Oxygen-enriched combustion oxygen supply method and device for rotary cement kiln

A cement rotary kiln and oxygen-enriched combustion technology, which is applied in combustion methods, combustion equipment, chemical instruments and methods, etc., to achieve the effects of reducing fuel heat loss, improving heat utilization, and increasing heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

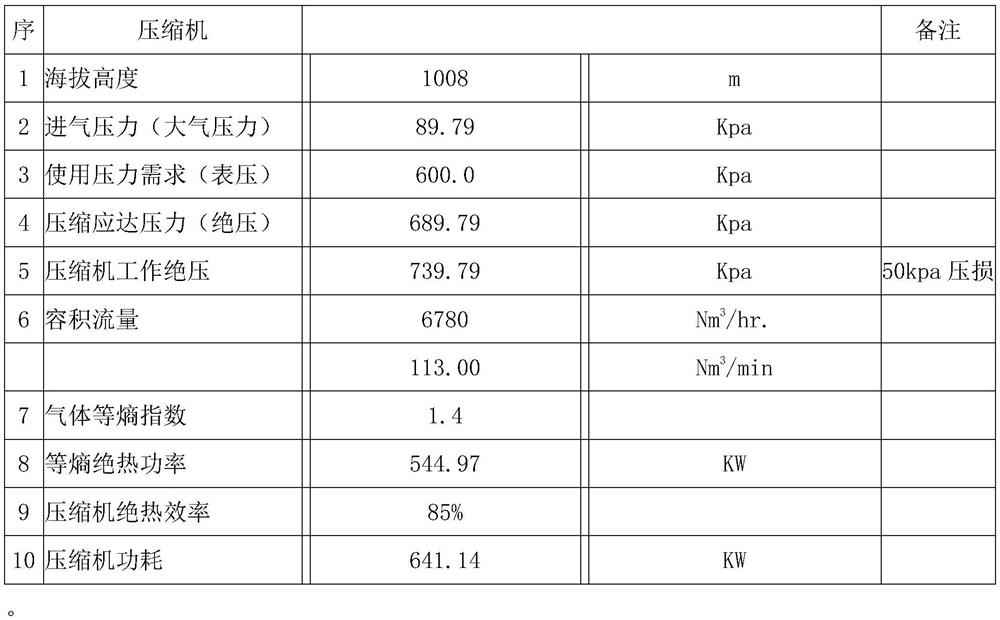

[0071] A cement plant with a local altitude of 1008m, clinker output of 4050TPD, high-quality coal with a calorific value of about 5800-6000kcal / kg is about 21.5T / h, the average electricity price is 0.48 yuan / KWH, and the average coal price is 780 yuan / ton. Flour processing fee is 30 yuan / ton, and the benefit of every additional ton of clinker production is 70 yuan, and the annual operation time is 310 days.

[0072] The factory has a total of 3 sets of 355KW, with a displacement of 62m 3 / min, outlet pressure 1.0MPa compressed air system, the total displacement is 3*62=186m 3 / min, mainly supplying compressed air for dust removal, blockage removal and other needs, the normal operating pressure of the air point is about 0.6MPa, and the actual used air volume is about 136m 3 / min.

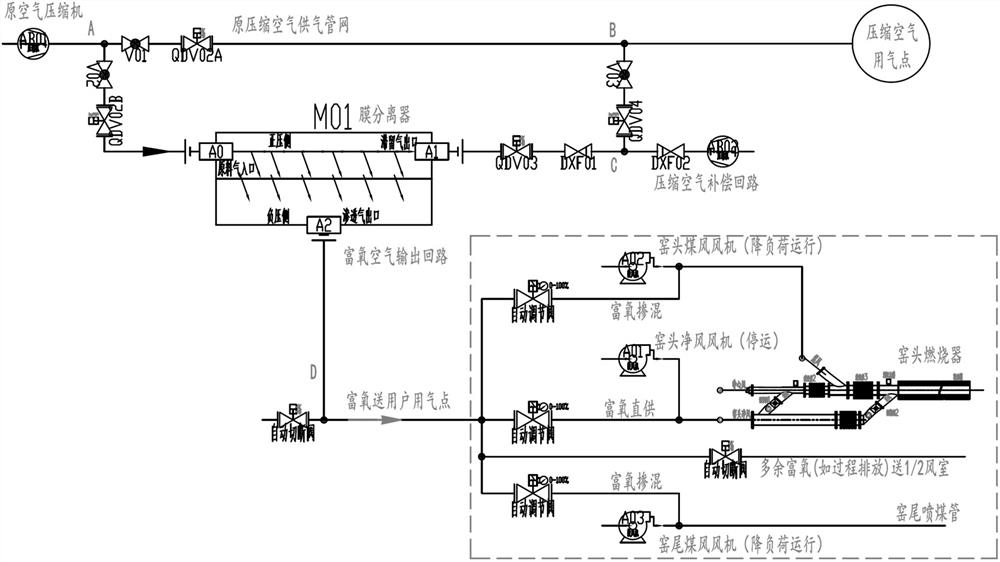

[0073] According to the method of the present invention, the membrane separation oxygen production technology is organically coupled to the original compressed air supply facility, and the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com