Furnace tube installation and fixing method applied to hydrocarbon-steam conversion hydrogen production conversion furnace

A fixed method and reformer technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as potential safety hazards, impact on thermal efficiency, and potential safety hazards, so as to reduce excess air coefficient, reduce heat loss, and avoid welding seam cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

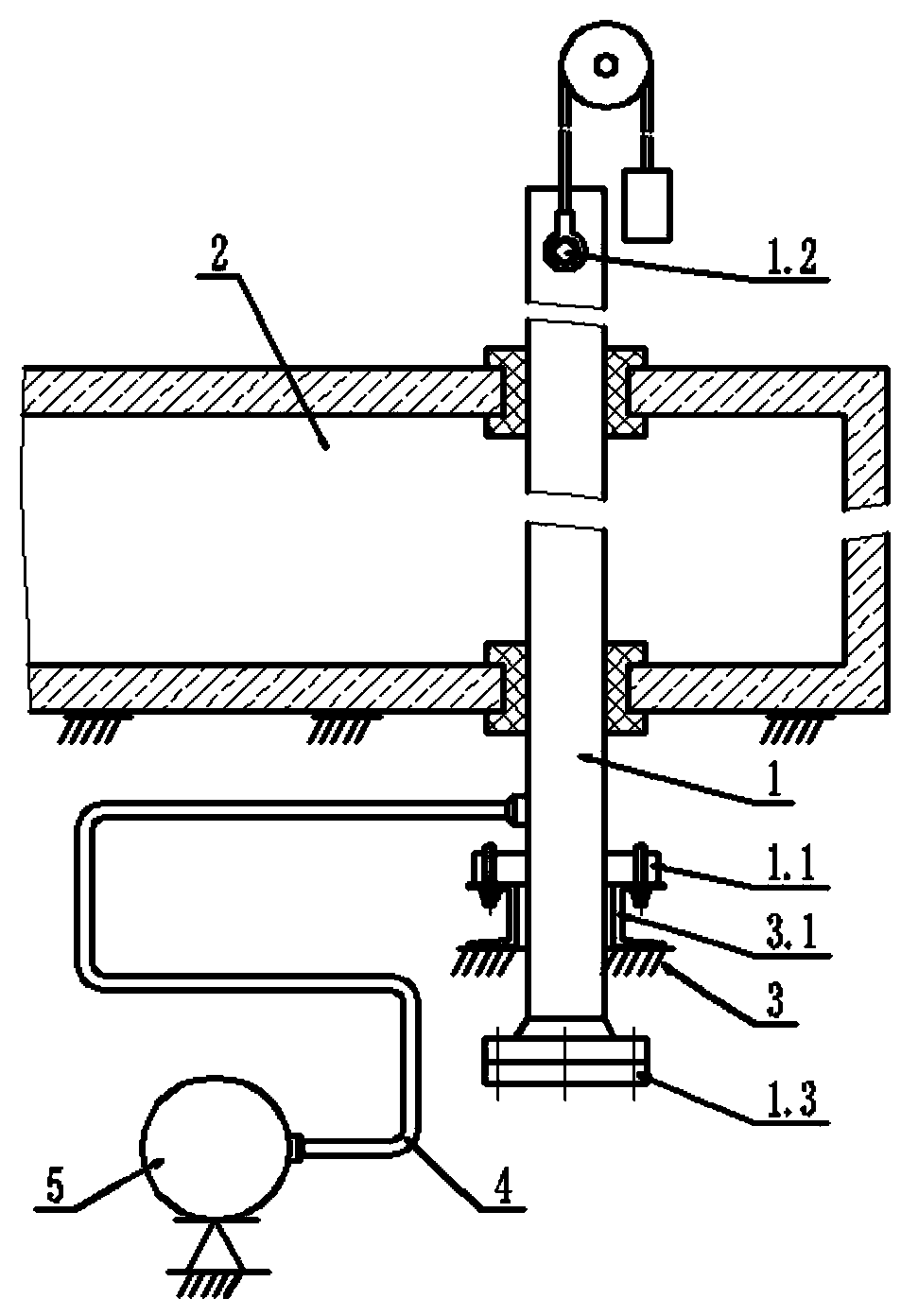

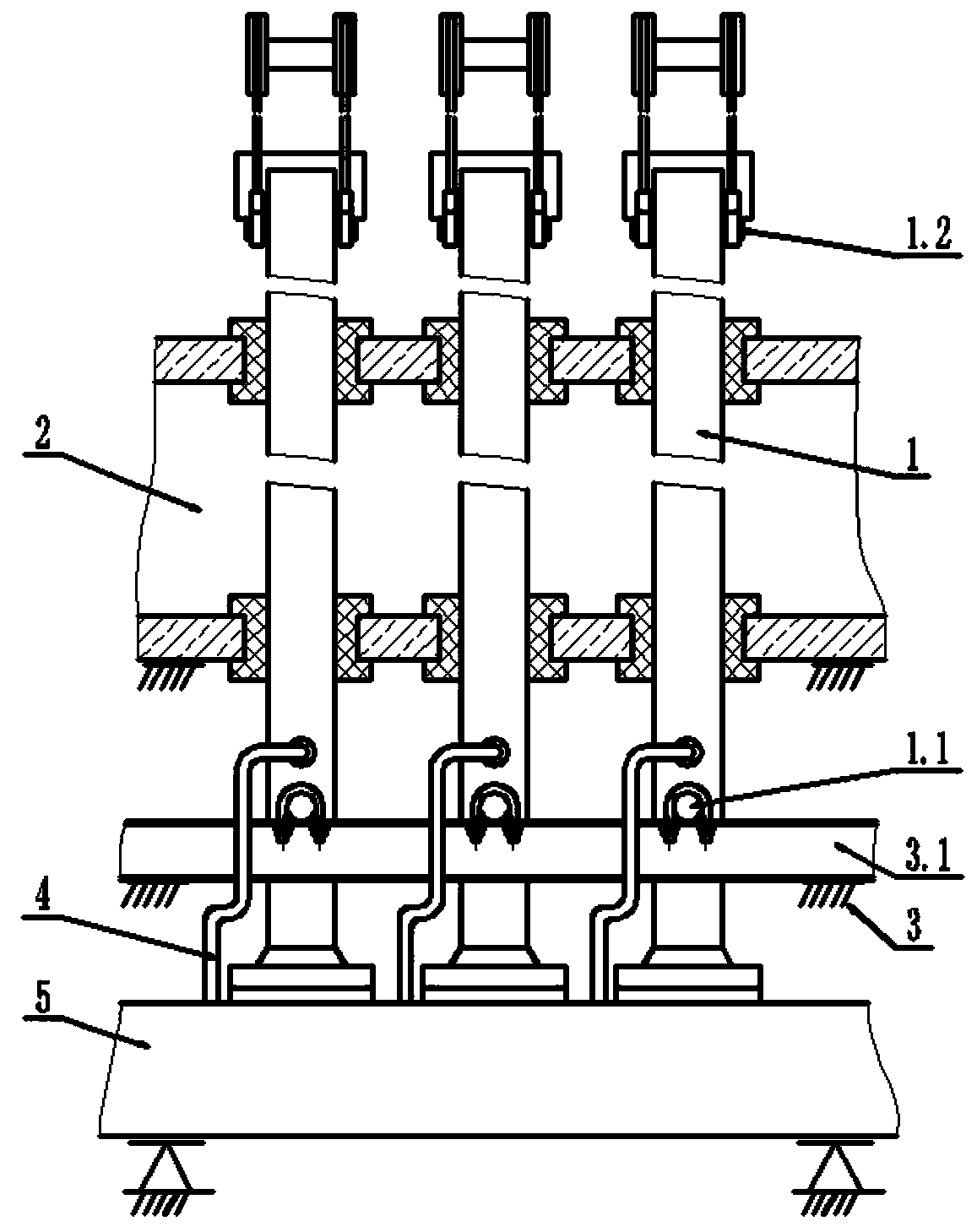

[0031] A furnace tube fixing structure applied to a hydrocarbon-steam hydrogen production reformer. The reformer includes a reformer furnace body 2 and a plurality of furnace tubes 1 arranged in multiple rows, and the plurality of furnace tubes 1 arranged in multiple rows run through vertically And stretch out the roof plate and the bottom plate of the furnace body 2 of the reformer. At the end of the furnace tube protruding downward from the furnace bottom plate, at a suitable position between the lower port flange of the furnace tube 1 and the furnace bottom plate, there are symmetrically welded fixed support members 1.1 fixedly connected with the furnace bottom steel structure. After installation, make the furnace tube 1 in a fixed state relative to the furnace bottom steel structure to avoid the sealing structure between the furnace tube 1 and the furnace bottom plate being affected by the displacement of the furnace tube 1 and the lower gas collecting pipe 4 due to thermal...

Embodiment 2

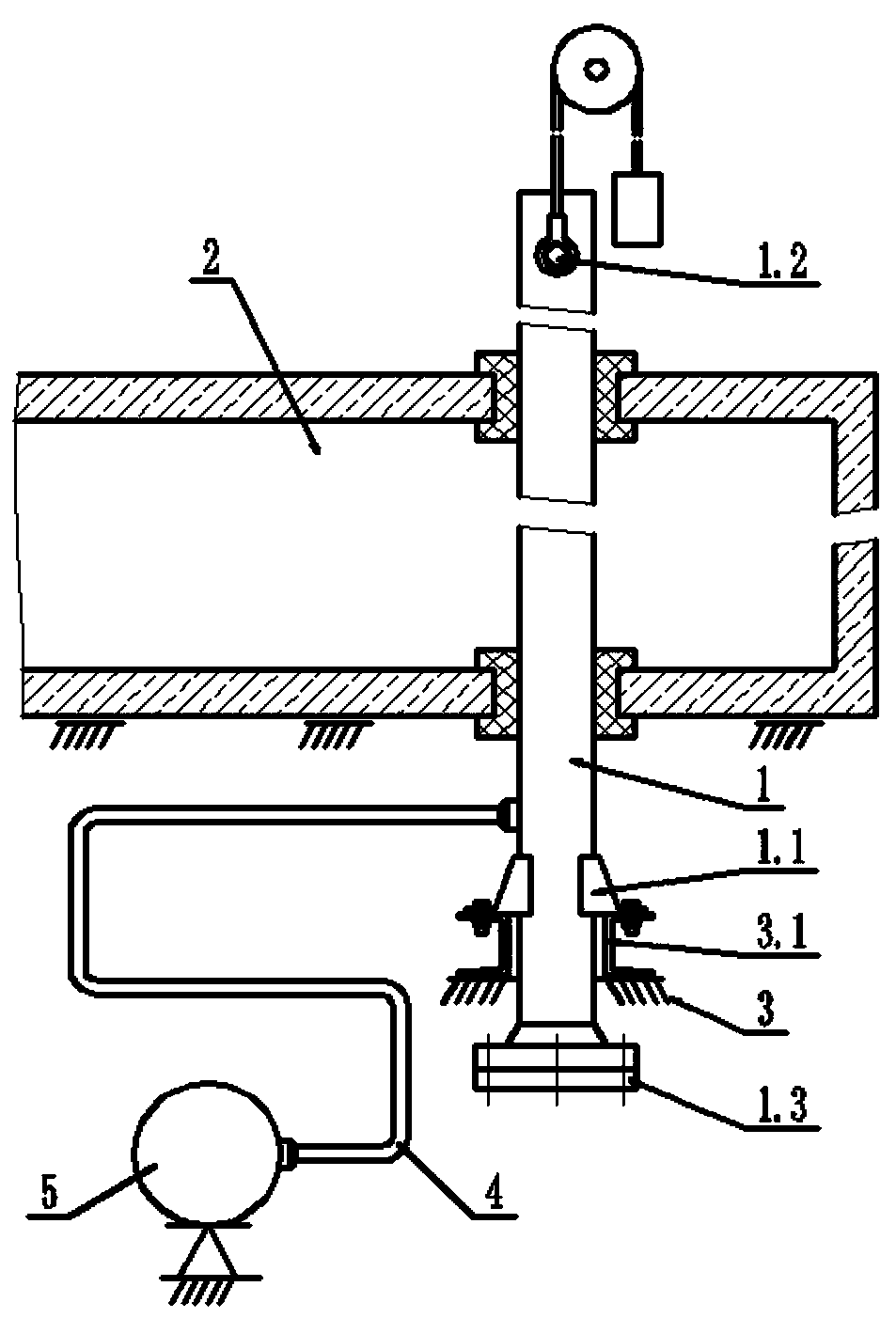

[0044] As described in Example 1, a furnace tube installation and fixing method applied to a hydrocarbon-steam reforming hydrogen production reformer, different from Example 1, such as image 3 As shown, the fixed support member 1.1 is a sheet metal part, which is symmetrically welded on both sides of the outer wall of the furnace tube 1 . The sheet metal parts on the furnace tube are placed on the channel steel 3.1, and are fixedly connected with the channel steel 3.1 by bolts.

[0045] Apparently, this connection method using sheet metal parts also achieves the effect described in Embodiment 1. There are various ways to achieve the same connection effect, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com