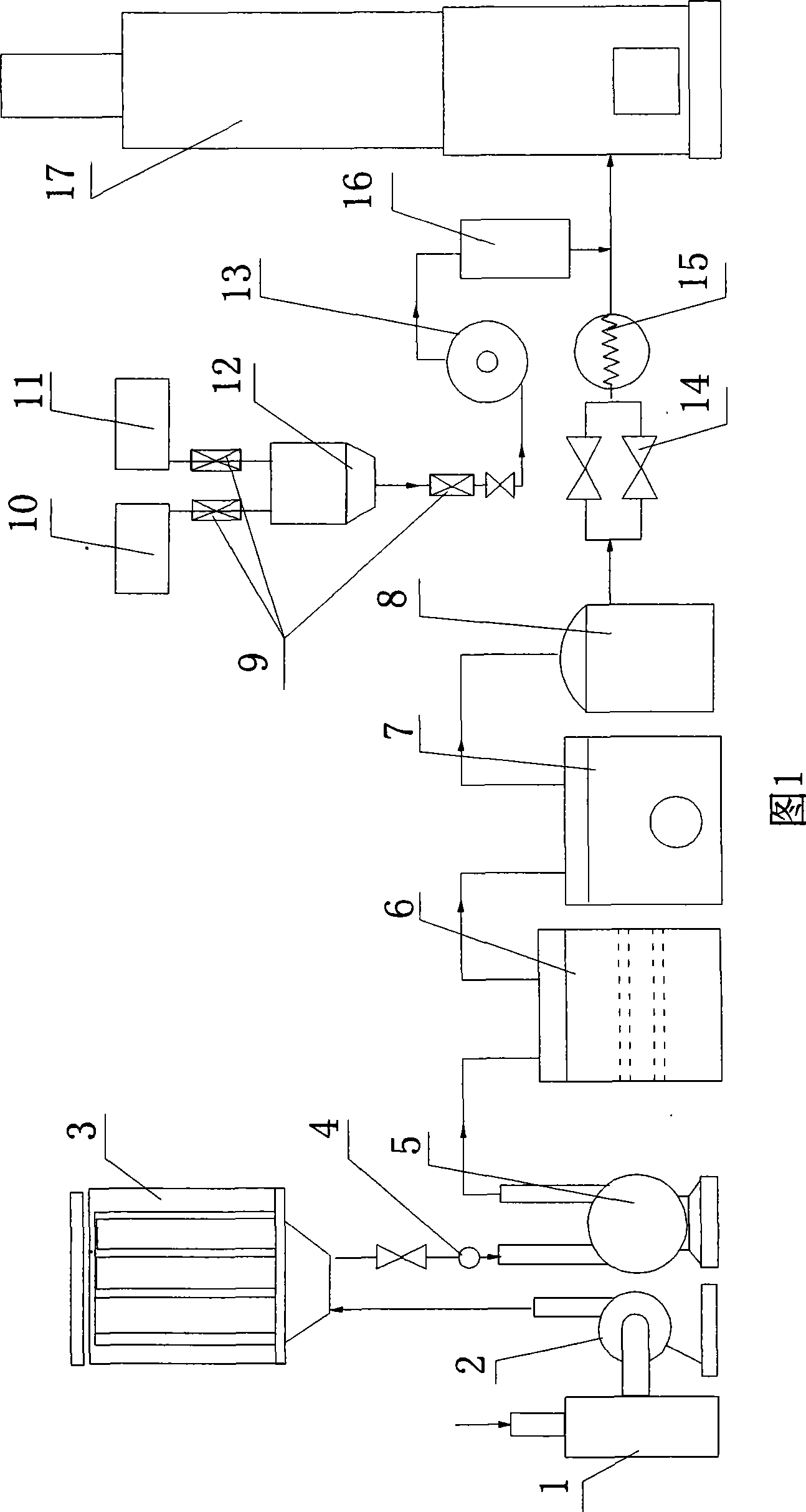

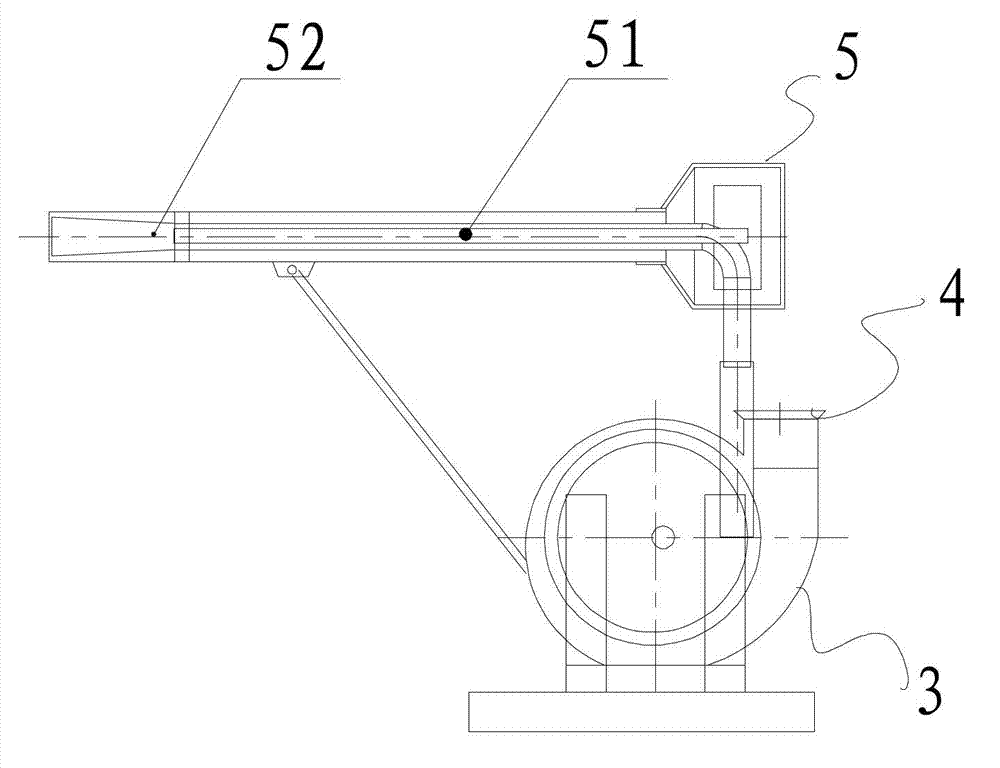

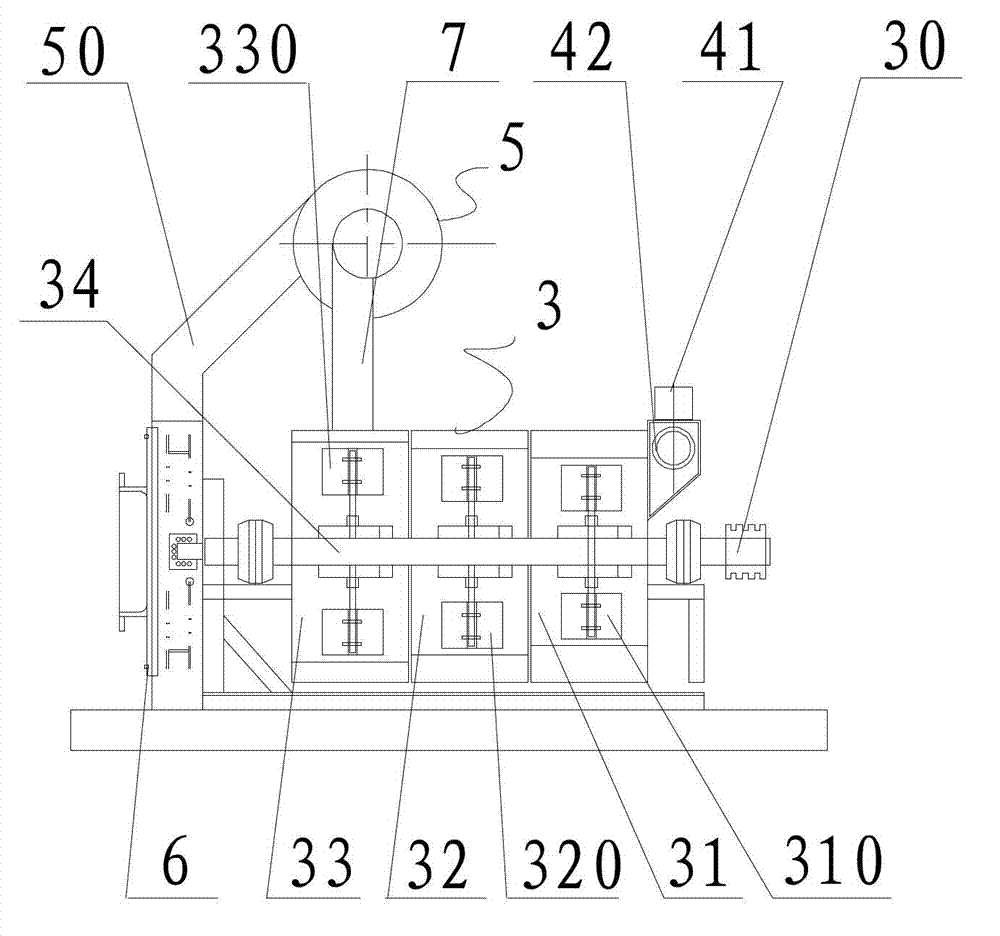

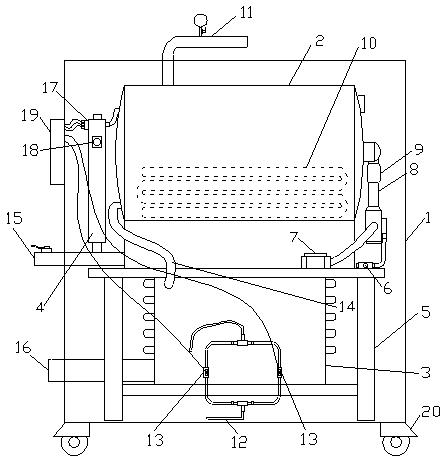

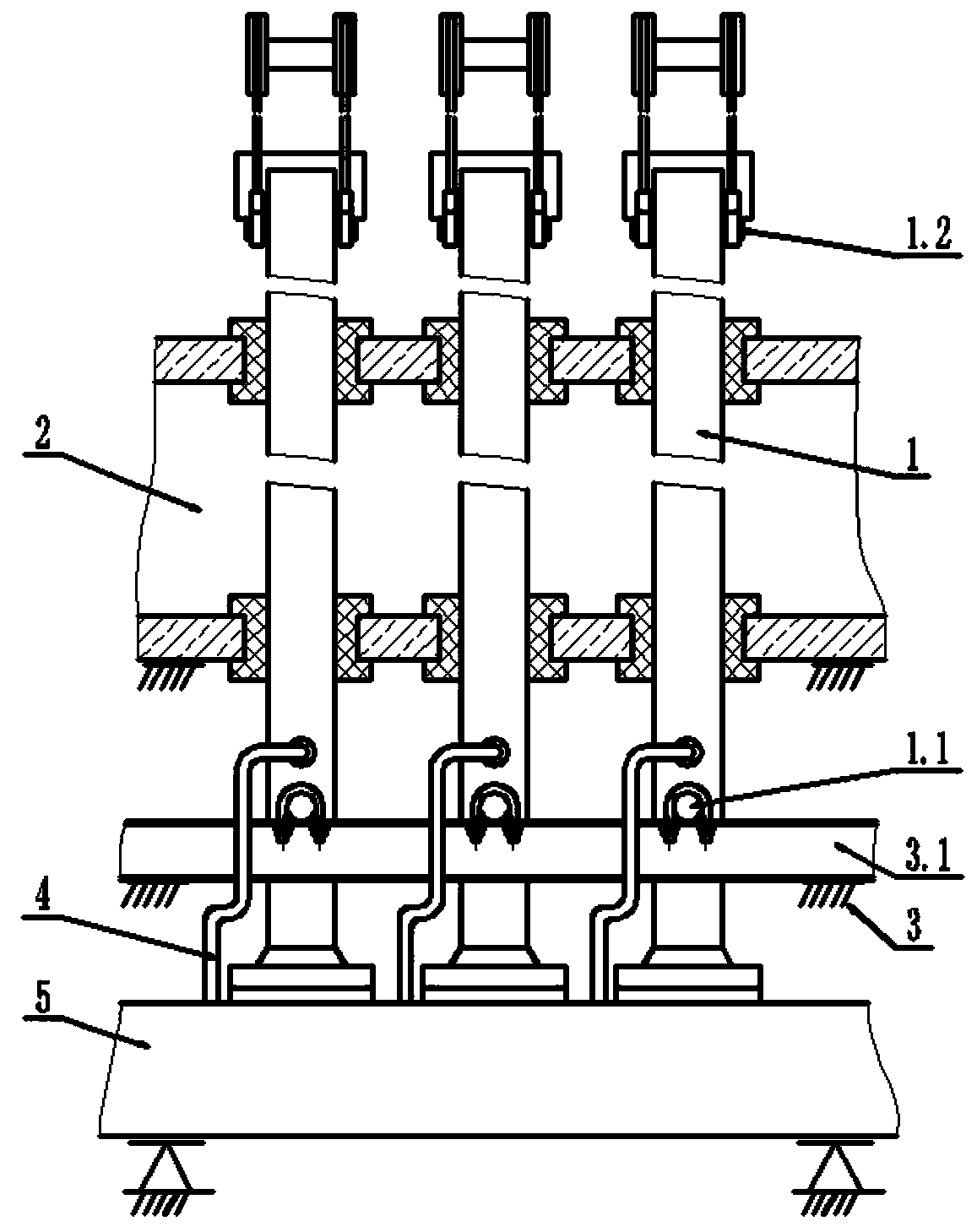

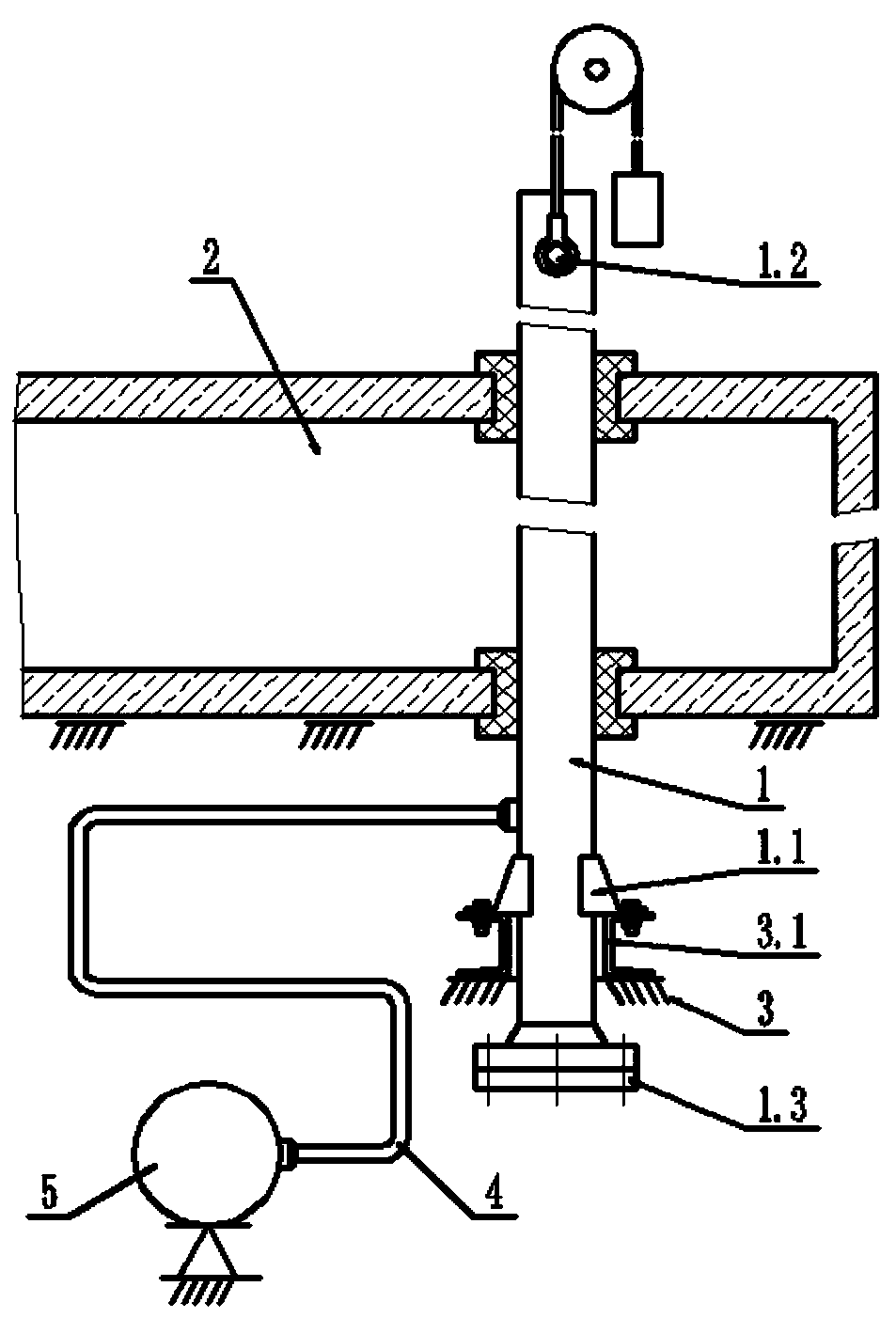

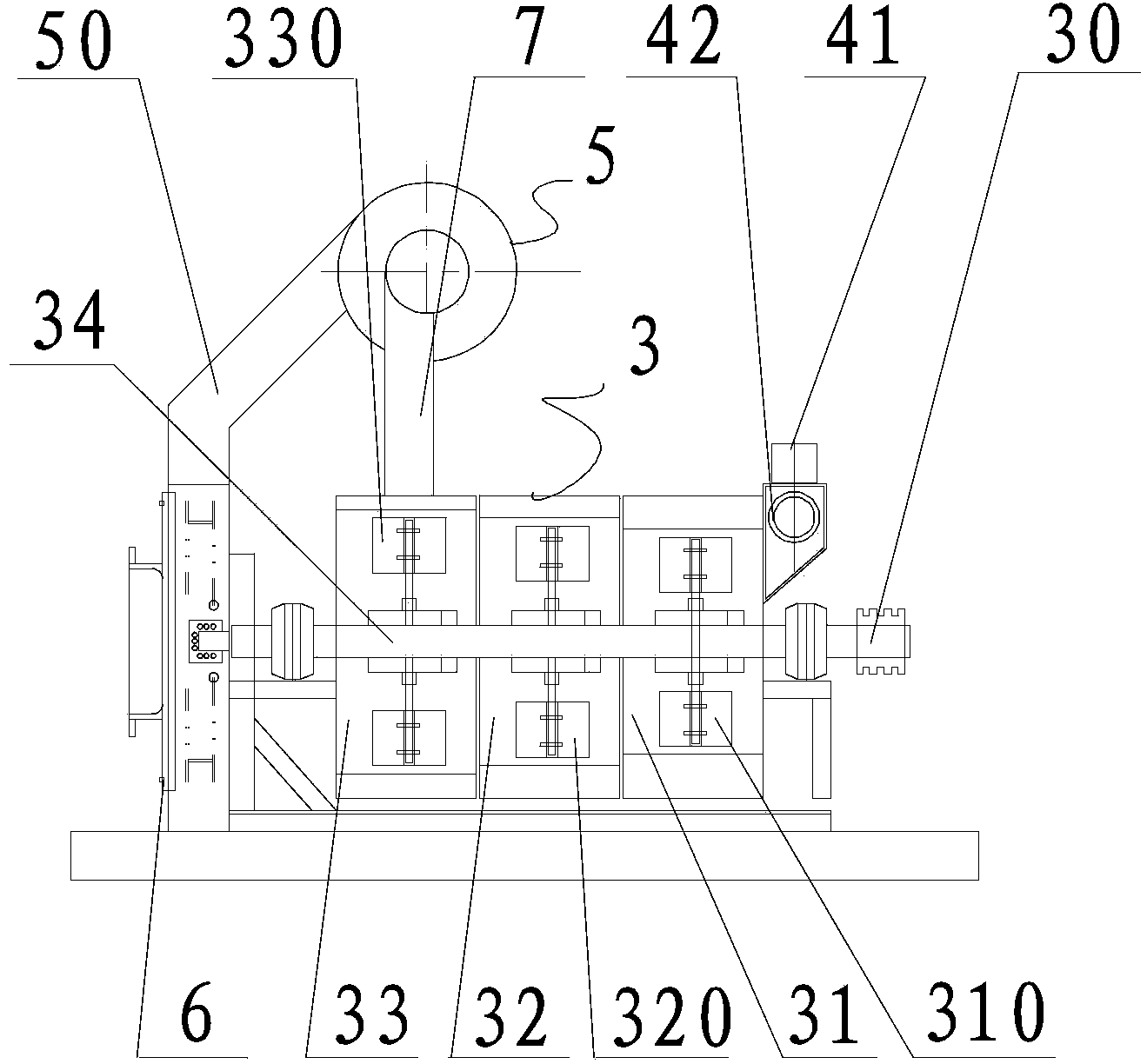

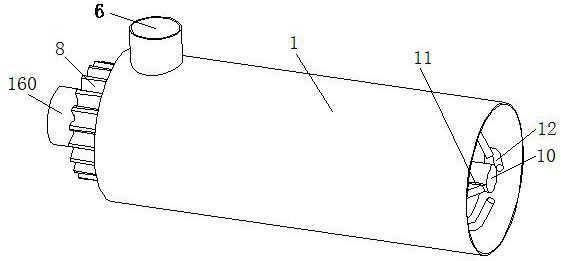

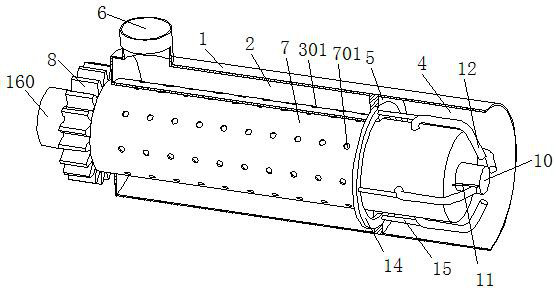

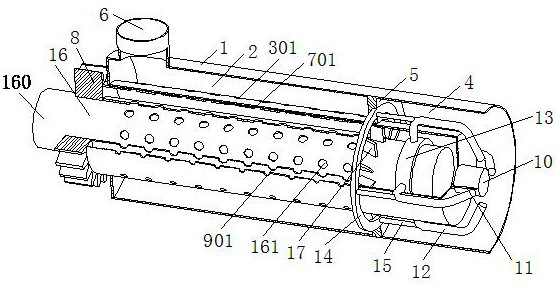

Pulverized coal co-combustion system of industrial boiler

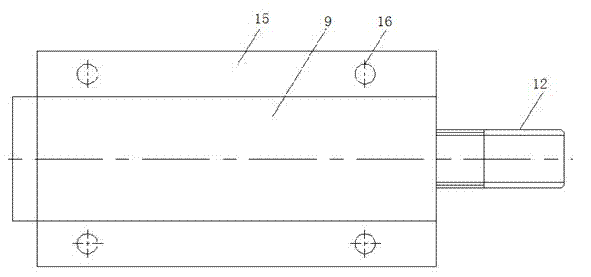

ActiveCN102901089AHigh flame temperatureImprove burnout ratePulverulent fuel combustion burnersLump/pulverulent fuel preparationCombustion systemImpeller

The invention discloses a pulverized coal co-combustion system of an industrial boiler. With the system, layer combustion and suspension combustion can form in a furnace. The system includes a boiler, a raw coal supply device and a co-combustion device. The boiler comprises a furnace, a coal inlet located at the lower part of a front end wall, and a chain grate disposed at the lower part of a furnace inner chamber. The raw coal supply device is connected to the coal inlet through a coal hopper. The co-combustion device is arranged at the boiler tail, and is composed of a boiler-front mill, a pulverized coal combustor and a pulverized coal conveying pipe. The boiler-front mill includes a rotation shaft running through a primary milling chamber, an intermediate milling chamber and a fine milling chamber connected in order, a primary hammer type impeller, an intermediate hammer type impeller and a final hammer type impeller. The front end wall upper part of the primary milling chamber is provided with a coal inlet, and the chamber wall upper part of the fine milling chamber is provided with a pulverized coal nozzle. The pulverized coal combustor includes a combustor body and a combustion nozzle. The combustor body is equipped with a secondary air inlet and a pulverized coal inlet. And the pulverized coal conveying pipe connects the pulverized coal inlet of the combustor body and the pulverized coal nozzle of the boiler-front mill.

Owner:SHANGHAI INDAL BOILER RES INST

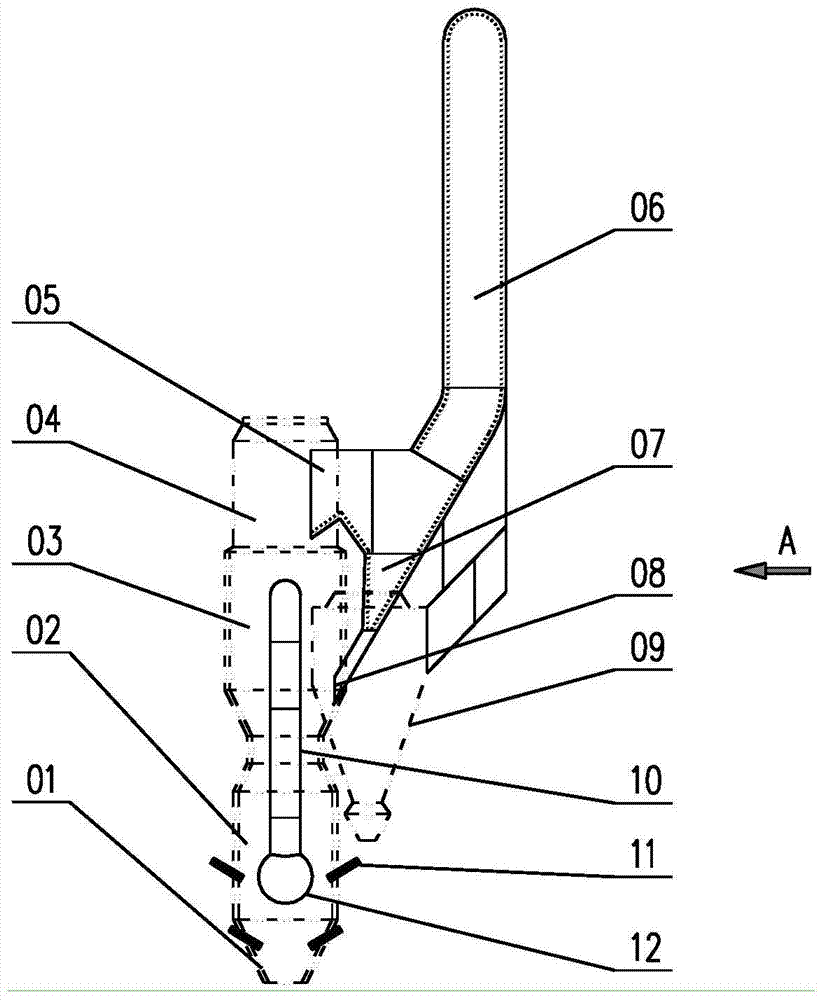

Energy conservation and emission reduction modification method for reducing emission load of nitric oxide of DDF decomposing furnace

ActiveCN105299625AIncrease volumeExtended dwell timeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelDecompositionNitric oxide

The invention discloses an energy conservation and emission reduction modification method for reducing the emission load of nitric oxide of a DDF cement decomposing furnace. By arranging an air gathering bellows and a gooseneck pipe on the DDF decomposing furnace with the small volume, the smoke standing time is prolonged; part of coal powder is distributed to the conical portion of the decomposing furnace, part of tertiary air is distributed to the upper middle portion of the decomposing furnace, the volume of the DDF decomposing furnace is enlarged, the position of part of coal powder entering the furnace is reduced, and the coal powder burn-off rate is improved. The coefficient of excess air in the lower middle portion of the decomposing furnace is smaller than 1.0. Under the condition of insufficient oxygen, CO of a large proportion is generated to become reducing agents for reducing and eliminating nitric oxide. An ash returning channel is arranged inside the air gathering bellows and feeds raw materials and coal powder particles subsided back to the position above a middle nozzle of the decomposing furnace, so that the problem of sintering blockage of accumulated ash is solved, the coarse particle processing capacity of the decomposing furnace is improved, the decomposition rate of raw materials entering the furnace is improved, and through the double effects of reducing emission of nitric oxide and reducing heat loss, the effective energy conservation and emission reduction of a cement calcining system are achieved.

Owner:BEIJING TRIUMPH INT ENG

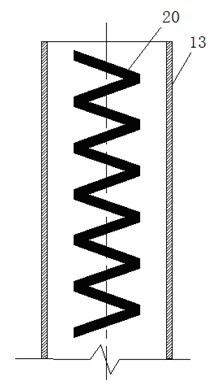

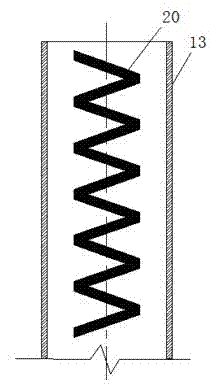

Full-premixing type condensation type steam generator

InactiveCN107842838ASpread fastEmission reductionSteam generation heating methodsBoiler controlAir filterEngineering

The invention discloses a full-premixing type condensation type steam generator. Gas communicates with a gas inlet of a premixing cavity through a proportional valve. Air communicates with an air inlet of the premixing cavity through an air filter. The premixing cavity is connected with a draught fan inlet. A draught fan outlet is connected with a mixer. A mixer outlet is connected with a combustor. After being ignited, mixed gas enters an S-shaped heat exchange coil pipe arranged in a combustion barrel, and an outlet of the S-shaped heat exchange coil pipe in the combustion barrel communicates with a secondary heat exchanger through a smoke guide-out pipe. The top and the bottom of an auxiliary water tank communicate with water supplementing pipes at the top and the bottom of the combustion barrel correspondingly. Three water level sensors are arranged in the auxiliary water tank so as to induct the high water level, the middle water level and the low water level in the combustion barrel. A full-premixing combustion structure is adopted in the combustion barrel, meanwhile, the secondary heat exchanger is utilized for conducting condensation heat exchange on high-temperature smoke,gas and a certain amount of air are sufficiently mixed before combustion, the flame propagation velocity is high, the excess air coefficient is very small, heat efficiency is effectively improved, and emission of pollutants is reduced.

Owner:耿大朋

Industrial boiler of multi-fuel burning using ultrafine coal dust as main fuel

InactiveCN100447484CImprove combustion efficiencyFully purchasedBurnersCombustion using multiple fuelsCombustionAutomatic control

The invention discloses an industrial boiler for mixed combustion of various fuels mainly based on ultrafine coal powder, which is mainly based on ultrafine coal powder (coal-water slurry) and supplemented by natural gas or oil products , is an industrial boiler with high combustion efficiency, low cost, automatic control, and reduced environmental pollution, especially suitable for small and medium-sized industrial boilers.

Owner:姜政华

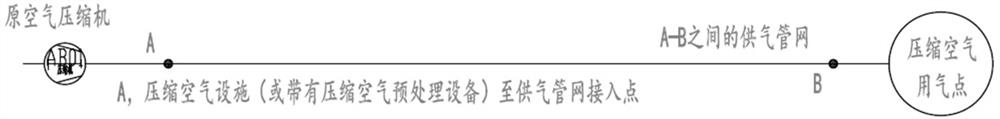

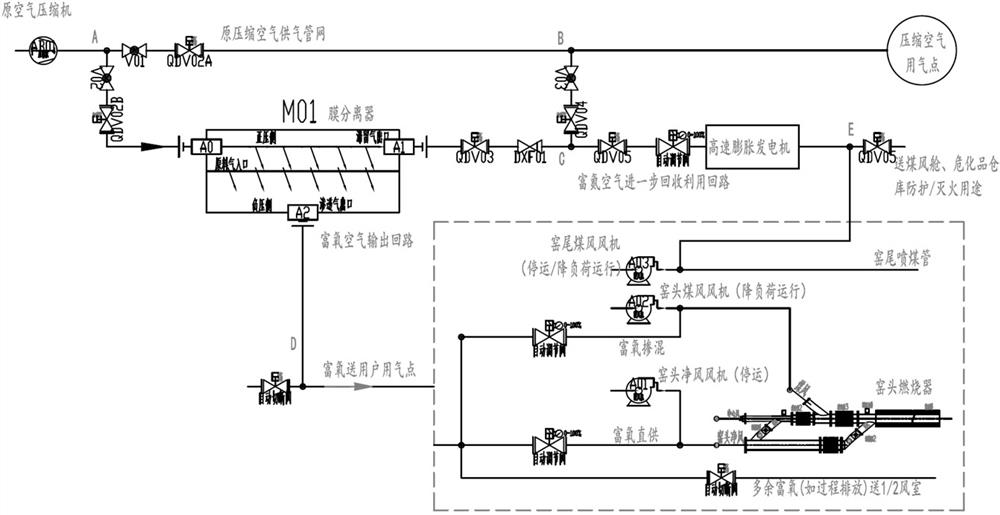

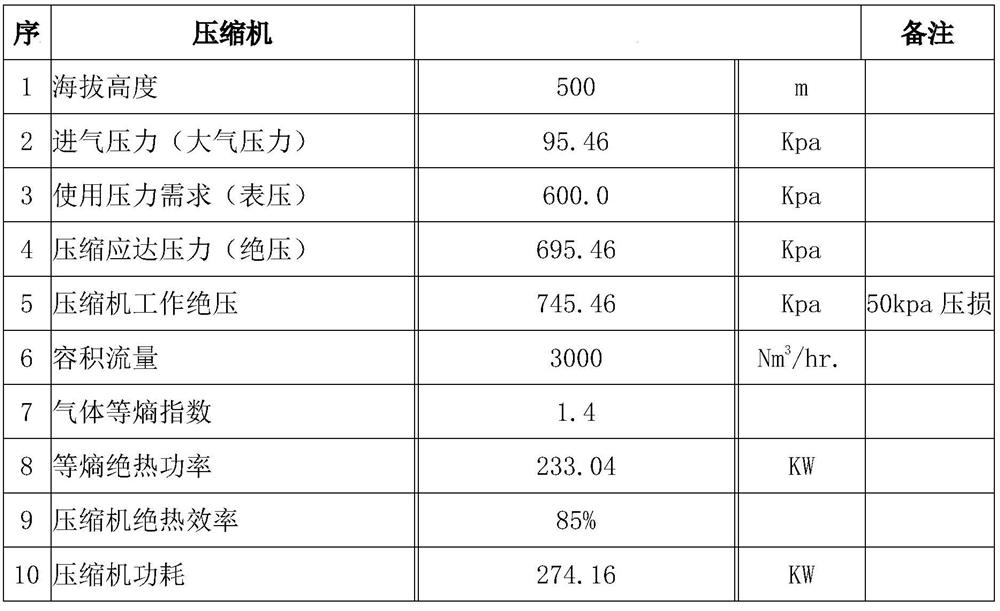

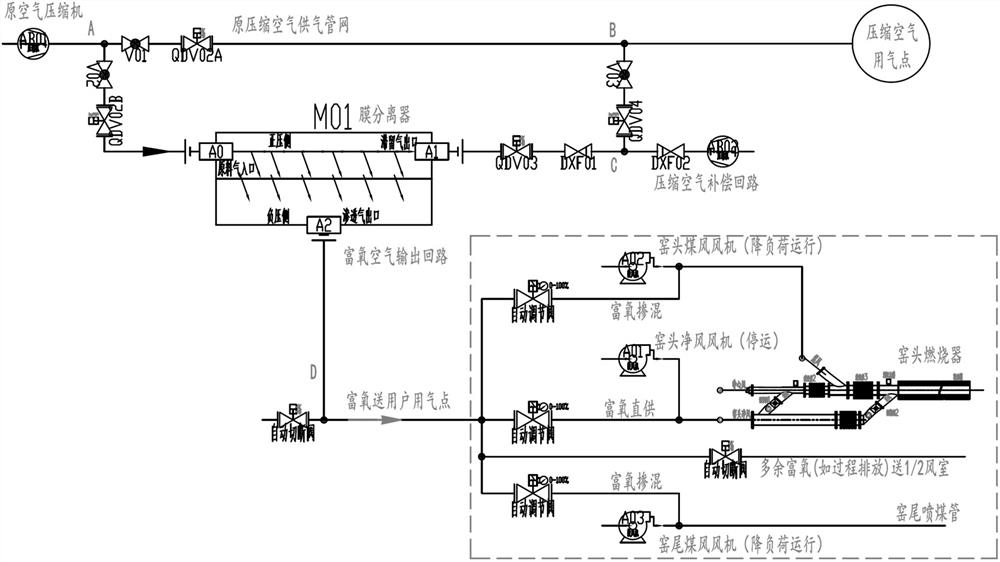

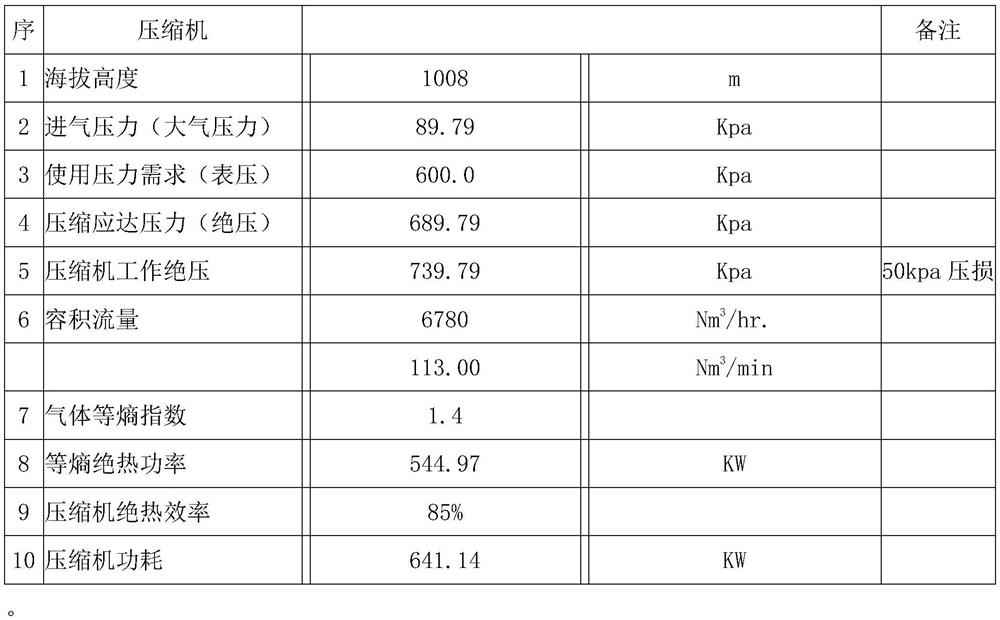

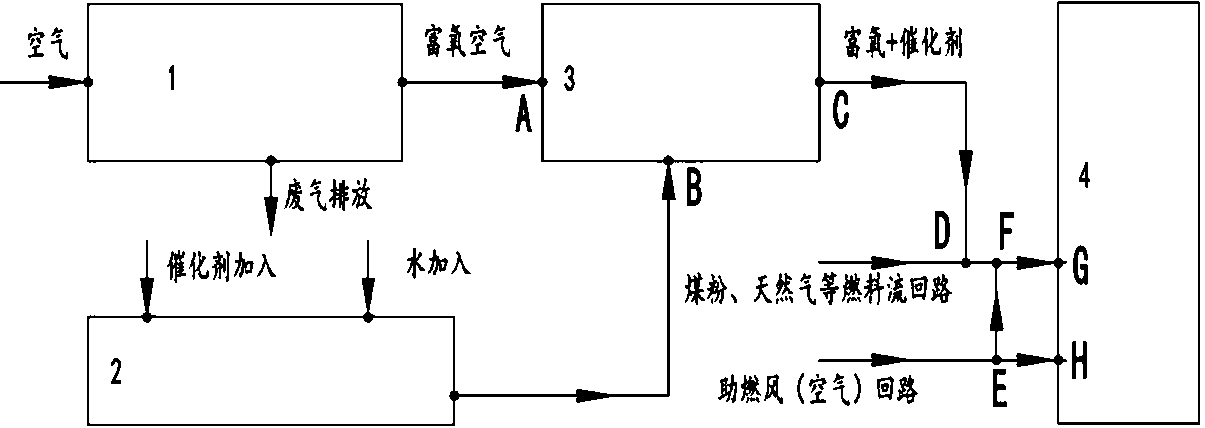

Cement plant kiln on-site oxygen production and gas supply device and method

PendingCN112815719AContinuous and stable acquisitionSupply balanceChemical industryMaintainance of heating chambersCement factoryThermodynamics

The invention belongs to the technical field of air separation, and particularly relates to a cement plant kiln on-site oxygen production and gas supply device and method. A membrane separation oxygen production technology is organically coupled to an original compressed air gas supply facility, and original compressed air is separated into two kinds of gas, rich nitrogen and rich oxygen; the generated rich nitrogen directly replaces the compressed air demand of an original factory, and compression energy is recycled; the generated rich oxygen can be sent to a furnace kiln to directly completely or partially replace original clean air and coal air to carry out oxygen-enriched combustion, the compression energy of a fan is recycled, and additional economic benefits are obtained due to oxygen-enriched combustion; the extreme condition of compressed air use is fully considered, a standby compressed air compensation loop is adopted for flow compensation, the oxygen supply scheme that oxygen is replaced with compressed air is achieved on the whole, and energy consumption of oxygen extraction is greatly reduced; and the equipment management and maintenance cost is low, potential safety hazards are avoided, and a preferred scheme for oxygen-enriched combustion energy-saving transformation of a cement plant is achieved.

Owner:上海穗杉实业股份有限公司 +1

Oxygen-enriched combustion oxygen supply method and device for rotary cement kiln

PendingCN112857030AReduce energy consumptionReduce operating frequencyChemical industryRotary drum furnacesCement factoryThermodynamics

The invention belongs to the technical field of air separation, and particularly relates to an oxygen-enriched combustion oxygen supply method and device for a rotary cement kiln According to the oxygen-enriched combustion oxygen supply method and device for the rotary cement kiln, a membrane separation oxygen production technology is organically coupled to an original compressed air supply facility, and original compressed air is separated into two gases: rich nitrogen and rich oxygen; the generated rich nitrogen directly replaces the compressed air demand of an original factory, and compression energy is recycled; the generated rich oxygen can be sent to the furnace kiln to directly and completely or partially replace the original clean air and coal air to carry out oxygen-enriched combustion, the compression energy of a draught fan is recovered, and additional economic benefits are obtained due to oxygen-enriched combustion; and the extreme condition of compressed air use is fully considered, a standby compressed air compensation loop is adopted for flow compensation, the oxygen supply scheme that oxygen is replaced with compressed air is achieved on the whole, and the energy consumption of oxygen extraction is greatly reduced. According to the oxygen-enriched combustion oxygen supply method and device for the rotary cement kiln, equipment management and maintenance cost is low, potential safety hazards do not exist, and the oxygen-enriched combustion oxygen supply method and device are the preferred scheme for oxygen-enriched combustion energy-saving transformation of a cement plant.

Owner:上海穗杉实业股份有限公司 +1

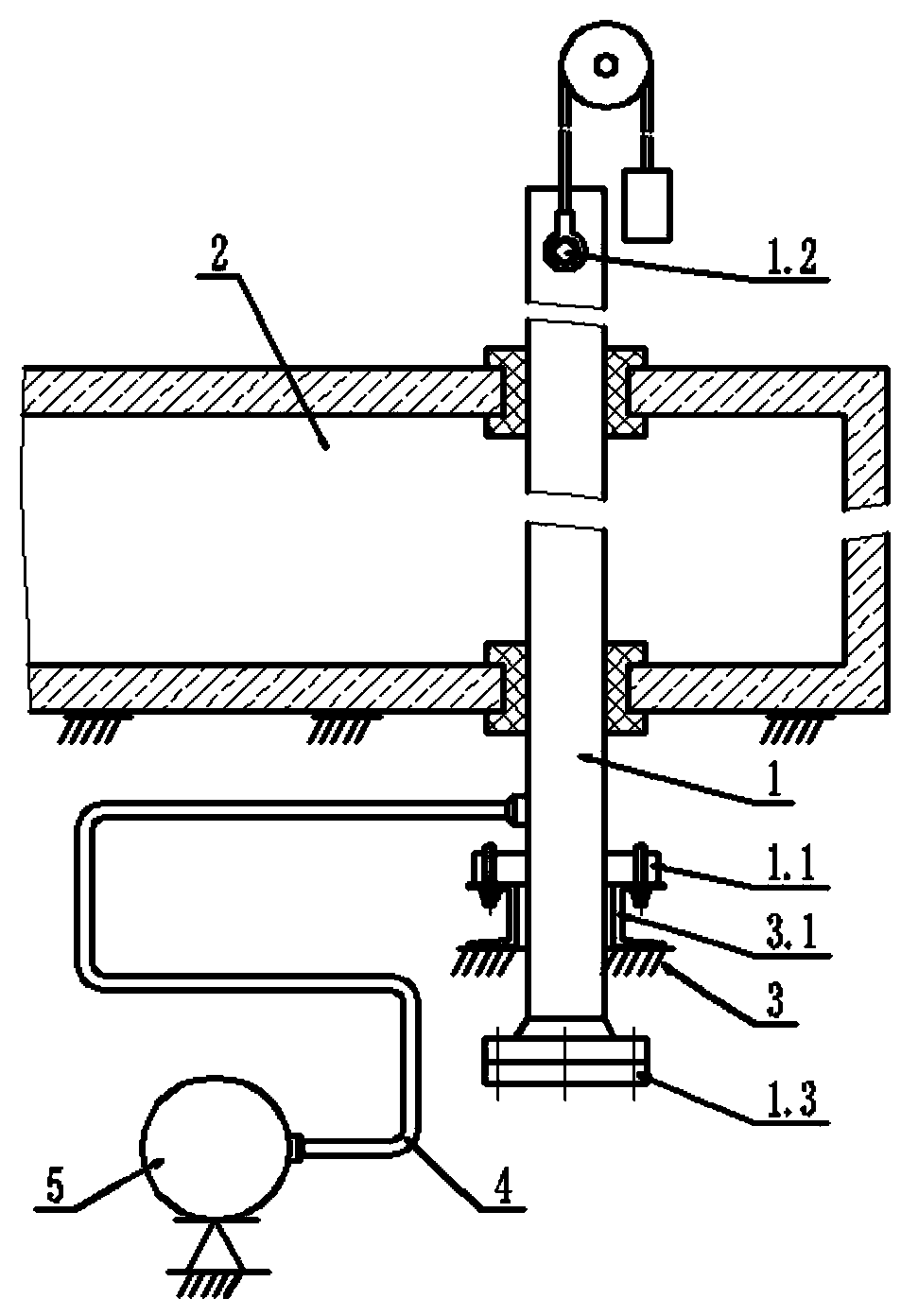

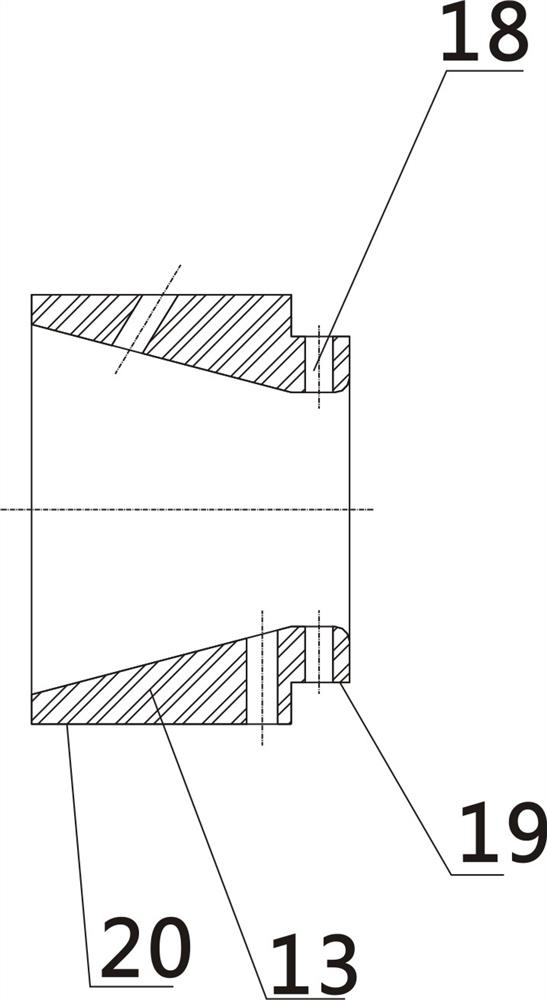

Furnace tube installation and fixing method applied to hydrocarbon-steam conversion hydrogen production conversion furnace

PendingCN110002401AAvoid lateral displacementGuaranteed coaxialityHydrogenChemical industryEngineeringThermal expansion

The invention discloses a furnace tube installation and fixing method applied to a hydrocarbon-steam conversion hydrogen production conversion furnace. The method is used for sealing connection between a plurality of rows of arranged furnace tubes and a conversion furnace body; the furnace tubes vertically penetrate through and extends out of a furnace top plate and a furnace bottom plate of the conversion furnace body; one end, stretching downwards out of the furnace bottom plate, of each furnace tube is provided with a fixing supporting piece for preventing the furnace tube from extending downwards or swinging transversely due to thermal expansion; and each fixing supporting piece is fixedly connected with a steel structure at the furnace bottom. According to the method, transverse displacement of the furnace tubes due to thermal expansion and extension of a lower gas collection tube is avoided, and coaxiality of the furnace tubes with the furnace top plate and a furnace bottom sealing structure can be guaranteed to the maximum extent, so that heat efficiency of the conversion furnace is improved, welding seam cracking caused by thermal expansion is avoided, and production safetyis ensured.

Owner:SHANDONG QILU PETROCHEM ENG +3

High-activity MgO roasting technology and special device thereof

The invention discloses a high-activity MgO roasting technology and device. The roasting technology comprises the following steps: firstly, enabling magnesium carbonate powder and hot air to be in contact and mixed to absorb heat, and pre-heating the material until the temperature is about 350 DEG C; then carrying out cyclone calcination and calcining and decomposing in a temperature range of 800DEG C to 1000 DEG C to obtain an MgO and CO2 mixture; conveying the cooled MgO and CO2 mixture into a separation device and carrying out gas-material separation; conveying collected powder into a finished-product cabin and storing; after treating escaped waste gas through a water gas treatment device, discharging the waste gas into the atmosphere through a chimney. According to the high-activity MgO roasting technology and device, disclosed by the invention, the disadvantages of an existing high-activity MgO calcination device of large equipment investment, short running period, large repairing strength, high heat consumption and great product quality fluctuation are changed and the High-activity MgO roasting technology and the special device thereof are developed; the device has the advantages of less investment, simple equipment, long service life, low repairing difficulty, low firing heat consumption and good product activity stability.

Owner:ZHENJIANG SOBUTE NEW MATERIAL CO LTD +1

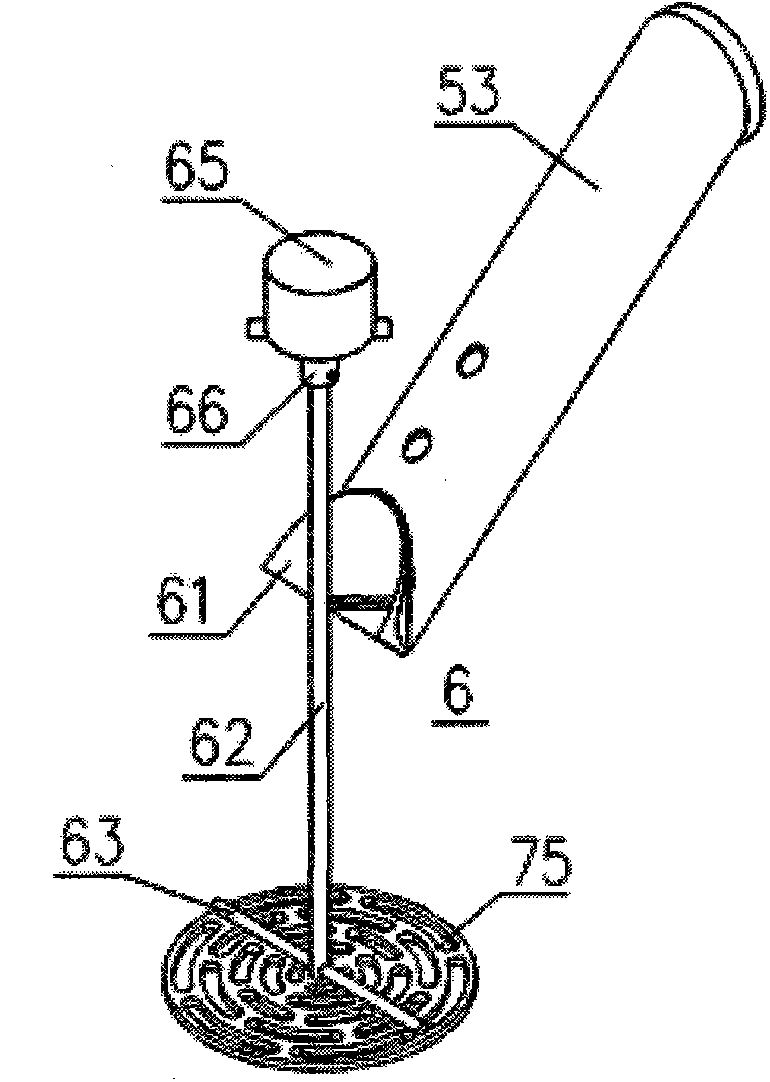

Furnace oxygen-enriched catalyzing combustion supporting method and device

PendingCN111121082AHigh outputHigh activityIndirect carbon-dioxide mitigationCombustion using catalytic materialPtru catalystSinglet oxygen

The invention relates to the technical field of thermal power engineering and particularly relates to a furnace oxygen-enriched catalyzing combustion supporting method and device. According to the furnace oxygen-enriched catalyzing combustion supporting method and device, oxygen-enriched air and catalyzing combustion are combined; oxygen-enriched air with the purity being 21-60% is directly made from air through a normal temperature air separation method; a catalyst is dissolved, enters a water solution and is used for stimulating singlet oxygen; and air or the made oxygen-enriched air servesas a gas source to jet the catalyst solution and is fed into a furnace along with fuel to carry out oxygen-enriched catalyzing combustion. The device comprises an oxygen extracting device, a catalystdissolving, stirring and pressurizing device and an oxygen-enriched jetting and atomizing device. According to the furnace oxygen-enriched catalyzing combustion supporting method and device, the essence is to getting energy from oxygen instead of fuels such as coal, methane and oil; and besides, the requirements for the flow and purity on an oxygen source is greatly lowered, the investment of oxygen equipment and operation maintaining cost of the equipment are greatly reduced, especially the energy consumption of oxygen generating plants is reduced, and significant economic benefits are achieved.

Owner:上海穗杉实业股份有限公司

Atmospheric gas radiation heating device

ActiveCN101900324BHigh blacknessImprove Radiation AbilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelPetrochemicalEngineering

The invention discloses an atmospheric gas radiation heating device which comprises a burner, a quartz glass radiant tube and an igniter, wherein the burner comprises a nozzle, an injection tube and a burner head part; the burner head part consists of an inner tube and an outer tube which are concentric, and one end of an annular belt between the inner tube and the outer tube is sealed; the injection tube is communicated with the annular belt; the end of the sealed annular belt of the inner tube is a secondary air inlet, while the other end of the inner tube is provided with an inner flame cover; a corresponding end of the outer tube is provided with an outer flame cover, and a flame hole is formed between the inner flame cover and the outer flame cover; and the inner tube is internally provided with a secondary air conditioning device. The invention has simple structure, convenient mounting, low manufacture and maintenance cost, high burning strength, long service life and large burner load regulation ratio, can meet the requirement of different heating powers to a larger extent and can be widely applied to industrial kilns of the industries of steel, petrochemical industry, machinery, building materials, boilers, waste incineration, and the like.

Owner:ENN CHINA GAS ENVESTMENT

Pulverized coal co-combustion system of industrial boiler

ActiveCN102901089BHigh flame temperatureImprove burnout ratePulverulent fuel combustion burnersLump/pulverulent fuel preparationCombustion systemImpeller

The invention discloses a pulverized coal co-combustion system of an industrial boiler. With the system, layer combustion and suspension combustion can form in a furnace. The system includes a boiler, a raw coal supply device and a co-combustion device. The boiler comprises a furnace, a coal inlet located at the lower part of a front end wall, and a chain grate disposed at the lower part of a furnace inner chamber. The raw coal supply device is connected to the coal inlet through a coal hopper. The co-combustion device is arranged at the boiler tail, and is composed of a boiler-front mill, a pulverized coal combustor and a pulverized coal conveying pipe. The boiler-front mill includes a rotation shaft running through a primary milling chamber, an intermediate milling chamber and a fine milling chamber connected in order, a primary hammer type impeller, an intermediate hammer type impeller and a final hammer type impeller. The front end wall upper part of the primary milling chamber is provided with a coal inlet, and the chamber wall upper part of the fine milling chamber is provided with a pulverized coal nozzle. The pulverized coal combustor includes a combustor body and a combustion nozzle. The combustor body is equipped with a secondary air inlet and a pulverized coal inlet. And the pulverized coal conveying pipe connects the pulverized coal inlet of the combustor body and the pulverized coal nozzle of the boiler-front mill.

Owner:SHANGHAI INDAL BOILER RES INST

A device and method for stable and efficient combustion of biomass pellet fuel

ActiveCN103912866BStable combustionEfficient and stable combustionSolid fuel combustionCombustion apparatusHigh energyPollutant emissions

The invention discloses a stable and effective biomass pellet fuel combustion device and method. The stable and effective biomass pellet fuel combustion device comprises a combustion furnace shell, a primary air device, a secondary air device, an ignition device, a feed device, a burner, a heat exchange device, a stirring device and an ash tray. The stable and effective biomass pellet fuel combustion device and method are capable of guaranteeing the stable and effective combustion of the fuel and preventing slagging and caking in combustion so as to realize continuous stable combustion. The volatile component and fixed carbon in the biomass are burnt in two stages, the air quality is controlled, and the pollutant emission is lowered in combustion. The ignition device achieves low ignition energy consumption and low ignition pollutant emission; the combustion is safely isolated from stored materials; the stable and effective biomass pellet fuel combustion device and method have high energy conservation and emission reduction benefit and application value.

Owner:济南长城空调公司

Low-nitrogen combustor capable of achieving intensive mixing

PendingCN113048476AFacilitate the combustion reactionReduce the formation of nitrogen oxidesGaseous fuel burnerNitrogen oxidesMechanics

The invention relates to the technical field of environmental protection, and discloses a low-nitrogen combustor capable of achieving intensive mixing. The low-nitrogen combustor capable of achieving intensive mixing comprises a fixed barrel, a rotating barrel I and a fuel barrel, wherein the fixed barrel comprises an air cavity, a middle cavity, a combustion cavity and a segmentation plate; the air cavity is separated from the combustion cavity through the segmentation plate; the middle cavity communicates with the combustion cavity; one side of the air cavity communicates with an air inlet pipe; the middle cavity is movably connected with a rotating cylinder I in a sleeved mode; one side of the rotating cylinder I is fixedly connected with a driving gear; the center of the other end of the rotating cylinder I is fixedly connected with a combustion nozzle; and the same end of the rotating cylinder I is fixedly connected with a fire maker. According to the low-nitrogen combustor capable of achieving intensive mixing provided by the invention, by designing the fixed barrel, the fuel barrel and the rotating barrel, a large amount of fuels and a small amount of air can intermittently enter a mixing cavity and are rapidly and uniformly mixed in a rotating and direct-impact manner under the influence of high and low pressure differences, so that the excess air coefficient is reduced, the combustion reaction is promoted, and the generation of nitrogen oxides is reduced from multiple aspects.

Owner:陆绍琼

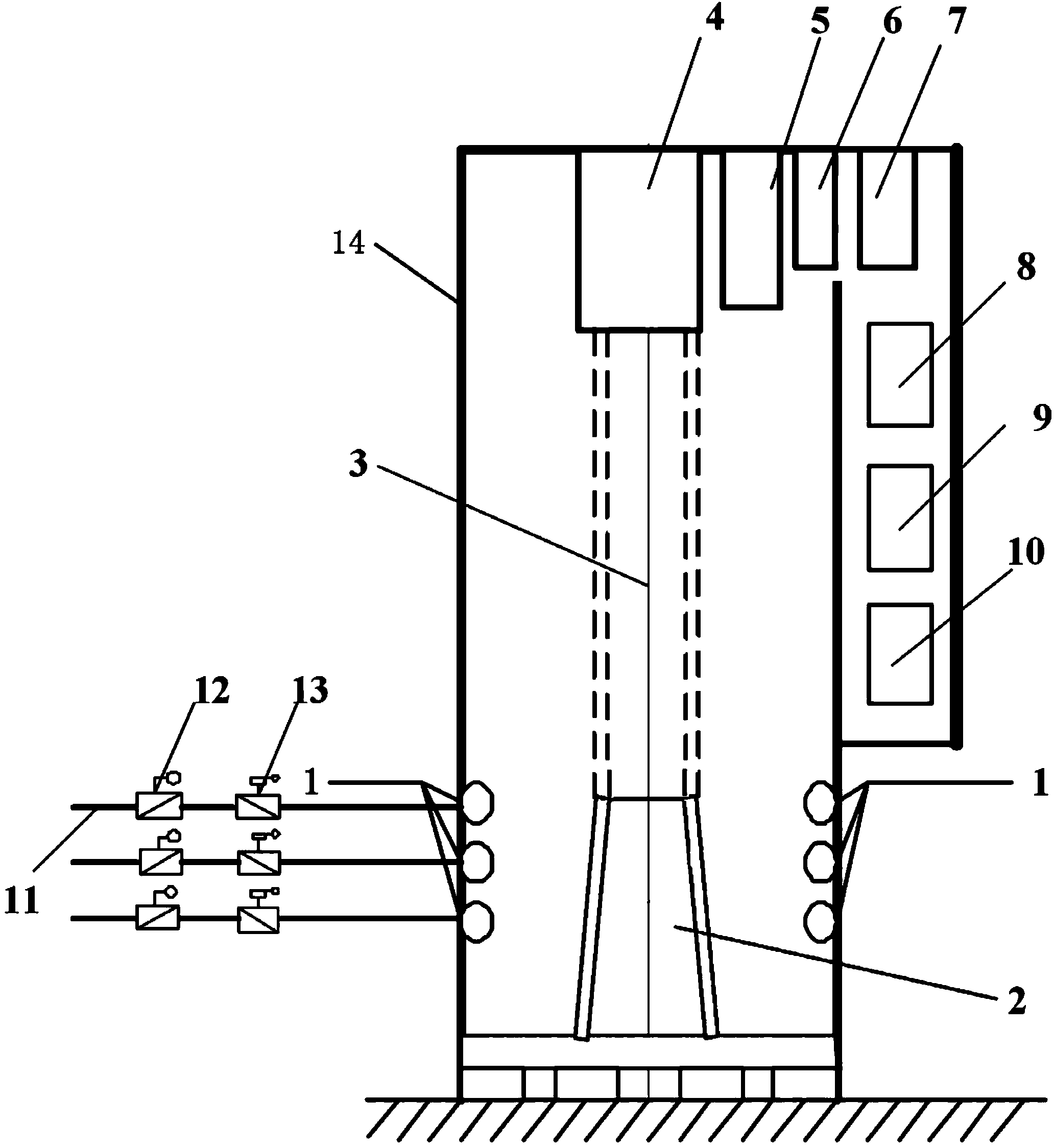

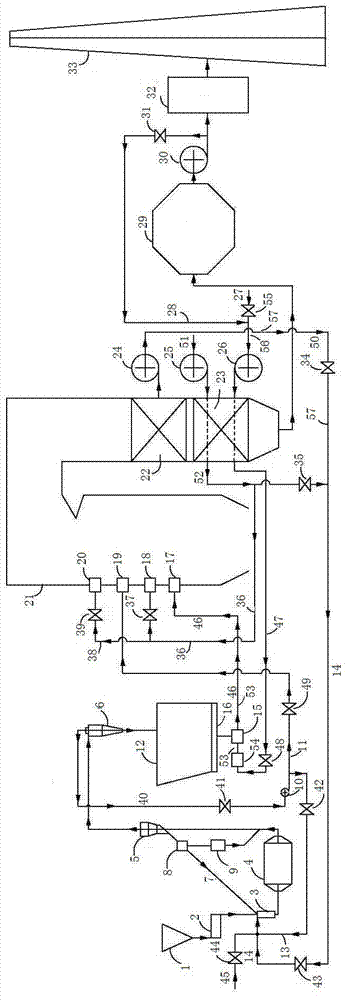

Coal-fired boiler coal pulverizer storage type nitrogen oxide reduction system

ActiveCN103216840BIncrease delivery temperatureTransportation safetyLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationAir preheaterPowder mixture

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

A retrofit method for energy saving and emission reduction to reduce the emission of nitrogen oxides from ddf decomposition furnace

ActiveCN105299625BIncrease volumeExtended dwell timeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelDecompositionOxygen

The invention discloses an energy-saving and emission-reduction transformation method for reducing the emission of nitrogen oxides from a DDF cement decomposition furnace. By setting a confluence box and a gooseneck for a DDF decomposition furnace with a small volume, the residence time of the flue gas is prolonged, and part of the coal The powder is distributed to the cone of the calciner, and part of the tertiary air is sent to the middle and upper part of the calciner. The enlarged DDF calciner volume and the lower part of the pulverized coal inlet position increase the burnout rate of the pulverized coal, and the excess air in the lower part of the calciner If the coefficient is less than 1.0, under the condition of insufficient oxygen, a large proportion of CO is produced, which becomes the reducing agent for reducing and eliminating nitrogen oxides. The ash return channel is set in the confluence box to send the settled raw material and coal powder particles back to the middle nozzle of the calciner, so as to solve the problem of ash accumulation and sintering blockage, improve the processing capacity of the calciner for coarse particles, and improve the production efficiency of the kiln. The decomposition rate of raw materials is improved, and the effective energy saving and emission reduction of the cement firing system are realized through the dual effects of reducing nitrogen oxide emissions and reducing heat consumption.

Owner:BEIJING TRIUMPH INT ENG

Special heating furnace for joint coke production

PendingCN113046100AReduce heat lossEnsure environmental complianceCombustible gas coke oven heatingCombustorFlue gas

The invention belongs to the technical field of joint coke production, and particularly relates to a special heating furnace for joint coke production, which comprises a furnace body, a chimney, a convection chamber, a radiation chamber, a burner and a furnace tube, the furnace body is provided with a furnace wall cast by adopting a castable, the inner wall of the furnace wall is provided with a compact ceramic lining, and the surface of the lining is sprayed with a high-temperature-resistant coating. The convection chamber is arranged on the upper portion of the radiation chamber, the burner is located at the furnace bottom, and a furnace tube is arranged in the furnace body. Light castable and a compact ceramic radiation chamber lining are adopted, a high-temperature-resistant energy-saving coating is sprayed on the surface of the lining, the heat dissipation loss of the surface of a furnace body is reduced by 3%, a high-efficiency, low-excess-air-coefficient and low-NOx burner is adopted, it is ensured that flue gas is environmentally friendly and qualified, after the heating furnace is adopted, the control and adjustment mode of the heating furnace is more intelligent, the labor intensity of personnel is reduced to a certain extent, the utilization rate of fuel gas is greatly improved, and the operation benefits of the device are improved.

Owner:山东京阳科技股份有限公司

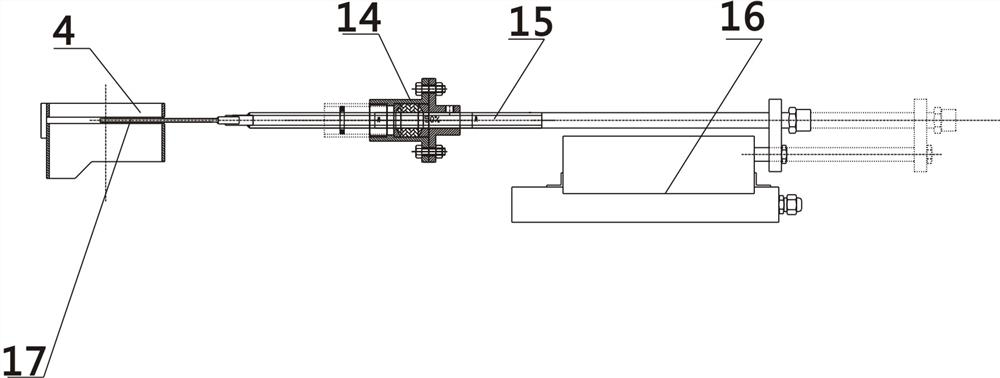

Flue gas internal circulation tail gas incinerator burner

PendingCN114135881AReduce peak flame temperatureReduce NOxAir/fuel supply for combustionIncinerator apparatusCombustorFlue gas

A smoke internal circulation tail gas incinerator burner relates to a burner and comprises a burner shell, a brazier brick, a gas spray gun and a tail gas mixing adjusting mechanism, the brazier brick is fixed inside the front end of the burner shell, the gas spray gun is arranged at the center of the burner shell, and an ignition incandescent light is fixed on a flange at the rear end of the burner shell; the combustor shell is provided with four layers from outside to inside, the lower portion of the outermost shell is provided with a secondary air inlet, the upper portion of the second shell is provided with a tail gas inlet, the third shell is provided with a tail gas mixing channel communicated with the tail gas inlet, and the tail gas mixing channel is arranged on the upper portion of the third shell in an extending mode and located in the tail gas inlet. A primary air inlet is formed in the lower part of the shell on the innermost layer; the burner is high in ignition success rate, simple in structure, convenient to operate, complete in combustion and convenient to replace quick-wear parts.

Owner:LUOYANG XINPU PETROCHEMICAL EQUIP DEV CO LTD

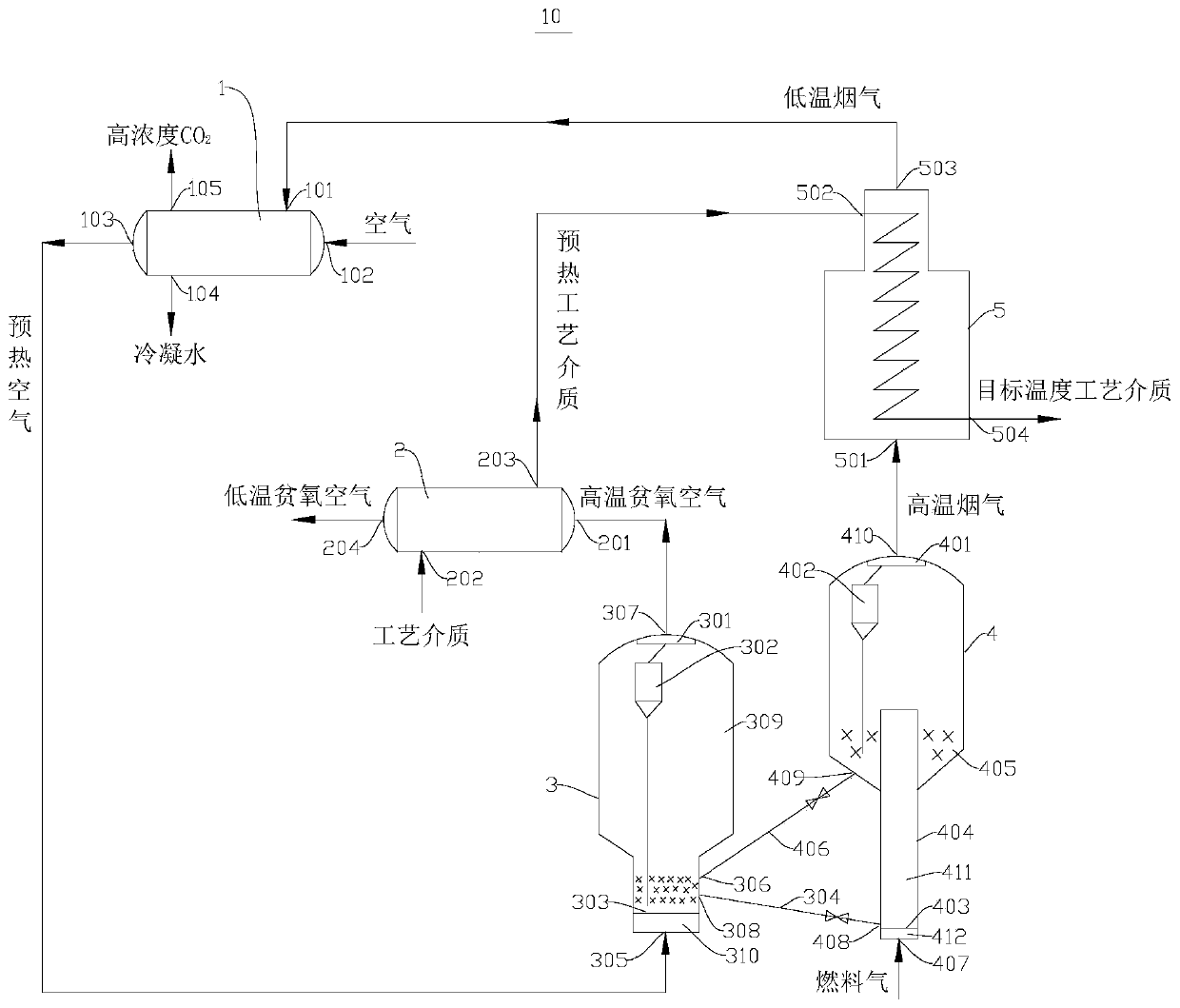

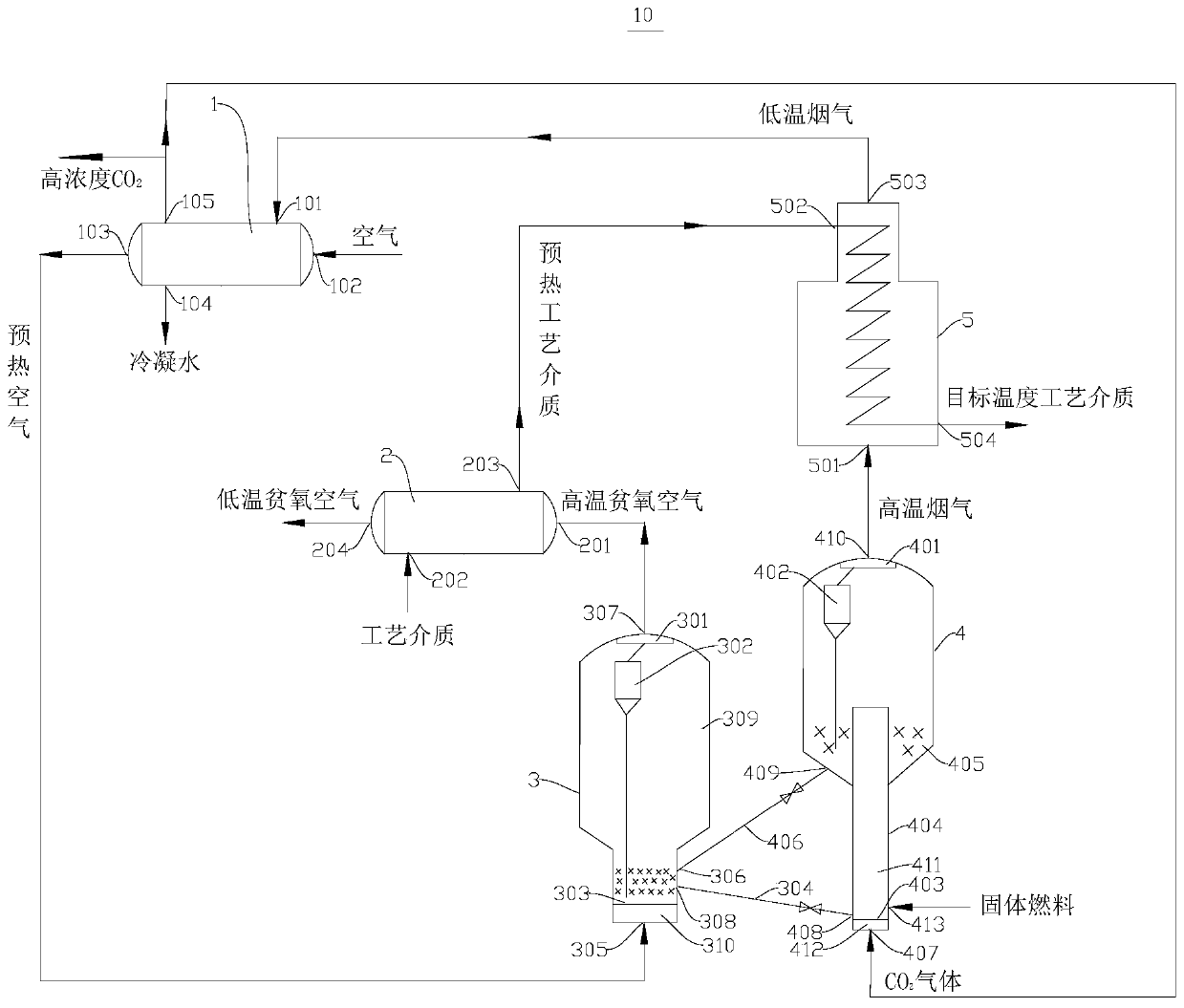

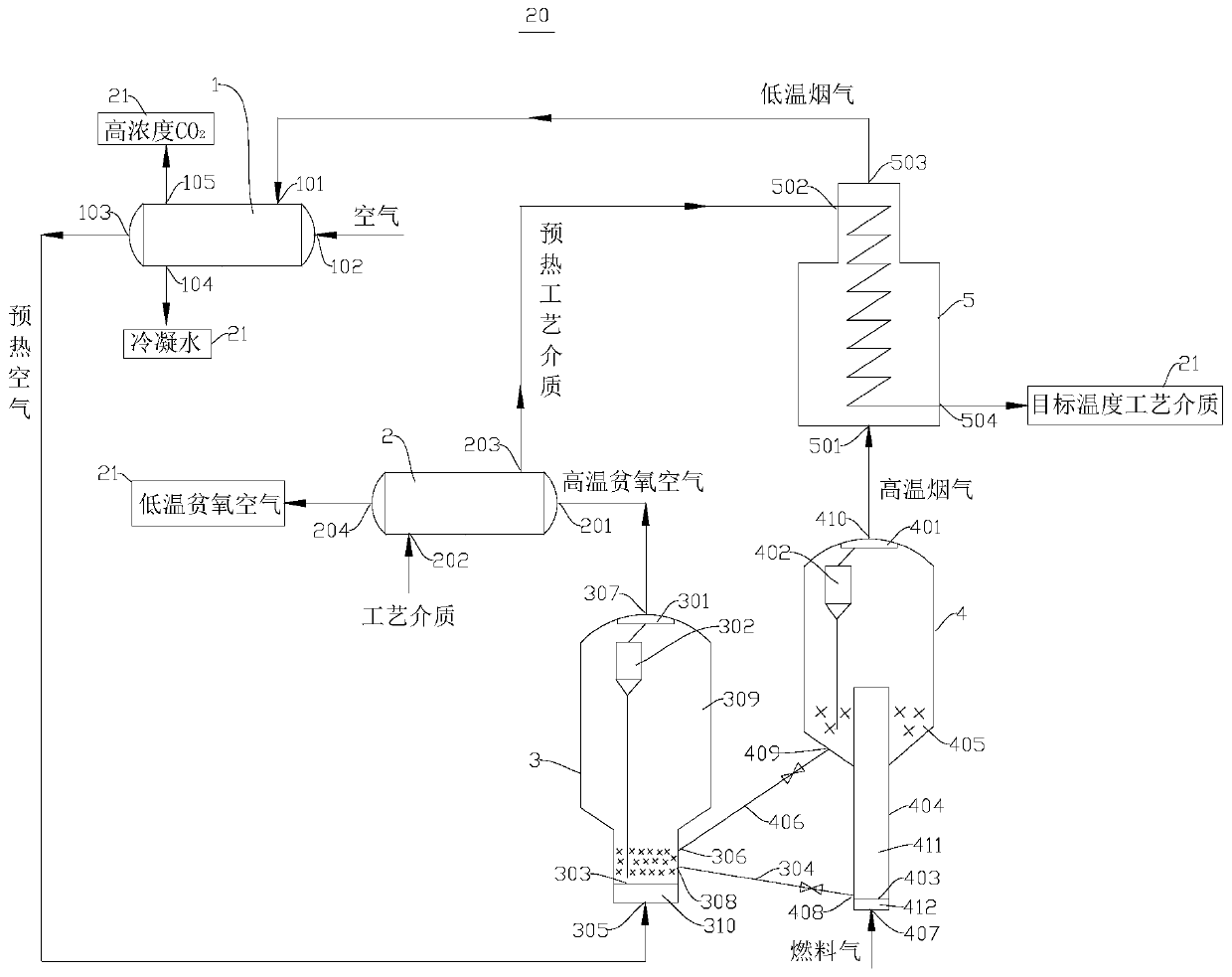

Heating furnace system and heating furnace equipment

ActiveCN108680017BLower exhaust gas temperatureHigh thermal efficiencyVapor condensationFurnace typesProcess engineeringHeating furnace

The invention provides a heating furnace system and heating furnace equipment, and belongs to the technical field of heating furnaces. The heating furnace system comprises a reduction reactor first inlet, a reduction reactor second inlet, a reduction reactor first outlet, a reduction reactor second outlet, a heating furnace first inlet, a heating furnace second inlet, a heating furnace first outlet, a heating furnace second outlet, a separator first inlet, a separator second inlet, a separator first outlet, a separator second outlet, a separator third outlet, an oxidation reactor first inlet,an oxidation reactor second inlet, an oxidation reactor first outlet, an oxidation reactor second outlet, a heat exchanger first inlet, a heat exchanger second inlet, a heat exchanger first outlet anda heat exchanger second outlet. According to the system, the problems that pollutants are generated and the heat efficiency is low in the operation process of a traditional heating furnace can be solved, so that the high-efficiency and low-emission operation of the heating furnace can be realized. The heating furnace equipment comprising the system is high in efficiency and low in operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

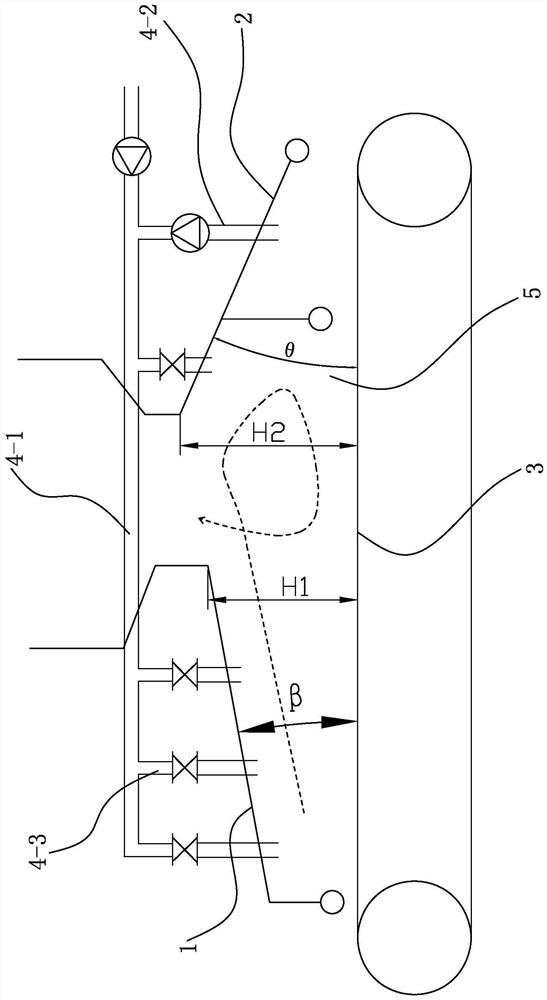

Combustion system and method of inverted-alpha shaped flame air distribution type layered boiler

ActiveCN112432159APrevent getting involvedRaise the combustion temperatureSolid fuel combustionIndirect carbon-dioxide mitigationCombustion systemAir preheater

The invention discloses a combustion system and method of an inverted-alpha shaped flame air distribution type layered boiler, and belongs to the technical field of boilers. The combustion system comprises a front arch, a rear arch, a fire grate and an air distribution system, wherein the front arch and the rear arch are separately arranged aslant; the top height of the front arch is less than that of the rear arch; the rear arch is shorter than the front arch; an included angle of the front arch and the rear arch is an obtuse angle; the front arch, the rear arch and a partitioning plate are divided into a front zone and a rear zone, the front zone is a combustion zone and the rear zone is a cooling area; the air distribution system comprises a main pipe, air blowers, a fume exhaust pipe and a plurality of air distribution pipes; the fume exhaust pipe and one end of each of the plurality of air distribution pipes are connected with the main pipe; the other end of each of the pluralityof air distribution pipes extends into a combustion chamber from the front arch or the rear arch; an adjusting valve is arranged on the each air distribution pipe; the other end of the fume exhaust pipe extends into a cooling fume exhaust zone, the main pipe communicates with an air pre-heater of an existing boiler; and the air blowers are separately arranged on the main pipe and the fume exhaustpipe. According to the system and the method disclosed by the invention, generation of nitrogen oxide can be reduced, and fume exhaustion loss is reduced.

Owner:HARBIN INST OF TECH

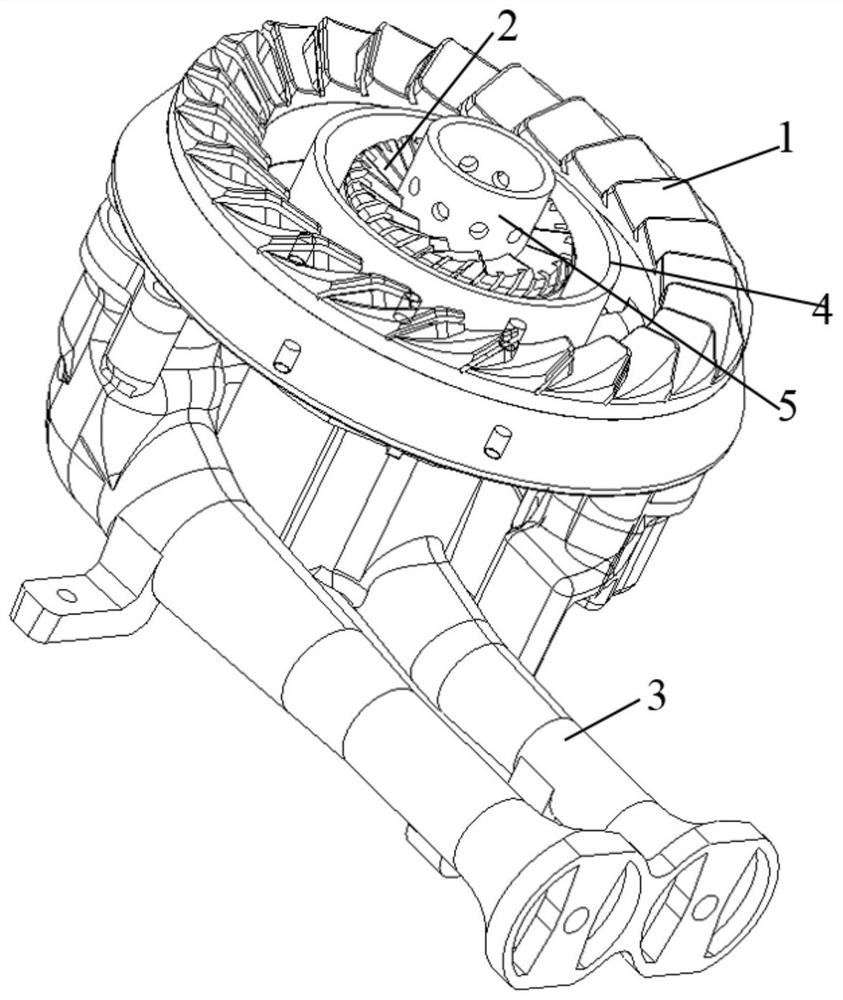

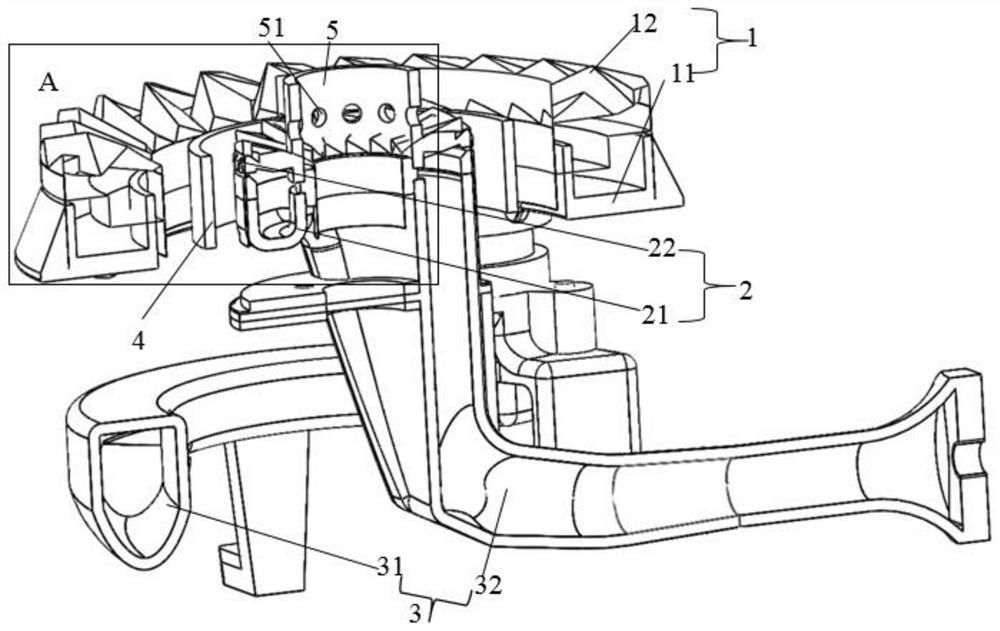

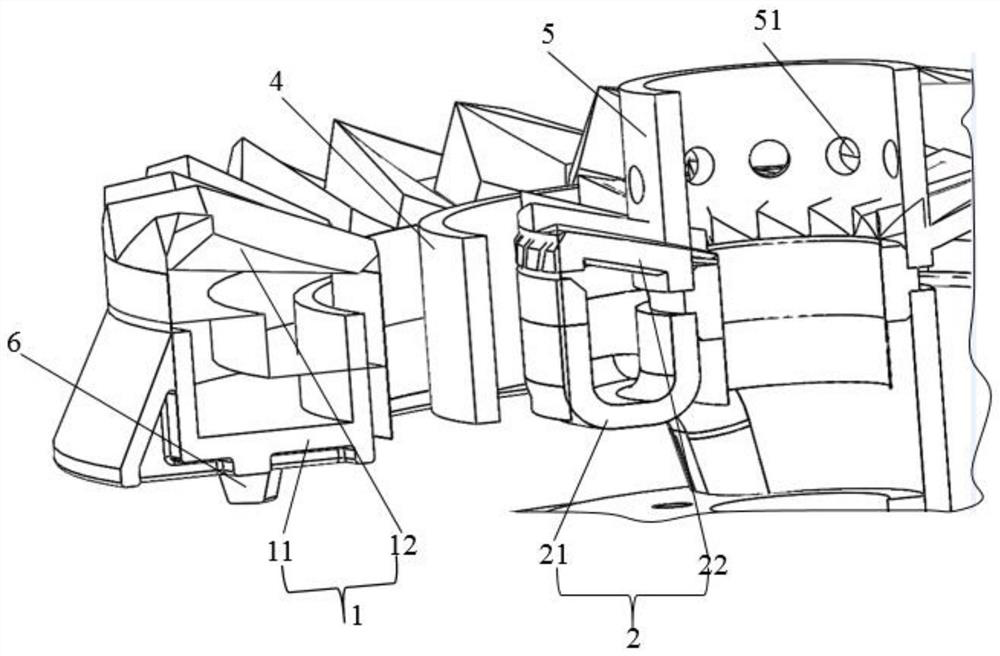

Burner

InactiveCN112524604AHigh thermal efficiencyReasonable secondary air supplyGaseous fuel burnerCombustorEngineering

The invention discloses a burner. The burner comprises an outer ring burning assembly, an inner ring burning assembly and a furnace end for supplying gas to the outer ring burning assembly and the inner ring burning assembly, and further comprises a heat gathering ring of a cylindrical structure, wherein the heat gathering ring is arranged between the outer ring burning assembly and the inner ringburning assembly. The heat gathering ring is arranged on the periphery of the inner ring burning assembly in a sleeving manner, an inner ring gap is formed between the heat gathering ring and the inner ring burning assembly, and an outer ring gap is formed between the heat gathering ring and the outer ring burning assembly. An air supplementing gap is formed between the bottom of the outer ring burning assembly and a cooking bench and communicates with the inner ring gap and the outer ring gap. According to the burner, because the heat gathering ring is used instead of a heat gathering disc,the cost of the burner is reduced on the basis of ensuring that heat can be gathered to improve the heat efficiency.

Owner:VATTI CORP LTD

Combustion control apparatus for internal combustion engine

InactiveCN100338347CReduce excess air ratioIncrease exhaust temperatureElectrical controlInternal combustion piston enginesParticulatesOperating point

A combustion control apparatus operates an internal combustion engine in a split retard combustion mode during regenerating an exhaust purifier such as a particulate filter. In the split retard combustion mode, the combustion control apparatus controls a first fuel injection to cause preliminary combustion at or near top dead center, and controls a second fuel injection to cause main combustion after an end of the preliminary combustion. In this manner, the combustion control apparatus controls an exhaust gas temperature, or an exhaust air-fuel ratio, without increasing exhaust smoke. During the split retard combustion mode, the combustion control apparatus controls an EGR rate of the engine. The EGR rate in the split retard combustion mode is set lower than in the normal combustion mode, in each operating point of the engine.

Owner:NISSAN MOTOR CO LTD

Composite combustion circulating fluidized bed

PendingCN112503514AReduce consumptionImprove combustion efficiencyFluidized bed combustionFluegas recirculationSteam pressureAutomatic control

The invention discloses a composite combustion circulating fluidized bed. The composite combustion circulating fluidized bed comprises an automatic control electric cabinet, a pulverizer, a hearth ofthe fluidized bed, a chimney, a flue for connecting the chimney and the hearth, hot air pipes, a powder pipe and a gas-powder mixing structure. The powder pipe comprises a main powder pipe and a branch powder pipe, and the main powder pipe is connected with the pulverizer and the branch powder pipe. One hot air pipe is communicated with the pulverizer and the flue, and the other two hot air pipesconnect the flue with the gas-powder mixing structure. The gas-powder mixing structure is used for mixing powder conveyed by the branch powder pipe and high-temperature flue gas conveyed by the hot air pipes and then spraying the mixture onto the two sides of the hearth. The flue is communicated with the chimney through an induced draft fan, the chimney is provided with an oxygen meter used for detecting the oxygen content in exhausted waste gas, and the hearth is further provided with a steam pressure meter used for detecting the steam pressure in the hearth. And the automatic control electric cabinet is respectively connected with the pulverizer, the gas-powder mixing structure, the induced draft fan, the steam pressure meter and the oxygen meter. The composite combustion circulating fluidized bed has the advantages of high combustion intensity, high temperature rise speed and high heat efficiency.

Owner:郭汉荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com